CPC Definition - Subclass C23C

This place covers:

Hot-dipping or immersion processes and apparatus for applying the coating material in the molten state without affecting the shape.

Coating by spraying, casting, by vacuum evaporation, by sputtering or by ion implantation and the different aspects of chemical coating which includes

Chemical coating by decomposition of either gaseous compounds, liquid or solid compounds, solutions or suspensions of the coating forming compounds, without leaving reaction products of surface material in the coating.

Coating starting from inorganic powder.

Coating with metallic material characterized only by the composition of the metallic material.

Chemical surface treatment of metallic materials, leaving reaction products of surface material in the coating.

All coatings referred to in this subclass are either "for metallic materials" or "by metallic material," with the exception of PVD (by vacuum evaporation, by sputtering or by ion implantation), and CVD (an aspect included in "the different aspects of chemical coating").

Solid state diffusion into metallic material surfaces.

Applying liquids or other fluent materials to surfaces in general are classified in B05; while C23C includes the coating of metallic material and the coating material with metallic material.

Making metal-coated products by extrusion is classified in B21C 23/22 while C23C includes surface treatment of metallic material by diffusion into the surface.

Metallizing of glass is classified in C03C and Metallizing mortars, concrete, artificial stone, ceramics or natural stone is classified in C04B 41/00.

Coating with paints, varnishes, lacquers is classified in C09D.

Covering with metal by connecting pre-existing layers to articles, see the relevant places, e.g. B21D 39/00, B23K.

Processes for the electrolytic or electrophoretic production of coatings are classified in C25D.

Processes for the electrolytic removal of materials from objects are classified in C25F.

Enameling of or applying a vitreous layer to, metals is classified in C23D.

Inhibiting corrosion of metallic material or incrustation in general is classified in C23F.

Cleaning or de-greasing of metallic material by chemical methods other than electrolysis, e.g. cleaning, pickling are classified in C23G

This place does not cover:

Making metal-coated products by extrusion | |

Covering with metal by connecting pre-existing layers to articles | |

Metallizing of glass | |

Metallizing mortars, concrete, artificial stone, ceramics or natural stone | |

Enameling of, or applying a vitreous layer to, metals | |

Treating metal surfaces or coating of metals by electrolysis or electrophoresis | |

Single-crystal film growth | |

Metallizing textiles | |

Decorating textiles by locally metallizing |

Attention is drawn to the following places, which may be of interest for search:

Applying liquids or other fluent materials to surfaces in general | |

Casting for building up linings or coverings | |

Casting by dipping | |

Working of metal by the action of a high concentration of electric current on a work piece using an electrode | |

Coating of shapes articles of macromolecular compounds | |

Paints, varnishes, lacquers | |

Inhibiting corrosion of metallic material or incrustation in general | |

Processes for the electrolytic removal of materials from objects | |

Details of scanning-probe apparatus, in general | |

Manufacture of printed circuits | |

Manufacture of semiconductor devices |

In this subclass, an operation is considered as pretreatment or after-treatment when it is specially adapted for, but quite distinct from, the coating process concerned and constitutes an independent operation. If an operation results in the formation of a permanent sub-layer or upper layer, it is considered as pre-treatment or after-treatment only if it has a direct impact on the layer above or below respectively.

In this place, the following terms or expressions are used with the meaning indicated:

Metallic Material | covers: Metals; Alloys which are metallic composite materials containing a substantial proportion of fibers or other somewhat larger particles; ceramic compositions containing free metal bonded to carbides, diamond, oxides, borides, nitrides or silicides, e.g. cermets, or other metal compounds, e.g. oxynitrides or sulfides, other than as macroscopic reinforcing agents. |

This place covers:

Metallic coatings obtained by dipping or immersing a substrate into a molten bath of the coating material, where the substrate itself remains essentially unchanged, as well as any methods and/or apparatuses specifically used thereof.

Enameling of, or applying a vitreous layer to metals is classified in C23D 5/00.

Formation of mono or polycrystalline Si coatings by pulling high temperature resistant wires and/or sheets through molten silicon is classified in C30B 29/06.

Single-crystal growth by pulling from a melt, pulling on a substrate C30B 15/007.

Production of homogeneous polycrystalline material with defined structure, from liquids, by pulling from a melt C30B 28/10.

Attention is drawn to the following places, which may be of interest for search:

Casting molten material on the substrate | |

Control devices or methods specially adapted for metal-rolling mills | |

Manufacture of coated wire or rods | |

Of tubes or metal hoses; Combined procedures for making tubes, e.g. for making multi-wall tubes | |

Using rods or strips of soldering material | |

Of coated strip material | |

Layered products essentially comprising metal | |

Controlling or regulating thickness in general |

Classification is given to well disclosed coatings and/or processes. Classification is further given to related processes, such as pre-treatment(s) of the substrate or after-treatment(s) of the coating. Classification is also further given to apparatus features important to the coating process.

In this main group, an operation is considered as pre-treatment or after-treatment when it is specially adapted for, but quite distinct from, the coating process concerned and constitutes an independent operation.

All well-disclosed, non-trivial examples of processes and/or coatings are classified. Precedence rules indicated in the headers of the subgroups are to be strictly followed, e.g. removal by air knives of an excess of molten material on a strip is to be classified only in C23C 2/20, and not also in C23C 2/26 and C23C 2/40.

Alloys based on a given metal are alloys where said metal makes up at least 50% by weight of said alloy (see in particular C23C 2/06, C23C 2/08, C23C 2/10 and C23C 2/12).

Magnetic energy being applied to the system is classified based upon the intended effect of the magnetic energy on the system.

C23C 2/00362 covers the use of magnetic energy to effect sealing or otherwise containing the molten material within the container at an opening in the wall which the substrate travels.

C23C 2/24 covers the use of magnetic or electric fields energy to remove excess molten coating or to otherwise control the thickness of the coating applied to the substrate after the substrate exits the coating bath.

C23C 2/32 covers the use of magnetic energy to cause vibrations of the liquid metal in the bath for stirring purposes etc. or the substrate while in the molten bath.

C23C 2/5245 covers the use of magnetic energy to reduce vibrations of the substrate travelling through the bath.

In this place, the following terms or expressions are used with the meaning indicated:

Metallic material | Metals and metals alloys, also including inorganic materials such as oxides, carbides, nitrides, borides, silicides and their mixtures |

This place covers:

Elements that are immersed within the bath, such as walls, baffles, pumps, elements supporting the substrate during coating or elements for moving the substrate through the bath. Non-moving immersed elements are classified here.

This place covers:

Elements that are immersed within the bath which are in motion relative to the bath, such as pumps (i.e. the internal impeller moves relative to the bath), mixers, impellers, rollers or bearings.

Devices for mixing or stirring of the bath with control or regulation should also be classified in C23C 2/54, C23C 2/542 or C23C 2/544 as appropriate.

This place covers:

Elements that are immersed within the bath and act to force movement of the substrate through the bath, such as rollers or portions thereof, e.g. bearings.

This place covers:

Elements that act upon the substrate to be coated to move the substrate through the bath, such as take-up rollers or supply rollers.

This place does not cover:

Rollers immersed within the bath |

This place covers:

Crucibles and heating devices. This area also covers the vessel for a holding bath.

In this place, the following terms or expressions are used with the meaning indicated:

Wall | Any portion of the receptacle which confines the bath is located below the upper surface of the bath and may include a side wall as well as a floor of the receptacle which the substrate passes through |

This place covers:

Pre-treatment chamber(s), and elements thereof, that are directly associated with the hot-dipping or immersion apparatus, such as specific structure of pretreatment chamber(s), chamber mechanisms, transportation mechanism, seals, or heat or atmospheric conditions.

In this place, the following terms or expressions are used with the meaning indicated:

Locally | The same physical location, e.g. plant, so as to exclude pre-treatment chamber(s) which treat a substrate which then require shipping the pre-treated substrate from one location to another |

This place covers:

Fixed enclosures between the furnace and the molten metal bath.

This place covers:

Processes or devices for conducting patterned or selective deposition on the substrate.

This place covers:

Methods or devices for forming patterned or selective deposition by means external to the substrate, e.g. using masking elements such as casings, shields, fixtures or blocking elements.

This place covers:

Pattern or selective deposition done by means of applying a masking layer to the substrate.

This place covers:

Pre-treatment of the material to be coated, an operation being considered as pre-treatment when it is specially adapted for, but quite distinct from, the coating process concerned and constitutes an independent operation.

For example:

- Cleaning or etching treatments

- Physical treatments such as roughening, grinding or polishing

- Deposition of sublayers, i.e. adhesion layers, masking layers

This place does not cover:

Fluxes or coverings on molten baths |

Attention is drawn to the following places, which may be of interest for search:

This place covers:

Application of complete or partial layers onto the substrate to be coated prior to entry into the bath. Examples of these layers are adhesion layers that promote adhesion between the substrate and the bath material, pre-applied alloying elements that mix with the bath material in the coating, and layers that protect the substrate from corrosion prior to entry into the bath.

Masking layers for forming patterned or selective deposition are not considered sub-layers and are classified in C23C 2/0064.

Attention is drawn to the following places, which may be of interest for search:

Apparatus for spreading or distributing liquids or other fluent materials already applied to a surface with a blast of gas or vapour | |

Machines or apparatus for drying objects with progressive movement |

This place covers:

Fluxes or covering materials for molten baths, e.g. fluxes materials used in hot dipping process

This place does not cover:

Removing excess of molten coatings from elongated material by rubbing |

In this place, the following terms or expressions are used with the meaning indicated:

Covering | A chemical compound and/or composition, usually immiscible with the melt and having a lower density, i.e. not a physical object. |

This place covers:

Application of vibrations using physical, magnetic or other means to the bath or to the substrate. An example of subject matter covered by this group is the use of ultrasonic energy to a substrate to cause vibrations of the substrate to enhance wettability of the substrate.

Application of vibratory energy to remove excess coating material is classified in C23C 2/14.

This place covers:

Processes for cleaning of the bath and the devices that perform the cleaning.

"Cleaning" is intended to cover removal, by chemical or physical means, of impurities within the bath, such as devices which skim material from the surface of the bath or which remove a portion of the bath for treatment to remove impurities before returning the treated portion to the bath.

This place covers:

Control or regulation of the coating process, wherein the control or regulation is performed responsive by a computer.

Examples include standard PID controllers, "fuzzy" logic controllers and artificial intelligence or machine-learning implemented control of the coating process.

This subgroup should be used in combination with any appropriate subgroups that are also indented under C23C 2/50.

This place covers:

Control or regulation of the coating process wherein at least one variable is measured or sensed.

"Measured or sensed" includes both electronic and mechanical detection of variables, as well as "measuring or sensing" by an operator of the coating process, such as visual inspection of the variable of the coating process.

This place covers:

Measuring or sensing the position of the substrate, which includes at least the location of the substrate with respect to fixed portions of the coating apparatus and any change in the location of the substrate over time, e.g. vibration of the substrate.

This place covers:

Using image processing techniques to investigate the surface quality of the substrate.

This place covers:

Methods or devices for controlling or regulating the mixing or stirring of the bath.

Devices for mixing or stirring of the bath without control or regulation are classified in C23C 2/003 or in C23C 2/00342 as appropriate.

This place covers:

Coating processes in which melted or partially melted materials are sprayed, i.e. propelled, onto a surface, as well as apparatuses specifically used thereof.

The material to be deposited is typically fed into the spray gun in powder, wire or rod form where it is rapidly heated and melted or partially melted by electrical (plasma or arc) or chemical means (combustion flame, detonation), before being accelerated towards the substrate to be coated.

The obtained coatings are characterized by a lamellar grain structure resulting from the rapid solidification of small globules, flattened from striking a cold surface at high velocities.

Protective layers or coatings deposited by spraying for specific articles is classified in this group and also classified in the appropriate places for said specific articles, e.g. F01D 5/288 for protective coatings for turbine blades; F28F 19/02, F28F 19/06 for protective coatings for heat exchangers; A61L 27/28 for coating materials for prostheses; B22C 3/00 for coating compositions for surfaces of moulds, cores or patterns.

Attention is drawn to the following places, which may be of interest for search:

Coating by simply casting molten material on the substrate | |

Spraying of powders in which no significant melting occurs before reaching the substrate | |

Coating materials for prostheses | |

Apparatus for spraying by means of detonations in general | |

Apparatus for spraying by means of flame in general | |

Apparatus for spraying by means of electric arc in general | |

Control of spray area by means of masking elements | |

Coating compositions for surfaces of moulds, cores or patterns | |

Making alloys containing fibres or filaments by thermal spraying of metal | |

Enamelling of, or applying a vitreous layer to, metals | |

Protective coatings for turbine blades | |

Protective coatings for heat exchangers | |

Plasma torches in general |

Classes are given to well disclosed coatings and/or methods. Classes are further given to related methods, such as pre-treatment(s) of the substrate or after-treatment(s) of the coating. Classes are also further given to apparatus features important to the coating method.

In this main group, an operation is considered as pre-treatment or after-treatment when it is specially adapted for, but quite distinct from, the coating process concerned and constitutes an independent operation.

All well-disclosed, non-trivial examples of methods and/or coatings are classified.

Precedence rules indicated in the headers of the subgroups are to be strictly followed.

In this place, the following terms or expressions are used with the meaning indicated:

Metallic material | Metals and metals alloys, also including inorganic materials such as oxides, carbides, nitrides, borides, silicides and their mixtures |

In patent documents, the following abbreviations are often used:

APS | Air plasma spraying |

HVOF | High velocity oxygen fuel |

HPPS | High pressure plasma spraying |

IGPS | Inert gas plasma spraying |

IPS | Inductive plasma spraying |

LPPS | Low pressure plasma spraying |

VPS | Vacuum plasma spraying |

This place covers:

Masking elements such as casings, shields, fixtures or blocking elements.

Stripping foreign matter from cavities by means of gas or water jets.

This place covers:

Pre-treatment of the material to be coated, an operation being considered as pre-treatment when it is specially adapted for, but quite distinct from, the coating process concerned and constitutes an independent operation.

For example:

- Cleaning or etching treatments

- Physical treatments such as roughening, grinding or polishing

- Deposition of sublayers, i.e. adhesion layers, masking layers

Attention is drawn to the following places, which may be of interest for search:

Only methods which are specially adapted for, but quite distinct from the main spraying coating process, and which result in sublayers having a direct impact on the main coating layer either above (e.g. adhesion) or below (e.g. masking) should be classified in this group.

Sprayed bond coats for thermal barrier coatings (TBC) are only to be classified if the TBC is also sprayed and the bond coat is well-defined and/or exhibiting unusual characteristics.

This place covers:

Spraying the coating material characterised by the coating composition that is not covered by the subgroups

This place covers:

Metals and metal alloys compositions mixed with inorganic hard particles such as oxides, borides, carbides, nitrides and/or silicides.

This place does not cover:

MCrAl(Y) alloys where M is nickel, cobalt or iron as coating material with or without non-metal elements, e.g. silicon. | |

Pure metals or metal alloys as coating material | |

Pure oxides, borides, carbides, nitrides, silicides or their mixtures as coating material | |

Pure oxide compositions as coating material |

This place covers:

MCrAl or MCrAlY alloys, also when further elements are present in said alloys, e.g. Si, ..., and/or hard particles.

This place covers:

Pure metals or metal alloys compositions.

This place does not cover:

MCrAl(Y) alloys where M is nickel, cobalt or iron as coating material with or without non-metal elements, e.g. silicon. |

This place covers:

Compositions including mixtures of any two or more of oxides, borides, carbides, nitrides and/or silicides, or pure borides, carbides, nitrides or silicides compositions.

This place does not cover:

Pure oxides compositions as coating material |

This place covers:

Pure oxides compositions

In patent documents, the following abbreviations are often used:

PSZ | Partially Stabilized Zirconia |

PLZT | Lead Lanthanum Zirconate Titanate |

PZT | Lead Zirconate Titanate |

YSZ | Yttria Stabilized Zirconia |

This place covers:

Coating processes characterised by the method of spraying being not covered by the subgroups.

All specific and well-defined methods and/or apparatuses should be classified in the relevant subgroups, C23C 4/123 - C23C 4/137.

This place covers:

Processes and apparatuses in which the material to be deposited is melted in a furnace, then the molten material is slowly poured through a conical tundish into a small-bore ceramic nozzle. The molten material exits the furnace as a thin free-falling stream and is broken up into droplets by an annular array of gas jets, and these droplets then proceed downwards, accelerated by the gas jets to impact onto a substrate.

This place does not cover:

Dipping in a molten bath | |

Casting molten material on a substrate | |

Continuous casting of metals |

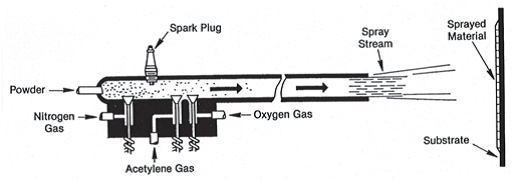

This place covers:

Processes and apparatuses where oxygen and fuel is fed into a barrel along with a charge of powder of the material to be deposited. A spark is used to ignite the gas mixture and the resulting detonation heats and accelerates the powder to supersonic velocity down the barrel, to deposit on the substrate.

Schematic diagram of a detonation process:

Attention is drawn to the following places, which may be of interest for search:

Apparatus for spraying by means of detonations in general |

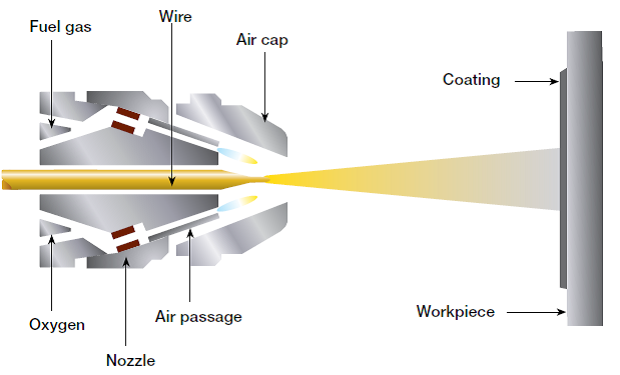

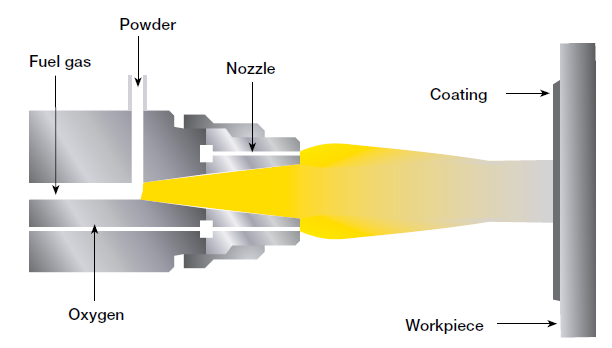

This place covers:

Processes and apparatuses in which the spray material, in form of a powder or a wire, is fed continually into a fuel gas-oxygen flame where it is typically melted by the heat of combustion. A powder feed carrier gas transports the powder particles into the combustion flame, and the mixed gases transport the material towards the prepared workpiece surface.

Schematic diagram of a wire flame process:

© Sulzer Metco

Schematic diagram of a powder flame process:

© Sulzer Metco

Attention is drawn to the following places, which may be of interest for search:

Apparatus for spraying by means of flame in general |

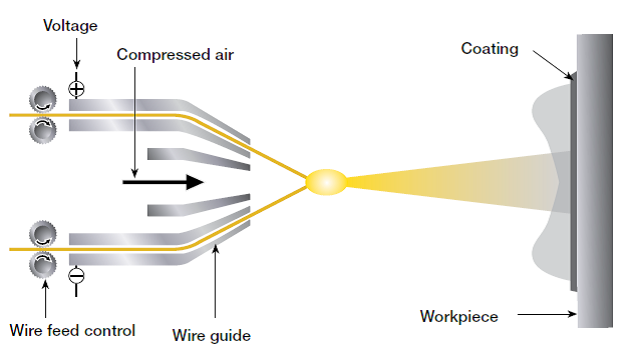

This place covers:

Processes and apparatuses using two metallic wires, usually of the same composition, as the coating feedstock. The two wires are electrically charged with opposing polarity and are fed into the arc gun at matched, controlled speeds. When the wires are brought together at the contact point, the opposing charges on the wires create enough heat to continuously melt the tips of the wires. Compressed air is used to atomize the now molten material and accelerate it onto the workpiece surface to form the coating.

Schematic diagram of a wire arc process:

© Sulzer Metco

Attention is drawn to the following places, which may be of interest for search:

Apparatus for spraying by means of electric arc |

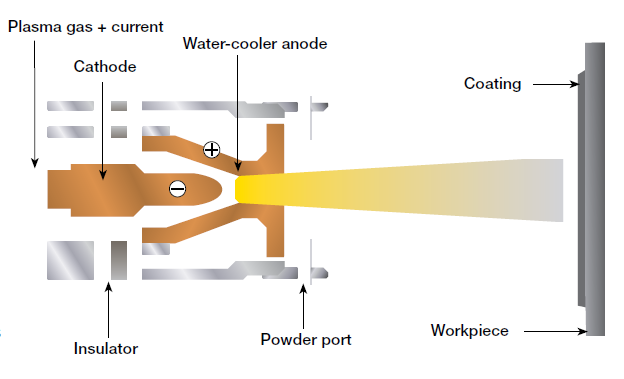

This place covers:

Processes and apparatuses where an electric arc is generated between an anode and a cathode. This ionizes the flowing process gases into the plasma state. Powdered feedstock material is injected into the plasma jet, melting the powder particles and propelling them to the surface of the workpiece.

Schematic diagram of a plasma spray process:

© Sulzer Metco

This place covers:

Coating by spraying in vacuum or in an inert gas chamber the coating material in the molten state, for example:

Spraying at below atmospheric pressure

Spraying using inert gas shrouds or in enclosures filled with inert gas

In patent documents, the following abbreviations are often used:

IGPS | Inert Gas Plasma Spraying |

IPS | Inductive Plasma Spraying |

LPPS | Low Pressure Plasma Spraying |

VPS | Vacuum Plasma Spraying |

This place covers:

Processes and apparatuses involving pouring molten, i.e. liquid, material onto a substrate to form a coating.

This place does not cover:

Dipping in a molten metal bath | |

Spraying molten metals | |

Casting molten macromolecular compounds, i.e. polymers, on a substrate | |

Enamelling of, or applying a vitreous layer to, metals |

Attention is drawn to the following places, which may be of interest for search:

Continuous casting of metals |

In this place, the following terms or expressions are used with the meaning indicated:

Material | Metals and metals alloys, also including inorganic materials such as oxides, carbides, nitrides, borides, silicides and their mixtures |

This place covers:

The diffusion of non-metal elements such as carbon, oxygen, nitrogen, but also boron, phosphor, sulfur, selenium or tellurium into a metal or metal alloy surface by contact with either a reactive gas (e.g. oxygen, hydrocarbons, nitrogen), a liquid (e.g. salt melts) or a solid (e.g. powders, pastes).

Coatings obtained by oxidising, carburising, nitriding, carbo-nitriding and/or boronising a metal or metal alloy surface.

This place does not cover:

Diffusion of only metal elements or silicon into a metallic surface | |

Diffusion of at least one non-metal element other than silicon and at least one metal element or silicon into metallic material surfaces | |

Coating by evaporation, by sputtering or by ion implantation of the coating forming material | |

Reactive after treatment of PVD coatings with sulfur, selenium and/or tellurium | |

Electroless plating | |

Conversion or passivation coatings obtained by reaction of the metallic surface with a reactive liquid, e.g. chromate, phosphate and/or silicate conversion coatings | |

Conversion coatings obtained by electrolytic surface reaction, e.g. anodisation, phosphatising, chromatising | |

Process or apparatus specially adapted for the manufacture or treatment of semiconductors devices, e.g. doping of semiconductors |

Attention is drawn to the following places, which may be of interest for search:

General methods or devices for heat treatment of ferrous or non-ferrous metals or alloys |

Classes are given to well disclosed coatings and/or methods. Classes are further given to related methods, such as pre-treatment(s) of the substrate or after-treatment(s) of the coating.

An operation is considered as pre-treatment or after-treatment when it is specially adapted for, but quite distinct from, the coating process concerned and constitutes an independent operation.

All well-disclosed, non-trivial examples of methods and/or coating are classified.

Precedence rules indicated in the headers of the subgroups are to be strictly followed.

In this place, the following terms or expressions are used with the meaning indicated:

Ferrous surfaces | Surfaces containing a majority of iron per weight, such as but not limited to steel and cast iron |

This place covers:

Cleaning or etching treatments

Physical treatments such as roughening, grinding or polishing

Deposition of sublayers, i.e. adhesion layers, masking layers

This place covers:

Masking elements such as casings, shields, fixtures or blocking elements, as well as masking layers or tapes.

Treatments on selected surface areas also not involving masking elements.

This place covers:

Treatment of the metallic surface with ionised gases, leaving reaction products of surface material in the coating, e.g. ionnitriding..

Attention is drawn to the following places, which may be of interest for search:

Coating by evaporation, sputtering or ion implantation | |

Chemical vapour deposition | |

Discharge tubes with provision for introducing objects or material to be exposed to the discharge |

This place covers:

The diffusion of metal elements or silicon into a metal or metal alloy surface by contact with either a reactive gas, a liquid (e.g. salt or metal melts) or a solid (e.g. powders, pastes).

This place does not cover:

Diffusion of non-metal elements other than silicon into a metal or metal alloy surface | |

Diffusion of at least one non-metal element other than silicon and at least one metal element or silicon into metallic material surfaces | |

Coating by evaporation, by sputtering or by ion implantation of the coating forming material | |

Electroless plating | |

Conversion or passivation coatings obtained by reaction of the metallic surface with a reactive liquid, e.g. chromate, and/or silicate conversion coatings | |

Conversion coatings obtained by electrolytic surface reaction, e.g. anodisation, chromatising | |

Process or apparatus specially adapted for the manufacture or treatment of semiconductors devices, e.g. doping of semiconductors |

Attention is drawn to the following places, which may be of interest for search:

General methods or devices for heat treatment of ferrous or non-ferrous metals or alloys |

Classes are given to well disclosed coatings and/or methods. Classes are further given to related methods, such as pre-treatment(s) of the substrate or after-treatment(s) of the coating.

An operation is considered as pre-treatment or after-treatment when it is specially adapted for, but quite distinct from, the coating process concerned and constitutes an independent operation.

All well-disclosed, non-trivial examples of methods and/or coatings are classified.

Precedence rules indicated in the headers of the subgroups are to be strictly followed.

In this place, the following terms or expressions are used with the meaning indicated:

Ferrous surfaces | Surfaces containing a majority of iron per weight, such as but not limited to steel and cast iron |

This place covers:

Pretreatments of the material to be coated, an operation being considered as pre-treatment when it is specially adapted for, but quite distinct from, the coating process concerned and constitutes an independent operation.

For example:

- Cleaning or etching treatments

- Physical treatments such as roughening, grinding or polishing

- Deposition of sublayers, i.e. adhesion layers, masking layers

This place covers:

Masking elements such as casings, shields, fixtures or blocking elements, as well as masking layers or tapes.

Treatments on selected surface areas also not involving masking elements.

This place covers:

The diffusion of at least one non-metal elements other than silicon and at least one metal element or silicon into a metal or metal alloy surface by contact with either a reactive gas, a liquid (e.g. salt or metal melts) or a solid (e.g. powders, pastes).

This place does not cover:

Diffusion of only non-metal elements other than silicon into a metallic surface | |

Diffusion of only metal elements or silicon into a metallic surface | |

Coating by evaporation, by sputtering or by ion implantation of the coating forming material | |

Electroless plating | |

Conversion or passivation coatings obtained by reaction of the metallic surface with a reactive liquid, e.g. chromate, and/or silicate conversion coatings | |

Conversion coatings obtained by electrolytic surface reaction, e.g. anodisation, chromatising | |

Process or apparatus specially adapted for the manufacture or treatment of semiconductors devices, e.g. doping of semiconductors |

Attention is drawn to the following places, which may be of interest for search:

General methods or devices for heat treatment of ferrous or non-ferrous metals or alloys |

This place covers:

- Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material, e.g. physical vapor deposition (PVD), reactive sputtering.

- Coating material

- Coating processes

- Pre-treatment of the substrate or after-treatment of the coating

- Apparatus features important to the coating method, e.g. crucibles for the source material in PVD

Attention is drawn to the following places, which may be of interest for search:

Multilayers | |

Deposition of organic layers | |

Cleaning | |

Carbon (fullerenes) | |

Surface treatment of glass | |

After-treatment of ceramics | |

Organometallic compounds | |

Epitaxial layers | |

Plasma apparatuses | |

Semiconductors |

General considerations.

CPC groups are given only as Invention symbols to well disclosed PVD (physical vapor deposition) coating methods.

CPC groups are further given only as Invention symbols to related methods, such as pre-treatment of the substrate or after-treatment of the coating.

CPC groups are further given only as Invention symbols to apparatus features important to the coating method, such as crucibles for the source material in PVD.

Trivial references to well-known PVD processes are not classified. As an example, "...the SiO2 layer was deposited by sputtering..." may be mentioned

In this subclass, an operation is considered as pre-treatment or after-treatment when it is specially adapted for, but quite distinct from, the coating process concerned and constitutes an independent operation.

If an operation results in the formation of a permanent sub-layer or upper layer, it is considered as pre-treatment or after- treatment only if it has a direct impact on the layer above or below respectively.

During classification in C23C 14/00 it is common that a document is vague about some of the subject-matter relating to PVD, making the classifier doubt if the document should be classified or not. The classifier should in these cases be guided by his/her own best judgement and the possible importance of the well disclosed subject-matter.

Specific considerations related to specific parts of the classification scheme:

Most of the groups in C23C 14/00 are self-explanatory. Below some explanation of non obvious aspects.

C23C 14/0021-C23C 14/0031: Material in the gas phase is achieved by evaporation, laser ablation etc and reacted with another gas before or during the coating of the substrate. After-treatment with reactive gas in any form is classified in C23C 14/5846-C23C 14/5866.

C23C 14/0036-C23C 14/0084: Material in the gas phase is achieved by sputtering and reacted with another gas before or during the coating of the substrate. After-treatment with reactive gas in any form is classified in C23C 14/5846-C23C 14/5866. Note that the sequential processes in C23C 14/0073 and C23C 14/0078 are not considered as after-treatments.

C23C 14/024-C23C 14/027: The sub-layers are classified only if they have a direct relation to the PVD coating above. Examples are improvement of the adhesion or influence on the structure or properties of the PVD coating above.

C23C 14/04-C23C 14/048: Deliberate action to avoid coating of some areas of the substrate. Merely coating of the front side of a substrate directed towards a source of coating material and not coating the side that the substrate rests on is not classified.

C23C 14/08-C23C 14/088: The alkaline earth, refractory and iron group metals are defined in IPC section C on one of the first pages. Mixed oxides from different groups are classified in C23C 14/08. Mixed oxides from one group is classified in that group. For example Al-Mg-O is classified in C23C 14/081 but Ti-Al-O is classified in C23C 14/08.

C23C 14/10: Note that these materials are usually based on Si-O, but other types of glass should also be classified here.

C23C 14/22: Here, coating processes are classified that does not fit the groups C23C 14/221-C23C 14/48. Examples are processes based on a combinations of CVD and PVD and combinations of different PVD processes.

C23C 14/24-C23C 14/32: Some ionization usually takes place during laser ablation (C23C 14/28) and electron beam induced evaporation (C23C 14/30). However, these documents are not classified in C23C 14/32 unless further ionization of the evaporated material takes place.

C23C 14/34-C23C 14/46. In C23C 14/3407 it is particularly important to classify the method used for building up the target-backing plate unit. Remember that the features of the electrodes as such are classified in H01J 37/34.

Note further that sputtering may be performed with other particles than ions.

A sputtering process is based on the use of the kinetic energy of a particle impacting a target surface releasing target material that is subsequently deposited on a substrate.

C23C 14/56: Normal vacuum pumping is classified here. Deliberate minimization of impurities is classified in C23C 14/564.

C23C 14/58-C23C 14/5893: C23C 14/58 includes after deposition treatment of a coating or film deposited by the techniques of C23C 14/00.

In C23C 14/5826 any treatment with charged particles not being ion beam bombardment is included such as for example plasma treatment.

Attention is drawn to the following places, which may be of interest for search:

Controlling or regulating in general |

This place covers:

Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, e.g. chemical vapour deposition (CVD), chemical coating by decomposition of gaseous compounds using electric discharge (plasma coating), using non excited gas phase coating.

- Coating material

- Chemical coating processes

- Pre-treatment of the substrate or after-treatment of the coating

- Apparatus features important to the coating method, e.g. gas inlets in CVD

This place does not cover:

Reactive sputtering or vacuum evaporation |

Attention is drawn to the following places, which may be of interest for search:

Multilayers | |

Deposition of organic layers | |

Cleaning | |

Carbon (fullerenes) | |

Surface treatment of glass | |

After-treatment of ceramics | |

Organometallic compounds | |

Epitaxial layers | C30B 23/00 and C30B 25/00 |

Conductors or Cables | |

Plasma apparatuses | |

Semiconductors |

General considerations.

CPC groups are given to well disclosed CVD coating methods.

CPC groups are further given to related methods, such as pre-treatment of the substrate or after-treatment of the coating.

CPC groups are further given to apparatus features important to the coating method, such as gas inlets in CVD.

Trivial references to well known CVD processes are not classified. As an example "...the SiO2 layer was deposited by decomposition of TEOS in the presence of oxygen..." may be mentioned.

In this subclass, an operation is considered as pre-treatment or after-treatment when it is specially adapted for, but quite distinct from, the coating process concerned and constitutes an independent operation. If an operation results in the formation of a permanent sub-layer or upper layer, it is considered as pre-treatment or after-treatment only if it has a direct impact on the layer above or below respectively. During classification in C23C 16/00 it is common that a document is vague about some of the subject-matter relating to CVD, making the classifier doubt if the document should be classified or not. The classifier should in these cases be guided by his/her own best judgement and the possible importance of the well disclosed subject-matter.

Specific considerations related to specific parts of the classification scheme.

Most of the groups in C23C 16/00 are self-explanatory. Below some explanation of non obvious aspects.

C23C 16/01: Any method for substrate coating separation is classified here, not only etching.

C23C 16/0272-C23C 16/029: The sub-layers are classified only if they have a direct relation to the CVD coating above. Examples are improvement of the adhesion or influence on the structure or properties of the CVD coating above.

C23C 16/04-C23C 16/047: Deliberately taking action to avoid coating on some areas of the substrate. Merely coating the front side of a substrate directed towards a source of coating material and not coating the side that the substrate rests on is not classified.

C23C 16/27: All processes for deposition of diamond not in the subdivisions C23C 16/271-C23C 16/279 , in particular hybrid and combination processes.

C23C 16/28: For description of the non metal elements see IPC section C one of the first pages. Here, also Ge is considered to be a non-metal as opposed to the definition in the IPC.

C23C 16/40-C23C 16/409: The alkaline earth, refractory and iron group metals are defined in IPC section C on one of the first pages. Mixed oxides from different groups are classified in C23C 16/40. Mixed oxides from one group is classified in that group. For example Al-Mg-O is classified in C23C 16/403 but Ti-Al-O is classified in C23C 16/40.

C23C 16/44: Here, coating processes are classified that does not fit the groups C23C 16/4401-C23C 16/545. Examples are processes based on a combinations of CVD and PVD and combinations of different CVD processes.

C23C 16/452: The most important aspect of this group is the CVD process where radicals but not ions from a plasma takes part in the deposition process.

C23C 16/453: These processes are only classified if a coating is made. Processes for creating "soot" for glass making are not classified here, but in C03C.

C23C 16/45525-C23C 16/45553: Sequentially exposing the substrate to the precursors: Reacting the first precursor with the surface of the substrate and subsequently reacting the first precursor on the surface of the substrate with the second precursor.

C23C 16/45563- C23C 16/4588: These groups relate largely to apparatus features that are important for the deposition process. These features are only classified if documents discloses a relation to a CVD coating method. General documents describing apparatus features are classified in the appropriate places such as H10 and B01J.

C23C 16/46 vs C23C 16/481: Note that C23C 16/481 takes precedence.

C23C 16/50-C23C 16/517: These groups relate to plasma CVD processes where in some cases apparatus features are important. These features are only classified if documents discloses a relation to a plasma CVD coating method. General document describing plasma apparatuses are classified in H01J 37/00.

This place does not cover:

Control of diamond crystallography | |

Pulsed pressure or control pressure |

Attention is drawn to the following places, which may be of interest for search:

Controlling or regulating in general |

This place covers:

- Chemical coating occurring through decomposition of either liquid compounds, solutions, dispersions or paste of the coating forming compounds without leaving reactions products of surface material in the coating

- Coating compositions, compounds or processes step specific to said coating

- Contact plating

Attention is drawn to the following places, which may be of interest for search:

Molten material spraying, e.g. Plasma spraying | |

Diffusion onto metallic substrate | |

Chemical surface reaction | |

Vapour coating through PVD | |

Vapour coating through CVD | |

Chemical surface treatment of metallic material by reaction of the surface with a reactive liquid | |

Coating of inorganic material not in molten state, e.g. cold spray, heat or pressure on metallic substrate | |

Superposed coating from at least 2 layers on metallic substrate | |

Medical implants | |

Process of fluid deposition | |

Glass | |

Ceramics | |

Polymer coating composition | |

Ink | |

Electroplating | |

Measuring thickness | |

Controlling or regulating | |

Capacitors | |

Printed circuit boards | |

Solar cells | |

Solution for the manufacture of photoactive layer | |

Semiconductors |

3 subgroups are present:

-C23C 18/02- C23C 18/14: thermal decomposition through heating or irradiation

-C23C 18/16-C23C 18/52: electroless deposition through use of a chemical reducing agent

-C23C 18/54: electroless deposition through substitution with a more electropositive metal than the one being substituted

These sub-groups and their corresponding sub-divisions are generally self-explanatory but more details is given for the following classes:

In this place, the following terms or expressions are used with the meaning indicated:

Contact plating | Plating of metal surface with a more electropositive metal |

Contact plating | displacement, immersion, cementation, exchange, dipping, replacement, substitution, "displacement replacement" |

This place covers:

Processes, apparatus compositions or compounds for chemical coating by thermal decomposition.

Processes of chemical coating by thermal decomposition characterised by the deposition of material other than inorganic material and involving particles

Apparatus for deposition of particles in general

Process of chemical coating by thermal decomposition characterised by the deposition of metallic material including particles.

Processes of chemical coating by thermal decomposition characterised by deposition of inorganic material other than metallic material, including or not particles are classified in C23C 18/12 subgroups.

This place does not cover:

Coating on selected surface areas, e.g. using masks |

This place covers:

Coating for which a pattern area is present, e.g. using masks.

Coatings on selected areas without shielding layer present

Keywords for coating on selected surfaces: | pattern, mask |

This place covers:

Coating for the deposition of metallic material per se and coating for the deposition of aluminium per se through thermal decomposition.

This place covers:

processes and product thereof whereby an inorganic material is deposited through thermal decomposition of its reactant/precursor

apparatus for said process and manufacture of product

4 parts with subdivision are present within this group covering:

C23C 18/1204-C23C 18/122: the composition of the product deposited.

C23C 18/1225: the production of multilayers.

C23C 18/1229-C23C 18/1245: the composition of the substrate onto which the inorganic coating is deposited.

C23C 18/125-C23C 18/1295: the features of the process.

All 4 subdivision have equal weight: classification occurs in any or all of the 4 when features present in claims.

This place covers:

Processes, compositions for chemical coating by thermal decomposition characterised by the deposition of metal oxides other than zeolites or glasses.

This place does not cover:

Coating of Zeolites, glasses |

This place covers:

Process for deposition of metallic or inorganic material through decomposition by irradiation.

Classification is also given to the material being deposited when known: C23C 18/08, C23C 18/12.

In patent documents, the following words/expressions are often used as synonyms:

- "decomposition by irradiation", "photochemical deposition"

In patent documents, the word/expression in the first column is often used instead of the word/expression in the second column, which is used in the classification scheme of this place:

Radiation, irradiation, e-beam, laser, UV | [decomposition by irradiation] |

This place covers:

- Electroless plating of metals or metal oxides, optionally with solid particles

- Constituent of electroless plating composition, i.e. special product not specific for a defined electroless metal composition

- Forming dispersion of solid particles in the product (composite) by electroless plating

- Electroless plating using dispersion containing solid particles

This place does not cover:

Contact plating |

In this place, the following terms or expressions are used with the meaning indicated:

Electroless plating | Process of depositing a coating with the aid of a chemical reducing agent in solution and without the application of external electrical power |

This place covers:

- Process or apparatus for chemical coating by reduction or substitution, for example:

- -process for deposition of material through reduction or substitution by use of a chemical reducing agent

- -process whereby application of reducing and metal solution are separated

Synonyms for process | -chemical plating/deposition/coating -non electrolytic plating/deposition/coating-autocatalytic plating/deposition/coating |

This place covers:

Coatings whereby the electroless coating is patterned.

Electroless deposition on selected surface areas by the use of mask is classified in C23C 18/1605.

Synonym for coating on selected surface areas | pattern |

This place covers:

Process whereby the electroless coating bath is purified or regenerated.

This place does not cover:

Control of the bath/process |

This place covers:

Pretreatment not specific to a particular substrate as well as pretreatment of metallic substrate to be coated.

- Pretreatment of inorganic substrate other than metallic substrate is classified in C23C 18/1851, an operation being considered as pre-treatment when it is specially adapted for, but quite distinct from, the coating process concerned and constitutes an independent operation.

- Pretreatment of organic substrate only is classified in C23C 18/20

- - C23C 18/2006 covers pretreatment which are not covered by any sub-groups C23C 18/2013 - C23C 18/30, e.g. gas pretreatment (ozone), corona discharge, cold plasma pretreatment.

In this place, the following terms or expressions are used with the meaning indicated:

Sensitising in C23C 18/28 and lower | pre-treatment to the activation step by activation of a reducing agent on the substrate surface for promoting the formation of metallic clusters on the substrate surface during the subsequent activation step, e.g. Sn based solution |

Activating in C23C 18/28 and lower | Formation of catalytic site on the substrate surface by reduction of metal ions and deposition of metallic clusters, thereby facilitating subsequent electroless plating steps, e.g. Pd, Ag, Au, based solution |

The steps of sensitising and activating are either used in a 2 step process or a 1 step process in the patent literature.

The term "sensitising" and "activating" are sometimes used interchangeably in the patent litterature.

This place covers:

Coating with metals through electroless plating process.

Attention is drawn to the following places, which may be of interest for search:

Electroplating composition |

- Coating with a reducing agent containing phosphorus or boron does not equate to coating of alloy

- Coating of alloy is an alloy of at least 2 metals

This place covers:

Plating of metal surface (e.g. Ni, Cu) with a more electropositive metal (e.g. noble metal).

Contact plating | displacement, immersion, cementation, exchange, dipping, replacement, substitution, "displacement replacement" |

The groups C23C 20/00-C23C 20/08 are not used. The subject matter is covered by the C23C 18/00 subgroups.

This place covers:

Methods, compositions and apparatus for chemical surface treatment of metallic material by reaction of the metallic surface with a reactive liquid to form conversion or passivation coatings thereon.

This group covers also suspensions containing reactive liquids and non-reactive solid particles.

Apparatus for treating metallic material to form conversion coatings thereon (C23C 22/00).

General methods or special ones for forming conversion coatings on metallic materials that do not have an appropriate subgroup (C23C 22/00).

Conversion coatings (C23C 22/00 - C23C 22/47).

C23C 22/02 . using non-aqueous solutions

C23C 22/05 . using aqueous solutions

C23C 22/70 . using melts

Passivation, oxidation coatings (C23C 22/48 - C23C 22/58).

Conversion coatings characterized by the process (C23C 22/73).

Pretreatment of the material to be coated (C23C 22/78).

After-treatment (C23C 22/82).

Regeneration of the coating bath (C23C 22/86).

Articles characterised by special methods of manufacture are not to be classified in this group but in the appropriate places for such articles, e.g. in F16C for shafts, bearings or parts thereof.

Attention is drawn to the following places, which may be of interest for search:

Coating by hot-dipping or immersion in molten material | |

Coating by spraying molten materials, e.g. oxides | |

Diffusion coatings (chemical surface reaction) | |

PVD coatings | |

CVD coatings | |

Chemical coating by decomposition | |

Sol-gel coatings | |

Powder coatings, e.g. by spraying molten material | |

Other coating methods for metallic substrates | |

Multilayer coatings, at least two superposed coatings either by methods not provided for in a single one of groups C23C 2/00-C23C 26/00 or by combinations of methods provided for in subclasses C23C and C25C or C25D | |

Coating a metal defined by the composition of the coating rather than the coating process | |

Coating materials for prostheses | |

Catalysts comprising oxides, or hydroxides of Mg, B, Al, C. Si, Ti, Zr, Hf | |

Protection of catalyst by coating | |

Process, in general, for preparing catalysts, e.g. by coating | |

Apparatus for depositing polymeric coatings | |

Process for applying monomolecular layers (SAM layers) | |

Pretreatment of surfaces to which liquids or other fluent are to be applied; After-treatment of applied coatings | |

Process for applying liquids or other fluent materials to obtain special surface effects, finishes or structures, e.g. for repairing damaged coatings | |

Processes specially adapted for applying liquids or other fluent materials to metal surfaces, e.g. car bodies, metallic pipes or tubes; or to internal surfaces of tubes or pipes | |

Processes for applying multilayers from a liquid; Painting | |

One specific pretreatment, e.g. phosphatation, chromatation, and one specific coating | |

Coatings for surface of moulds, cores or pattern | |

Preliminary treatment of areas to be soldered | |

Non-corrosive coatings; primers applied before welding | |

Non-metallic compositions, e.g. coatings of interest in soldering or welding | |

Bonding rubber to metal (mechanical) | |

Laminates, self-supporting layers | |

Chemical or electrical treatment of printing surfaces with a chromium compound, a silicon compound, a phosphorous compound or a compound of a metal group IVB | |

Coating containing alkyl silicates or metals silicates | |

Coating containing alkali metals silicates | |

Coatings containing phosphates binders | |

Bonding rubber or polymer to a metal (chemical) | |

Coatings with alkali metal silicates | |

Coatings with siloxanes | |

Corrosion-inhibiting coatings (anti-corrosive paints, anti-corrosion oils) for metallic material | |

Wash primers | |

Coatings based on homopolymers or copolymers having one or more unsaturated aliphatic radicals | |

Coatings with polyesters | |

Coating with polyamines | |

Coatings with polysilcates, polysiloxanes | |

Adhesive bonding involving pretreatment of the surface to be joined | |

Lubricating composition containing more than 10 % water and not containing mineral or fatty oils | |

Local protective coating | |

Chemical treatment of the metal surfaces prior to coating by enamelling, or by applying a vitreous layer to metals | |

Enamelling of, or applying a vitreous layer to, metals | |

Pretreatment of metallic material, by etching | |

Corrosion inhibitors | |

Pretreatment of metallic material, by cleaning/pickling | |

Electrolytic recovery | |

Electrolytic coating | |

Electrochemical coating with inorganic materials | |

Electrochemical Phosphatising | |

Electrochemical Chromatising | |

Particular treatment of turbine blades | |

Protective coatings for turbine blades | |

Protective coatings for heat exchangers | |

Corrosion protection, e.g. by coating of magnetic steels | |

Applying non-metallic protective coatings | |

Improving adhesion between the insulating substrate and the metal by conversion of the metal surface, e.g. by oxidation | |

Improving adhesion between the insulating substrate and the metal by the use of a coupling agent, e.g. silane |

In this group it is MANDATORY to classify ALL EXAMPLES of Compositions or Methods.

Other well-disclosed and non-trivial aspects are also classified.

Rejuvenating of the bath is classified in the appropriate place for the specific bath composition.

C23C 22/24 - C23C 22/33, C23C 22/04, C23C 22/37, C23C 22/38, C23C 22/43, C23C 22/67 - treatment with acidic aqueous solutions containing hexavalent chromium compounds - an old technology being phased out due to the carcinogenic effects of hexavalent chromium compounds (see, Restriction of Hazardous Substances (RoHS) - European Union Directive 2002/95/EC).

Classification of additional information

In many cases the classification of additional information is very useful for retrieving the document, and therefore very desirable, although not compulsory. Well-known (trivial) aspects or features are not classified.

For example:

If a document discloses a "conversion process and composition for treatment of aluminium" (C23C 22/56), which in the description is also described as being suitable "for treating magnesium", and if this additional information is per se new /inventive ("non-trivial"), it is classified, namely C23C 22/57 as well.

In some cases the additional information is broadly defined as any secondary information useful for search that is not relevant per se, but that could be interesting for search when considered together with the important (invention-like) information, then it is classified with (Indexing Code), e.g. C23C 2222/10 for searching conversion coatings based on Cr(III) with no Cr(VI), C23C 2222/20 for searching conversion coatings containing or corrosion inhibiting compositions based on silanes or hydrolysis or condensation products thereof.

It is mandatory to classify additional information concerning conversion coating compositions based on Cr(III) in C23C 2222/10. It is mandatory to classify additional information concerning conversion coating compositions based on silanes or hydrolysis or condensation products in C23C 2222/20.

Subgroups and head group

In the head group C23C 22/00, the specific technical information is relevant to the apparatus for treating metallic material to form conversion coatings thereon; and the general methods or special ones for forming conversion coatings on metallic materials that do not have an appropriate subgroup.

In subgroups C23C 22/02 - C23C 22/86, in the absence of an indication to the contrary, classification is made in the last appropriate place.

In the subgroup C23C 22/17 the specific technical information is relevant to the chemical treatment of metallic material with acidic aqueous phosphating solutions which, besides zinc ions, oxidants (nitrite, nitrate, chlorate), contains organic acids, or hydroxylamines, or nitrocompounds, such as nitrobenzene sulfonate.

In the subgroup C23C 22/73 the specific technical information is relevant to the process, e.g. two consecutive treatments or the way how the coating is applied to metallic surfaces.

In the subgroup C23C 22/74 the specific technical information is relevant to the process of conversion coatings formed by chemical reactions of concentrated reactive solutions followed by a thermal treatment (curing step) at temperatures more than 100 - 120 °C.

In the subgroup C23C 22/84 the specific technical information is relevant to the after-treatment (post-treatment) of conversion or passivation coatings by dyeing (coloration). If the conversion or passivation coating is coloured, no classification in C23C 22/84.

In this place, the following terms or expressions are used with the meaning indicated:

Metallic material | covers metals and alloys (attention is drawn to the Note following the title of subclass C22C). |

Phosphate coatings | Phosphate coatings are processes of chemical conversion on a metal surface to produce thin adherent phosphate compound coatings. The phosphate crystals formed on the surfaces of materials can be iron, zinc, or manganese phosphates. Among these phosphates, manganese phosphate is more suitable for wear applications. Phosphate coatings are usually applied to carbon steel, low-alloy steel, and cast iron. They can also be applied to zinc, cadmium, aluminum, and tin. Phosphate processes are hard to apply on high alloys for these alloys are likely immune to the phosphoric acid. In short, phosphating is one of the most useful non-metallic conversion coatings. |

Chromate coatings | Chromate coatings, similar to phosphate coatings, are processes of chemical conversion. But the chromate coatings are formed by the reaction of water solutions of chromic acid or chromium salts. The coatings can be applied to aluminum, zinc, cadmium, and magnesium. The coatings usually have good atmospheric corrosion resistance. Chromate coatings are widely used in protecting common household products, such as screws, hinges, and many hardware items with the yellow-brown appearance. |

Oxide coatings | The oxide coatings are in fact corrosion products which is a thin, usually less than 2.5 µm oxide with good adhesion. The oxide treatments are done by heat, chemicals, or electrochemical reactions. |

Bluing-type oxidations | gun -bluing -type oxidations are done by heating the metals, generally steel, at 370ºC in a steam atmosphere. Chemical baths produce coatings similar to a gun bluing coating by immersion techniques. |

Black oxide or blackening coatings | Black oxide or blackening coatings is a conversion coating for steel, copper, zinc, powder metals and silver solder, and most for stainless steel by treating with hot caustic soda (blackening agent). Some pastes can be rubbed on surfaces to produce similar results. |

In patent documents, the following abbreviations are often used:

Passivation | oxidation, bluing |

Conversion | phosphating or phosphatation, chromating or chromatation black oxide or blackeningcerium oxide conversion coatings |

Anodizing or anodising | electrochemical conversion coating |

Burned-in | cured |

Condensed phosphates | polyphosphates |

Dyeing | postcoloration of the conversion or passivation coating |

Attention is drawn to the following places, which may be of interest for search:

Controlling or regulating in general |

This place covers:

Coating methods where the material to be coated is applied in powder form on the surface of the substrate to be coated, e.g. cold spray methods.

Also methods where the coating material is applied in form of a slurry as long as said methods result in obtaining a coating, and not in a modification of the surface of the substrate or in a diffusion into the substrate.

This place does not cover:

Spraying of the coating material in molten state, starting from a powder | |

Solid state diffusion of only non-metal elements into metallic material surfaces | |

Solid state diffusion of only non-metal elements into metallic material surfaces using solids, e.g. powders, pastes | |

Solid state diffusion of only metal elements or silicon into metallic material surfaces using solids, e.g. powders, pastes | |

Solid state diffusion of at least one non-metal element other than silicon and at least one metal element or silicon into metallic material surfaces | |

Manufacture of composite layers, workpieces or articles by sintering metallic powder | |

Friction welding | |

Coating mortars, concrete, artificial stone or ceramics, using a powder as coating material | |

Coating mortars, concrete, artificial stone or ceramics, with vitreous materials |

Attention is drawn to the following places, which may be of interest for search:

In this place, the following terms or expressions are used with the meaning indicated:

Metallic material | Metals or metal alloys, optionally comprising hard particles, e.g. oxides, carbides or nitrides |

This place covers:

Cold spray methods, i.e. spraying methods in which the sprayed particles are not significantly melted before reaching the substrate.

This place does not cover:

Spraying of the coating material in molten state, starting from a powder |

This place covers:

Any method of coating a metallic surface and/or of coating a substrate with a metallic material which is not already described in any of groups C23C 2/00 - C23C 24/00

This place does not cover:

Applying liquids or other fluent materials to surfaces in general | |

Making metal-coated products by extrusion | |

Connecting objects or parts, e.g. coating with sheet metal otherwise than plating | |

Working of metal by the action of a high concentration of electric current on a workpiece using an electrode | |

Plating by soldering or welding | |

Metallising of glass | |

Metallising mortars, concrete, artificial stone, ceramics or natural stone | |

Paints, varnishes, lacquers | |

Enamelling of, or applying a vitreous layer to, metals | |

Treating metal surfaces or coating of metals by electrolysis or electrophoresis | |

Electrolytic stripping of metallic layers or coatings | |

Single-crystal film growth | |

Manufacture of printed circuits | |

Manufacture of semiconductor devices |

This place covers:

Any method of coating a metallic surface with a molten material or molten metallic material to a substrate which is not already described in any of groups C23C 2/00 - C23C 24/00, e.g. brazing, arc welding, laser welding, friction welding, laser alloying

This place covers:

Multi-layered coatings, where the different layers composing the coating have been deposited by at least two different methods as disclosed in group C23C 2/00 - C23C 26/00 or by a combination of one method from C23C and one method from C25D.

Articles characterised by special methods of manufacture are not to be classified in this group but in the appropriate places for such articles, e.g. optical coatings of optical elements G02B 1/10, magnetic record carriers G11B 5/00, resistors H01C 7/00, capacitors H01G 4/00, semiconductor and/or solid-state devices H10, batteries and/or fuel cells H01M, semiconductor lasers H01S 5/00 and so on.

If a multilayered product classified in B32B is obtained by at least two different methods as disclosed in groups C23C 2/00 - C23C 26/00 or by a combination of methods provided for in subclasses C23C and C25, then the combination of methods should be classified in C23C 28/00 subgroups.

This place does not cover:

Deposition of sublayers, e.g. to promote adhesion of the coating, prior to the deposition of a coating by PVD | |

Deposition of sublayers, e.g. to promote adhesion of the coating, prior to the deposition of a coating by CVD |

- Classes are given to well disclosed coatings. Classes are given for all and every aspects/features present in the multi-layered coating being classified, in order to enable an easy cross-searching.

- Multi-layered coatings where all layers are made of a metallic material, as defined in the glossary above, are classified in C23C 28/02 and subgroups.

- Multi-layered coatings where all layers are made of an inorganic non-metallic material, as defined in the glossary above, are classified in C23C 28/04 and subgroups.

- Multi-layered coatings comprising a mixture of metallic and non-metallic layers as defined in the glossary above, are classified in C23C28/06 and subgroups.

- Multi-layered coatings comprising alternating layers following a pattern and/or a periodic or defined repetition are classified additionally in C23C28/08 and subgroups.

- Coatings characterized by a main coating and an adhesion (sub)-layer are not to be classified in C23C 28/00, even if said adhesion layer is deposited using a different method as the method used for the main coating, but according to the method used for the main coating, e.g. for a PVD method in C23C 14/024, for a CVD method in C23C 16/0272.

- Multi-layered coatings that cannot be classified in any one of the single groups C23C 28/02, C23C 28/04 or C23C28/06 and their subgroups, but still fall within the definition statement of the main group are to be classified in C23C 28/00.

In this place, the following terms or expressions are used with the meaning indicated:

Metallic material | Metals and metals alloys, not including inorganic materials such as oxides, carbides, nitrides, borides, silicides and their mixtures, with the exception where said inorganic materials are embedded in a metal matrix as hard particles, e.g. Cermets and MMC. |

Inorganic non-metallic materials | Oxides, carbides, nitrides, borides, silicides and their mixtures, enamels, phosphates and sulphides. |

This place covers:

Coatings obtained by any of the methods of group C23C 2/00 - C23C 26/00 but characterized either by the peculiarity of their compositions or of their structures, e.g. columnar thermal barrier coatings, metal matrix composite coatings, two/multi-phase metallic coatings, quasicrystalline coatings, etc.

This place covers:

Essentially coated cutting tools where the coating has been obtained by any of the methods of group C23C 2/00 - C23C 26/00 .

Cutting tools of which the bits, tips or cutting inserts are of a special material are per se classified in B23B 27/14 and not systematically cross-classified in C23C 30/005 when said special material includes a coating.

Cutting tools coated with multi-layered coatings should also be classified in C23C 28/00, when said multi-layered coatings are of a particular interest.

In this place, the following terms or expressions are used with the meaning indicated:

Hard metal substrates | Includes cemented carbide substrates |