CPC Definition - Subclass B22F

This place covers:

Metallic powders per se.

Treatment of metallic powder, e.g. thermal, thermo-mechanical or chemical treatments, making agglomerates.

Manufacture of workpieces or articles from metallic powder characterised by the manner of compacting or sintering or by the special shape of the product.

Manufacture of composite layers, workpieces, or articles, comprising metallic powder, by sintering the powder, with or without compacting.

Manufacture of articles from scrap or waste metal particles.

Making metallic powder or suspensions thereof using physical or chemical processes.

Powder metallurgical apparatus or equipment specifically adapted therefor, e.g. furnaces, retorts or sintering apparatus.

Additive manufacturing of workpieces or articles from metallic powder and apparatus or devices therefor.

Subclass B22F covers the making of metallic powder including a metallic powder with specific physical characteristics. Non-metal particles or inorganic compounds coated with metal as well as metal particles coated with non-metals or inorganic compounds are classified in subclass B22F. Subclass B22F covers powders containing a substantial proportion of non-metallic material. It means that, when the metal is in a significant proportion that cannot be seen as an impurity in the metallurgical process, it must be classified in subclass B22F. When the metal is present only as an impurity, it is classified in other places in the IPC. When the subject matter does not refer to a manufacturing process or to articles characterized by having a special shape but only refers to the use of the metallic powder, it is classified in the other places in the IPC, e.g. dental implants using metallic powder are classified in A61C 8/00.

Group C22B 1/14 covers agglomerating; briquetting, granulating, binding or sintering of ores or scrap for obtaining metals

Groups C22C 1/04, C22C 1/05, C22C 26/00, C22C 29/00, C22C 33/02 and C22C 47/14 cover the making of alloys by powder metallurgy including using mixtures of metallic powder with non-metallic powder, fibres or filaments.

Subclass C22F covers changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working, including special physical methods, e.g. treatment with neutrons.

Subclass C04B covers preparing or treating powders of inorganic compounds in preparation to the manufacturing of ceramic products, e.g. group C04B 35/622. When the proportion of metallic powder is present not as an impurity in the compounds, it is classified in subclass B22F.

Subclass C08K covers use of inorganic substances including metals as compounding ingredients in compositions based on macromolecular compounds.

Group B01J 2/00 covers chemical or physical processes or devices for granulating materials in general.

Subclass B02C covers crushing, grinding or milling, in general.

Subclass B22F covers the manufacture of workpieces from metallic powder, e.g. by rolling, extrusion or forging. Other aspects of mechanical metal-working without essentially removing material are covered by class B21. In particular, subclasses B21B and B21H cover rolling of metal, subclass B21C covers extrusion of metal and subclasses B21J and B21K cover forging of metal.

Magnets made by pressing, sintering or bonding metals or alloys in the form of particles, e.g. powder, are classified in groups H01F 1/08, H01F 1/22, and in subclass B22F for the process of manufacturing the metallic powder, the powder itself and the process for making the magnet by powder metallurgical techniques.

This place does not cover:

Making non-ferrous alloy compositions by powder metallurgy | |

Making non-ferrous alloys from mixtures of metallic powder with non-metallic powder | |

Alloys containing diamond | |

Alloys based on metal compounds, e.g. cermets | |

Non-ferrous alloys containing metal compounds | |

Making ferrous alloys by powder metallurgy | |

Making alloys containing metallic or non-metallic fibres or filaments by powder metallurgy |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Making ceramics by compacting or sintering | |

Shaped ceramic products characterised by their composition | |

Burning or sintering process for ceramic compositions | |

Production or refining of metals; Pretreatment of raw materials | |

Sintering; Agglomerating of raw materials for obtaining metals | |

Electrolytic production, recovery or refining of metallic powder | |

Magnets or magnetic bodies characterised by the magnetic materials in the form of particles, e.g. powder | |

Magnets made by pressing, sintering or bonding metals or alloys in the form of particles, e.g. powder, together | |

Magnetic cores made from powder | |

Devices using superconductivity or hyperconductivity characterised by the material |

Attention is drawn to the following places, which may be of interest for search:

Dental implants | |

Prostheses implantable into the body | |

Use of metals or alloys for artificial teeth, for filling or for capping teeth | |

Use of metals or alloys for prostheses or for coating prostheses | |

Chemical or physical processes or devices for granulating materials in general | |

Catalysts comprising metals | |

Methods for preparing or activation of catalysts | |

Crushing, grinding or milling in general | |

Disposal of solid waste | |

Melting down metal particles in a mould | |

Soldering or unsoldering; Welding; Cladding or plating by soldering or welding | |

Abrasive tools | |

Cutting tools | |

Presses specially adapted for forming articles from material in particulate or plastic state | |

Layered products characterised by features of a layer formed of particles, e.g. chips, chopped fibres, powder | |

Printing | |

Chemical aspects of powdering or granulating of macromolecular substances | |

Metallic pigments or fillers | |

Compressing powdered coating material, e.g. by milling | |

Earth or rock drilling tools | |

Structural composition and use of special materials in brasses, bushes and linings of sliding contact bearings | |

Conductive material dispersed in non-conductive organic material | |

Elements or alloys used as active materials in battery in electrodes | |

Printed circuits | |

Selection of a metal for the legs of a junction of a thermoelectric device |

Combination Sets (C-Sets):

In this subclass, C-Sets classification is applied to the following groups, listed in the table below, if the document discloses a pertinent combination of technical features that cannot be covered by the allocation of a single symbol. The fourth column of the table indicates the place where the detailed information about the C-Sets construction and the associated syntax rules can be found, in the definition section "Special rules of classification".

C-Sets ID | Base Symbols | Subsequent Symbols | C-Sets Formula; Location of C-Sets Rules |

#B22Fa | B22F 1/00 - B22F 2207/20, C22C 1/00 - C22C 2204/00 (including breakdown indexing codes), other subclasses | (B22F, B22F); a process relating to powder metallurgy; see B22F 2998/00 | |

#B22Fb | B22F 1/00 - B22F 2207/20, C22C 1/00 - C22C 2204/00 (including breakdown indexing codes), other subclasses | (B22F, B22F); a process relating to powder metallurgy characterized by the sequence of the steps; see B22F 2998/10 | |

#B22Fc | B22F 1/00 - B22F 2207/20, C22C 1/00 - C22C 2204/00 (including breakdown indexing codes), other subclasses | (B22F, B22F); a process relating to aspects linked to processes or compositions used in powder metallurgy; see B22F 2999/00 |

The specific C-Sets rule is located at only one place of the base symbol in the section "Special rules of classification" in the definition. If the C-Sets rule is applicable to all groups of a subclass, it is located at the subclass level only. If the same C-Sets rule is applicable to multiple groups or subgroups within the same subclass, the C-Sets rule is placed at the highest group or subgroup of the multiple groups.

In this place, the following terms or expressions are used with the meaning indicated:

Compacting | join or press firmly together. |

Sintering | forming powder into a coherent mass by heating the powder whereby adjacent particles are joined by diffusion or superficial melting. |

Alloy | a composition of plural elements at least one of which is a metal in the oxidation state zero. Also includes material containing any combination of fibres, filaments, whiskers and particles, e.g. carbides, diamond, oxides, borides, nitrides or sulfides, embedded in a metallic matrix. |

Furnace | covers kilns, ovens or retorts |

In patent documents, the following words/expressions are often used as synonyms:

- "apparatus", "equipment" or "device"

- "residue", "waste", "remain", "scrap", "rejects" or "shred"

- "compacting" or "compressing"

This place covers:

Metal particles per se as well as mixtures of metal particles with a lubricant, binding agent or organic material. Particles per se can have a specific size, size distribution, shape or structure. Treatment of metallic powder and coating thereof is also covered.

A special case, which is also covered by this subclass, concerns non-metallic or inorganic particles which have a metallic coating. Equally metal particles coated with non-metals or inorganic compounds are classified in subclass B22F 1/00. B22F 1/00 also covers powders containing a substantial proportion of non-metallic material. When the metal is present in a proportion significantly relevant so that it could not be seen as an impurity in the metallurgic process it must be classified in B22F 1/00.

Main group B82Y 5/00 covers nanobiotechnology or nanomedicine. Furthermore, main group B82Y 5/00 is for obligatory supplementary classification of subject matter containing an aspect of nanobiotechnology or nanomedicine already classified in other classification places.

Main group B82Y 30/00 covers nanotechnology for materials or surface science. Furthermore, main group B82Y 30/00 is for obligatory supplementary classification of subject matter containing an aspect of nanotechnology for materials or surface science already classified in other classification places.

Compositions of metal and ceramic powder, e.g. cermets, are classified in C22C.

Attention is drawn to the following places, which may be of interest for search:

Shot peening | |

Ammunition shot |

In this place, the following terms or expressions are used with the meaning indicated:

"Nanosize" or "nanoscale" | relate to a controlled geometrical size below 100 nanometres (nm) in one or more dimensions. |

This place covers:

Apart from the manufacturing of workpieces or articles from metallic powder, also the manufacturing of parts which are based on metallic fibres only (no matrix material) as well as processes starting from decomposable or reducible metal compounds.

Attention is drawn to the following places, which may be of interest for search:

Although B22F 3/12 specifies processes including both compacting and sintering, this group is mainly used for information concerning the container or model used during the compacting and sintering. For the compacting and sintering step, the more detailed subgroups under B22F 3/02 (compacting) and/or B22F 3/10 (sintering) are applied.

This place covers:

Press apparatuses specially adapted for metal powder pressing.

Attention is drawn to the following places, which may be of interest for search:

Presses in general |

Methods or special apparatuses for the filling of the moulds with powder are classified in B22F 3/003.

This place covers:

Processes in which compacting is accomplished through the use of shock waves or explosive forces, including processes that utilize a time-related detonating effect

Attention is drawn to the following places, which may be of interest for search:

Application of shock-waves for chemical reactions or for modifying structures in general | |

Generating shock-waves in general |

- Flyer impact effect: B22F 3/087

- Compression in the presence of a magnetic field: B22F 3/087 and/or with Indexing Code B22F 2202/05

This place covers:

Compaction aided by vibrations or friction.

This place covers:

All sintering processes involving EM-wave energy: electric current, plasma, laser, microwave, etc and ultra-sonic bonding.

This place does not cover:

Making porous workpieces or articles | |

Manufacture of workpieces or articles by spraying molten metal |

Attention is drawn to the following places, which may be of interest for search:

Stereolithographic techniques for making dental prostheses | |

Laser welding and relative movement between laser beam and workpiece | |

Selective sintering of ceramic or cementitious material | |

Rapid manufacturing and prototyping of 3D objects by additive depositing, agglomerating or laminating of plastics material | |

Selective printing |

This place covers:

(hot) spraying of molten metal wherein the sprayed material forms the product (i.e. not as a coating process).

This place does not cover:

Cold spraying of metal |

Attention is drawn to the following places, which may be of interest for search:

Adding compound dispersions to the spray | |

Thermal spraying fibre reinforced material |

These documents are also classified in C23C 4/123 (spraying molten metal) and C23C 4/185 (separation of coating from substrate) as well as B22D 23/003 (moulding by spraying metal on a surface).

This place covers:

Chemical or thermal after-treatments and mechanical treatments only in as far as material is removed from the surface, such as making recesses or grooves, honing, polishing, milling, grinding, carving etc.

The after-treatment is further specified by means of an Indexing Code.

This place does not cover:

Porous articles or workpieces formed by impregnation remaining porous |

Attention is drawn to the following places, which may be of interest for search:

Apparatus for impregnation | |

Impregnating a ceramic preform with molten metal | |

Non-ferrous alloys obtained by impregnation of a powder metallurgy product | |

Making ferrous alloys by impregnation |

This place covers:

Processes in which a defined geometrical configuration of a final product is specified, and also moulds, turbine components other than blades, engine parts different from piston rings, flat products and articles to be fractured or separated into parts.

Attention is drawn to the following places, which may be of interest for search:

Making turbine blades (by machining)from one piece from several pieces | |

Turbine blades |

Attention is drawn to the following places, which may be of interest for search:

Making screw-threaded elements (e.g. nuts, bolts) | |

Screw bolts |

Attention is drawn to the following places, which may be of interest for search:

Gear wheels by stamping | |

Gear wheels by rolling | |

Gear wheels forged or pressed | |

Coupling members, e.g. clutch systems | |

Making gears or toothed racks | |

Making gear wheels by "other" processes | |

Mechanically actuated clutches | |

Toothed gearings |

This place covers:

Manufacture of composite parts (limited geometry) and layers ("infinite"), including porous layers or parts, comprising metallic powder, by sintering the powder, with or without compacting

This place does not cover:

Coatings applied by use of metal powder (not involving compression and/or sintering) |

Attention is drawn to the following places, which may be of interest for search:

Layered products characterised by the non-homogeneity or physical structure of a layer, comprising fibres or filaments formed of particles foamed or porous material combinations thereof in at least 2 layers | |

Layered products characterised by the relation between layers | |

Layered products, essential comprising metal | |

Methods or apparatus for laminating |

Attention is drawn to the following places, which may be of interest for search:

Tools for cutting or boring with bits of special material or diamond bits | |

Connecting cutting edges by brazing | |

Making cutting tools | |

Tools for grinding, with metallic binder | |

Hand cutting tools | |

Earth or rock drilling bits, with diamond insertswith button type inserts |

This place covers:

Only connecting (i.e not co-forming or in-situ forming) or repairing.

Attention is drawn to the following places, which may be of interest for search:

Repairing methods or devices for turbine blades |

In this place, the following terms or expressions are used with the meaning indicated:

Scrap, waste | swarf, residue, remains, rejects, shred |

This place covers:

Solidification by means of quenching rates above 104 C/s.

This place covers:

Only starting from melts.

This place covers:

Processes employing a gaseous precursor of the powder, plasma, or the evaporation of metal.

This place covers:

Including the recovery of one metal from a mixture/solution containing multiple metals.

Attention is drawn to the following places, which may be of interest for search:

By hydrogen absorption / desorption | |

Electrolytic production, recovery or refining of metal powders |

Direct reduction of iron ores: C21B 13/00

General processes of reducing to metals: C22B 5/00

Dry reduction processes for obtaining specific non-ferrous metals: C22B

Attention is drawn to the following places, which may be of interest for search:

Controlled atmosphere, or pulverulent material; Adjusting the composition of the atmosphere |

This place does not cover:

Manufacturing of iron from iron carbonyl | |

General method of reducing metals from metal carbonyls |

This place covers:

Technologies involving the use or application of processes or apparatus that produce three dimensionally shaped structures by selectively depositing successive layers of metallic powder one upon another.

Processes of additive manufacturing, i.e. making, repairing or modifying articles of manufacture by the selective application of multiple layers of metallic powder.

Either the complete product may be built up layer-by-layer or powder can be applied on a prefabricated part, wherein the pre-fabrication step is not limited to additive manufacturing. The powder can be applied as a layer, of which only a part is consolidated and used for the product, or locally at the consolidation area.

In addition to metallic powder, mixtures of metallic particles with organic or inorganic material are also covered by this group. For example, metallic particles having an organic or a (non-metallic) inorganic coating and (non-metallic) inorganic particles having a metallic coating.

Group B29C 64/00 covers additive manufacturing of plastics or materials in a plastic state, not otherwise provided for.

Subclass B33Y covers additive manufacturing, irrespective of the process or material used. Furthermore, subclass B33Y is for obligatory supplementary classification of subject matter containing an aspect of additive manufacturing already classified as such in other classification places.

Groups B28B 1/00 and C04B 35/00 cover additive manufacturing of ceramics. Reference is made to making ceramic green bodies or pre-forms by computer aided shaping in C04B 2235/6026, to aspects relating to heat treatments of ceramic bodies such as green ceramics or pre-sintered ceramics, including local sintering, e.g. laser sintering, in C04B 2235/665 and (ceramic) mixtures specially adapted for three-dimensional printing in C04B 2111/00181.

The relevant groups under B29C 64/00, B22F, or B28B or C04B are applied according to the nature of the end product—polymer, metallic or ceramic, respectively.

Metallic articles manufactured by additive manufacturing, but where the manufacturing method is only described in general (e.g. simply as "additive manufacturing" or "3D printing", or where several methods are listed with no particular emphasis), should only be classified in B33Y 80/00 and B22F 5/00 and/or the specific product class.

Workpieces or articles from metallic powder characterised by the special shape of the product are classified in group B22F 5/00.

Compositions are classified in the appropriate groups in subclass C22C.

Repairing turbine components by additive methods is covered in B23P 6/007.

Generation and modification of 3D models of the shape as such (voxel models, boundary representations or polygon meshes) is covered by G06T 17/00.

Aspects of computer-aided design, such as design optimisation and analysis/simulation, are covered by G06F 30/00.

This place does not cover:

Apparatus or devices specially adapted for additive manufacturing |

Attention is drawn to the following places, which may be of interest for search:

Preparation of cocoa products | |

Shaping or working of foodstuff | |

Making of dental prostheses | |

Making customized prostheses implantable into the body | |

Making customized prostheses not-implantable into the body | |

Materials for prostheses or for coating prostheses | |

Moulds or cores for foundry moulding | |

Build-up welding by means of gas flame | |

Build-up welding by means of arc | |

Build-up welding by means of plasma | |

Build-up welding by means of resistance heating | |

Build-up welding by means electron beam | |

Build-up welding by applying impact or other pressure | |

Build-up welding by means of slag | |

Build-up welding by laser | |

Repairing turbine components by build-up welding | |

Producing shaped articles from ceramic or cementitious material | |

Moulds, cores or mandrels for shaping clay or other ceramic compositions | |

Additive manufacturing of plastics | |

Ancillary operations in connection with laminating processes | |

Forme preparation for the manufacture or reproduction of printing surfaces | |

Typewriters or selective printers for marking on special material | |

Braille printing | |

Processes for producing ornamental structures by superimposing layers | |

Forming processes for shaped ceramic products | |

Culture of cells | |

Blades and blade-carrying members for non-positive displacement machines | |

Making sintered bearings by built-up welding | |

Photosensitive materials for photographic purposes | |

Photographic processes | |

Photomechanical production of textured or patterned surface | |

Electrographic processes using a charge pattern | |

Electric numerical control systems for the surface or curve machining, making 3D objects | |

Computer-aided design [CAD] | |

3D modelling for computer graphics | |

Models for surveying; Models for geography, e.g. relief models | |

Discharge tubes for applying thin layers on objects | |

Apparatus or processes for manufacturing printed circuits using printing techniques to apply the conductive material |

This place covers:

Processes where a green body is first formed and where the metallic article is usually obtained by subsequent de-binding and sintering.

The green body comprises metallic powder bonded by a binder which may include organic or inorganic material.

This place covers:

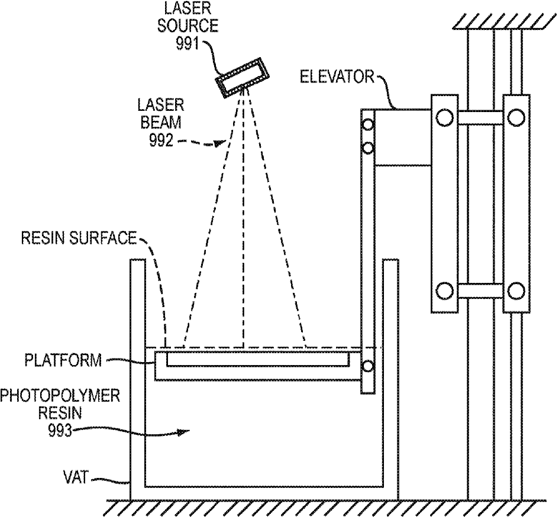

Processes where a light source is used to cure a mixture comprising a photopolymer (light-activated resin) and a metallic powder to form a green body.

In the stereolithography [SLA] process, the light source traces the contour of a part, solidifying the photopolymer of the mixture.

In the digital light processing [DLP] process, the solidification of the photopolymer of the mixture occurs using a digital light projector screen to flash an image of each layer at once.

Illustrative examples of subject matter classified in this place:

1. Stereolithography [SLA]

2. Digital light processing [DLP]

This place covers:

The deposition of a liquid bonding agent onto a thin layer of metallic particles forming a powder bed to join the metallic particles and build up a green body layer by layer.

The bonding agent may include organic and inorganic materials.

The powder bed may be formed from mixtures of metallic particles with (non-metallic) inorganic particles, for example (non-metallic) inorganic particles having a metallic coating or metallic particles having a (non-metallic) inorganic coating.

Illustrative example of subject matter classified in this place:

Binder jetting

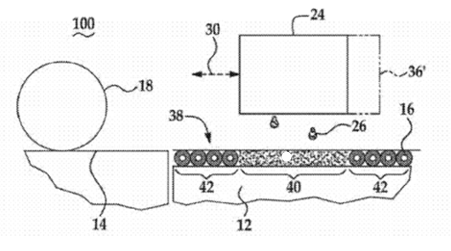

This place covers:

The formation layer by layer of a green body by selectively depositing a viscous material comprising activating a binder embedded in a powder bed of metallic particles.

The binder might be activated by a heat source (such as a laser beam, IR-light, etc.) to bond the metallic particles.

The binder may include organic and inorganic materials and may be present in the powder bed as a mixture with the metallic particles or may be present as a coating on the metallic particles.

The powder bed may be formed from mixtures of metallic particles with (non-metallic) inorganic particles, for example (non-metallic) inorganic particles having a metallic coating or metallic particles having a (non-metallic) inorganic coating, with an additional binder embedded in the said powder bed.

Illustrative example of subject matter classified in this place:

1.a

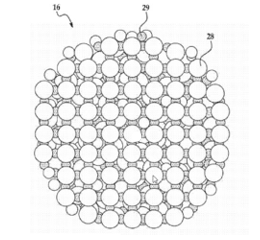

Binder jetting comprising selectively depositing a patterning fluid (26) onto granules (16) of build material.

1.b

Granules (16) of the build material comprising metal particles (28) bound by a polymeric binder (29).

This place covers:

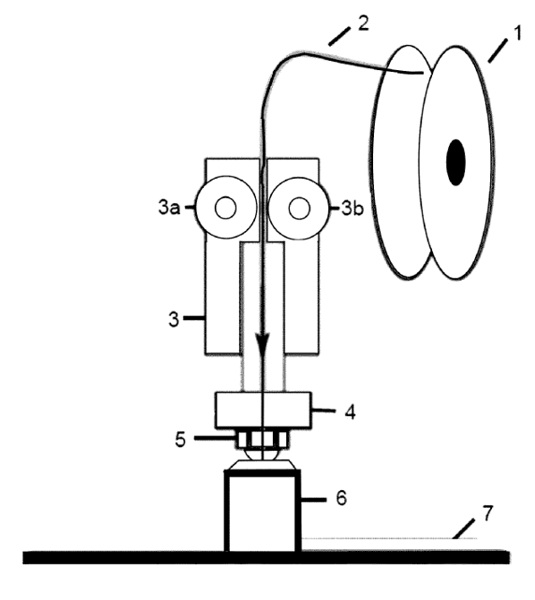

The formation layer by layer of a green body by selectively depositing beads of a viscous material composed of a mixture of metal particles embedded in a binder, the mixture having the form of a filament. The binder may include organic and inorganic materials.

For example, the filament material might be extruded by a nozzle in beads.

Illustrative example of subject matter classified in this place:

Fused filament fabrication

This place covers:

Manufacture of articles where the final metallic part is formed directly without need for subsequent sintering. The latter in this case is considered an after treatment.

Illustrative example of subject matter classified in this place:

Inverted laser sintering [ILS]

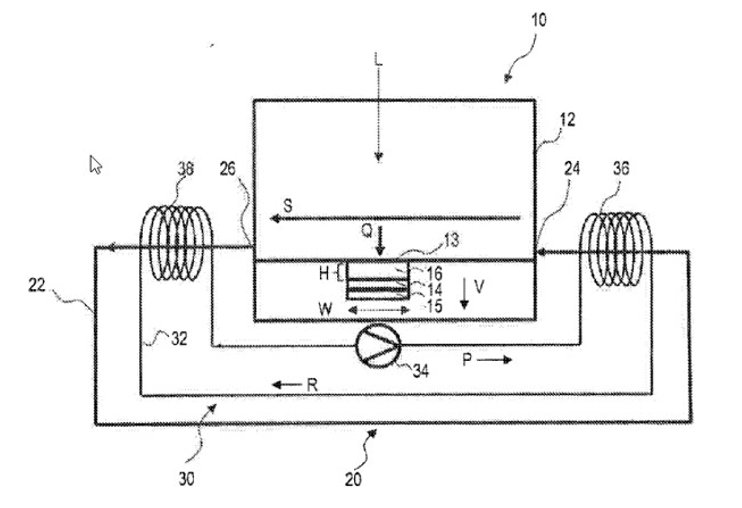

This place covers:

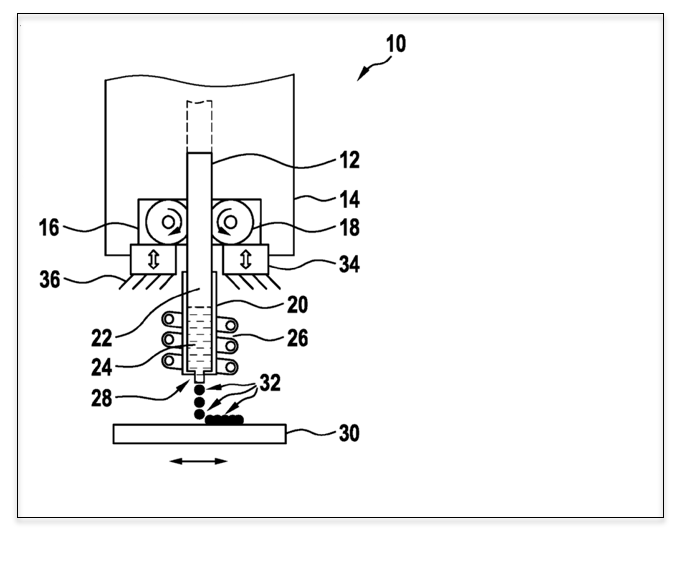

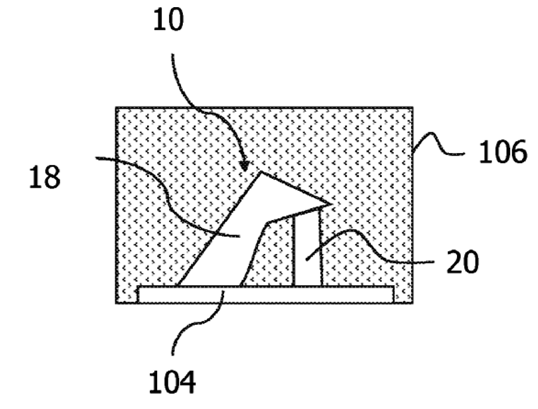

Processes where molten metal is deposited directly onto a substrate or previously fabricated preform, for example, as droplets, i.e. drop-on-demand [DOD].

Illustrative example of subject matter classified in this place:

Additive manufacturing using a print head (10) for ejecting droplets (32) of liquid metal (24). The wire (12) in a solid phase (22), is pushed into a melting chamber (20) and melted into its liquid phase (24). At the far end of the melting chamber is an exit orifice (28) for the ejection of gobs (32) of molten wire.

Attention is drawn to the following places, which may be of interest for search:

Manufacture of workpieces or articles from metallic powder by spraying molten metal, i.e. spray sintering or spray casting | |

Moulding by spraying metal on a surface | |

Coating by spraying molten metal | |

Separation of the coating material from the substrate |

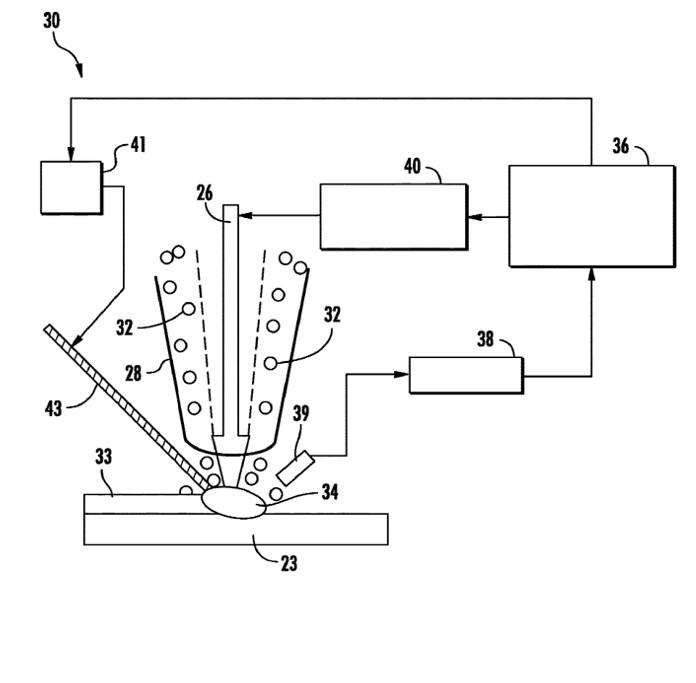

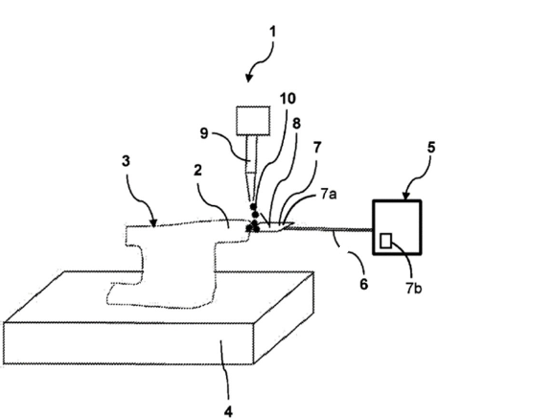

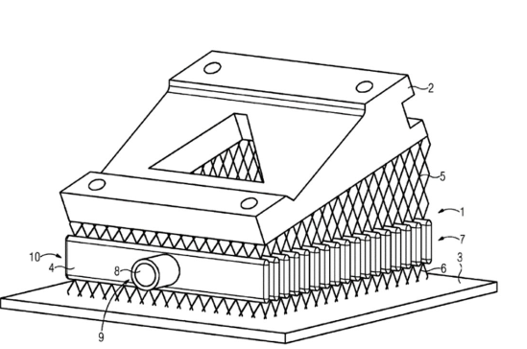

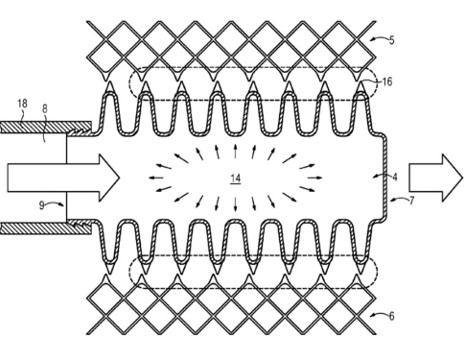

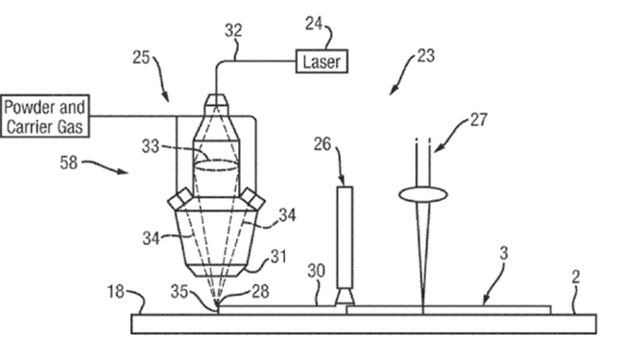

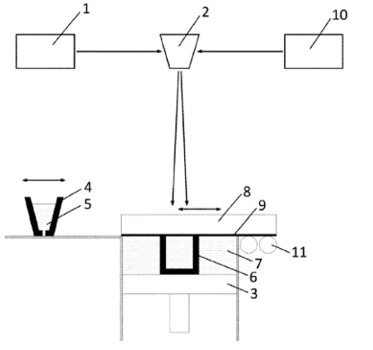

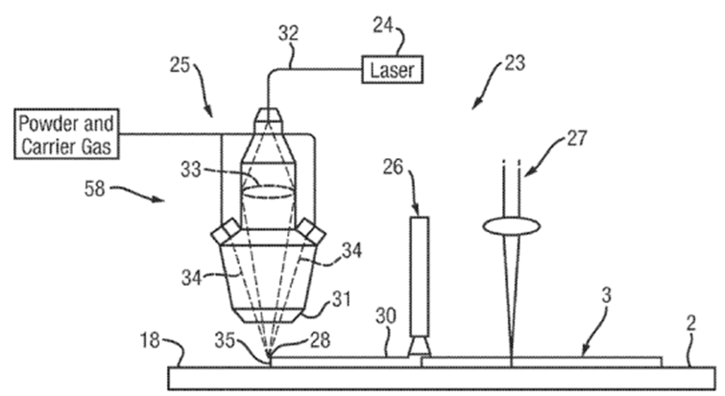

This place covers:

Processes where metal particles are deposited into a melt pool that has been generated on the surface of a substrate or previously fabricated preform by using an energy source, forming an article layer by layer. Typical energy sources are laser and electron beams and plasma.

Illustrative example of subject matter classified in this place:

Direct metal deposition [DMD]

Laser (26), DMD head (28), powder (32) and melt pool (34) are disclosed.

Attention is drawn to the following places, which may be of interest for search:

Metal wire melting to create build up weld |

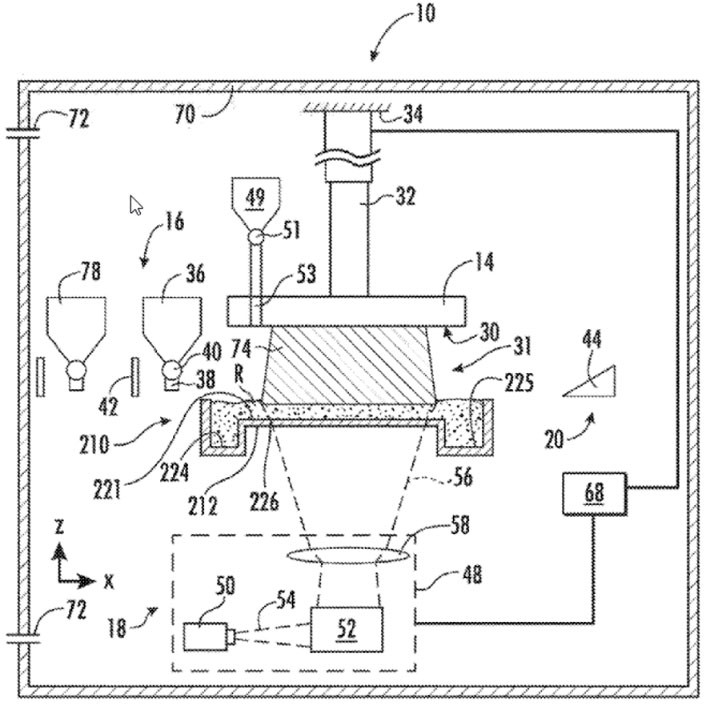

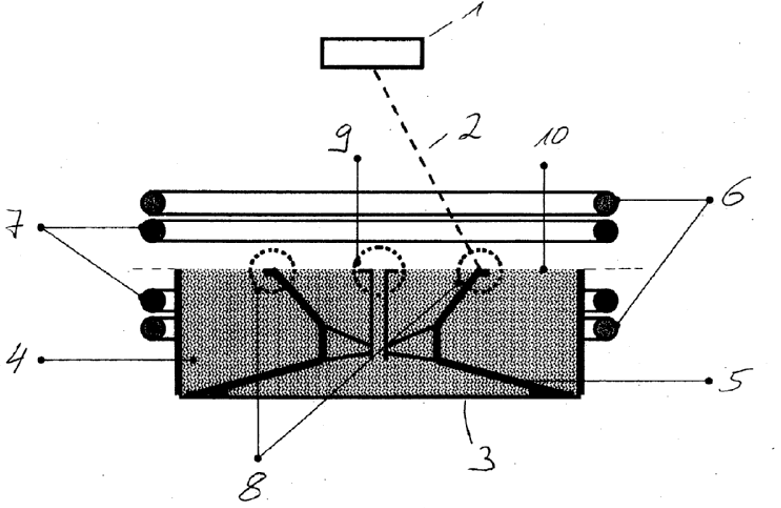

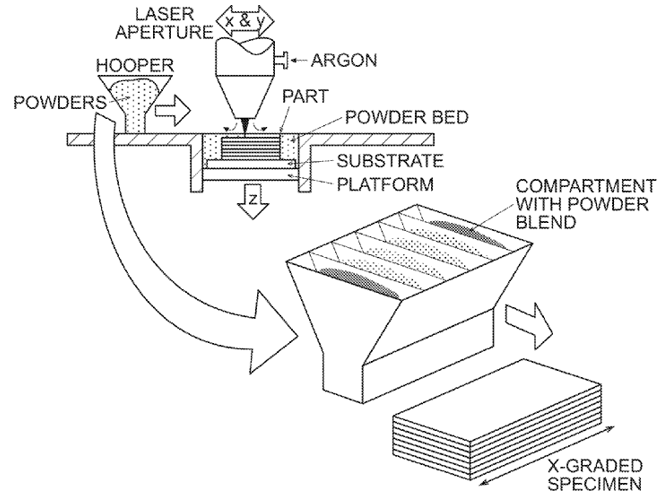

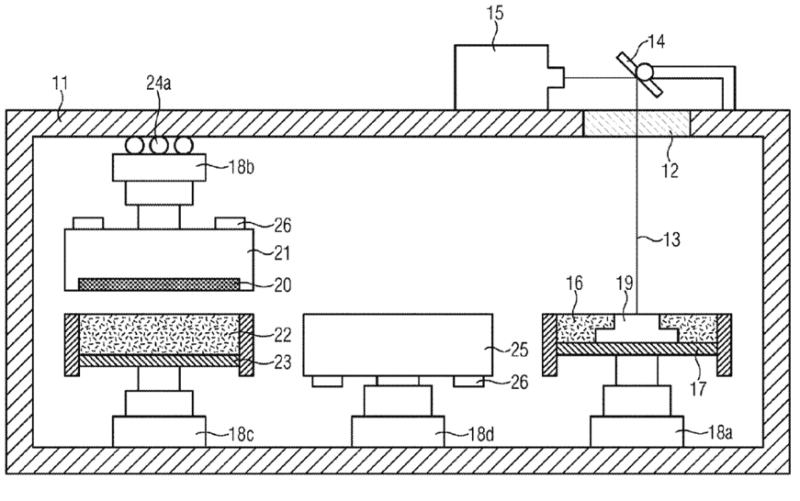

This place covers:

Processes where metal particles are selectively consolidated by melting or sintering them together using a heat source such as laser or electron beam. The powder surrounding the consolidated part acts as support material.

Illustrative examples of subject matter classified in this place:

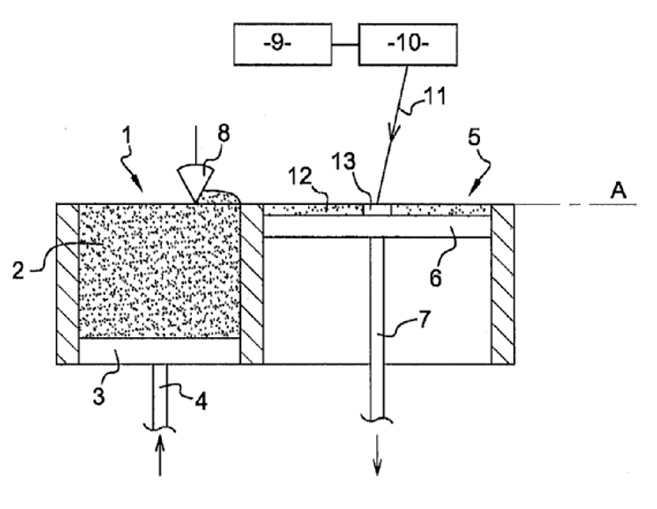

1.

Selective melting in powder bed using laser or electron beam (11).

2.

Electron beam (122) melting in powder (142) bed.

This place covers:

Operations performed before or during the additive manufacturing specially adapted for managing the additive manufacturing process by one or more additive manufacturing apparatuses.

This group typically comprises acquiring, sending or receiving data that will be used in additive manufacturing, either internal or external to the additive manufacturing apparatus.

Group B29C 64/393 concerns processes for additive manufacturing of plastics.

Group B22F 10/85 concerns data acquisition or data processing for controlling or regulating additive manufacturing processes.

This place covers:

Process control with the purpose of calibrating either process steps or apparatus settings, e.g. before or during manufacturing.

For example, the position of the laser beam spot is calibrated within the building plane in selective laser melting [SLM].

Illustrative example of subject matter classified in this place:

Calibration of irradiation system in SLM

This place covers:

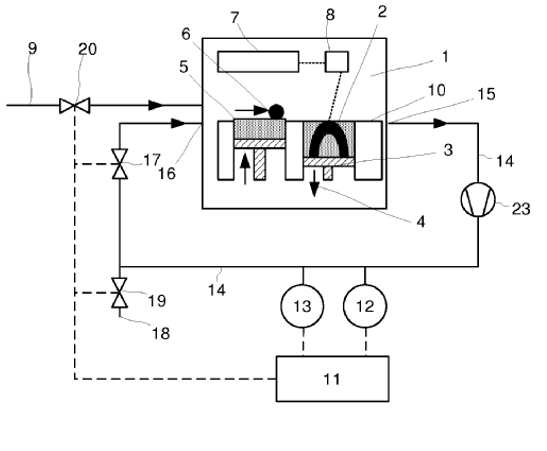

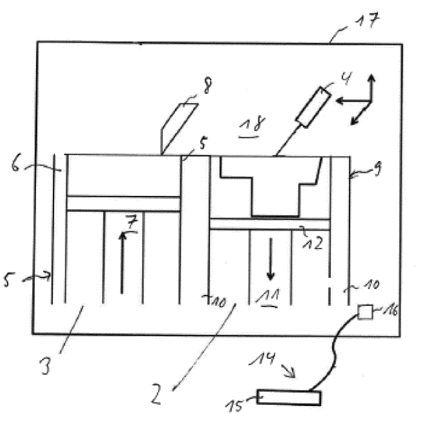

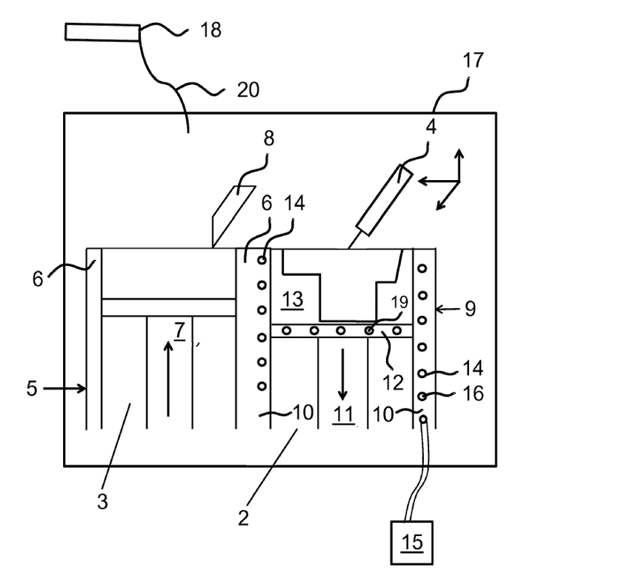

Process control with the purpose of controlling the atmosphere within the additive manufacturing apparatus, e.g. composition or pressure within a build chamber.

Illustrative example of subject matter classified in this place:

Atmosphere control for SLM using a hydrogen sensor (12) and an oxygen sensor (13) for controlling the atmosphere in the processing chamber (1) based on the sensor values.

Attention is drawn to the following places, which may be of interest for search:

Recycling of gas |

This place covers:

Process control with the purpose of controlling the gas flow, e.g. rate or direction, within the additive manufacturing apparatus before or during the additive manufacture.

Process control such as removal of fumes generated during the additive manufacture.

Illustrative examples of subject matter classified in this place:

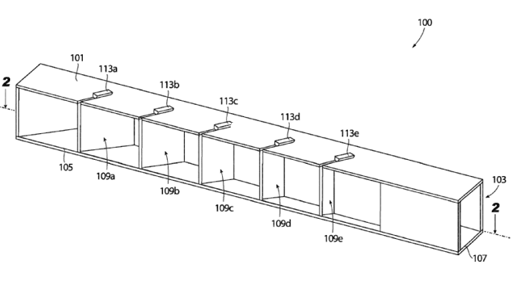

1.

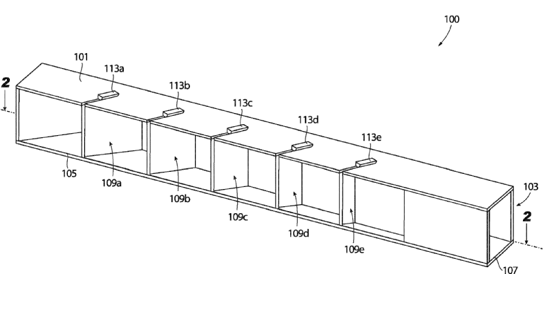

Controlling gas flow above the build plate, where flow filed sensor data is used to modify the flow with the help of actuators (113 a-e) connected to baffles (109 a-e) of an exhaust manifold (100).

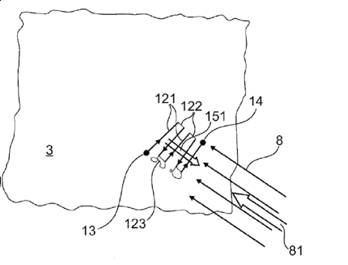

2.

Controlling shielding gas flow direction (81) dependent on, e.g. the direction of scanning (151).

Attention is drawn to the following places, which may be of interest for search:

Recycling of gas | |

Gas flow means |

This place covers:

Control of the powder characteristics before or during the additive manufacture. The powder characteristics are controlled or selected in a particular way.

Process control with respect to properties of powders before they are fed to the powder bed, such as control during mixing of powders, or while drying or protecting powders from oxidation.

Illustrative examples of subject matter classified in this place:

1.

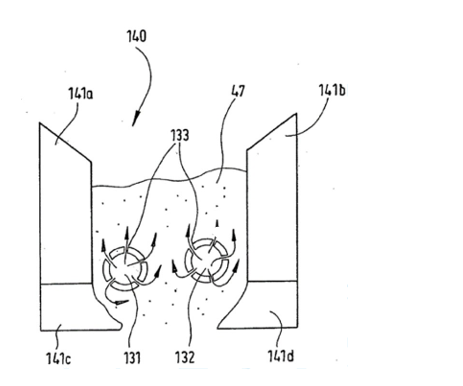

Control of fluidization of powder material (47) comprised in an application device (40) through a fluidization device integrated into the longitudinal walls (41a and 41b) of the application device (40).

2.

Control of fluidization of powder material (47) comprised in an application device (140) through a fluidization device (131 and 132) integrated within said application device (140).

The powders and their characteristics per se are classified in group B22F 1/00.

In this group, C-Sets (#B22Fc) are used. The detailed information about the C-Sets construction and the associated syntax rules are found in the "Special rules of classification" in B22F.

For example, where a particular aspect mentioned in B22F 1/00 is controlled, a C-Set should be included of the form (B22F 2999/00, B22F 10/34, B22F 1/00 and subgroups).

This place covers:

Process control related to the energy beam. Note that process control of other types of energy sources, such as LED arrays or lamps, is also classified here.

Controlling energy beam parameters, such as scan speed and intensity, is classified in B22F 10/36, while controlling energy beam parameters for the purpose of calibration is classified in B22F 10/31.

This place covers:

Process control with the purpose of providing preheating within the additive manufacturing apparatus by controlling the energy beam parameters, such as power or spot size, wherein preheating refers to any heating operation that takes place prior to the selective treatment of the powder, such as sintering, melting or binding, to form a section of the workpiece.

Preheating may relate to the heating of the metallic powder or may relate to the heating of the additive manufacturing apparatus, such as a build platform.

Illustrative example of subject matter classified in this place:

Preheating in selective laser melting/sintering [SLM/SLS]

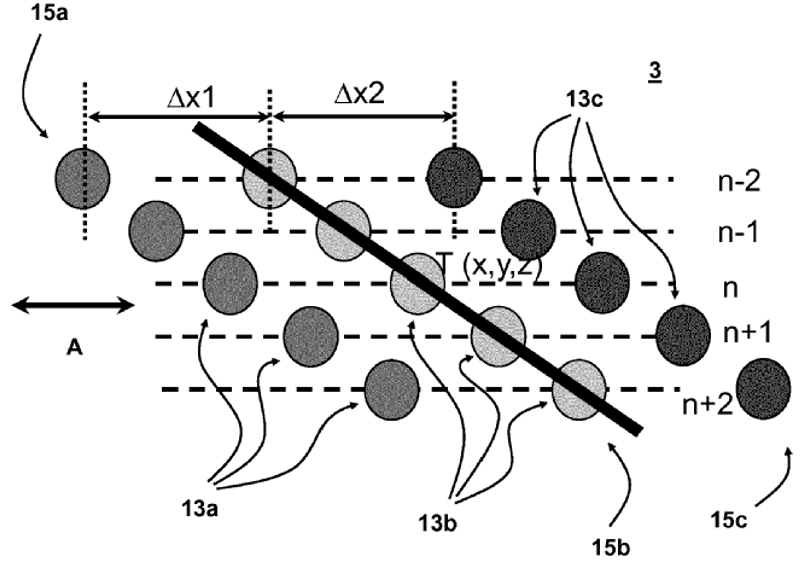

This place covers:

Process control with the purpose of providing post-heating within the additive manufacturing apparatus by controlling the energy beam parameters, such as power or spot size, wherein post-heating refers to any heating operation that takes place after the selective treatment of the powder, such as sintering, melting or binding, to form a section of the workpiece.

Post-heating may relate to the remelting of the section of the workpiece, typically for smoothening the surface.

Illustrative example of subject matter classified in this place:

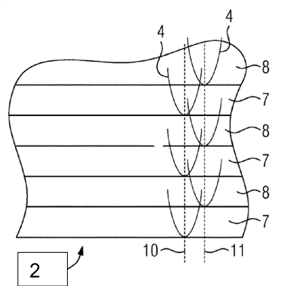

Arrays (15a‐c) of beam spots (13a‐13c) for both preheating (a) and post‐heating (c) in addition to fusing (b).

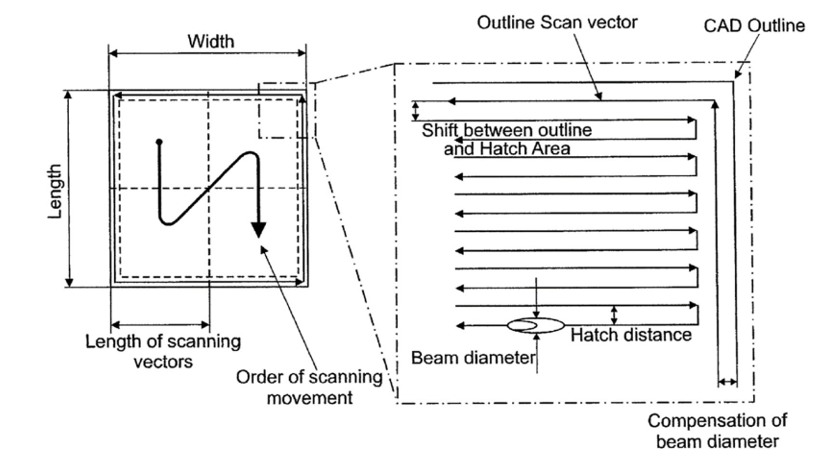

This place covers:

Process control with the purpose of controlling the beam parameters to implement a desired scanning. The aspect control may relate to scanning parameters, such as hatch distance, scan path, rastering, or overlap, or scan strategies to selectively sinter or fuse the powder in SLM or SLS, for example to improve productivity, optimize thermal conductivity or modify the microstructure of the workpiece.

Illustrative examples of subject matter classified in this place:

1. Track alignment in selective laser melting [SLM]

2.

SLS, where a contour position (10,11) of the object (2) is different for different layers (7,8).

This place covers:

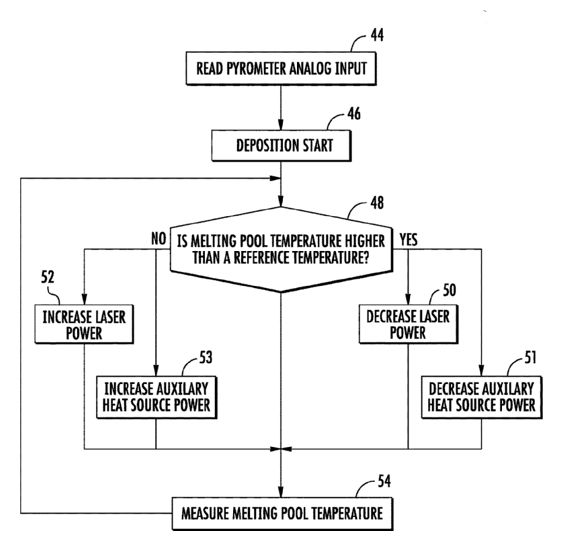

Process control with the purpose of controlling temperature or temperature gradients. The process aspect control may relate to operations such as controlling the temperature in the melt pool in SLM or temperature gradients within the workpiece (or within the powder bed in SLS or SLM).

Illustrative example of subject matter classified in this place:

Temperature control of melt pool

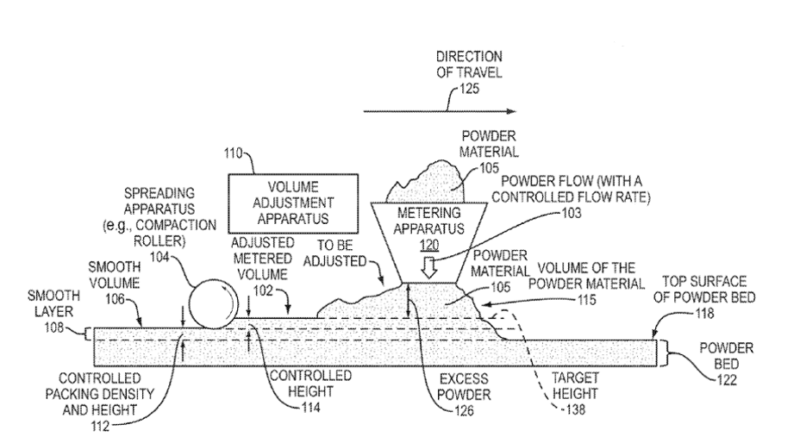

This place covers:

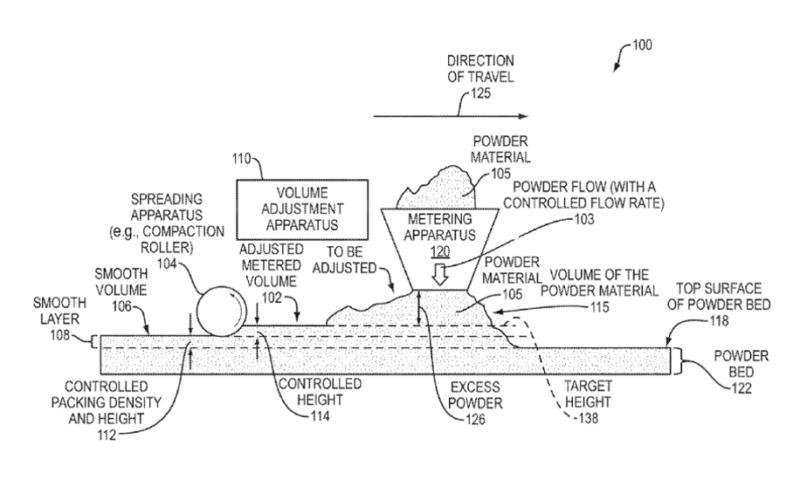

Powder bed aspects, e.g. smoothness of the bed, its density or the presence of defects, e.g. spatters.

Illustrative examples of subject matter classified in this place:

1. Control of powder bed aspect, packing density and height

2. Control of the fluidisation of the powder contained in the powder bed

Classification in group B22F 10/37 is made if the powder bed is seen as a distinct aspect or entity.

This place covers:

Process control with the purpose of achieving specific properties of the manufactured product, such as surface smoothness, density, porosity or specific microstructure or grain orientation.

Illustrative example of subject matter classified in this place:

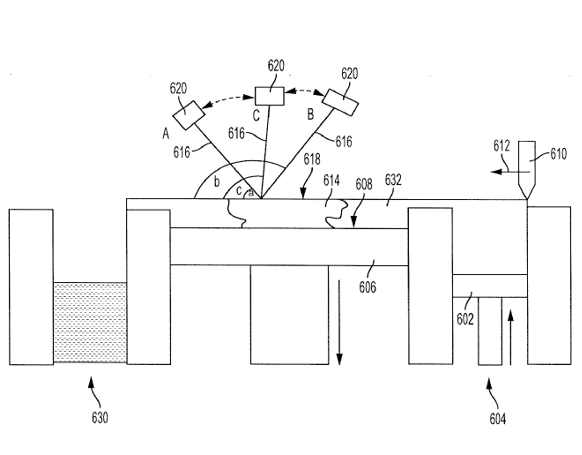

Additively manufacturing a turbine engine component, where grain orientation is controlled by varying the laser (616) irradiation angle (a, b, c) of the galvanometric scanner (620).

This place covers:

Processes to control the formation of overhanging structures including down-skin surfaces and hollow portions inside the product by means other than support structures.

Illustrative example of subject matter classified in this place:

A method for manufacturing a component having an overhang, wherein a local build-up angle (α), which occurs between two consecutive layer sections (15) of an overhang, does not fall below a predetermined minimum build-up angle to the base layer.

Attention is drawn to the following places, which may be of interest for search:

Structures for supporting workpieces or articles during manufacture and removed afterwards |

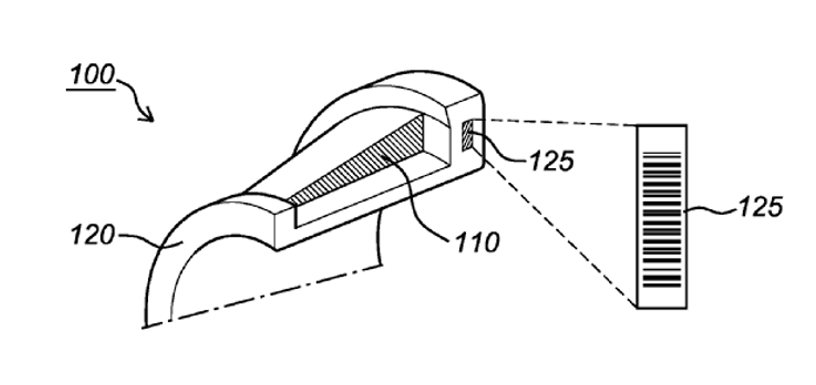

This place covers:

Process control concerning the history of a workpiece by means of documented recorded identification.

The history of the workpiece may include information relating to any step occurring before, during or after the additive manufacture of the workpiece, such as the material used to manufacture the workpiece, parameter values during the additive manufacture, plant location or customer name.

Traceability may be achieved by incorporating an identifier into the workpiece.

Illustrative example of subject matter classified in this place:

Identification barcode (125).

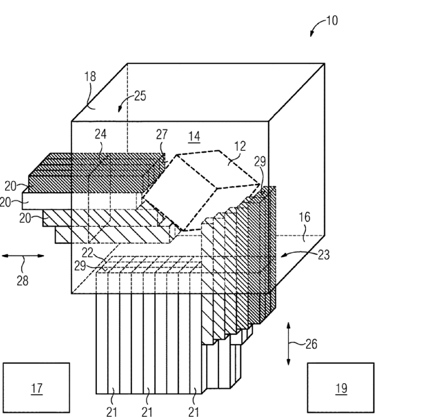

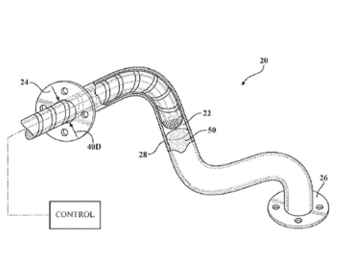

This place covers:

Process aspects relating to the provision of a support structure for the workpiece during its manufacture.

The term support structure may relate to a structure additively generated simultaneously with the workpiece, as it is typically the case in powder bed techniques, or may relate to an external support provided to enable the generation of a specific portion of the workpiece subjected to (mechanical) stress, such as may be the case in direct deposition techniques. The support structure is removed afterwards to recover the workpiece. The support structure does not need to be attached to the object to fulfil the requirement of conducting heat away from the object as in powder bed fusion.

Support devices as an alternative to additively manufactured support structures are also included in this group.

Illustrative examples of subject matter classified in this place:

1.

Support device (5) with at least one movable support arm (6) for temporary holding of at least one support element (7) arranged on the support arm during the additive manufacturing of a particular component (3) above the building platform (4).

2.

Bar elements (20, 21) for supporting manufactured article (12).

Attention is drawn to the following places, which may be of interest for search:

Structures for supporting 3D objects during manufacture and intended to be sacrificed after completion thereof |

This place covers:

Process aspects relating to the material selected to form the structure supporting the workpiece during its manufacture. The material is selected for a specific purpose, such as to facilitate the removal of the support structure or to improve its thermal conductivity.

Illustrative example of subject matter classified in this place:

Support structure (20) material with high thermal conductivity.

This place covers:

Process aspects relating to structural features of the structure supporting the workpiece during its manufacture. The structural features serve a specific purpose, such as to facilitate the removal of the support structure or to improve the mechanical support.

Illustrative example of subject matter classified in this place:

1a.

The support structure (1) connects the printed part (2) to the building plate (3). It comprises a first part (6), being arranged on the building plate (3), and a second part (5), being arranged below the printed part (2). The support structure (1) comprises a third part (4) which is arranged at a centre part (10) of the structure part (1), above the first part (6) and below the second part (5).

1b.

The bellows (4) comprises a pipe connector (8), forming one open end portion (9). The geometry of the bellows (4) makes it flexible and gives it the capability of elongating when a pressure (14) is applied on its internal surface.

This place covers:

Process aspects relating to treatment applied to the workpiece during the additive manufacturing process itself, such as treatment provided to a specific section of the workpiece to achieve a specific purpose, e.g. to change the microstructure or improve the mechanical properties.

The treatments might be:

- chemical, such as leaching, coating or passivation;

- mechanical, such as removing material for forming recesses, removing material for grinding/polishing the surface or calibration or partial local deformation of the surface, e.g. sand blasting, shot peening, laser shock peening or ultrasonic peening;

- by means of electric, magnetic or electromagnetic fields;

- thermal treatment.

Illustrative examples of subject matter classified in this place:

1.

Direct energy deposition (25) of metallic powder + cryogenic quenching treatment (26) + laser shock peening (27).

2.

Applying laser shock peening between forming subsequent layers in SLM.

This place covers:

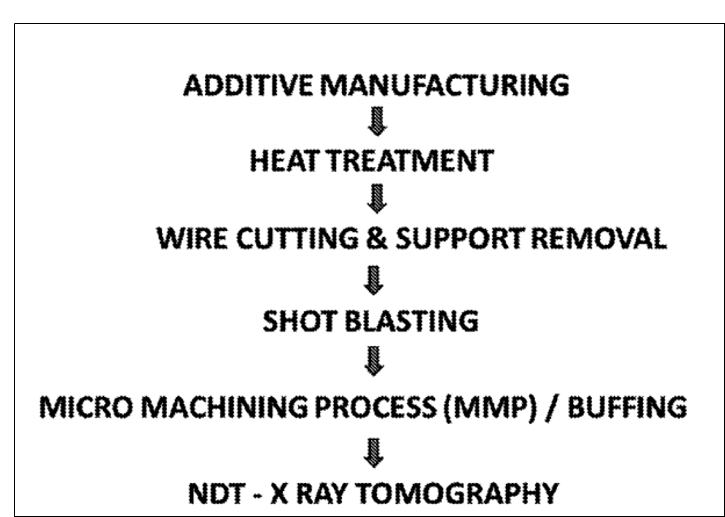

Process aspects relating to treatments applied to the workpiece after its manufacture.

Removing support structures.

B22F 3/24 concerns after treatment of powder metallurgy articles in general, whereas B22F 10/60 concerns after treatment of articles made by additive manufacturing.

Attention is drawn to the following places, which may be of interest for search:

Structures for supporting workpieces or articles during manufacture and removed afterwards |

This place covers:

Process aspects relating to chemical treatments applied to the workpiece after its manufacture to serve a specific purpose such as to improve wear-, corrosion- or heat- resistance or to reduce surface rugosity. Typical chemical treatments may include leaching, coating or passivation.

Removing support structures by chemical means such as dissolution or electrochemistry.

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Coating metallic material; Coating material with metallic material; Surface treatment of metallic material by diffusion into the surface, by chemical conversion or substitution; Coating by vacuum evaporation, by sputtering, by ion implantation or by chemical vapour deposition, in general | |

Processes for the electrolytic or electrophoretic production of coatings | |

Processes for the electrolytic removal of material from objects |

This place covers:

Process aspects relating to thermal treatments applied to the workpiece after its manufacture to serve a specific purpose such as to remove organic binders or to reduce porosity or modify the microstructure or mechanical properties. Typical thermal treatments may include thermal de-binding, sintering, hot isostatic pressing or annealing.

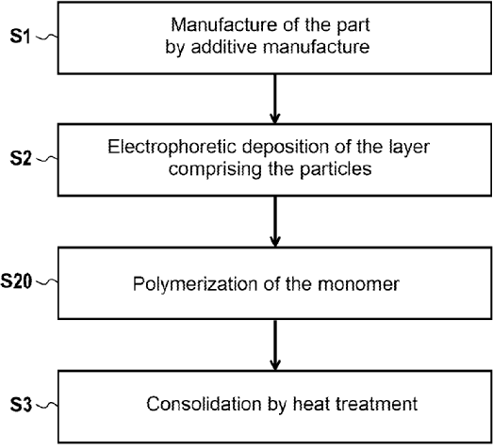

Illustrative example of subject matter classified in this place:

1.a

Step 1: Manufacture of a workpiece by selective laser sintering/melting [SLS/SLM].

1.b

Step 2: Hot isostatic pressing after SLS/SLM to increase the density of the workpiece.

This place does not cover:

Control of energy beam parameters for post heating |

Attention is drawn to the following places, which may be of interest for search:

Sintering | |

Removal of binder or filler | |

Hot isostatic pressing | |

Both compacting and sintering in successive or repeated steps | |

Thermal after-treatment of workpieces or articles |

In this group, C-Sets are used. The detailed information about the C-Sets construction and the associated syntax rules are found in the Special rules of classification in B22F.

For example, after-treatments corresponding to specific processes in B22F 3/00, e.g. hot isostatic pressing [HIP] in B22F 3/15 or removal of binder in B22F 3/1021, should also be classified with a C-Set of the following type, the example being for SLM followed by HIP: (B22F 2998/10, B22F 10/64, B22F 3/15).

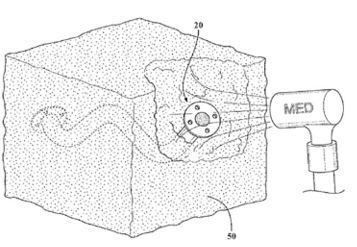

This place covers:

Process aspect relating to mechanical treatments applied to the workpiece after its manufacture to serve a specific purpose such as to modify the shape, surface finish, mechanical properties or microstructure of the workpiece.

Typical mechanical treatments applied to the workpiece may include removing material such as by grinding, polishing, sand blasting or local deformation of the workpiece surface such as shot peening, laser shock peening or ultrasonic peening.

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Partial deformation or calibration in the successive or repeated steps of manufacture of metallic workpieces or articles from metallic powder | |

Making recesses, grooves etc. on the surface by removing material | |

Removing material: carving, cleaning, grinding, hobbing, honing, lapping, polishing, milling, shaving, skiving or turning the surface |

When classifying the treatment of the workpieces in B22F 10/66, the after treatments corresponding to specific processes in B22F 3/00 should also be classified there, e.g. removing material should be classified in B22F 2003/247.

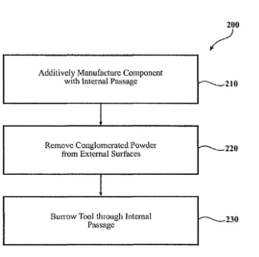

This place covers:

Process aspects relating to cleaning or washing operations performed on the workpiece after its manufacture.

Depowdering, i.e. cleaning or washing operations relating to the removal of residual powder within or on the workpiece.

Illustrative examples of subject matter classified in this place:

1.

2.

3.

Attention is drawn to the following places, which may be of interest for search:

After-treatment of metallic workpieces or articles by removing material: carving, cleaning, grinding, hobbing, honing, lapping, polishing, milling, shaving, skiving or turning the surface | |

Cleaning in general; Prevention of fouling in general |

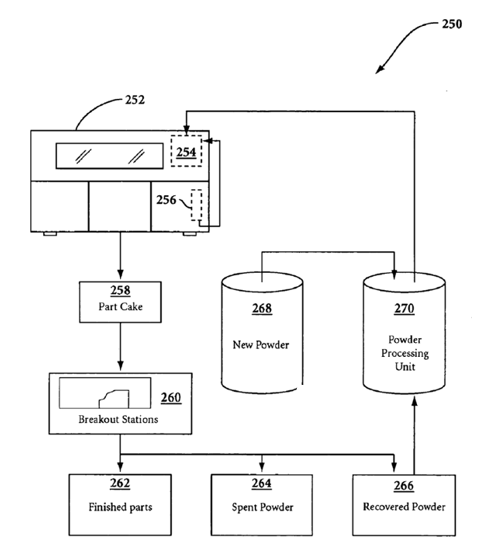

This place covers:

Process aspects relating to recycling operations, which may occur before, during or after the additive manufacture of the workpiece.

This place covers:

Process aspects relating to recycling operations of the powder used for the additive manufacture of the workpiece. The process aspects may relate to operations such as recycling powder overflow when laying down a layer of powder in selective laser sintering [SLS] or selective laser melting [SLM], or to recycling of powder resulting from cleaning operations of the workpiece after build-up.

Illustrative example of subject matter classified in this place:

This place covers:

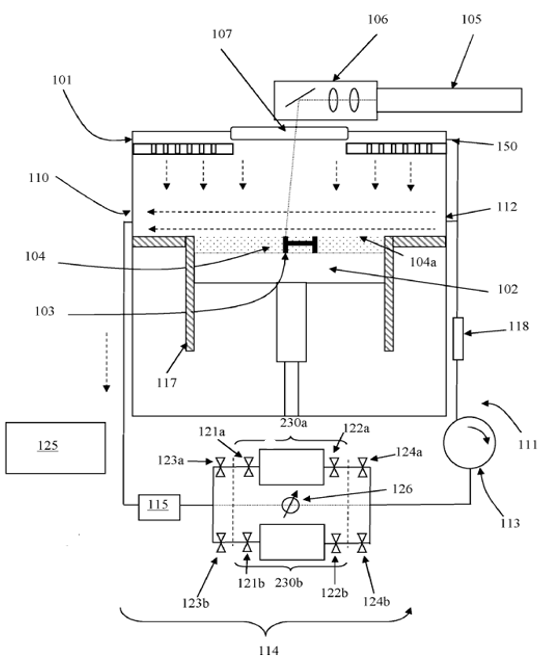

Process aspects relating to recycling operations of gas used for the additive manufacture of the workpiece. The process aspects may relate, for example, to filter arrangements for cleaning the process gas from fumes or particles generated by the selective irradiation of powder in SLM or SLS.

Illustrative example of subject matter classified in this place:

SLS/SLM apparatus with filter system (114). Process emissions, such as spatters and condensates are removed from the process gas by the filter system (114) before gas recirculation within the build chamber (101).

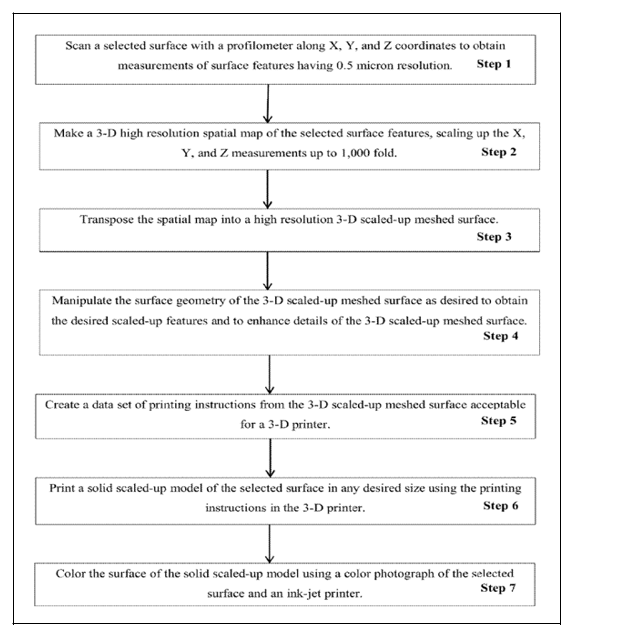

This place covers:

Process aspects relating to data acquisition or data processing, which take place before, during or after the additive manufacture of the workpiece.

Simulation steps for generating a three-dimensional model of the workpiece to be manufactured.

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Electric digital data processing | |

Computer-aided design applied to additive manufacturing |

This place covers:

Process aspects relating to data acquisition or data processing for controlling the additive manufacture of the workpiece. For instance, using a database of previous manufacturing runs to determine process parameters.

Data acquisition for quality checks of the workpiece and/or the functioning of the manufacturing apparatus itself during or after build-up.

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Apparatus for additive manufacturing of plastics or material in a plastic state; Details thereof or accessories therefor | |

Apparatus for additive manufacturing; Details thereof or accessories therefor | |

Typewriters or selective printers for marking on special material | |

Electron guns | |

Discharge tubes for applying thin layers on objects | |

Electron sources; Electron guns, arrangements of electrodes and associated parts for generating or controlling the discharge,with provision for introducing objects or material to be exposed to the discharge | |

Devices using the process of light amplification by stimulated emission of radiation [laser] to amplify or generate light; Devices using stimulated emission of electromagnetic radiation in wave ranges other than optical | |

Apparatus or processes for manufacturing printed circuits using printing techniques to apply the conductive material |

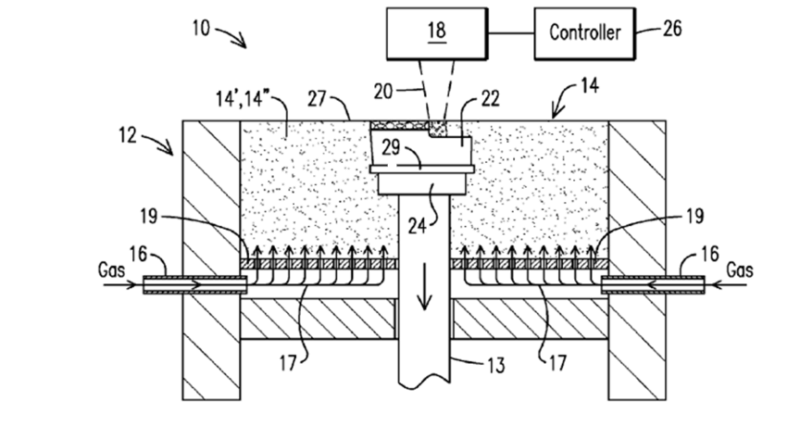

This place covers:

Devices comprising auxiliary heating means for a purpose other than preheating the powder material or heating the build chamber or build platform. The auxiliary heating means may relate to heating means for heating a process gas or the manufactured article, for example.

Illustrative examples of subject matter classified in this place:

1.

Heating means (36) to heat the process gas.

2.

Induction heating coils (6, 7) and heating component (5) in powder bed in container (3).

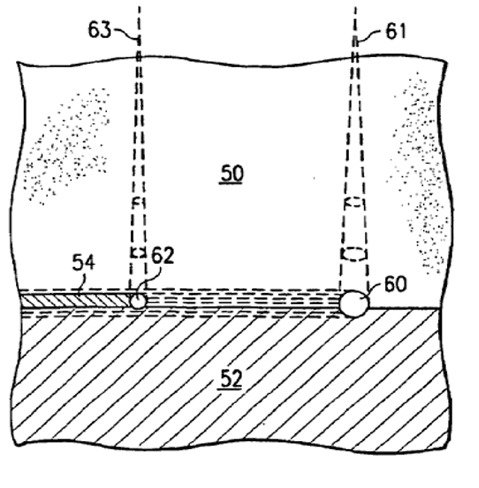

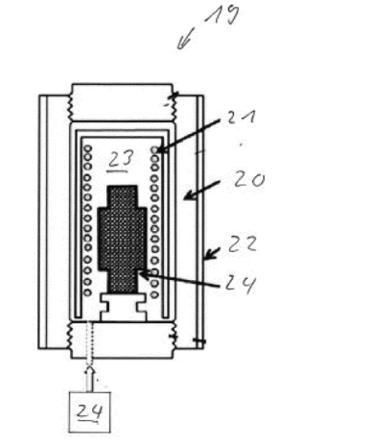

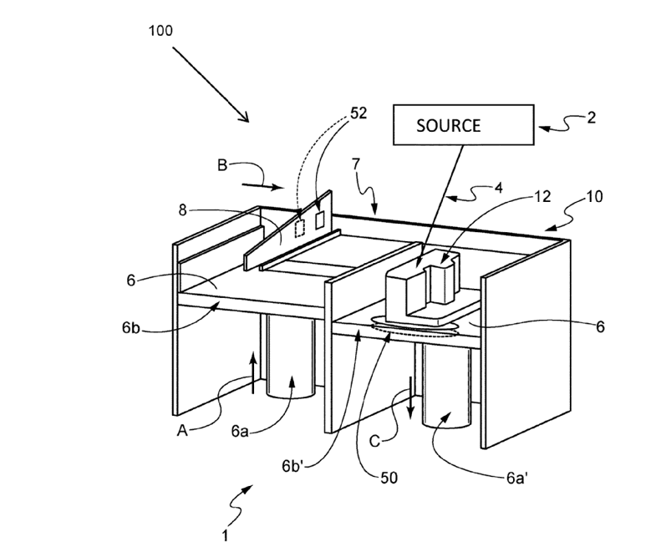

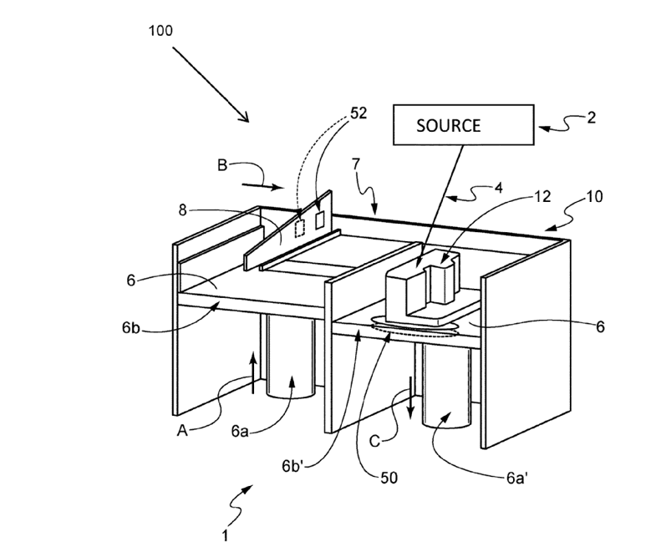

This place covers:

Devices comprising auxiliary heating means for directly preheating the powder material used to additively manufacture a workpiece. For instance, lamps or coils above the powder bed. Auxiliary heating means for heating a material in the powder feeding device, e.g. hopper.

Illustrative example of subject matter classified in this place:

Illuminators (52) to preheat the powder in the powder bed (6), where the manufacture of the workpiece (12) takes place.

This place covers:

Devices comprising auxiliary heating means for heating the build chamber or platform.

Illustrative example of subject matter classified in this place:

Induction system (50) to heat the build platform (6b').

In this place, the following terms or expressions are used with the meaning indicated:

build chamber | powder bed sleeve |

This place covers:

Devices comprising cooling means such as cooling fluid circuits in the build platform or build chamber housing in selective laser sintering [SLS] or selective laser melting [SLM] devices or cooling fluid nozzles above the powder bed.

Illustrative examples of subject matter classified in this place:

1.

Cooling chamber (14) in the wall (10) of the build chamber of an SLS/SLM apparatus.

2.

Direct energy deposition (25) of metallic powder with subsequent cryogenic quenching treatment (26).

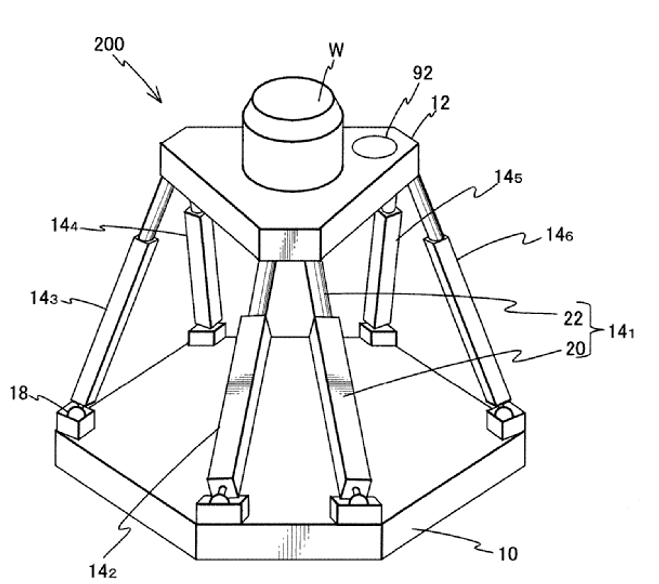

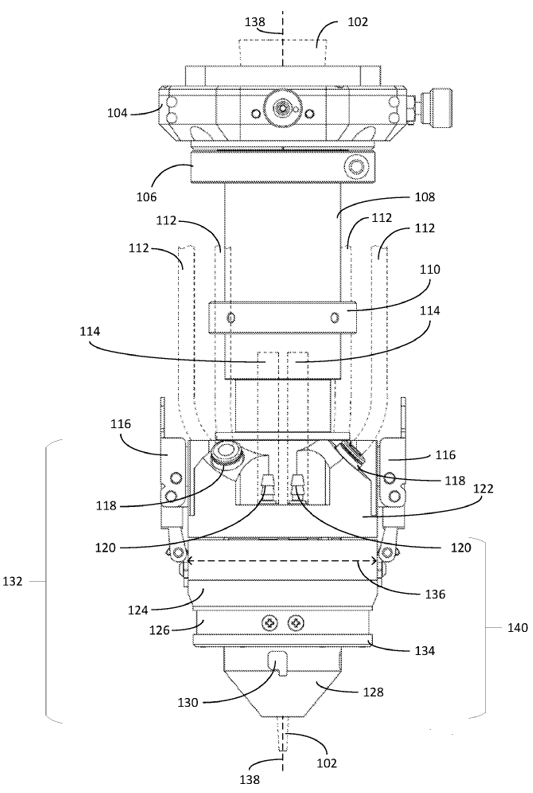

This place covers:

Driving means capable of motion along all directions, possibly including rotation.

Illustrative example of subject matter classified in this place:

Table (12) for holding workpiece (W), positionable with 6 degrees of freedom by pneumatic control of rods (14).

In this group, C-Sets are used. The detailed information about the C-Sets construction and the associated syntax rules are found in the Special rules of classification in B22F.

For example, a type of motion of the radiation means or platform not provided for in the respective subgroups and motion of other components can be classified using a C-Set. A cooling means with vertical motion is classified as (B22F 2999/00, B22F 12/20, B22F 12/222).

When the invention is in the construction of the driving means for moving a platform or radiation means, the appropriate group(s) under B22F 12/22 should be given in addition to the groups related to movement of those components in general:

- Translatory movement of the radiation means is covered by B22F 12/46.

- Movement of the platform by translation in the deposition place is covered by B22F 12/33 and rotation of the platform by B22F 12/37.

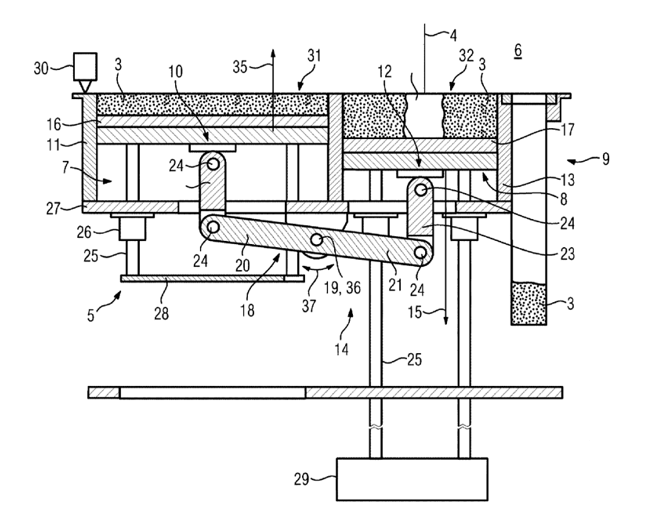

This place covers:

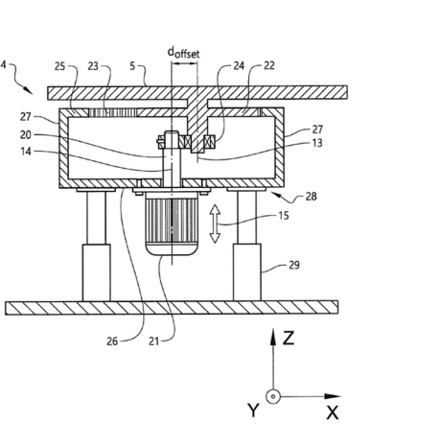

Devices comprising driving means for motion along a direction orthogonal to the plane of a build layer.

Illustrative example of subject matter classified in this place:

Lever device (14) providing vertical motion of build plate carrier (12) and dose plate carrier (10) in a selective laser sintering melting [SLS/SLM] apparatus.

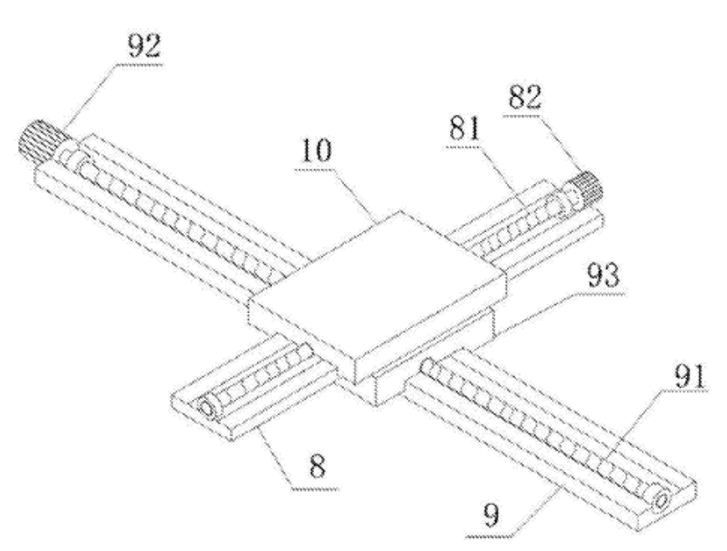

This place covers:

Devices comprising driving means for motion along a direction within the plane of a build layer.

Illustrative example of subject matter classified in this place:

A platform (10) movable in the deposition plane using screw motors (82, 92).

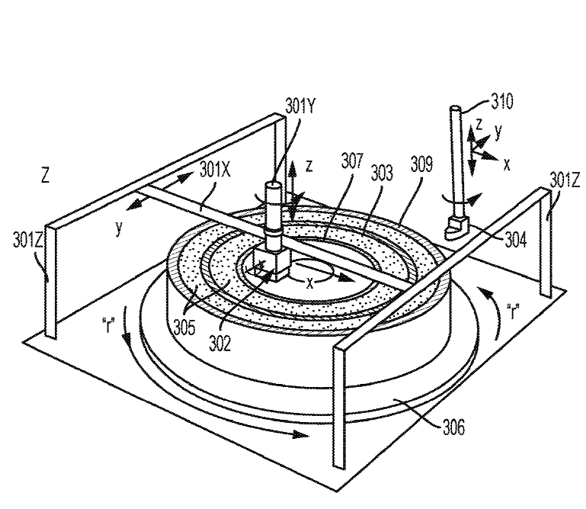

This place covers:

Devices comprising driving means for rotary motion.

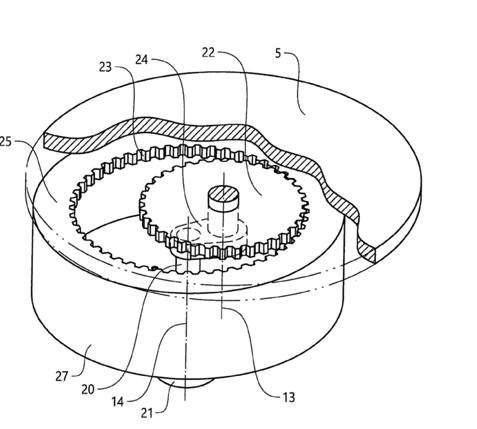

Illustrative examples of subject matter classified in this place:

1.

Driving means (20‐25) to provide rotation and increase tangential speed at the centre region of the build platform (5) in a selective laser sintering/melting [SLS/SLM] apparatus.

2.

Driving means (20‐25) to provide rotation of the build platform (5) in an SLS/SLM apparatus.

This place covers:

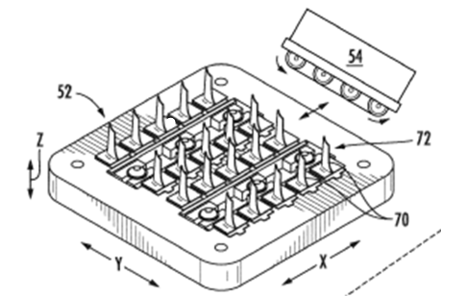

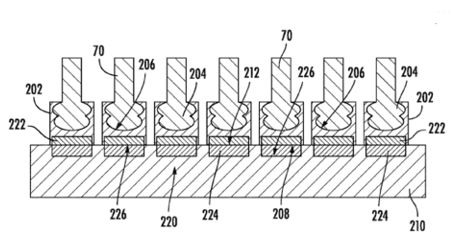

Means for receiving the material from which workpieces will be additively manufactured. Typical means are, for example, a build platform in an SLM or SLS device movable in a vertical direction.

Illustrative example of subject matter classified in this place:

1a.

1.b

Build platform (210) for powder bed based additive manufacturing gas turbine blades (70) comprising component fixtures (202) for holding worn air foils.

In this group, C-Sets are used. The detailed information about the C-Sets construction and the associated syntax rules are found in the Special rules of classification in B22F.

For platforms movable in a more complex fashion than translation and rotation, a C-Set together with groups B22F 12/22 - B22F 12/226 can be used. For example, a platform that is movable with 6 degrees of freedom is classified as (B22F 2999/00, B22F 12/30, B22F 12/22).

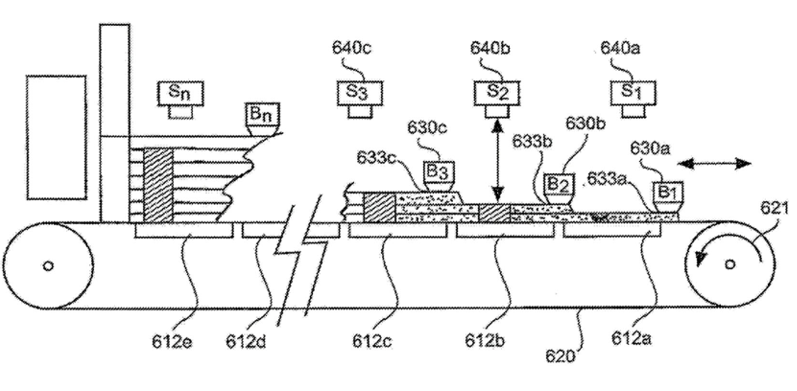

This place covers:

Means for receiving the material from which workpieces will be additively manufactured and which are able to move in translation in the deposition plan, such as platforms moved by a belt.

Illustrative example of subject matter classified in this place:

Substrates (612a‐e) in translator movement within deposition plane.

This place covers:

Means for receiving the material from which workpieces will be additively manufactured and which are rotatable or can be tilted. For example, a rotatable build platform in an SLS/SLM device.

Illustrative example of subject matter classified in this place:

Rotatable build platform (306) for powder bed fusion.

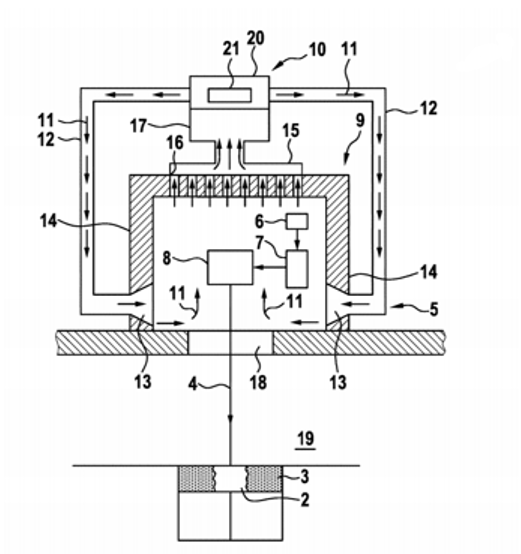

This place covers:

Specific features of any housing within the additive manufacturing apparatus, not just the housing of the apparatus as a whole. For example, the features may relate to the build chamber housing, the powder reservoir housing (build box) or the energy source housing.

The features of the housing may relate to aspects such as thermal insulation, gas- or powder-tightness or gas flow.

Illustrative example of subject matter classified in this place:

Housing (9) for irradiation device provided with stream inlet (13) and vents (16) for generating a gas stream.

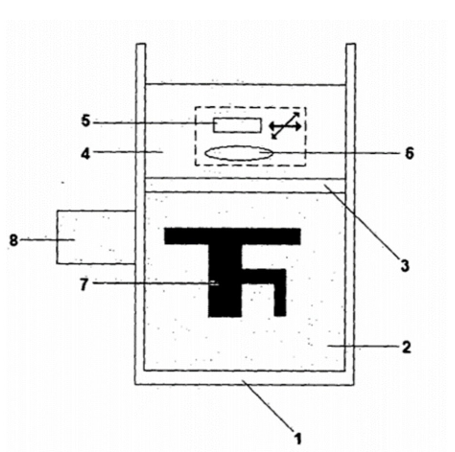

This place covers:

Device aspects relating to the type of radiation means for selectively fusing or binding particles together.

The radiation means may be of the electromagnetic type, such as laser, ultraviolet or infrared lamps, or of the particulate type, such as an electron beam, or of the acoustic type, such as ultrasound.

Illustrative example of subject matter classified in this place:

Focused ultrasound additive manufacturing powder bed (2) with ultrasound source (5) and ultrasound optics (6).

Attention is drawn to the following places, which may be of interest for search:

Auxiliary heating means | |

Welding for purposes other than joining | |

Electron-beam welding for purposes other than joining | |

Non-electric welding by making use of vibrations, e.g. ultrasonic welding | |

Build-up laser welding |

This place covers:

Devices comprising light emitting diodes [LED] as radiation means.

Illustrative example of subject matter classified in this place:

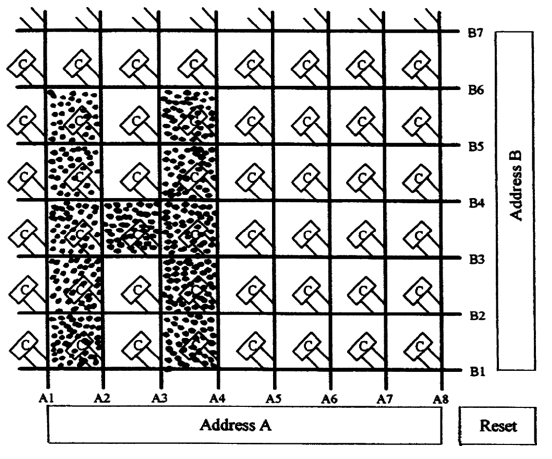

Programmable planar LED light source matrix for curing binder in a metal powder bed to bind the metallic powder in a selected area (H) at once to increase the build speed compared to a point-by-point illumination.

This place covers:

Devices comprising pulsed, frequency modulated radiation means such as, for example, pulsed laser for selectively fusing or binding particles together in selective laser sintering [SLS] or selective laser melting [SLM].

Illustrative examples of subject matter classified in this place:

1.

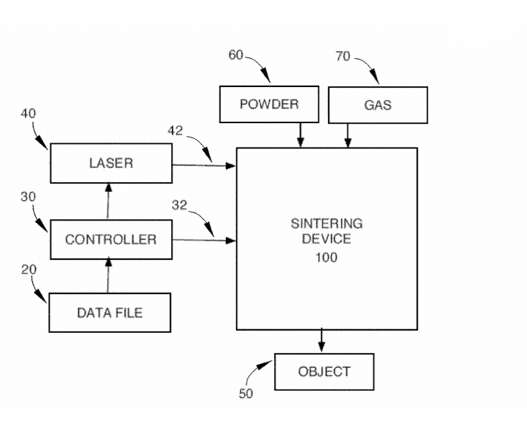

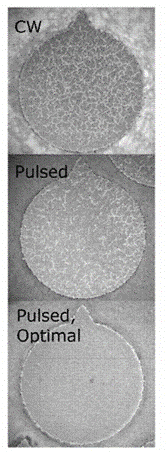

Selective laser melting/sintering [SLM/SLS] by pulsed laser (40) to reduce porosity or microcracks in Al alloys.

2.

Comparison of pulsed wave/continuous wave laser [CW] for Al alloys reduction of microcracks with pulsed wave laser.

This place covers:

Devices characterised by a spatial relation or features of the radiation means.

Illustrative example of subject matter classified in this place:

SLM apparatus with a laser source (10) and optics for creating a focused beam (58, 96) and an unfocused beam.

This place covers:

Devices with multiple radiation means.

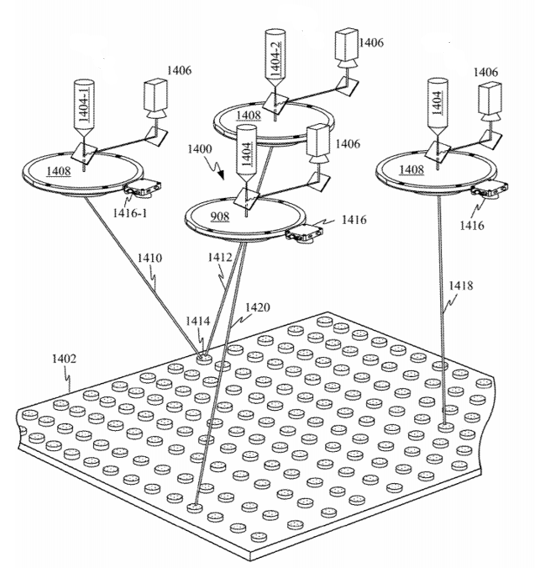

Illustrative example of subject matter classified in this place:

Selective laser melting [SLM] with multiple lasers (1404, 1404‐1, 1404‐2). Each laser is configured to fuse particles in a defined region of the build plane (1402).

This place covers:

Devices comprising radiations means able to move in translation.

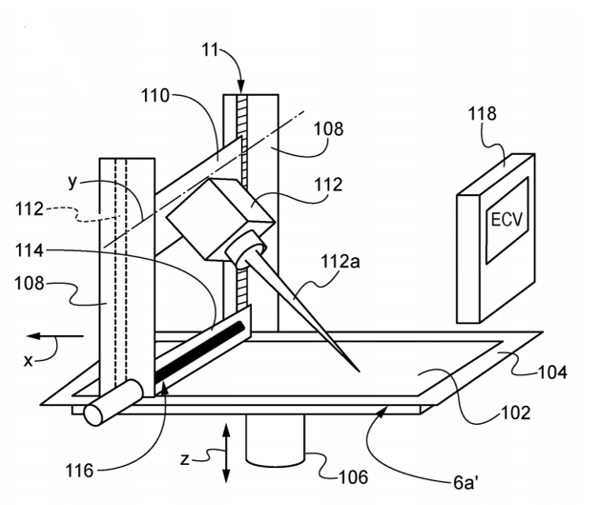

Illustrative example of subject matter classified in this place:

SLM with a laser diode source (112) moving in translation along direction x and vertically by means of cross member (110).

In this group, C-Sets are used. The detailed information about the C-Sets construction and the associated syntax rules are found in the Special rules of classification in B22F.

For radiation means movable in a more complex fashion than translation, a C-Set together with groups B22F 12/22 - B22F 12/226 can be used. For example, a radiation means movable with 6 degrees of freedom is classified as: (B22F 2999/00, B22F 12/40, B22F 12/22).

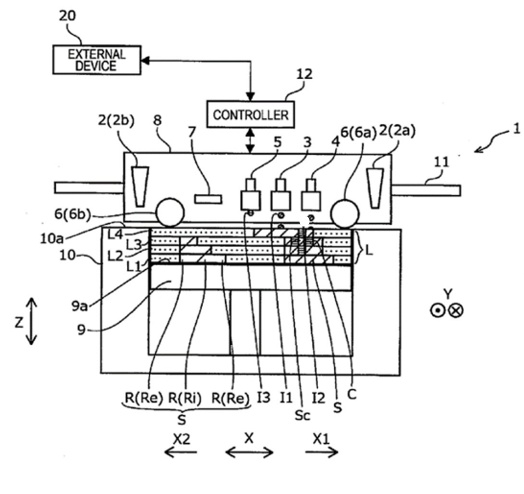

This place covers:

Devices comprising radiation means able to move in translation within the deposition plane, such as a laser moving in translation within the deposition plan in selective laser sintering [SLS], selective laser melting [SLM] or direct metal deposition [DMD].

This place covers:

Devices comprising radiation means able to move in the vertical direction, such as a laser moving vertically in selective laser sintering [SLS], selective laser melting [SLM], or direct metal deposition [DMD].

This place covers:

Devices for scanning an energy beam along the surface of, e.g. the powder bed.

Devices such as galvanometric scanners and digital micromirror devices.

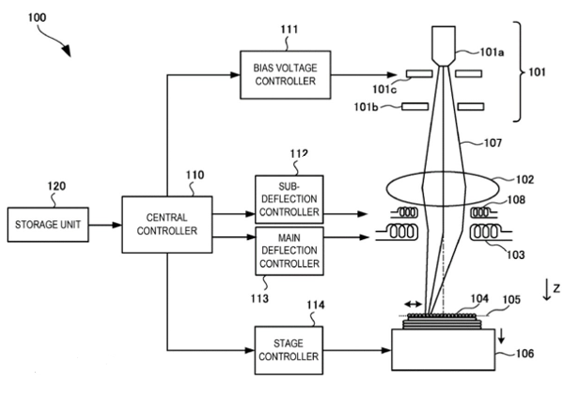

Illustrative example of subject matter classified in this place:

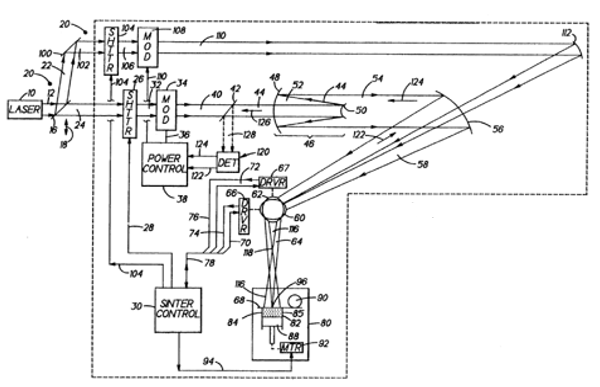

Electron beam melting apparatus (100) with a main deflector (103) and a sub-deflector (108).

This place covers:

Means for feeding materials, e.g. build or support materials, to the process or apparatus.

For instance, containers alongside the powder bed build sleeve, from which powder is supplied to a recoater blade by raising the bottom of the reservoir.

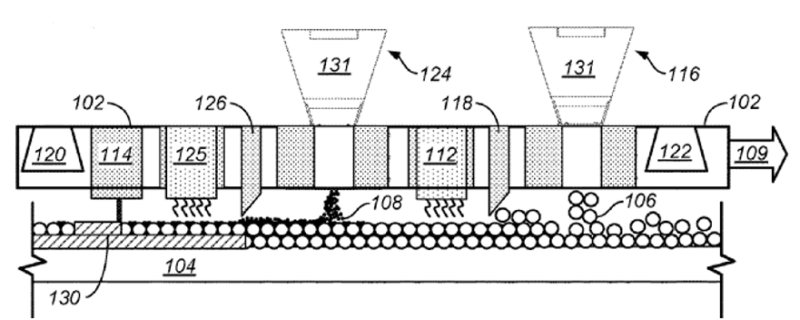

Illustrative example of subject matter classified in this place:

Printhead (102) for powder bed devices comprising means for feeding material (131).

This place covers:

Hoppers for feeding, e.g. build or support material. For instance, in powder bed devices, the hoppers are reservoirs from which powder is supplied to a recoater blade by the powder being deposited on the working surface from above.

Illustrative example of subject matter classified in this place:

Powder hopper for SLM

This place covers:

Nozzles for feeding of material. For instance, nozzles for depositing metallic particles, such as in DMD, molten metal or a mixture comprising metal particles and a binder, such as deposition by extrusion, onto a platform or substrate. Nozzles such as those for feeding organic binder in powder bed devices should also be classified here.

Illustrative examples of subject matter classified in this place:

1.

System assembly (70) for extruding material, comprising a binder and a filler. The assembly (70) comprises a mixing device (76, 78), a heating device (80) and an outlet nozzle (82).

2.

Laser metal deposition head (132) comprising a nozzle assembly (140). The powder is provided to powder inlets (118) and guided through the nozzle assembly (140) to the focal point of the laser beam (102).

Attention is drawn to the following places, which may be of interest for search:

Spraying apparatus; Nozzles | |

Apparatus for applying fluent materials to surfaces | |

Heads, nozzles of additive manufacturing apparatus for plastics | |

Selective printing mechanisms, i.e. mechanisms printing otherwise than from a form |

This place covers:

Multiple means for feeding material. For instance, one feeding mean on each side of a build platform or substrate in powder bed devices.

This place covers:

Means for metering material. For instance, means for metering powder material to be deposited onto a build platform or substrate in powder bed devices.

Illustrative example of subject matter classified in this place:

Powder bed device

The powder material (105) is metered onto the top surface (118) of the powder bed.

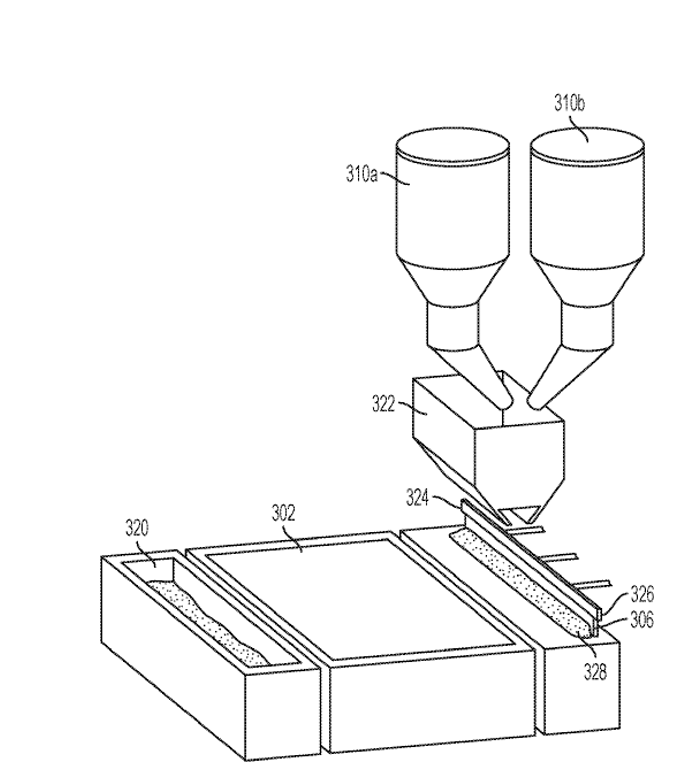

This place covers:

Means for changing the material composition. For instance, means for mixing powder material to be deposited onto a build platform or substrate in powder bed devices.

Illustrative example of subject matter classified in this place:

Powder bed device comprising a first powder reservoir (310a) with a first powder composition and a second powder reservoir (310b) with a second powder and a dispenser (322) for receiving a blend of the first and second powder according to a desired composition of the blend.

This place covers:

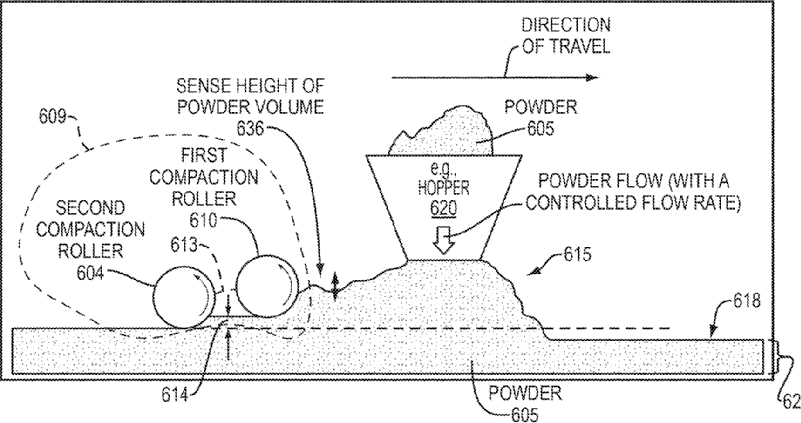

Planarisation or compression devices.

Illustrative example of subject matter classified in this place:

Selective laser melting [SLM]

Compacting plate (25) for compacting layer (20) in dosing device (21) before application of layer (20) on powder bed (16).

This place covers:

Rollers for compressing the powder layer.

Illustrative example of subject matter classified in this place:

This place covers:

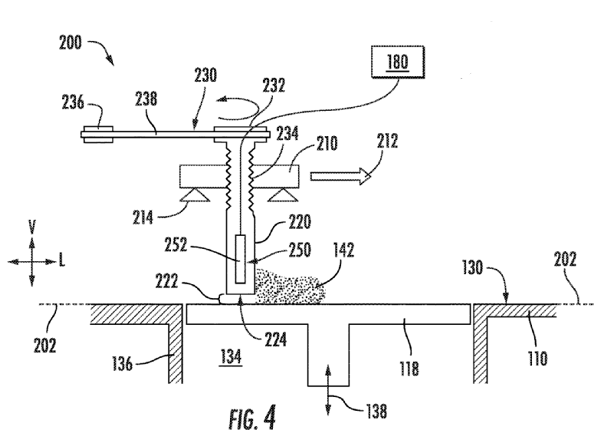

Arrangements where a recoater blade (doctor blade) is used to flatten the powder layer on the powder bed.

Illustrative example of subject matter classified in this place:

Recoating assembly (200) with a recoater blade (220) movably coupled to a support beam (210).

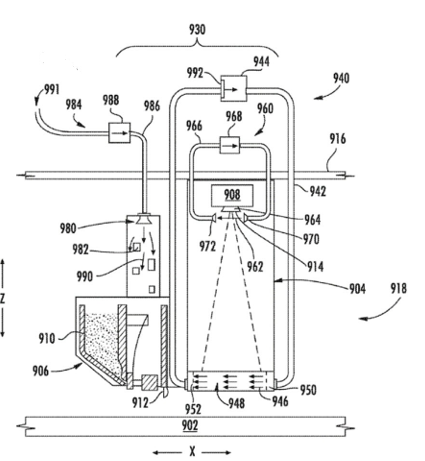

This place covers:

Units either within or connected to the additive manufacturing apparatus for gas flow.

Illustrative examples of subject matter classified in this place:

1.

Gantry (916) movable above the build platform (902) having a condensate evacuation subsystem (940) circulating a first gas (946) through the build area (918) and a closed loop subsystem (960) for circulating a second gas (962) over a sensitive component (964).

2.

Additive manufacturing system comprising an exhaust manifold (100) with baffles (109a‐e) movable with actuators (113a‐e).

3.

Powder-bed-based additive manufacturing device comprising a movable pair of nozzles (112a and 112b) for blowing an inert gas, and a movable suction device (110a and 110b) for exhausting contaminated gas.

4.

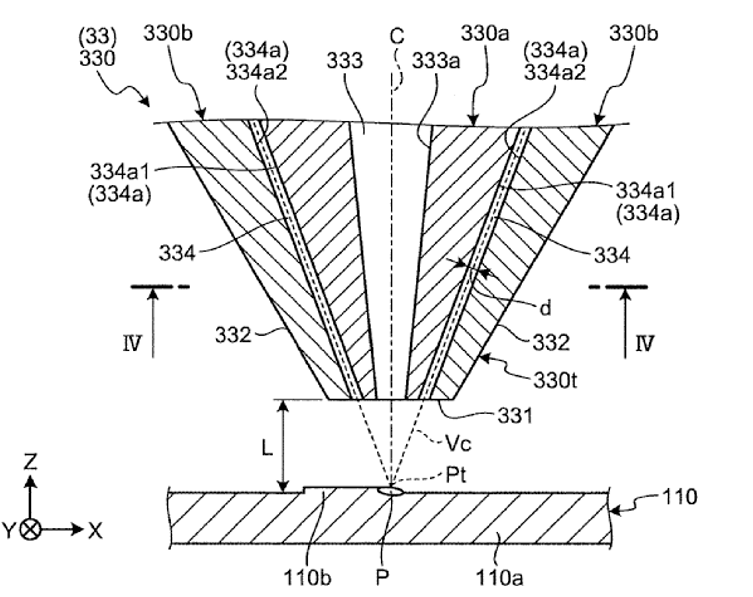

Nozzle for direct metal deposition of metallic powder onto the surface of a base (110a) or onto the surface of an object (110) with constant gap (d) between body component (330a) and (330b) of the nozzle.

This place covers:

Additive manufacturing [AM] production plants and production lines, modular designs for AM systems.

Illustrative example of subject matter classified in this place:

AM apparatus with an interchangeable module (16) incorporating a powder supply and recovery apparatus.

This place covers:

Systems where an additive manufacturing apparatus or device is combined with other processing devices.

Illustrative example of subject matter classified in this place:

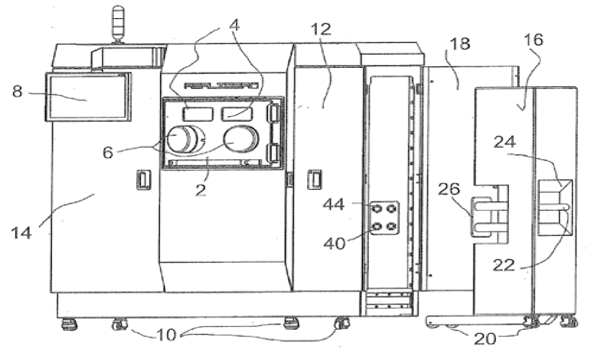

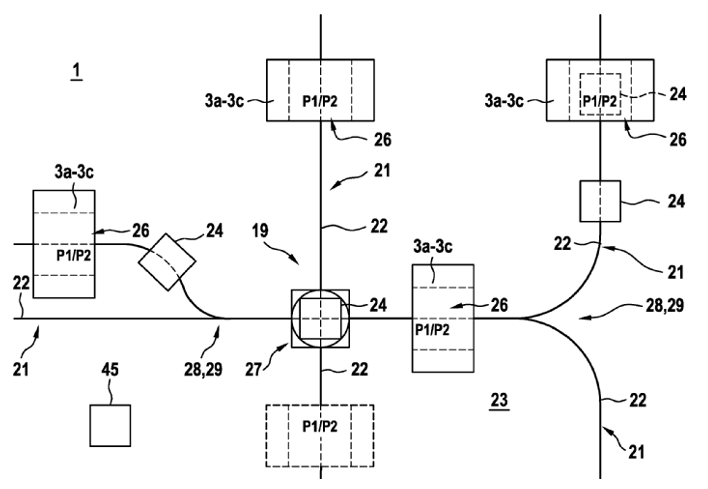

Plant (1) with several machines (26) with process stations for preprocessing (3a), additive manufacturing (3b) and post‐processing (3c).

This place covers:

Systems where additive manufacturing and other processing of articles can be performed in parallel within a single device.

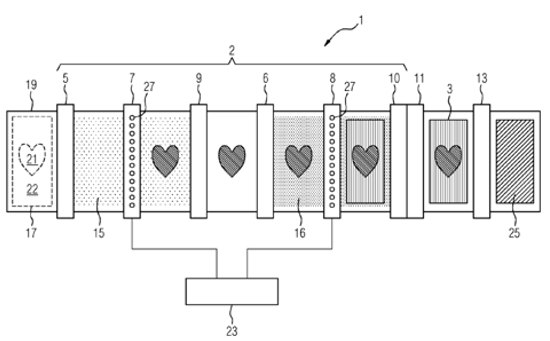

Illustrative example of subject matter classified in this place:

Additive manufacturing apparatus (1) with deposition (5), fusing (7) and powder removal (9) units for first material (15) and corresponding units (6,8,10) for second material (16), followed by sintering (11) and coating (13) units.

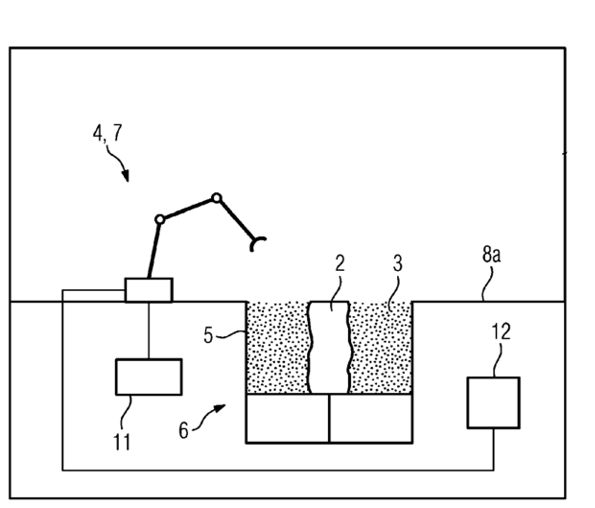

This place covers:

Modular set-up of workstations connected to each other by, e.g. robots or continuous transport means, but clustered.

Illustrative examples of subject matter classified in this place:

1.

System (8) where a component (100) is formed in the chamber (12) and undergoes post‐processing in the chamber (14). It is transferred between the chambers (10, 12, 14) by means of belt or conveyor (30, 58, 62).

2.

Mobile AM installation (10) with an AM machine (M1) and auxiliary functions.

This place covers:

Moving and handling of additively manufactured products.

Also, unpacking devices and devices for removing leftover powder by rotating and/or vibrating the article after manufacturing. Unpacking devices may comprise any manipulation devices (e.g. robot, crane or gantry) configured to grasp/seize the three-dimensional article after manufacturing and to release it from surrounding unused build material.

Illustrative example of subject matter classified in this place:

Unpacking device (4) for unpacking article (2) from unsolidified construction material (3).

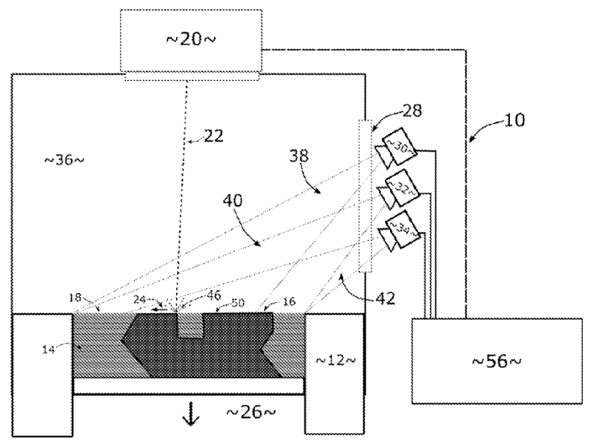

This place covers:

Arrangements of sensors for monitoring or process control.

Illustrative example of subject matter classified in this place:

A plurality of image sensors (30, 32, 34) and a processor (56) for combining the fields of view of the sensors to a single image.

Combination sets (C-Sets):

C-Sets statement: #B22Fa

- In group B22F 2998/00, supplementary information concerning processes related to powder metallurgy is classified in the form of C-Sets.

- In these C-Sets, the base symbol is B22F 2998/00, whereas the subsequent symbol(s) representing the processes related to powder metallurgy are taken from the groups B22F 1/00 - B22F 2207/20, C22C 1/00 - C22C 2204/00 (including breakdown indexing codes), and other subclasses from other fields.

- C-Sets #B22Fa is always allocated as additional information (ADD).

- #B22Fa is actually rarely used in practice.

C-Sets syntax rules:

- Each C-Sets can contain two or more symbols.

- Duplicate symbols are not allowed in these C-Sets.

- Breakdown codes are allowed as subsequent symbols.

- The order of C-Sets is as follows: B22F 2998/00 is always used as a base symbol, while the order of the subsequent symbols in these C-Sets is not relevant.

- The subsequent symbols are not arranged in alphanumerical order.

C-Sets examples:

- #B22Fa: A method of forming (B22F 2998/00) a product can be by injection moulding, additive manufacturing or extrusion, not being particularly claimed or having a preference, is classified as (B22F 2998/00, B22F 3/225, B22F 3/20, B22F 10/00) (ADD).

Combination sets (C-Sets):

C-Sets statement: #B22Fb

- In group B22F 2998/10, supplementary information concerning processes characterised by process steps is classified in the form of C-Sets.

- In these C-Sets, the base symbol is B22F 2998/10, whereas the subsequent symbol(s) representing the processes or composition related to powder metallurgy are taken from the groups B22F 1/00 - B22F 2207/20, C22C 1/00 - C22C 2204/00 (including breakdown indexing codes), and other subclasses from other fields.

- C-Sets #B22Fb is always allocated as ADD.

C-Sets syntax rules:

- Each C-Sets can contain two or more symbols.

- Duplicate symbols are allowed in these C-Sets but not consecutively.

- Breakdown codes are allowed as subsequent symbols.

- The order of symbols in these C-Sets is relevant. B22F 2999/00 is always used as a base symbol, while subsequent symbols reflect the sequence of steps performed in the process.

- In these C-Sets the symbols are not arranged in alphanumerical order.

C-Sets examples:

- #B22Fb: A process (B22F 2998/10) comprising specifically a mixture of metal powder and resin (B22F 1/10), a mould filled with this powder (B22F 3/004), pressed (B22F 3/02) and sintered with removal of binder (B22F 3/1021) is classified as (B22F 2998/10, B22F 1/10, B22F 3/004, B22F 3/02, B22F 3/1021) (ADD).

- #B22Fb: A process (B22F 2998/10) comprising specifically a workpiece manufactured by selective laser melting (B22F 10/28) followed by hot isostatic pressing (B22F 3/15) is classified as (B22F 2998/10, B22F 10/28, B22F 3/15) (ADD).

Combination sets (C-Sets):

C-Sets statement: #B22Fc

- In group B22F 2999/00, aspects linked to processes or compositions used in powder metallurgy is classified in the form of C-Sets.

- In these C-Sets, the base symbol is B22F 2999/00, whereas the subsequent symbol(s) representing the processes or composition related to powder metallurgy are taken from the groups B22F 1/00 - B22F 2207/20, C22C 1/00-C22C 2204/00 (including breakdown indexing codes), and other subclasses from other fields.

- C-Sets #B22Fc is always allocated as ADD.

C-Sets syntax rules:

- Each C-Sets can contain two or more symbols.

- Duplicate symbols are not allowed in these C-Sets.

- Breakdown codes are allowed as subsequent symbols.

- The order of symbols in these C-Sets is relevant. B22F 2999/00 is always used as base symbol, while subsequent symbols are arranged to represent subject matter(s) with increasing specificity.

- In these C-Sets, the subsequent symbols are not arranged in alphanumerical order.

C-Sets examples:

- #B22Fc: Aspect (B22F 2999/00) concerning vacuum (B22F 2201/20) applied during the step of filling mould with powder (B22F 3/004) and the use of vibration (B22F 2201/01) to equalise the powder distribution in the mould is classified as (B22F 2999/00, B22F 3/004, B22F 2202/01, B22F 2201/20) (ADD).

- #B22Fc: Aspects (B22F 2999/00) concerning sweep gas system (B22F 12/70) and driving means for a motion of said system along a direction within the plane of a layer (B22F 12/224) during additive manufacturing is classified as (B22F 2999/00, B22F 12/70, B22F 12/224) (ADD).