CPC Definition - Subclass B26D

This place covers:

Cutting of non-metallic sheet material or metal foil in general and cutting other forms of non metallic materials not otherwise provided for; apparatus or machines therefor; cutting members therefor. Cutting is defined as a process of severing material with a sharp edge penetrating into material , e.g. a blade as cutting member, without removing material in form of chips.

- Characterised by the nature or movement of a cutting member which does not travel with the work, e.g. stationary or linearly movable cutting members reciprocating or rotating cutting members;

- Characterised by the nature or movement of a cutting member which travels with the work, i.e. flying cutter, e. g. mounted on a movable arm or carriage;

- Characterised by the nature of the cut made, e. g. beveling, grooving, scoring, forming notches, or splitting/separating layers by cutting; Apparatus therefore;

Arrangements for operating and controlling machines or devices for cutting, cutting-out, stamping out, punching, perforating and also for severing by means other than cutting, e. g.

- Means for moving the cutting member into its operative position for cutting, or for actuating the cutting member to effect the cut;

- Arrangements with interrelated action between the cutting member and work feed, or between work feed and clamp, or with means operable by the moving work to initiate the cutting action;

- Details of apparatus for cutting, cutting-out, stamping out, punching, perforating and also for severing by means other than cutting

- Means for holding, positioning, clamping or for removing cut-out material or waste;

- Means for mounting or adjusting the cutting member or the stroke of the cutting member;

- Means for treating work or cutting member to facilitate cutting, e.g. by sharpening the cutting member;

- Means for performing other operations combined with cutting, e. g. counting the number of cuts, conveying ,weighting the cut product;

- Cutting beds;

- Safety devices specially adapted for cutting machines;

- Cutting apparatus combined with punching or perforating apparatus or with dissimilar cutting apparatus or combinations of several similar cutting apparatus

With regard to the aspect of cutting itself, irrespective of the material:

- The term cutting as used in groups of subclass B26D covers severing material with a sharp edge penetrating into the material, e.g. a blade as cutting member, without removing material in the form of chips. Therefore severing otherwise than by cutting, e.g. by shearing or tearing, and cutting whereby chips of material are removed, e.g. working material by turning, boring, milling, sawing is not covered by the subclass B26D.

- Hand- held cutting tools are covered by subclass B26B, particularly hand- held motor- driven cutting tools.

With regard to the material to be cut:

- For the material aspect, subclass B26D covers cutting non-metallic sheet material or metal foil in general, whereby metal foils are covered in so far as they are workable in a manner analogous to paper (as typical non-metallic sheet material). Other forms of non-metallic materials not otherwise provided for are also covered by subclass B26D.

- B26D does not cover cutting metal other than the aforementioned metal foils:

- Cutting by machine tools used for working metal by removing material is covered by class B23, e.g. for turning, boring, milling, planing, slotting, sawing metal.

- Shearing or similarly severing metal is covered by B23D 15/00 - B23D 35/00.

- Cutting of sheet metal or other metal stock material like metal rods, metal tubes or metal profiles, is covered by subclass B21D, e.g. press-cutting in B21D 28/00. Cutting or splitting metal wire is covered by B21F 11/00 and B21F 13/00.

- Particular aspects of cutting other forms of non-metallic materials are covered by places within subclasses of B27 for wood and similar materials and within main group B28D 1/00 for stone or stone-like materials. B27L covers for example cutting veneer strips from trunks or splitting wood, B28D 1/22 covers working stone by cutting, e.g. by incising with cutting discs.

- Cutting plastic material (or other non-metallic materials) is covered by places within subclasses of B23, where the term 'metal working' covers other materials unless the context requires otherwise.

With regard to details common to machines for severing:

- This subclass also covers features specific to machines for cutting, perforating, punching, cutting-out, stamping-out, or severing by means other than cutting, which relate to a requirement or problem of a nature which is not peculiar to a machine for these purposes, that is, details of or arrangements for operating or controlling such machines, although the realisation of such features may differ according to the kind of machine concerned. This subclass covers such features in general even if the feature, in any particular case, is to some extent peculiar to, or is claimed only for, a machine designed for perforating, punching, cutting-out, stamping-out, or for severing other than by cutting.

- If the details or arrangements have no essential features specific to cutting, perforating, punching, cutting-out, stamping-out or severing machines, the more general classes, e.g. F16, take precedence.

This place does not cover:

.

Disintegrating by knives or other cutting or tearing members which chop material into fragments | |

Punching or perforating of metal | |

Cutting of the kind used for metal-working | |

Blast guns generating high velocity abrasive fluid jets for cutting materials | |

Hand-held cutting tools | |

Perforating, cutting out, stamping out or punching, or severing by means other than cutting |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Soil-working | |

Harvesting or mowing | |

Hand-operated implements for cutting-up straw, hay or the like | |

Cutting of straw, hay or the like | |

Cutting implements specially adapted for horticulture and forestry | |

Cutting of butter during butter manufacturing | |

Cutting, stamping, slotting, slitting or perforating of dough and cutting or slicing of baked articles other than bread | |

Slaughtering | |

Processing meat, poultry, or fish | |

Cutting for tobacco, cigars or cigarettes | |

Marking-out, perforating or making buttonholes | |

Manufacturing or repairing footwear | |

Brushmaking | |

Surgical instruments, devices or methods | |

Devices or methods specially adapted for bringing pharmaceutical products into particular physical or administering forms | |

Cutting of wood or similar material | |

Cutting shaped articles made of clay or other ceramic compositions | |

Cutting of stone | |

Working of plastics or substances in a plastic state | |

Making boxes, cartons, envelopes or bags, of paper or similarly worked materials, e.g. metal foil | |

Auxiliary cutting of sheets or webs in rotary printing presses | |

Cutting related to typewriters or selective printing mechanisms | |

Cutting related to apparatus or devices for manifolding, duplicating, or printing or related to addressing machines or like series-printing machines | |

Sharpeners for pencils or leads | |

Devices for opening envelopes | |

Cutting for severing webs for packaging, or for separating joined packages | |

Cutting-off the web from the wound web roll, cutting of the web for changing web rolls | |

Article or web delivery apparatus incorporating cutting or line-perforating devices | |

Hand- or power-operated cutting devices for opening closed containers | |

Cutting of leather or upholstery | |

Cutting of glass | |

Cutting explosives | |

Making matches | |

Cutting of peat | |

Cutting of soap | |

Reducing the size of material from which sugars are to be extracted | |

Cutting of sugar | |

Cutting of textile material | |

Working rails, sleepers, baseplates, or the like | |

Forming cuts into roads or like surfaces | |

Cutting in connection with devices or accessories for making or mounting lamellar blinds or parts thereof | |

Cutting in earth or rock drilling and mining | |

Devices for withdrawing samples by cutting | |

Preparing the ends of light guides, e.g. cutting | |

Cutting processed photographic material | |

Cutting of a semiconductor body into separate parts | |

Cutting for removing insulation or armouring from cables |

Attention is drawn to the following places, which may be of interest for search:

Crushing, pulverising or disintegrating in general | |

Sharpening cutting edges | |

Blasting with jets acting as abrasive jets, but not containing particulate material in the case of jet milling of local recessions like e.g. grooves | |

Blasting with jets acting as abrasive jets, but not containing particulate material in the case of deburring | |

Blasting with jets acting as abrasive jets, but not containing particulate material in the case of removal of extended surface areas |

In this place, the following terms or expressions are used with the meaning indicated:

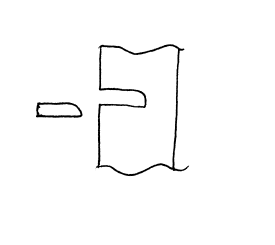

guillotine | a cutter with a knife moving down and guided on both sides |

Thin material | material that can be handled similar to paper, e.g. aluminium foils |

This place covers:

Cutting through work characterised by the nature or movement of the cutting member; Apparatus or machines therefor; Cutting members therefor. E.g. cutting blades, linearly moving blades, cutting members rotating about an axis or rotating about a movable axis.

This place covers:

Cutting machines having a stationary cutting member; e.g. trimming the edges of a running web with a stationary cutting member.

This place does not cover:

Cutting by band knives | |

Cutting by wires | |

Involving a cutting member which travels with the work |

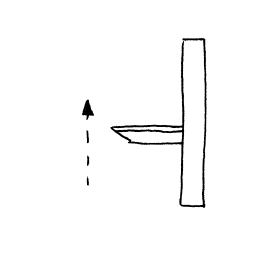

This place covers:

Cutting device having a linearly-movable cutting member, e.g. photo cutter with a cutting member mounted on a carriage and cutting can be performed only in one direction.

This place does not cover:

Paper cutters where the cutting is performed by moving the cutting element back and forth |

Attention is drawn to the following places, which may be of interest for search:

Inserting blades in running web; e.g. for tearing goes to |

This place covers:

Cutting device having a linearly-movable cutting member wherein the cutting member reciprocates, e.g. mechanics for oscillating cutters, cutting in both directions..

Attention is drawn to the following places, which may be of interest for search:

Cutting by cup or disc cutter on a carriage | |

Cutting by cup or like cutting members |

This place covers:

Cutting device having a linearly-movable cutting member wherein the cutting member reciprocates, e.g. paper cutters having a blade suitable for cutting in both directions.

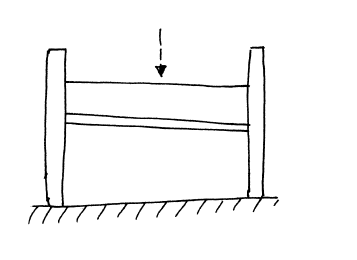

This place covers:

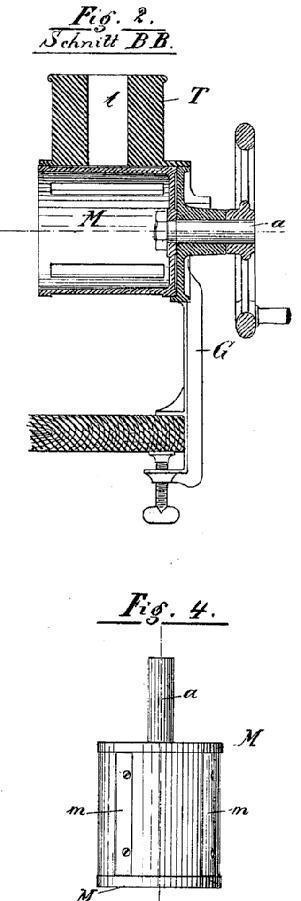

guillotines in general

This place does not cover:

Blind cutters for metal |

This place covers:

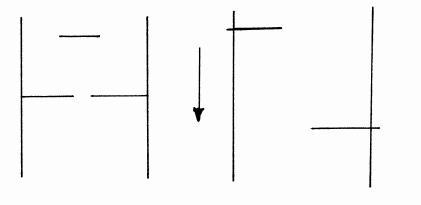

Cutting device having a plurality of linearly-movable cutting members wherein the cutting members reciprocate, e.g. so-called three side trimmers for printed products.

Attention is drawn to the following places, which may be of interest for search:

Bookbinding in general |

This place covers:

Cutting device having a plurality of linearly-movable cutting members wherein the cutting members reciprocate like a "jig saw".

Attention is drawn to the following places, which may be of interest for search:

Cutting by cup or like cutting members |

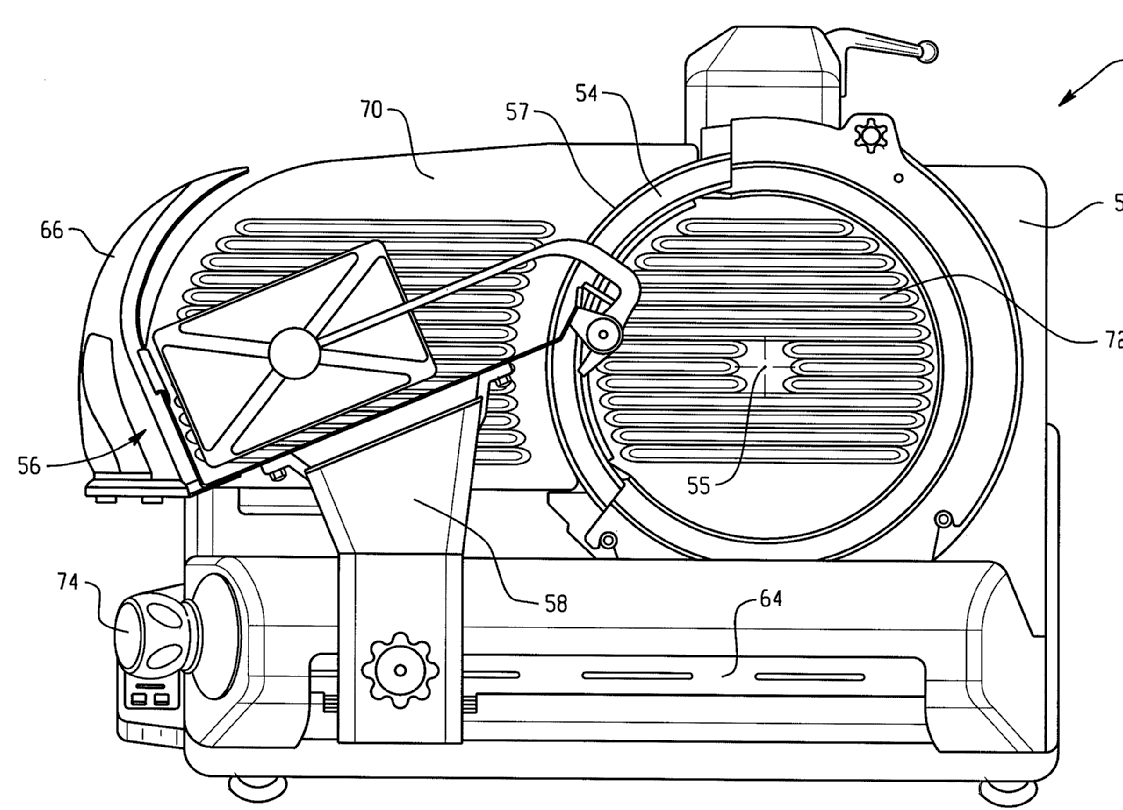

This place covers:

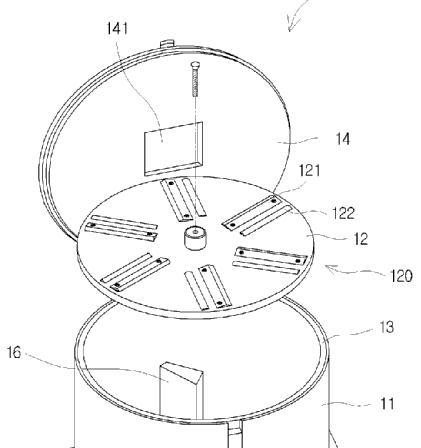

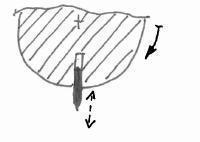

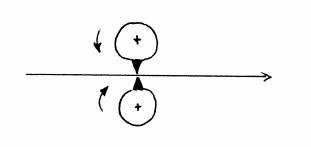

Cutting machines having a cutting member moving about a stationary axis, e.g. a food slicer as shown below.

This place covers:

Cutting machine having a cutting member moving about an axis and mounted on a movable carriage for thin material; e.g. a disc cutter mounted on a carriage and operating on a cutting mat.

This place does not cover:

The disc cutter cooperates with a fixed member |

This place covers:

Cutting machine having a cutting member moving about an axis and mounted on a movable carriage for thin material and coacting with a fixed member like a counter blade.

This place covers:

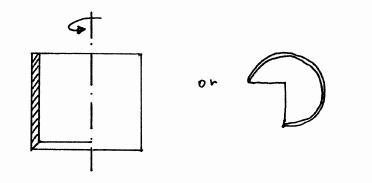

Cutting machine with a non-circular cutting member and rotating continuously in one direction during cutting; even when the cutting member is rotated manually.

This place covers:

Cutting machine with a non-circular cutting member and rotating continuously in one direction during cutting with cutting member mounted in the plane of a rotating disc.

Attention is drawn to the following places, which may be of interest for search:

Miscellaneous implements for preparing or holding food with grating discs or drums. |

This place covers:

Cutting machine with a non-circular cutting member with limited pivotal movement to effect cut, e.g. a paper cutting knife.

This place covers:

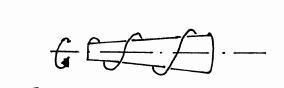

Cutting machine with a cutting member moving about an axis parallel to the line of cut.

This place covers:

Cutting machine with a cutting member moving about an axis parallel to the line of cut and rotating continuously in one direction during cutting, e.g. mounted on a rotary cylinder.

This place does not cover:

Cutting by flying cutting |

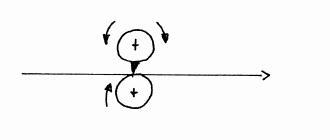

This place covers:

Cutting machine with a cutting member moving about an axis parallel to the line of cut and rotating continuously in one direction during cutting, and coacting with a rotary member; e.g. a cutter coacting with an anvil drum.

This place does not cover:

Cutting by two cooperating rotary blades (e.g. flying shears on drums) |

This place covers:

Cutting machine with a cutting member moving about an axis parallel to the line of cut and rotating continuously in one direction during cutting, and slidably mounted in a rotary member, e.g. a drum with a linearly in radial direction moving blade in the drum.

This place covers:

Cutting machine with a cutting member moving about another axis, e.g. mounted on the surface of a cone or curved body

This place covers:

Cutting machines having a cup or like cutting member.

This place does not cover:

cutting out discs |

Attention is drawn to the following places, which may be of interest for search:

Strap saw sawing machines |

This place covers:

Cutting machine involving a cutting member which travels with the work, e.g. flying cutter.

Attention is drawn to the following places, which may be of interest for search:

Flying shears for metal | |

Flying saws for metal |

This place covers:

Cutting machine involving a cutting member which travels with the work and is rotating about an axis parallel to the line of cut, e.g. mounted on a rotary cylinder.

This place does not cover:

Rotary cutting cylinders cooperating with an anvil drum |

This place covers:

Cutting work characterised by the nature of the cut made, apparatus therefore, e.g. cutting tubes, making grooves on surfaces, splitting layers from work, halving devices etc.

This place covers:

Cutting through work of particular materials not otherwise provided for; cutting rubber strips, e.g. for tire production or so-called reinforced strips.

This place does not cover:

Cutting profile in tyres |

This place covers:

Cutting through work of particular materials not otherwise provided for; cutting of plastic blocks e.g. cutting foam blocs like styropor.

This place covers:

Cutting through work of particular materials not otherwise provided for; where the material slides along the cutting member, e.g. cutting of plastic blocks e.g. cutting foam blocs like styropor.

This place covers:

Cutting machines for slitting marginal portions of the work, i.e. forming cuts, without removal of material, at an angle, e.g. a right angle, to the edge of the work.

This place does not cover:

Making a superficial cut in the surface of the work without removal of material, e.g. scoring, incising. |

This place covers:

Cutting for splitting layers from work; separating layers by cutting.

Attention is drawn to the following places, which may be of interest for search:

Recovery of plastics or other constituents of waste material containing plastics |

This place covers:

Arrangements for operating and controlling machines or devices for cutting, cutting-out, stamping-out, punching, perforating, or severing by means other than cutting. This includes all kind of electronic or computer control devices but also mechanical actuating mechanisms to effect the cut.

This place covers:

Arrangements for operating and controlling machines or devices for cutting, cutting-out, stamping-out, punching, perforating, or severing by means other than cutting with means operable by the moving work to initiate the cutting action with interrelated action between work feed and clamp.

This place covers:

Details of apparatus for cutting, cutting-out, stamping-out, punching, perforating, or severing by means other than cutting. All kind of devices dedicated to cutting machines such as hoods, safety devices, feeding arrangements, means for mounting the cutting member.

This place does not cover:

Cutting blades, or cutting elements |

Attention is drawn to the following places, which may be of interest for search:

Arrangements for guiding hand cutting tools | |

Punching tools or dies |

This place covers:

Arrangements for feeding or delivering work of other than sheet, web, or filamentary form, e.g. pushers, carriages.

Attention is drawn to the following places, which may be of interest for search:

Feeding or discharging sheets, webs, or filaments |

This place covers:

Means for treating work or cutting member to facilitate cutting, e.g. vibrating the cutting blade ultrasonically.

This place does not cover:

Tensioning band cutters |

This place covers:

Safety devices specially adapted for cutting machines.

Attention is drawn to the following places, which may be of interest for search:

Safety devices in general |

This place covers:

Cutting apparatus combined with punching or perforating apparatus or with dissimilar cutting apparatus, e.g. production processes with punching and cutting stations arranged sequentially or in parallel.

This place covers:

Combinations of several similar cutting apparatus, being identical or working with the same cutting principle.

E.g. production processes with similar cutting stations arranged sequentially or in parallel.