CPC Definition - Subclass B29C

This place covers:

Processes and apparatus for:

- shaping or joining of plastics;

- shaping of material in a plastic state when a specific material is not identified;

- shaping of material in a plastic state, not otherwise provided for.

Products obtained by processes provided for in this subclass, as long as the products are characterised by said processes.

Subclass B29C is often connected with the following areas:

- B29B, related to preparation or pre-treatment of the material to be shaped, making granules or preforms, beyond recovery of plastics or other constituents of waste material containing plastics;

- B29D, related to processes and apparatus for the production of particular articles characterised by their global structure, e.g. flat, hollow, or tubular articles, by their structural features, e.g. provided with screw threads, corrugations, grooves or projections, or by their purpose, e.g. buttons, optical elements, tyres or footwear. Attention should be paid to B29 note (3), i.e. classification according to production of particular articles in subclass B29D is restricted to:

- B32B, related to layered products (products built-up of strata of flat or non-flat, e.g. cellular or honeycomb form) as well as methods or apparatus for making layered products;

- C08K, related to the use of inorganic or non-macromolecular organic substances, or mixture thereof, as additives in composition of macromolecular compounds;

- C08L, related to composition of organic macromolecular compounds, such as polysaccharides and derivate, rubbers and derivate, macromolecular compounds obtained by reactions involving or not carbon-to-carbon unsaturated bonds, natural macromolecular compounds and derivatives.

This place does not cover:

Making preforms | |

Methods or apparatus for laminating | |

Ancillary operations in connection with laminating processes | |

Layout of apparatus or plants for lamination processes | |

Arrangements for controlling or monitoring lamination processes |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

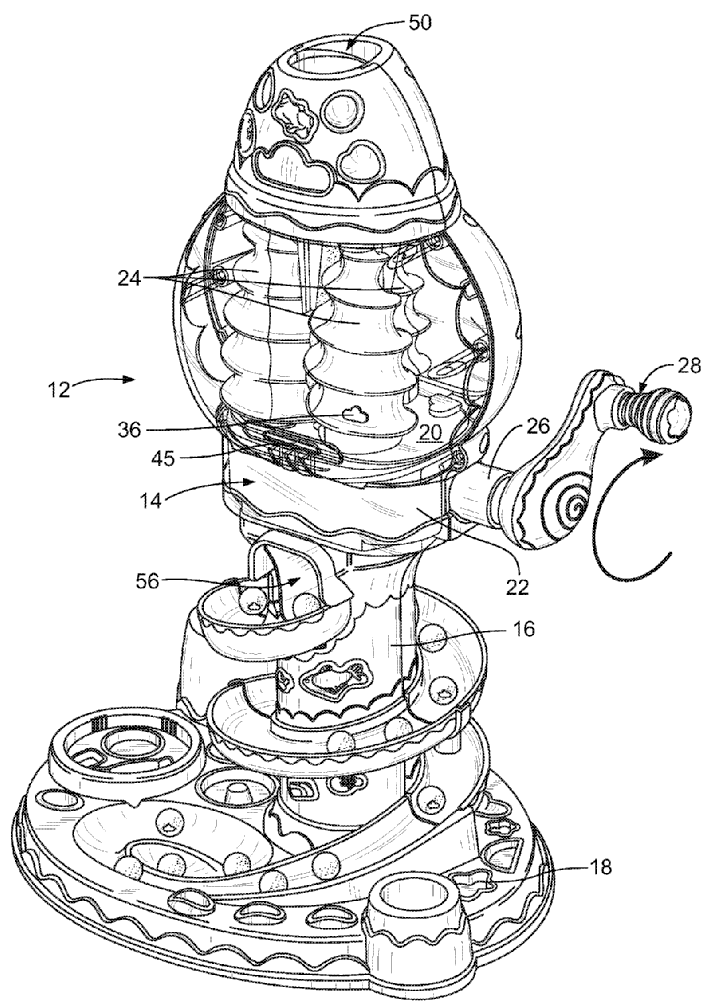

Moulding devices for producing toilet or cosmetic sticks |

Attention is drawn to the following places, which may be of interest for search:

Processing doughs | |

Processing meat | |

Working chocolate | |

Foundry moulding | |

Casting of Metals | |

Working metallic powder | |

Machine tools | |

Grinding or polishing | |

Machines, devices or processes for grinding or polishing of optical elements | |

Cutting work and details of apparatus related with | |

Means of perforating, punching, cutting-out, stamping-out and severing | |

Shaping clay or other ceramic compositions | |

Preparing clay and mixtures containing thereof | |

Presses in general | |

Extrusion presses | |

Making wound articles of paper, cardboard or material worded in a manner analogous to paper | |

Working glass | |

Preparation, chemical working-up and compositions of organic macromolecular compounds | |

Candle making | |

Making soap | |

Manufacture of artificial filaments, threads, fibres, bristles or ribbons | |

Manufacture of articles from cellulosic fibrous suspensions or from papier-mâchè |

In this subclass, the following rules must be applied:

- The working of plastics is, as far as possible, classified primarily according to the particular shaping technique used in this subclass;

- Combined operations for making a particular article which are not fully classifiable in this subclass must be classified in subclass B29D.

Products per se are not classified in this subclass. However, if a product is characterised by the way it is produced and not by its structure or composition, the production method should be classified in this subclass.In this subclass:

- repairing of articles shaped or produced by using techniques covered by this subclass or subclass B29D is classified in group B29C 73/00;

- component parts, details, accessories or auxiliary operations which are applicable to more than one moulding technique are classified in groups B29C 31/00 - B29C 37/00;

- component parts, details, accessories or auxiliary operations which are only applicable or only of use for one specific shaping technique are classified only in the relevant subgroups of groups B29C 39/00 - B29C 71/00.

In this place, the following terms or expressions are used with the meaning indicated:

A plastic | is a macromolecular compound or composition based on such a compound |

In a plastic state | refers to a state in which the material is more or less easily deformable, locally or as a whole, by force in any direction, to assume and retain any desired shape. |

In patent documents, the following abbreviations are often used:

Resins | Japanese patent applications usually refer to resins instead of plastics |

This place does not cover:

Discharging moulded articles from the mould, using means operable from outside the mould between mould parts, e.g. robots | |

Handling tyres or parts thereof, e.g. supplying, storing, conveying | |

Building tyres; devices for transferring annular tyre components during the building-up stage, e.g. from the first stage to the second stage building drum |

Attention is drawn to the following places, which may be of interest for search:

Feeding material to presses | |

Transport or storage devices | |

Measuring volume, volume flow, mass flow, or liquid level |

This place covers:

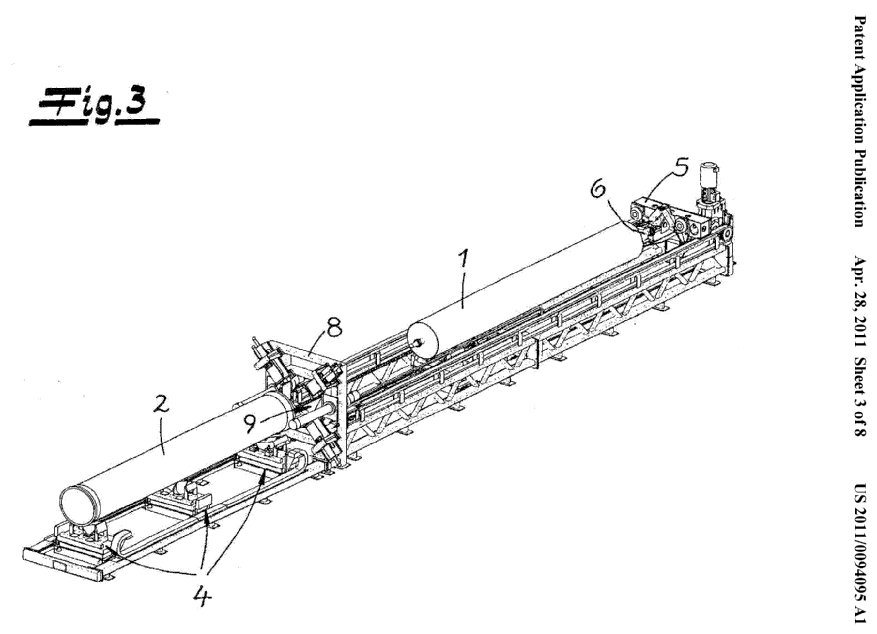

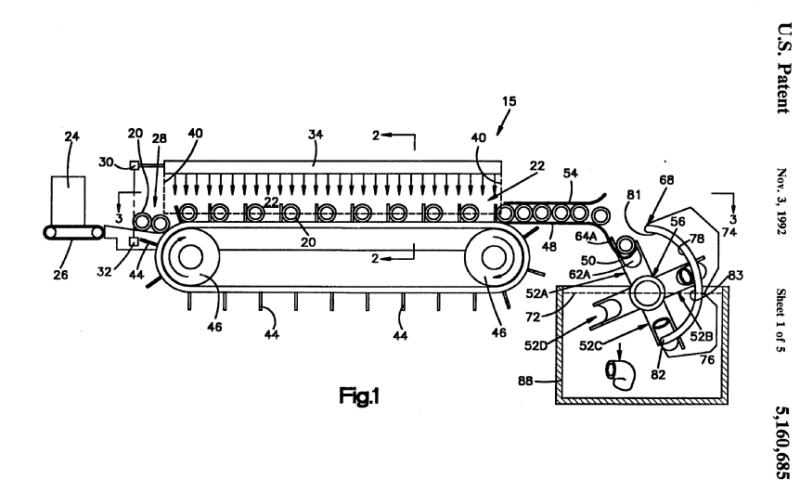

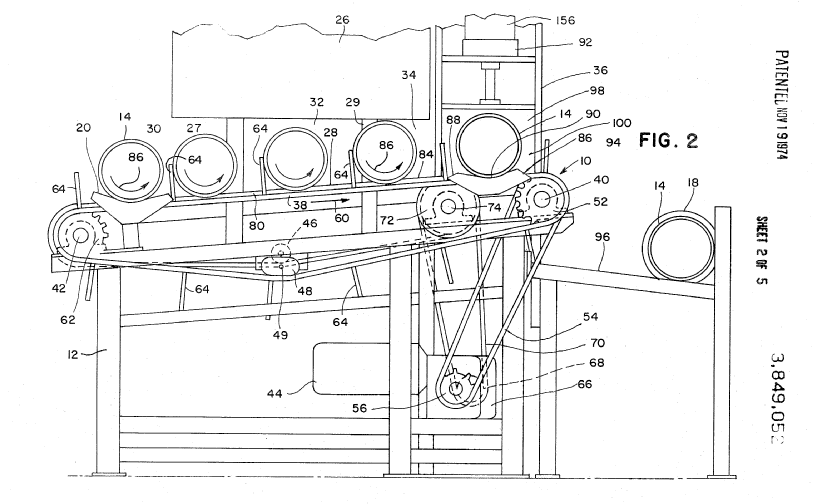

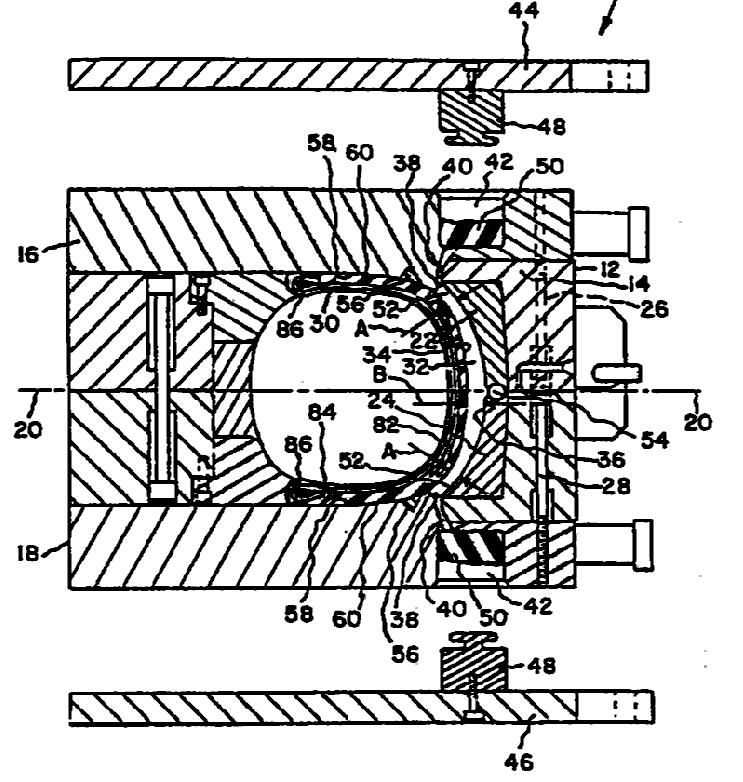

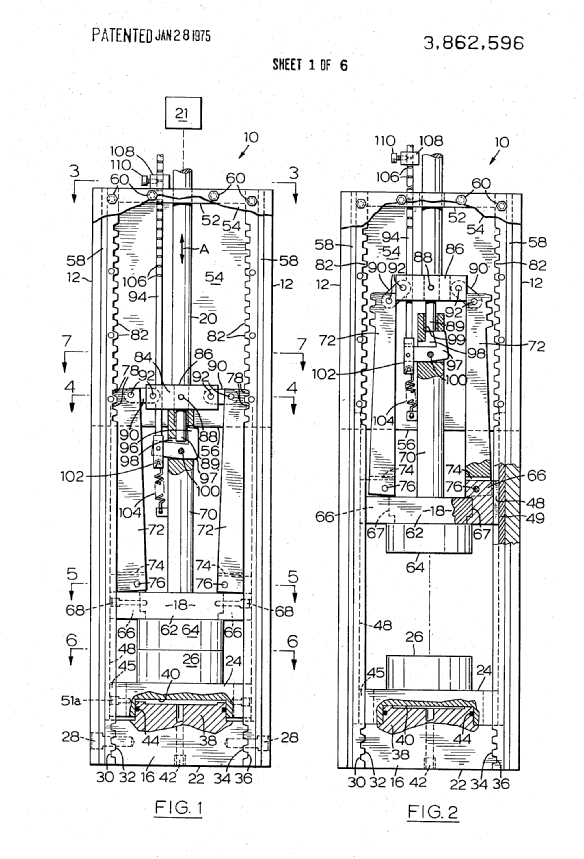

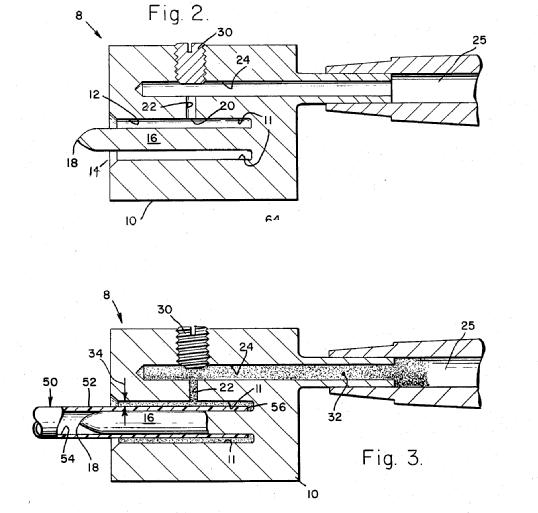

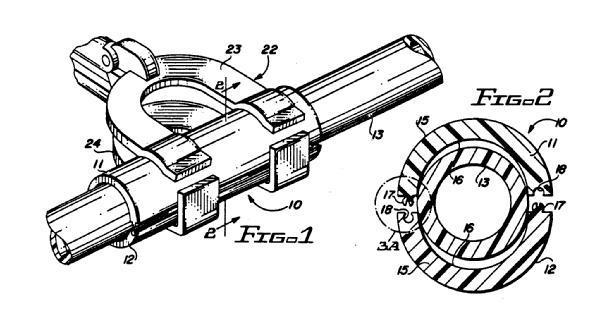

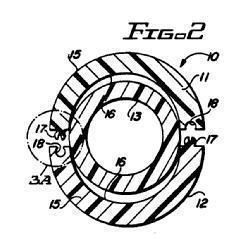

US-A-3,849,052

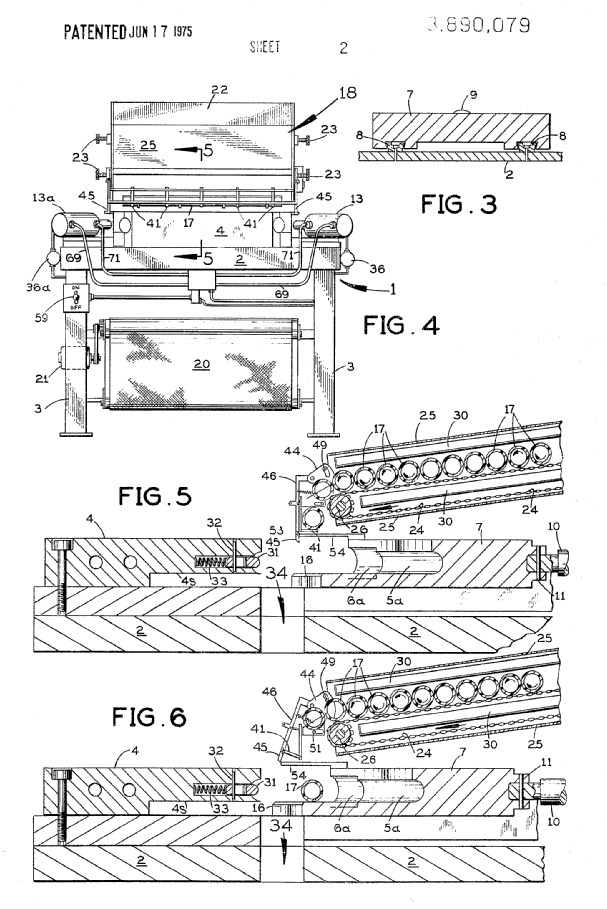

US-A-3,890,079

This place does not cover:

Conditioning or physical treatment of the material to be shaped, by heating hollow bodies, e.g. tubes or profiles | |

Conditioning or physical treatment of the material to be shaped, by heating tube ends |

Attention is drawn to the following places, which may be of interest for search:

Blow-moulding; handling means, e.g. transfer, loading or discharging | |

Shaping by bending of tubes | |

Shaping of tube ends; e.g. flanging, belling, closing. Apparatus therefor | |

Shaping tubes or blown tubular films; turning tubes inside out | |

Producing tubular articles |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Shaping by thermoforming, handling means, e.g. transfer means, feeding means | |

Advancing webs in general | |

Advancing webs; by looping or like devices |

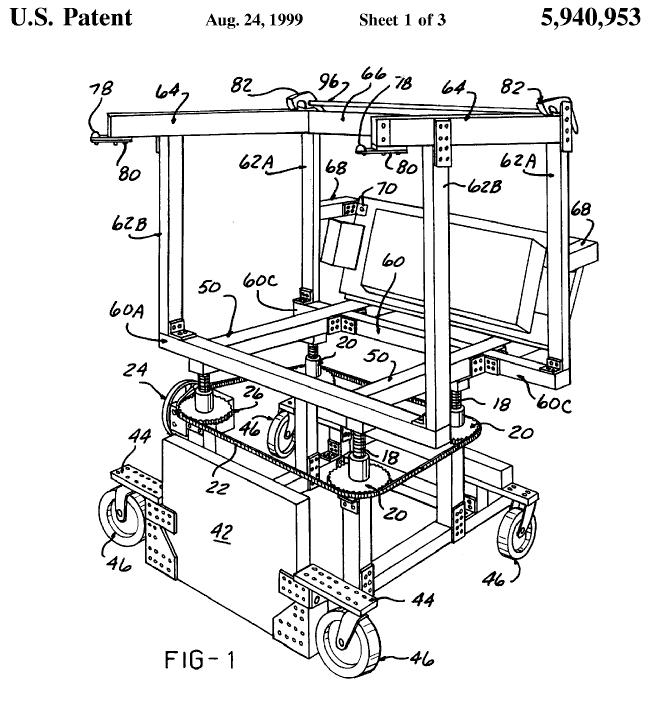

This place covers:

e.g. storing moulds;

e.g. clamping mould halves outside the machine,

e.g. using a clamp for transporting.

Attention is drawn to the following places, which may be of interest for search:

- Moulds; mounting of moulds or moulds support plates | |

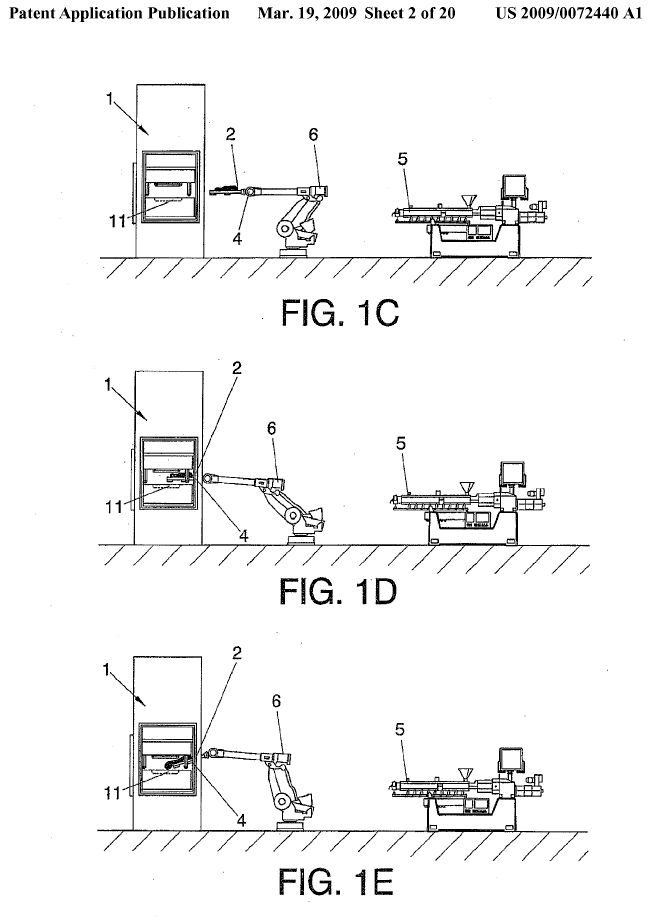

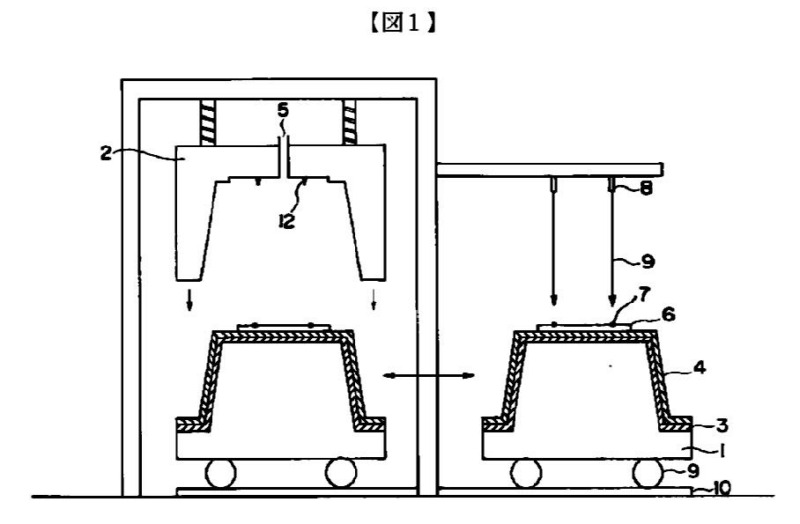

Movable moulds or cores, e.g. to or from the moulding station | |

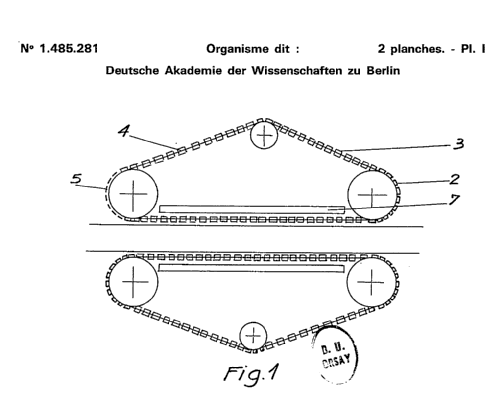

Continuously movable moulds, in one direction, e.g. in a closed circuit | |

Injection moulding; handling of moulds or mould parts, e.g. mould changing means | |

Devices holding, supporting, or positioning work or tools, of a kind normally removable from the machine | |

Arrangements for handling work specially combined with or arranged in, or specially adapted for use in connection with, machine tools, e.g. for conveying, loading, positioning, discharging, sorting | |

-Producing contact lenses; auxiliary operations, e.g. conveying moulds from a storage to the production line in an inert atmosphere | |

Presses, loading or unloading of dies, platens or press rams |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Shaping by casting; incorporating preformed parts or layers, e.g. casting around inserts or for coating articles | |

Compression moulding; incorporating preformed parts or layers, e.g. compression moulding around inserts or for coating articles | |

Foaming; incorporating or moulding on preformed parts, e.g. inserts, reinforcements | |

Injection moulding; incorporating preformed parts or layers; inserting articles into the mould | |

Extrusion moulding; incorporating preformed parts or layers, e.g. extrusion moulding around inserts or for coating articles | |

Blow moulding; inserting labels or films into blow moulds, e.g. in-mould-labellers | |

Thermoforming; lining or labelling |

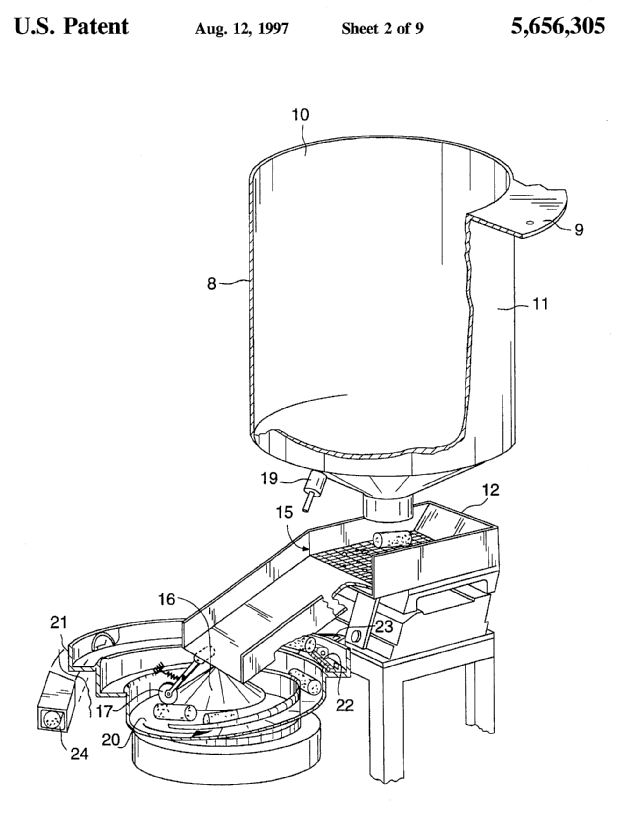

This place covers:

Attention is drawn to the following places, which may be of interest for search:

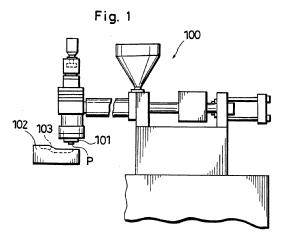

Injection moulding; feeding the material into the injection moulding apparatus, i.e. feeding the non-plastified material into the injection unit | |

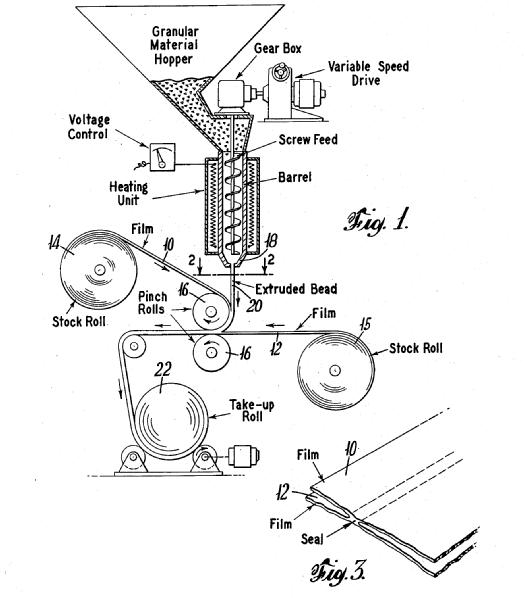

Extrusion moulding, feeding the material to the extruder | |

Methods or devices for filling or emptying bunkers, hoppers, tanks or like containers | B60G65/30 |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Shaping by casting; feeding the material into the mould | |

Shaping by coating; feeding the material on to the mould, core or other substrate | |

Shaping by casting; feeding the material into the mould | |

Compression moulding; feeding the material to the mould or the compression means | |

Foaming; feeding the material to be shaped | |

Injection moulding; feeding the material into the injection moulding apparatus, i.e. feeding the non-plastified material into the injection unit | |

Extrusion moulding; feeding the material to the extruder | |

Accessories for mixers, feed mechanisms | |

Producing lenses, machine for filling the moulds | |

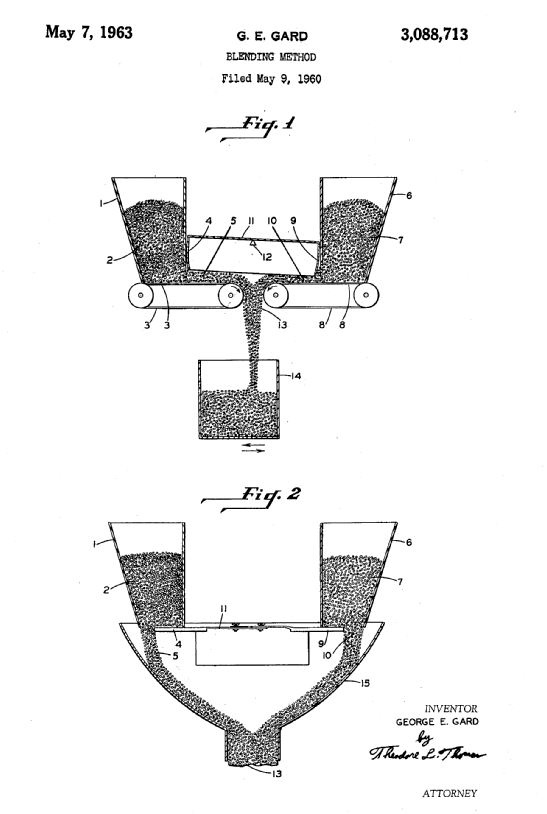

Feeding material in particulate or plastic state to moulding presses |

This place covers:

This place covers:

This place covers:

This place covers:

Attention is drawn to the following places, which may be of interest for search:

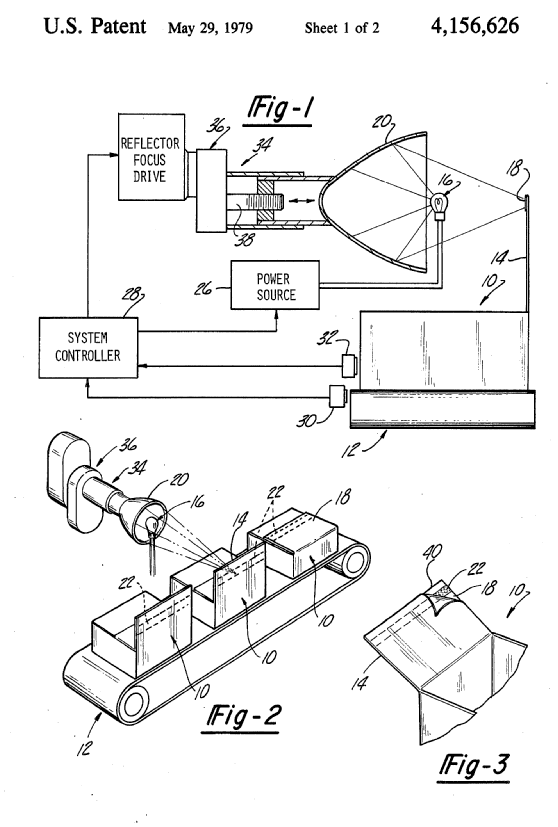

Apparatus in which liquid or other fluent material is projected, poured or allowed to flow on to the surface of the work; by relative movement according to a predetermined path |

This place covers:

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Compression moulding; for articles of definite length; using movable moulds with circular movement; the material being fed in a continuous form | |

Compression moulding; feeding the material to the mould or the compression means |

This place covers:

This place does not cover:

Mixing, kneading; continuous, with mechanical mixing or kneading devices; feeding in measured doses, e.g. proportioning of several materials: B29B 7/603.

Attention is drawn to the following places, which may be of interest for search:

Injection moulding; feeding the material into the injection moulding apparatus, i.e. feeding the non-plastified material into the injection unit; feeding measured doses |

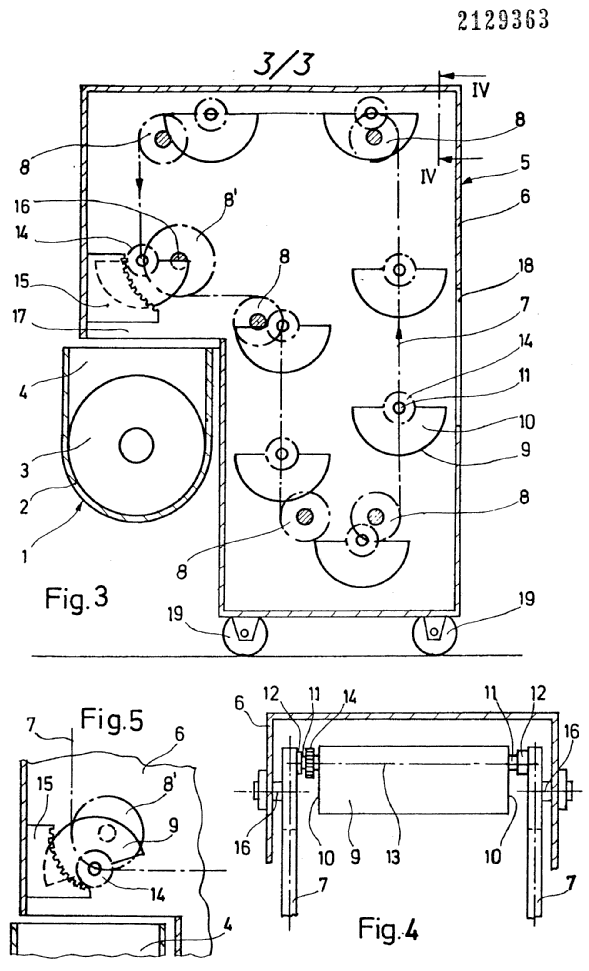

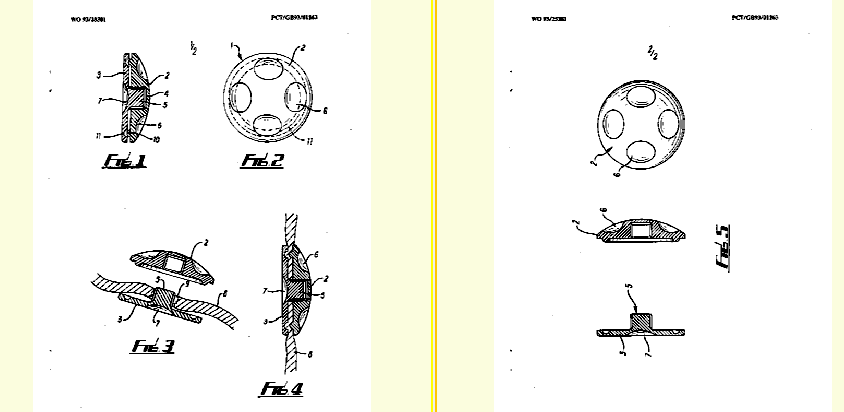

This place covers:

GB-2129363

Attention is drawn to the following places, which may be of interest for search:

Apparatus requiring external operation and adapted at each repeated and indentical operation to measure and separate a predetermined volume of fluid or fluent solid material from a supply or container without regard to weight and to deliver it, with measuring chambers moved during operation |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Feeding material in particulate or plastic state to moulding presses; by using feed frames or shoes with relative movements | |

For multi-layer articles |

This place covers:

This place covers:

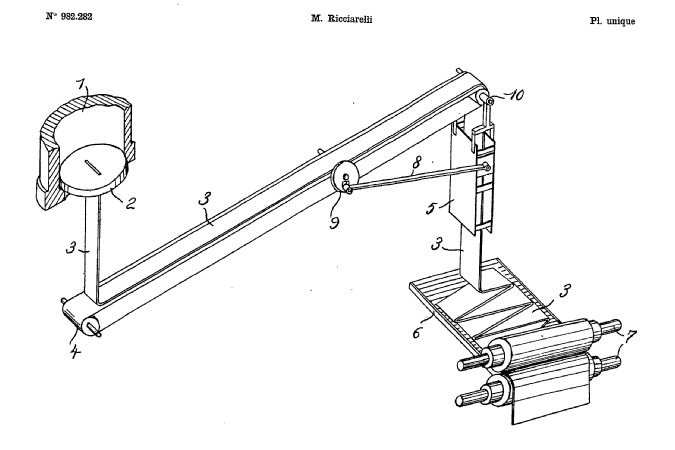

FR-A-982.282

Attention is drawn to the following places, which may be of interest for search:

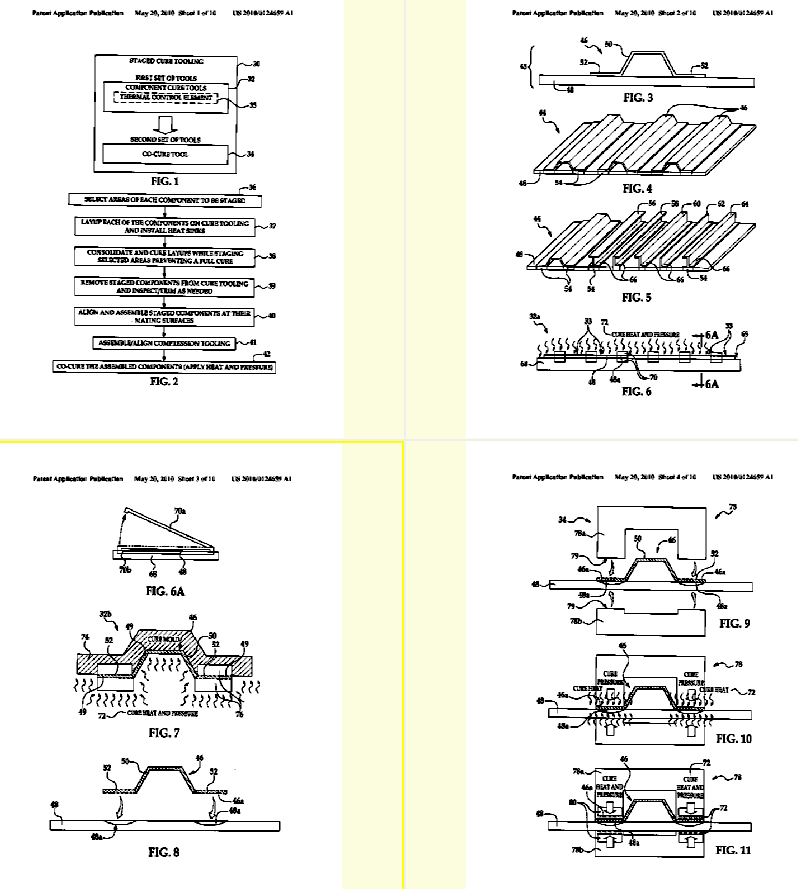

Shaping composites; positioning reinforcements in a mould |

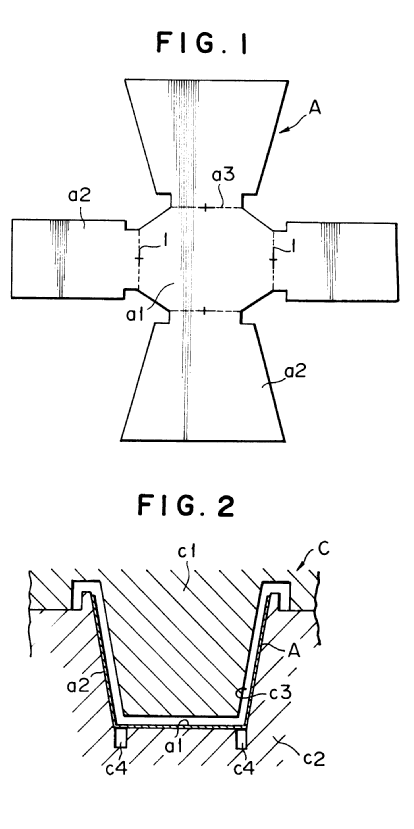

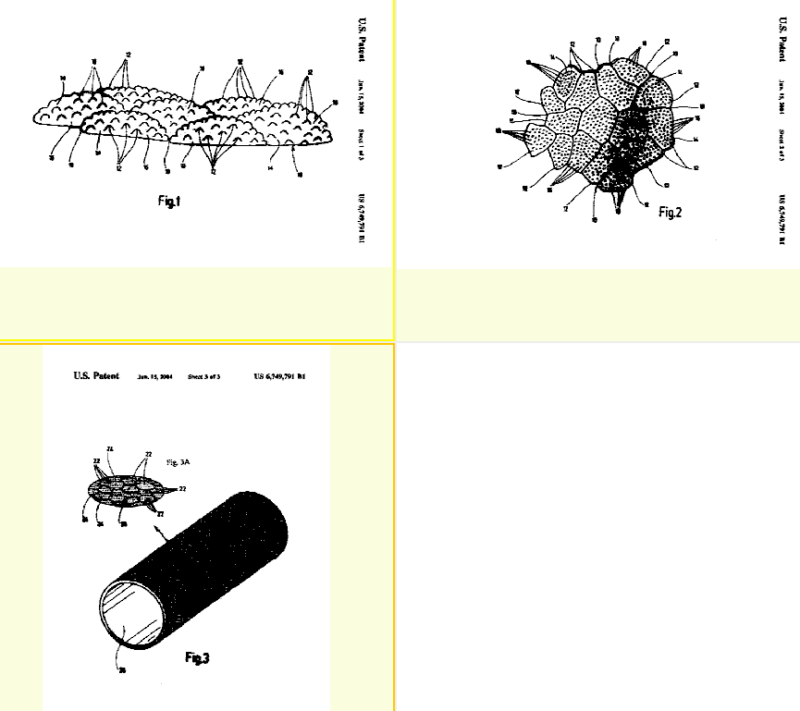

This place covers:

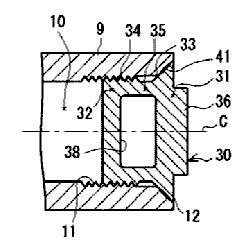

Moulds or dies being the tool used to shape the plastic parts in moulding processes in its desired form. A mould typically comprises a cavity to shape a plastic part.

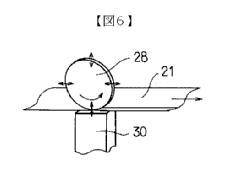

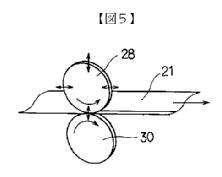

Rolls used in continuous moulding processes

Making of moulds

Designing moulds.

The scope of B29C 33/00 is limited to moulds for shaping substances being in a plastic state

Moulds for shaping other substances are not covered by this class, but by the class in their field of application

This place does not cover:

Moulds for making tyres |

Attention is drawn to the following places, which may be of interest for search:

Moulds for pressure die casting | |

Moulds for shaping clay or other ceramic products |

Moulds specific for a single moulding technology are classified in that technology: e.g. moulds for injection moulding B29C 45/26, moulds for blow moulding B29C 49/48.

Since the classification scheme present in B29C 45/00 is much more detailed, for reasons of search efficiency, classification in B29C 45/00 is preferred above a classification in B29C 33/00 in the case that both classifications would be applicable.

In patent documents, the following words/expressions are often used as synonyms:

- "Mould"," mold" and "die"

Attention is drawn to the following places, which may be of interest for search:

heating using liquids, gas or steam in presses |

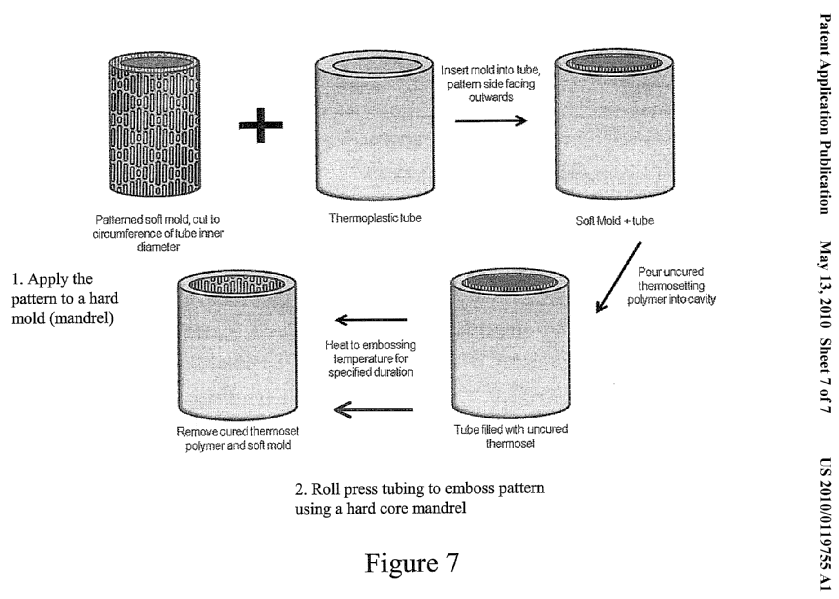

This place covers:

Making of moulds made out of a plastic substance. The application of the created mould, does not necessarily need to be in the field of B29C

This place does not cover:

Making of moulds by metal processing | B22, B23, in particular B23P 15/24 |

Attention is drawn to the following places, which may be of interest for search:

Mould materials, implicitly disclosed by the process of making them |

Attention is drawn to the following places, which may be of interest for search:

Modular mould systems [MMS], e.g. plates, blocks, rods in general | |

Constructional features of the moulds for pneumatic tyres, the moulds being made of a plurality of laminations |

This place does not cover:

Mechanical ejectors for injection moulding |

Attention is drawn to the following places, which may be of interest for search:

Discharging by stripping articles from cores |

This place does not cover:

Moulds with incorporated heating or cooling means | |

Thermal after-treatment of shaped articles | |

Curing devices for plastic dental prostheses | |

Thermal treatment of the material to be shaped before moulding | |

Conditioning or physical treatment of the material to be shaped |

Attention is drawn to the following places, which may be of interest for search:

Crosslinking of macromolecular substances |

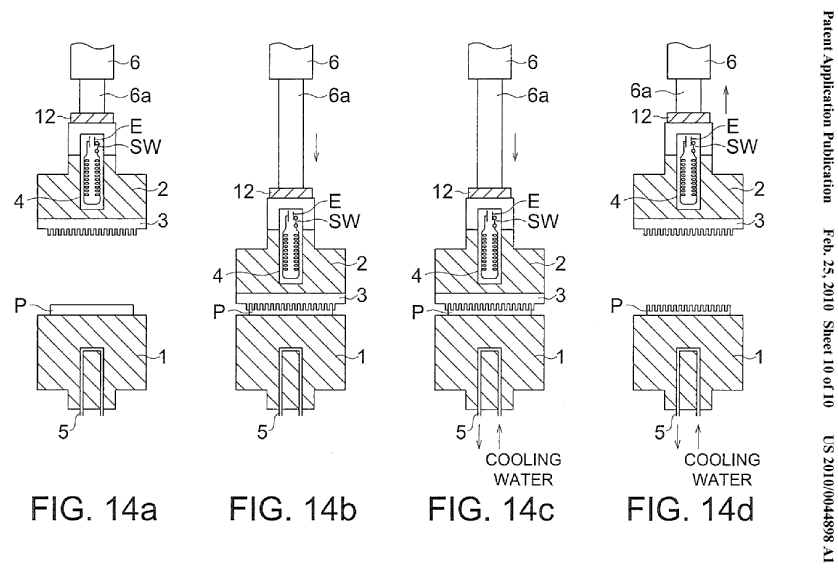

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Moulds or cores with incorporated heating or cooling mean, using liquids, gas or steam | |

Injection moulding, heating or cooling of the mould, control circuit therefor |

Attention is drawn to the following places, which may be of interest for search:

Moulds or cores with incorporated heating or cooling means | |

Shaping by casting, heating or cooling | |

Shaping by coating, heating or cooling | |

Compression moulding, heating or cooling | |

Shaping by swelling, foaming, heating or cooling | |

Injection moulding, heating or cooling | |

Extrusion moulding, heating | |

Blow-moulding, heating or cooling | |

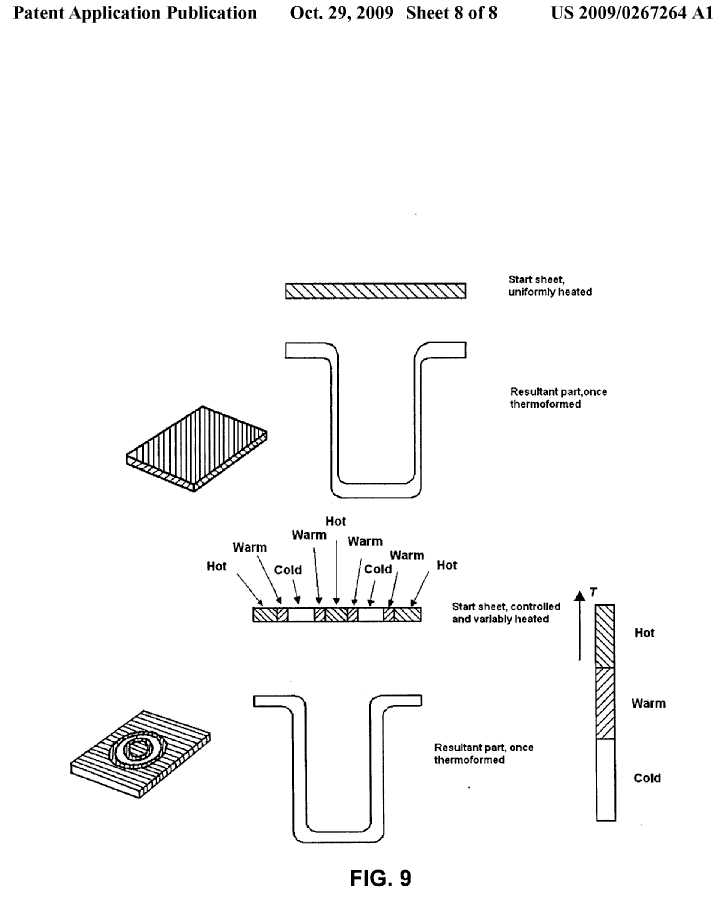

Shaping by thermoforming, heating or cooling | |

Shaping by bending, folding, heating or cooling | |

Lining or sheathing, heat treatment | |

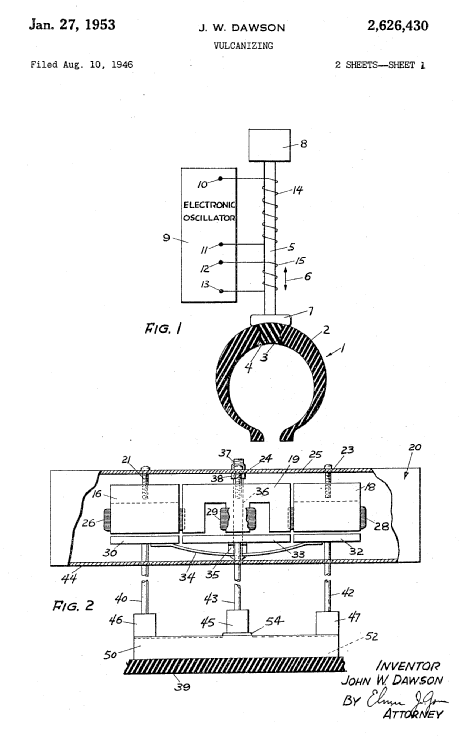

Producing pneumatic tyres, vulcanising tyres, vulcanising presses for tyres | |

Heating or cooling presses or parts therefor |

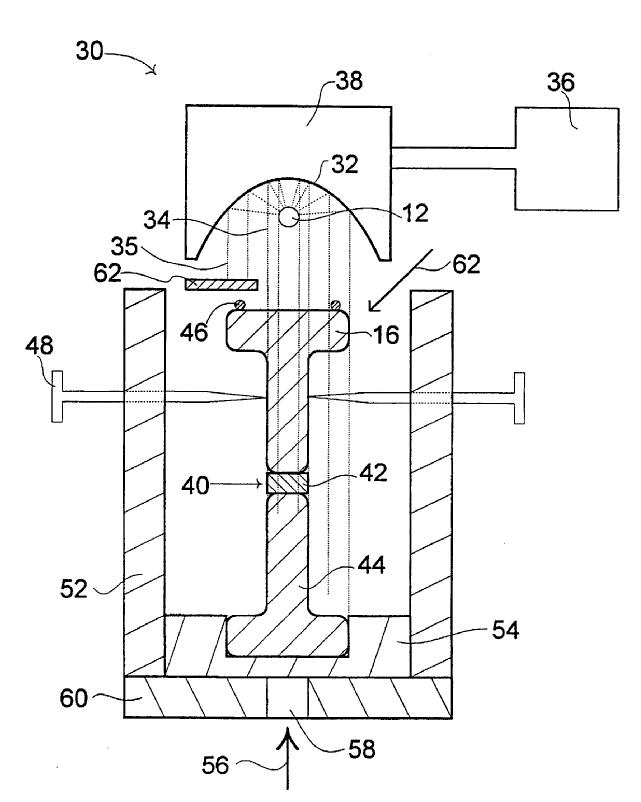

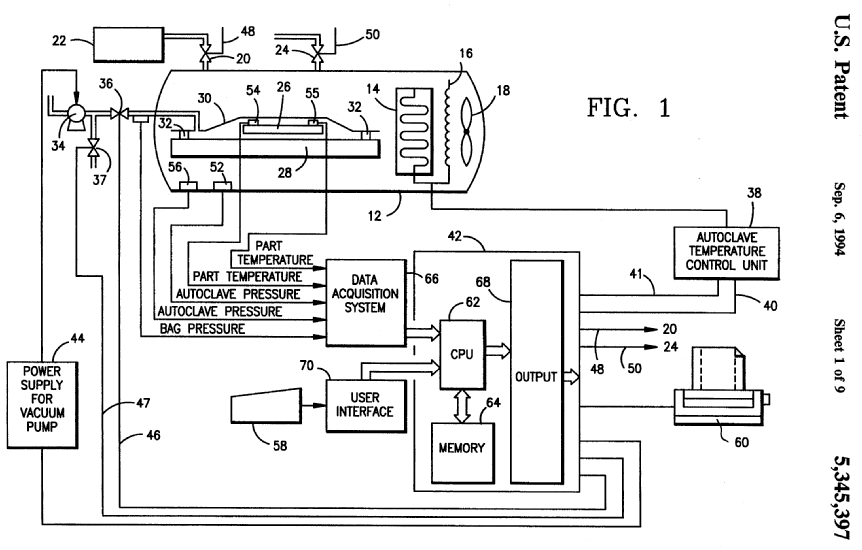

This place covers:

Attention is drawn to the following places, which may be of interest for search:

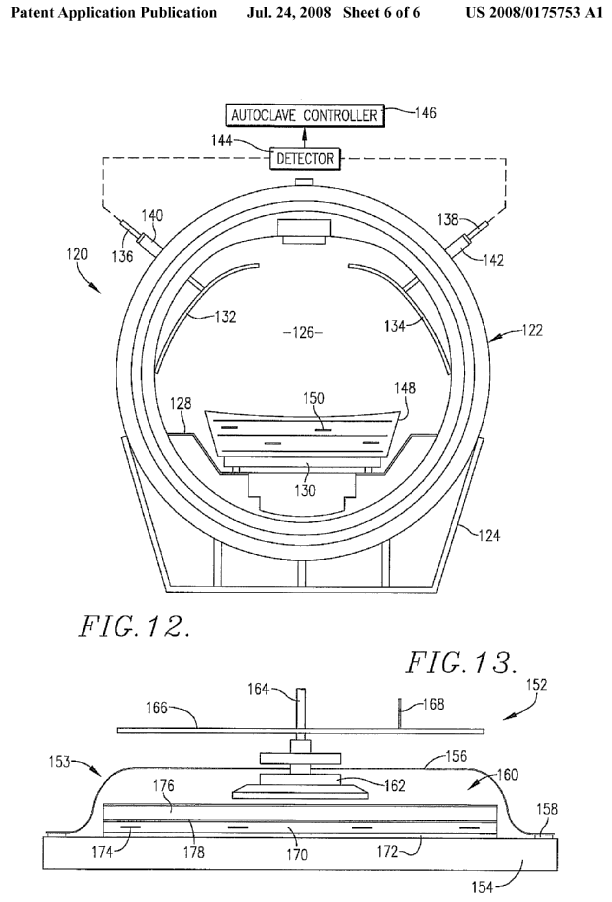

Shaping composites, using isostatic pressure, e.g. autoclave | |

Processes of utilising sub-atmospheric or super-atmospheric pressure to effect chemical or physical change of matter, pressure vessels, autoclaves |

This place covers:

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Chemical or physical process in general, conducted in the presence of fluids and solid particles, with fluidised particles, according to "fluidised bed" technique |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Chemical or physical process in general, conducted in the presence of fluids and solid particles, with fluidised particles, according to "fluidised bed" technique, for treatment of endless filamentary, band or sheet material |

Attention is drawn to the following places, which may be of interest for search:

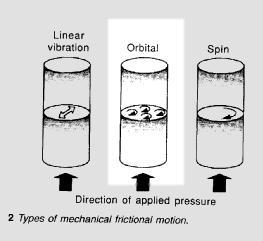

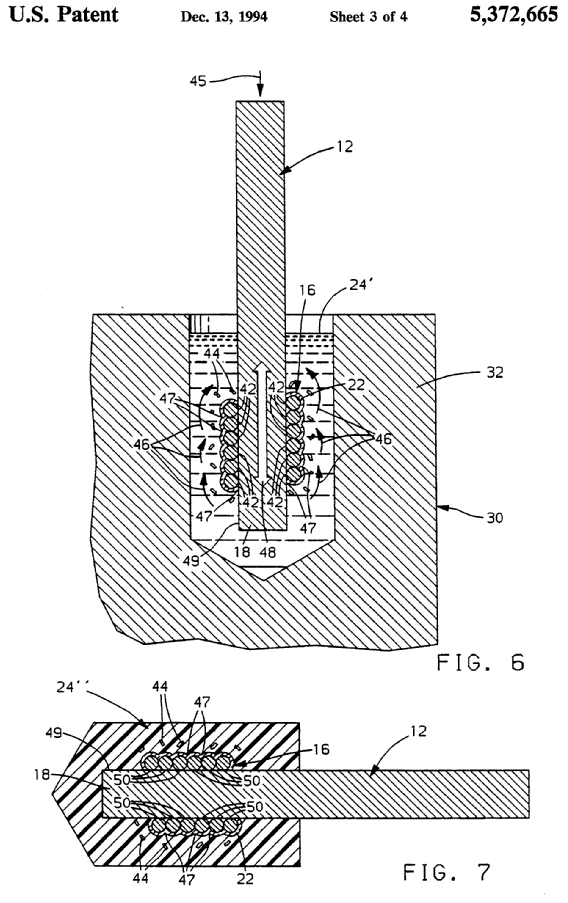

Joining of preformed parts, by heating, using friction |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

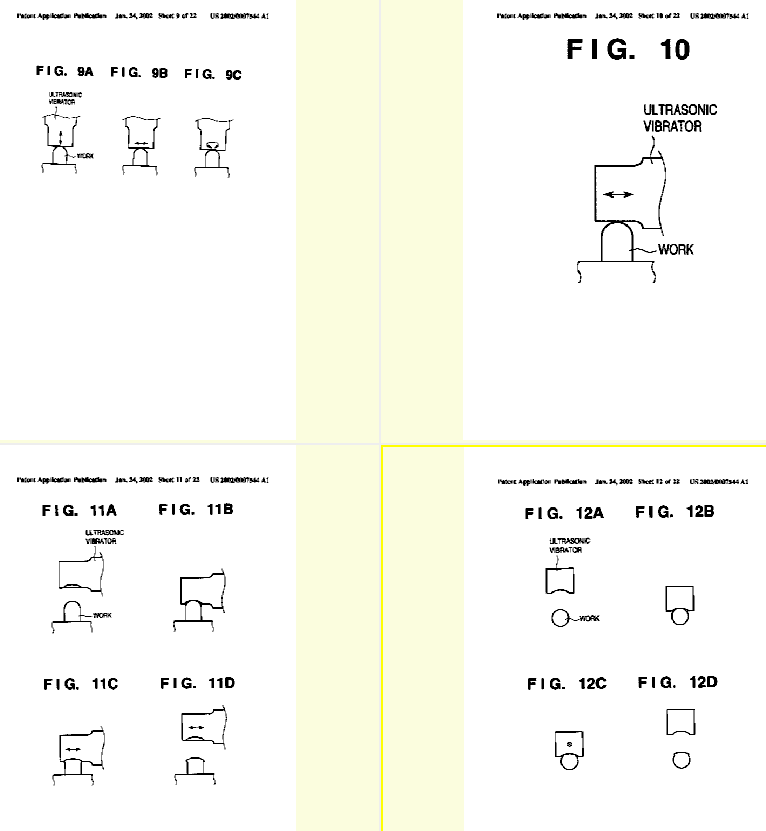

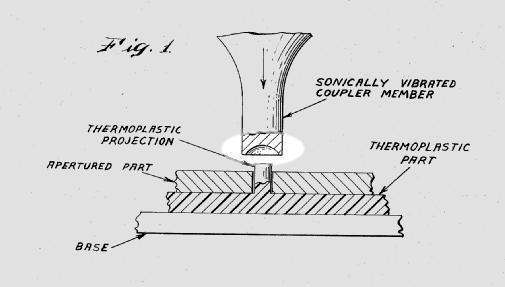

Joining of preformed parts, by heating, using ultrasonic vibrations | |

Chemical, physical or physico-chemical processes in general, employing sonic or ultrasonic vibrations |

Attention is drawn to the following places, which may be of interest for search:

Shaping by liberation of internal stresses, making preforms comprising incorporated or associated heating means | |

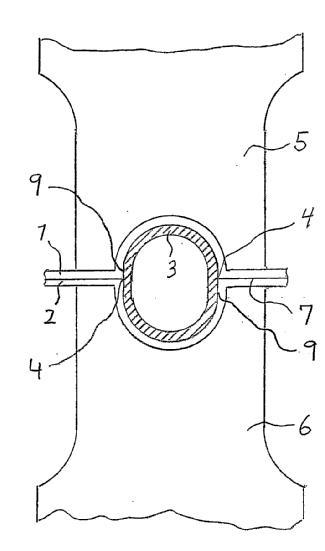

Joining of preformed parts, by heating, using heated elements which remain in the joint |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Movable moulds or cores | |

Continuously movable moulds or cores |

Attention is drawn to the following places, which may be of interest for search:

Thermal after-treatment of articles without altering their shape |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Shaping by casting, measuring, controlling or regulating | |

Shaping by coating, measuring, controlling or regulating | |

Compression moulding, measuring, controlling or regulating Shaping by swelling, foaming, measuring, controlling or regulating | |

Injection moulding, measuring, controlling or regulating of temperature | |

Extrusion moulding, measuring, controlling or regulating | |

Blow-moulding, measuring, controlling or regulating | |

Shaping by thermoforming, measuring, controlling or regulating |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Joining of preformed parts; e.g. welding of plastics materials; making use of hot liquids, i.e. the liquid is in contact with the material to be joined | |

Joining of preformed parts; e.g. welding of plastics materials; using hot gases | |

Joining of preformed parts; e.g. welding of plastics materials; using flames |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Extrusion moulding; heating the stream of extruded material |

Attention is drawn to the following places, which may be of interest for search:

Using wave energy for welding | |

Using laser for welding | |

Using induction heating for welding | |

Dental auxiliary appliances, apparatus for curing resin by radiation | |

Chemical, physical or physico-chemical processes in general, employing particle radiation or gamma-radiation | |

Chemical, physical or physico-chemical processes in general, employing electromagnetic waves | |

Producing optical elements, curing the lens material | |

Processes of treating or compounding macromolecular substances, treament by wave energy or particle radiation | |

Irradiation devices | |

Induction heating |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Producing optical elements, curing the lens material | |

Photomecanical, e.g. photolithographic, production of textured or patterned surfaces, lithigraphic processes using patterning methods other than those involving the exposure to radiation, e.g. by stamping |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Extrusion moulding; heating the stream of extruded material |

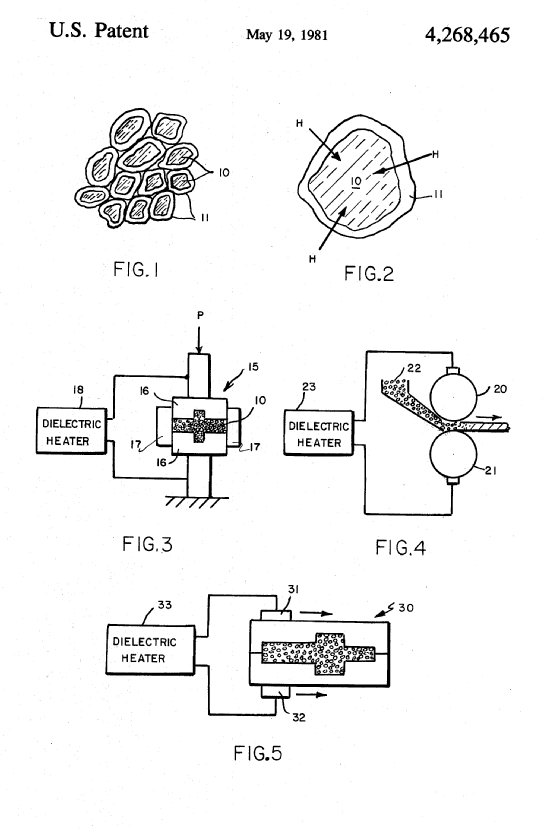

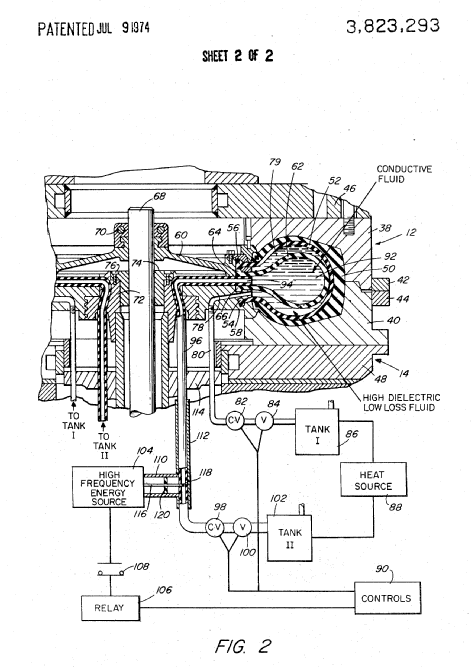

This place covers:

.

.

Attention is drawn to the following places, which may be of interest for search:

Moulds or cores with incorporated heating means for dielectric heating | |

Dielectric heating for welding |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Extrusion moulding; heating the stream of extruded material |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Moulds or cores with incorporated heating or cooling means | |

Extrusion moulding, cooling the stream of extruded material | |

Blow-moulding, thermal conditioning of preforms by cooling hot or molten preforms | |

Blow-moulding; cooling by refrigerant introduced into the blown article |

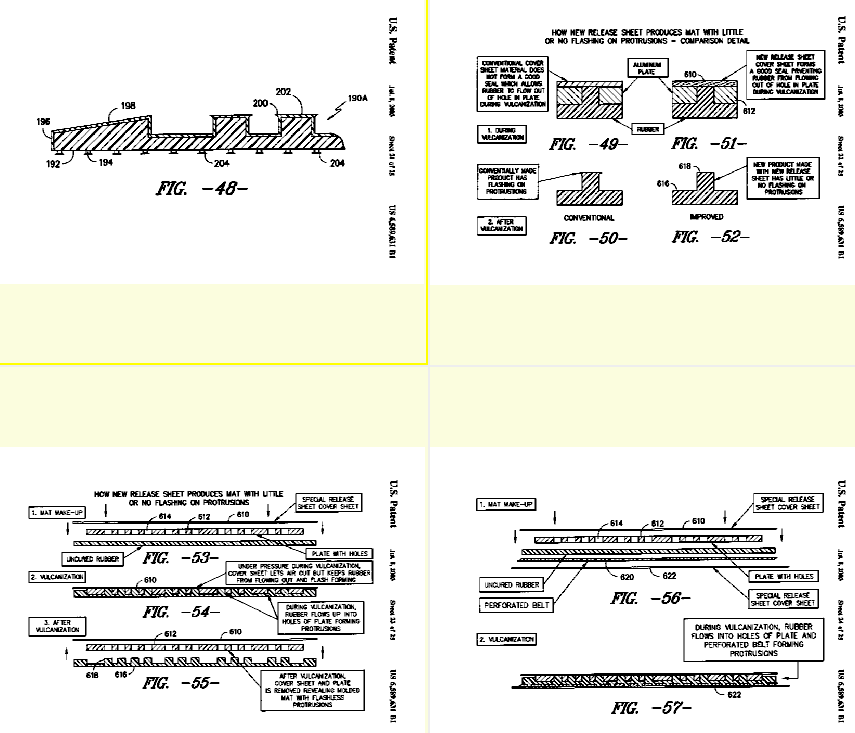

This place covers:

Methods and processes for removing articles from the mould,

Applying surface layers to moulded articles during moulding, e.g. in mould coating,

Methods for compensating volume or shape change during moulding,

Method for degassing moulded articles during moulding (e.g. draining off gas during moulding),

Methods wherein separating agents are used during or after moulding,

Methods for obtaining anchoring effects between layers during moulding,

Method for trouble-shooting during starting or stopping moulding apparatus,

Methods for deburring or deflashing moulded articles.

Attention is drawn to the following places, which may be of interest for search:

measuring or controlling heating, curing | |

measuring, controlling or regulating casting | |

measuring, controlling or regulating moulding by coating | |

measuring, controlling or regulating compression moulding | |

measuring, controlling or regulating foaming | |

dehumidifying moulds during injection moulding | |

measuring, controlling or regulating injection moulding | |

detecting absence or presence of articles during injection moulding after ejection | |

measuring, controlling or regulating extrusion | |

measuring, controlling or regulating blow moulding | |

measuring, controlling or regulating thermoforming | |

detecting absence or presence of articles during welding |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Discharging casting moulds | |

Discharging coated moulds | |

Discharging compression moulds | |

Discharging injection moulds | |

Discharging blow moulds | |

Discharging thermoforming moulds | |

Demoulding optical elements, e.g. lenses | |

Producing tyres, loading or unloading tyres presses |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Discharging injection moulds, using means movable from outside the mould |

This place covers:

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Discharging injection moulds, by flexible movement of undercut article |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Moulds or cores with means for the removal of articles; with mechanical ejector or drive means for stripping articles from a mould core, e.g. using striper plates |

This place covers:

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Compression moulding of definite length, incorporating preformed linings | |

Injection moulding, incorporating preformed parts or layers, multilayered articles |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Injection moulding, making multilayered or multicoloured articles |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Shaping by coating a mould, making multilayered or multicoloured articles of definite length | |

Injection moulding, making multilayered articles, applying surface layers inside the mould cavity, e.g. in mould coating (IMC) |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Shaping by casting; compensating volume change, e.g. retraction | |

Shaping by coating a mould or a core; compensating volume change, e.g. retraction | |

Compression moulding, compensating volume change, e.g. retraction |

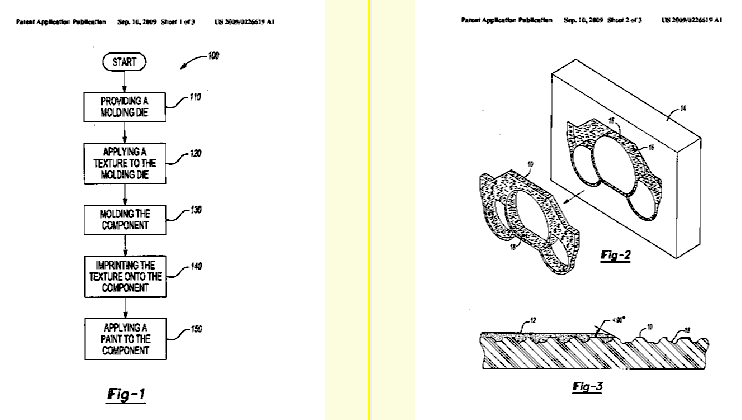

This place covers:

Attention is drawn to the following places, which may be of interest for search:

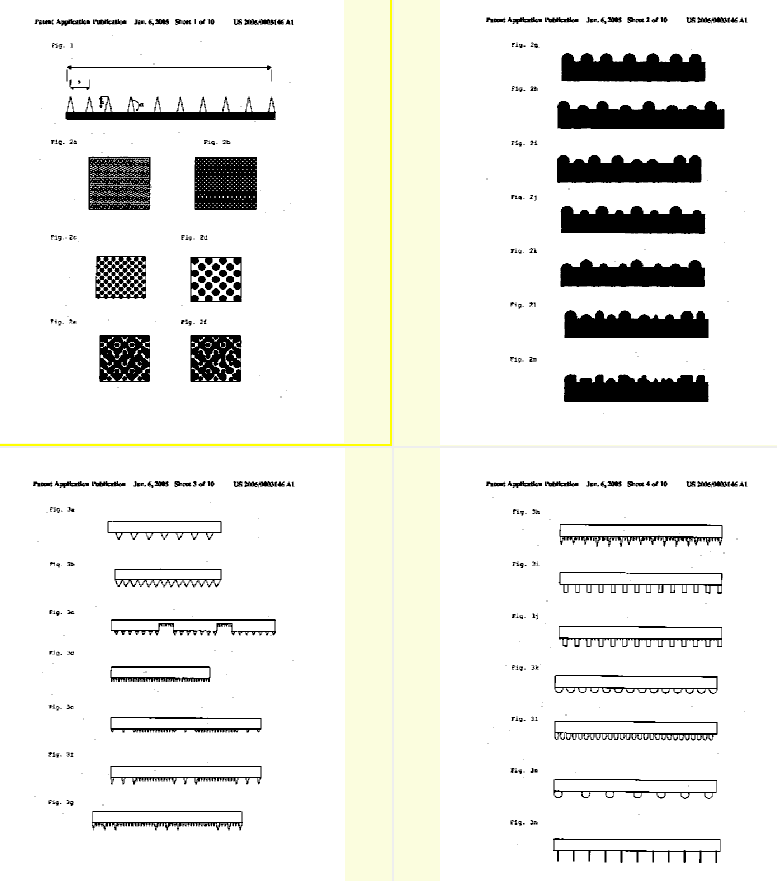

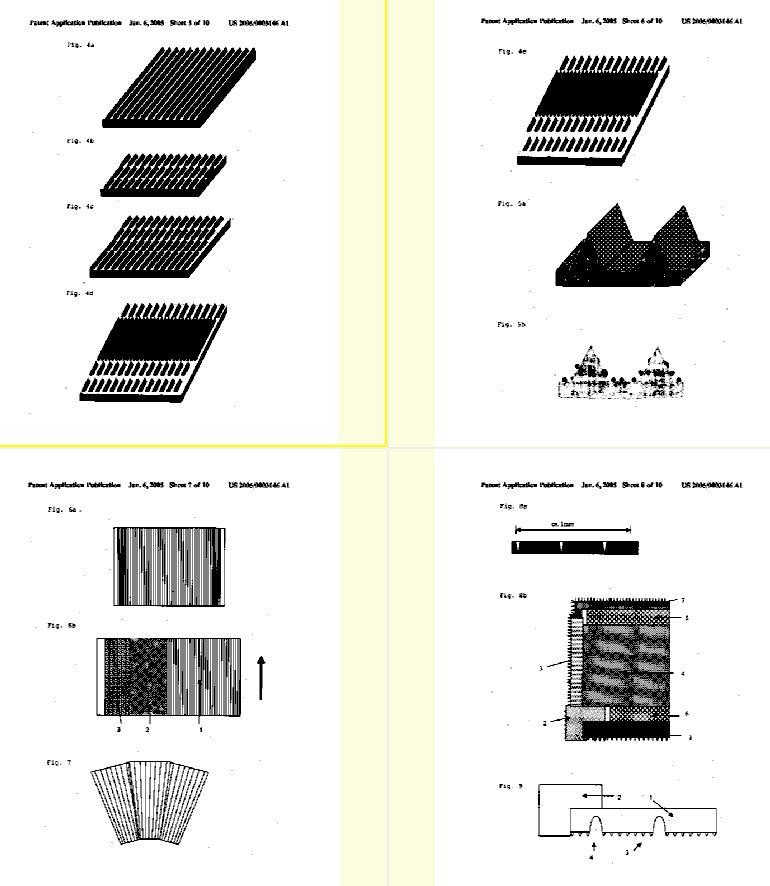

Moulds or cores characterized by the shape of the moulding surface, e.g. ribs, grooves | |

Shaping by casting, making articles of definite length characterised by the shape of the surface | |

Compression moulding of article of definite length chatracterised by the shape of the surface | |

Injection moulding, mould cavity walls provided with means for marking or patterning | |

Blow moulding moulds having decorating or printing means | |

Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces, lithographic processes using patterning methods other than those involing the exposure to radiation, e.g. by stamping |

This place covers:

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Shaping by casting; casting under special conditions, e.g. vacuum: | |

Degassing, draining off gases, as after treatment | |

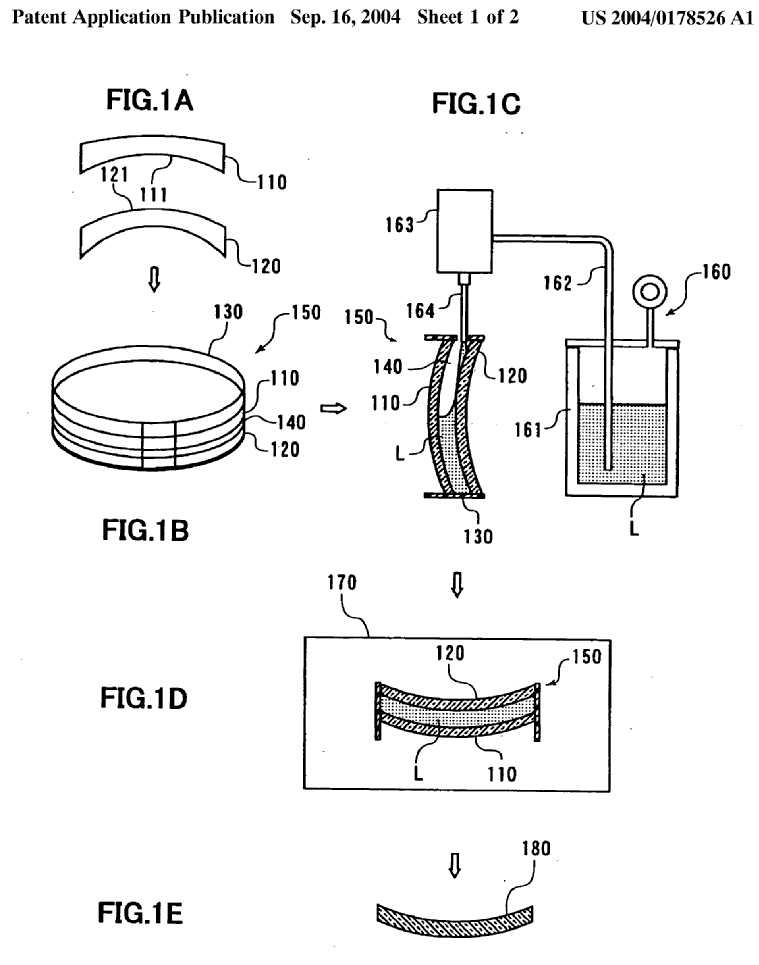

Producing lenses, removing oxygen from the mould |

Attention is drawn to the following places, which may be of interest for search:

Moulds or cores, coatings, applying the releasing agent | |

Moulds or cores, coatings, releasing, lubricating or separating agent |

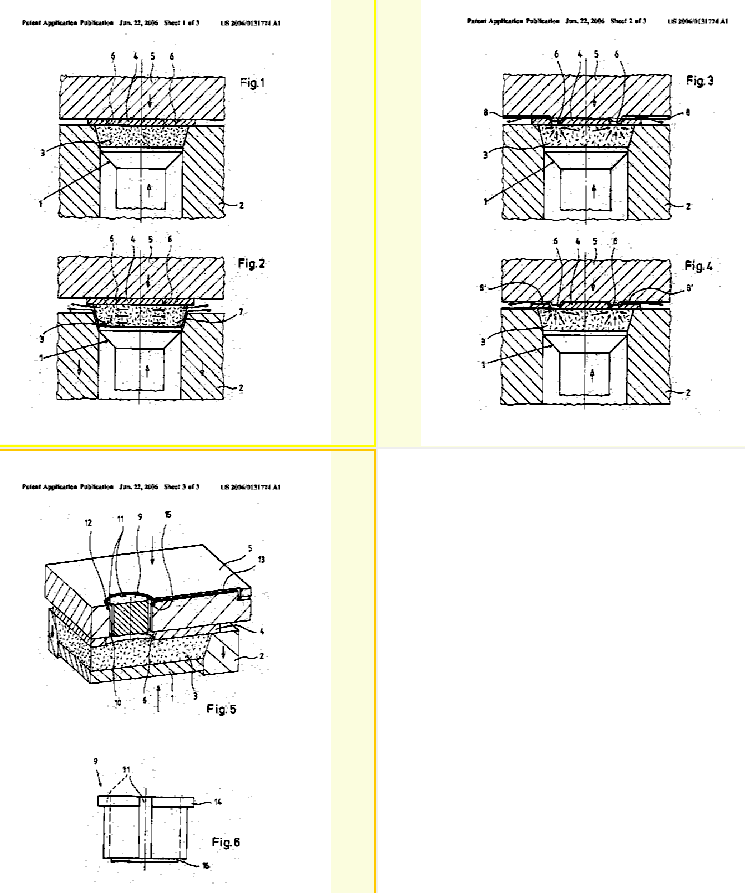

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Release sheets for moulds or cores |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Shaping composites, comprising fillers only, the filler influencing the surface characteristics of the material, e.g. by concentrating near the surface or by incorporating in the surface by force |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Injection moulding in or through a hole in the article | |

Joining by riveting |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Sealings between relatively moving surfaces which permits material to be continuously conveyed |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Drying in general |

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Blow-moulding; deflashing outside the mould; deflashing the neck portion | |

Cutting work characterised by the nature of the cutting made | |

Method, machines, or devices for working metals by removal of material for thermal deburring | |

Machines or devices designed for grinding edges or bevels on works or for removing burrs characterised by a special design for grinding plastic materials | |

Methods for use of abrasive blasting for polishing surfaces for deburring | B24C/08B |

Abrasive blasting machines or devices | |

Machines or devices designed for polishing or abrading surfaces on work by means of tumbling appartus | B24D31/00 |

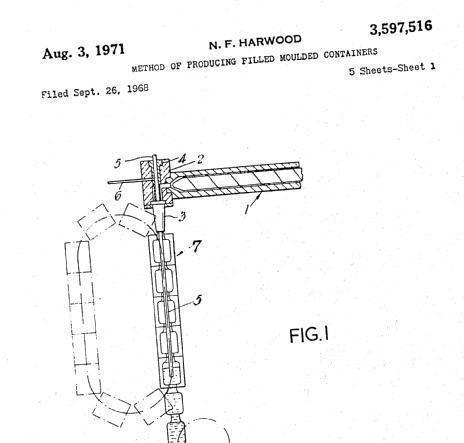

This place covers:

Low or zero pressure casting methods of polymers or their pre-cursors into a mould or between confining surfaces, apparatus and articles obtained by casting, when these articles are characterised by the casting method.

This place does not cover:

Spin casting | |

Casting of dental prostheses | |

Casting of membranes, | |

Centrifugal casting specially adapted for tyres or parts thereof | |

Casting of microstructured devices |

Attention is drawn to the following places, which may be of interest for search:

Shaping by internal pressure generated in the material, e.g. swelling, foaming | |

Joining by applying molten plastics or by moulding | |

Screen moulding | |

Molding wax | |

Liquid injection molding of liquid silicone rubbers, polyurethanes and other highly reactive materials under high pressure | |

Spinning of moulds for a specific filler concentration or distribution of the filler | |

Encapsulating inserts having non-encapsulated projections, e.g. terminal portions of electrical components | |

Moulding sealings into closures | |

Casting of foodstuff or confectionary | e.g. A23G 3/2023, A23G 1/205 |

Casting cosmetic material, such as lipsticks | |

Making brushes by casting a body around bristles | |

Methods for making crowns for teeth | |

Encapsulating hollow fibres, e.g. for filters, | |

Metal casting | |

Casting of ceramics or other cementitious material | |

Moulding, e.g. casting of optical elements, e.g. lenses, prisms | |

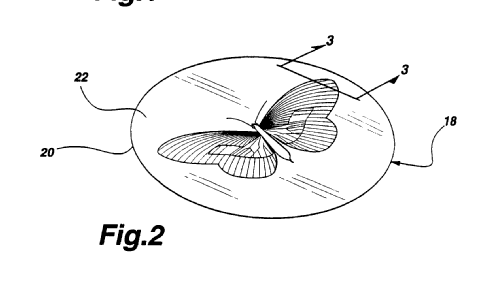

Designs imitating natural patterns | |

Manufacture of films or sheets | |

Encapsulation, potting and similar processes used in electronics | H10W 74/01, H01F 41/005, H01F 41/127, H10W 74/00, H05K 3/284, H05K 3/101 |

In patent documents, the following words/expressions are often used as synonyms:

- "casting", "moulding", "pouring", "potting" and "encapsulating"

This place covers:

depositing material and stripping-off the shaped article

Processes for applying liquids or other fluent materials are provided in B05D 1/00 e.g. coating by rotation: B05D 1/002; coating by spin coating B05D 1/005; coating by dipping B05D 1/18; coating performed by gravity only B05D 1/30.

The difference with the processes provided in the group B29C 41/00, is that in addition to coating step, a step of stripping of the article is provided (cf. the title of B29C 41/00 "...i.e. by depositing material and stripping-off the shaped article...")

This place does not cover:

Shaping by spraying of fibres on a mould, former or core: |

Attention is drawn to the following places, which may be of interest for search:

Spinning the mould for a specific filler concentration or distribution | |

Gloves | |

Automotive skins |

In patent documents, the following words/expressions are often used as synonyms:

- spraying, slush moulding or casting, rotational moulding, rotomoulding, moulding by spinning, spin casting, centrifugal casting.

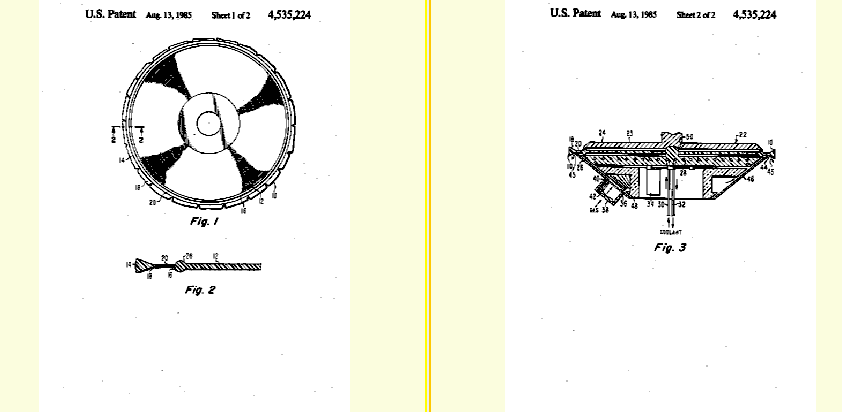

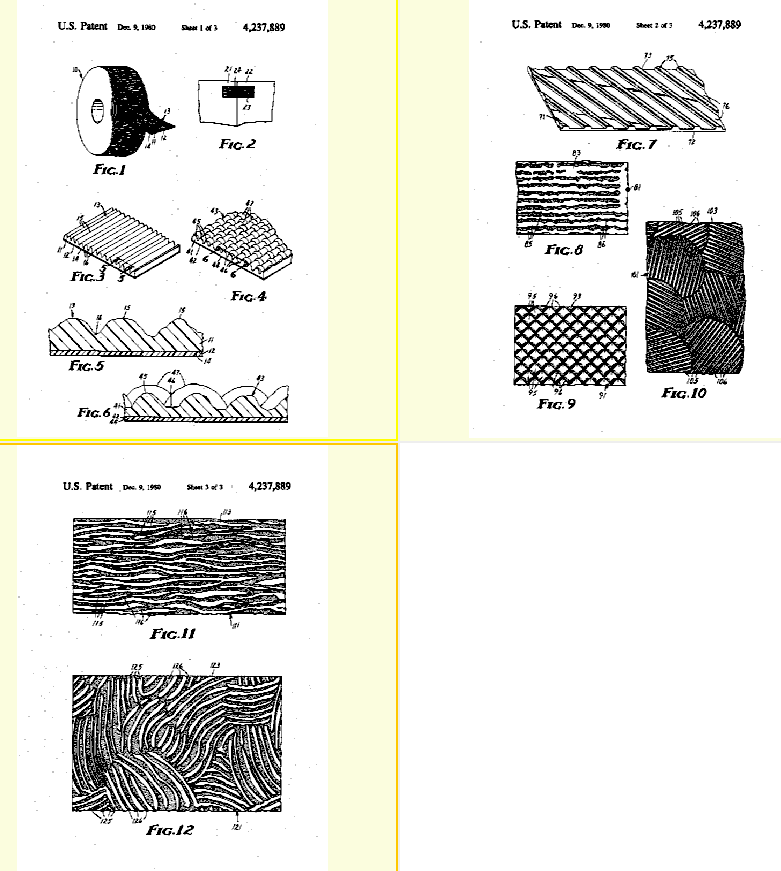

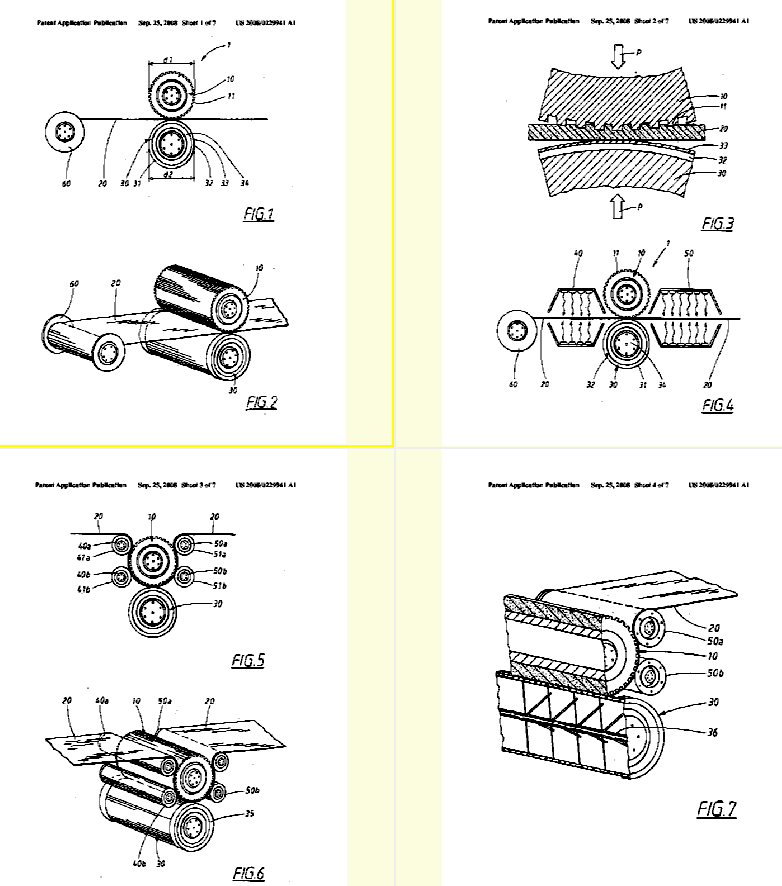

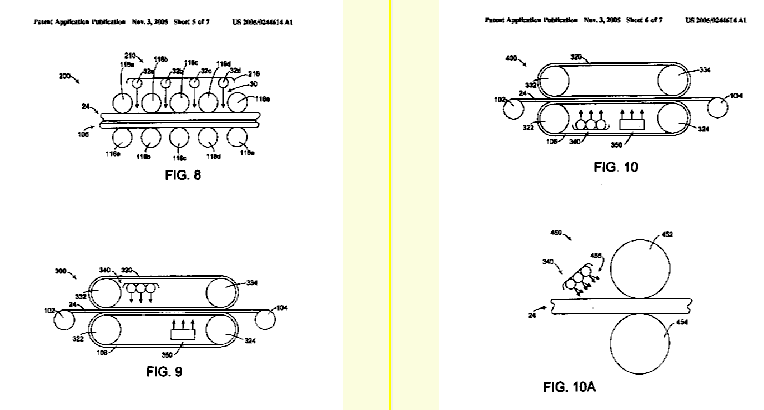

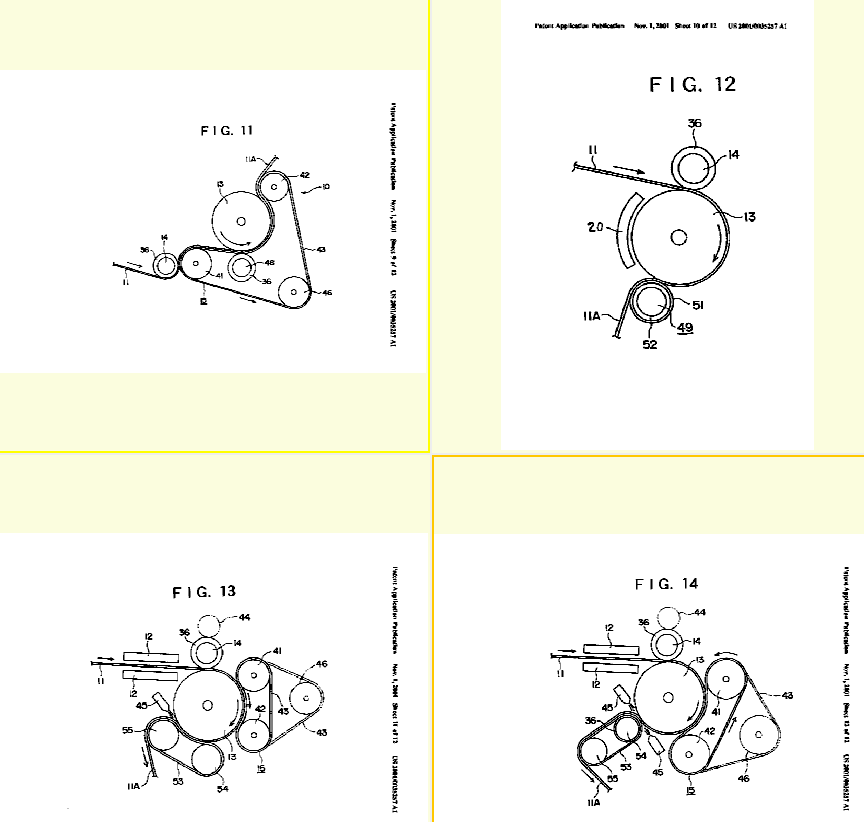

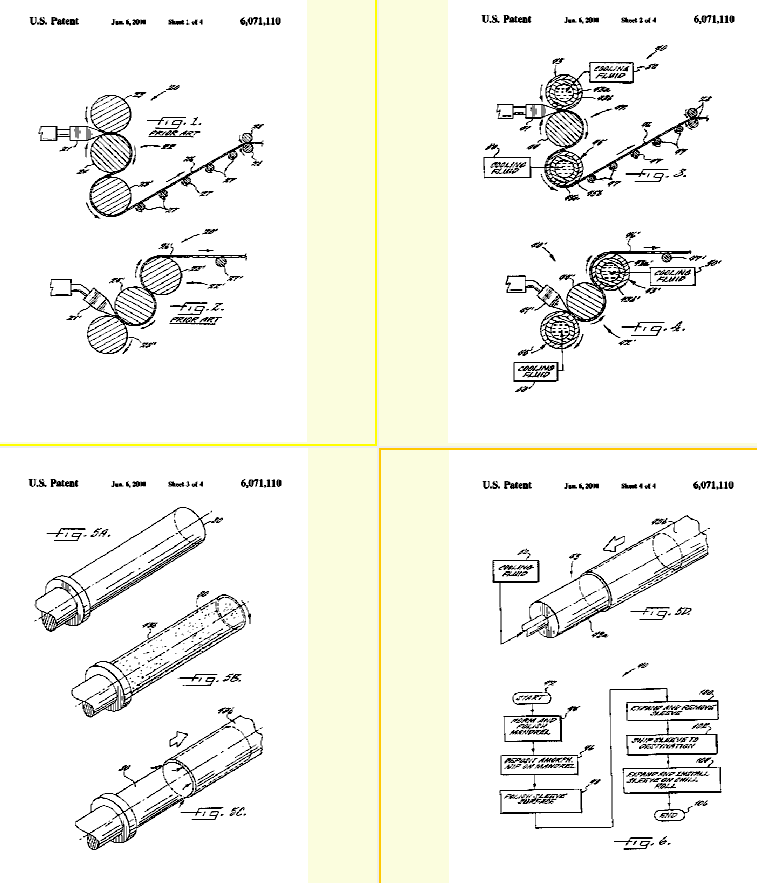

This place covers:

Compression moulding refers to shaping polymeric materials by using moulding devices movable against the material to apply pressure for shaping and achieving a residual filling of a cavity;

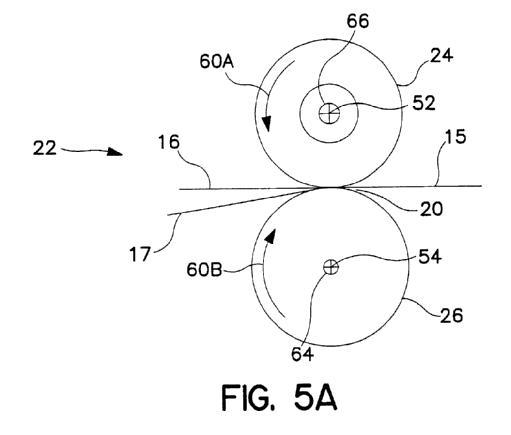

Continuous compression moulding refers to making indefinite articles by using rotatable devices, e.g. wheels or rollers or calenders;

Devices to supply the material to the compression moulding device.

Related moulding processes are:

- Transfer moulding, i.e. transferring the required volume of moulding material by a plunger from a "shot" cavity into a mould cavity. Transfer moulding is classified in B29C 45/02.

- Injection compression moulding, i.e. injecting the polymeric material under pressure into a mould followed by moving the mould or mould parts to compress the material to achieve filling of the cavity and the final shape of the article, wherein initially the mould can be open or closed and/or the cavity can be in a state with enlarged or reduced size. Injection compression moulding is classified in B29C 45/561.

- Shaping by thermoforming (i.e. shaping sheets or sheet-like preforms after heating), e.g. shaping sheets by matched moulds or by deep-drawing and apparatus therefor. Thermoforming is classified in B29C 51/00.

- Surface shaping of already moulded polymeric articles, e.g. by embossing and apparatus therefor. In the case of mechanical embossing, the surface shaping requires a reheating step for the surface to be embossed. Surface shaping of already moulded polymeric articles is classified in B29C 59/00.

- Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts, are classified in B29C 70/00. The use of moulding compounds comprising chopped or short fibres are classified in the moulding technique used, e.g. for compression moulding are classified in B29C 43/003 or B29C 43/006, for injection moulding using fibre reinforcements are classified in B29C 45/0005 or for extrusion moulding using fibre reinforcements are classified in B29C 48/2886.

This place does not cover:

Shaping by liberation of internal stresses, the force created by the liberation of the internal stresses being used for compression moulding |

Attention is drawn to the following places, which may be of interest for search:

Manufacturing of articles by compacting or sintering metallic powders | |

Shaping clay or other ceramic compositions using presses | |

Presses in general | |

Photomechanical production of textured or patterned surfaces by imprinting or stamping whereby the pattern is fixed via light or thermal curing. |

In this place, the following terms or expressions are used with the meaning indicated:

Compression moulding | shaping of polymeric materials by using moulding devices movable against the material to apply pressure for shaping and achieving residual filling of a cavity |

Continuous compression moulding | making of indefinite articles by shaping polymeric materials using rotatable devices, e.g. calenders or rollers or wheels |

In patent documents, the following words/expressions are often used with the meaning indicated:

"compacting" | "compression moulding". |

This place covers:

compression moulding processes characterised by the choice of material, e.g. using organic, inorganic or mineral fillers or fibres, using plasticised particulate materials bonded by resin, recycled materials

Attention is drawn to the following places, which may be of interest for search:

Moulding processes characterised by the choice of the material, e.g. wax, aggregates: | |

Pressing of glass: | |

Making brake linings: |

This place covers:

e.g. pressing fleeces made of thermoplastic fibres;

hot-fusion under pressure particles, granules or fibres etc, particles are heated and compressed to partial melt and bond together; thermal bonding under pressure; shaping monoliths

Attention is drawn to the following places, which may be of interest for search:

Sintering (without pressure) | |

Surface fusion and bonding of particles to form voids | |

Moulding processes characterised by the choice of mineral aggregates bonded with resin as the moulding material | |

Prostheses | |

Sintering metallic powders | |

Preheating powders | |

Partial melting of one or more layers to form the bond | |

Sintering fibres | |

Making brake linings |

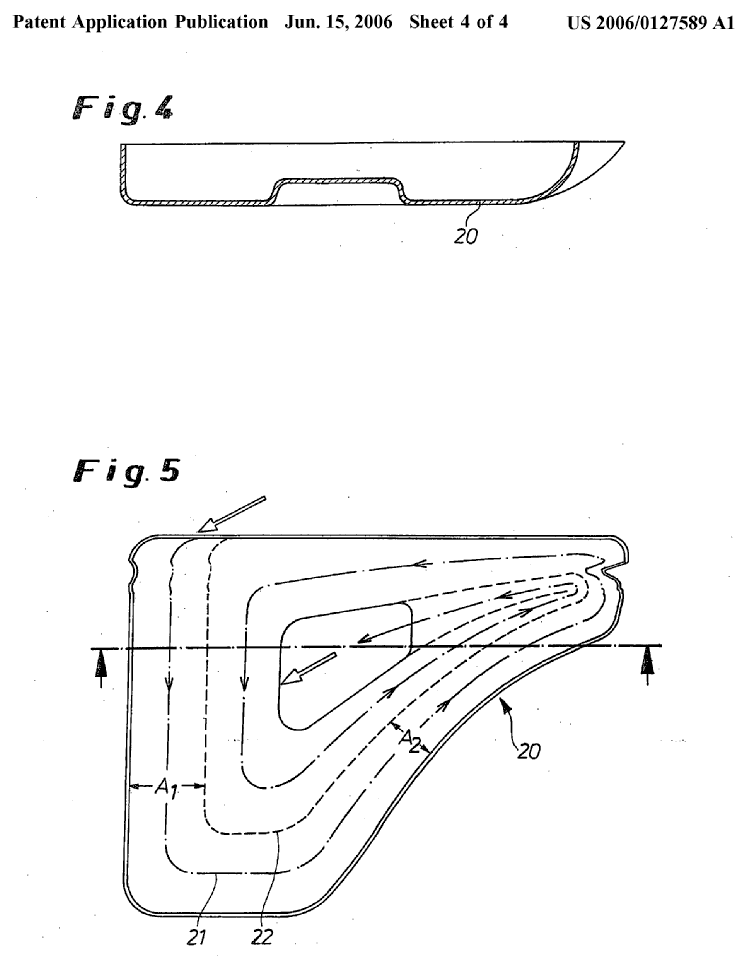

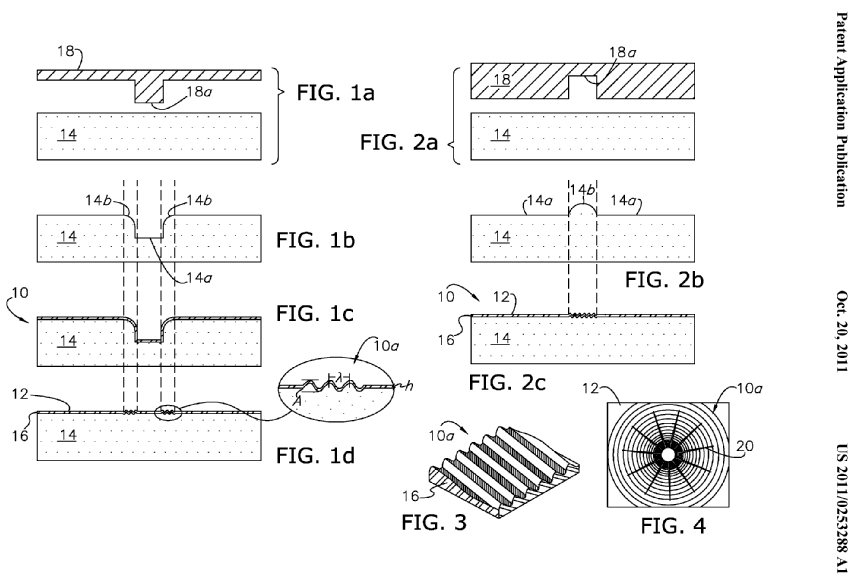

This place covers:

making articles characterised by the shape of the surface

Attention is drawn to the following places, which may be of interest for search:

Grooves | |

Folding lines | |

Surface shaping | |

Moulding of lenses | |

Moulding of Fresnel lenses | |

Imprinting | |

Embossing machines | |

Decorative arts | |

Packages or encapsulation of microstructural systems | |

Processes for packaging: MEMS | |

Fresnel lenses | |

Apparatus for making LCD's | |

Lithographic processes using stamping | |

Fine patterning magnetic record carriers | |

Optical record carriers | |

Masters, stampers: | |

Manufacturing printed circuits | |

Laminating circuit boards | |

Apparatus for mechanical treatment of semiconductors | |

Making masks on semiconductor bodies |

Attention is drawn to the following places, which may be of interest for search:

Moulds or cores characterised by the location of the parting line of the mould parts | |

Moulding single grooves or ribs, e.g. tear lines | |

Forming folding lines by pressing or scoring |

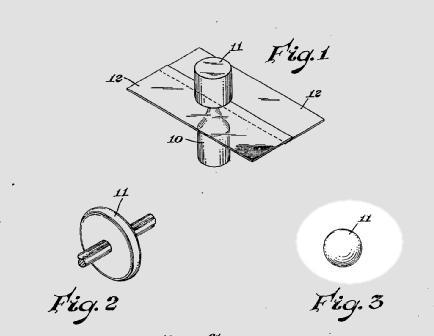

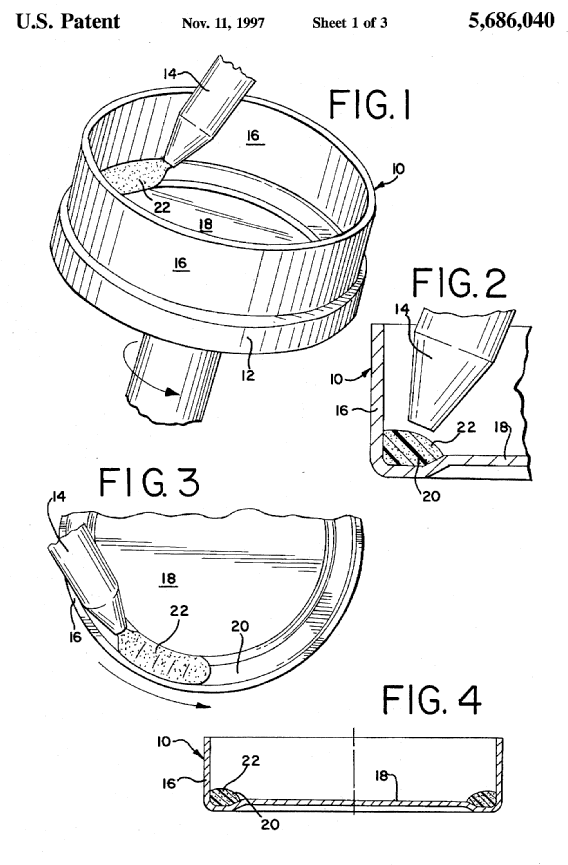

This place covers:

Compression moulding of symmetrical articles, e.g. balls or ring-like shaped articles or tubular articles.

This place does not cover:

Isostatic pressing using rigid mould parts specially adapted for moulding articles having an axis of symmetry |

Attention is drawn to the following places, which may be of interest for search:

Apparatus or methods for manufacturing balls | |

Making spherical articles, e.g. balls | |

Moulded articles with a profiled transverse cross-section | |

Ring or ring-like shaped moulded articles |

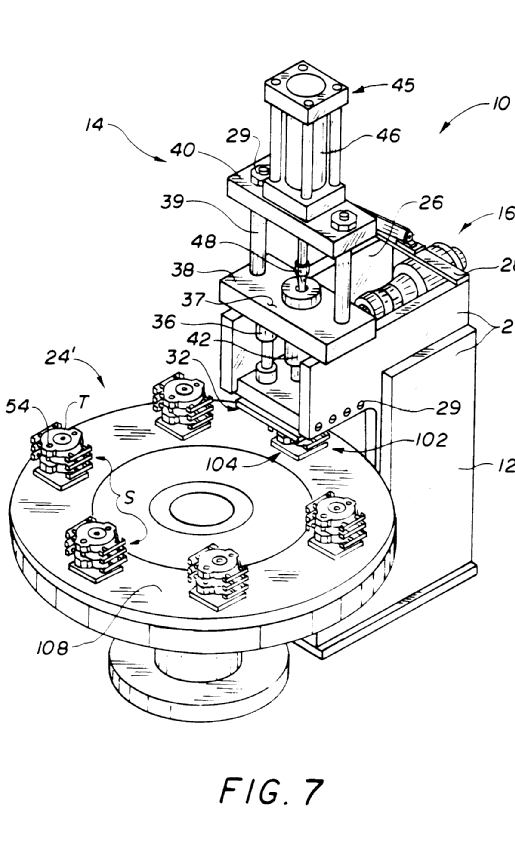

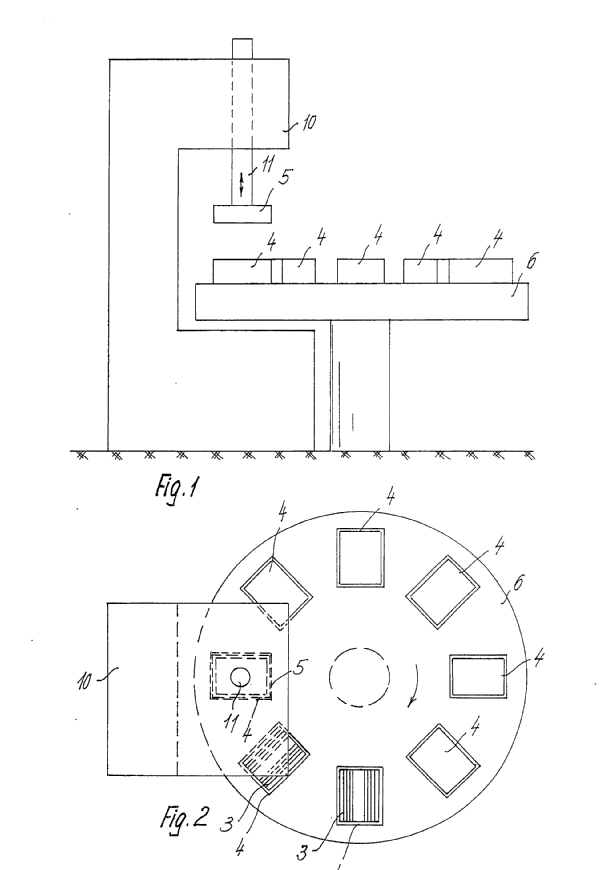

This place covers:

movable moulds with the movement being other than open, closing, clamping, or pressurising, e.g. for curing in a closed mould outside the pressure exerting means, transferring moulds or mould parts between a feeding and a compressing station

Attention is drawn to the following places, which may be of interest for search:

Handling of moulds in general | |

Movable moulds in general | |

Movable moulds for injection moulding | |

Movable moulds for blow moulding |

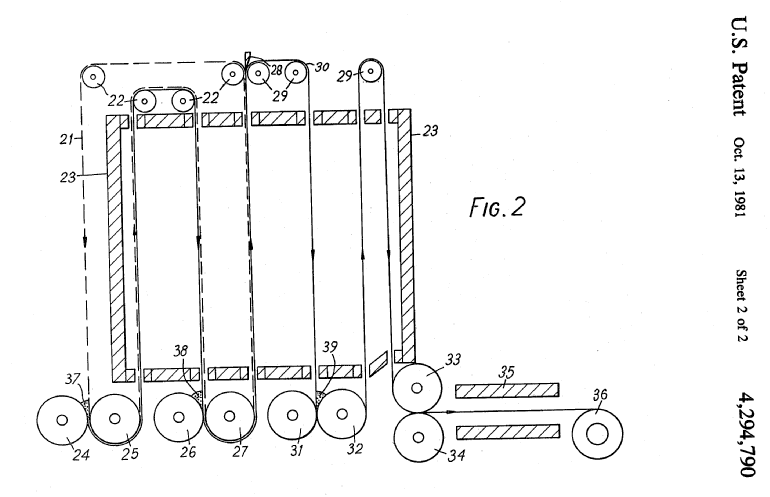

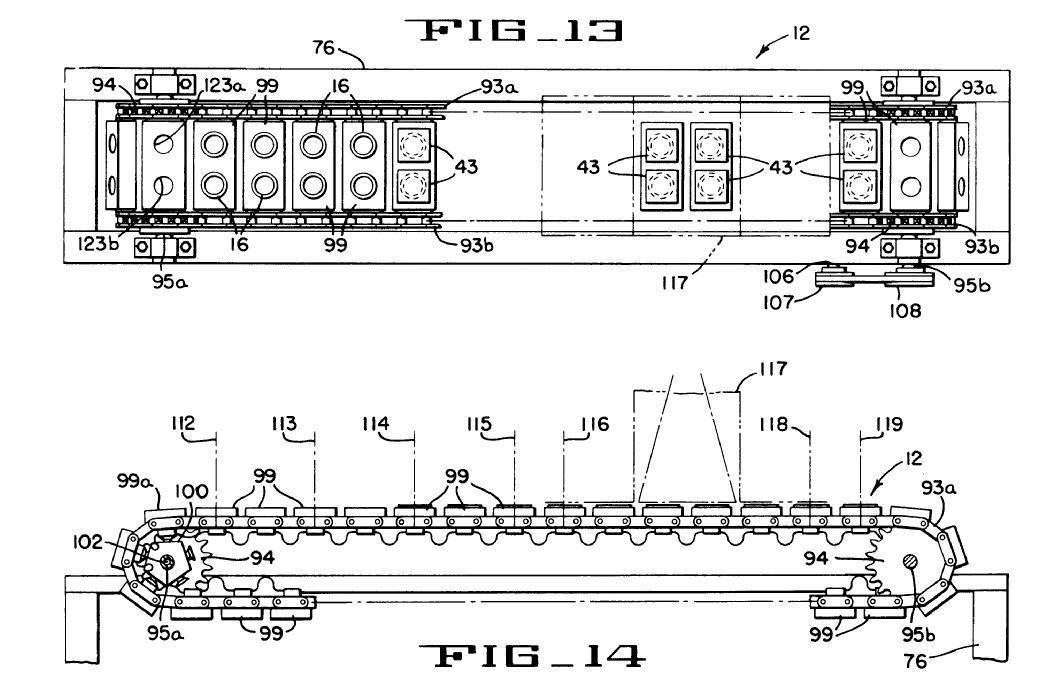

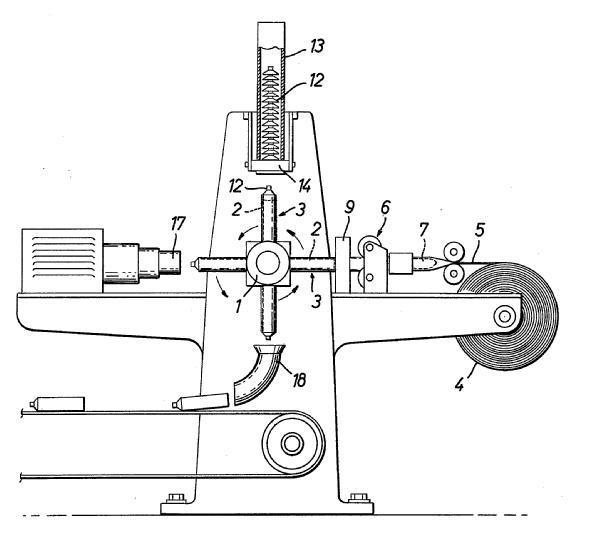

This place covers:

e.g. moulds or mould parts travelling continuously along a path

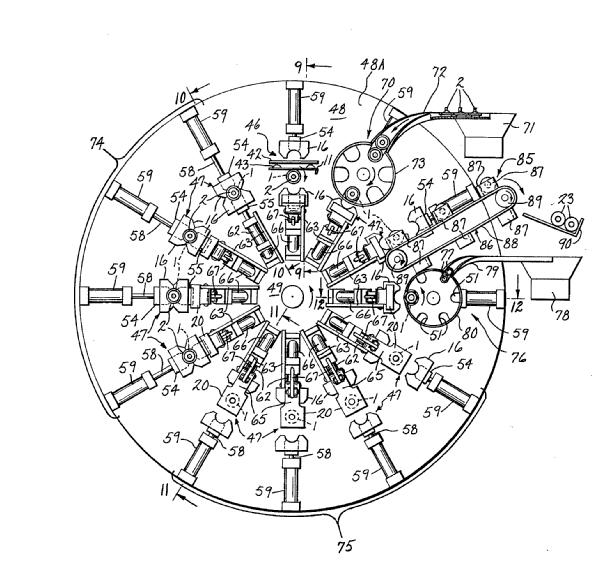

This place covers:

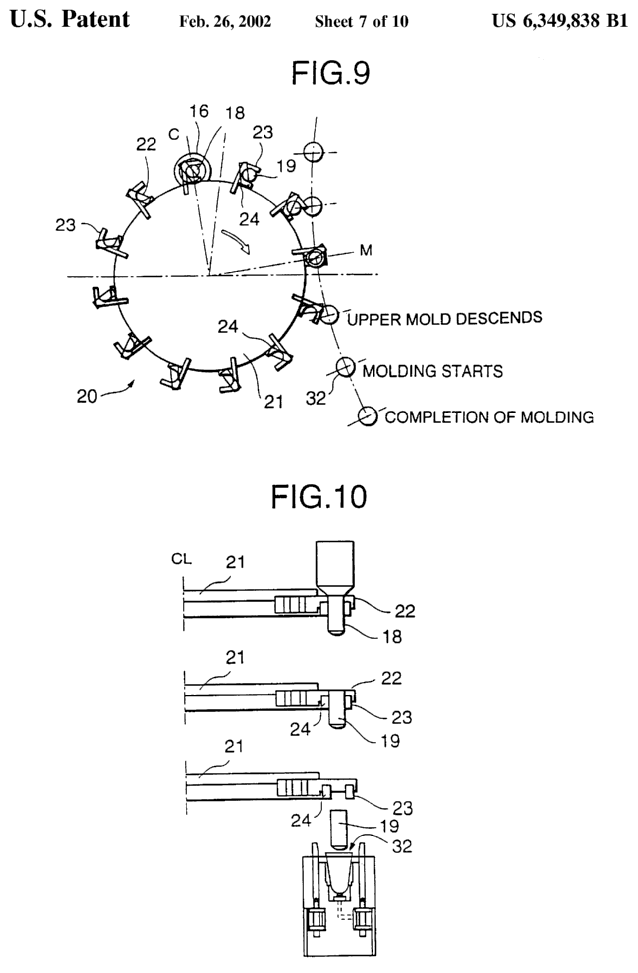

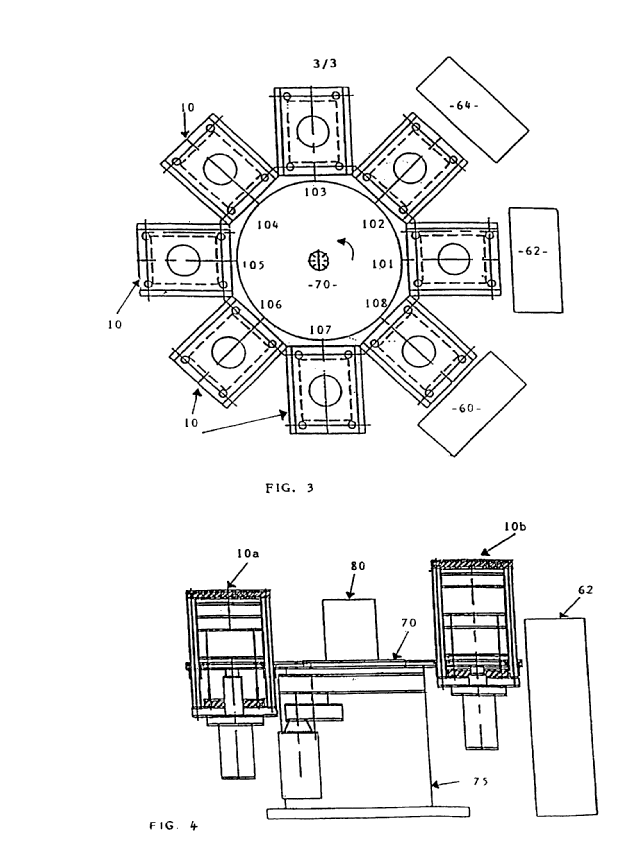

moulds or mould parts mounted on rotating supporting constuction, rotary machines, e.g. turntables, drums, carousels, star wheels

Attention is drawn to the following places, which may be of interest for search:

For injection moulding | |

For blow moulding | |

For presses |

This place covers:

Flexible pressure exerting means, e.g. material characteristics of the pressure exerting member (e.g. special density, composition or syntactic foam).

Attention is drawn to the following places, which may be of interest for search:

Flexible collapsible moulds for facilitating demoulding | |

Applying pressure through membranes | |

Vacuum bagging | |

Hydroforming | |

Bladders for making tyres | |

Flexible pressing means | |

Membrane presses | |

Isostatic pressing in general | |

Laminating glass sheets | |

Vacuum laminating |

This place covers:

Compression moulding processes by using vacuum or inflatable bags.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Shaping or impregnating composites of definitive length by compression using isostatic pressure | |

Flexible cores for vulcanising tyres |

Attention is drawn to the following places, which may be of interest for search:

For indefinite articles |

Attention is drawn to the following places, which may be of interest for search:

Outsert moulding |

Attention is drawn to the following places, which may be of interest for search:

Completely encapsulating inserts |

Attention is drawn to the following places, which may be of interest for search:

Joining of preformed parts using adhesives |

Attention is drawn to the following places, which may be of interest for search:

Joining of preformed parts by heating, with or without pressure, and applying molten plastics | |

Joining of preformed parts using adhesives |

Attention is drawn to the following places, which may be of interest for search:

Joining of preformed parts by heating |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

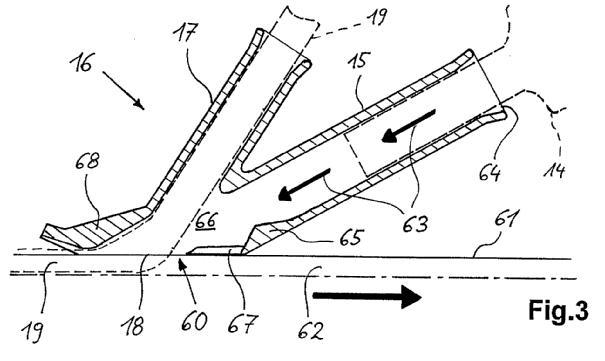

Shaping or impregnating composites by compression for producing articles of indefinite length |

Attention is drawn to the following places, which may be of interest for search:

Floor coverings obtained by sintering or gluing the granules together |

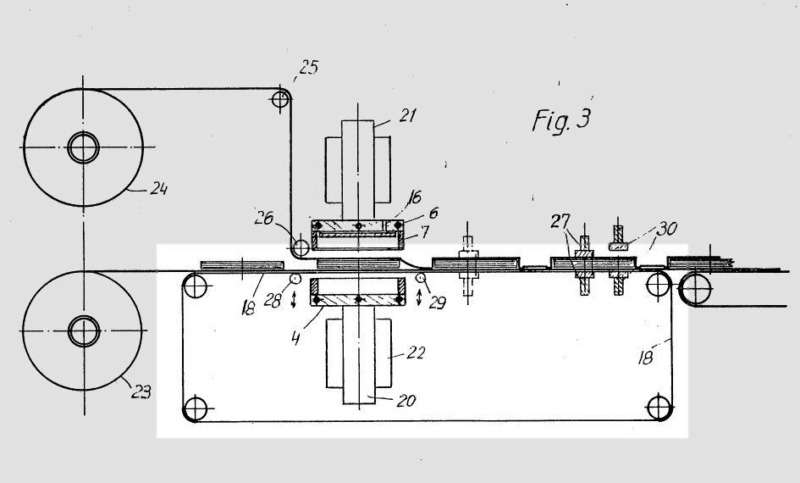

This place covers:

e.g. measuring and regulating calender banks

This place covers:

Pressure exerting means or methods (mechanical, e.g. deformable nets or springs or non-mechanical, e.g. thermal expansion), e.g. pressure equalising means or methods.

Attention is drawn to the following places, which may be of interest for search:

Material characteristics of the isostatic pressure exerting member |

This place covers:

Single pressing elements, e.g. magnets or vibrating elements.

Attention is drawn to the following places, which may be of interest for search:

Compression moulds as such |

This place does not cover:

Feeding material in a continuous form to continuous movable compression moulds |

Attention is drawn to the following places, which may be of interest for search:

Feeding of the material to be moulded in general |

Attention is drawn to the following places, which may be of interest for search:

Dispensing from vessels |

Attention is drawn to the following places, which may be of interest for search:

Feeding using dispensing heads | |

Applying fluent material for coatings | |

Extrusion coating |

Attention is drawn to the following places, which may be of interest for search:

Feeding using moving dispensing heads | |

Applying fluent material for coatings | |

Extrusion coating |

Attention is drawn to the following places, which may be of interest for search:

Injection-compression moulding |

Attention is drawn to the following places, which may be of interest for search:

Feeding in general by using volumetric measuring chambers moving between a charging station and a discharge station | |

Turntables as movable moulds | |

Feeding materials to moulding presses | |

Transfer turntables |

Attention is drawn to the following places, which may be of interest for search:

Transfer stars |

Attention is drawn to the following places, which may be of interest for search:

Turntables as movable moulds |

Attention is drawn to the following places, which may be of interest for search:

Moulds with incorporated means for positioning inserts | |

Positioning articles in the mould for injection moulding |

Attention is drawn to the following places, which may be of interest for search:

Moulding lenses | |

Ram pressing | |

Ram press cooperating with fixed mould | |

Forming pockets in sheets |

Attention is drawn to the following places, which may be of interest for search:

Flexible cores for vulcanising tyres |

Attention is drawn to the following places, which may be of interest for search:

Applying pressure through membranes | |

Vacuum bag-moulding | |

Bladders for making tyres | |

Flexible pressing means | |

Membrane press | |

Vacuum laminating |

Attention is drawn to the following places, which may be of interest for search:

Applying pressure through membranes | |

Vacuum bagging | |

Bladders for making tyres | |

Flexible pressing means | |

Membrane press | |

Vacuum laminating |

Attention is drawn to the following places, which may be of interest for search:

Flexible moulds | |

Deep drawing membranes | |

Vacuum bagging | |

Bladders for making tyres | |

Flexible pressing means | |

Membrane press | |

Vacuum laminating |

Attention is drawn to the following places, which may be of interest for search:

Elastomeric moulds | |

Plastic moulds or cores | |

Isostatic pressing |

Attention is drawn to the following places, which may be of interest for search:

Details of caul plates for shaping composites comprising reinforcements only |

Attention is drawn to the following places, which may be of interest for search:

Lost moulds | |

Moulds for making articles with holes | |

Fusible cores | |

Making porous articles |

Attention is drawn to the following places, which may be of interest for search:

Rollers for making indefinite articles | |

Roller presses | |

Turntable presses |

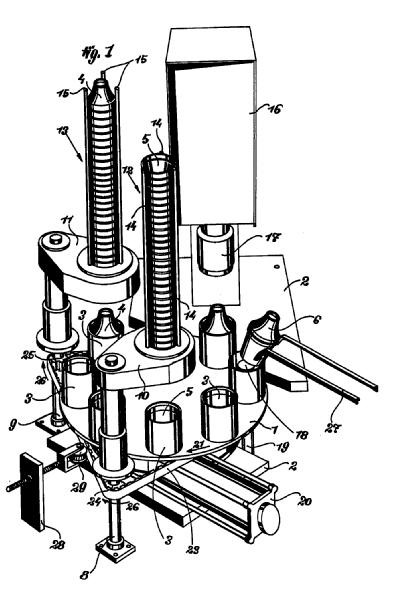

Attention is drawn to the following places, which may be of interest for search:

Press rams on turntables | |

Presses adapted for forming shaped articles using a press ram cooperating with moulds on turntables |

Attention is drawn to the following places, which may be of interest for search:

Moulds for moulding articles provided with holes in general | |

Moulds for undercut articles in general | |

Manufacture of work pieces or articles provided with cavities or holes from metallic powder |

Attention is drawn to the following places, which may be of interest for search:

Collapsible cores or mandrels |

This place covers:

e.g. exchanging rollers or belts;

e.g. exchanging the coating of rollers;

e.g. adjusting rollers;

Attention is drawn to the following places, which may be of interest for search:

driving arrangements for rollers |

Attention is drawn to the following places, which may be of interest for search:

rollers for mixing plastic material to be shaped | |

rollers with deflection compensating systems, e.g. hydraulic systems |

Attention is drawn to the following places, which may be of interest for search:

Calendering |

Attention is drawn to the following places, which may be of interest for search:

Calendering |

Attention is drawn to the following places, which may be of interest for search:

Using a rotating movement to unscrew articles |

Attention is drawn to the following places, which may be of interest for search:

Collapsible cores or mandrels |

Attention is drawn to the following places, which may be of interest for search:

Blow moulding machines rotatable about one axis | |

Handling means for blow moulding machines |

Attention is drawn to the following places, which may be of interest for search:

Press plates with heating or cooling means |

This place covers:

e.g. compression moulding using vibrations;

e.g. compression moulding while steaming

Attention is drawn to the following places, which may be of interest for search:

Moulds or cores with incorporated venting means | |

Vacuum bag-moulding | |

Vacuum laminating |

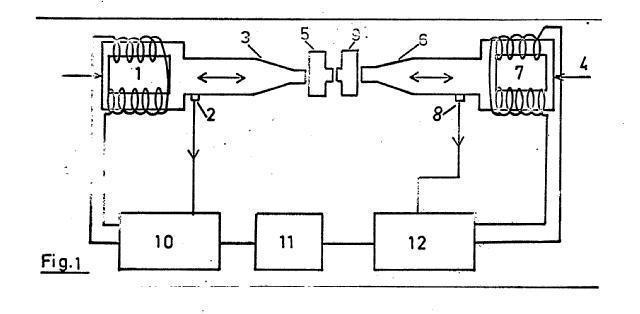

This place covers:

- enabling a value, or its relation to a datum, to be determined in the sense of measuring as defined in Note 2 of class G01;

- affecting a variable of the compression moulding process in any way, e.g. changing its direction or its value, maintaining its constant or limiting its range of variation;

- maintaining a variable at a desired value or within a desired range of values;

- selecting a specific value for a parameter, e.g. temperature or pressure, that has a substantial influence on the compression moulding process.

The mere selection of optimum or workable values or ranges of values, without accompanying disclosure of the influence on the compression moulding process or its objective does not qualify for classification in this group.

This place does not cover:

Measuring and regulating calender parameters, e.g. bank quantity |

Attention is drawn to the following places, which may be of interest for search:

Compensating shrinkage |

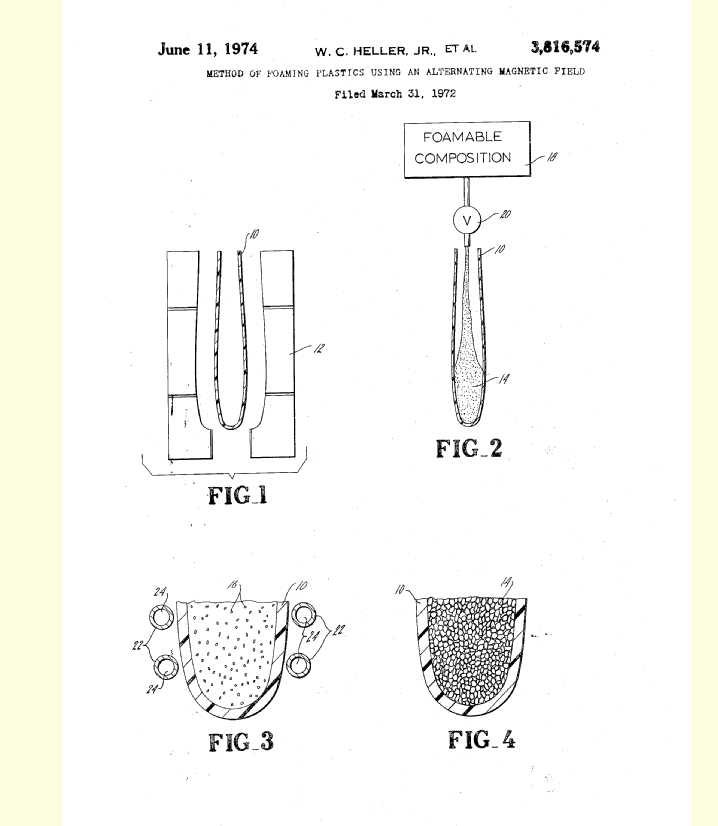

This place does not cover:

Chemical aspects of foaming |

Attention is drawn to the following places, which may be of interest for search:

Metal foams | |

Ceramic foams |

In this place, the following terms or expressions are used with the meaning indicated:

reticulated | cell wall membranes are removed, leaving a framework only. |

In patent documents, the following words/expressions are often used with the meaning indicated:

"foaming" | "expanding" and "swelling". |

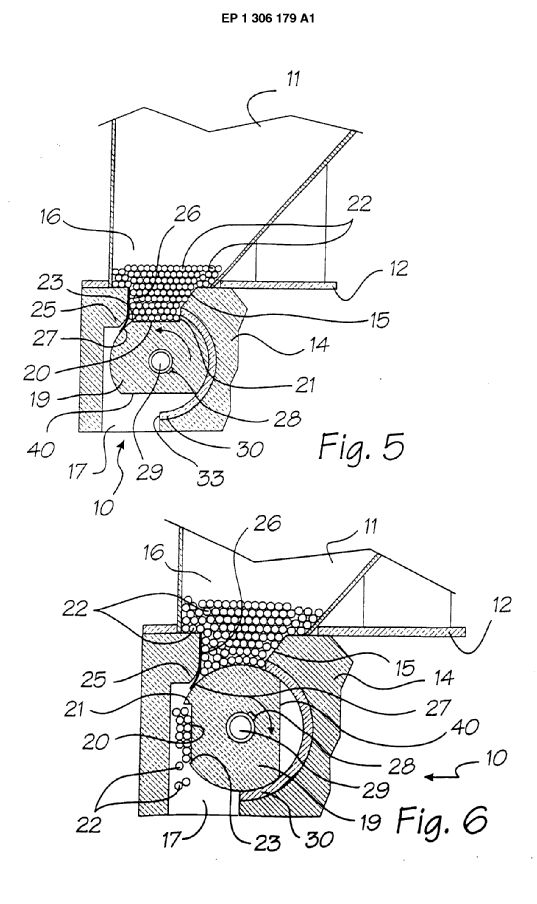

This place covers:

e.g. a soft, porous core covered by a skin or lining when they are made in the same procedure

This place does not cover:

incorporating preformed parts |

Attention is drawn to the following places, which may be of interest for search:

Filling cushion pads |

Attention is drawn to the following places, which may be of interest for search:

Insulating elements for vehicles | |

Foam in superstructures for vehicles |

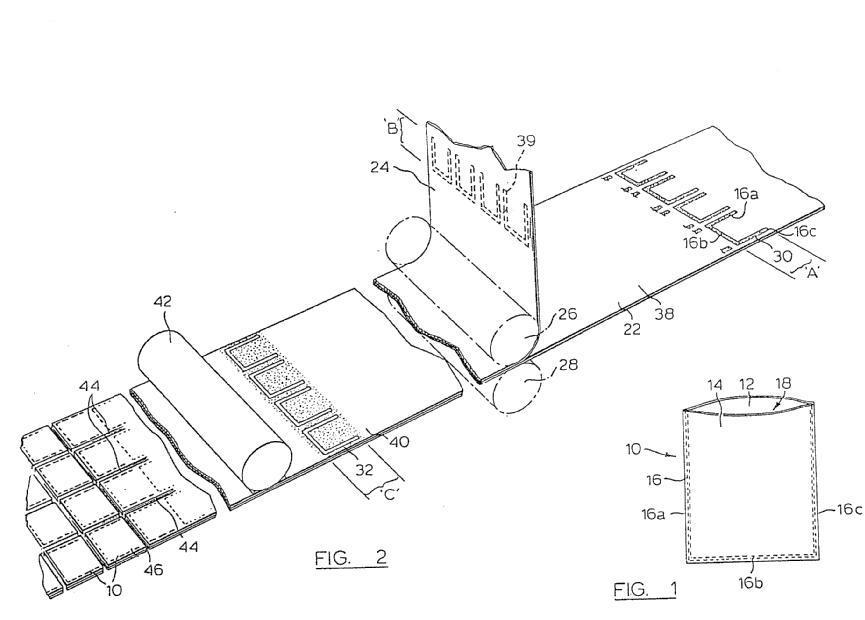

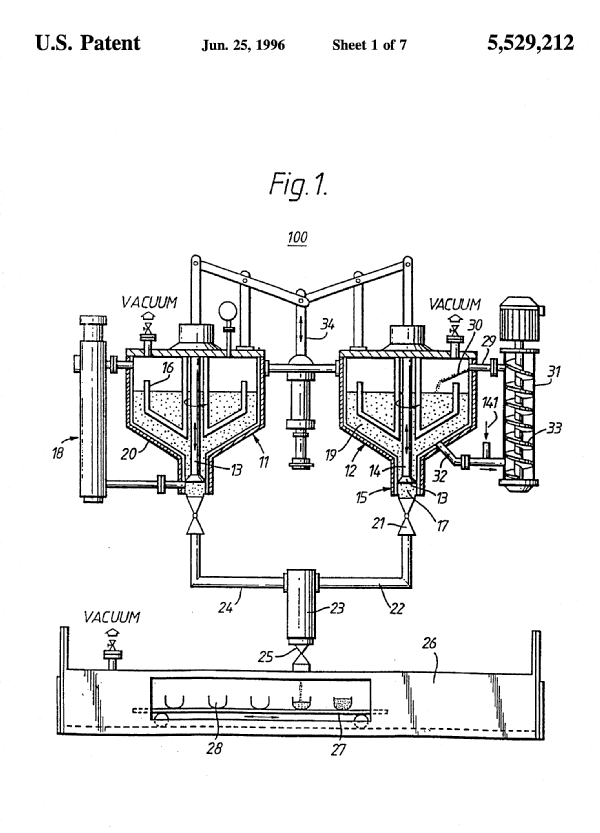

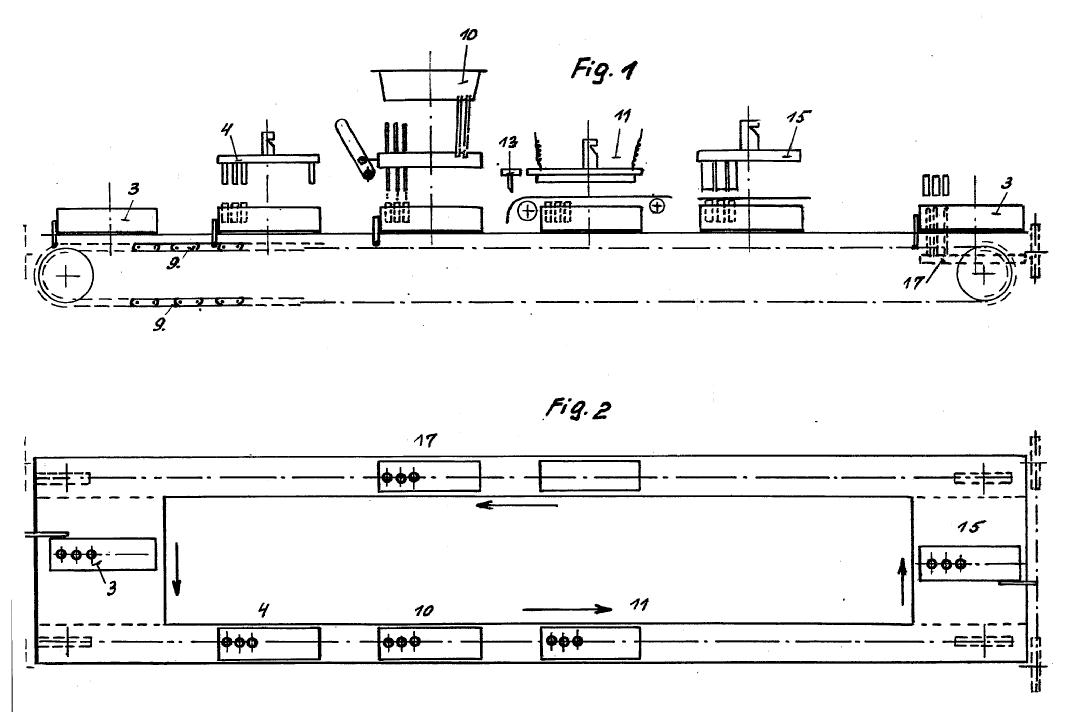

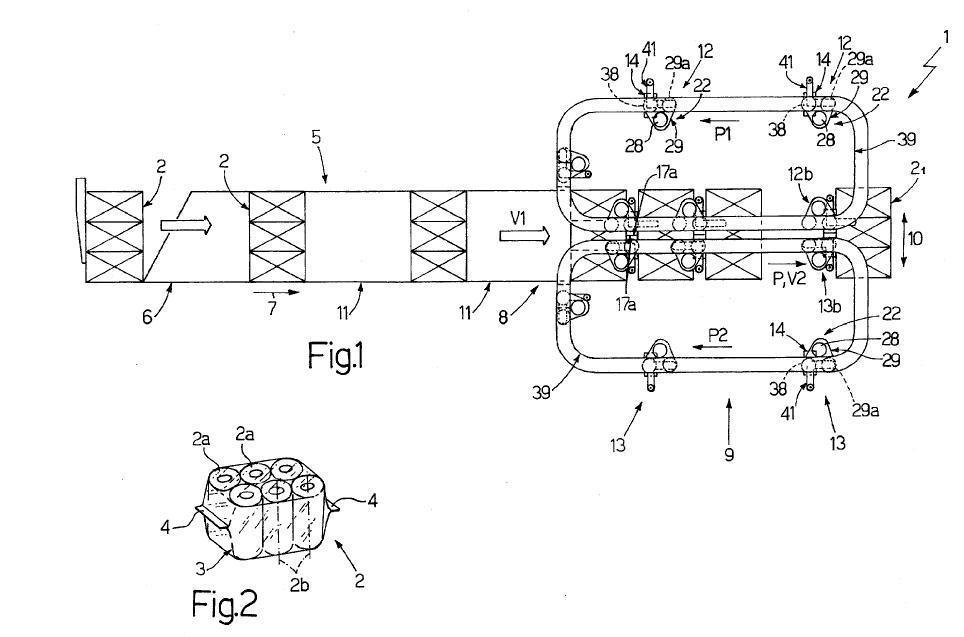

This place covers:

continuous processes, even if it is followed by a subdivision into separate articles

This place covers:

particular characteristics of the heating or cooling method

Attention is drawn to the following places, which may be of interest for search:

Feeding moulds with granules | |

Making granules | |

under-water, e.g. underwater pelletizers |

Attention is drawn to the following places, which may be of interest for search:

Making or treating expandable particles |

This place covers:

Characteristics of methods for working on an already foamed object

This place covers:

e.g. putting a foam layer and a lining in a mould, followed by compression moulding and joining

Attention is drawn to the following places, which may be of interest for search:

Venting of moulds in general | |

Injection moulds with venting means |

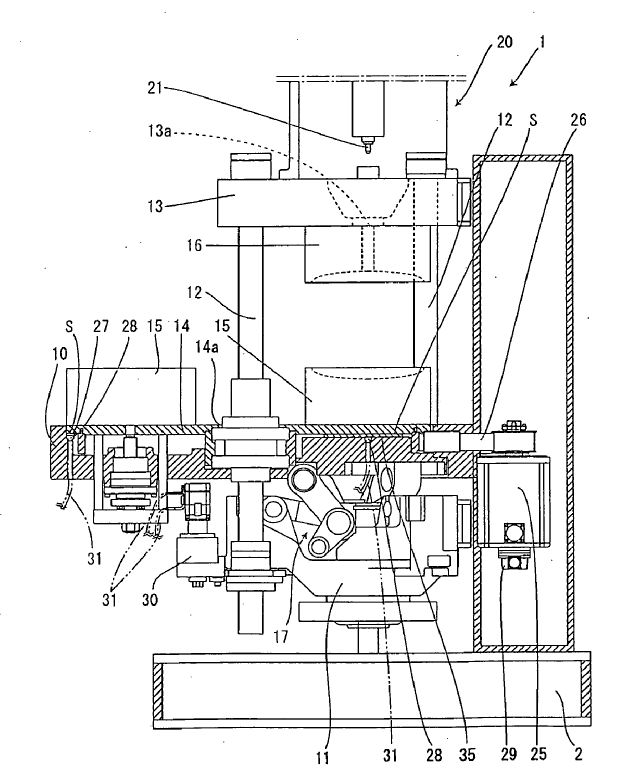

This place covers:

Injection moulding methods

Injection moulding apparatuses

Articles obtained by injection moulding, as far as these articles are characterised by the injection moulding method

This place does not cover:

Reaction injection moulding, liquid injection moulding |

This place covers:

Injection moulding processes characterised by the plastic material. The group contains documents concerning injection moulding with a special material or a process adapted for a certain material.

This place does not cover:

Injection moulding characterised by the use of fibres. | |

Injection moulding characterised by the use of fillers |

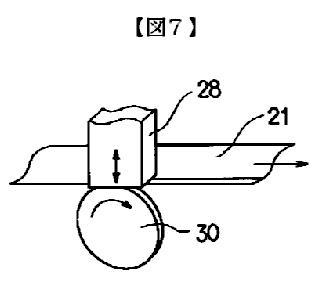

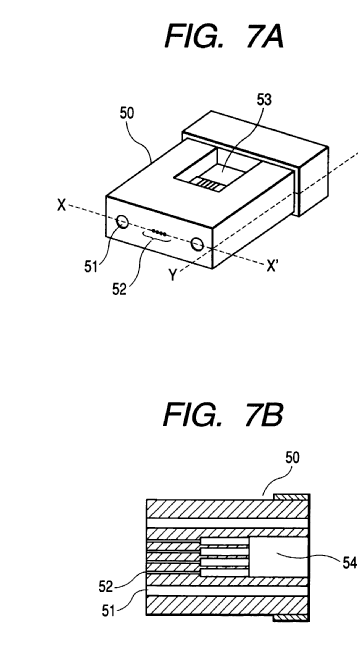

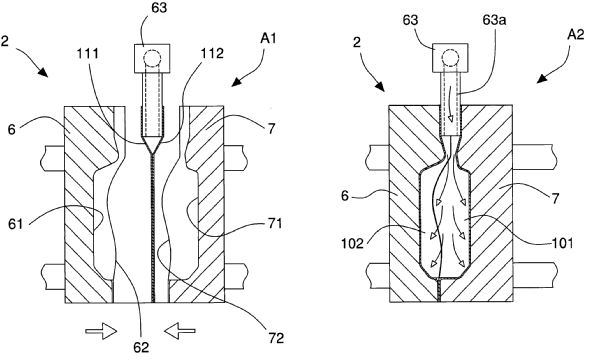

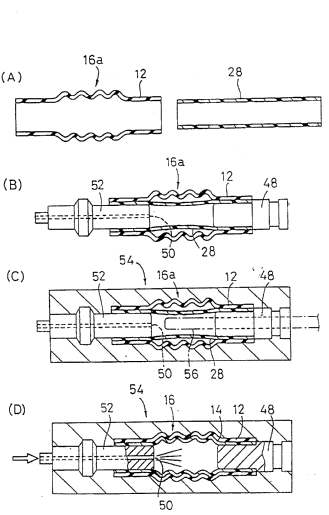

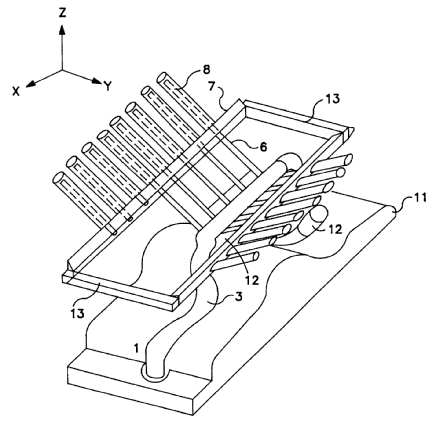

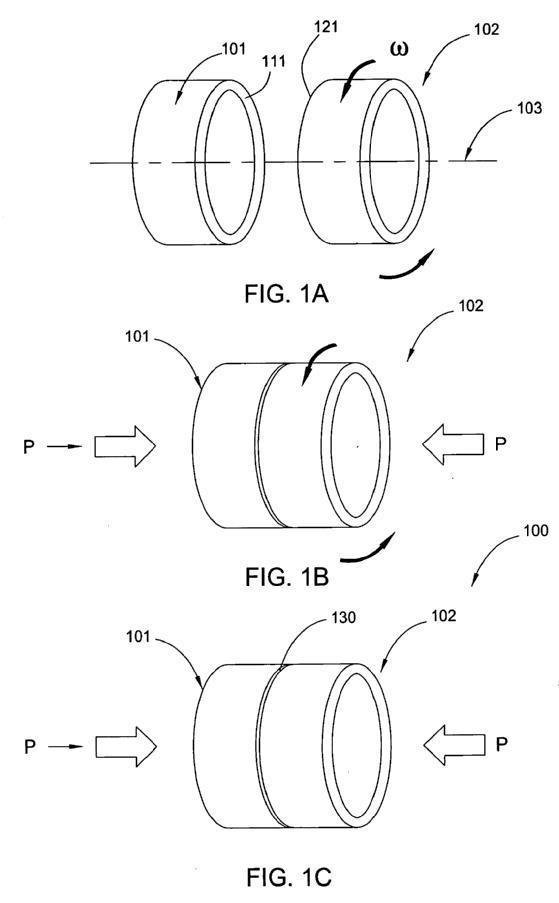

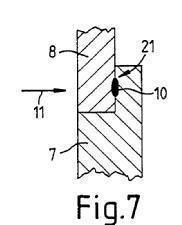

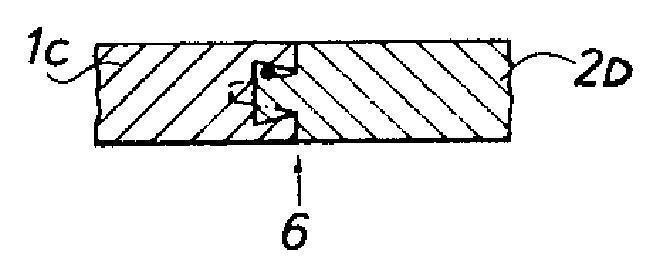

This place covers:

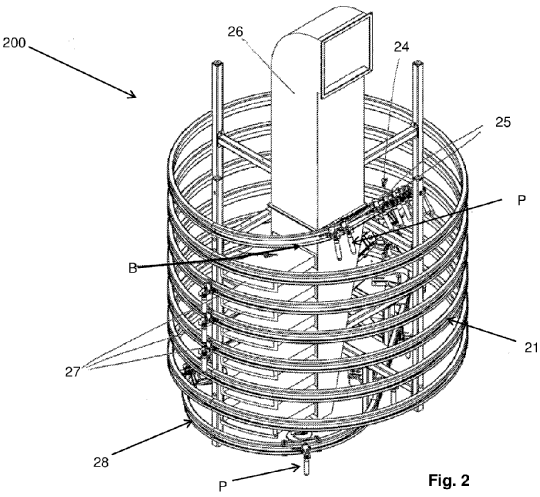

Injection moulding processes of continuous or endless articles.

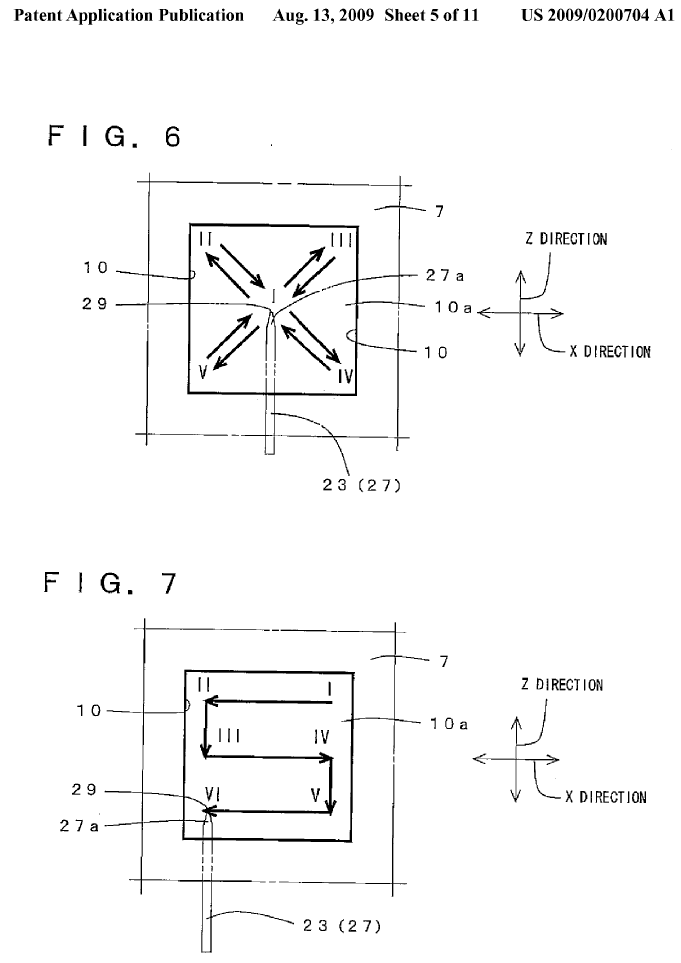

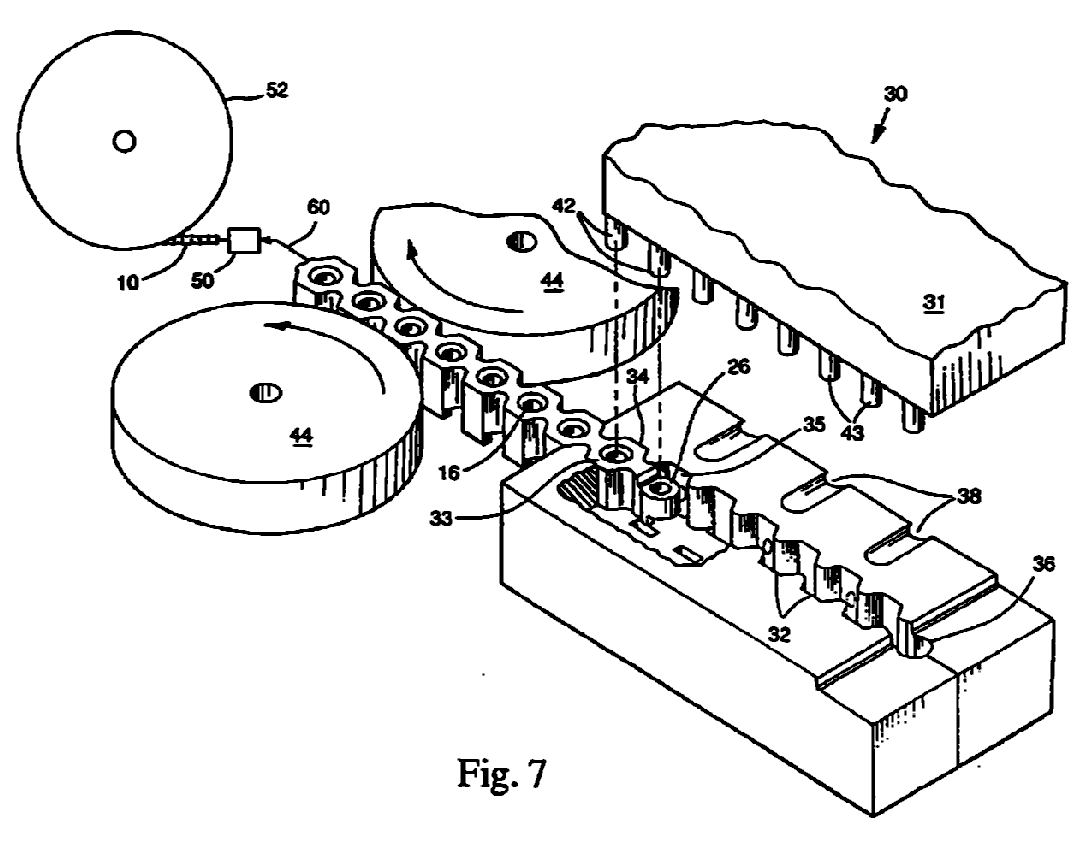

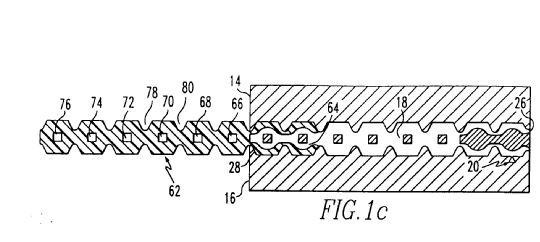

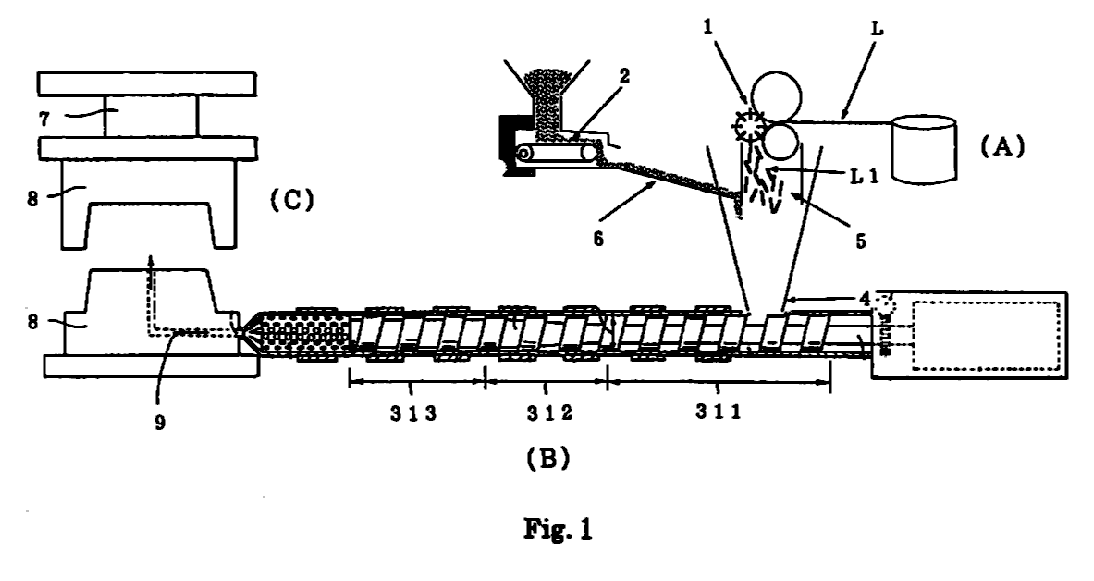

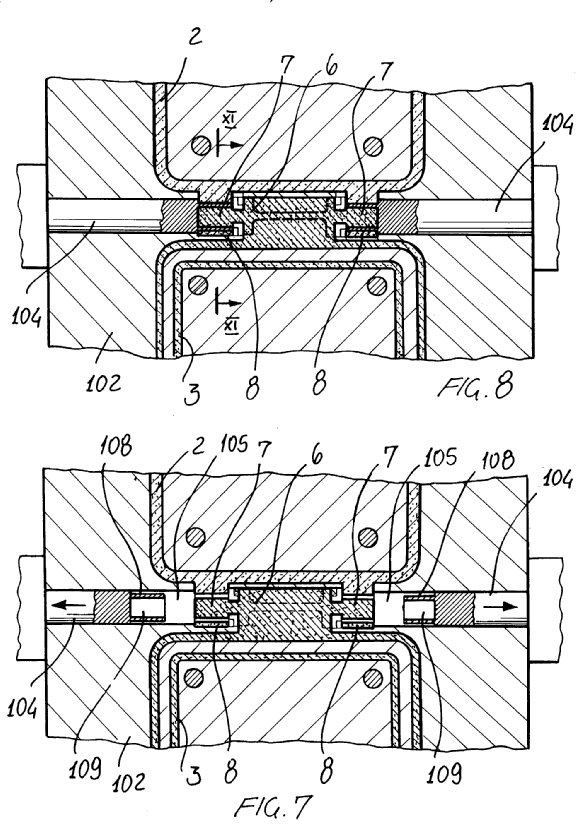

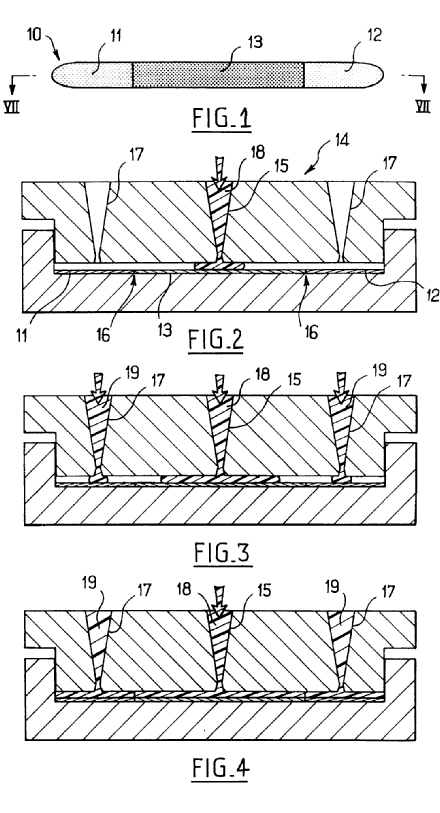

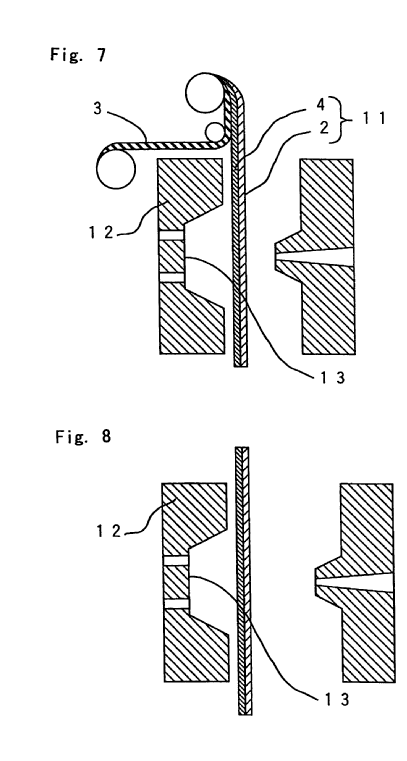

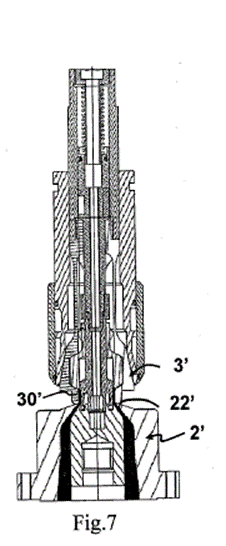

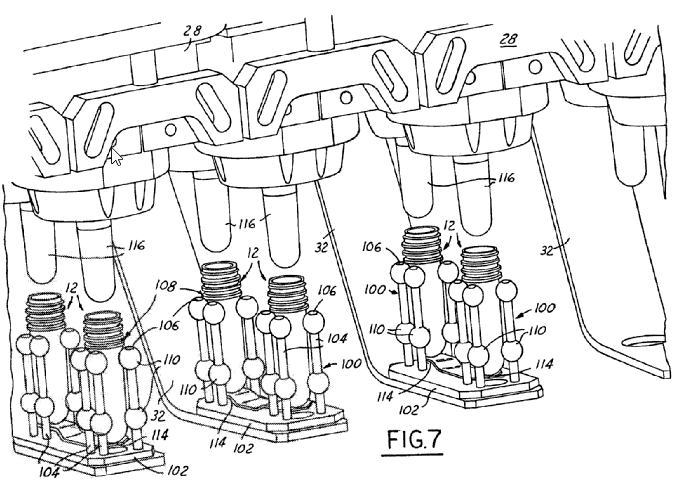

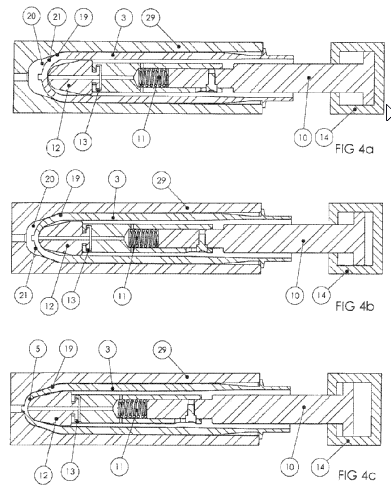

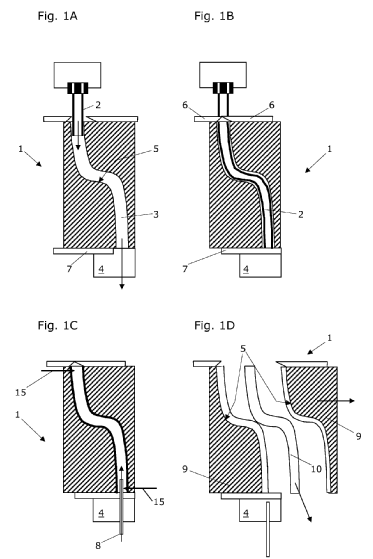

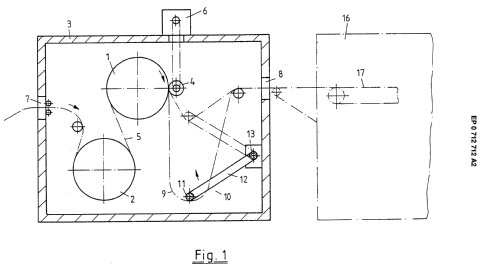

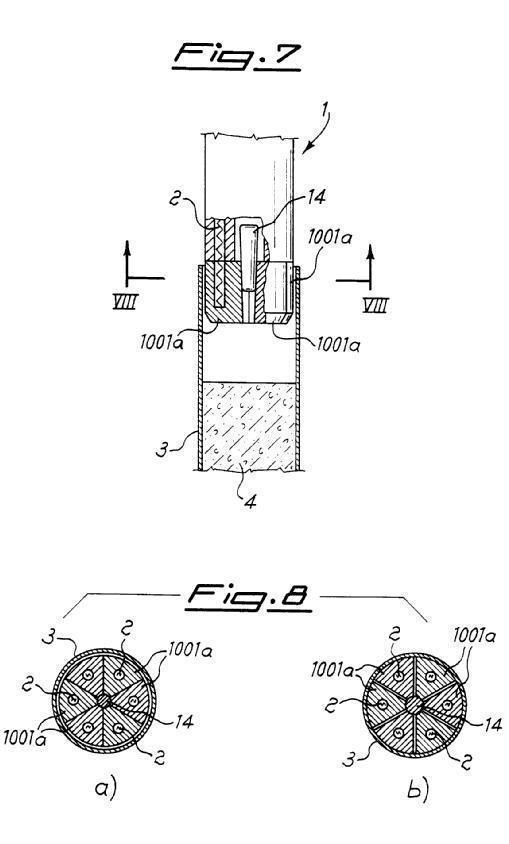

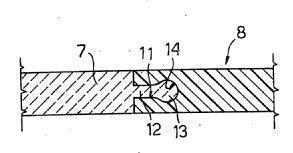

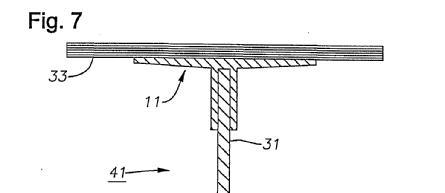

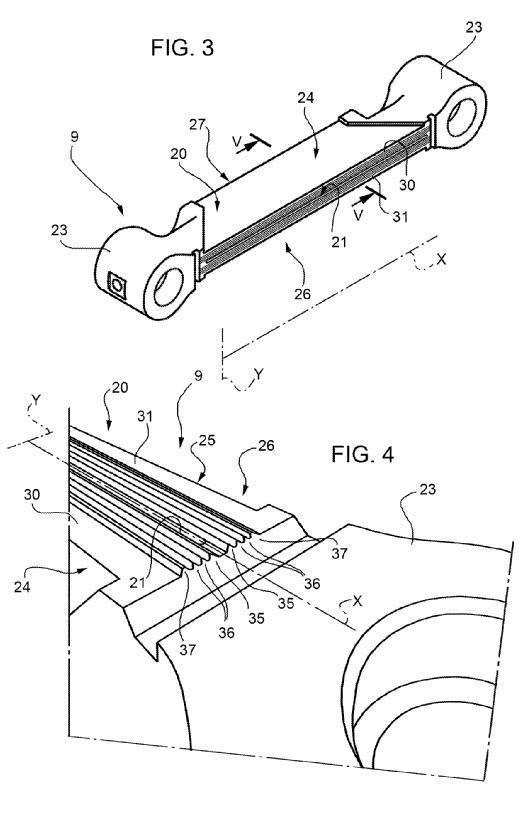

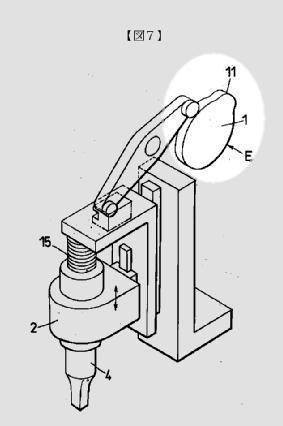

EP847112, fig 7,

EP826475 fig 1c.

Although this group covers a combination of several injection steps, the documents are not classified in B29C 45/16

This place covers:

Injection moulding processes, whereby the fibres are dispersed in the plastic material. The dispersion is usually randomly.

Example EP893228

Attention is drawn to the following places, which may be of interest for search:

Coating reinforcement | |

Coating fibrous material or fibre containing material | |

Resin transfer moulding | |

Injection moulding with short fibres | (Japanese F-term) 4F206/AB25 |

Injection moulding with long fibres | (Japanese F-term) 4F206/AD16 |

Attention is drawn to the following places, which may be of interest for search:

Shaping composites comprising fillers only |

In this place, the following terms or expressions are used with the meaning indicated:

Fillers | relatively inert substances in the form of particles, powder, beads, flakes or spheres, which improve the physical properties or increases the bulk or weight of an article and are randomly dispersed in the material, e.g. additives, dyestuff, colouring material, recycled material |

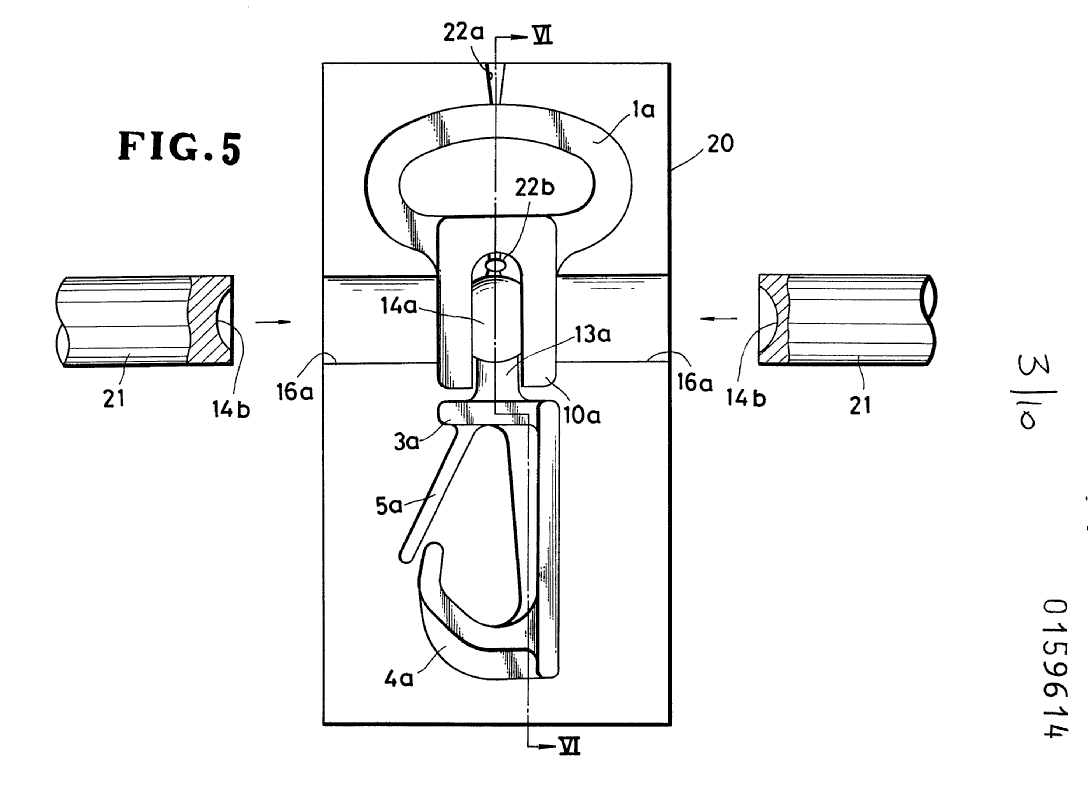

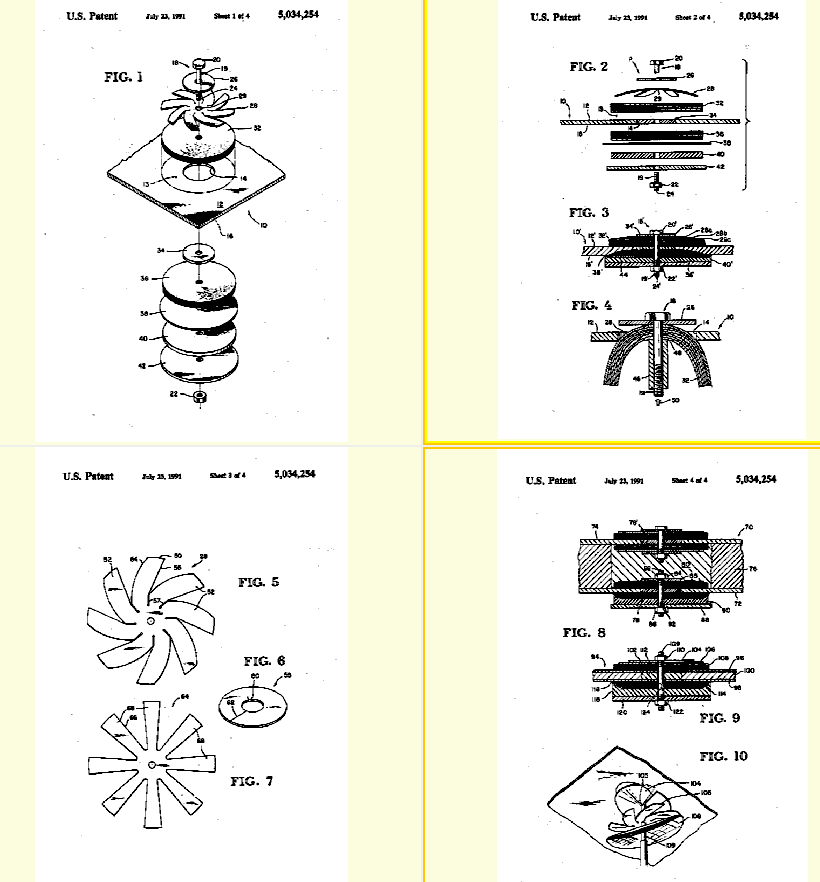

This place covers:

Moulding of movable interconnected elements in a two step moulding process, without applying inserts.

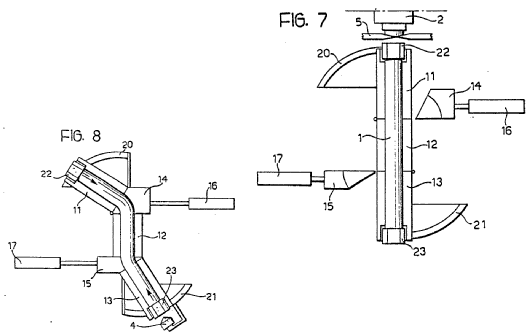

EP159614, fig 5

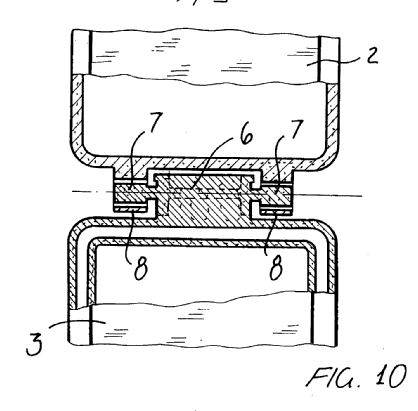

WO0189795, fig 7,8,10

Attention is drawn to the following places, which may be of interest for search:

Metal casting of rotational elements: | |

Manufacturing of ventilating devices: |

Documents contained in this group are NOT additionally classified in B29C 45/16 and/or B29C 45/26

This place covers:

Moulding processes to avoid the occurrence of burrs, sink marks, warping, location of gate marks or the like on the moulded article

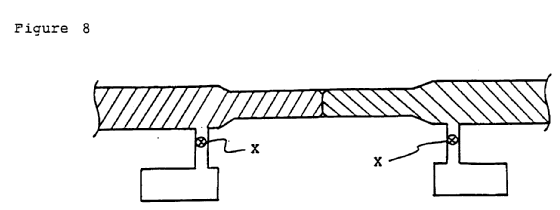

EP508732, fig 8

This place does not cover:

Applying external gas moulding technology for avoiding shrinkage marks |

Attention is drawn to the following places, which may be of interest for search:

Compensation volume change during moulding | |

Details relating to the flow path during moulding |

Attention is drawn to the following places, which may be of interest for search:

Moulds with means for removing excess material, e.g. with overflow cavities |

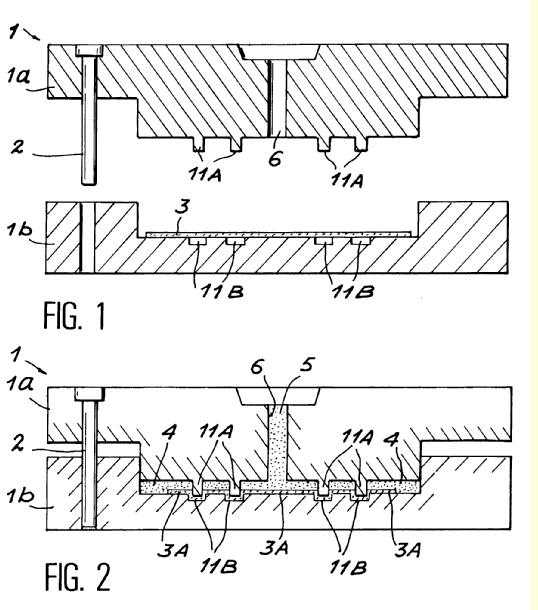

This place covers:

Moulding processes concerning the filling pattern of flow characteristics. Typically this is related to the moulding of parts having thin and thick sections, e.g. for avoiding weld lines.

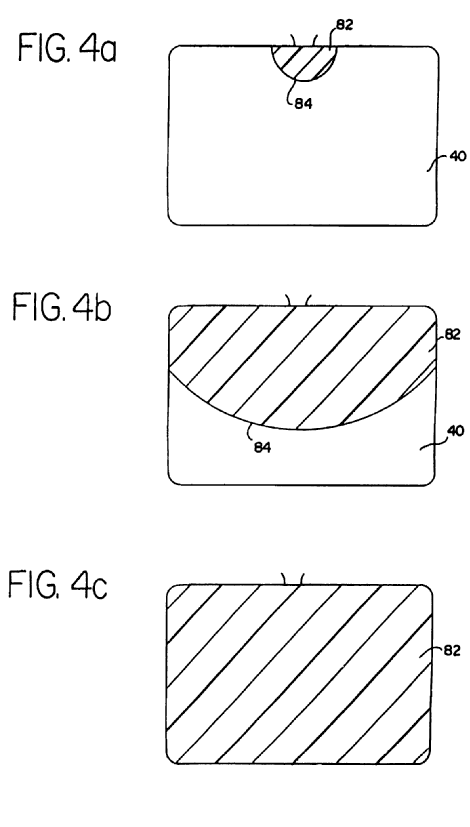

EP749821 fig 4

EP666159 fig 1, relates to filling, flow patterns.

EP362648, fig 6

Attention is drawn to the following places, which may be of interest for search:

Preventing defects on the moulded articles |

Documents are classified in B29C 45/0046 only, if the inventions concerns only the filling pattern.

Documents are classified in B29C 45/0025 and B29C 45/0046, if the inventions concerns the relation between the filling pattern and the weld line.

This place covers:

e.g. irradiation

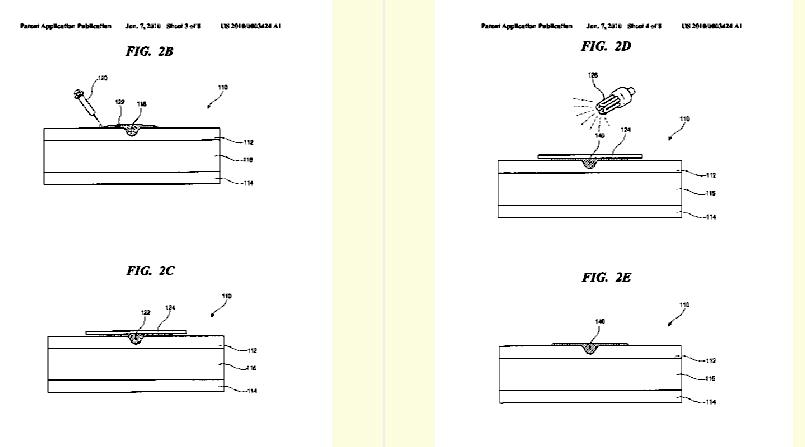

US20100156007 figure 1,

addition of an insert

EP495219, fig 2

This place does not cover:

Post thermal treatment of articles |

Attention is drawn to the following places, which may be of interest for search:

In-mould coating |

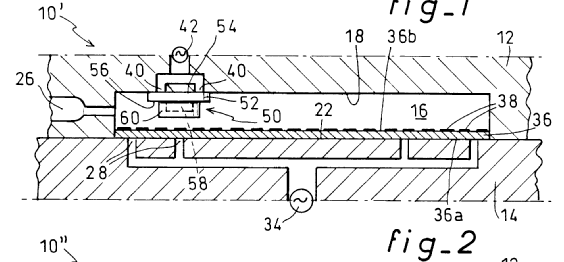

This place covers:

Moulding processes comprising a shaping step after moulding.

Shaping refers to after treatment by mechanical means, e.g. bending, cutting, drilling, punching.

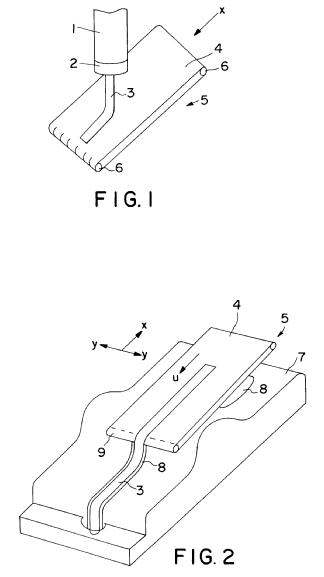

EP546950 shows in fig 1 & fig 2 a bending step.

EP381023

Documents classified in this group are not additionally classified in B29C 45/16

Attention is drawn to the following places, which may be of interest for search:

Moulds having several axially spaced mould cavities |

Attention is drawn to the following places, which may be of interest for search:

Deburring or deflashing in general |

This place covers:

Moulding processes, whereby the thin section is part of the moulded material

EP775639, figures 3, 4.

This place does not cover:

Using movable wall parts for making orifices in or through the moulded article |

Attention is drawn to the following places, which may be of interest for search:

Moulding single grooves, ribs, e.g. tear lines in general |

This place covers:

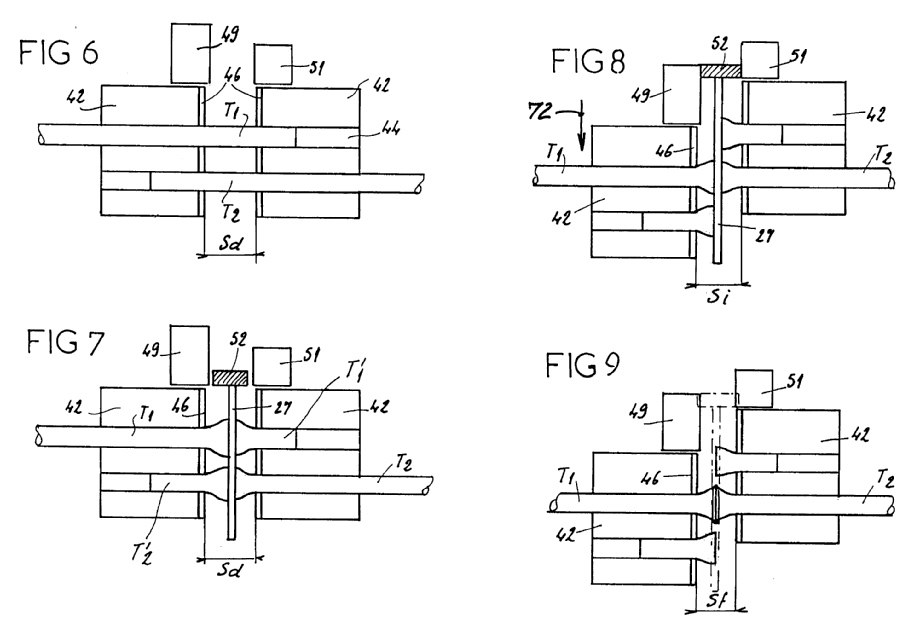

Moulding processes whereby the material is 'swung' between several positions in/around the cavity. The material flow is not limited to one direction.

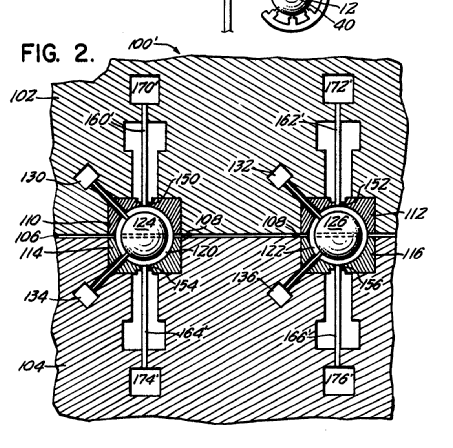

EP188120 figures 2 & 3

EP442255 fig 3,4.

This place does not cover:

Applying vibration to mould parts |

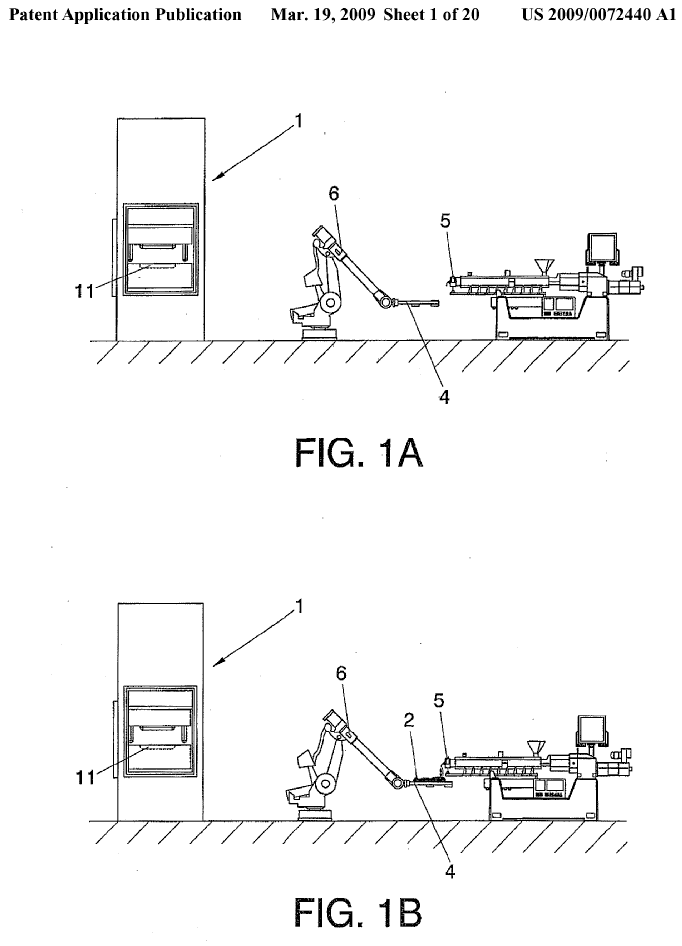

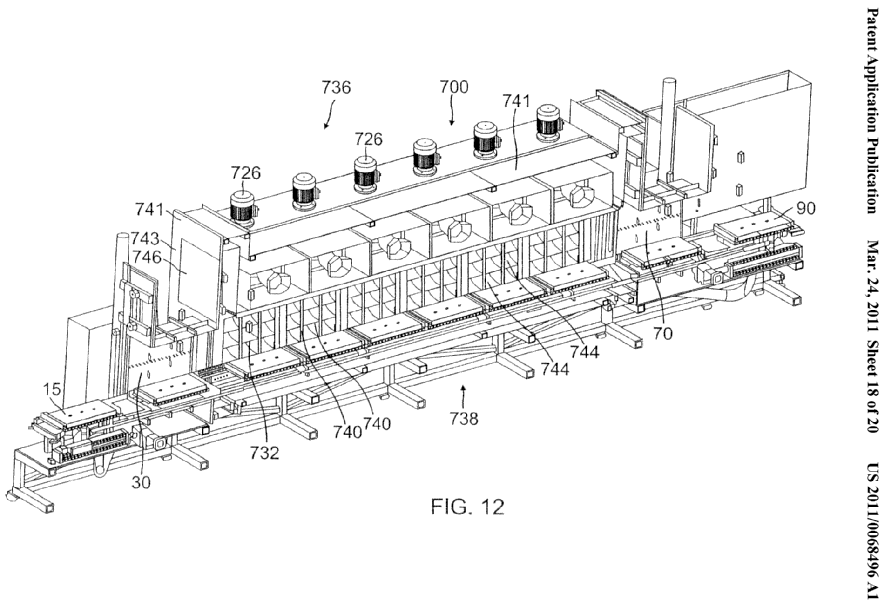

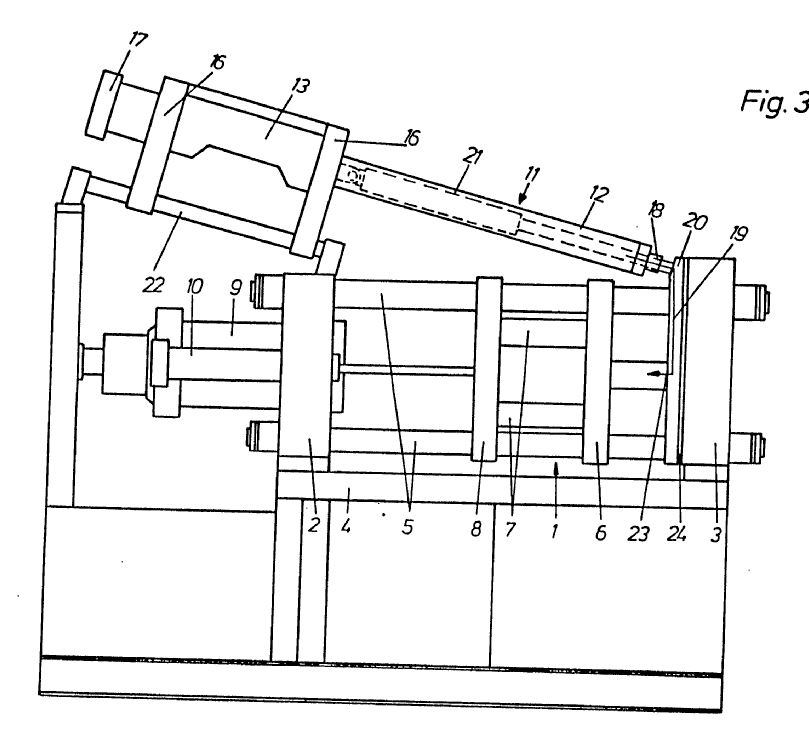

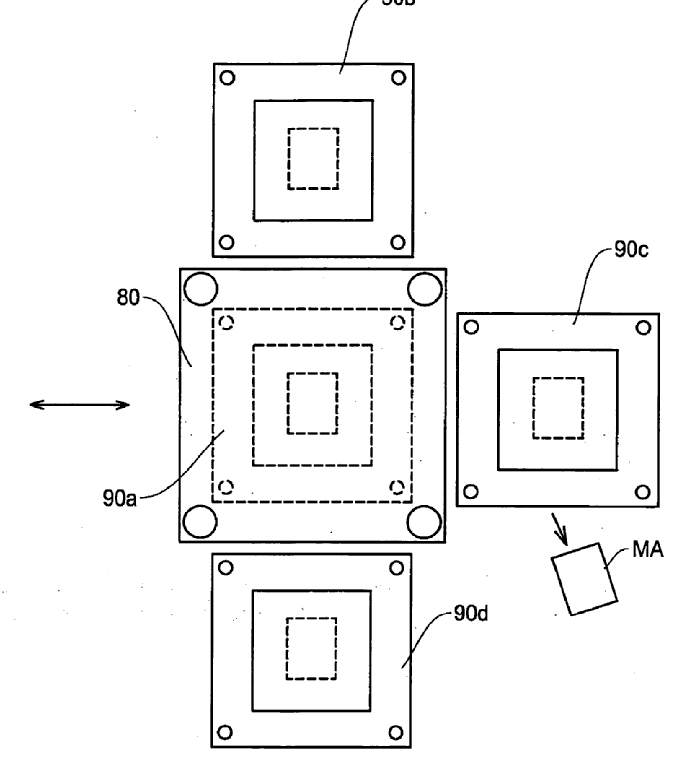

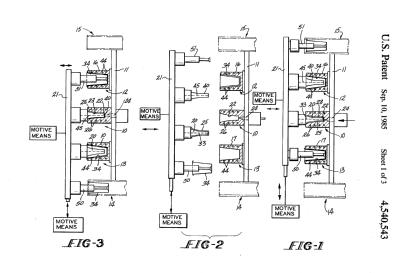

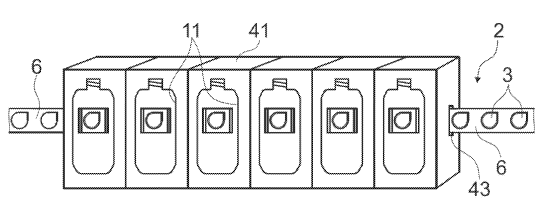

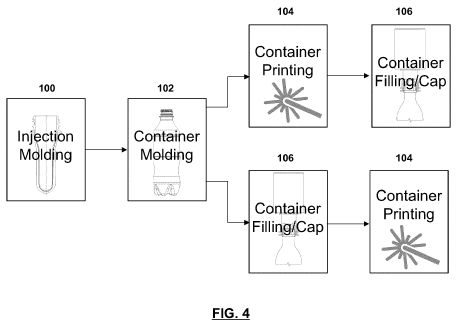

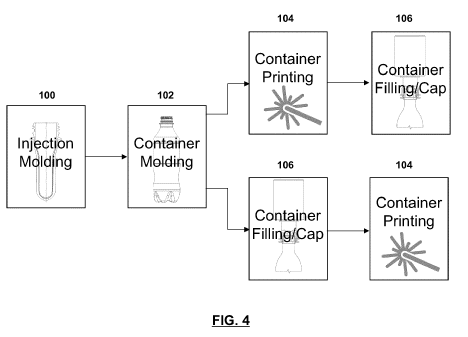

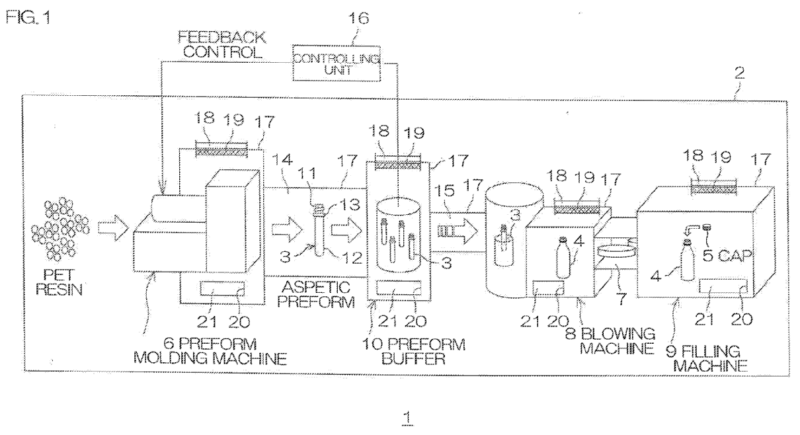

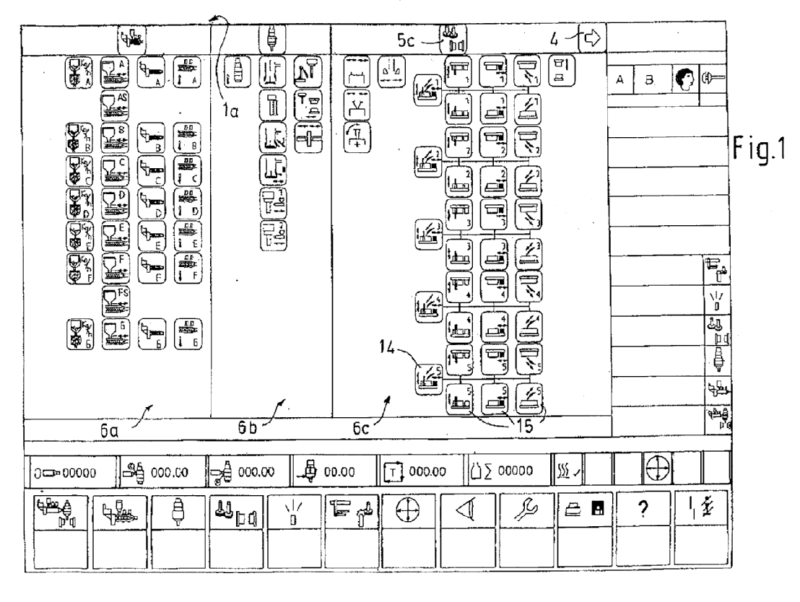

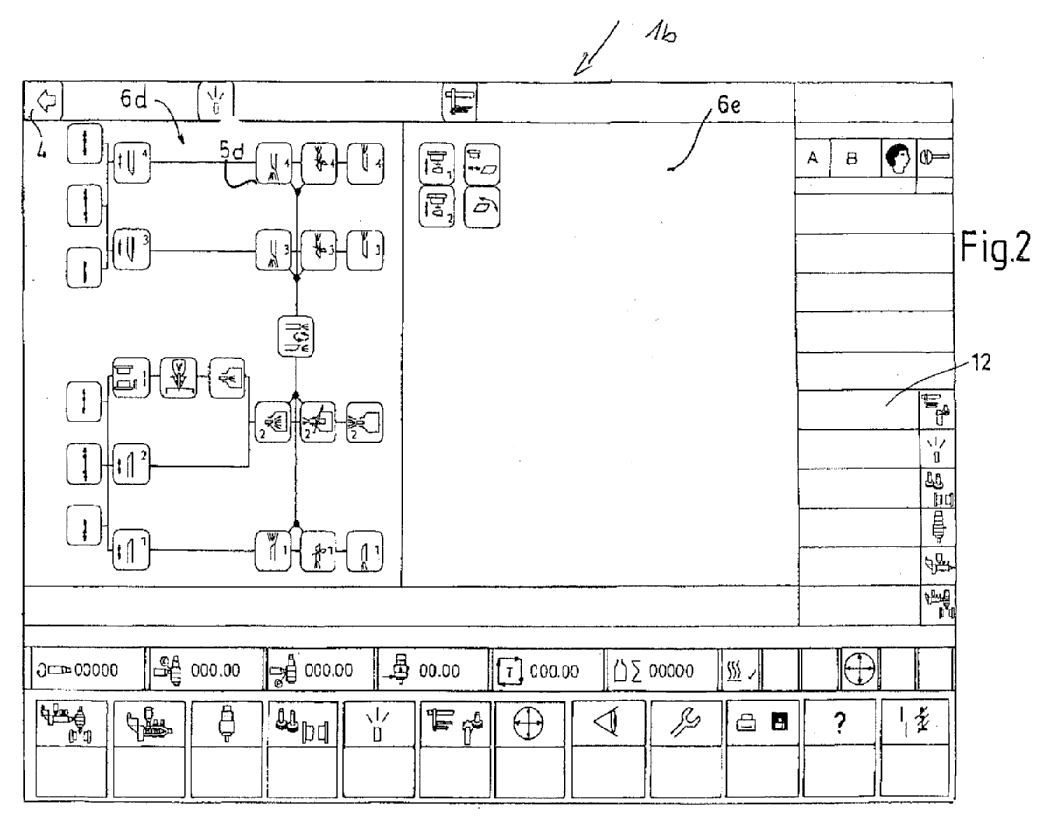

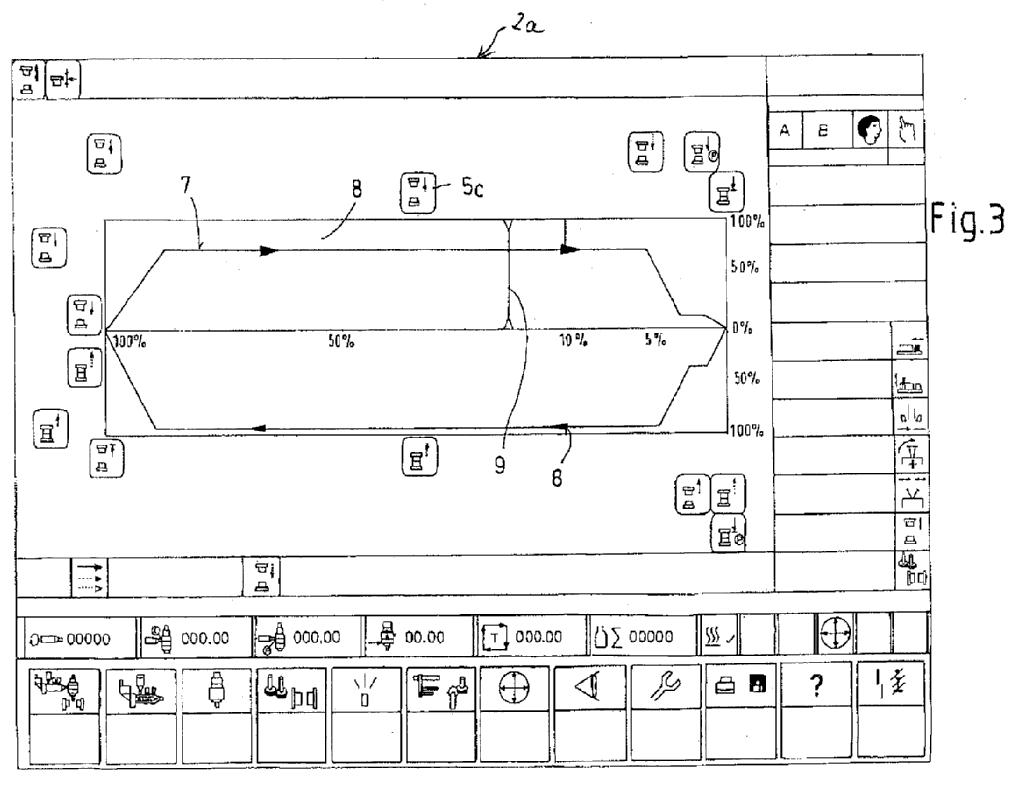

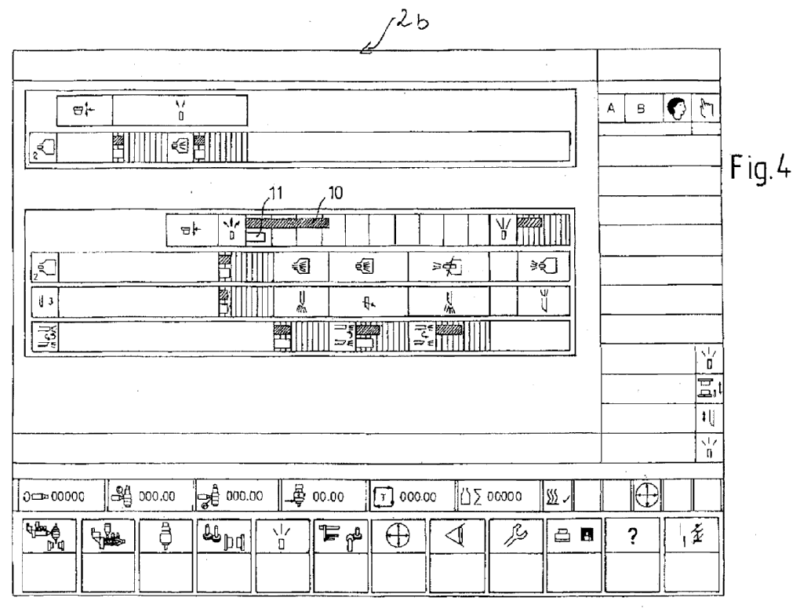

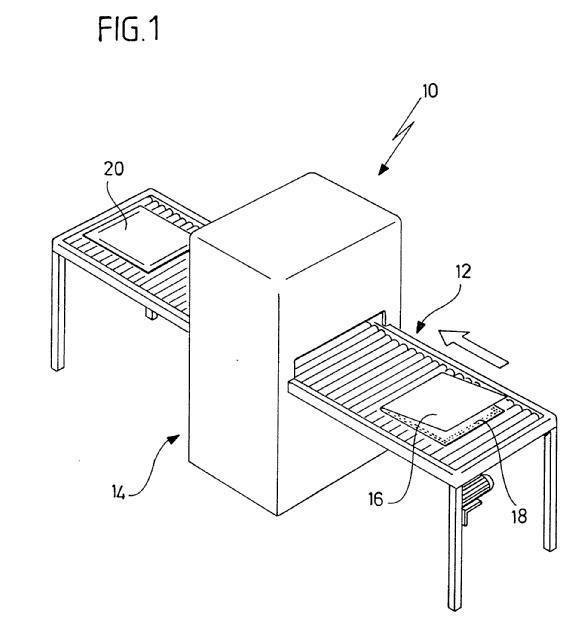

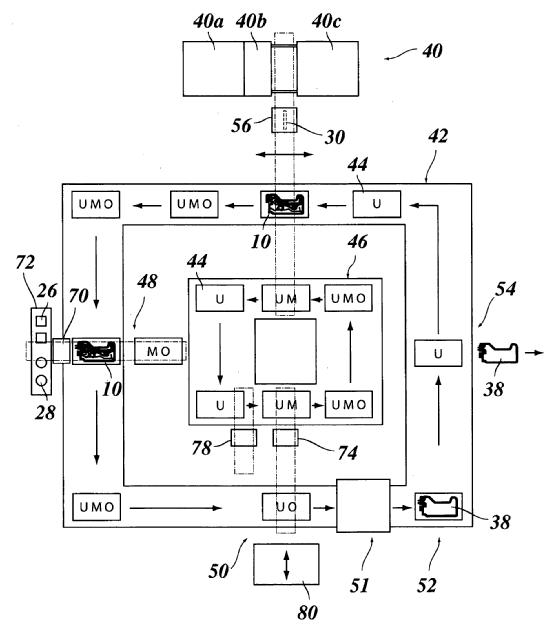

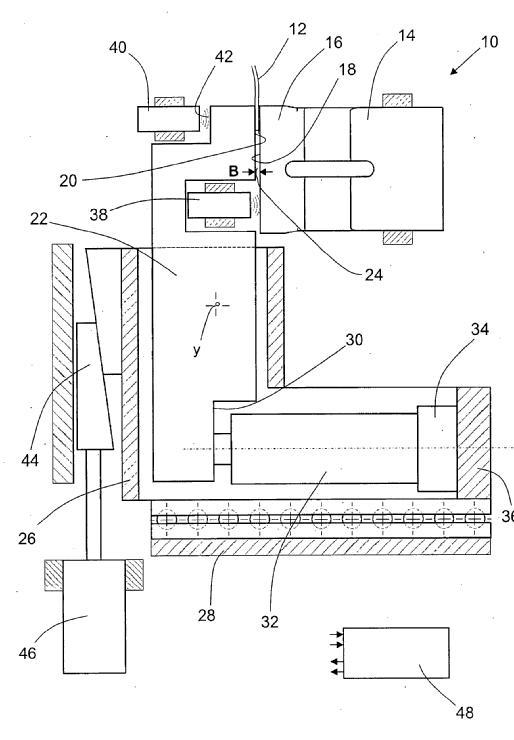

This place covers:

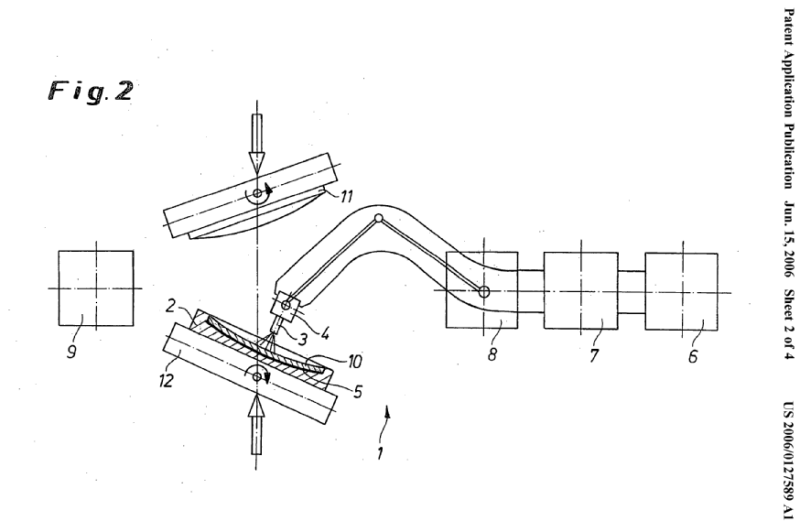

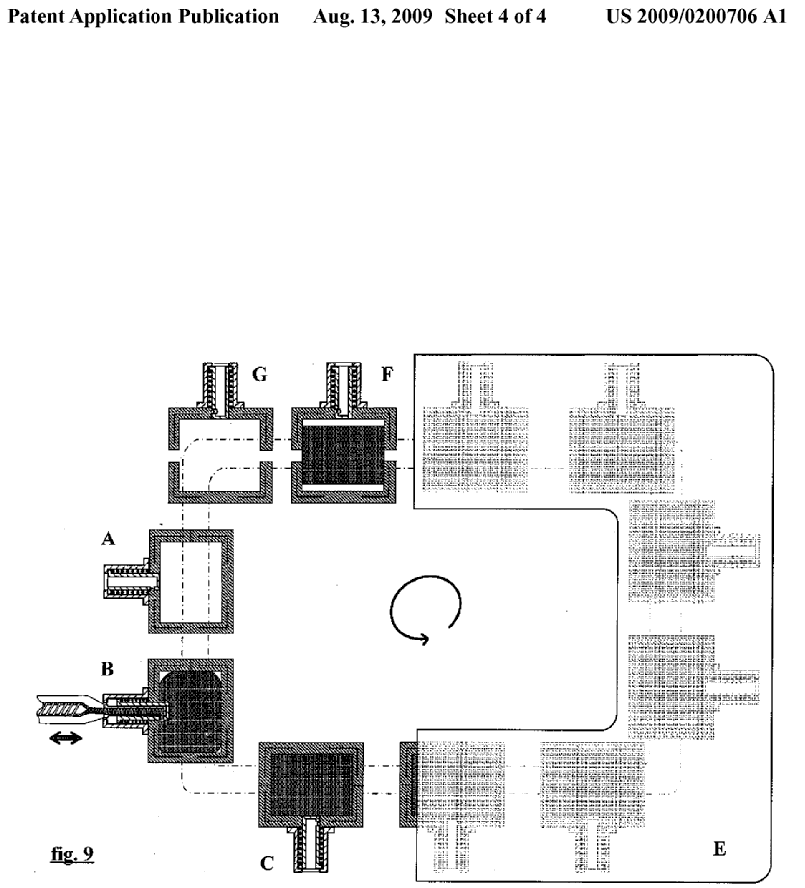

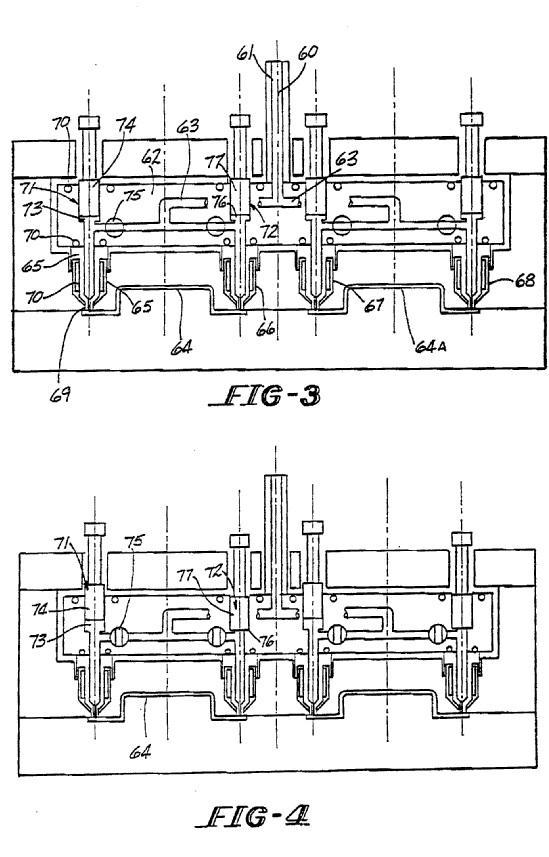

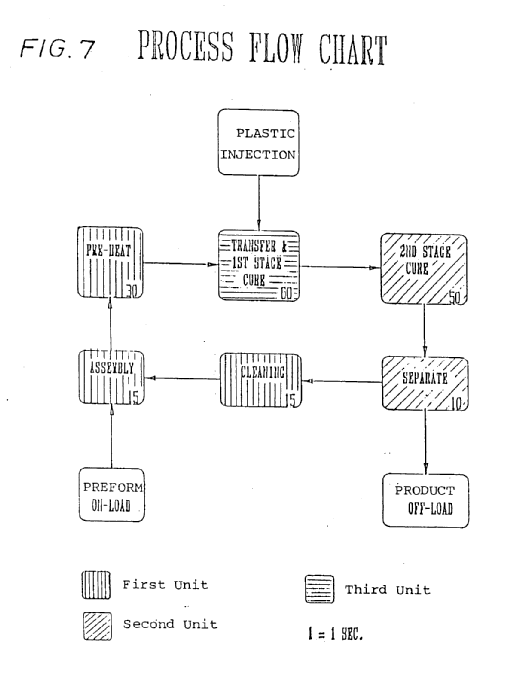

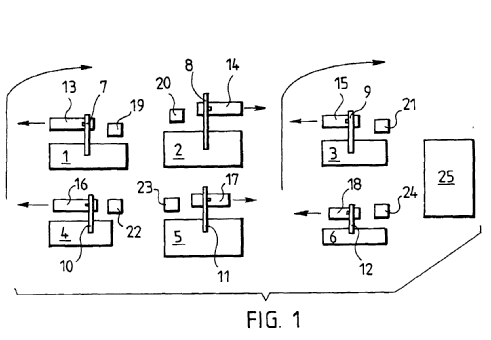

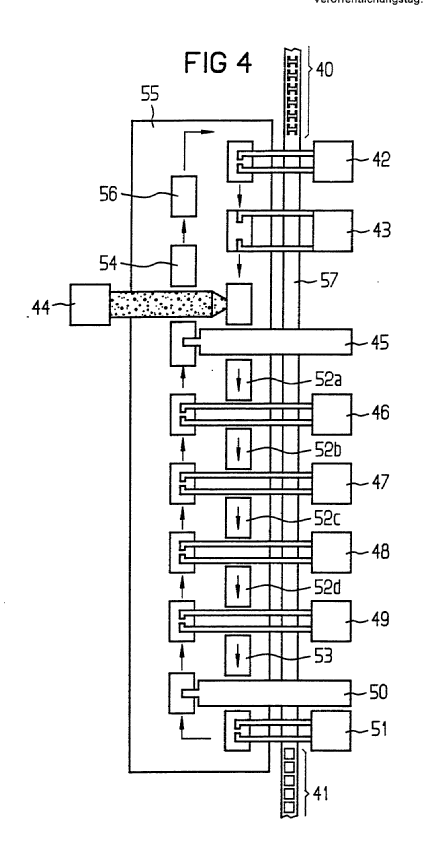

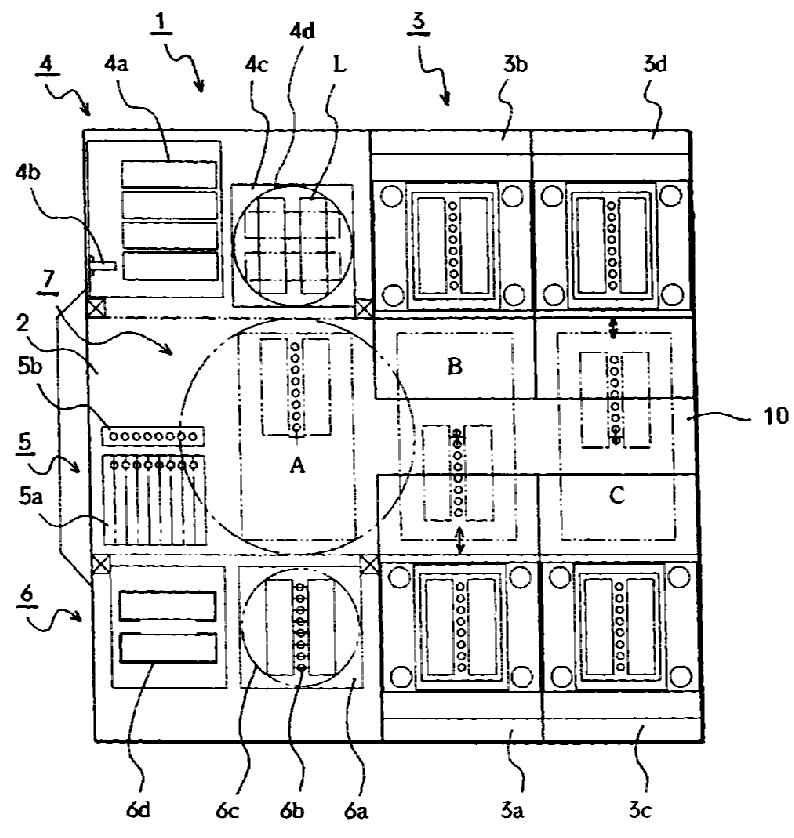

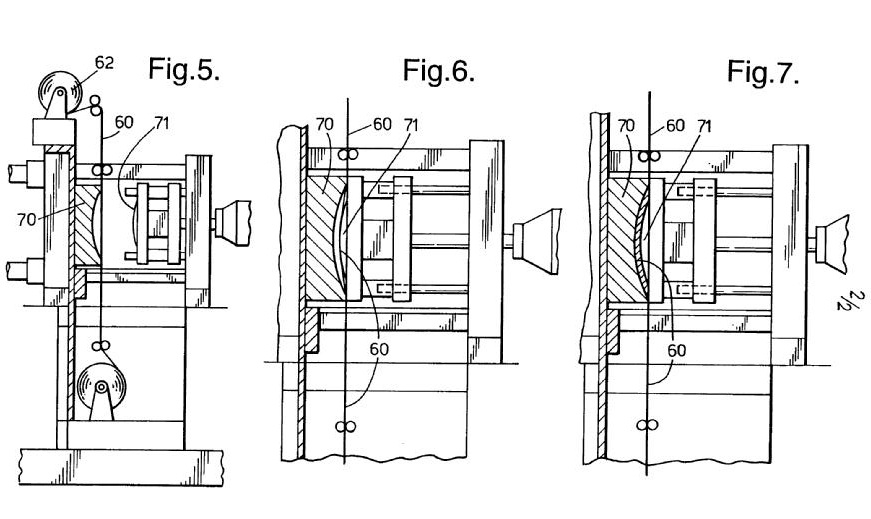

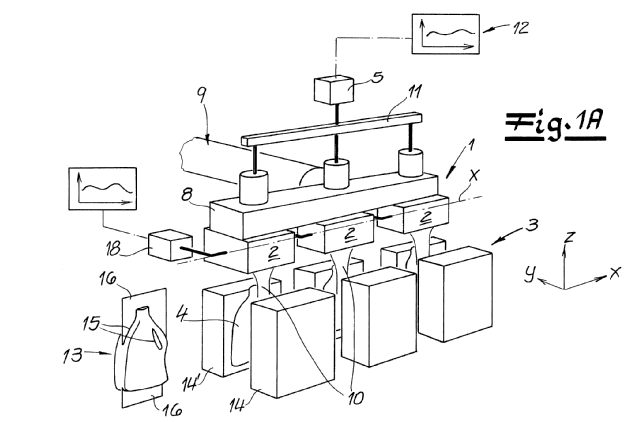

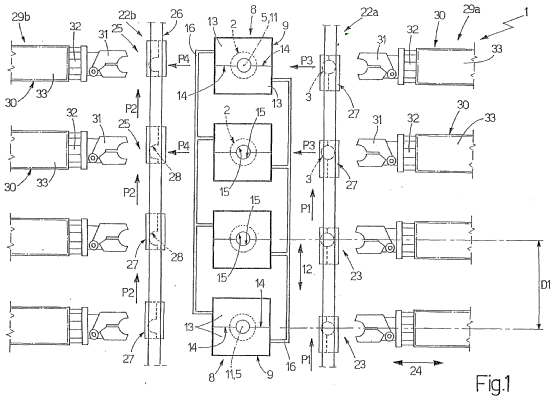

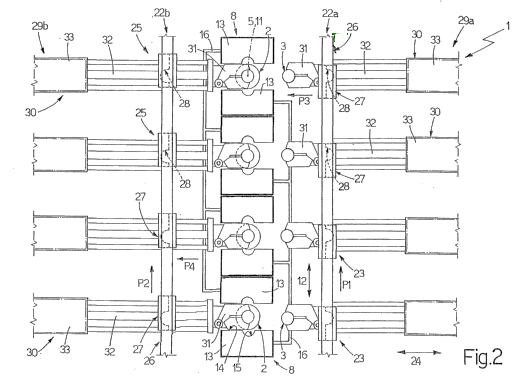

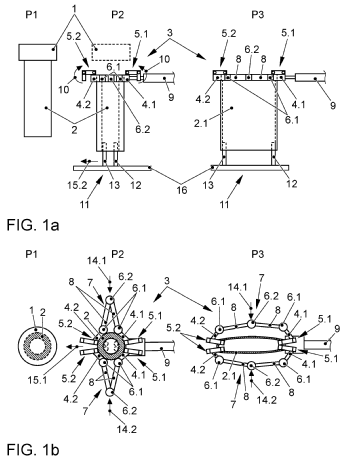

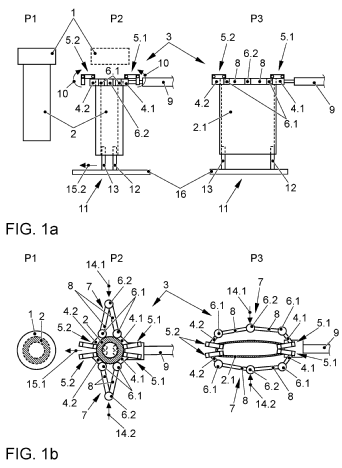

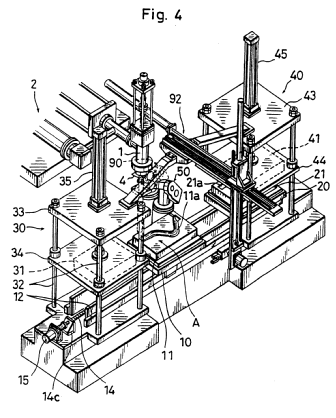

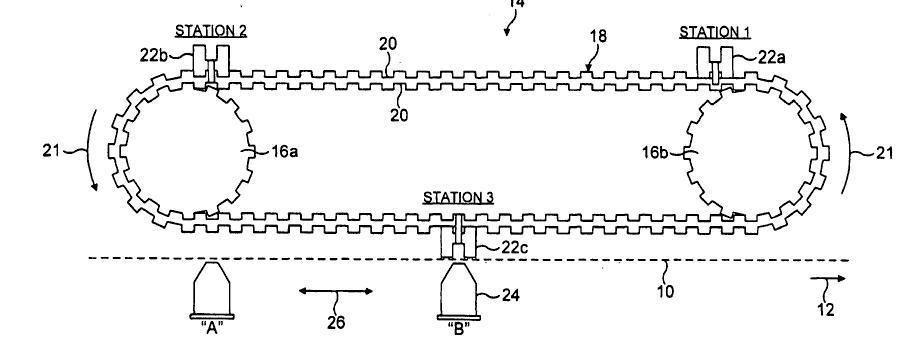

Plants showing several working positions or operations, e.g. EP576196

Lay out of plants, e.g.

EP765726

DE19634843, fig 4.

This place does not cover:

Plants for encapsulating articles mounted on a carrier, e.g. lead frame |

This place covers:

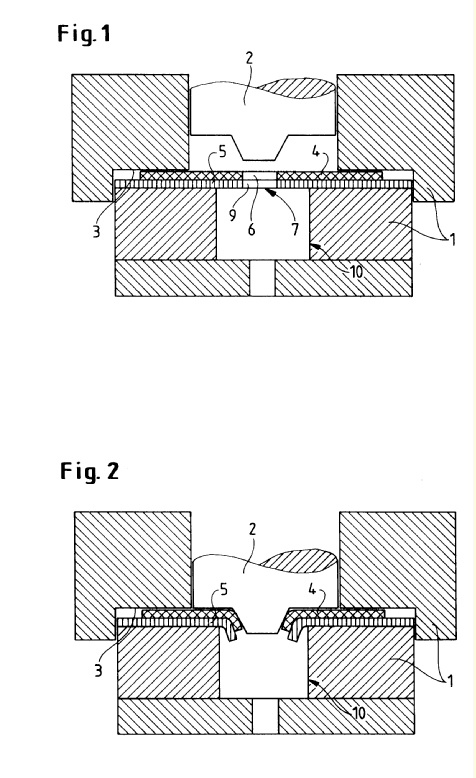

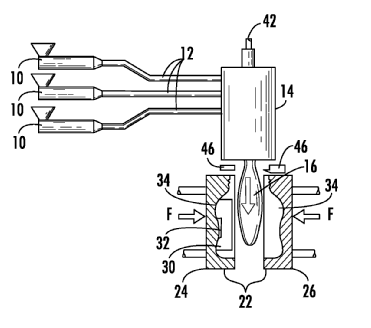

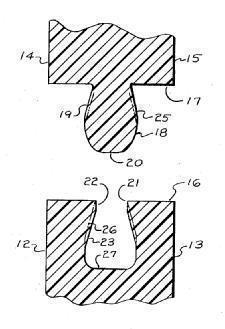

Transfer moulding, whereby a shot cavity is provided within the mould. The material is transferred from the shot cavity into the mould cavity/cavities. The plunger is also part of the mould, the transfer takes place within a closed mould.

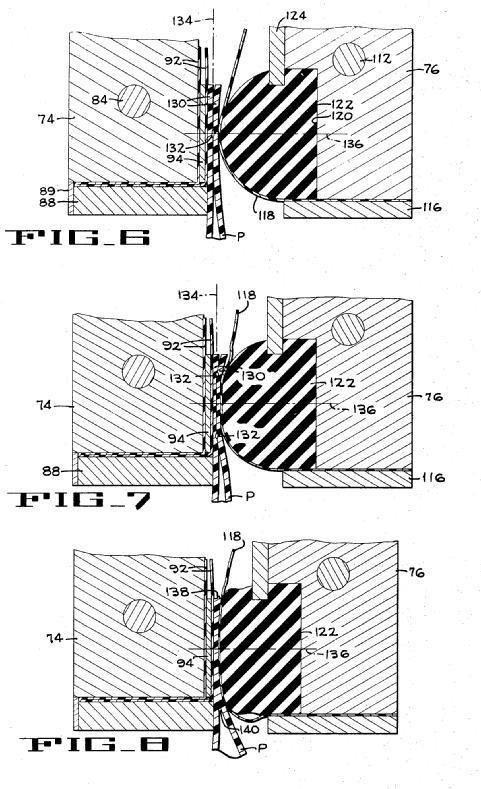

EP646948, fig 3.

The difference between transfer moulding and compression moulding, is that in case of the latter, the material is compressed while closing the mould and not by separate mould parts after closing.

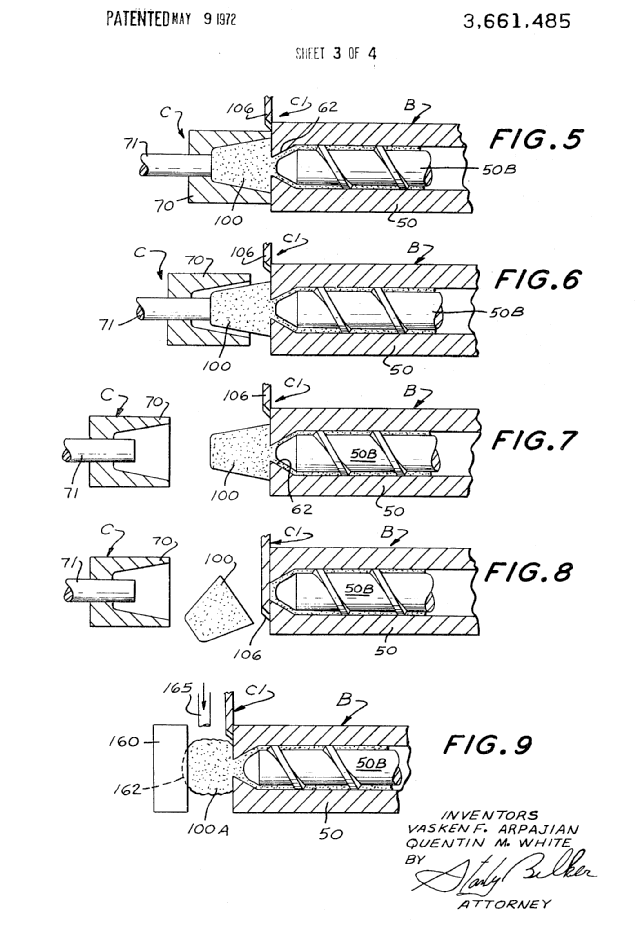

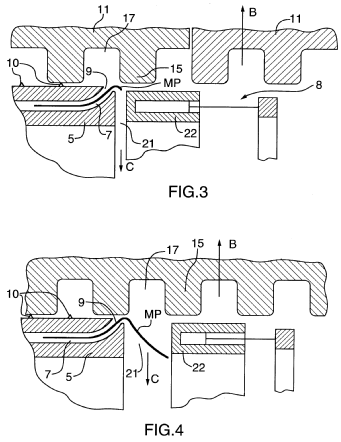

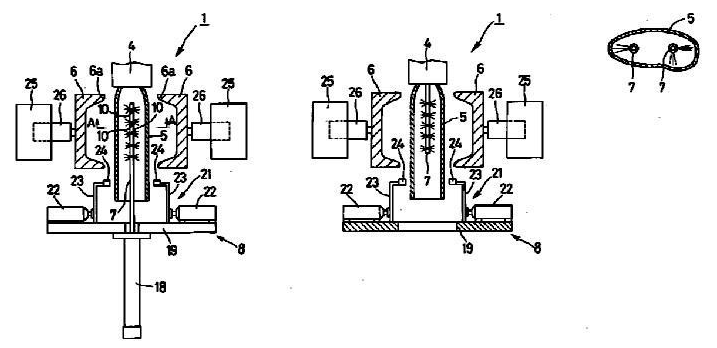

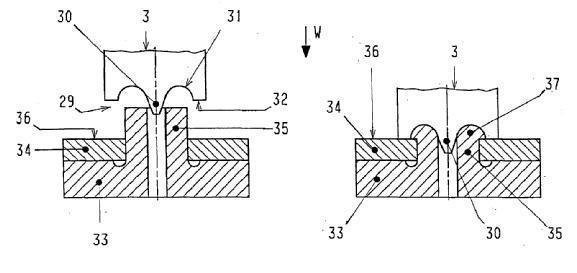

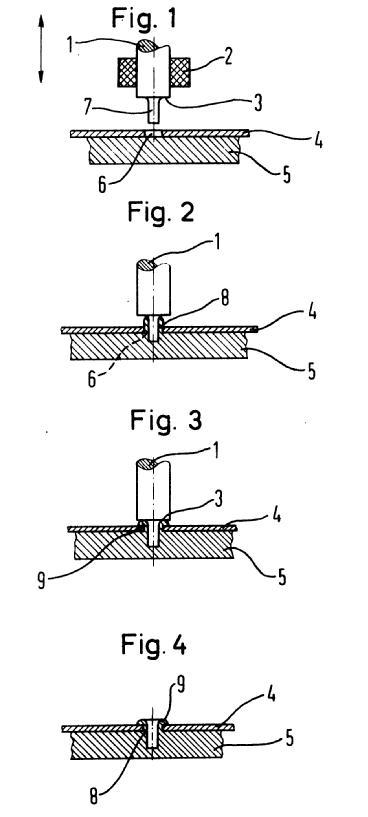

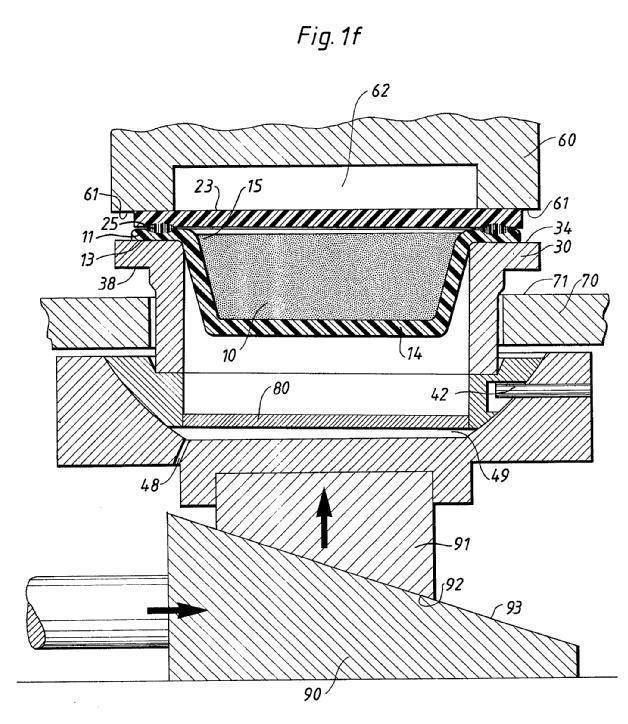

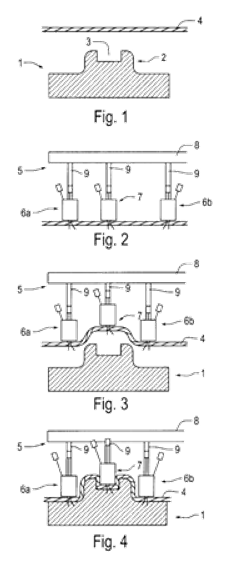

A typical example of compression moulding

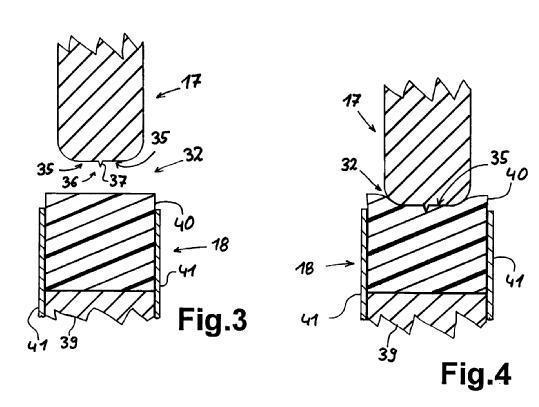

EP510414, fig 3 & 4

This place does not cover:

Resin transfer moulding |

Attention is drawn to the following places, which may be of interest for search:

Compression moulding with pressing members independently movable of the parts for opening and closing the mould |

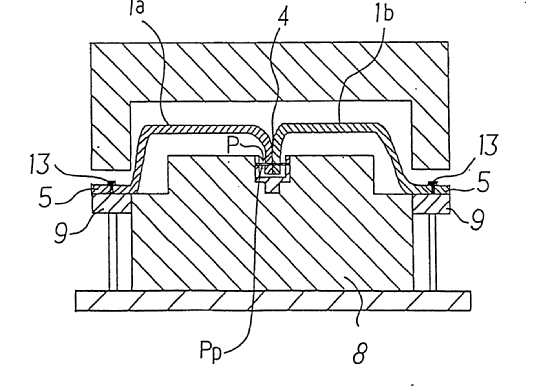

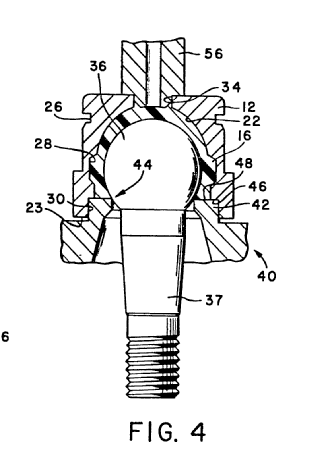

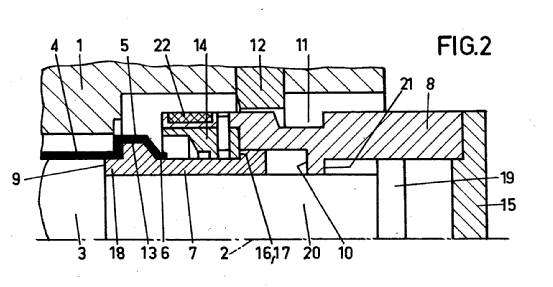

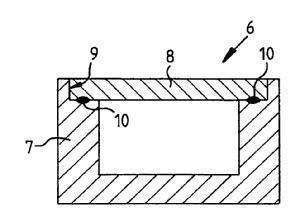

This place covers:

Drives or pressure equalizing means.

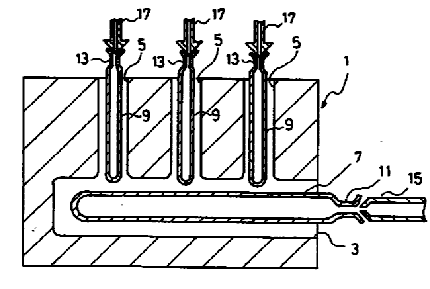

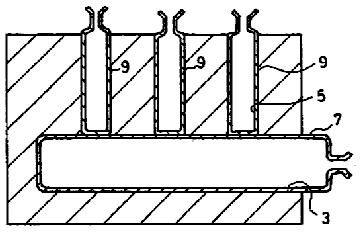

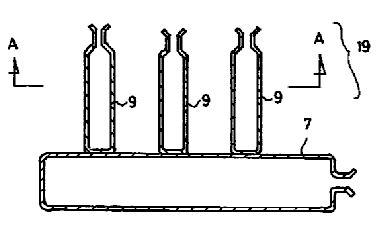

JP5329870, hydraulic chamber 9.

EP0778116

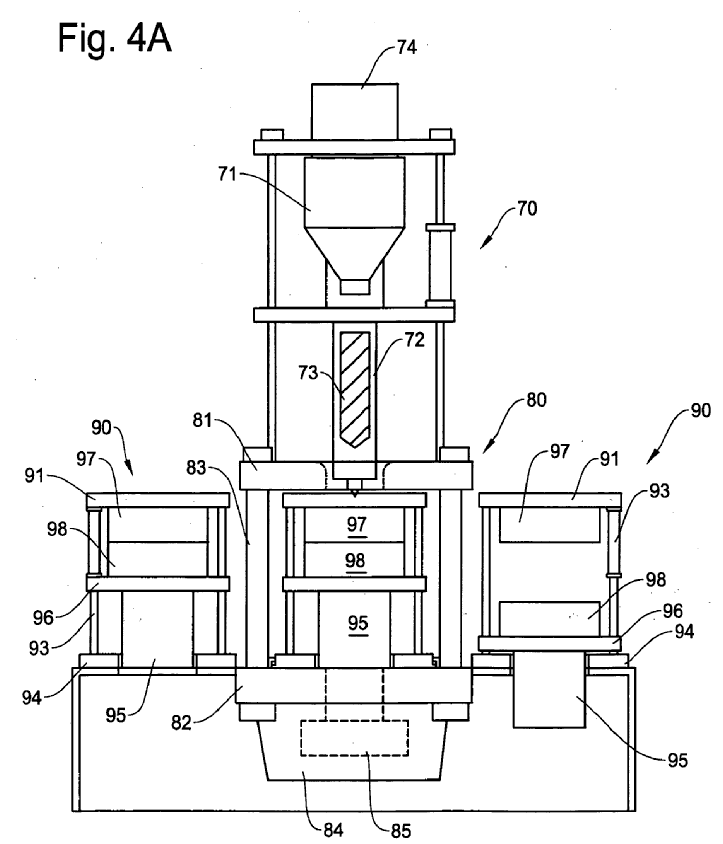

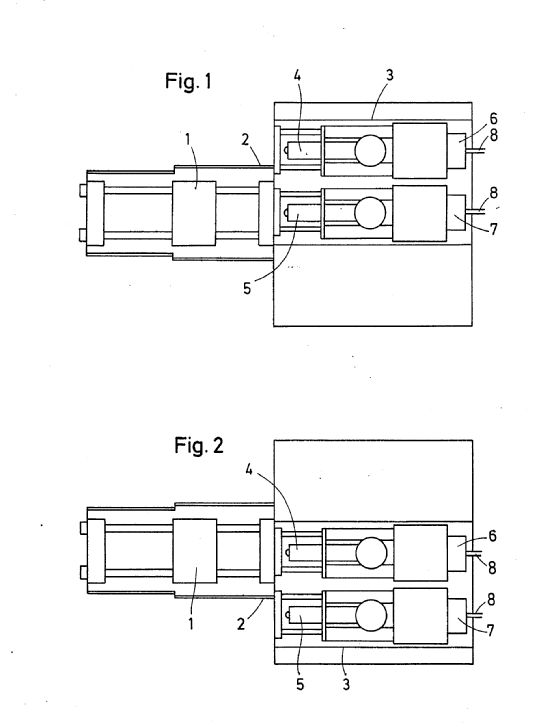

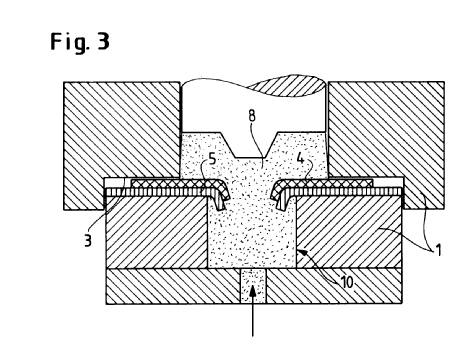

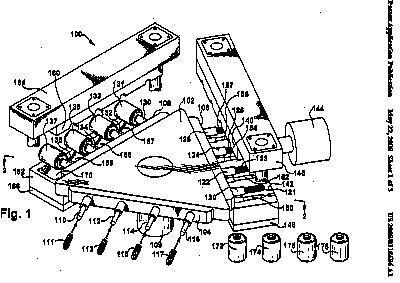

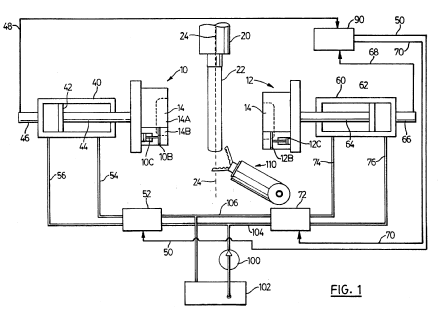

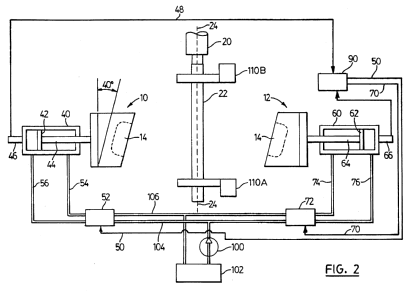

This place covers:

The configuration of the injection moulding apparatus

EP34203, fig 3.

This place does not cover:

Injection apparatuses combining the feeding means with opening, closing or clamping means |

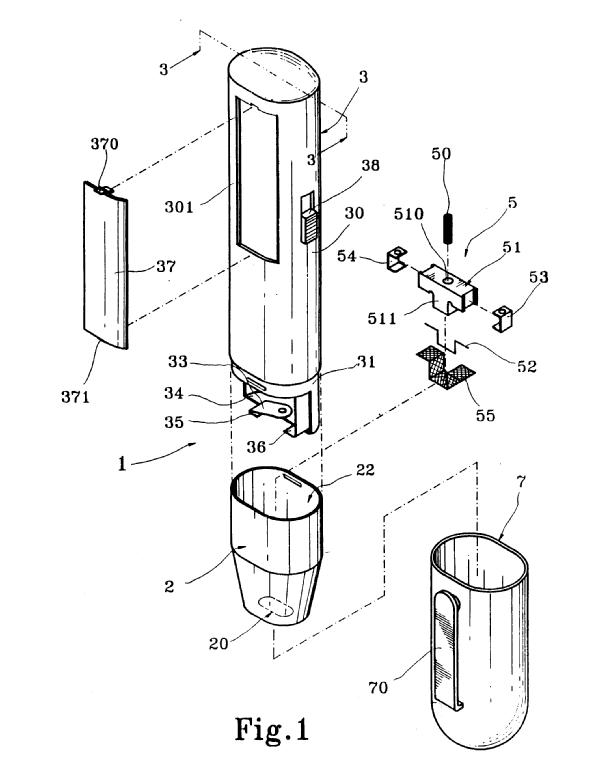

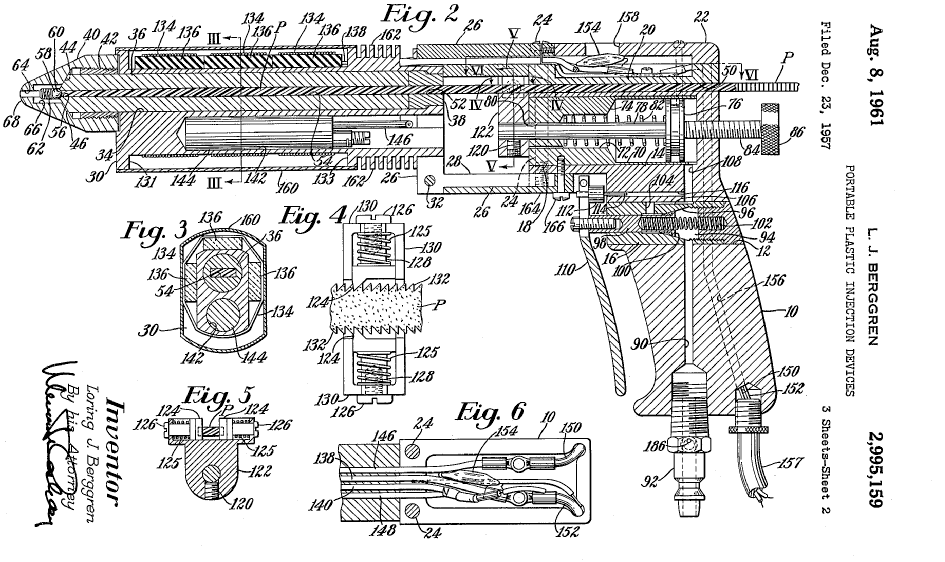

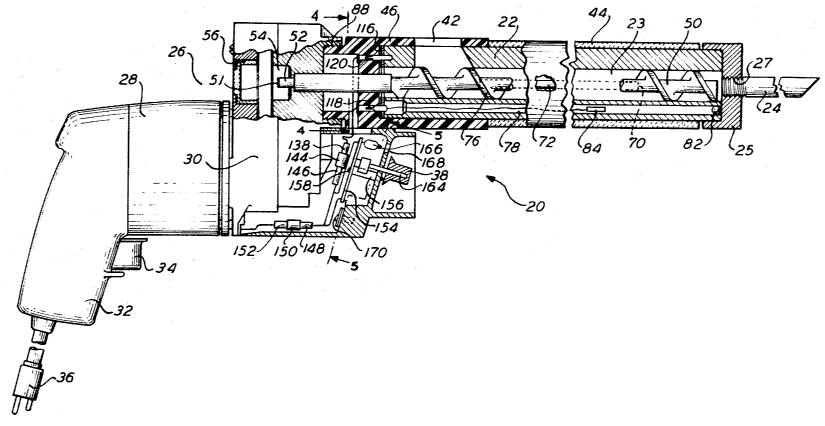

This place covers:

Mainly hand-held injection moulding machines

US2995159

Attention is drawn to the following places, which may be of interest for search:

Spray-up equipment for coating a mould, a core or other equipment: | |

Hand tools for applying fluid in general |

This place covers:

EP0268174

This place does not cover:

Movable moulds for making multilayered or multicoloured articles |

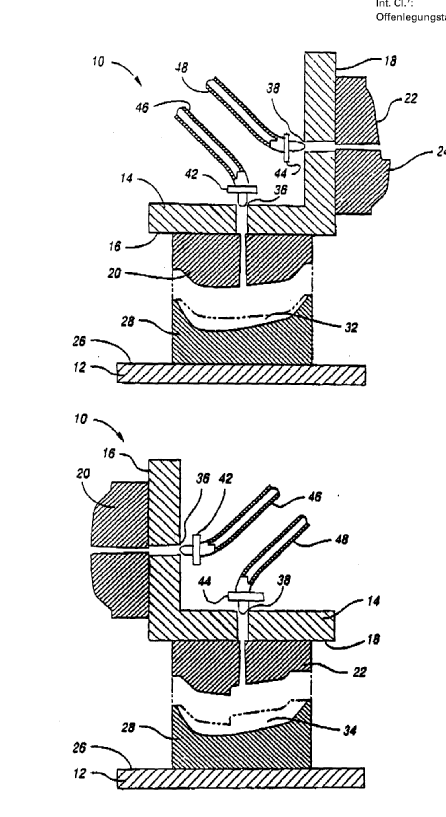

This place covers:

US20060172039

This place covers:

DE10120267

EP351895, fig 9/10.

This place does not cover:

Rotatable moulds or mould halves mounted on a turntable |

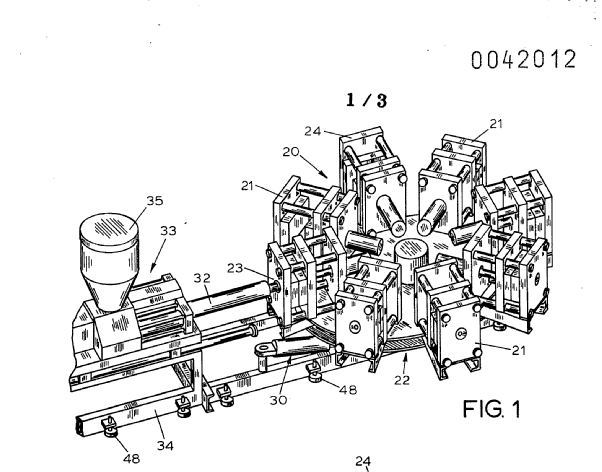

This place covers:

EP42012

In patent documents, the following words/expressions are often used with the meaning indicated:

"circumference" | "surface " |

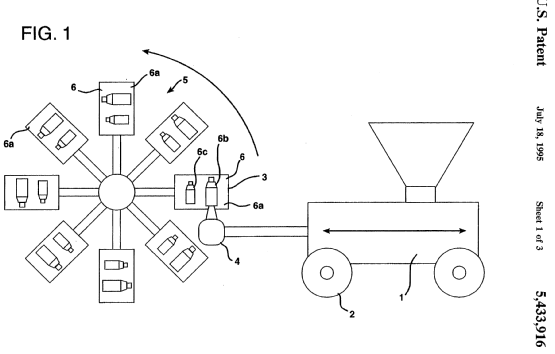

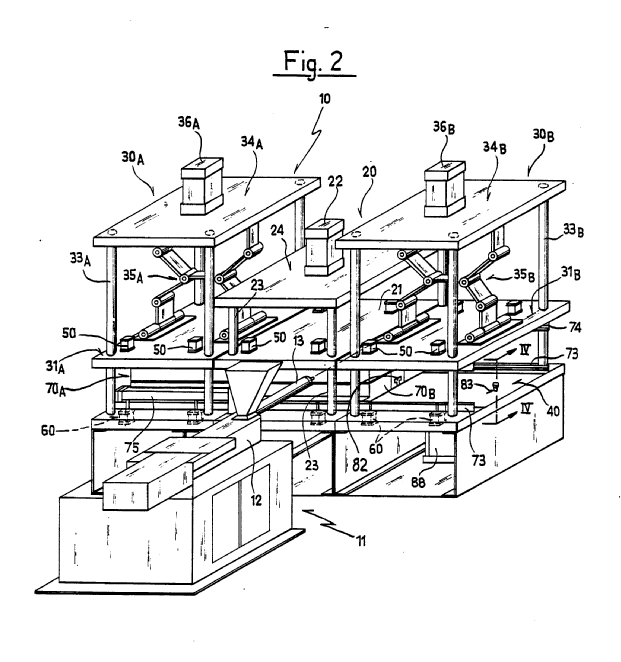

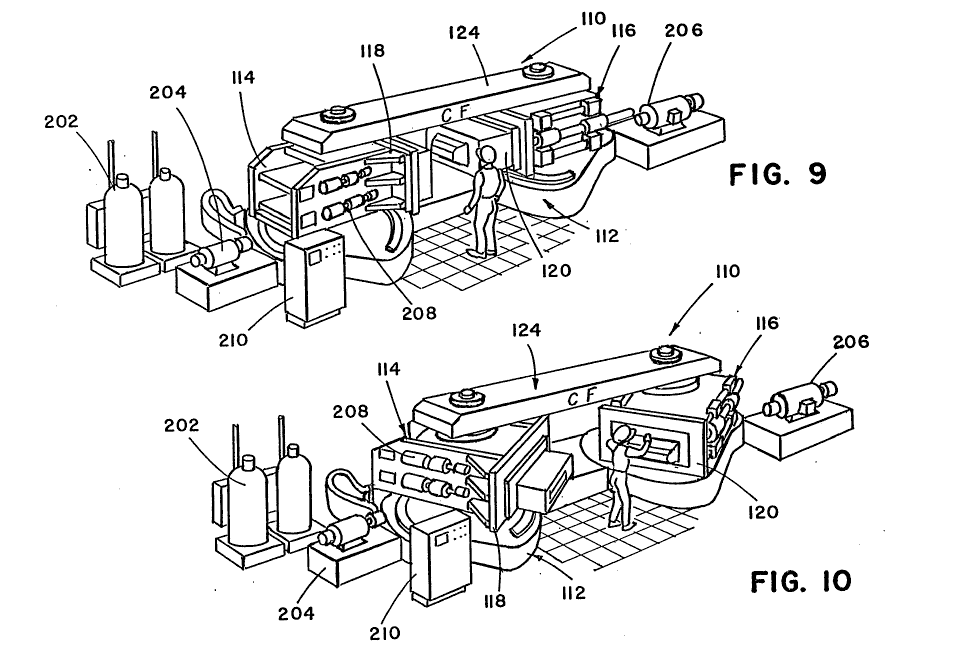

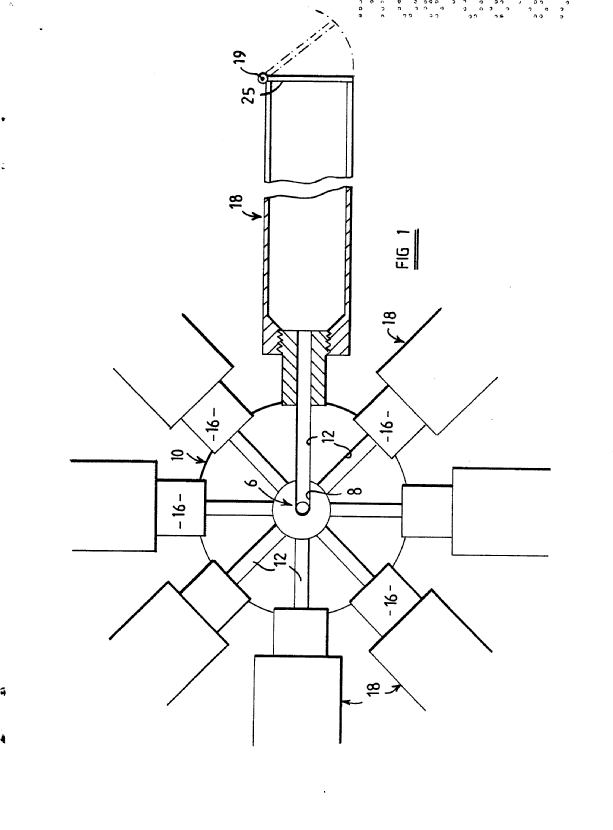

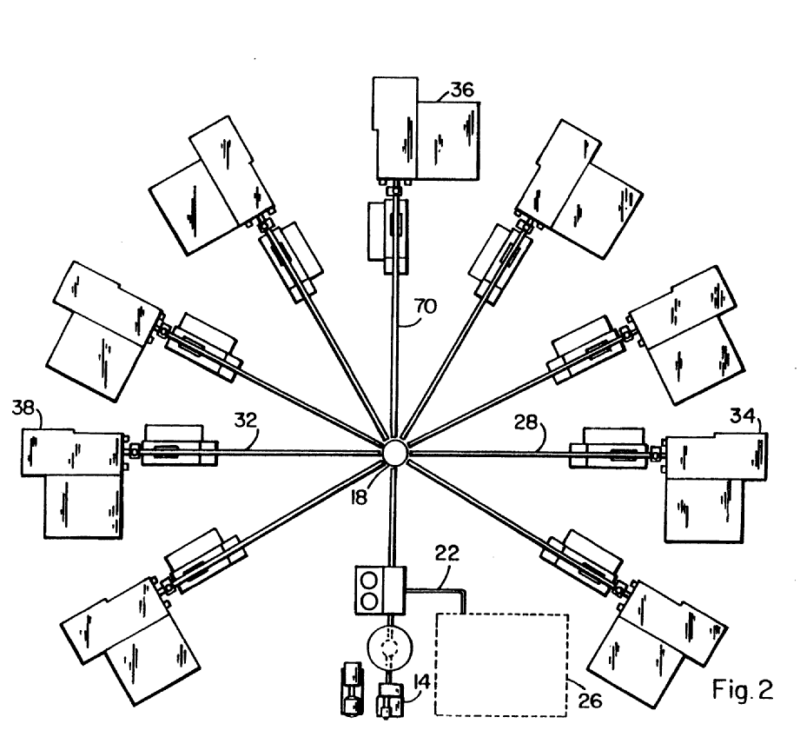

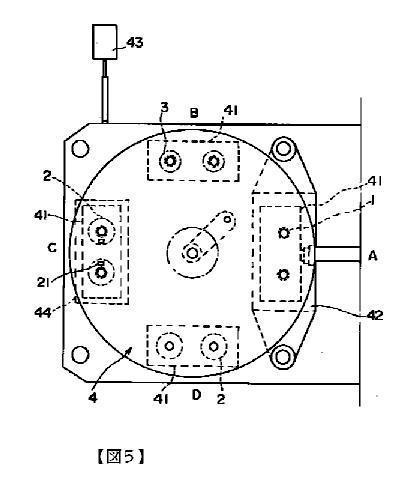

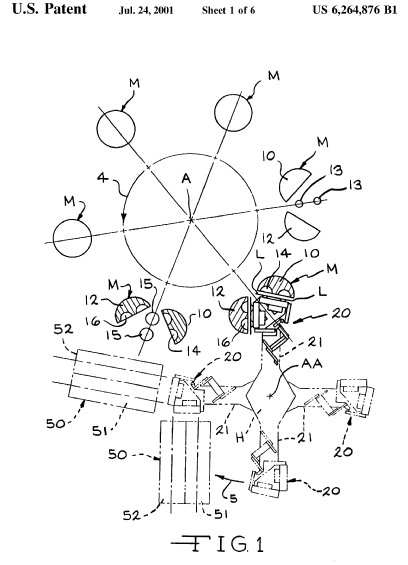

This place covers:

Injection moulding machines comprising a turntable, being a horizontal moving table with complete moulds or mould halves (the mould halves are covered by B29C 45/062). The rotation axis is normally parallel to the open/closing axis of the moulds.

WO9739870

,

,

EP0529940

Attention is drawn to the following places, which may be of interest for search:

Turntables for presses |

This place covers:

EP300068 fig 1

US20060177539

This place covers:

Injection moulding processes, whereby EACH moulding cycle, the injection unit is MOVED and removed.

US3924994, fig 1& 2.

This place covers:

EP438721 fig 1,2 position A & B

This place covers:

Injection moulding processes, whereby the injection unit and the mould move at the same time. FR2155808 dashed line 5

This place covers:

Different arrangements or combinations concerning the mould AND the injection unit.

Different arrangement of the mould and injection unit DE2543448, fig 1 & 2

Different combination of the mould and injection unit EP138169, fig 1 & 2

Note that the different arrangement or combination are not related to one moulding cycle but to a long period of use.

This place does not cover:

Moulds in different combinations |

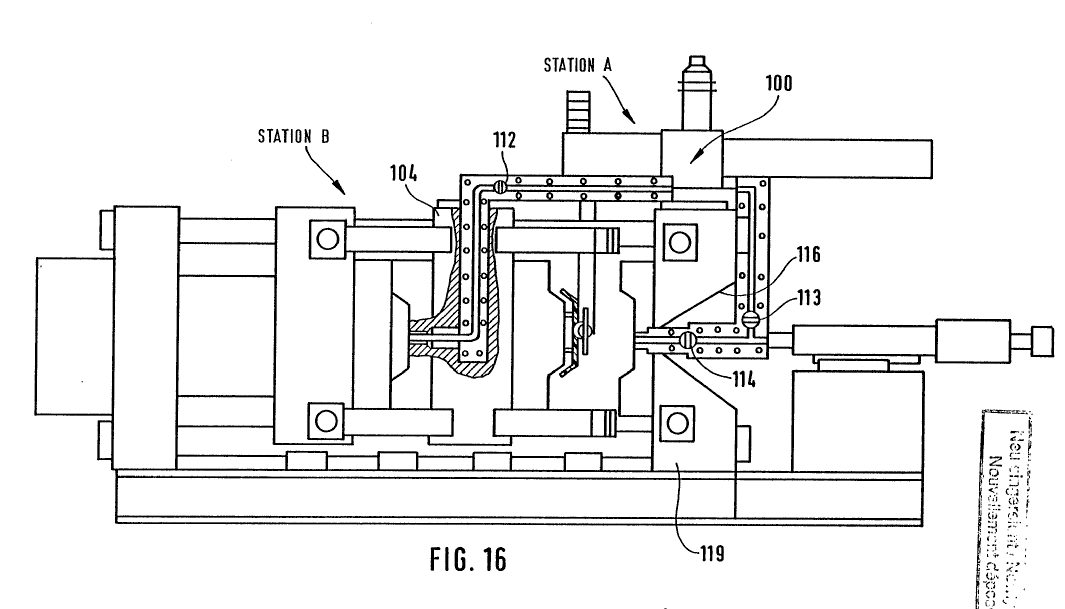

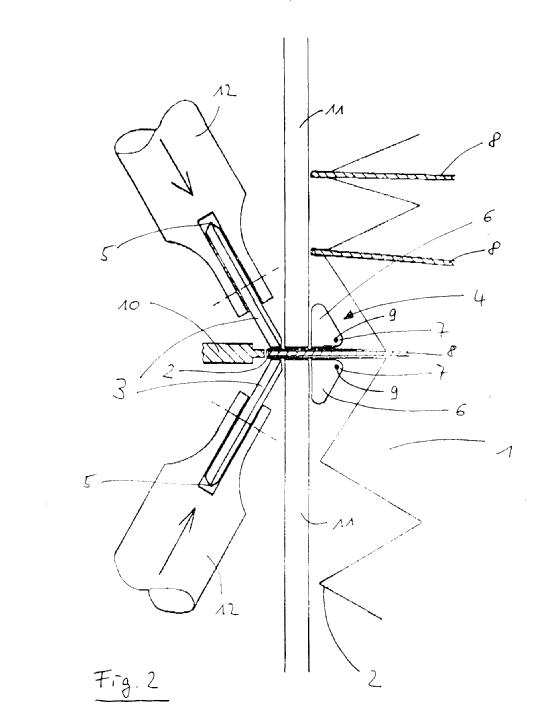

This place covers:

The INJECTION UNIT cooperates with BOTH MOULDS through a runner channel.

EP326175, figure 16

Attention is drawn to the following places, which may be of interest for search:

Stack moulds |

This place covers:

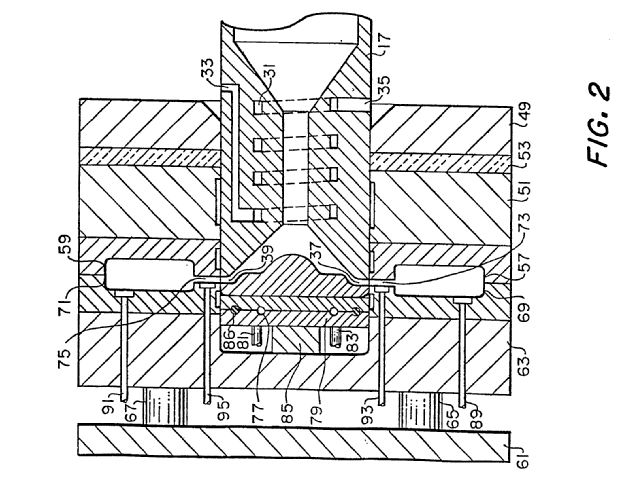

EP265603 fig 1

EP13118 fig 2,

WO9702126 fig 2.

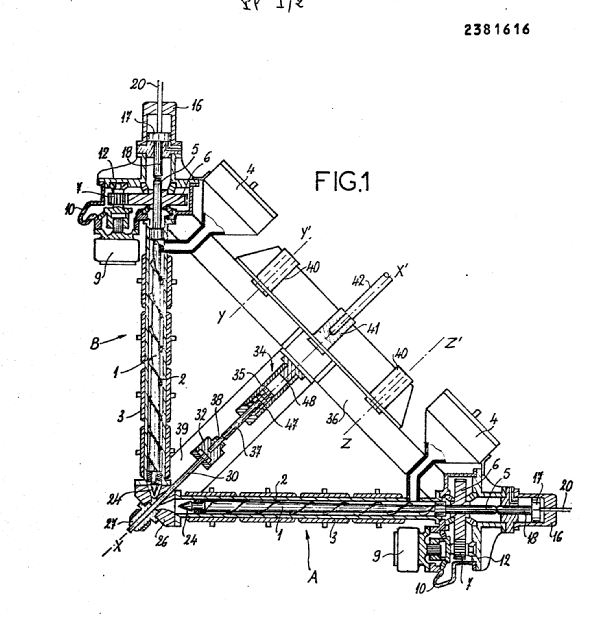

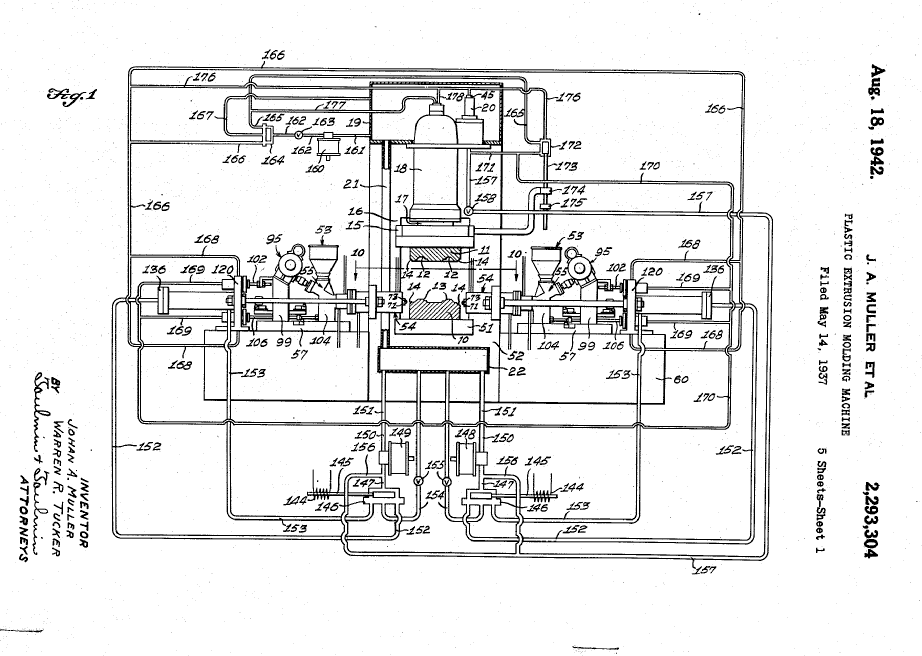

This place covers:

Several injection units, typically for quickly filling one mould.

FR2381616, figure 1

US2293304, figure 1

Attention is drawn to the following places, which may be of interest for search:

Multi-component injection moulding |

This place covers:

EP492052 fig 1 & 2, label A.

In patent documents, the following words/expressions are often used as synonyms:

- "inserts","preformed parts", "articles", "films" and "preformed layers"

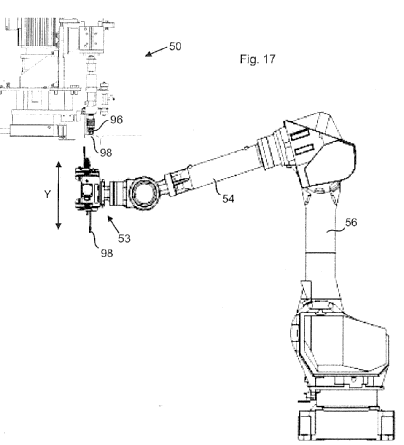

This place covers:

Usually robots for inserting the to be overmoulded articles into the mould cavity

EP373023, figure 1

Attention is being paid to the difference between B29C 45/14008 and B29C 45/14065, B29C 45/14008 concerns the inserting of the articles INTO the mould. B29C 45/14065 concerns the positioning of the already inserted article WITHIN the mould (cavity).

Attention is drawn to the following places, which may be of interest for search:

Handling of preformed parts in general | |

Inserting labels or films into blow moulds | |

Feeding of linings or labels for thermoforming | |

Locating or holding inserts in metal casting | |

Orienting articles in an article feeder for assembling machines |

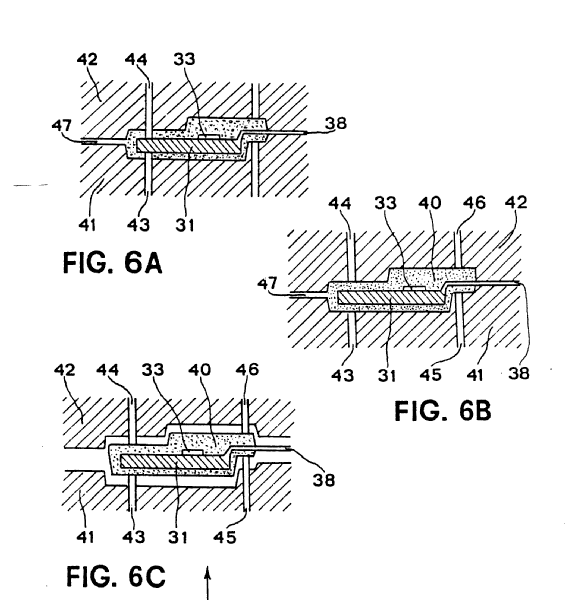

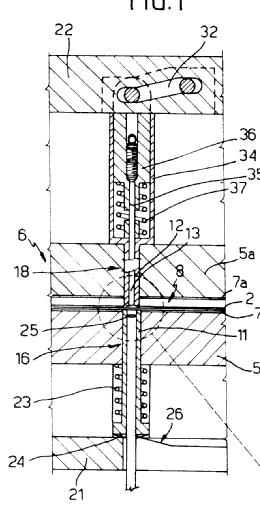

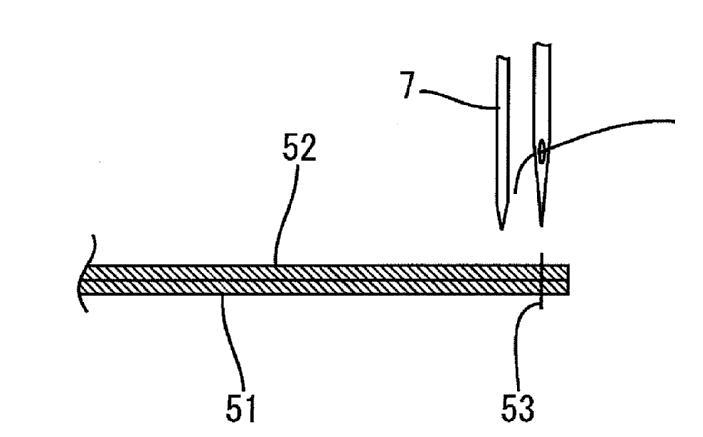

This place covers:

Non-continuous feeding of a film

EP101095, fig 2

This place covers:

EP231670, punch mechanism 3

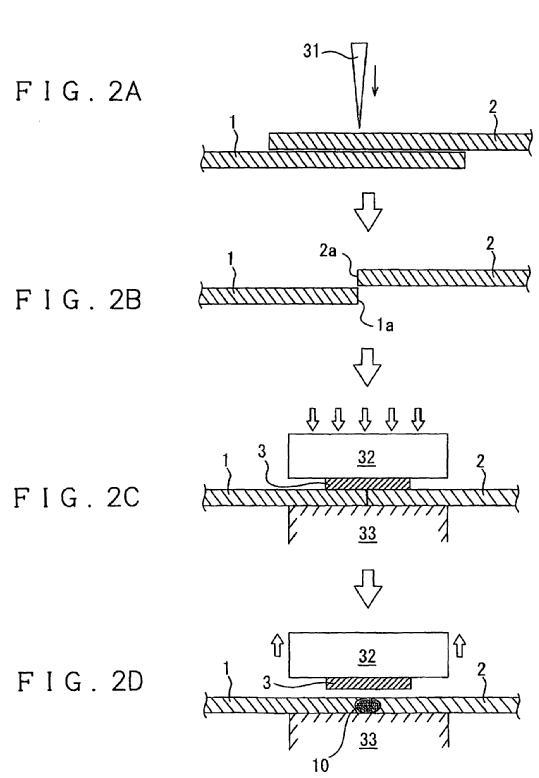

This place covers:

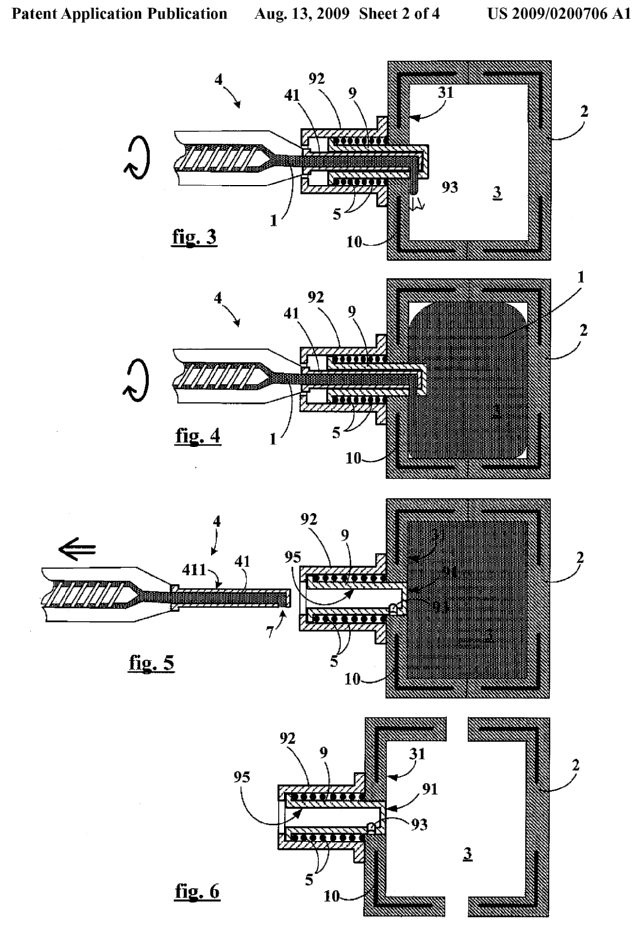

EP37032 fig 3 & 4.

Inserts are introduced in storage space 10 inside the mould and when the mould is closed, one insert is transferred each moulding cycle by transfer means 27.

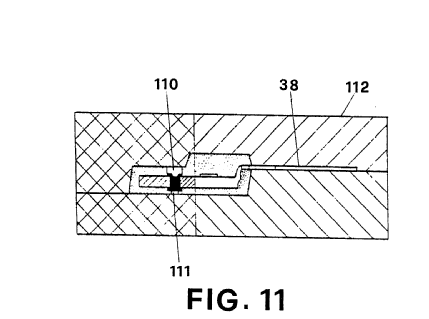

This place covers:

EP257681 pin 110 in fig 11(means are here part of the insert)

Where B29C 45/14008 concerns the inserting of the insert INTO the mould, B29C 45/14065 concerns the positioning or centering in the cavity of the already inserted insert.

Attention is drawn to the following places, which may be of interest for search:

Moulds with incorporated means for centering inserts in general | |

Moulds using magnetic means for positioning inserts in general | |

Moulds using vacuum to position inserts in general |

This place covers:

EP257681, retracting pins

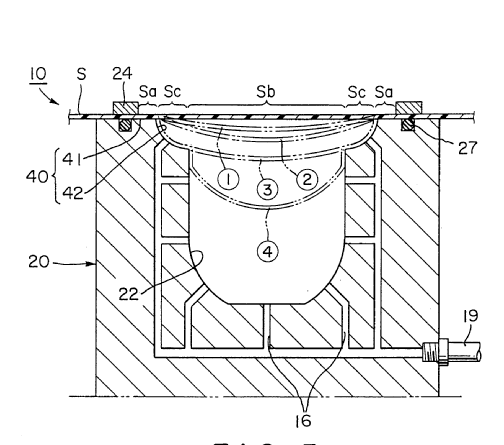

This place covers:

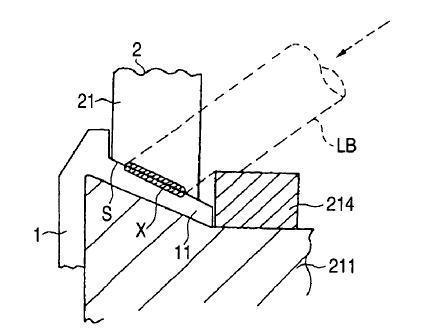

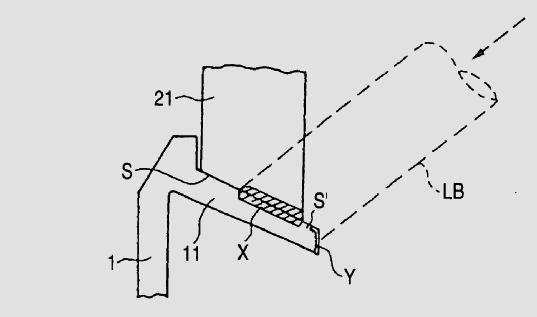

EP782908 insert S

Attention is drawn to the following places, which may be of interest for search:

Shaping linings by compression of the moulding material |

This place covers:

Moulding of edge wrapped articles

Attention is drawn to the following places, which may be of interest for search:

Lining or sheeting by folding, winding, bending or the like |

This place covers:

Deformation by mechanical means

EP721831, fig 1-3,

EP592768, fig 1,

P517614, parts 11a, fig 1

This place does not cover:

Deformation by injection pressure |

This place covers:

Bonding means, e.g. adhesives, chemical means, locking configurations

EP976519, perforation in fig 2.

Attention is drawn to the following places, which may be of interest for search:

Measures or configurations for obtaining an anchoring effect in contacting areas general |

This place covers:

Moulding processes, whereby a part of the insert is outside the cavity during the moulding process. EP1013392 fig 7, insert 4, coating 6 & 8

EP727289, only handle of the insert

This place does not cover:

Coating the edge of articles at spaced locations | |

Coating a portion of tubular articles |

This place covers:

outsert moulding: EP65220, insert 8 is, at least partially OUTSIDE the moulding material 14

Attention is drawn to the following places, which may be of interest for search:

Permeable inserts | |

Moulding in general on a relative small portion of the preformed part e.g. outsert moulding |

This place covers:

The use of an additional fastening element in combination with partial coating of an insert only (note: B29C 45/14467 takes precedence)

EP468713, fig 2 insert 2 and additional fastening means 12

EP436438 with additional fastening means 22 & 27 (fig 2 & 3).

Attention is drawn to the following places, which may be of interest for search:

Moulding in general on a relative small portion of preformed parts to be joined |

This place covers:

EP676268

Attention is drawn to the following places, which may be of interest for search:

Brushes characterised by mouldable materials for fixing the bristles | |

Moulding or casting a brush body around bristles or tufts |

This place covers:

GB1431460, fig 2 corner 5;

US4778550 end part 22

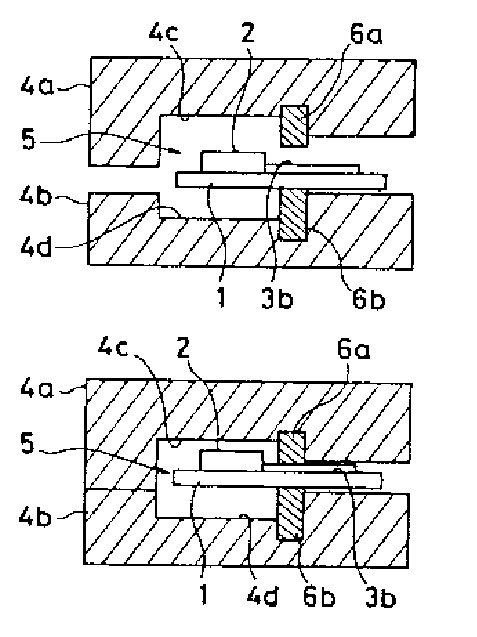

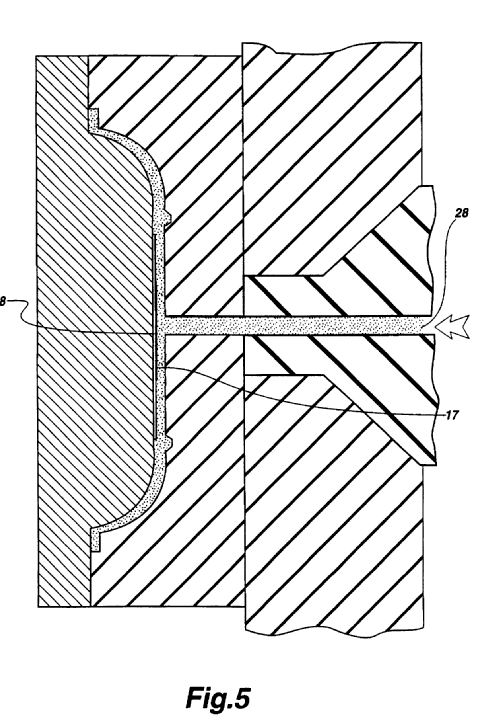

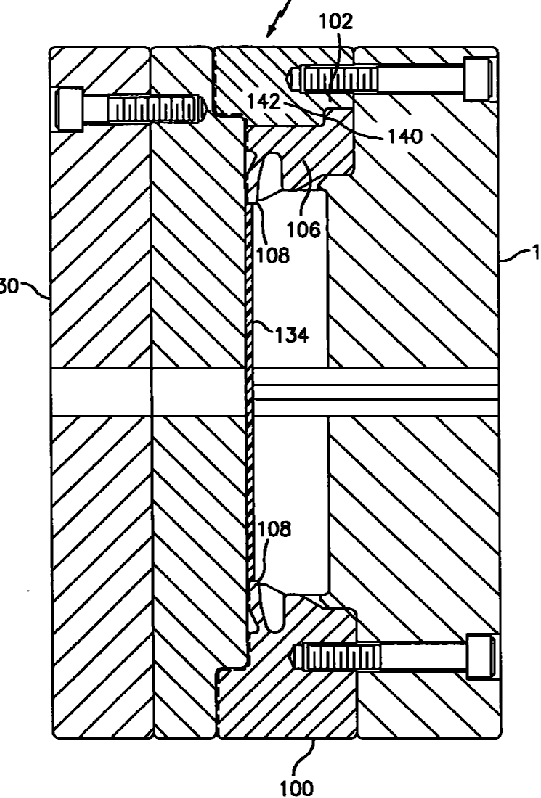

This place covers:

The application of separate sealing means, as well as sealing by mould parts, e.g. core mould and cavity walls

EP0845340-fig 4, seals 140 & 142,

JP63-67127, sealing members 3 & 4

JP63-89313, seals 6a & 6b,

Attention is drawn to the following places, which may be of interest for search:

Sealing means for sealing off parts of the insert during moulding in general |

This place covers:

Moulding on glass inserts

Moulding on windscreens, whereby the windscreen is not made out of the brittle material glass, but out of a transparent plastic.

This place covers:

EP792960, fig 2 parts 1 & 7, connected by material 10

This place does not cover:

Joining articles moulded in separate cavities as final operation | |

Joining tubular articles |

Attention is drawn to the following places, which may be of interest for search:

Joining preformed parts by the expansion of the moulding material | |

Joining of preformed parts by moulding | |

Moulding in general on preformed parts to be joined | |

Casting around parts for joining | |

Key-type connections formed by solidification of injected material |

This place covers:

FR2272816 fig 1 & 2

GB1360801 fig 1 part 5

Attention is drawn to the following places, which may be of interest for search:

Machines for making boxes by folding sheets combined with injection moulding for joining opposed edges |

In this place, the following terms or expressions are used with the meaning indicated:

Juxtaposed | is being defined as lying next to each other within the same plane, while the juxtaposed parts touch each other along one edge |

This place covers:

WO0024561, fig 2, parts 31 and 33 connected by plastic 29

This place covers:

EP953423 fig 1-3, articles 11-13

EP376263, fig 4, sheets 1a, 1b.

EP829337 fig 6 & fig 10.

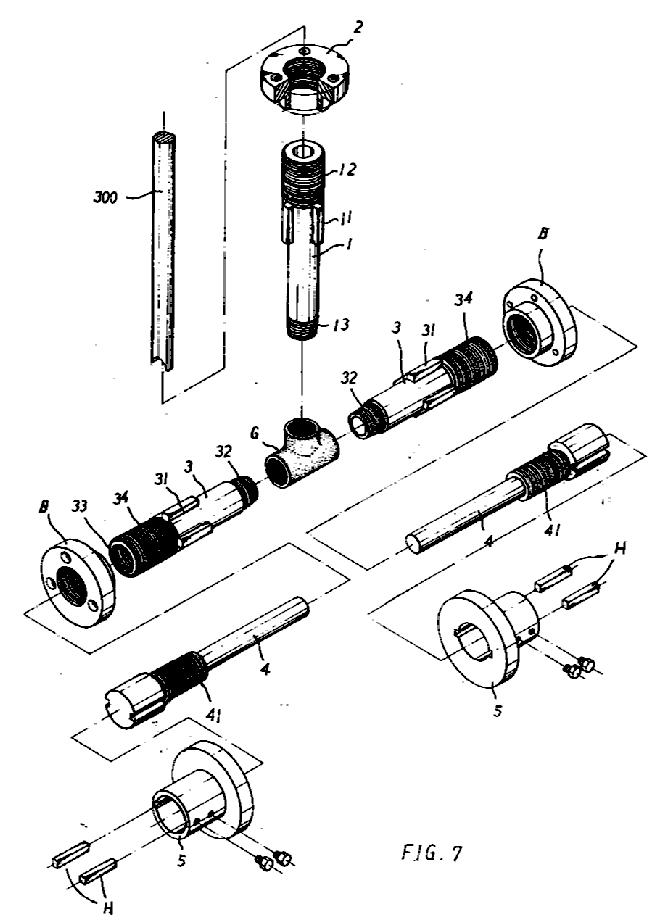

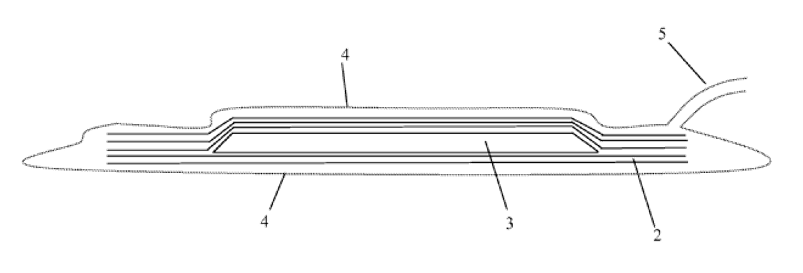

This place covers:

EP719628, figure 1, rod like insert 21

EP33848, figure 5 insulator insert 11

WO9107934, figure 3.

Attention is drawn to the following places, which may be of interest for search:

Assembly methods and manufacture of light guides |

This place covers:

EP225846, fig 4 wire 3, several plastic locations 21

.

.

EP221851, fig 6. Insert 1, plastics 22,23

This place covers:

EP641637 Insert 1, 24 at THE EDGE, at SPACED LOCATIONS.

Attention is drawn to the following places, which may be of interest for search:

Pressure die casting of slide fasteners | |

Producing fasteners with separate interlocking members |

This place covers:

GB1128619 Inserts 20 & 20, plastic 18,

FR1435472, figure 2, wire 11 & 21, plastic 20

This place covers:

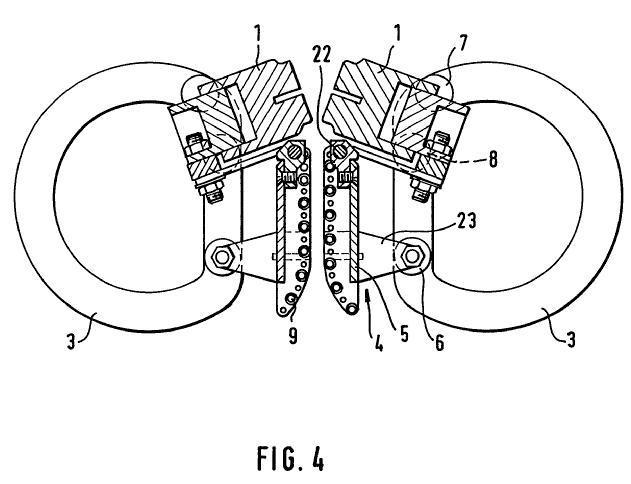

Insert moulding processes for making rollers, wheels, bearings, tyres

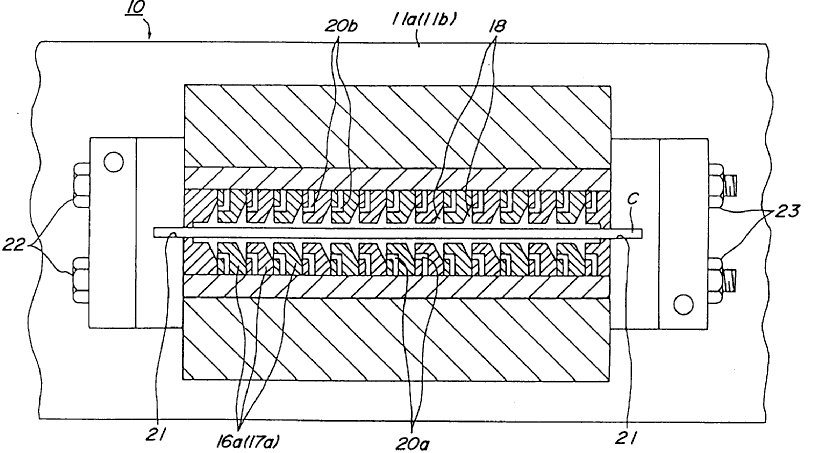

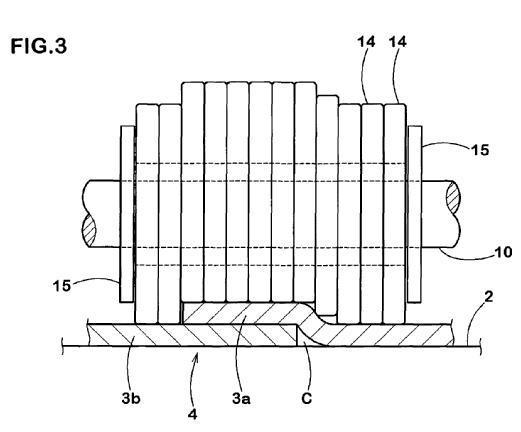

EP712708 fig 1. Insert 21 & 22 - annular cavity C.

EP287495, fig 1. Retreading of a tyre.

Attention is drawn to the following places, which may be of interest for search:

Producing roller bodies | |

Assembling wheels on an axle for making a castor | |

Guiding rollers, wheels or the like formed by or on the outer element of a single bearing |

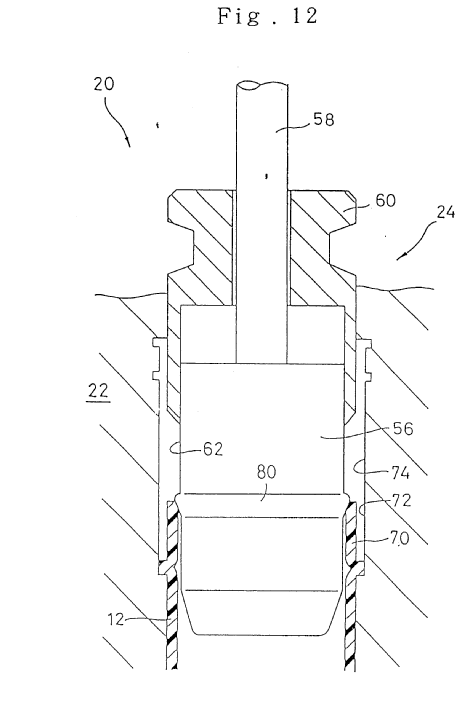

This place covers:

US6210621, fig 4- 6 Part 61 is moulded onto part 8d.

EP810073, fig 12

Attention is drawn to the following places, which may be of interest for search:

Moulding on the end part of tubular articles in general | |

Producing rollers of cylinders |

Note that although the article is often coated only partly, the classification is only done in B29C 45/14598, since it takes precedence over B29C 45/14336

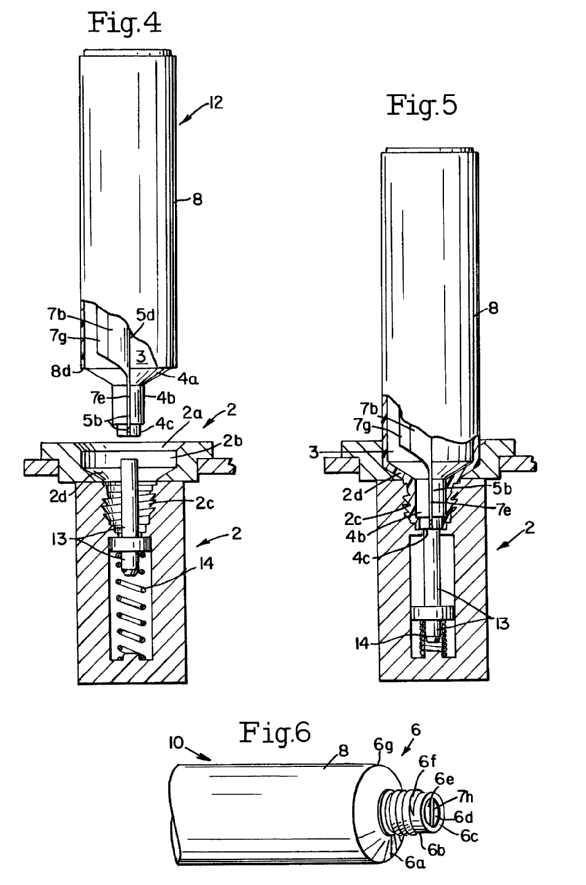

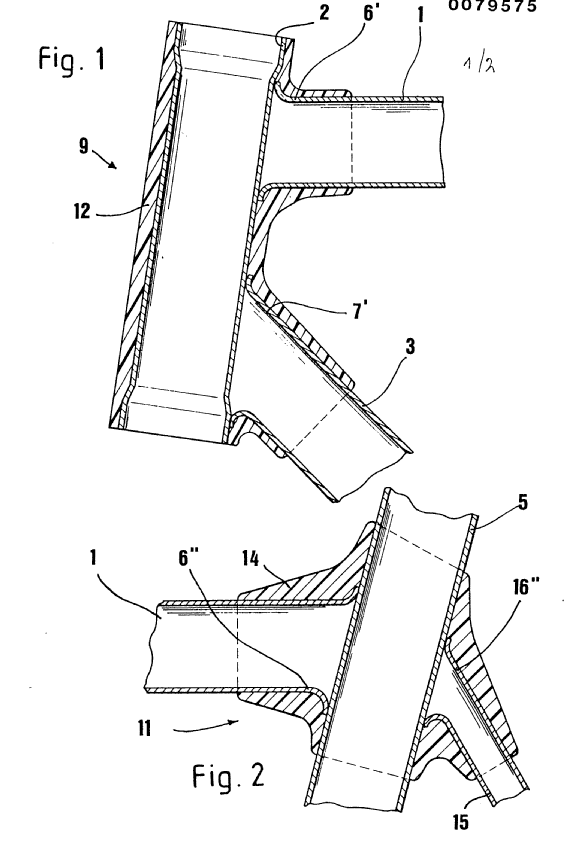

This place covers:

EP79575, fig 1 & 2. Plastic 12 and 14 connect the tubes 1, 2 and 3.

This place covers:

WO9317847, fig 1-6, tubular article 12, core inside for pressure compensation, lining 30

This place covers:

Overmoulding of reinforcements, being an insert not forming a part of the moulding material before the moulding process:

e.g. overmoulding single wires or fibres, overmoulding metal parts used as reinforcement.

EP487476

EP439033

Attention is drawn to the following places, which may be of interest for search:

Injection moulding using fibre reinforced plastics | |

Incorporating articles with special properties | |

Resin transfer moulding |

This place covers:

Overmoulding only when the disclosed moulding process is of importance due to the potentially very wide scope of possible applications (see also the informative references).

EP446489, fig 11

Attention is drawn to the following places, which may be of interest for search:

IC or chip cards | |

Cables, conductors | |

Resistors | |

Transformer, windings | |

Capacitors | |

Plugs, electric contacts | |

Repairing electric cables, joints, connectors | |

Machine engines, motors | |

Sealed casings | |

Apparatus or processes specially adapted for manufacturing or adjusting assemblages of electric components | |

LEDs |

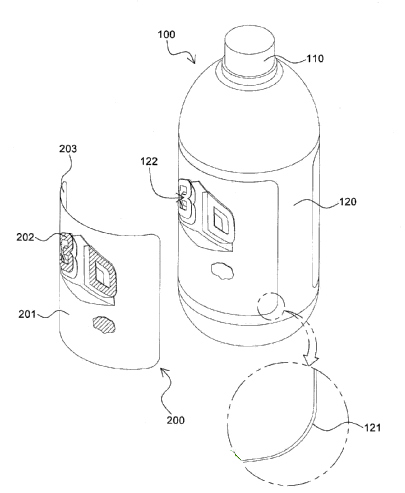

This place covers:

Moulding processes, whereby the chip is embedded during the moulding process.

EP481557

Attention is drawn to the following places, which may be of interest for search:

Identity cards and the like | |

Mounting details of chip cards in general |

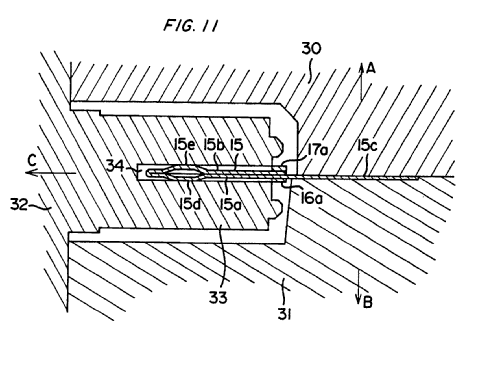

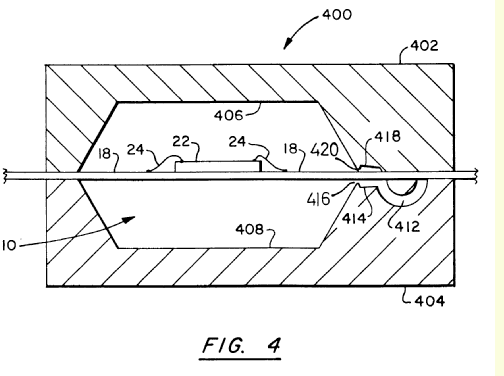

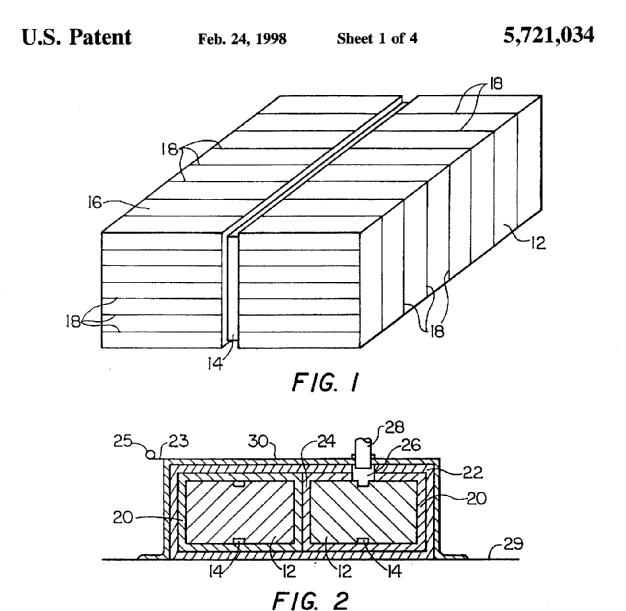

This place covers:

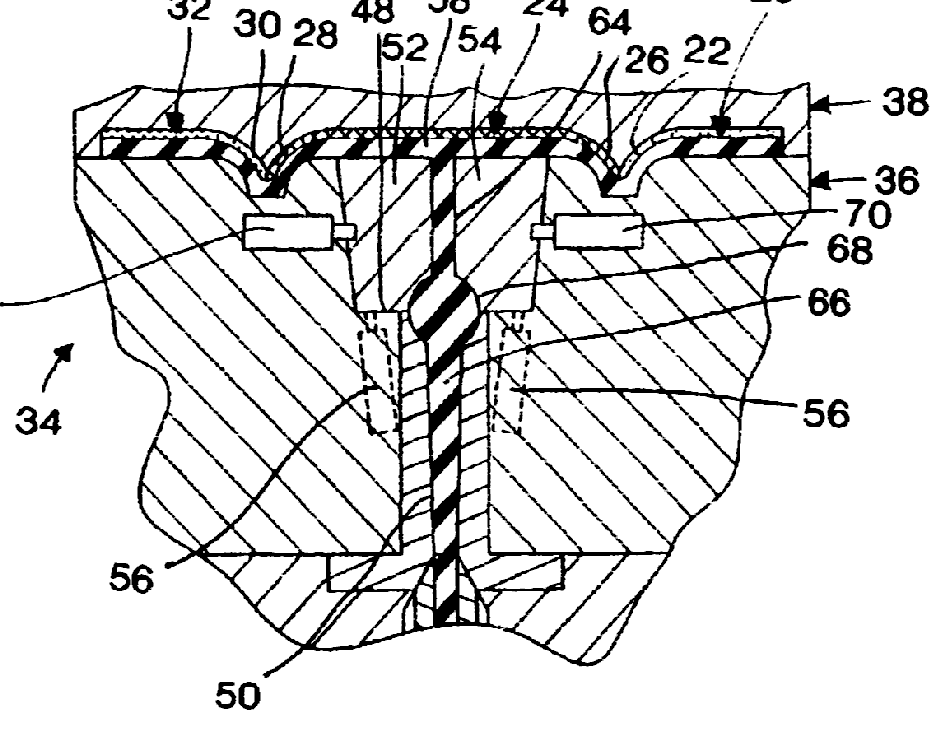

EP489349, fig 4, chip 22, lead frame 18. Runner 412 & Gate 416, 418. The moulding step in this group usually concerns transfer moulding.

The scope of this group is small in comparison to a typical related product group like H10W 74/016, since B29C 45/14655 is limited to disclosures related to the moulding process as such.

Attention is drawn to the following places, which may be of interest for search:

Apparatus for sealing, encapsulating for manufacturing or treating semiconductor or solid state devices | |

Moulds for encapsulating semi-conductors |

This place covers:

EP825006, fig 1. Loading, unloading, etc.

Attention is drawn to the following places, which may be of interest for search:

Plants in general |

In B29C 45/14688, the insert is the decoration itself or the insert comprises a decoration and nothing more.

In the case with a plurality of layers where the decoration layer is one of them, the classification is B29C 45/14811

Furthermore, typical for B29C 45/14688 is that the moulding process is adapted or optimised for coating articles with a decoration.

Standard film overmoulding is classified B29C 45/14778, even if the film is provided with a decoration.

WO98/09790, fig 2 & 5, insert 18 and plastic 28.

This place does not cover:

Incorporating decorated single layer or multi layered films by standard moulding processes | |

Applying transfer foils |

In this place, the following terms or expressions are used with the meaning indicated:

Decoration | A film provided with ink, paint or like means to create a decorative effect or information. |

This place covers:

Overmoulding inserts that can move relatively to the plastic after finishing the moulding process. Typically applied for making bearings and to preventing adhesion.

EP27770, insert 37 and plastic 16.

This place covers:

E.g. moulding on films

In this group, it is of upmost importance that the material, condition or the property of the insert is identified by allocating the appropriate Indexing Code as provided in the subclass B29K

This place covers:

Moulding processes whereby inserts are coated, but not impregnated

EP547625, insert 13 is not completely impregnated but coated at only one side

JP5269785

The difference between B29C 45/14786 and resin transfer moulding (B29C 70/48) is the way of coating.

In the group B29C 45/14786, the fibrous insert is not completely impregnated but coated at only one side.

A process, whereby an insert of fibrous material is complete impregnated refers to resin transfer moulding, even if the process is done by injection moulding.

Coating of single fibres/wires is classified B29C 45/14631

Attention is drawn to the following places, which may be of interest for search:

Coating reinforcement | |

Resin transfer moulding |

This place covers:

EP743155 fig 8a-8d, directly injection on two layers of foam.

Note the difference between B29C 45/14795 and B29C 45/14811.

Moulding processes, whereby material is injected directly on foam, is covered by B29C 45/14795.

In the case of a multilayer insert where one of the layers consist of foam, the classification is B29C 45/14811

Attention is drawn to the following places, which may be of interest for search:

Coating multilayered articles |

This place covers:

EP1025973, fig 1, release layer, protecting layer, etc.

Injection fig 7 & 8.

Concerning the preference of B29C 45/14827, it should be taken into account that this preference concerns either a double layered product where one layer is the transfer foil or a multilayered product, but were the invention concerns the use transfer foil as such (the identity of the other layers are not important for the invention).

Moulding processes, where the invention concerns the making of the multilayered inserts and where the fact that one of the layers can be removed is only disclosed on the level of additional information, is covered by the group B29C 45/14811.

This place does not cover:

Insert and adhesive layer only | |

Insert with only decoration, paint, ink | |

Coating a porous layer |

Attention is drawn to the following places, which may be of interest for search:

laminated inserts overmoulded by injection moulding (Japanese F-term) | 4F206/AD20, 4F206/AG03 |

In this group, it is highly desirable to identify every layer of the insert by allocating the appropriate Indexing Code as provided in the subclass B29K, or even the ones provided in B29L

Typical examples:

Fabric layers: B29K 2713/00

Scratch resistant layers, Abrasion resistant layers, protection layers: B29K 2995/0089

Barrier layers for gases: B29K 2995/0067

Decorative layers: B29K 2995/002

Porous layers, foam layers: B29K 2715/003

Adhesive layers: B29K 2715/006

Paint layers: B29L 2009/006

Metal layers: B29K 2705/00, B29L 2009/003

Layers with a metalized surface: B29L 2009/008

Hydrophobic layers: B29K 2995/0093

Hologram layers: B29L 2031/7224

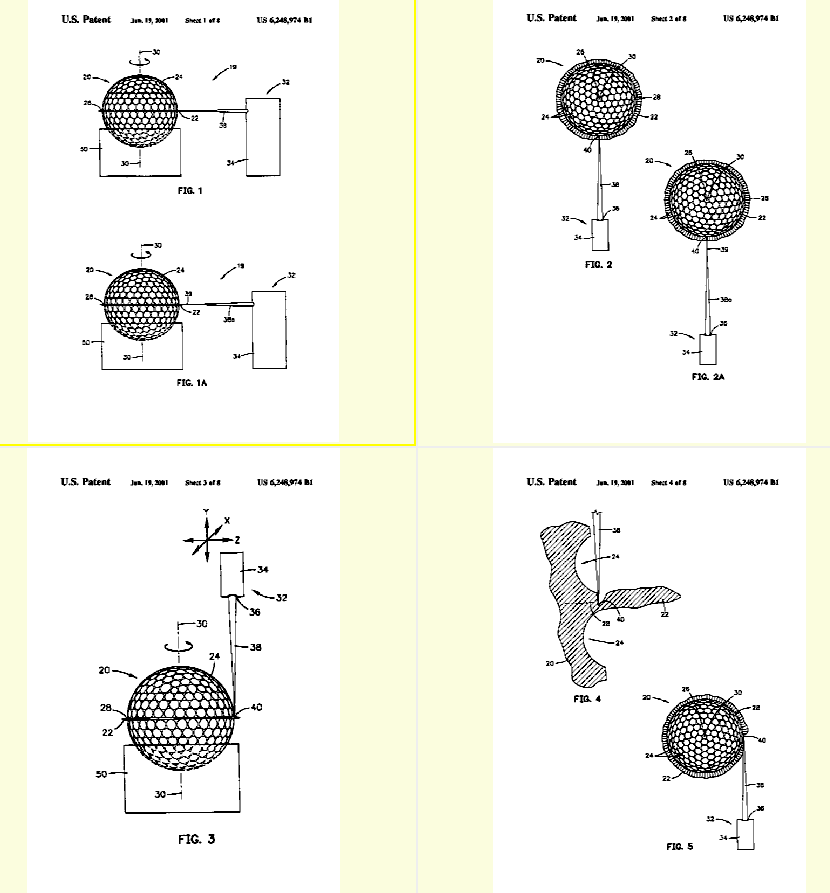

This place covers:

Making of golf balls by insert moulding

EP425933

This place does not cover:

Completely encapsulating reinforcement |

Attention is drawn to the following places, which may be of interest for search:

Positioning articles in the mould by means being retractable during the injection |

This place covers:

E.g. applying transfer foils to obtain decorative moulded articles.

Multilayered inserts whereby one layer is transfer foil to be removed from the remaining insert during the moulding process.

WO9516555, the dye material is transferred from the support layer to the plastic, the support layer is afterwards removed.

Attention is drawn to the following places, which may be of interest for search:

Memory cards or chip cards |

Attention is drawn to the following places, which may be of interest for search:

Sealing means between mould and article |

This place does not cover:

Injection moulding of successively moulded portions rigidly joined to each other | |

Injection moulding of interconnected elements which are movable with respect to each other | |

Joining articles injection moulded in separate cavities by injection moulding as final operation |

If of general interest, classification as provided in the B29C 45/04 and it subgroups can be allocated to documents classified in this group, typically at additional information level to identify the type of mould movement. Exceptionally the classification in B29C 45/04 or its subgroup can be added at inventive level, if the alleged invention relates to the movement of the mould, whereby said movement is of general interest and use.

Attention is drawn to the following places, which may be of interest for search:

Co-extruding a multicoloured striated pattern |

This place covers:

Multi-component injection moulding processes whereby the second cavity is present before movement of the displaceable mould part.

This place does not cover:

Multiway nozzles |

Attention is drawn to the following places, which may be of interest for search:

Blow moulding of parisons with at least one injected layer |

In this class it is highly desirable to identify all aspects related to insert moulding by allocating the appropriate classification as provided for in B29C 45/14 and subgroups at additional information level.

This place does not cover:

Multi-component injection moulding using different moulding stations |

Attention is drawn to the following places, which may be of interest for search:

Blow moulding of parisons with at least one injected layer |

Attention is drawn to the following places, which may be of interest for search:

Making multi-layered or multicoloured articles with a non-uniform dispersion of the moulding material in the article, e.g. resulting in a marble effect |

This place covers:

filters not in the nozzle located

exchanging runner channels

locking of mold halves during transport

This place covers:

Moulding in an environment of inert gasses, reactive gasses, e.g. for preventing mould sweating or plastic oxidation

This place does not cover:

Injection moulding in vacuum environment |

Attention is drawn to the following places, which may be of interest for search:

Casting under special conditions | |

Compression moulding under special conditions | |

Blow moulding in a particular environment | |