CPC Definition - Subclass C04B

This place covers:

Chemical aspects of the processing of lime, magnesia or dolomite and of molten slag.

Compositional aspects of:

- inorganic binders, such as hydraulic cements ;

- mortars, concrete and artificial stone, e.g. the choice of fillers or active ingredients therefore;

- shaped ceramic products, e.g. clay-wares, refractories , non-oxides.

Physico-chemical aspects of methods for obtaining mortars, concrete, artificial stones or ceramics , e.g. for delaying the setting time of mortar compositions.

Treatment including defibrillating of materials such as fillers , agglomerated or waste materials, or refuse to enhance their filling properties in mortars, concrete or artificial stone.

Porous mortars, concrete, artificial stone or ceramic ware, and the preparation thereof.

Methods and apparatus for:

- burning or slaking lime;

- obtaining mineral binders, e.g. Portland cement or hemihydrate plaster;

- the expansion of mineral fillers , such as clay, perlite or vermiculite.

After- treatment of artificial stones, mortars, concrete and ceramics , e.g. coating or impregnation of green concrete after primary shaping.

Non-mechanical treatment of natural stone.

Processing powders of inorganic compounds in preparation to the manufacturing of ceramic products .

The joining of burned ceramics with other articles by heating.

This place does not cover:

Granulating apparatus | |

Mechanical features relating to the working of mortars, concrete, stone, clay-wares or ceramics , e.g. mixing or shaping ceramic compositions, boring natural stone | |

Chemical preparation of powders of inorganic compounds | |

Devitrified glass-ceramics | |

Compositions containing free metal bonded to carbides, diamond, oxides, borides, nitrides, silicides, e.g. cermets, or other metal compounds, such as oxynitrides or sulfides, other than as macroscopic reinforcing agents | |

Building elements or constructions; Finishing work on buildings |

Attention is drawn to the following places, which may be of interest for search:

Materials for prostheses or for coating prostheses | |

Chemical or biological purification of waste gases | |

Layered products | |

Treating inorganic non-fibrous materials to enhance their pigmenting or filling properties | |

Adhesives | |

Cementing or plastering compositions for boreholes or wells | |

Alloys based on refractory metals | |

Shaft or vertical furnaces in general | |

Hydraulic hardening materials , e.g. concretes, ceramics or refractories for protection against radiation, i.e. shielding |

In this subclass, for the parts C04B 2/00-C04B 32/00, C04B 38/00, C04B 40/00, C04B 41/00 the CIS indexing system is used. For details, see below

Combination set (C-sets)

1. Introduction

1.1 This manual relates to the rules to be applied when classifying documents using C-sets in the "cement part" of subclass C04B. With the "cement part" we mean the whole of the subclass, with the exception of the range C04B 33/00 - C04B 37/00.

However, symbols of the range C04B 33/00 - C04B 35/00 can be used as Indexing Codes (when the classification is in C04B 38/00 or C04B 41/00).

1.2 C-sets are used in three major areas:

- C04B 2/00 - C04B 32/00 and C04B 40/00: Compositions of cement/concrete mixtures or of artificial stone like materials

- C04B 38/00: porous materials

- C04B 41/00: after treatment.

1.3 Symbols that are used in the present C-set system are chosen from:

- C04B 2/00 - C04B 41/00 (with the exception of C04B 37/00):

these are symbols which can be used as classification as well as symbols in the combination sets (C-set),

these are symbols used as additional information (CCA) or within the C-set (see below).

1.4 The principles of Combination sets are based on the possibilities offered by the IPC (until IPC7) for using classification symbols also as (linked) Indexing Codes.

The C-sets are present in EPODOC:

/CCI : CPC classification symbol

/CCA: Additional information

/CLC: the combination sets (C-sets) of symbols linked to the classification (CCI) or to the additional information (CCA)

The first symbol of a C-set is referred to as the "base class". Symbols in the C-set are separated by a comma (,).

The base group can be an CCI or CCA group

2. C-sets in the range C04B 2/00 - C04B 32/00 and C04B 40/00

2.1 This part of C04B relates to cement-, mortar-, concrete- and artificial stone compositions or their constituents or ingredients.

As a general rule such compositions (further referred to as "mixtures") contain three types of ingredients:

- one or more binders (organic or inorganic)

- fillers (inactive ingredients)

- active ingredients, e.g. accelerators.

[Exception: main group C04B 30/00 relates to compositions not containing binders].

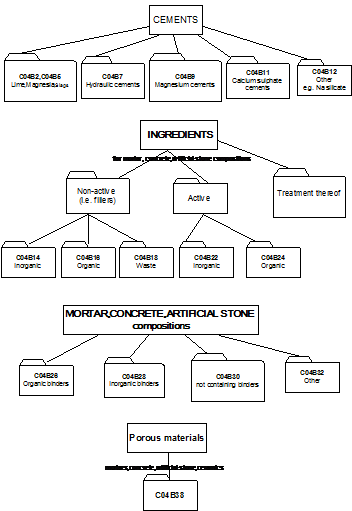

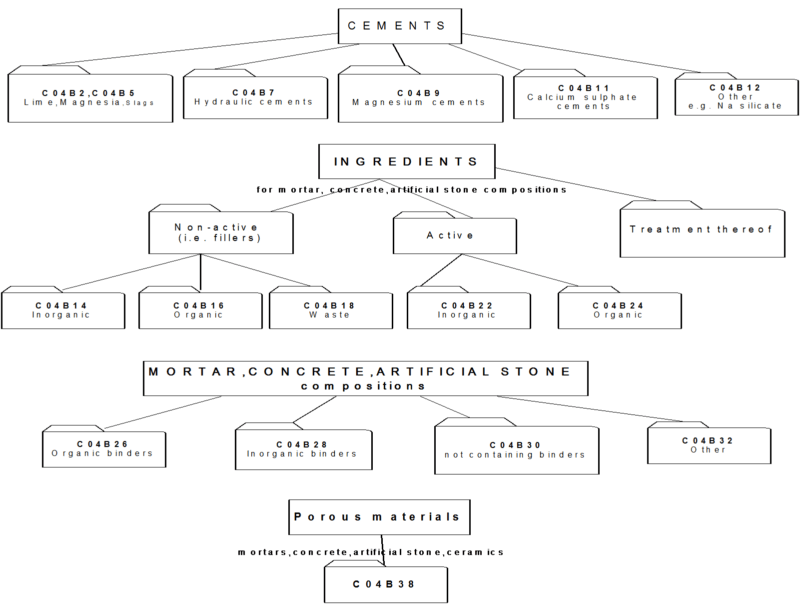

2.2 Overview of main groups:

- C04B 2/00 - C04B 12/00 : relate to inorganic binders as such

- C04B 14/00 - C04B 20/00 : relate to fillers

- C04B 22/00 - C04B 24/00 : relate to active ingredients

- C04B 26/00 - C04B 32/00 : relate to the mixtures

- C04B 40/00 : relates to characteristics / preparation of the mixtures

2.3 Classification rules:

2.3.1 When an invention relates to an individual ingredient, classification is made in the range C04B 2/00 - C04B 12/00 if this ingredient is a binder, in the range C04B 14/00 - C04B 20/00 if the ingredient is a filler and in the range C04B 22/00 - C04B 24/00 if it is an active ingredient.

2.3.2 When an invention relates to a mixture, classification is made in the range C04B 26/00 - C04B 32/00, according to the binder used while applying the last place rule (LPR). So if a combination of an organic and an inorganic binder is present, classification is made in C04B 28/00, not in C04B 26/00. If a combination of two inorganic binders is present, classification is done in C04B 28/00 according to the LPR for one of the binders, the others are added as symbols in the C-set and are chosen from C04B 7/00-C04B 12/00 groups. If one of the ingredients is (suspected to be) new or unusual, or special details describing this ingredient are given, classification is also made for this ingredient.

2.3.3 When the invention merely relates to the preparation or characteristics of the mixture, classification is made in C04B 40/00. If the mixture as such or one of its ingredients is considered to be new or unusual, classification is made for these aspects too. For obtaining porous materials see point 3. below.

2.3.4 When the invention relates to an active additive which is a mixture on its own, e.g. the combination of two specific polymers and a specific inorganic salt, classification is made in C04B 40/0039. If the use of one of the ingredients as such is new to the field, classification for this ingredient as such is made also.

2.4 C-set rules:

2.4.1 Primary goal of the combination set is to identify the individual constituents of the mixtures, using the classification symbols for these ingredients as part of a C-set, linked to the classification symbol which already identifies (one of) the binder(s).

Example 1:

A mixture containing a mixed binder of aluminium cement, Portland cement and a polymeric co-binder, next to diatomaceous earth and an inorganic sulfate will be classified - according to the LPR - in C04B 28/06, the other ingredients being identified by the appropriate symbols in the C-set:

CCI: C04B 28/06 C-set (CLC) : C04B 28/06, C04B 7/02, C04B 14/08, C04B 22/142, C04B 24/26

An organic co-binder next to an inorganic binder is indexed as an active organic ingredient (main group C04B 24/00).

Because in this example, all ingredients as such are known in the field, no further classification is made.

2.4.2 When for one of the ingredients alternatives are mentioned, separate C-sets are made.

Example 2:

If in the example 1, an inorganic chloride was mentioned as an alternative to the sulfate, the indexing would look like:

Set 1: C04B 28/06, C04B 7/02, C04B 14/08, C04B 22/142, C04B 24/26

Set 2: C04B 28/06, C04B 7/02, C04B 14/08, C04B 22/12, C04B 24/26

(Putting C04B 22/12 and C04B 22/142 in the same set would mean they are both present in the same mixture).

2.4.3 When classification is made for individual (active) ingredients, their function or in some cases their characteristics can be identified using the C04B 2103/00 series.

Example 3:

A new organic sulfonated plasticizer:

/CCI : C04B 24/16 /CCA : C04B 2103/30

When for a mixture, many alternatives for the same ingredient with a specific function are mentioned, instead of making a set for each alternative, only one C-set with the C04B symbol in the C-set for the function can be made. If one of the alternatives is preferred in the document a second set with the symbol for that alternative can be made too.

Example 4:

In a concrete mixture, a superplasticizer is added. This superplasticizer can be chosen from many alternatives, for each of which a C04B 24/00 entry exist. However a lignosulfonate is preferred.

/CCI : C04B 28/02 C-set 1 C04B 28/02, C04B 2103/32

C-set 2 C04B 28/02, C04B 24/18

2.4.4 In a similar way, characteristics or uses of the mixtures are identified with symbols of the C04B 2111/00 series. These symbols are always used as additional information.(CCA)

Example 5:

The composition of example 1 is used for sound insulation:

In addition to the above sets CCA: C04B 2111/52

2.4.5 When information is given about the preparation or characteristics of

the mixtures - this information not being the "main" information - additional symbols of main group C04B 40/00 can be added in the C-set.

Example 6:

The mixture of example 1 is hardened using microwaves:

C-set : C04B 28/06, C04B 7/02, C04B 14/08, C04B 22/142, C04B 24/26, C04B 40/0218

The mixture of example 1 is of the deferred action type:

C-set: C04B 28/06, C04B 7/02, C04B 14/08, C04B 22/142, C04B 24/26, C04B 40/06

2.4.6 When the process of making is the main invention a CCI in C04B 40/00 can be given. As a general rule, when classifying in C04B 40/00, symbols in the C-set are used to identify the kind of mixture, not to identify the individual ingredients. If it is important to identify these ingredients, further classification is made as mixture and the ingredients are identified by symbols linked to the classification symbol of the mixture in the C-set.

Example 7:

If only common ingredients are used:

/CCI : C04B 40/0286 C-set: C04B 40/0286, C04B 28/06

If also the composition of the mixture is of interest:

/CCI C04B 40/0286 and C04B 28/06

C-set 1: C04B 40/0286, C04B 28/06

C-set 2: C04B 28/06, C04B 14/386, C04B 22/0013

2.4.7 A special case within main group C04B 40/00 are the pre-mixtures of ingredients.

Here the same principle as for point 2.4.1 is applied, i.e. the classification symbols identifying the ingredients are linked to C04B 40/0039 (CCI) and a symbol from the range C04B 26/00 - C04B 32/00 is added to the C-set to indicate for which kind of mixture the pre-mixture is intended to be used.

Example 8:

/CCI :C04B 40/0042 C-set : C04B 40/0042, C04B 14/08, C04B 22/142, C04B 24/26, C04B 28/06

2.4.8 In the range for inorganic binders as such (C04B 2/00 - C04B 12/00) symbols can also be used in a C-set to identify aspects for which a classification symbol exists, but which aspects as such are not important enough to be classified.

Example 9:

/CCI: C04B 7/47 C-set : C04B 7/47, C04B 7/364

Example 10:

/CCI : C04B 11/26 C-set : C04B 11/26, C04B 11/024

2.4.9 For agglomerated materials (= artificial aggregates or fillers), which are classified in C04B 18/021 and subgroups, the starting materials other than the binder can be identified with further symbols in the C-set.

Example 11:

Making artificial gravel from a mixture of cement and mining refuse:

/CCI : C04B 18/021 C-set : C04B 18/021, C04B 18/12

2.4.10 Main group C04B 20/00 is a general group for fillers. When classification is made in this group, very often the specific filler involved is identified by adding the specific filler symbol in the C-set..

Example 12:

Expanding perlite in a rotary kiln:

/CCI: C04B 20/061 C-set: C04B 20/061, C04B 14/18

Example 13:

Coating alumina with metal:

/CCI : C04B 20/1062 C-set : C04B 20/1062, C04B 14/303

2.4.10a Groups C04B 20/123 and C04B 20/126 are used in the C-set only in combination with C04B 20/12 to indicate:

-in the case of C04B 20/123 that a coating is an alternative to the previous indicated coating

Example 14:

-in the case of C04B 20/126 that the coating layer is the same as a previous coating layer

Example 15:

3.Classifying in main group C04B 38/00.

3.1 This part of C04B relates to porous or lightweight cement-, mortar-, concrete-and artificial stone compositions and porous or lightweight ceramics.

More generally we could say that C04B 38/00 relates to inorganic foamed materials or bodies, with the exception of foamed metal.

Subdivision of C04B 38/00 is largely based on the methods used for obtaining the porosity or the reduction in weight, e.g. by adding lightweight filler (C04B 38/08), by adding a gas forming agent (C04B 38/02) or by burning out a burnable additive (C04B 38/06).

3.2 Classification and C-set rules:

3.2.1 Officially in main group C04B 38/00, there is no LPR. Nonetheless when porosity is obtained by a combination of methods, as a general rule, classification is made in the last appropriate place. The second method, not identified by classification (CCI), is identified by a C04B 38/00 symbol in the C-set. If of interest, documents can be even classified twice (see further point 3.2.3)

3.2.2 The central idea for classification/indexing in C04B 38/00 is:

- classification according to the method (see 3.2.1) and

- Indicating the nature of the material that is made porous or lightweight.

For identifying the nature of the material, symbols can be chosen from C04B 26/00 - C04B 35/00. In very exceptional cases also C04B 14/00 symbols can be used.

Example 16:

Obtaining a porous silicon carbide body by dissolving out a soluble salt.

/CCI : C04B 38/04 C-set: C04B 38/04, C04B 35/565

Example 17:

Obtaining porous porcelain by burning out a monolithic PUR sponge impregnated with clay slip:

/CCI : C04B 38/0615 C-set : C04B 38/0615, C04B 33/24

HOWEVER there is a fundamental difference in approach when classifying "cement type" mixtures and "ceramic type" materials or bodies: see points 3.2.6 and 3.2.7 below!

3.2.3 When a combination of methods is used, the method that is not identified by the classification is given a C04B 38/00 symbol in the C-set.

Example 18:

To the material of example 14 there is also added a gas forming agent:

/CCI : C04B 38/04 C-set: C04B 38/04, C04B 35/565, C04B 38/02

3.2.4 In the same way other aspects of interest can be identified by giving further C04B 38/00 symbols.

Example 19:

The material of example 18 is characterised by the dimensions of the nanosized pores and the overall % of porosity:

/CCI : C04B 38/04 C-set: C04B 38/04, C04B 35/565, C04B 38/0054, C04B 38/0074, C04B 38/02

3.2.5 When classifying in main group C04B 38/00, in the same way as for the indexing of mixtures as described in point 2 above, symbols of the series C04B 2111/00 can be used to indicate properties are uses, e.g. sound insulation.

Example 20:

The material of example 17 is used for electronic applications:

/CCI: C04B 38/0615 CCA : C04B 2111/00844 C-set: C04B 38/0615, C04B 33/24

3.2.6 Porous or lightweight ceramics are always classified in C04B 38/00 according to rules 3.2.1 to 3.2.5

3.2.7 Porous or lightweight cement-, concrete-, artificial stone- and like mixtures:

3.2.7a These type of mixtures are classified as such mixtures, so in the range C04B 26/00 - C04B 32/00, according to the rules of point 2 above. The appropriate C04B 38/00 symbols are added in the C-set.

Example 21:

Reinforced portland cement based concrete containing also carbon fibres and made porous by adding Al particles (Al will react with Ca(OH)2 liberated during cement hardening and thus produce H2 gas):

/CCI : C04B 28/04 C-set: C04B 28/04, C04B 14/386, C04B 22/04, C04B 32/02, C04B 38/02

Example 22:

Foaming gypsum by adding specific sulfonated foaming agent:

/CCI: C04B 28/14 C-set: C04B 28/14, C04B 24/16, C04B 38/10

3.2.7b When one or more of the other symbols give sufficient "C04B 38/00 information", no further C04B 38/00 symbols are given.

Example 23:

Expanded clay containing concrete will NOT receive symbol C04B 38/08, because C04B 14/12 already gives sufficient information:

/CCI: C04B 28/02 C-set: C04B 28/02, C04B 14/12

3.2.7c So as a general rule these kind of mixtures are not classified in main group C04B 38/00. Classification is made in this main group only when the invention relates to the process of obtaining the porosity or the reduction of weight. When the composition as such is still interesting in such a case, further classification is made for the mixture.

Example 24:

The characteristic feature of the invention of example 21 is the way in which the Al particles are handled in the context of obtaining the gas concrete:

/CCI : C04B 28/04 and C04B 38/02

C-set 1: C04B 28/04, C04B 14/386, C04B 22/04, C04B 32/02, C04B 38/02

C-set 2: C04B 38/02, C04B 28/04

3.2.8 While in general the LPR is applied in main group C04B 38/00, exception is made for obtaining porous or lightweight ceramic particles C04B 38/009. As a general rule, this group takes precedence over the other C04B 38/00 groups.

Example 25:

Obtaining porous alumina particles by burning out polymeric core:

/CCI C04B 38/009 C-set: C04B 38/009, C04B 35/10, C04B 38/0615

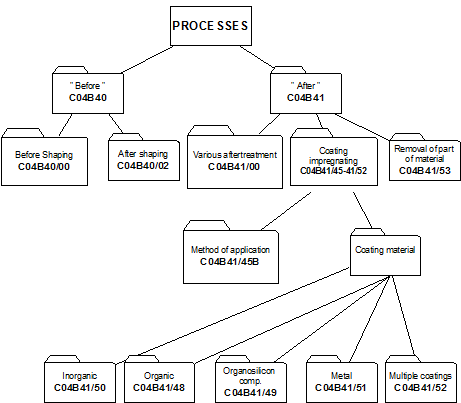

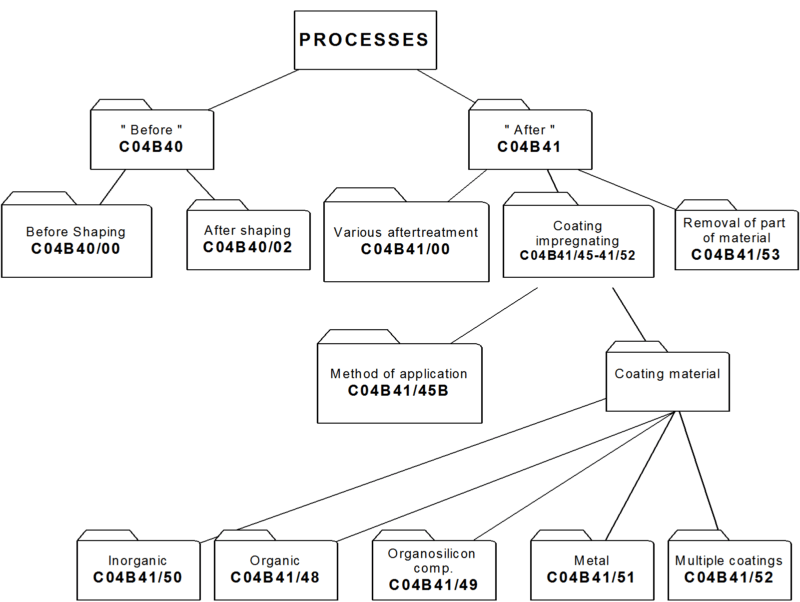

4. Classifying in main group C04B 41/00

i.e. after-treatment of cement-, mortar-, concrete- and artificial stone products as well as ceramic materials AND natural stone. Hereinafter the treated materials are referred to as "substrates".

While other kinds of after-treatment are not excluded, C04B 41/00 relates to after-treatment of substrate, mainly to :

- coating or impregnation of the substrates: C04B 41/45 and subgroups

- removing material from the substrates: C04B 41/53 and subgroups.

In main group C04B 41/00, no distinction is made between coating or impregnation. Therefore the terms coating, impregnation and layer are considered equivalent.

4.2 Classification and C-set rules:

4.2.1 As a general rule subdivision of main group C04B 41/00 is based on aspects relating to the method of after-treatment, such as the selection of the method for applying the coating material on the substrate, e.g. by CVD (C04B 41/4531) or the selection of the coating or impregnation material with which the substrate is treated, e.g. coating with carbon (C04B 41/5001).

When using C-set, only the range C04B 41/00 - C04B 41/5392 is used . Documents classified in the range C04B 41/60 - C04B 41/91 always get also a class in C04B 41/00 - C04B 41/5392, which may be combined with one or more C-sets.

4.2.2 To identify the substrate that is after-treated, the class C04B 41/009 is given and C-sets are created using complementary symbols chosen from:

- C04B 14/02 - C04B 14/36 when natural stone is treated

- C04B 26/00 - C04B 32/005 when artificial stone, e.g. concrete is treated

- C04B 33/00 - C04B 35/83 when ceramics are treated

- C04B 38/00 - C04B 38/106 when porous materials are treated

- C04B 14/38 - C04B 14/48 when ceramic fibres are treated, i.e. only when classifying in C04B 41/4584.

When the substrate is further defined e.g. a wood fiber/particle board, which in itself is information that does not require classification in the substrate class itself e.g. C04B 28/02 , then the C04B 41/009 set will be:

If a class in C04B 28/00 is also required because the mixture per se is interesting and is part of the invention information, then the C04B 41/009 set will comprise only the C04B 28/02 symbol

Example 26:

Impregnating a natural marble stone with polyester:

/CCI: C04B 41/4826 and C04B 41/009 C-set : C04B 41/009, C04B 14/285

Example 27:

Concrete based on aluminium cement is treated with waterglass (Na-silicate):

/CCI: C04B 41/5089 and C04B 41/009 C-set : C04B 41/009, C04B 28/06

Example 28:

A silicon nitride body is glazed:

/CCI: C04B 41/5022 and C04B 41/009 C-set :C04B 41/009, C04B 35/584

Example 29:

Coating alumina fibres with aluminium:

/CCI: C04B 41/4584 and C04B 41/009

C-set 1:C04B 41/009, C04B 14/4625

C-set 2: C04B 41/4584, C04B 41/5155

So for classification, C04B 41/4584 takes precedence over other C04B 41/00 groups when ceramic particles or fibres are treated!

Multiple coating of particulate or fibrous material is usually also classified in C04B 41/52 so that it is possible to attribute C-sets for each coating layer (see point 4.2.5 below).

4.2.3 In main group C04B 41/00, the LPR applies. As most subgroups relate to specific methods of applying coatings are subgroups of C04B 41/4505, while the groups identifying the nature of the coating material are further down in the scheme, this LPR in general results in a classification according to the material applied. One or more symbols identifying aspects of the method used are added in the C-set.

Example 30:

The process of example 26 is carried out under vacuum and increased temperature:

/CCI: C04B 41/4826 and C04B 41/009

C-set 1: C04B 41/009, C04B 14/285

C-set 2: C04B 41/4826, C04B 41/0072, C04B 41/4515

However, when the invention relates to the process proper, classification is made in the process group and a further symbol is used in the C-set for identifying the applied material on the substrate. If more ample information has to be given about the nature of the coating, classification is also made for this aspect in combination with a further C-set.

Example 31:

The process of example 26 is carried out under an atmosphere of very specific composition, this composition being the essential feature of the invention:

/CCI: C04B 41/4519 and C04B 41/009

C-set 1:C04B 41/009, C04B 14/285

C-set 2: C04B 41/4519, C04B 41/4826

Example 32:

In the example 31, the polyester can be mixed with other polymers:

/CCI: C04B 41/4519 and C04B 41/4826 and C04B 41/009

C-set 1: C04B 41/009, C04B 14/285

C-set 2: C04B 41/4519, C04B 41/4826

C-set 3:C04B 41/4826, C04B 41/4519, C04B 41/4811, C04B 41/4823

Exception on the LPR: for classification, C04B 41/4584 takes precedence over other groups of C04B 41/00 when treatment of ceramic fibres or particles is concerned (see example 29).

4.2.4 When alternatives are to be identified, the same procedure is applied as for concrete and like mixtures, i.e. two or more C-sets of symbols are made. There might be alternatives both for the process and the material applied to the substrate.

Example 33:

The treatment of example 27 can be carried out either under vacuum or under inert atmosphere:

/CCI: C04B 41/4826 and C04B 41/009

C-set 1: C04B 41/009, C04B 14/285

C-set 2: C04B 41/4826, C04B 41/4515

C-set 3: C04B 41/4826, C04B 41/4517

4.2.5 Multiple coating or impregnation.

When the same substrate is coated with two or more layers, classification is made in C04B 41/52. If one of the layers as such might be new in the field, classification for this layer as such is made too.

For each layer a separate C-set is made, each starting with C04B 41/52, the first set relating to the first layer, the second set relating to the second layer etc.

Example 34:

A clay ware body is first coated with an engobe and then with a glaze:

/CCI: C04B 41/52 and C04B 41/009

C-set 1: C04B 41/009, C04B 33/00

C-set 2: C04B 41/52, C04B 41/504

C-set 3: C04B 41/52, C04B 41/5022

Example 35:

The engobe used in example 34 looks new to the field:

/CCI: C04B 41/52 and C04B 41/009 and C04B 41/504

C-set 1: C04B 41/009, C04B 33/00

C-set 2: C04B 41/52, C04B 41/504

C-set 3: C04B 41/52, C04B 41/5022

Exception: when the different coatings result in layers of the same composition, classification is made according to the nature of that layer and C04B 41/52 is added to the C-set !

Example 36:

A boron carbide body is coated with two or more layers, which might slightly differ in composition, but which all result in a carbon coating:

/CCI: C04B 41/5001 and C04B 41/009

C-set 1: C04B 41/009, C04B 35/563

C-set 2: C04B 41/5001, C04B 41/52

As for single layer coatings, additional C04B 41/00 codes can be added to the C-set to identify other interesting aspects of the respective coatings.

4.2.6 When, in the case of multiple coating, alternatives are mentioned, the following procedure is followed.

If, e.g. for layer 2 an alternative is to be identified, the third C-set will represent this alternative layer, with at the end the symbol C04B 41/522. [This symbol is not to be used for classification.] So in this case, a possible third layer will be identified by the fourth C-set, because the third one refers to an alternative of the second layer (represented by the second set).

Example 37:

In the example 34, a porcelain layer can be used as an alternative to the engobe layer:

/CCI: C04B 41/52 and C04B 41/009

C-set 1: C04B 41/009, C04B 33/00

C-set 2: C04B 41/52, C04B 41/504

C-set 3: C04B 41/52, C04B 41/5038, C04B 41/522

C-set 4: C04B 41/52, C04B 41/5022

-When a coating layer is the same as a previous coating layer, a similar procedure as above is followed, adding the symbol C04B 41/524 at the end of the layer that is identical to a previously identified layer

Example 38

4.2.7 For the sake of classification/C-sets in C04B, treatment of "green" concrete or ceramics, i.e. concrete that has not hardened yet, resp. ceramic products that are not fired yet, is considered to be covered by C04B 41/00. Such documents will receive C04B 41/4578 as an extra symbol in the C-set. Only in exceptional cases, classification can be made in this group.

Example 39:

The substrate of example 25 is treated before hardening of the concrete:

/CCI: C04B 41/5089 /SI : C04B 28/06 C-set: C04B 41/5089, C04B 41/5007

4.2.8 Group C04B 41/53 relates to the removal of part of the materials of the treated article. A coating process including a step like polishing, roughening or etching is however not classified in C04B 41/53 or a subgroup (what could be expected applying the last place rule), but is classified applying the general rules for coatings above and adding C04B 41/53 or a subgroup to the C-set. If however the removal is the essential step of the invention, classification in C04B 41/53 is (also) made.

4.2.9 In the same way as when classifying/C-sets in the other parts of C04B, mentioned above, symbols of the series C04B 2111/00 can be used to identify uses or characteristics of the products obtained.

Example 40:

The material of example 36 is used for electronic applications:

/CCI: C04B 41/5001 , C04B 41/009

/Indexing Code: C04B 2111/00844

C-set 1: C04B 41/009, C04B 35/563 and

C-set 2: C04B 41/5001, C04B 41/52

In this place, the following terms or expressions are used with the meaning indicated:

Active ingredients | Ingredients having an effect on the mortar-, concrete- or artificial stone composition during processing or on the characteristics of the final product, e.g. as set accelerator, as dispersant or as gas generating agent. Other examples are processing aids or property improvers, e.g. grinding aids, used after the cement burning process or in the absence of such a burning process. |

Cement | The binder proper, i.e. excluding any additional ingredient or additive added to the finished binder as such, with the exception of mixtures of binders. |

Clinker | The unground sintered product leaving the cement kiln. In patent literature this term might be used literally, i.e. to indicate the unground sintered product leaving the cement kiln, or it might be used to indicate the ground cement without any additive, i.e. not interground with additives such as gypsum. |

Ceramics | Inorganic, non metallic products obtained by a process involving a shaping step and a sintering or comparable heat treatment step, with the exclusion of cements , cermets and glasses, glazes, vitreous enamels and devitrified glass ceramics. |

Fillers | Inactive ingredients, include pigments, aggregates and fibrous reinforcing materials. |

Fine ceramics | Ceramics having a polycrystalline fine-grained microstructure, e.g. of dimensions below 100 micrometer. |

Hydraulic binder | For the purpose of classification and search in this subclass, the terms " cement " and " hydraulic binder " are considered to be equivalent, even if in literature, an hydraulic binder might be defined as a mixture of cement and one or more inorganic additives. |

Mortar- , concrete- and artificial stone compositions | They are considered as a single group of materials, are mixtures of one or more binders with fillers or other ingredients. In the context of such compositions, the terms " cement " and "binder" are considered equivalent. |

Resin mortar or resin concrete | Mortar or concrete containing resin as a binder instead of cement , i.e. excluding any inorganic binder and containing a considerable amount of inorganic filler compared with the amount of the organic binder. |

Refractories | Ceramics or mortars withstanding high temperatures of at least about 1500 degrees C. For classification and search in this subclass no substantial distinction is made between the terms " refractories " and " ceramics ". |

Porous materials | Materials which are deliberately made porous, e.g. by adding gas-forming, foaming, burnable or lightweight additives to the composition they are made of. |

This place covers:

Lime binders as such; Preparation thereof;

C-set is used only incidentally in this class. If so, symbols are chosen from other C04B 2/00 groups and C04B. A C04B 2/00 symbol in a C-set set having a C04B 28/00 CPC class indicates the presence of a second binder.

This place does not cover:

Hydraulic lime cements | |

Mixtures containing lime as a binder |

This place does not cover:

Obtaining Ca(OH)2 otherwise than by simple slaking of quick lime |

This place covers:

Slaking, with water including air slaking, filtering after slaking

This place does not cover:

Devices for filtering after slaking | |

Simultaneous dehydrating of gypsum and slaking of lime | |

Warming up food and the like, e. g. by slaking lime | |

Hydration of MgO | |

Chemical heat sources |

This place does not cover:

Hydrating cement clinker | |

Quenching coke |

This place covers:

Devices for slaking lime, e.g. devices for preparing milk of lime or for purifying slaked lime e.g. by filtering

This place does not cover:

Mechanical aspects | |

Manufacture of slag wool | |

Other cast stone | |

Treatment of slag in, or for the production of metals |

In this place, the following terms or expressions are used with the meaning indicated:

Metallurgical slag | Slag from metallurgy processes |

This place covers:

Hydraulic cements as such and their manufacturing methods.

This place does not cover:

Porsal cement |

CIS is used only incidentally in this class. If so, index codes are chosen from other C04B 7/00 groups and C04B. A C04B 7/00 index code in a CIS set having a C04B 28/00 EC class indicates the presence of a second binder.

In this place, the following terms or expressions are used with the meaning indicated:

Hydraulic cement | - like cements setting under the influence of water and - cements hardening in the air and under water |

This place covers:

Portland cement (PC),

i.e. hydraulic cement produced by firing limestone or chalk and clay (or other silica, alumina, iron bearing materials) so that Ca-silicate sand aluminates are formed. Average composition: 45% C3S, 25%C2S, rest C3A, C4AF;

i.e. average oxide composition: SiO2 17-24, Al2O3 3-7, Fe2O3 1-5, CaO60-65, MgO 1-5, alkali 1, SO3 1-3;

i.e. average water : cement ratio is 0.4 - 0.6;

i.e. during hydration Ca(OH)2 is formed, given thus an alkaline reaction;

i.e. PC clinker mostly coground with gypsum to retard setting;

e.g. WHITE PC: low proportion of iron oxide by the choice of raw materials or by firing in reducing flame;

e.g. MEDUSA CEMENT = white PC ;

e.g. LOW HEAT CEMENT : high % of C2S and C4AF, low % of C3S and C3A;

e.g. MASONRY CEMENT for more plastic mortar, often produced by grinding more finely than ordinary PC , a mixture of PC and limestone (or colloidal clay, diatomaceous earth);

e.g. RAPID HARDENING PC = ground finer than PC, slightly altered, setting time similar but strength developed more rapidly;

e.g. SULPHATE RESISTANT PC = high % of C3S and C2S, low % of C3A and C4AF. Should not contain C3A to avoid formation of ettringite (="cement bacillus")

This place covers:

Portland cement using raw materials containing gypsum, e.g. using CaSO4 instead of chalk or limestone as raw material in the combined production of cement and H2SO4 (actually production of SO2)

This place does not cover:

Ca-aluminosulfate cements |

This place does not cover:

Slag cements | |

Cements based on fly ash | |

Cements based on combustion residues, e.g. from coal | |

Pozzuolans as fillers | |

Compositions based on (fly) ash, without addition of lime (producing) compound | |

Lime-pozzuolana based compositions |

Attention is drawn to the following places, which may be of interest for search:

Artificial pozzuolana cements | C04B 7/24 and subgroups |

In this place, the following terms or expressions are used with the meaning indicated:

Pozzuolana | a material that, ground and mixed with lime and water, produces at ordinary temperatures compounds with hydraulic properties; |

Pozzuolana cement | obtained by grinding together a pozzuolana with cement clinker or (hydraulic) lime; |

In patent documents, the following words/expressions are often used as synonyms:

- " Natural pozzuolanas "," Santorini earth "," Trass "," Volcanic ash "and " Diatomaceous earth "

This place covers:

Hydraulic cements comprising slags as raw material, e.g. cements having low heat of hydration, cements with higher glass content (improved hydraulic characteristics)

This place does not cover:

Mâchefer (= slag from coal combustion) | |

Slags from combustion of coal, or waste incineration | |

Silicates added as active ingredients before/during the burning process |

This place covers:

Hydraulic cement containing metallurgical slag,

Examples of metallurgical slag :

blast furnace slag .;

STEELMAKING SLAGS.

L.D. slags, (as such not suited as hydraulic cement because of high content of CaO and MgO (lime and magnesia are sprayed on the bath during the oxygen injection for decarburizing and refining the steel)

This place does not cover:

Treatment of slag |

In this place, the following terms or expressions are used with the meaning indicated:

Scorie | metallurgical byproduct based on silicates |

In patent documents, the following abbreviations are often used:

Laitier = scorie de haut fourneau = blast furnace slag

Laitier d'aciéries = steelmaking slags

LD slags = scorie d'aciéries

This place covers:

Hydraulic cement containing metallurgical slag with other inorganic cementitious materials or other activators,

e.g. basic slags + PC clinker or anhydrite;

This place does not cover:

Ingredients added to the slag in the molten state |

In patent documents, the following abbreviations are often used:

METAAL CEMENTEN = basic slags + PC clinker or anhydrite;

when the alkali activated slag results in a polymeric - Davidovits type - cement, additional classification in C04B 12/005 should be given

In this place, the following terms or expressions are used with the meaning indicated:

waterglass | Sodium silicate |

This place covers:

Hydraulic cement containing metallurgical slag mixed with calcium oxide containing activators,

e.g. SLAG CEMENT = "cold process slag cement" = obtained by cogrinding granulated B.F. slag

In patent documents, the following abbreviations are often used:

BF slag = ciment de laitier

slakkencementen (BE) = ciment de laitier à la chaux (FR)

This place covers:

Hydraulic cement containing metallurgical slag mixed with Portland cements,

e.g. PORTLAND BLAST FURNACE CEMENT (GB) = cogrinding 65% B.F. slag +PC clinker (no gypsum);

e.g. PORTLAND BLAST FURNACE SLAG CEMENT (US) = 25-65% granulated B.F.slag;

e.g. CIMENTS DE HAUT-FOURNEAU (BE) = 30-70% granulated B.F. slag;

e.g. CIMENTS PERMETALLIQUES (BE) = more than 70% B.F. slag;

e.g. CIMENTS PORTLAND DE FER (FR) = 25-35% B.F. slag;

e.g. CIMENTS METALLURGIQUES MIXTES (FR) = 45-55% B.F. slag;

e.g. CIMENTS DE HAUT-FOURNEAU (FR) = 65-75% B.F. slag;

e.g. CIMENTS DE LAITIER AU CLINKER (FR) = more than 80% B.F. slag;

e.g. EISENPORTLANDZEMENT (DE) = less than (35 or) 40% B.F. slag;

e.g. HOCHOFENZEMENT (DE) = 36 (or 41) -85% B.F. slag;

In patent documents, the following abbreviations are often used:

Portland cements = ciments de haut-fourneau = ciment permétallique,= ciments Portland de fer = ciments métallurgiques mixtes = ciments de laitier au clinker = eisenportalndzement = hochofenzement

This place covers:

Hydraulic cement containing metallurgical slagmixed with calcium sulfate containing activators,

e.g. SUPERSULPHATED CEMENT = granulated B.F. slag + CaSO4 + small % PC or lime

This place does not cover:

Cement containing metallurgical slag mixed with alkali metal containing activators |

In patent documents, the following abbreviations are often used:

Supersulphated cement = ciment métallurgique sursulfaté = ciment sursulfaté = sulfathüttenzement

This place covers:

Hydraulic cement using as raw materials oil shales, residues or waste resulting from different processes, e.g. combustion waste, demolition waste, household, not being slag

This place does not cover:

Waste as additive to the raw material | |

Waste as fillers for concrete compositions |

This place covers:

Hydraulic cements produced from oil shales, residues or wastes mixed with activators or composition-correcting additives

Attention is drawn to the following places, which may be of interest for search:

when the alkali activated waste results in a polymeric - Davidovits type - cement, additional classification in C04B 12/005 should be given

In this place, the following terms or expressions are used with the meaning indicated:

Activator | Material used to enhance the hydraulic activity of (waste) raw materials |

In patent documents, the following abbreviations are often used:

Composition correcting additives = activators

This place does not cover:

Hydraulic cements from oil shales, residues or wastes other than slag mixed with activators or composition-correcting additives |

This place covers:

Hydraulic cements produced from combustion residues,

e.g. artificial pozzuollans other than slags or fly ashes.

This place does not cover:

Hydraulic cements from oil shales, residues or waste other than slag mixed with activators or composition-correcting additives | |

Hydraulic cements from raw materials containing flue dust | |

Concrete compositions containing artificial pozzuollans |

This place covers:

Hydraulic cements produced from oils shale, from oil shale residues, from lignite processing,

e.g. simultaneous production of cement and combustion gas from coal

In patent documents, the following abbreviations are often used:

Schistes houillers = bitumineus kalksteen

This place covers:

Hydraulic aluminous cements, obtained by melting (or sintering) a mixture of bauxite and chalk; cooling; grinding.

Composed of :3CaO.Al2O3 (tricalcium dialuminate), CaO.2Al2O3 (calciumtetraaluminate), CaO.Al2O3 (calcium metaaluminate).

Comp.: CaO 37.7 ,Al2O3 38.5 , Fe2O3 12.7 , FeO 3.9 , SiO2 5.3 , SO3 0.1 .

Hydration: -->mostly 3CaO.Al2O.6H2O + Al(OH)3 formed;

i.e. characteristics: less aggressive to the skin than PC,

* very rapid strength development (24h = 28 days for PC)

*setting time = similar to PC

* sulphate/seewater resistant

* colour =black ,

* to be used to -10 C

used for castable refractories;

e.g. high alumina cement;

e.g. 11CaO.7Al2O3.CaX2

This place covers:

Hydraulic calcium aluminosulfate cements

e.g. 4CaO.3Al2O3.SO3;

This place covers:

i.e. HYDRAULIC LIME : obtained from limestone containing clay, burnt at 1000 - 1200 C ..>; beta-C2S, C2AS, C4AF .

WATERKALK. The more hydraulic the closer to cement;

i.e. ROMAN CEMENT = ROCK CEMENT = obtained by calcining a natural mixture of clay and limestone;

i.e. NATURAL CEMENT = idem (below sintering);

e.g. SELENITIC CEMENT = lime + 5 - 10% plaster of lime;

e.g. HYDRAULIC HYDRATED LIME = hydrated dry cement. Product obtained by calcining limestone containing silica and alumina to a temper. short of incipient fusion --->; sufficient free CaO formed to permit hydration and leaving unhydrated suffic. calc. silicate;

e.g. HIGH CALCIUM HYDRAULIC HYDRATED LIME = hydraulic hydrated lime containing <= 5% MgO;

e.g. HIGH MAGNESIUM HYDRAULIC HYDRATED LIME = hydraulic hydrated lime containing >= 5% MgO;

This place covers:

Controlling, monitoring hydraulic cement manufacturing processes,, e.g.. automation

This place covers:

Manufacture of hydraulic cements preventing environmental pollution during the process e.g. desulfuration

This place covers:

Manufacture of hydraulic cements by treating raw materials with active ingredients added before or during the burning processes e.g. additives for obtaining white cement

This place does not cover:

Blended cements with slags | |

Adding ingredients after the burning process |

This place covers:

Manufacture of hydraulic cements by treating raw materials with acids or salts added before or during the burning processes e.g. vanadates

This place does not cover:

Automatisation aspects | |

Desulfuration | |

Aspects only relating to the installation | |

Furnaces, kilns, ovens and details thereof |

This place covers:

Manufacture of hydraulic cement by preheating without addition of fuel during the preheating step, for example by using exhaust gases, e.g. RSP = reinforced suspension preheater

This place covers:

Manufacture of hydraulic cement by preheating with addition of fuel , e.g. with addition of fuel in the calcining step, besides the addition of fuel in the kiln itself

This place covers:

Treatment or selection of the fuel for the burning during the manufacture of hydraulic cement e.g. fuel for burning other raw material; waste hot gases

e.g. heavy fuel oil (S-content >1%)

This place does not cover:

Refuse consuming furnaces |

This place does not cover:

Calcination in fluidised beds |

This place covers:

Electric burning or melting during the manufacture of hydraulic cement

This place does not cover:

Non-electric melting |

This place covers:

Clinker hydration during manufacture of hydraulic cement, i.e. in principle for the hydration of the lime content of the clinker;

e.g. hydrating ground clinker

This place does not cover:

Hydrating ground clinker | |

Still contains grinding aids | |

Grinding aids | are classified as active ingredients, e.g. in C04B 24/00, and receive C04B 2103/52 as an Indexing Code |

Grinding aids in general |

This place does not cover:

Obtaining spherical cement particles in the manufacture of hydraulic cement |

This place covers:

Cements characterised by fineness obtained by the clinker grinding e.g. "microcement": particles with diameter smaller than 15 micrometer

This place does not cover:

Unground clinker |

This place does not cover:

Avoiding environmental pollution |

Attention is drawn to the following places, which may be of interest for search:

For aspects relating to cement kiln dust |

This place covers:

Cements are based on magnesium, e.g. Mg oxychloride, Mg oxysulfate; Preparation thereof;

CIS is used only incidentally in this class. If so, index codes are chosen from other C04B 9/00 groups and C04B. A C04B 9/00 index code in a CIS set having a C04B 28/00 EC class indicates the presence of a second binder.

This place covers:

Process of manufacturing magnesium cements or similar cements, e.g. burning, calcining

This place does not cover:

Preheating, burning, calcining or cooling lime stone, magnesite or dolomite |

This place covers:

Calcium sulfate cements,

e.g. Natural forms of CaSO4.2H2O: SELENITE, MARIAGLAS, TERRA ALBA,SATINITE, ALABASTER;

e.g. MORMOR CEMENT = Ca-sulphate;

e.g. MACK'S CEMENT = plaster of Paris + K2SO4 or Na2SO4;

e.g. LANDPLASTER = CaSO4.2H2O ;

e.g. aging of calcined gypsum

CIS is used only incidentally in this class. If so, index codes are chosen from other C04B 11/00 groups and C04B.

This place covers:

Methods and apparatus for dehydrating gypsum,

e.g. PLASTER = mostly alpha + beta.

e.g. regeneration of gypsum molds: (classification being //( C04B 11/02; C04B 11/262) or other way around)

This place does not cover:

Drying alpha-hemihydrate | |

Calcining in general | |

For other purposes than cement manufacture |

This place covers:

e.g. drying of alpha-gypsum;

e.g. quick setting alpha-plaster + K2CO3;

used for making moulds for the ceramic industry.

This place does not cover:

Attention | |

Take precedence |

The presence of C04B 11/032 in a c-set indicates that alpha-hemihydrate form is used

This place covers:

Devices for the dry process of dehydrating gypsum

This place does not cover:

C04B 11/0281 - C04B 11/0288 take precedence

The presence of C04B 11/036 in a c-set indicates that beta-hemihydrate form is used

Attention is drawn to the following places, which may be of interest for search:

Alkali metal silicates per se and their preparation | |

Ammonium silicates per se and their preparation |

Attention is drawn to the following places, which may be of interest for search:

In or for the manufacturing of ceramics |

This place covers:

Inorganic materials used ad fillers for mortars, concrete or artificial stone, and their treatment to enhance their filling properties e.g. inorganic pigments other than oxides;

C04B 14/00 and subgroups are used as substrate codes for coatings of natural stone

This place does not cover:

Oxide pigments | C04B 14/30 and subgroups |

Expanding or defibrillating materials |

This place covers:

Carbon used as fillers for mortar, concrete or artificial stone, elemental carbon, e.g. COKE, KOKS (=90%C), LIGNITE, COCKES, "TEERKOKS";

In patent documents, the following abbreviations are often used:

"MINERAL NOIR" = shale (70% SiO2, 30%C) = coal black = " NOIRMINER" = "NOIR D´ IVOIRE"

This place covers:

Silica-rich materials, silicates used as fillers for mortars, concrete or artificial stone

e.g. "LOESS";

e.g. GREYWACKE, GRAYWACKE = conglomerate rock (round pebbles + sand, cemented together.)

Attention is drawn to the following places, which may be of interest for search:

Clay |

This place covers:

Magnesium silicates used as fillers for mortars, concrete or artificial stone,

e.g. SEPIOLITE; ASBESTINE

This place covers:

Alkali-metal containing silicates, Al-alkali metal silicates used as fillers for mortars, concrete or artificial stone,

e.g. PETALITE Li2O.Al2O3.8SiO2;

e.g. SPODUMENE LiO2.Al2O3.4SiO2;

e.g. EUCRYPTITE LiO2.Al2O3.2SiO2;

e.g. NEPHELINE SYENITE;

e.g. MAGADIITE

This place does not cover:

Waterglass |

This place covers:

Quartz, sand used as filler for mortar, concrete or artificial stone,

e.g. SILICA (SiO2) is polymorphic i.e. capable of existing in two or more crystal forms. Main forms of crystalline silica : QUARTZ,TRIDYMITE, CRISTOBALITE.

e.g. vitreous silica, amorphous silica;

e.g. precipitated silica; pyrogenic silica;

e.g. SILT = fine sand;

e.g. CHERT; FLINT; MOLDING SAND;

This place covers:

microsilica used as filler for mortar, concrete or artificial stone, e.g. colloidal silica 0.001-0.2 microns

This place does not cover:

C04B 18/146, C04B 12/04 take precedence

Preparing microsilica slurries or suspensions |

In this place, the following terms or expressions are used with the meaning indicated:

Microsilica | Silica having micro- or nanosize particles |

This place covers:

Silica aerogel used as filler for mortar, concrete or artificial stone,

e.g. silica aerogel being obtained by forming a SiO2 gel impregnated with a solvent, and evaporating the solvent under hypercritical conditions

This place covers:

Specific natural sands used as filler for mortar, concrete or artificial stone, e.g. BARKHAN SAND, BARHAN SAND

This place covers:

Diatomaceous earth used as filler for mortar, concrete or artificial stone,

e.g. hydrated amorphous silica, skeletons of Diatomacea which are related to brown algae

e.g. INFUSORIAL EARTH;

e.g. TRIPOLITE;

e.g. FOSSIL FLOUR,, MOUNTAIN FLOUR;

In patent documents, the following abbreviations are often used:

FOSSIL FLOUR= FARINE FOSSILE= MOUNTAIN FLOUR

KIESELGUHR, KIESELMEHL

"DIATOMEEN PELITE";

"MOLERERDE"

BERGHMEHL

This place covers:

Clay used as filler for mortar, concrete or artificial stone,

e.g. Al silicates;

e.g. BALL CLAY;;FULLERS EARTH;;

e.g. MARL;

e.g. PORCELANITE

This place does not cover:

Sepiolite | C04B 14/042, some older document are in C04B 14/10 |

Chamotte, fireclay, fired clay, grog | C04B 18/025 (older documents have a C-set C04B 14/10; C04B 18/023) |

In patent documents, the following abbreviations are often used:

BALL CLAY= GLAISE = FULLERS EARTH= LEEM;

MERGEL" = "MARNE" = MARL

OCRE

This place covers:

Bentonite, e.g. montmorillonite used as filler for mortar, concrete or artificial stone,

e.g. HECTORITE, synthetic hectorite;

e.g. BLEACHING EARTH, "BLEICHERDE" = Al-Mg-Silikate

This place does not cover:

Waste bleaching earth |

This place covers:

Kaolin used as filler for mortar, concrete or artificial stone,

Kaolin is not sintered

e.g. METAKAOLIN, KAOLINITE;

e.g. SMECTITE [9212];

This place covers:

Shale, slate used as filler for mortar, concrete or artificial stone

This place does not cover:

Shale residues, colliery shale |

In patent documents, the following abbreviations are often used:

SHALE = SLATE = "SCHISTE" = "SCHIEFER" = "LEISTEEN" (harde klei) =ARDOISE

This place covers:

Expanded clay used as filler for mortar, concrete or artificial stone

e.g. porous clay; expanded shale;

This place covers:

Mineral of volcanic origin used as filler for mortar, concrete or artificial stone

e.g. natural pozzuolanes (pozzolana, puzzolan) other than diatomaceous earth;

e.g. IGNEOUS ROCK

e.g. ANDESITE, RHYOLITE, PORFIER;

e.g. OBSIDIAN = vulcanic glass with little or no crystal water;

e.g. TRASS = TUFF = unconsolidated vulcanic ashes;

This place does not cover:

Granite |

In this place, the following terms or expressions are used with the meaning indicated:

TUF | porous rock formed from cemented volcanic ashes or from calcareous deposits in lakes or springs |

In patent documents, the following abbreviations are often used:

IGNEOUS ROCK = "ERGUSSGESTEIN " = "ROCHE EFFUCIVE

UITVLOEIINGS GESTEENTE" = "GESTOLDE LAVA"

"PECHSTEIN" = acidic vulcanic glass;

This place covers:

Porous minerals of volcanic origin used as filler for mortar, concrete or artificial stone

e.g. PUMICE = porous volcanic rock;

e.g. LIPARITE =(Ca pegmatite) e.g. SHIRAZU, SHIRASU = volcanic ash;

e.g. PUMIZITE = volcanic glass

e.g. SCORIA, CINDER

In patent documents, the following abbreviations are often used:

PUMICE = "PIERRE PONCE " = "PUIMSTEEN" = "BIMS"(12mm)

FLUGSAND = like bims but finer (7-10mm);

This place covers:

Perlite being mineral of volcanic origin used as filler for mortar, concrete or artificial stone e.g. volcanic glass

This place covers:

Expanded perlite (mineral of volcanic origin) used as filler for mortar, concrete or artificial stone

e.g. expanded by evaporation of crystal water

This place covers:

Mica, vermulite used as filler for mortar, concrete or artificial stone

e.g. "GLIMMER", KAl3Si3O10(OH)2;

e.g. BIOTITE = dark or magnesia mica (rich in Mg and Fe);

e.g. MUSCOVITE = (Na,K)2O.3Al2O3.6SiO2.2H2O;

e.g. TRACHYLIPARITE;

e.g. sericite

This place does not cover:

Punching of mica | |

Mechanical splitting | |

Mica treatment | |

Pulp or paper comprising mica or vermiculite |

This place covers:

Vermiculite used as filler for mortar, concrete or artificial stone

e.g. = hydrated biotite mica (OH)2(Mg Fe)3(SiAlFe)4O10.4H2O;

This place does not cover:

Delamination of mica | |

Chemical delamination |

This place does not cover:

Ion exchanged silicates |

This place does not cover:

Mechanical delamination |

This place covers:

Any type of glass used as filler for mortar, concrete or artificial stone

e.g. recuperated, waste glass;

e.g. frits, email

This place does not cover:

Vitreous SiO2 |

This place does not cover:

Lightweight materials |

This place covers:

Carbonates used as filler for mortar, concrete or artificial stone

e.g. MAGNESITE, DOLOMITE, "DOLOMIE"

This place covers:

Carbonates of calcium used as filler for mortar, concrete or artificial stone

e.g. TRIPOLI;

e.g. SHELLS, CORAL, MOTHER OF PEARLS,

e.g. CHALK,

e.g. ICELAND SPAR = pure crystalline calcite (CaCO3)

In patent documents, the following abbreviations are often used:

"ARDUIN" = blue stone

Chalk = "NEUBERGER KREIDE", "KIESELKREIDE

This place covers:

Oxides other than silica used as filler for mortar, concrete or artificial stone

e.g. simple oxides;

e.g. oxides used as pigments;

This place does not cover:

Ferrites | |

Oxides as active ingredients |

used as CIS codes for refractory filler in concrete

This place covers:

Alumina used as filler for mortar, concrete or artificial stone

e.g. Al(OH)3;

e.g. BAUXITE;

This place does not cover:

Gelatinous Al(OH)3 |

This place covers:

Iron oxide used as filler for mortar, concrete or artificial stone

e.g. CAPUT MORTUUM = ENGLISH RED = Fe2O3

This place covers:

Inorganic materials not classified in groups C04B 14/022, C04B 14/04 - C04B 14/34 used as filler for mortar, concrete or artificial stone

e.g. mineral salt (NaCl);

e.g. LITHOPONE = BaSO4 + ZnS (=pigment);

e.g. SPINEL = MgAl2O4

This place covers:

Soil used as filler for mortar, concrete or artificial stone

e.g. mud, sapronel, laterite

This place does not cover:

Harbour/river sludge |

In patent documents, the following abbreviations are often used:

mud, sapronel, = "Faulschlamm

This place does not cover:

Fibres in general |

This place does not cover:

Carbon nanotubes | |

Fabrication of carbon fibres |

This place does not cover:

- treating asbestos fibres see D06M 7/005, D02G 3/20;

- coating of asbestos in general see C03C 25/00;

- coating of asbestos CIS example C04B 20/10, C04B 14/40;

- disposal of asbestos see B09B 3/00;

- asbestos from old buildings CIS example ( C04B 14/40, C04B 18/16)

In this place, the following terms or expressions are used with the meaning indicated:

CHRYSOTILE (serpentine family) | 3MgO.2SiO2.2H2O |

CROCIDOLITE (amphibole family) | BLUE ASBESTOS3Na2O.6FeO.2Fe2O3.16SiO2.H2O |

AMOSITE (amphibole family) | 2Ca.5MgO.8SiO2.H2O |

TREMOLITE | amphibole family |

ANTHOPHYLLITE | (Mg,Fe)7Si8O22(OH)2 |

ASBESTINE | fibrous variety of talc +tremolite |

This place covers:

Glass fibers, glass whiskers used as filler for mortar, concrete or artificial stone

This place does not cover:

Composition of (alkali-resistant) glass fibres | |

Coating glass fibres used for cement reinforcement | |

Glass fibres for resin matrix |

This place does not cover:

Composition of alkali resistant glass fibres | |

Coating of glass fibres |

This place does not cover:

Take precedence | |

Ceramic fibres as such |

This place covers:

Oxides , hydroxides of rock wool used as filler for mortar, concrete or artificial stone

This place does not cover:

TiO2 |

This place covers:

Titanates, TiO2 of rock wool used as filler for mortar, concrete or artificial stone

This place does not cover:

Cellulosic fibres | |

Cellulosic waste materials, e.g. sawdust, rice husks |

This place covers:

Macromolecular organic compounds used as filler for mortar, concrete or artificial stone e.g. glass-clear thermoplastic MBS resin (methacrylate-butadiene-styrene) for packaging , medical applications

This place does not cover:

Cellulosic materials as fillers for mortars, concrete or artificial stone |

This place covers:

Fibrous organic macromolecular compounds used as filler for mortar, concrete or artificial stone

e.g. regenerated cellulose fibers;

e.g. textile waste,

In patent documents, the following abbreviations are often used:

textile waste="Textilschnitzel"

This place covers:

Fibrilles used as filler for mortar, concrete or artificial stone

e.g. polyalkanes;

e.g. stretched films,

e.g. "pulp" aramid fibers = very short , highly fibrillated with very fine fibrils or subfibers attached to core fibre

This place does not cover:

Fibrillated films in general |

In patent documents, the following abbreviations are often used:

stretched films= films "etirés"

This place covers:

Fibrilles of polyamaide, of polyaramides used as filler for mortar, concrete or artificial stone e.g. aromatic polyetheramide fibers;

e.g. ARAMID fibers = poly (p-phenylene terephtalamide)

e.g. NYLON = aliphatic polyamide

This place covers:

Porous organic macromolecular compounds used as filler for mortar, concrete or artificial stone

e.g. PS, EPS;

e.g. expanded PS

This place does not cover:

Working up macromolecular substances to porous or cellular articles or materials |

This place does not cover:

Takes precedence |

This place covers:

Organic materials used as fillers for mortar, concrete or artificial stone characterised by their shape

This place does not cover:

Fibrous macromolecular compounds | |

Porous macromolecular compounds | |

Only characterised by the form |

This place does not cover:

Use of waste materials for the manufacture of cement | |

Granulating materials in general | |

Making microcapsules or microballoons |

Attention is drawn to the following places, which may be of interest for search:

Temporary compacting of cement | |

Temporary compacting of gypsum | |

Conditioning silica fume |

In this place, the following terms or expressions are used with the meaning indicated:

Artificial aggregates, synthetic aggregates | Aggregates which are not "natural" in the way that crushed rocks or sands and gravels are. These are implied to be human-made materials, whether they are by-products of some other industry or even if they are deliberately manufactured. |

Attention is drawn to the following places, which may be of interest for search:

Lightweight agglomerated materials, e.g. artificial aggregates | |

Waste materials or refuse from building or ceramic industry |

For agglomerated materials (artificial aggregates or fillers) which are classified in C04B 18/021 or other equivalent subgroups of C04B 18/00, the starting materials, other than the binder, can be identified in the C-set with Indexing Symbols. Symbols are chosen from C04B 14/00, C04B 16/00, C04B 18/00 and less often from C04B 22/00 or C04B 24/00.

Attention is drawn to the following places, which may be of interest for search:

Lightweight agglomerated materials, e.g. artificial aggregates |

See the special rules under C04B 18/021.

This place covers:

Agglomerated materials wherein a melting or firing step takes place during the agglomeration.

Attention is drawn to the following places, which may be of interest for search:

Expanded clay | |

Porous fired material | |

Pelletizing fly ash | |

Expanding clay, perlite, vermiculite or like granular materials, which are (a) used as fillers for mortars, concrete or artificial stone, (b) specially adapted to enhance their filling properties in mortars, concrete or artificial stone, or (c) expanding or defibrillating materials | |

Porous or hollow ceramic granular material |

See the special rules under C04B 18/021.

A lightweight material (C04B 18/027) which is fired or melted (C04B 18/023) is classified as (C04B 18/027, C04B 18/023).

This place covers:

Grog used as fillers for mortars, concrete or artificial stone

e.g. crushed refactory materials added to ceramic mixes to reduce lamination in clays and shrinkage on drying,

e.g. crushed pottery, firekrick, quartz quartzite, burned ware, saggers;

e.g. CHAMOTTE, FIRED CLAY, FIRECLAY as filler for concrete

Before [9105] documents were classified in C04B 14/10 and received C04B 20/04 index code in the C-set

This place covers:

Agglomerated materials wherein a melting step takes place during the agglomeration

This place does not cover:

Glass, devitrified glass used as filler for mortar, concrete or artificial stone |

This place covers:

Low density or porous agglomerated material used as filler for mortar, concrete or artificial stone.

Attention is drawn to the following places, which may be of interest for search:

Expanded clay | |

Porous glass | |

Expanding clay, perlite, vermiculite or like granular materials, which are (a) used as fillers for mortars, concrete or artificial stone, (b) specially adapted to enhance their filling properties in mortars, concrete or artificial stone, or (c) used as expanding or defibrillating materials | |

Porous or hollow ceramic granular material for porous mortars, concrete, artificial stone or ceramic ware; Preparation thereof |

For crushed porous concrete aggregate, one set of symbols is used with C04B 18/027 or C04B 38/00 and an alternative classification in C04B 18/16.

A lightweight material (C04B 18/027) which is fired or melted (C04B 18/023) is classified as (C04B 18/027, C04B 18/023).

This place covers:

Waste materials or refuse, e.g. from industrial or other processes or Si-Stoff, or a waste from alumina production. This place also covers mixtures of wastes.

Attention is drawn to the following places, which may be of interest for search:

Waste added during the cement production, i.e. in the kiln raw materials | |

Waste glass | |

Making harmful chemical agents harmless | |

Destroying solid waste or transforming solid waste into something useful or harmless, e.g. disposal of asbestos | |

Solidification of sludges | |

Solidification of liquid or solid radioactive waste |

This place covers:

Waste from the purification of bauxite used as filler for mortar, concrete or artificial stone

Attention is drawn to the following places, which may be of interest for search:

treatment of waste from aluminium production |

In this place, the following terms or expressions are used with the meaning indicated:

Red mud, red sludge | solid waste product of the Bayer process, composed of a mixture of solid and metallic oxide-bearing impurities (high content of oxidised iron) |

This place covers:

Dry waste materials used as fillers for mortars, concrete or artificial stone,

Wet waste materials that is dried before use as fillers for mortars, concrete or artificial stone

This place does not cover:

Other slurries or sludges |

Attention is drawn to the following places, which may be of interest for search:

Soil | |

Waste materials in general |

This place covers:

Synthetic gypsum form waste material used as filler for mortars, concrete or artificial stone.

This place does not cover:

Gypsum from smoke purification |

In this place, the following terms or expressions are used with the meaning indicated:

Synthetic gypsum, flue-gas desulfurisation gypsum | byproduct of coal-fired power plants (coal burned with flue gas desulfurisation) |

In this place, the following terms or expressions are used with the meaning indicated:

Bleaching earth | (waste) bleaching earth is used as absorbent material for cleaning/bleaching of mineral, natural oils, fats and waxes. After the use it becomes "fat" bleaching earth. The fats/oils are removed as much as possible by boiling with soda and salt giving a low fat ("mager") bleaching earth |

This place covers:

Other specific industrial waste materials not provided in the other subgroups of C04B 18/00 used as fillers for mortars, concrete or artificial stone

e.g. PYRITE CINDER Fe2O3;

In patent documents, the following abbreviations are often used:

kiesabbraende

This place covers:

Combustion residues used as fillers for mortars, concrete or artificial stone, e.g. purification products of smoke, fumes or exhaust gases, bottom ash, coal ash or cinders.

Attention is drawn to the following places, which may be of interest for search:

Collecting residues from parts of furnace plants |

This place covers:

Ashes from fluidised bed furnaces used as fillers for mortars, concrete or artificial stone, e.g. AFBC ashes = atmospheric fluidised bed combustion ashes

fly ashes from fluidised bed furnaces take two alternative sets of codes one with C04B 18/061 and one with C04B 18/08

This place covers:

Residues from coal gasification used as fillers for mortars, concrete or artificial stone

e.g. residues from the partial oxidation of coal

This place covers:

Flue dust, fly ash; which is used as fillers for mortars, concrete or artificial stone.

Examples include:

- Class N fly ash;

- Class F fly ash;

- Class C fly ash;

Attention is drawn to the following places, which may be of interest for search:

Slaking of lime in the presence of fly ash |

In this place, the following terms or expressions are used with the meaning indicated:

Flue dust | by-product of the burning of pulverised coal |

In patent documents, the following abbreviations are often used:

PFA | Pulverised Fuel Ash |

EFA | Electrofilter Ash |

HVFA | High Volume Fly Ash |

Class F Fly Ash | pozzolanic, usually from bituminous coal, low Ca, glass part is reactive with cement |

Class C Fly Ash | pozzolanic and cementitious, normally from lignite or sub-bituminous coal |

This place covers:

Flue dust from brown coal or lignite used as filler for mortars, concrete or artificial stone,

In patent documents, the following abbreviations are often used:

Lignite fly ash = Braunkohlefilterasche"

This place covers:

Cenospheres used as fillers for mortars, concrete or artificial stone,

e.g. = floating fraction of PFA = hollow spheres (20-200micron) of aluminosilicate glass;

e.g. ARMOSPHERES, FILLITE, EXTENDOSPHERES

This place covers:

Pelletizing fuel dust used as filler for mortars, concrete or artificial stone,

Melting fuel dust to form aggregate;

e.g. sintered PFA

Attention is drawn to the following places, which may be of interest for search:

For LYTAG | |

Agglomerated fired materials | |

Expanding clay, vermiculite, perlite and the like |

This place covers:

Burned or pyrolised refuse used as filler for mortars, concrete or artificial stone, e.g. municipal solid waste, slags from waste incineration or burned paper processing waste.

Attention is drawn to the following places, which may be of interest for search:

In patent documents, the following abbreviations are often used:

MSW | Municipal solid waste |

This place covers:

Burned rice husks or other burned vegetable material used as filler for mortars, concrete or artificial stone

e.g. expanded rice hull ash, reburned rice hull ash

This place covers:

Burned or pyrolised sludges used as filler for mortars, concrete or artificial stone,

e.g. SSA = SEWAGE SLUDGE ASH / SLAG

This place covers:

Gaseous combustion products or dusts collected from waste incineration used as filler for mortars, concrete or artificial stone,

e.g. AQCS =Air quality combustion system = fly ash + desulfurisation products

This place covers:

Waste materials form quarries, mining or the like used as filler for mortars, concrete or artificial stone.

In patent documents, the following abbreviations are often used:

Tailings = BERGE", "BERGEMATERIAL", "GRUBENBERGE", "WASCHBERGE

This place covers:

Waste materials from metallurgical processes used as filler for mortars, concrete or artificial stone, such as nephelin slurry from Al production.

This place does not cover:

Treatment of molten slag |

Attention is drawn to the following places, which may be of interest for search:

Cements containing slag |

This place covers:

Slags from metallurgical processes used as filler for mortars, concrete or artificial stone, e.g. blast furnace slag;

e.g. cupola slag, "

In patent documents, the following abbreviations are often used:

cupola slag = KUPOLOFENSCHLACKE

This place covers:

Filter dust from silicon metal or ferrosilicon alloy production;

(non-thixotropic)

Attention is drawn to the following places, which may be of interest for search:

Thixotropic silica fume e.g. CAR-BO-SIL |

In patent documents, the following words/expressions are often used as synonyms:

- "MICROSILICA", "ferrosilicon dust", "silica flue dust" and "amorphous silica"

This place covers:

Waste materials from metallurgical processes other than silica fume or slag used as filler for mortars, concrete or artificial stone,

e.g. EAFD, electric arc furnace dust

This place covers:

Waste materials or refuse from building or ceramic industry used as filler for mortars, concrete or artificial stone, e.g. reclaiming cement slurry or broken ceramic tiles.

Attention is drawn to the following places, which may be of interest for search:

Materials agglomerated by a mineral binder | |

Lightweight materials | |

Separating of concrete slurry as refuse |

Foamed concrete as aggregate: two C-Sets are given, one with C04B 18/16 and one with C04B 18/027.

This place covers:

Cement kiln dust or lime kiln dust used as filler for mortars, concrete or artificial stone.

Dust resulting from cement production.

Attention is drawn to the following places, which may be of interest for search:

Recuperation of cement kiln dust during cement fabrication |

This place covers:

Organic waste materials used as filler for mortars, concrete or artificial stone, such as hair, feathers, leather, manure, mest or wool fibers.

This place does not cover:

Burned or pyrolised refuse |

Attention is drawn to the following places, which may be of interest for search:

Recycled expanded polystyrene | |

Recovery from working up of polymers |

This place covers:

Vegetable refuse, cellulosic materials used as fillers for mortar, concrete or artificial stone

e.g. CORK, SISAL, PEAT, KAPOK;

e.g. VEGETABLE IVORY = CORAJO = TAGUA;

e.g. COMPOST;

e.g. expanded cellulosic material i.e. puffed rice, popcorn is classified in this group and received the C-set containing C04B 20/06

This place does not cover:

Regenerated cellulose fibers | C04B 16/06 ( C04B 18/24 still to be cleaned) |

Processing, machining of boards fabricated from pressed wood fibers | |

"Spaanplaten" |

This place covers:

Paper products used as fillers for mortar, concrete or artificial stone,

e.g. pulp from bark;

e.g. waste paper

Attention is drawn to the following places, which may be of interest for search:

Still contains older documents | |

Wood pulp |

This place does not cover:

Burned paper processing waste |

Attention is drawn to the following places, which may be of interest for search:

Waste paper itself |

This place covers:

Cork, bark used as filler for mortars, concrete or artificial stone.

Attention is drawn to the following places, which may be of interest for search:

Mechanical working of cork |

Wood and bark are not synonymous, wood used as filler being classified in C04B 18/26.

Attention is drawn to the following places, which may be of interest for search:

Vegetable refuse, e.g. rice husks, maize-ear refuse, peat or algae; Cellulosic materials, e.g. paper or cork |

This place covers:

Wood used as fillers for mortars, concrete or artificial stone,

e.g. BAMBOO;

e.g. ARBOLITE = wood chips/waste cement boards;

e.g. FIBROLITE = wood wool cement boards

This place covers:

Mineralising vegetable refuse, compositions therefor used as filler for mortars, concrete or artificial stone

Attention is drawn to the following places, which may be of interest for search:

With organic materials | C04B 20/1018, older documents still present in C04B 18/28. |

In this place, the following terms or expressions are used with the meaning indicated:

Mineralising | Treatment with a mineral substance |

This place does not cover:

Takes precedence |

Attention is drawn to the following places, which may be of interest for search:

Nanotechnology for materials or surface science | |

Manufacture or treatment of nanostructures | |

Reinforcing elements for concrete |

Attention is drawn to the following places, which may be of interest for search:

Lightweight agglomerated material | |

Hollow or porous ceramic granular material |

This place covers:

Mixtures of different fibres. Fibrous materials wherein the fibre type is important but not a singular type.

In this place, the following terms or expressions are used with the meaning indicated:

fibre | relatively short, elongated member of natural or artificial material |

filament | endless or quasi-endless, elongated member of natural or man-made material |

yarn | unitary assembly of fibres or filaments, usually produced by spinning |

thread | assembly of yarns or filaments usually produced by twisting |

This place covers:

Mixtures of fibres of different physical characteristics used as materials for mortars, concrete or artificial stone, e.g. obtained by twisting.

This place covers:

Materials used as fillers for mortars, concrete or artificial stone according to more than one of groups C04B 14/00 - C04B 18/00 and characterised by the grain distribution.

In this place, the following terms or expressions are used with the meaning indicated:

fine aggregate | material less than 5 mm |

coarse aggregate | material at or more than 5 mm |

concrete | material with more than 50% coarse aggregate |

granules 0-3 | material less than or equal to 3mm |

mortar | material with no coarse aggregate |

This place covers:

Treatment specially adapted to enhance filling properties of materials used as fillers for mortars, concrete or artificial stone according to more than one of the groups C04B 14/00 - C04B 18/00, e.g. removing dust from particles or forming circular particles from scrap glass.

Attention is drawn to the following places, which may be of interest for search:

Cation exchange of vermiculite | |

Temporarily agglomerated materials |

This place covers:

Heat treatment of materials according to more than one of the groups C04B 14/00 - C04B 18/00 specially adapted to enhance their filling properties in mortars, concrete or artificial stone, e.g. drying.

This place covers: