CPC Definition - Subclass F17C

This place covers:

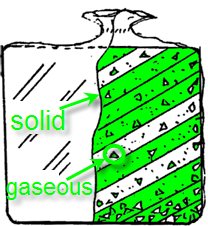

- Gas vessels for the storage of compressed, liquefied or solidified gas. The complete pressure range is covered: sub-atmospheric, low pressure like vapour pressure of liquefied gas, up to very high pressure without upper restriction. Storage and transport of gas are the only purpose of pressure vessels of this subclass. Gases are stored in the pressure vessel in gaseous, liquefied or solidified state.

- Pressures vessels that are cooled and insulated to maintain a certain state of contents.

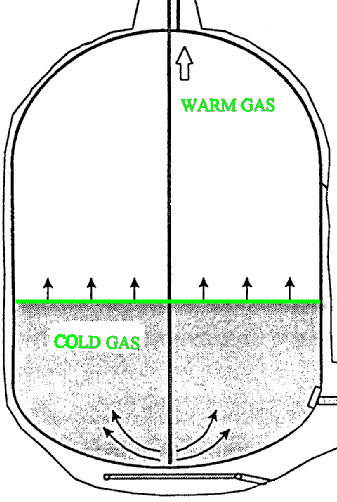

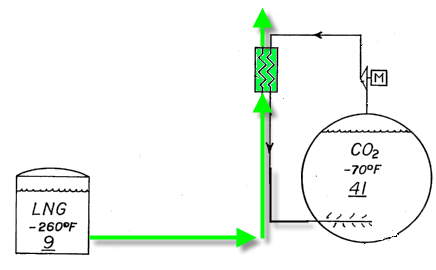

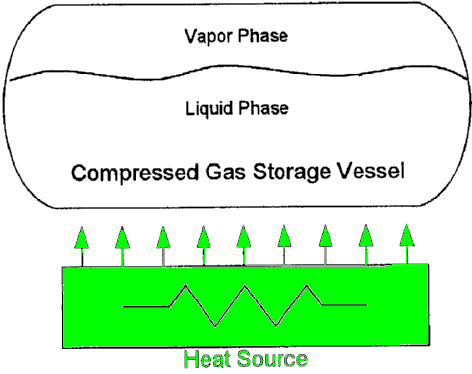

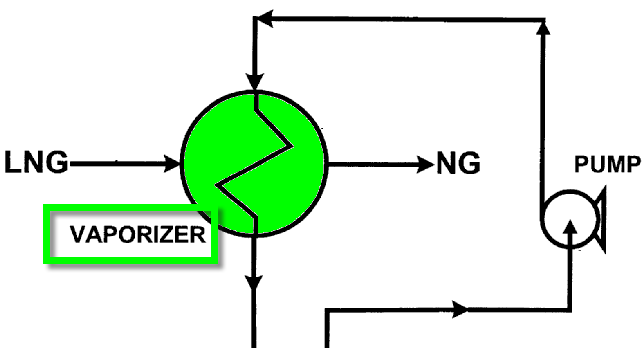

- The only processes that might take place inside pressure vessel of this subclass are sublimation and vaporisation, usually due to voluntary or accidental heat input into the vessel. Sublimation and vaporisation that takes place outside the pressure vessel is to be classified too, as long as it happens in the context of voluntary regasification of liquefied gas to deliver the fluid in gaseous form to a user or accidental heat input.

Groups in the 2000-range:

The groups F17C 2201/00 - F17C 2209/00 cover features of the pressure vessel itself:

- the pressure vessel's form and size

- the pressure vessel's wall structure and the material the wall is made of

- Arrangements for mounting or grouping pressure vessels

- Components in connection with the pressure vessel.

- the pressure vessel's manufacturing methods

The groups F17C 2221/00 - F17C 2227/00 consider the fluid contained in the pressure vessel and its charging and discharging into and from the pressure vessel.

- the fluid's composition and state before and after the transfer.

- the methods of filling and emptying the pressure vessel and ways to transfer the fluid into and out of the pressure vessel

- Group F17C 2250/00 for dealing with the controlling, indicating, monitoring or regulating of various parameters in relation with the vessel or the fluid, like pressure or temperature

- Group F17C 2260/00 for purposes or effects achieved by the gas storage and its handling

- Group F17C 2270/00 for applications or the locations where pressure vessels are used

Layout of definition statements:

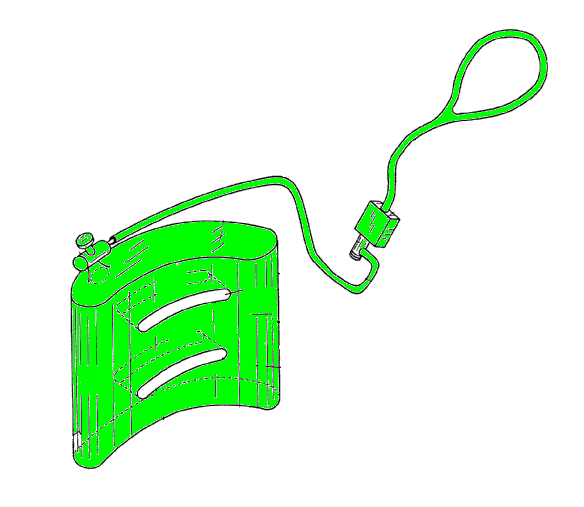

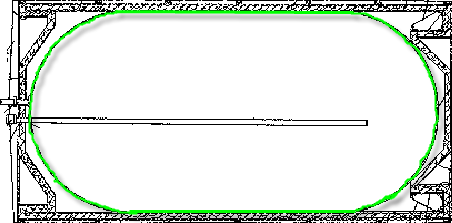

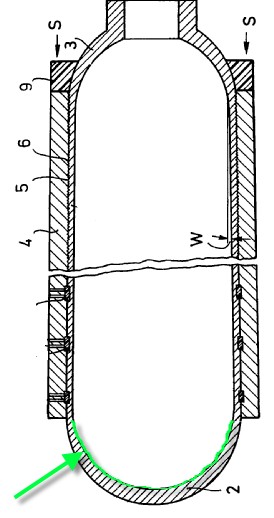

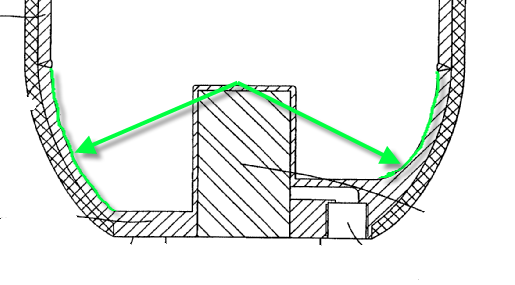

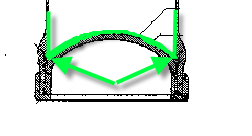

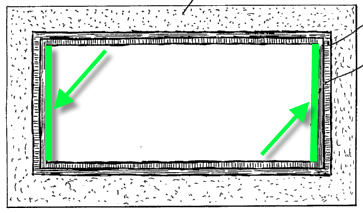

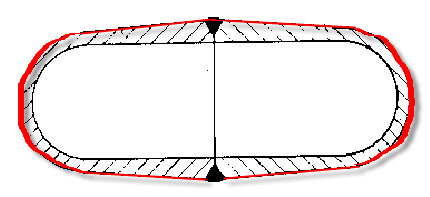

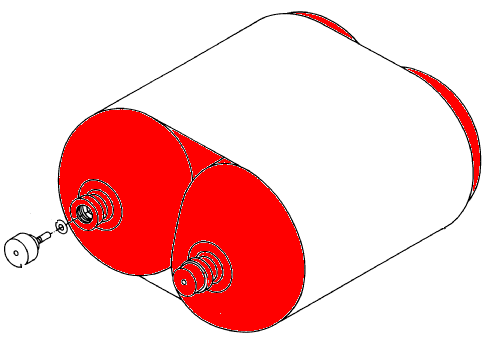

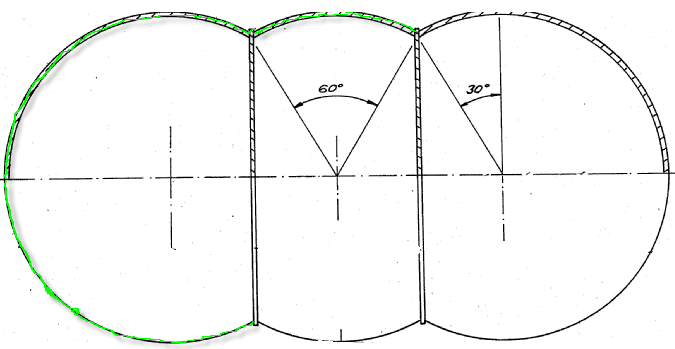

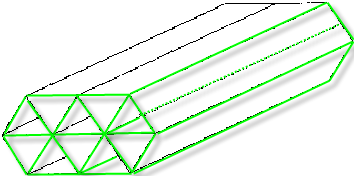

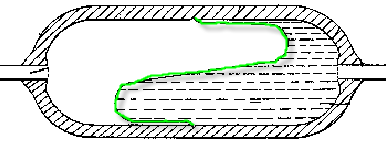

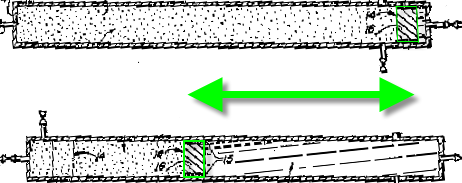

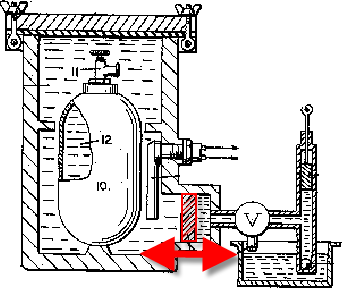

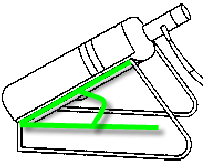

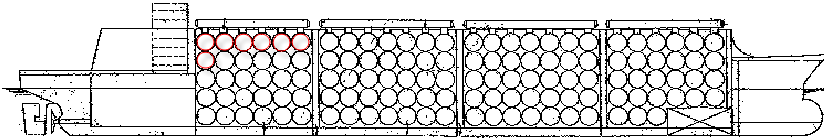

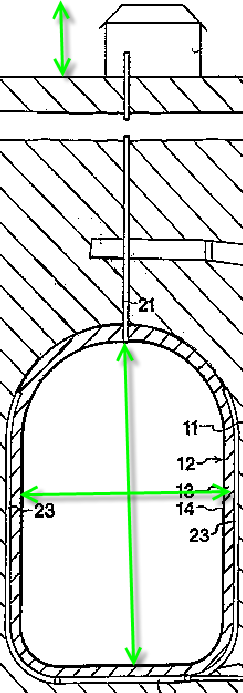

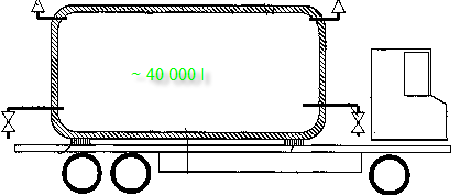

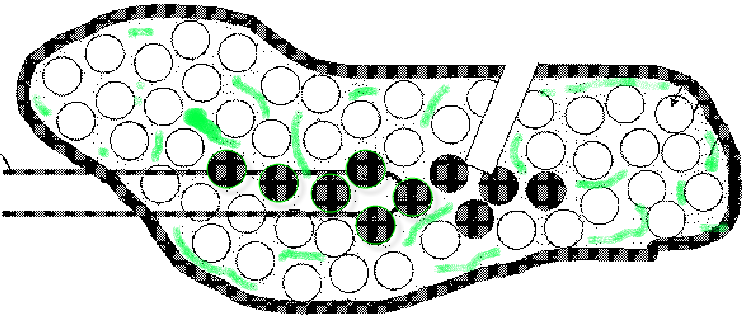

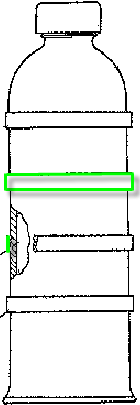

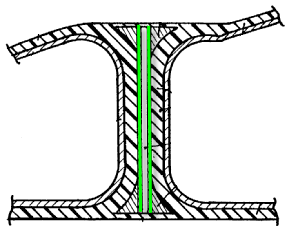

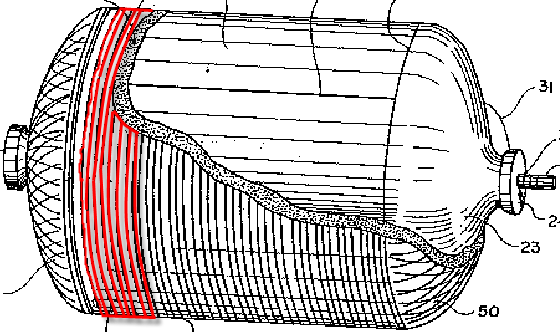

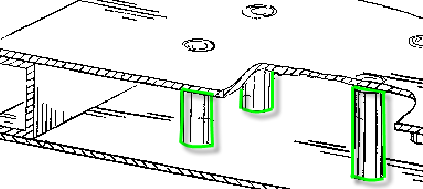

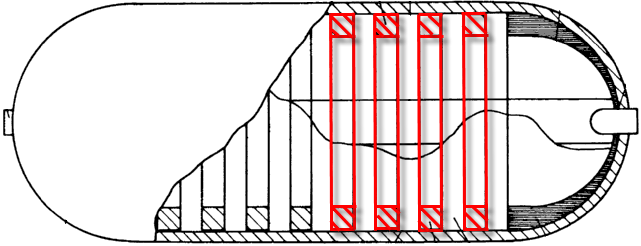

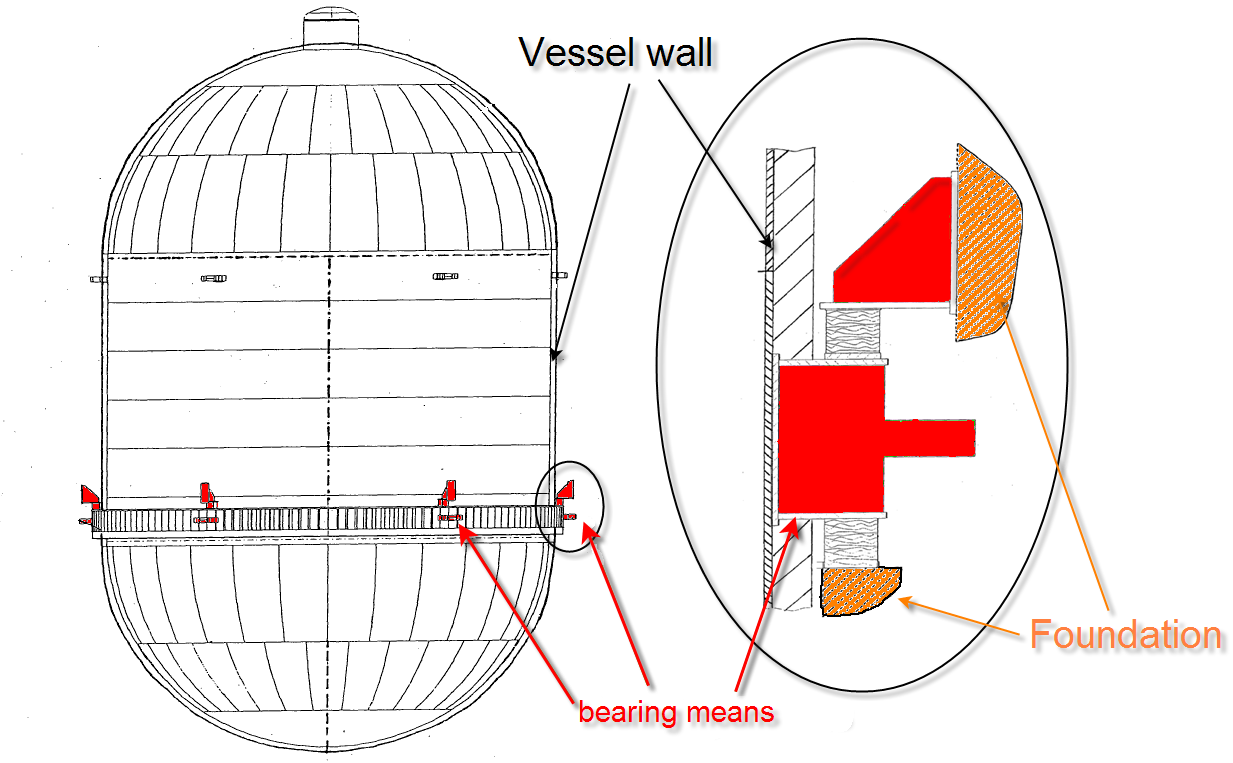

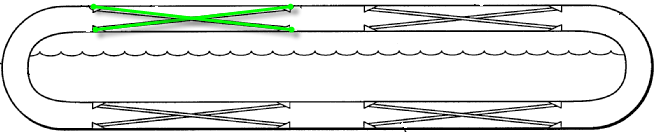

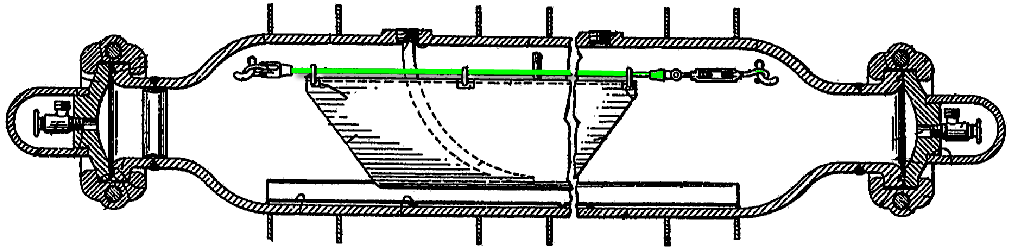

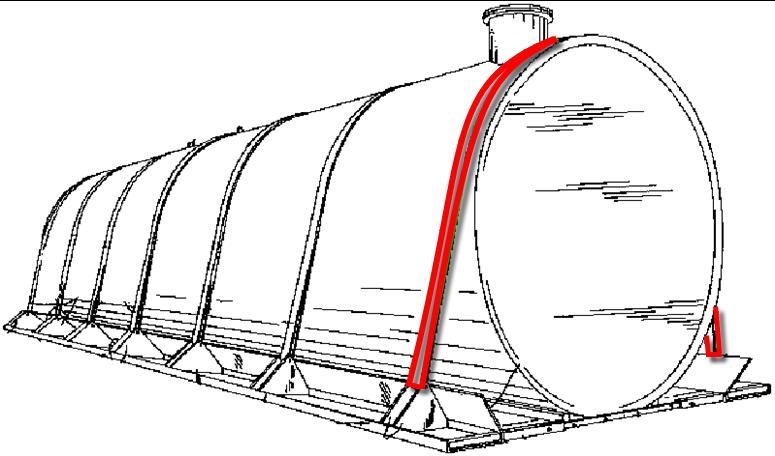

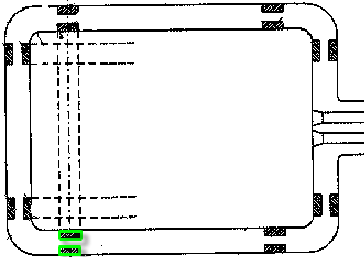

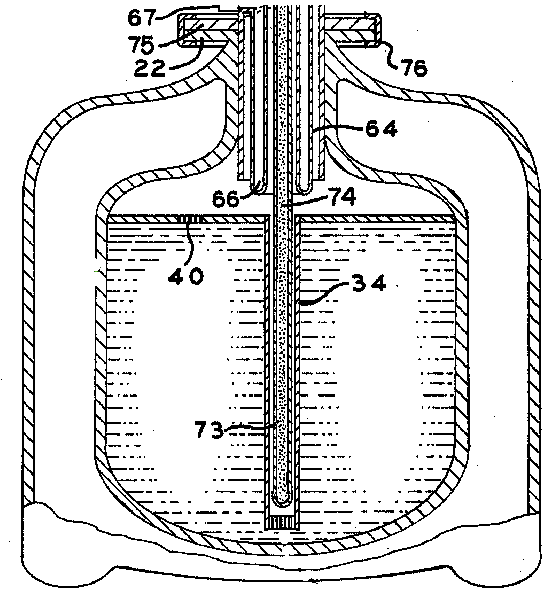

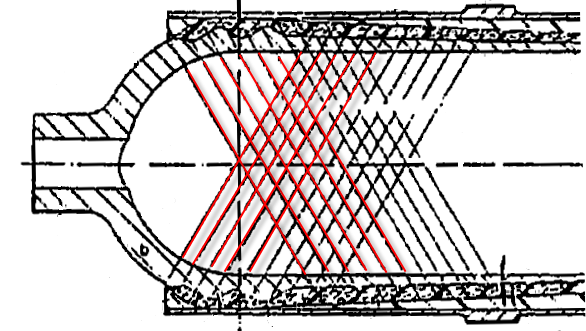

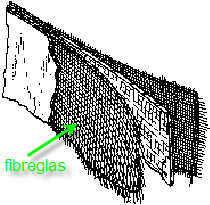

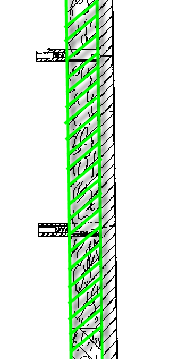

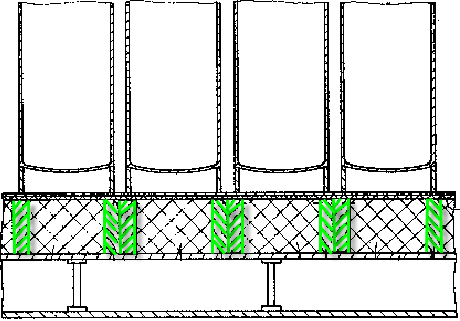

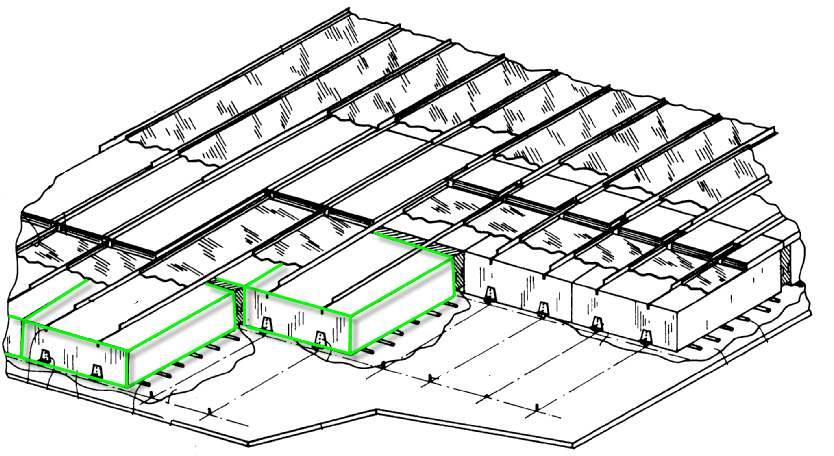

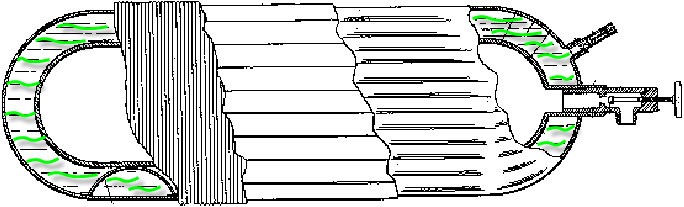

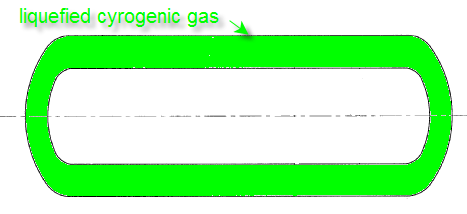

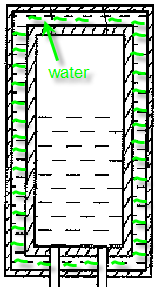

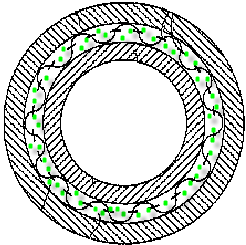

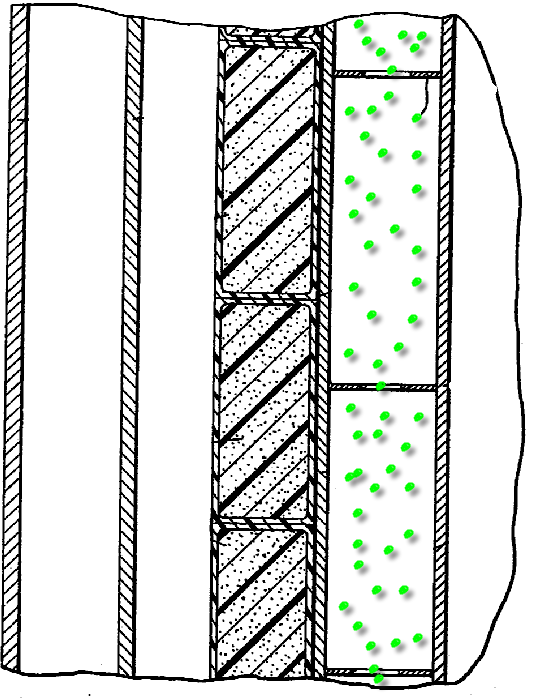

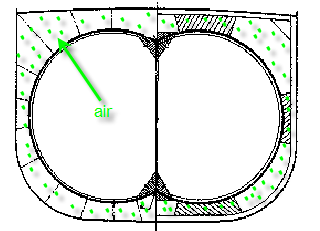

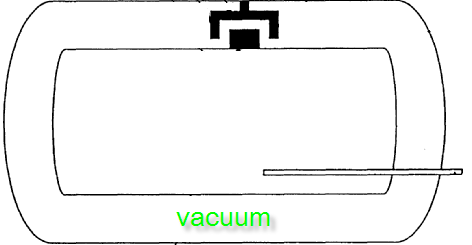

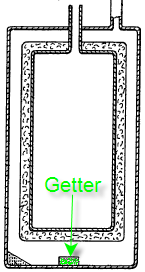

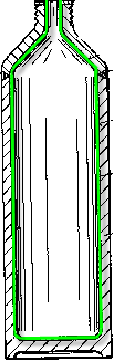

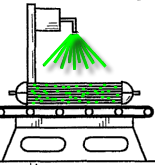

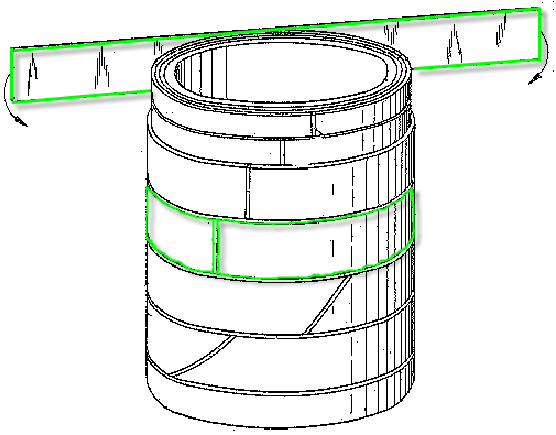

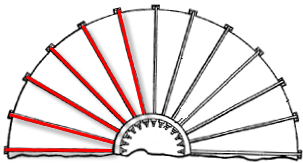

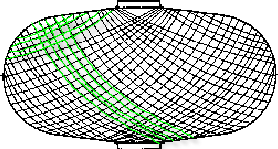

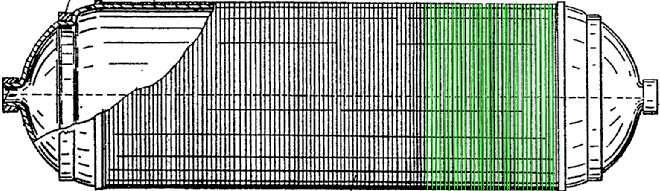

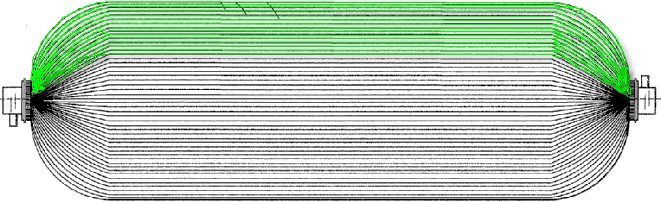

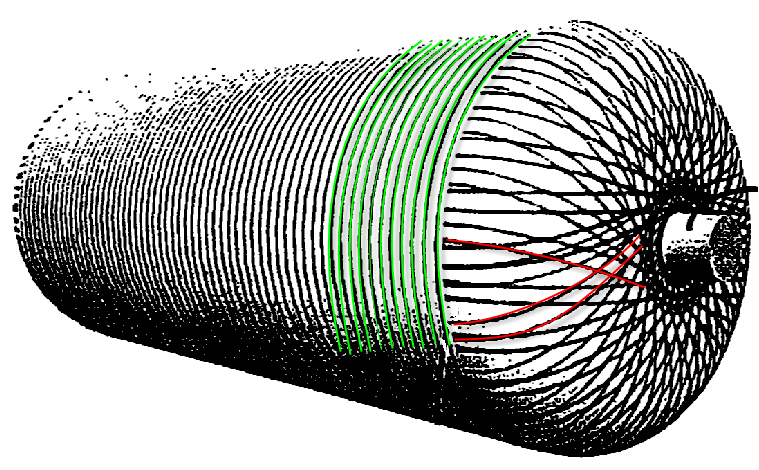

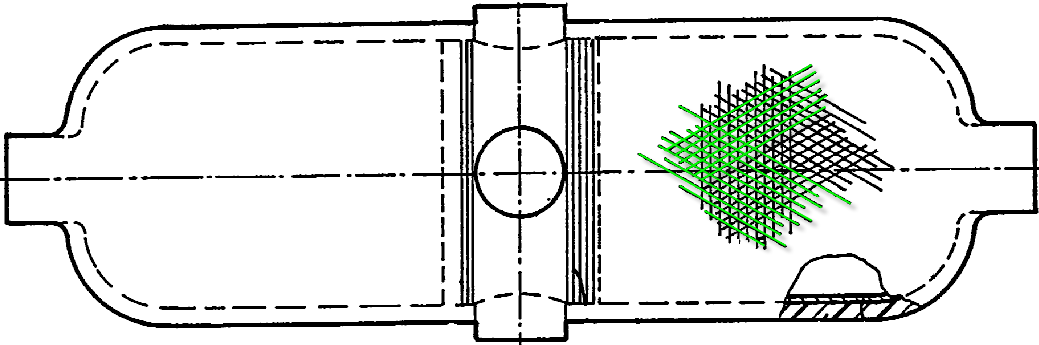

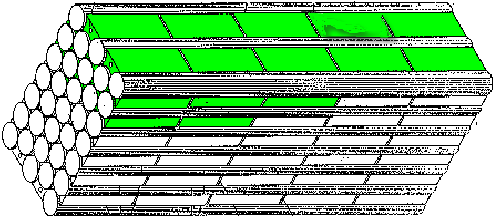

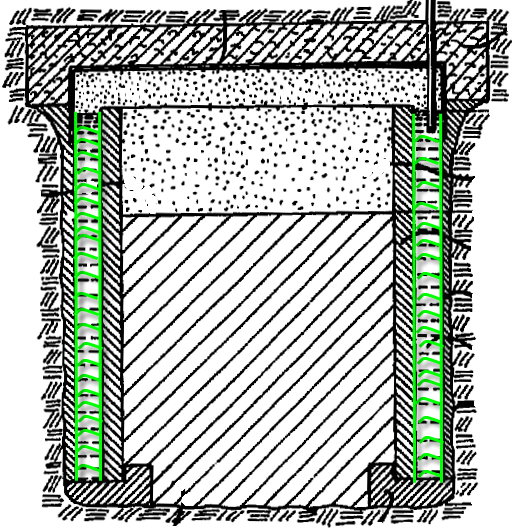

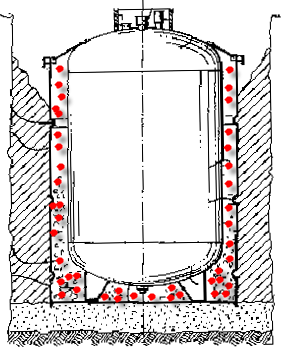

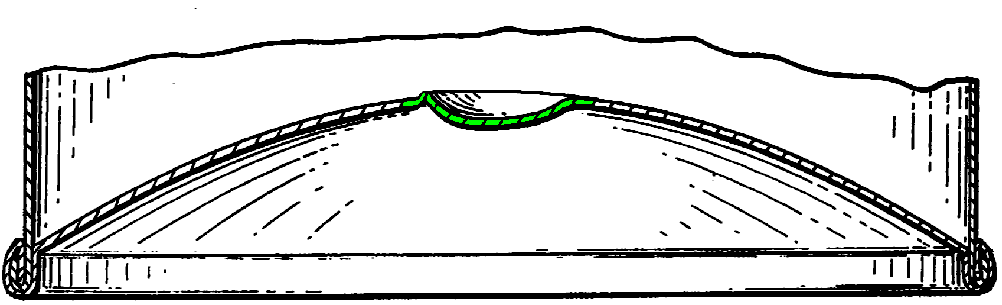

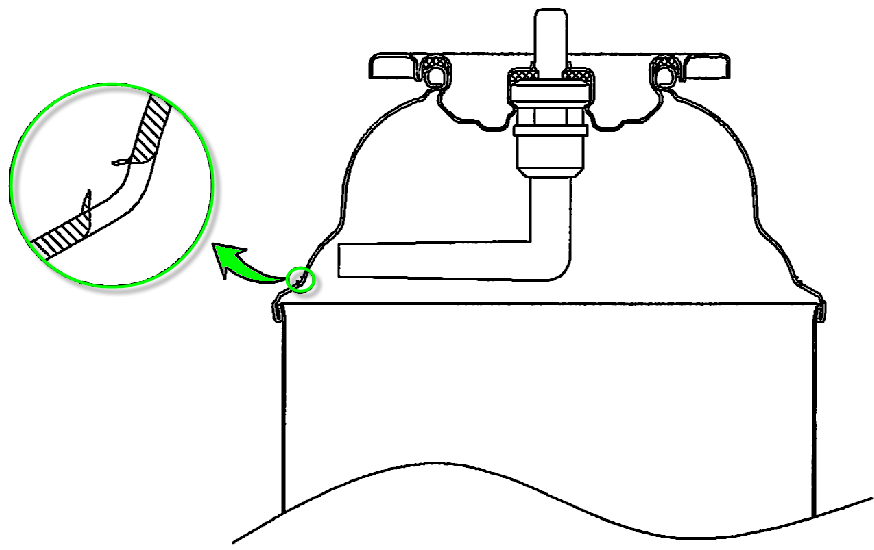

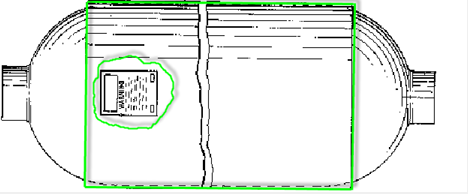

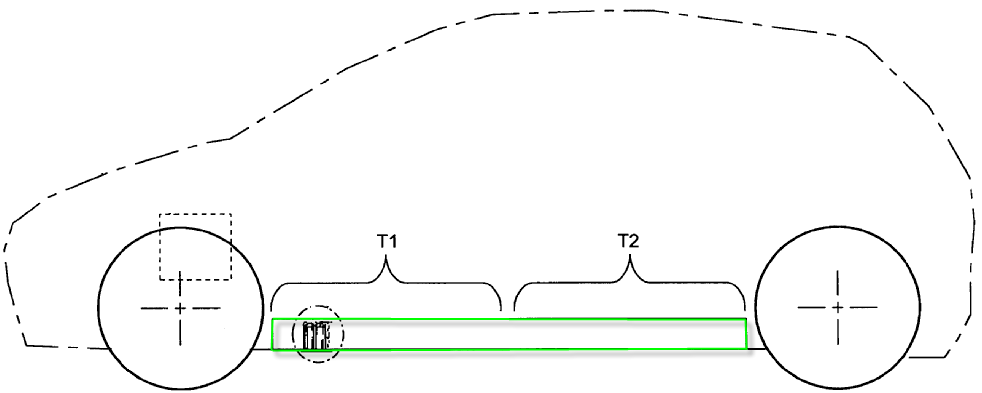

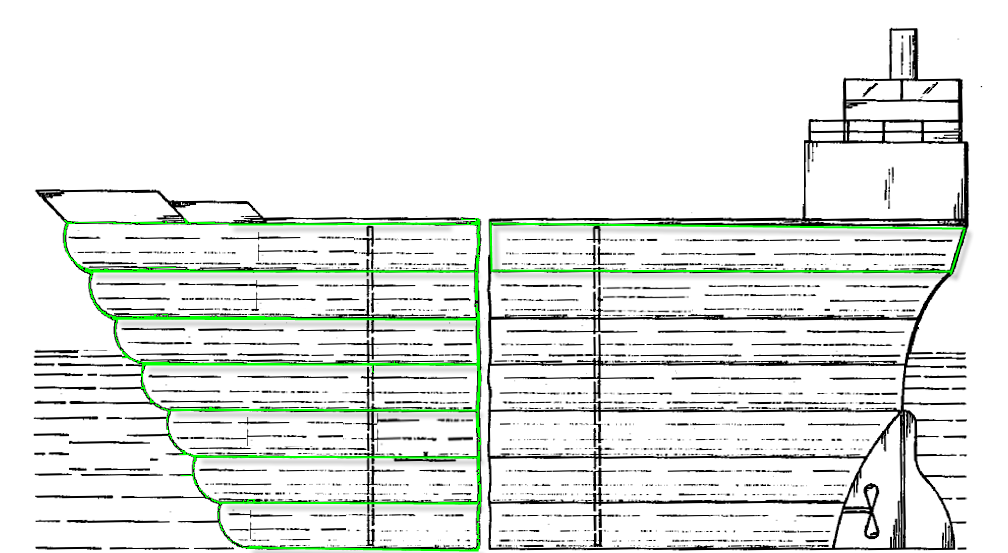

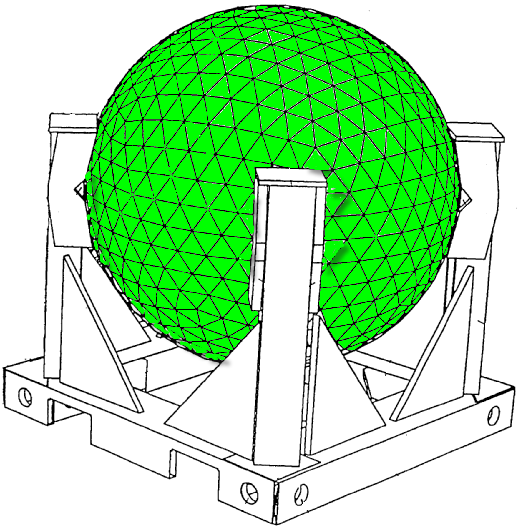

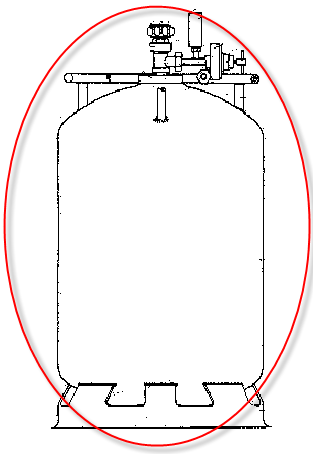

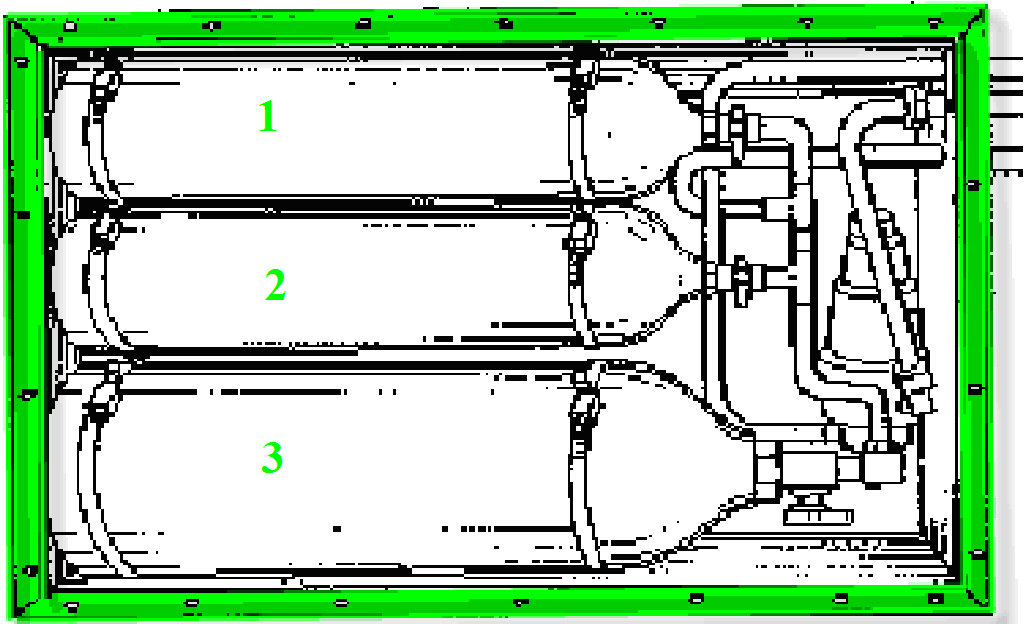

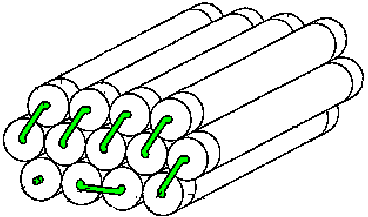

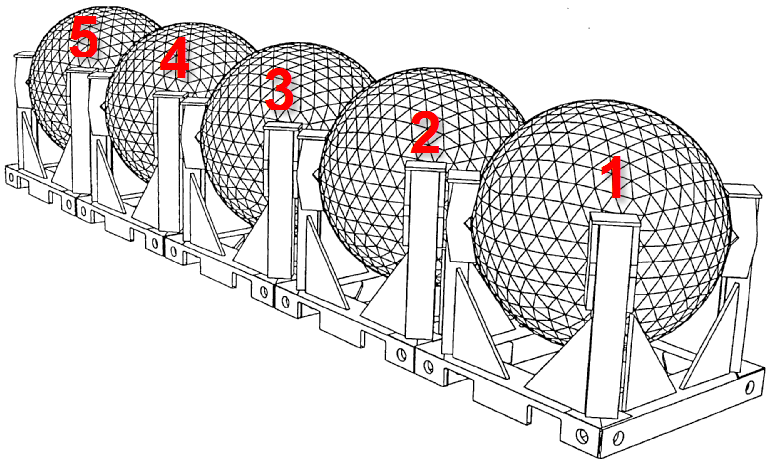

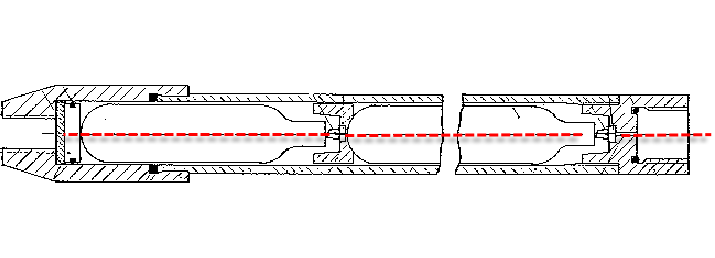

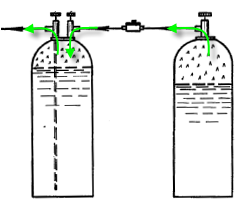

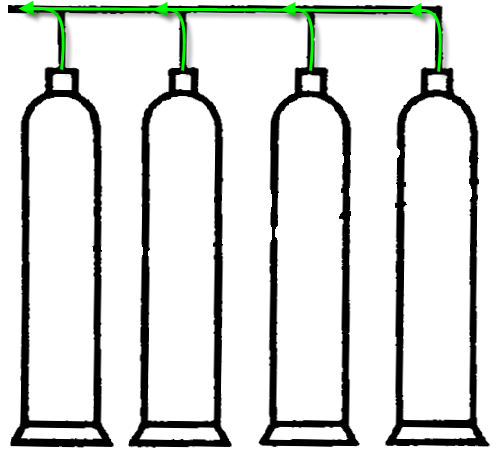

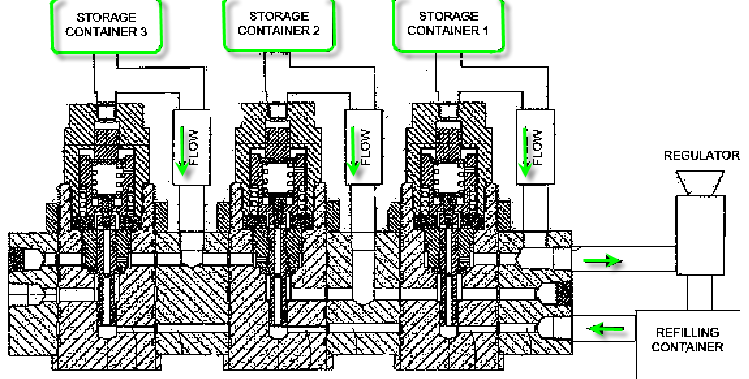

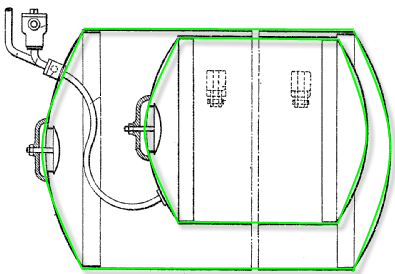

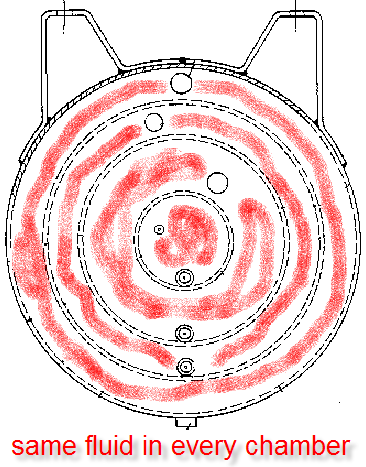

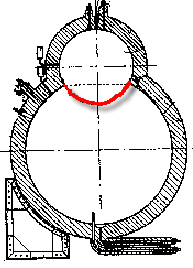

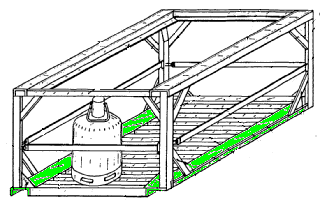

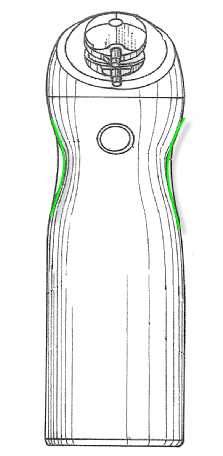

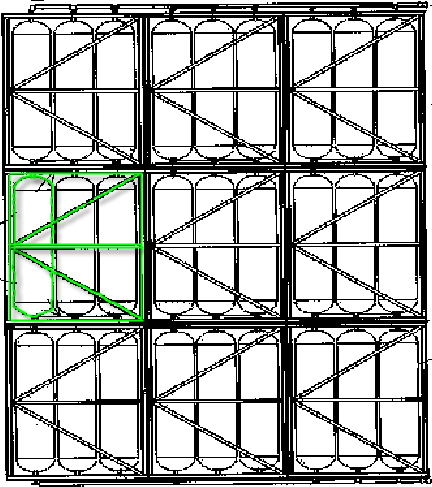

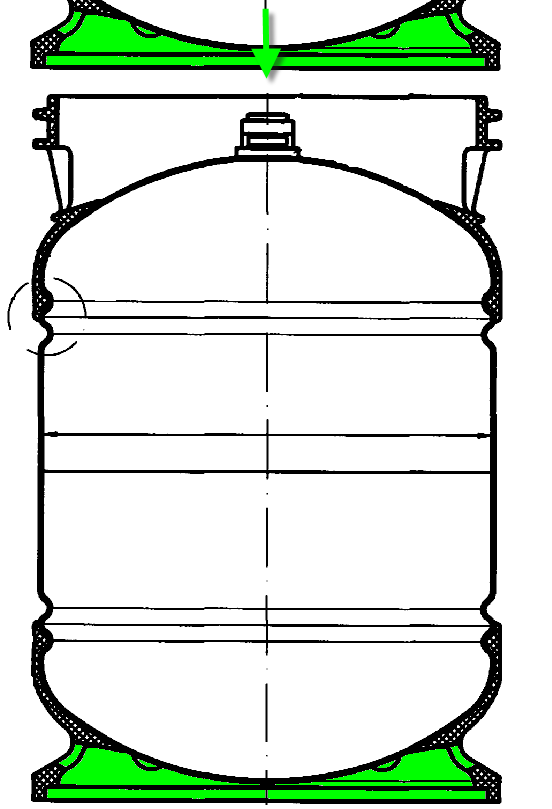

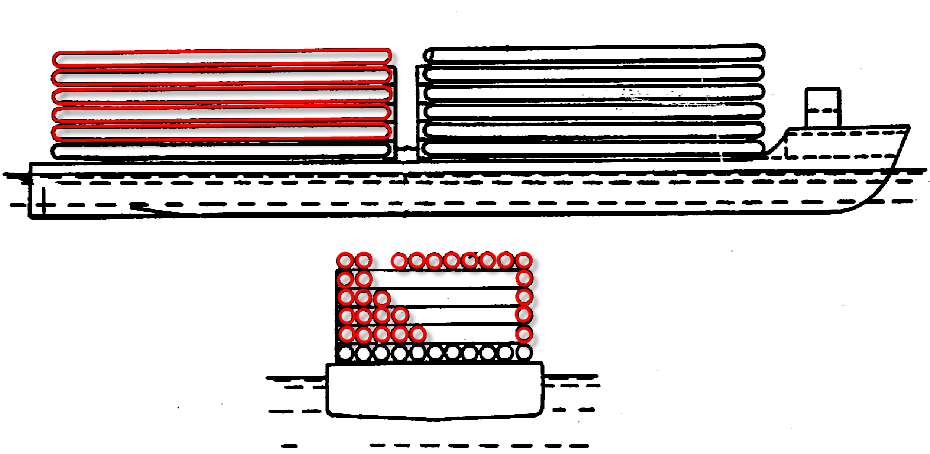

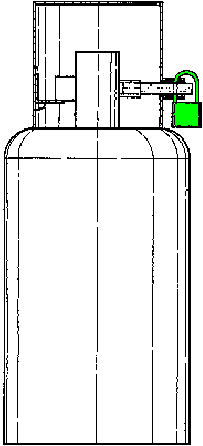

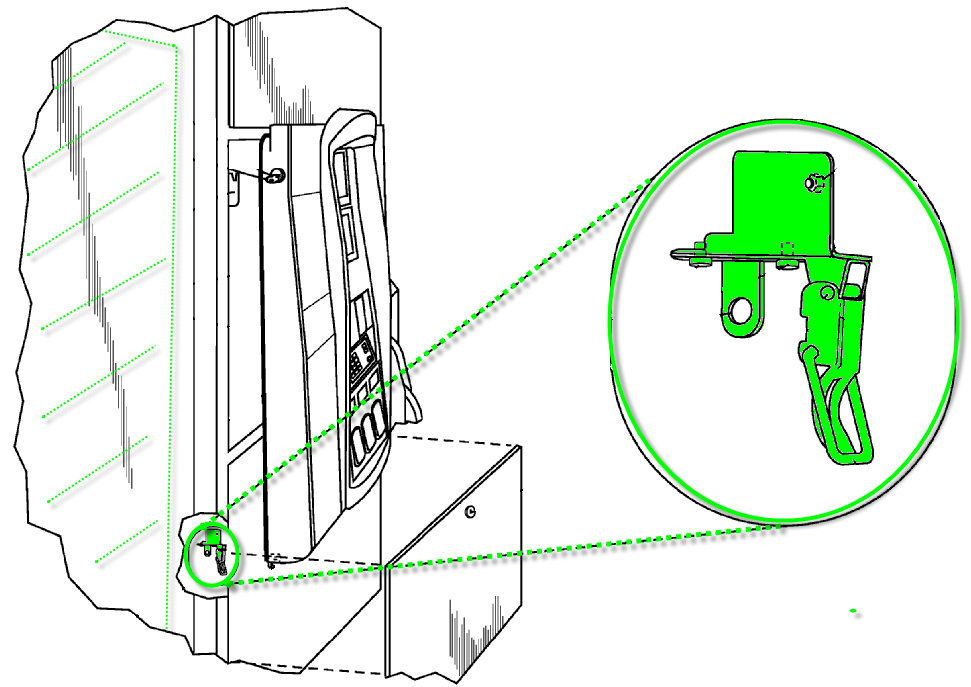

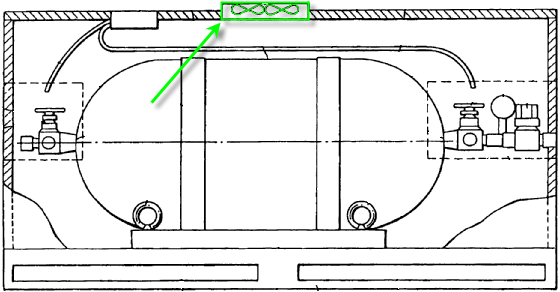

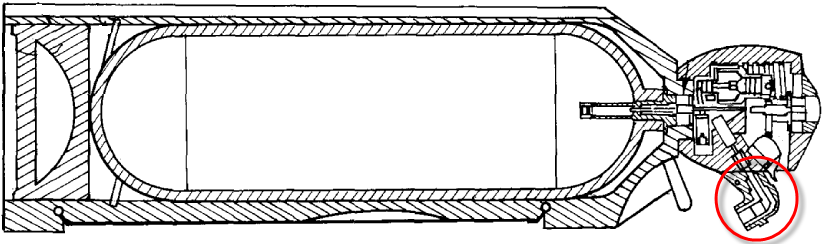

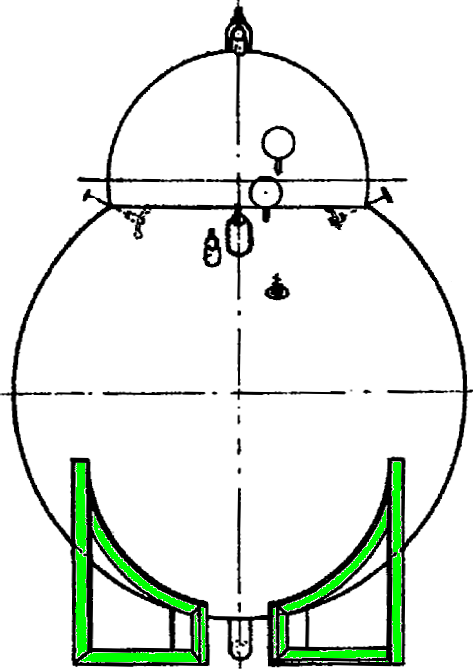

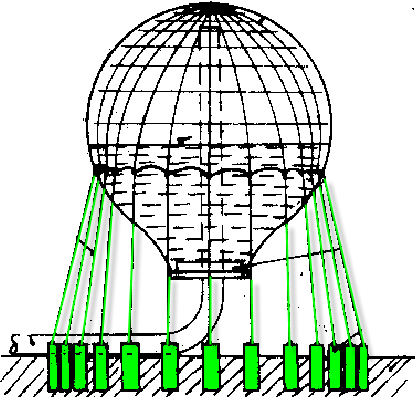

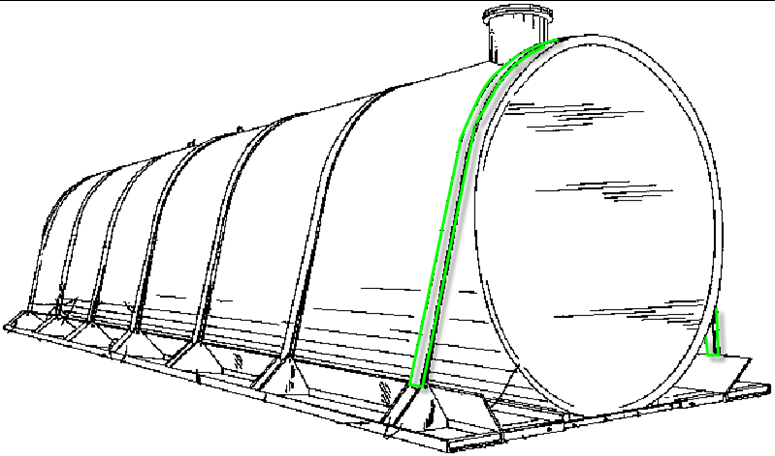

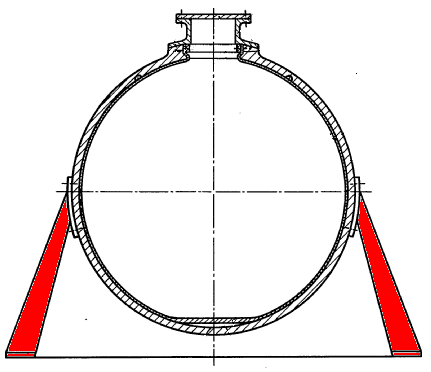

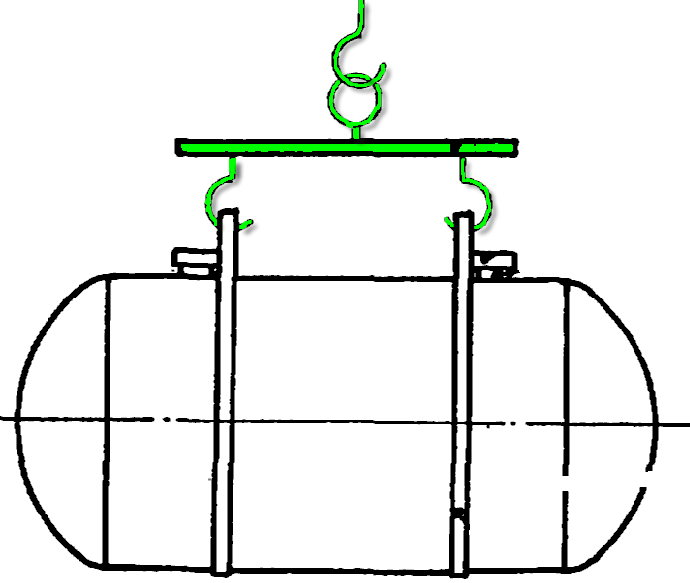

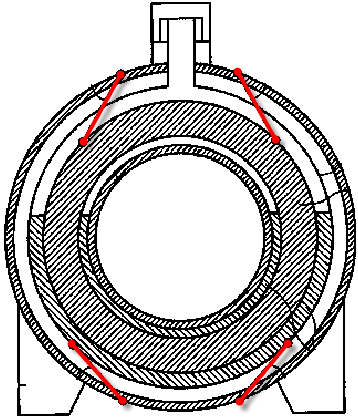

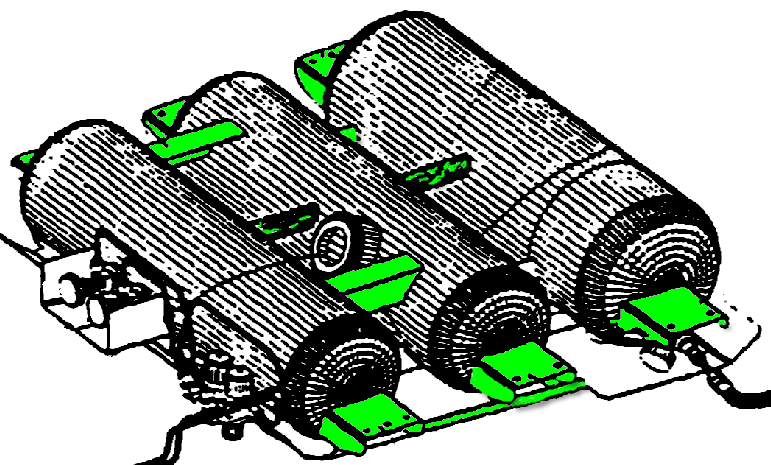

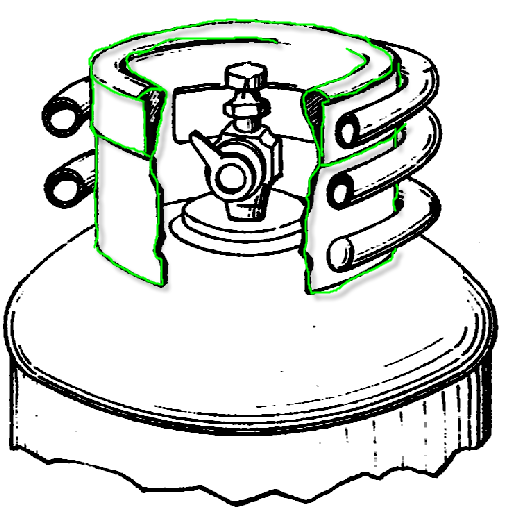

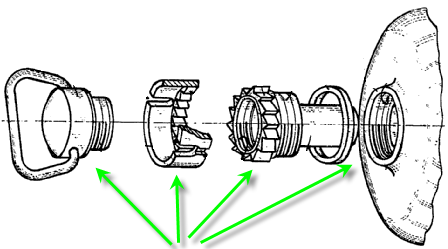

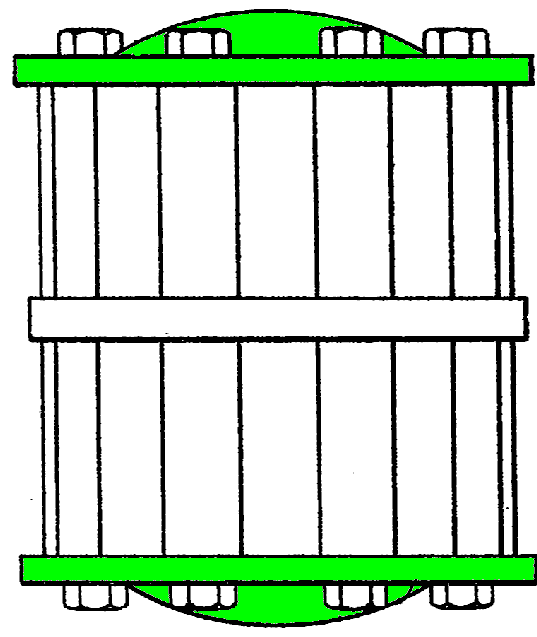

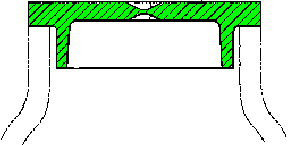

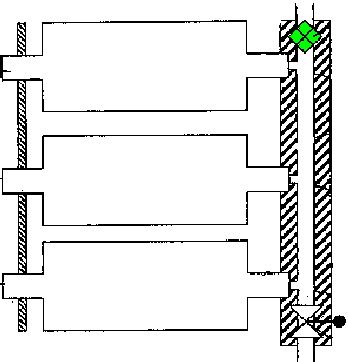

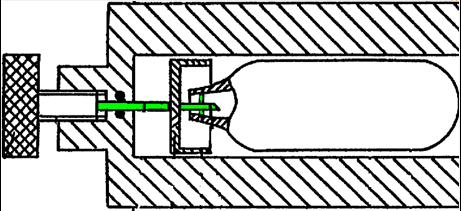

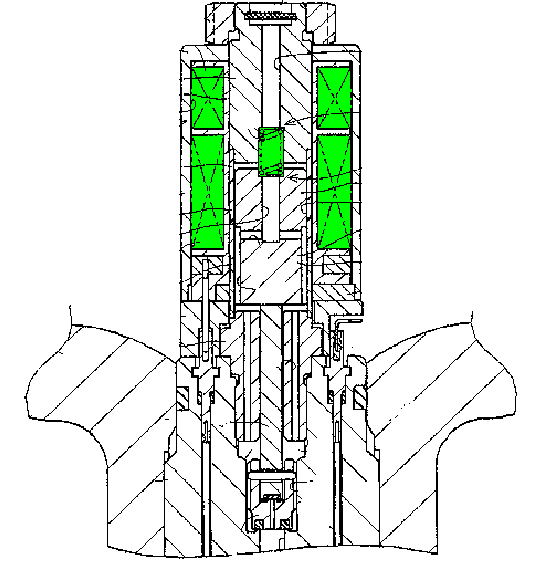

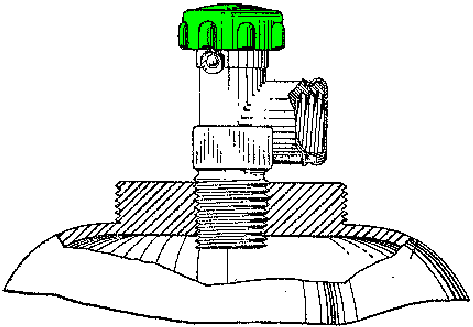

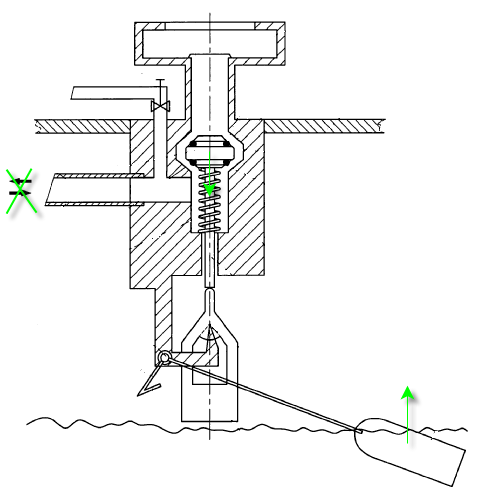

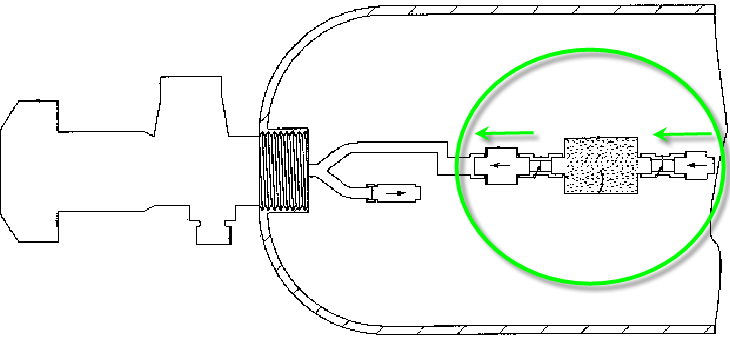

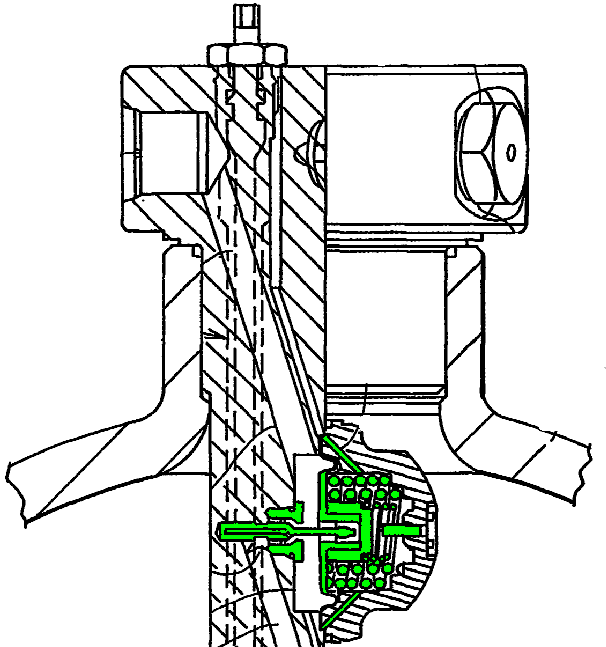

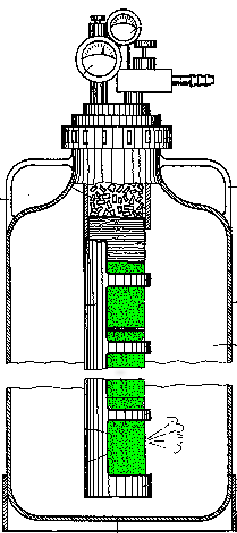

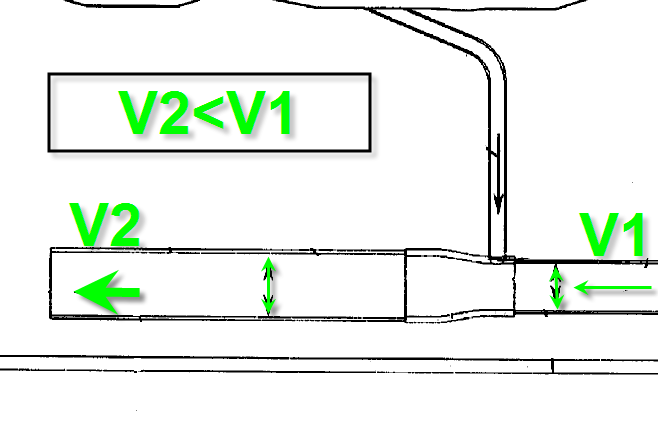

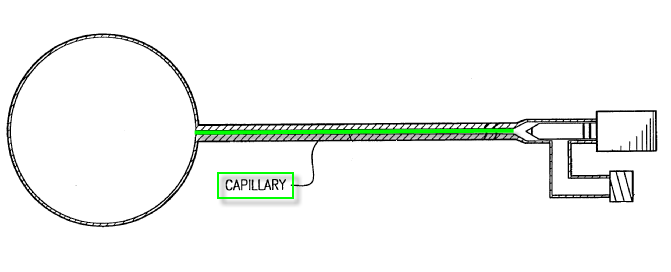

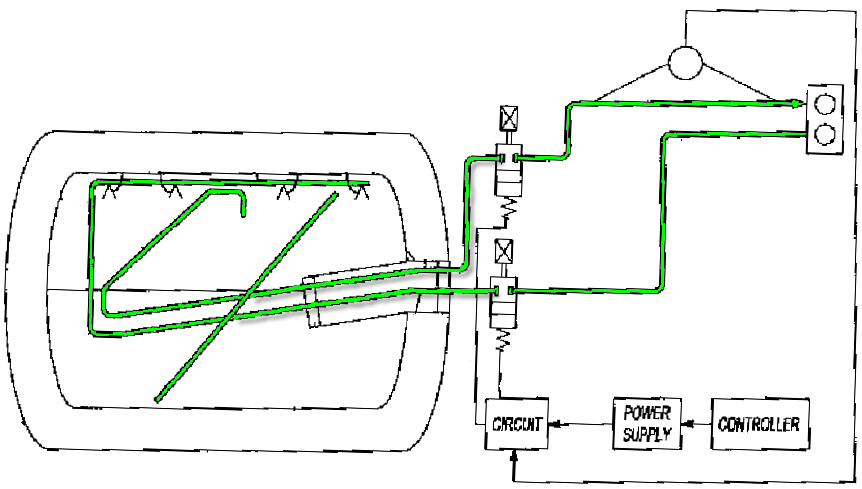

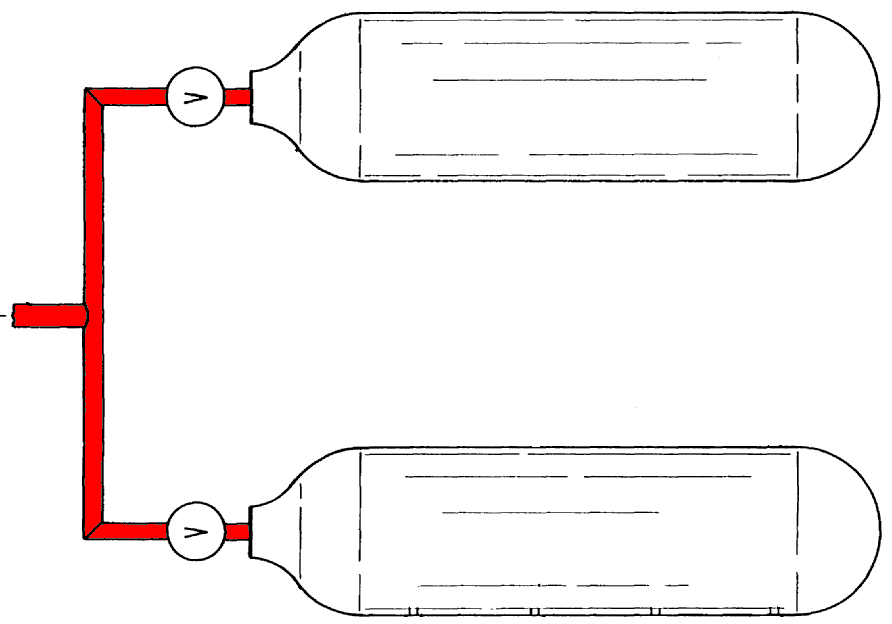

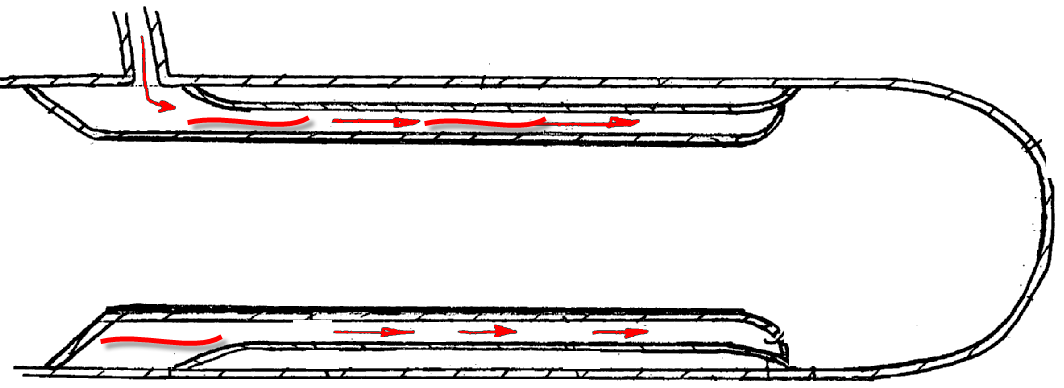

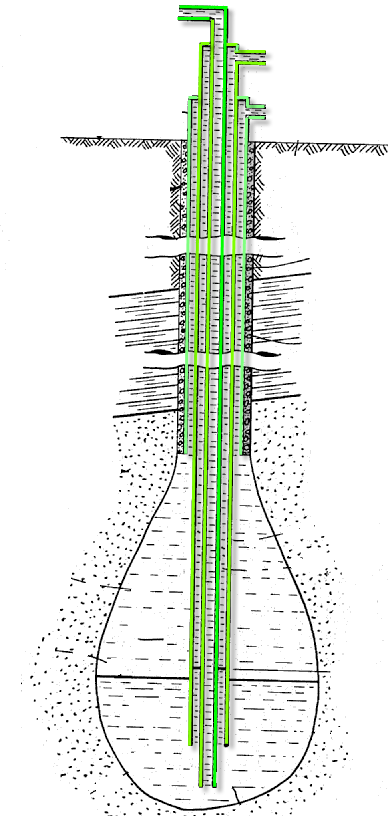

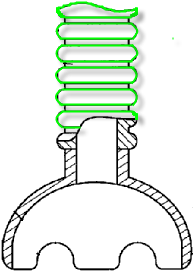

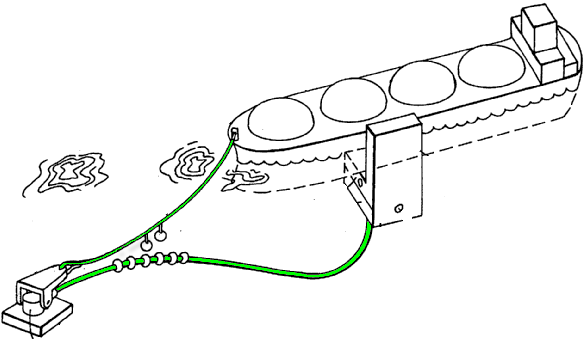

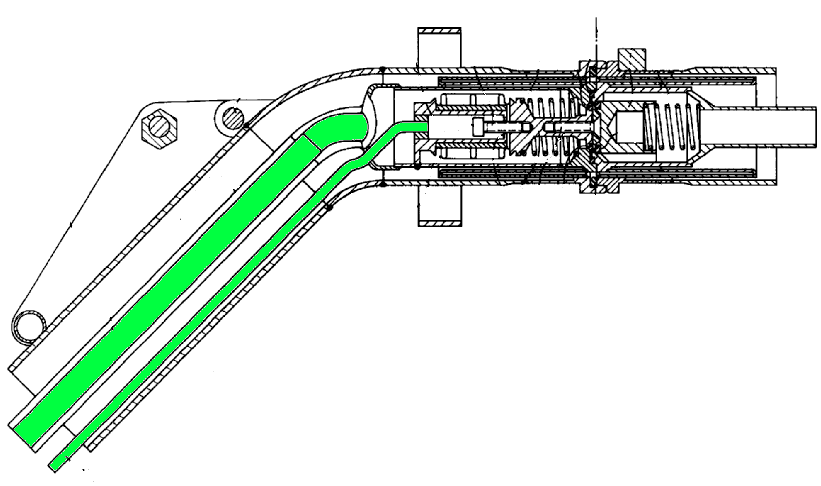

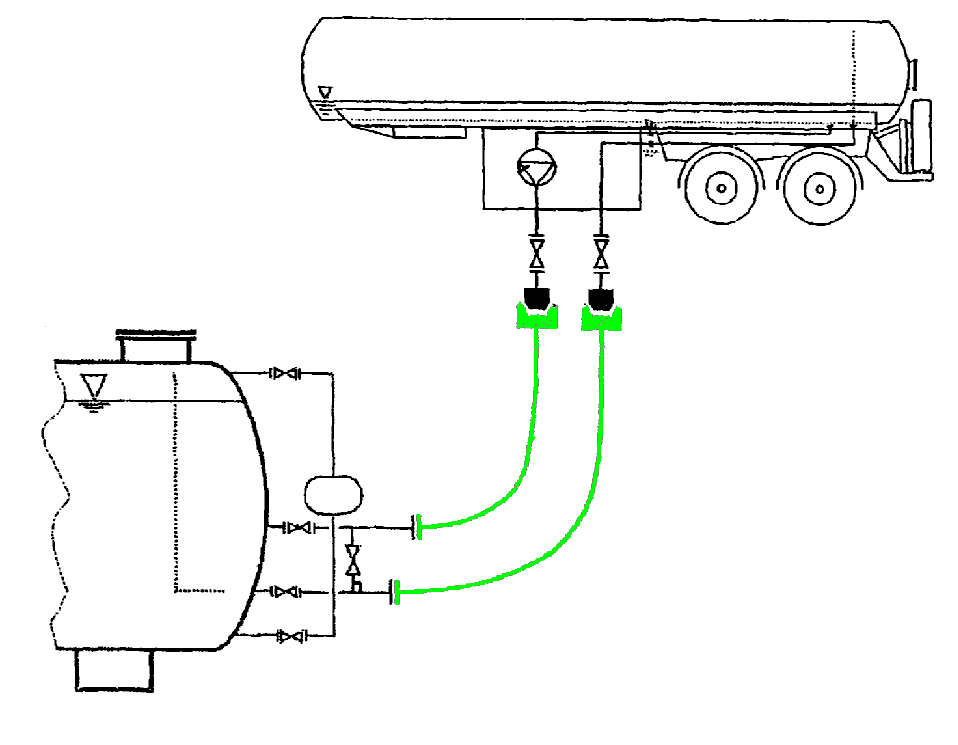

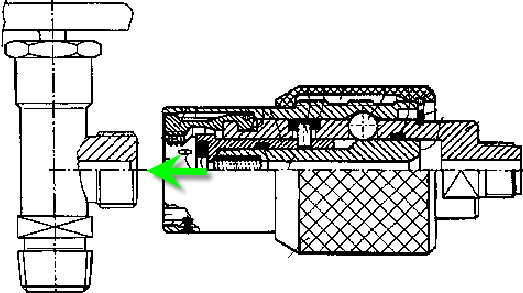

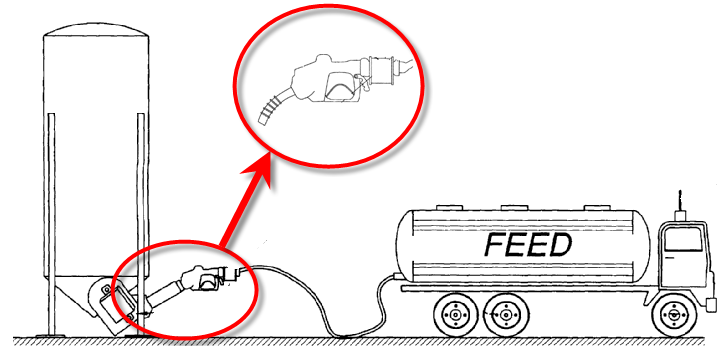

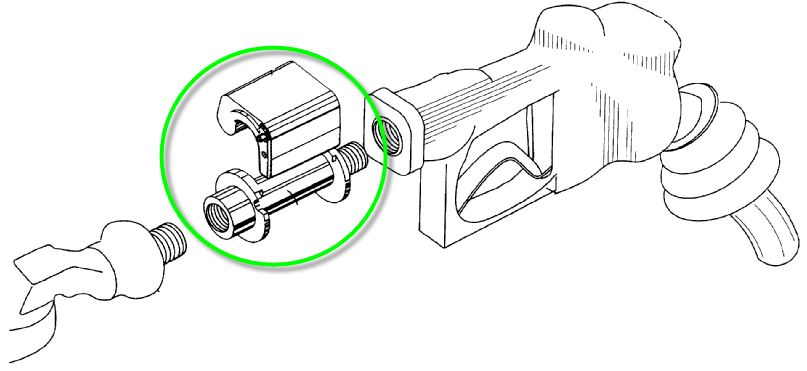

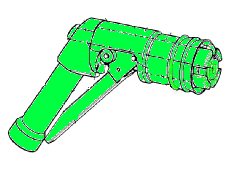

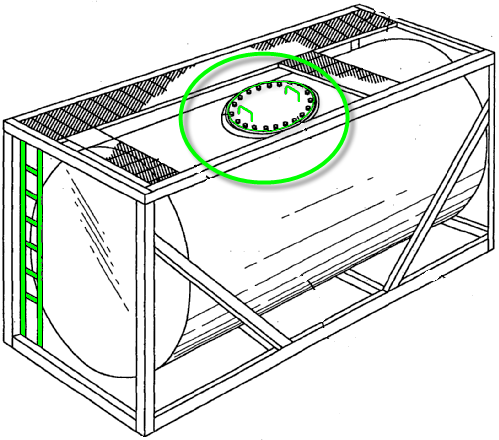

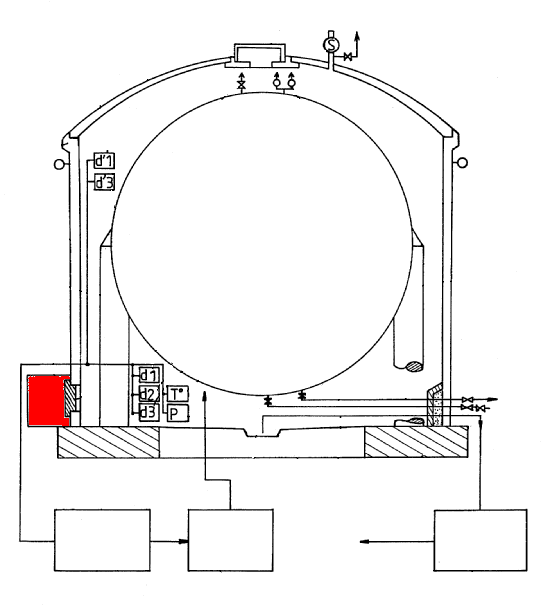

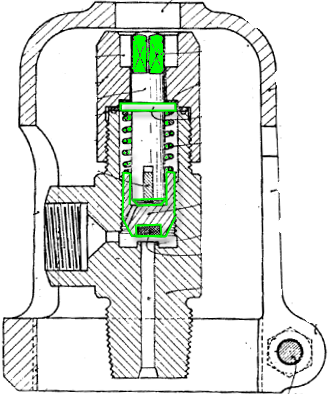

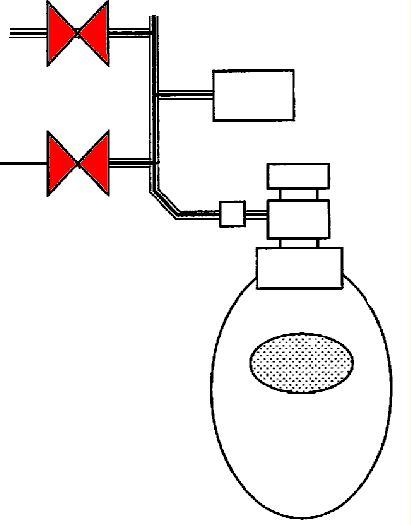

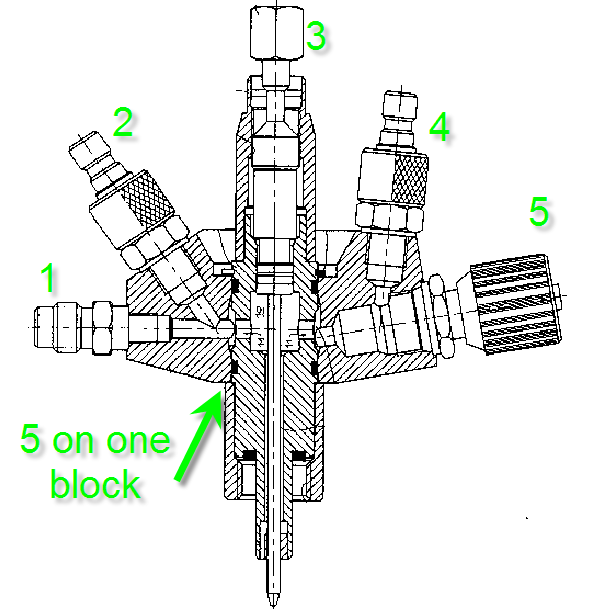

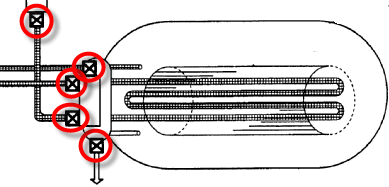

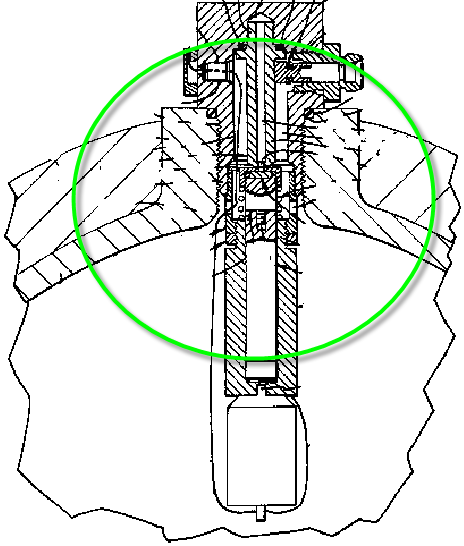

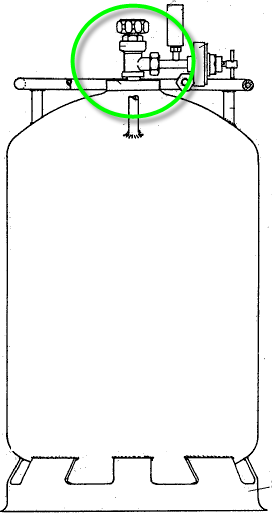

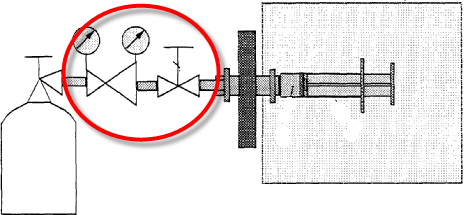

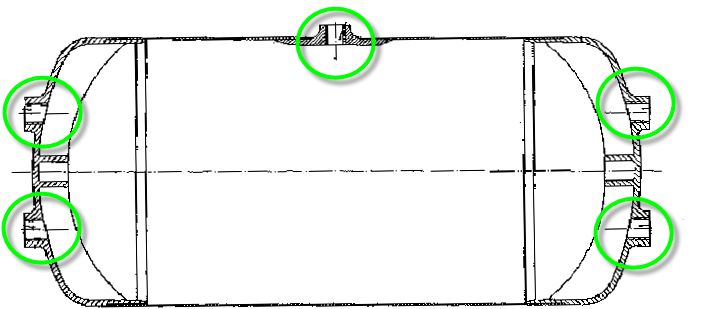

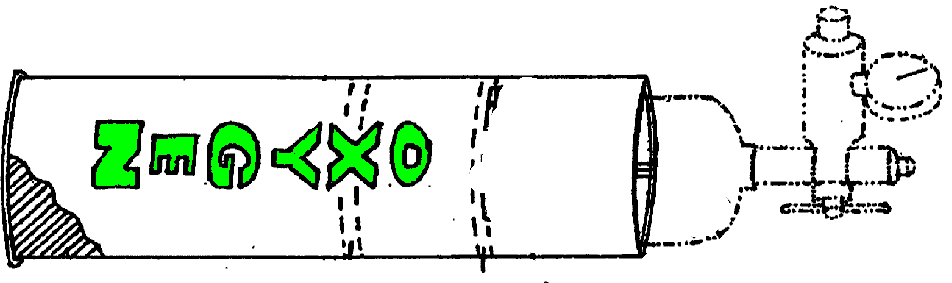

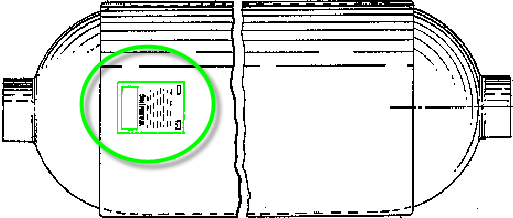

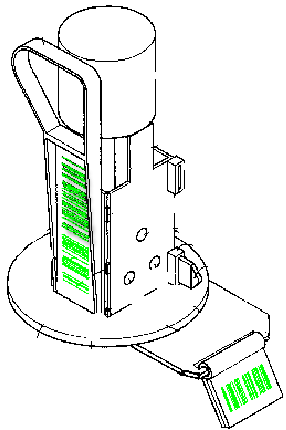

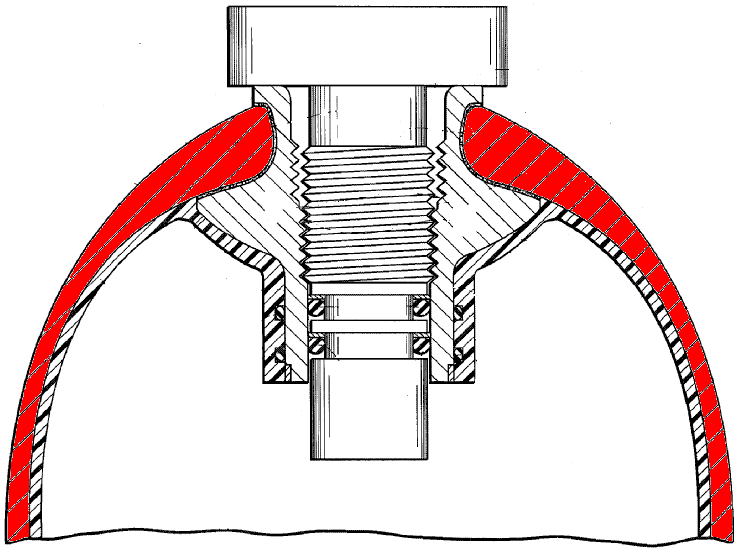

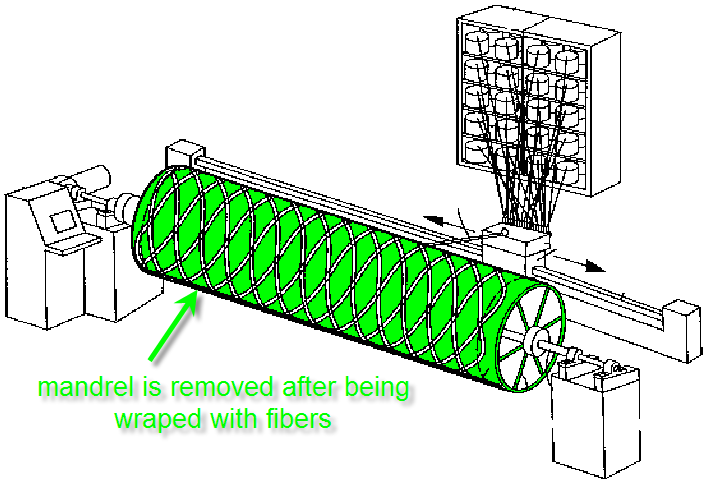

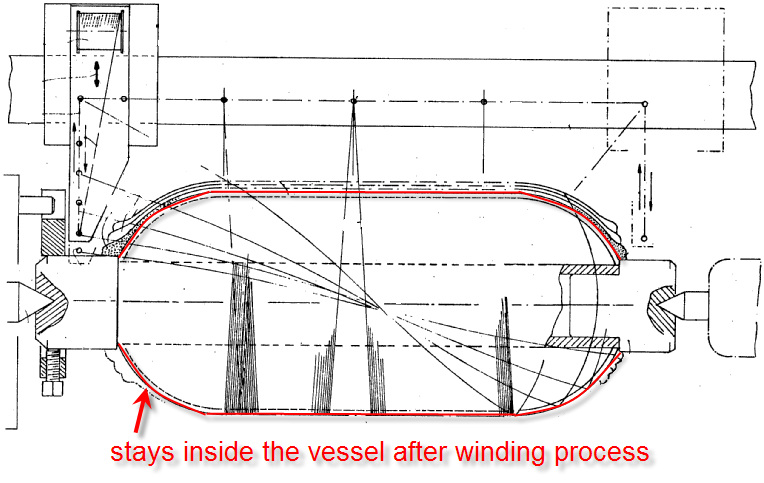

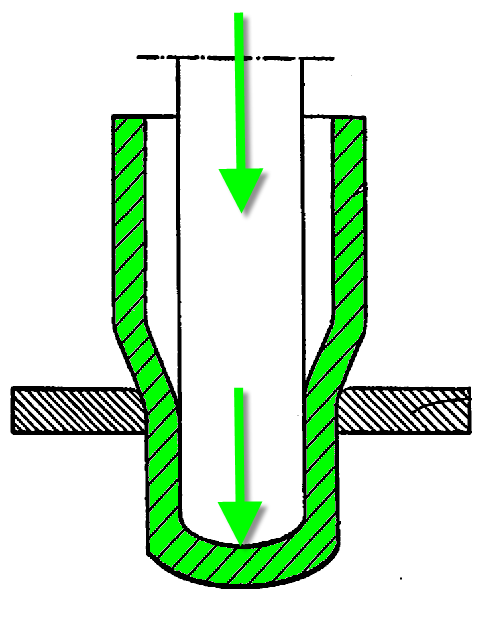

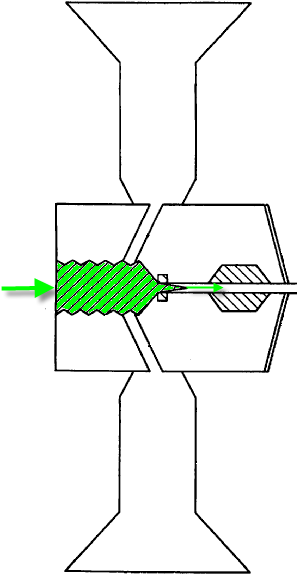

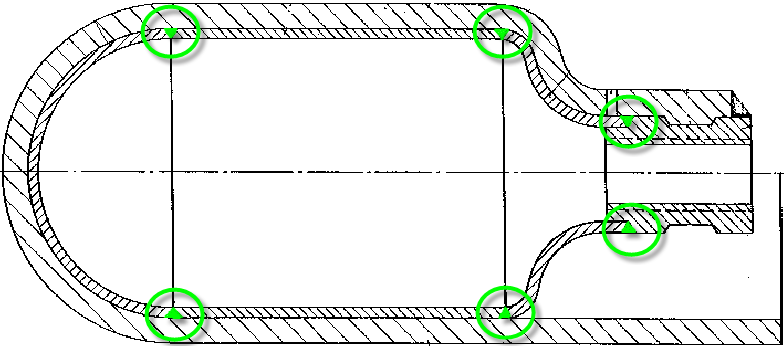

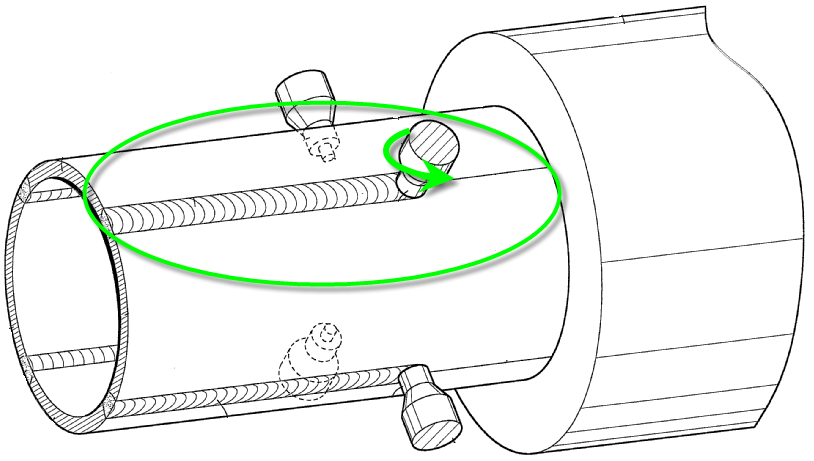

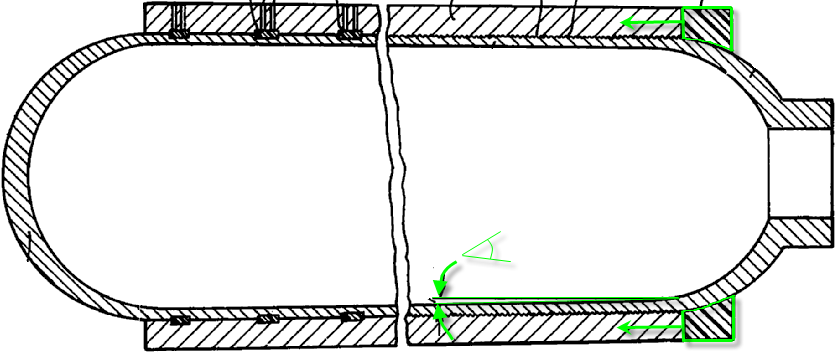

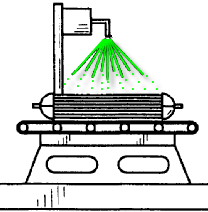

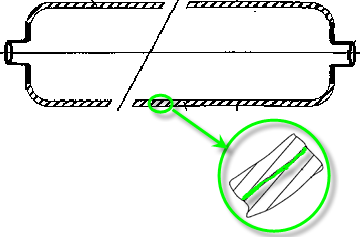

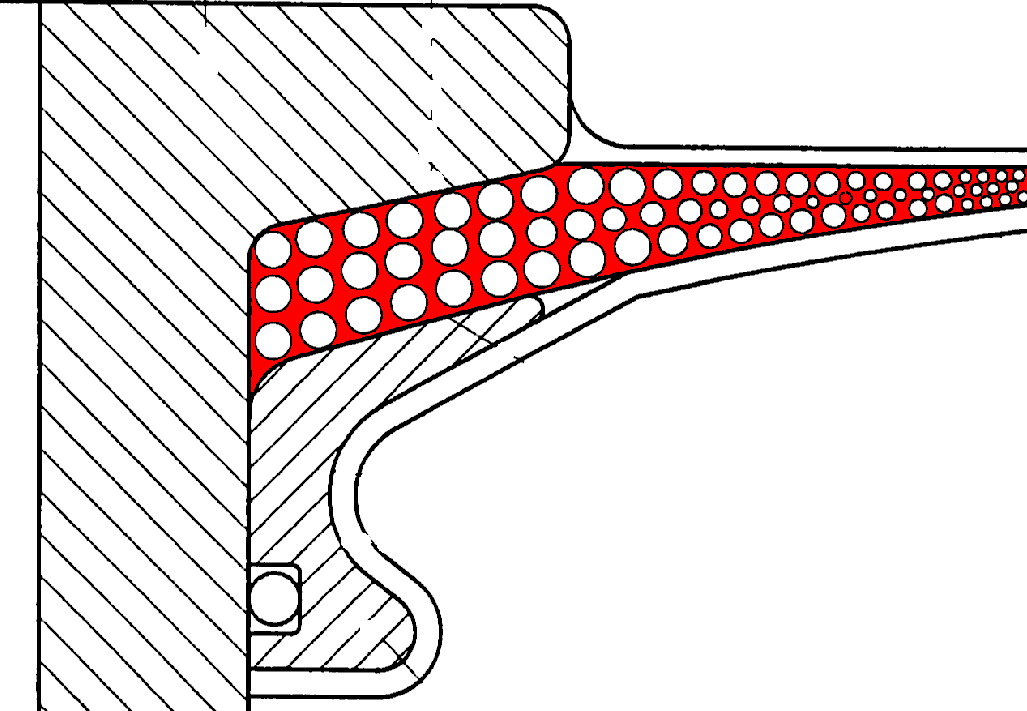

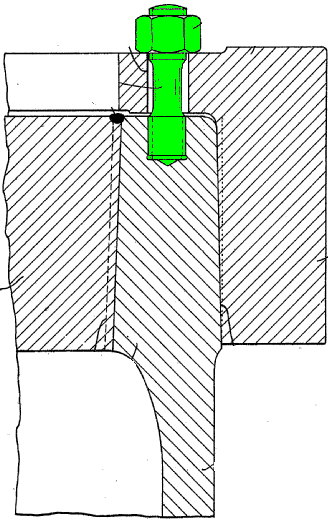

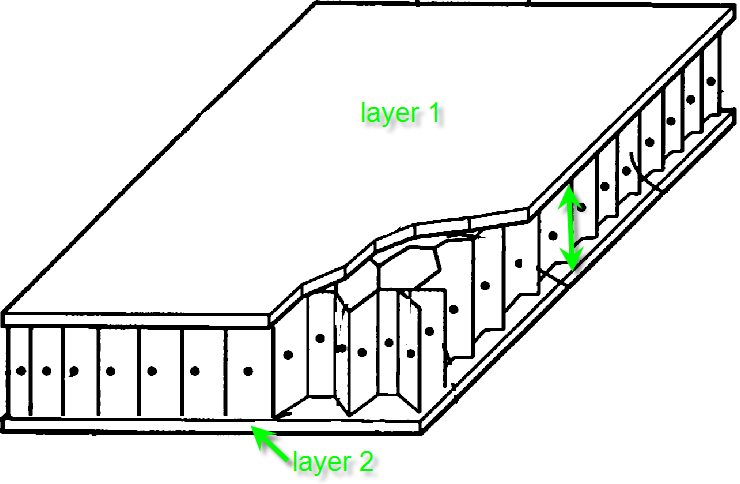

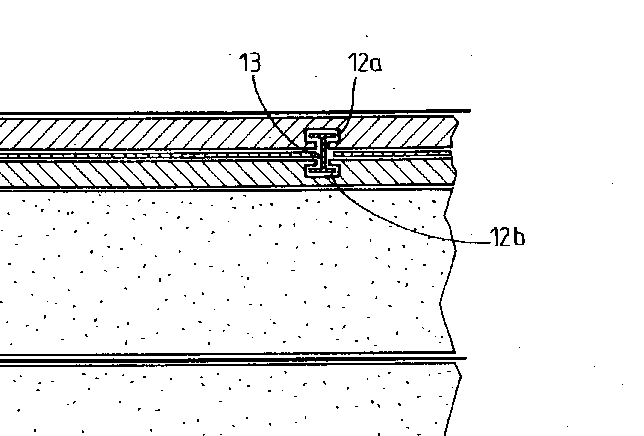

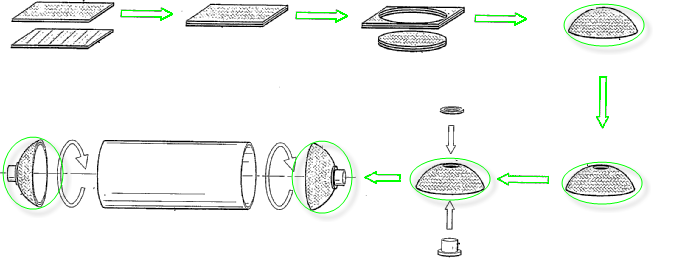

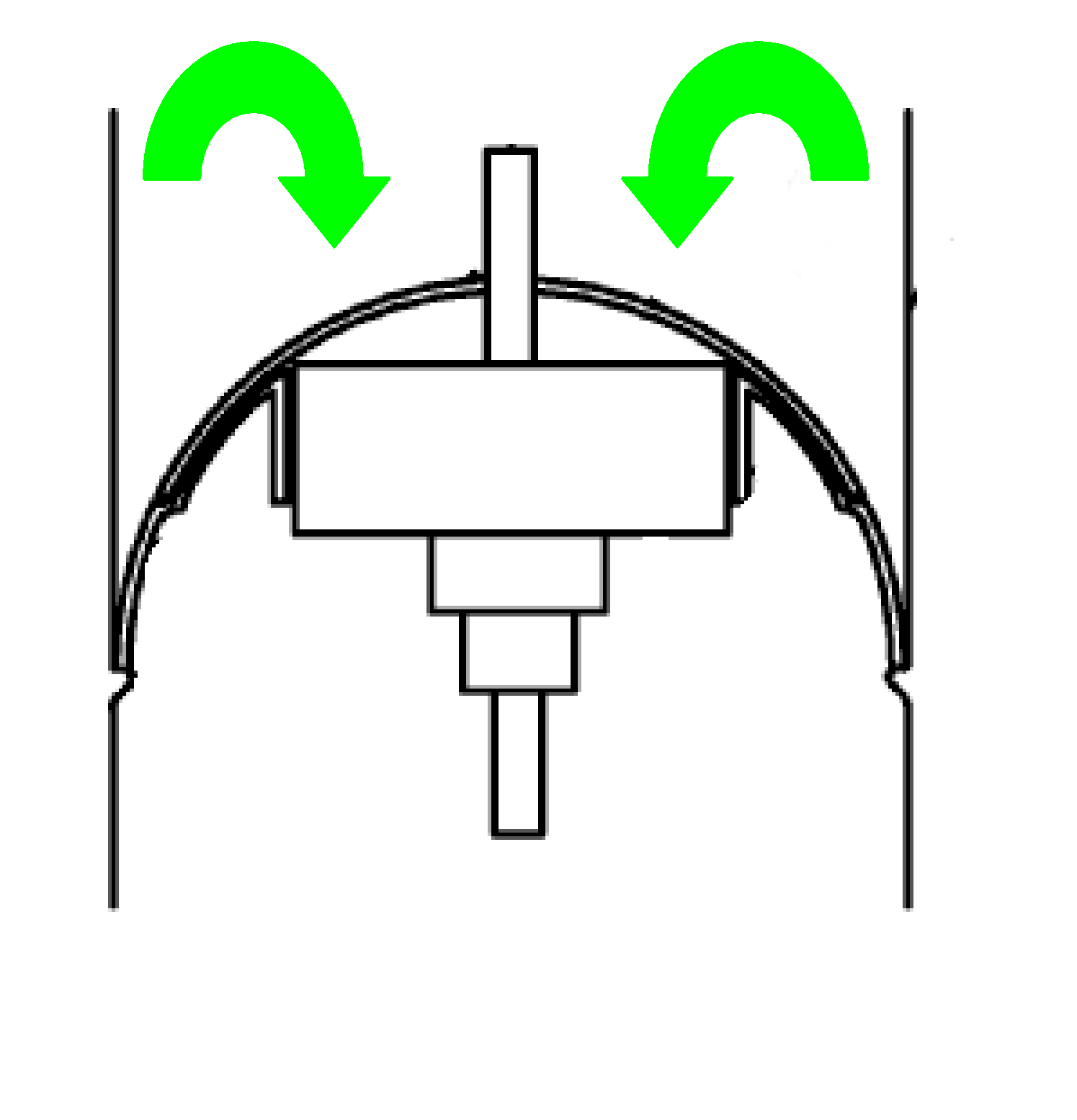

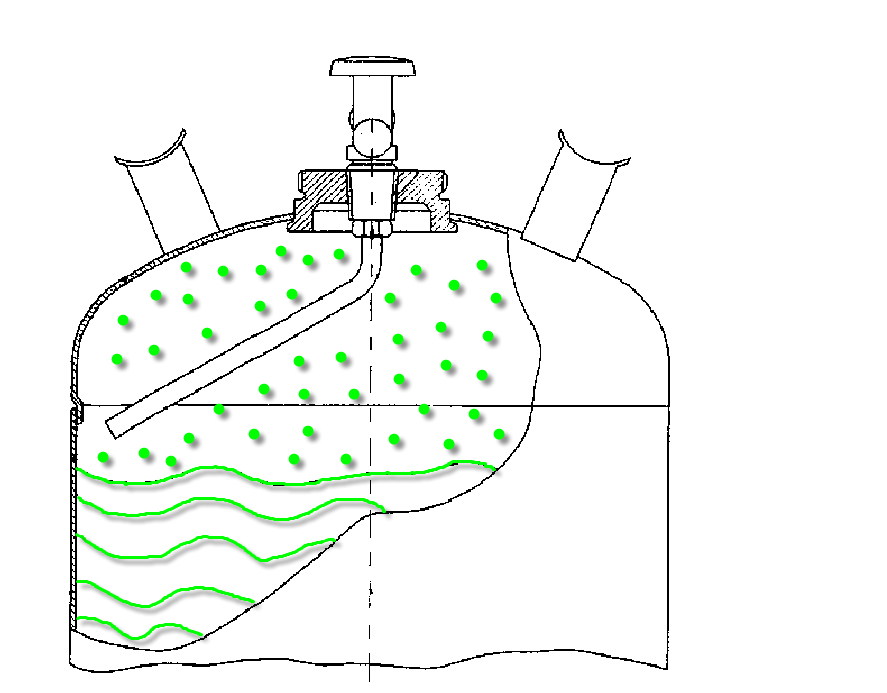

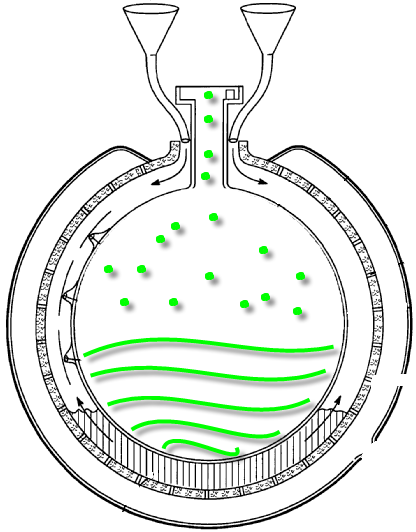

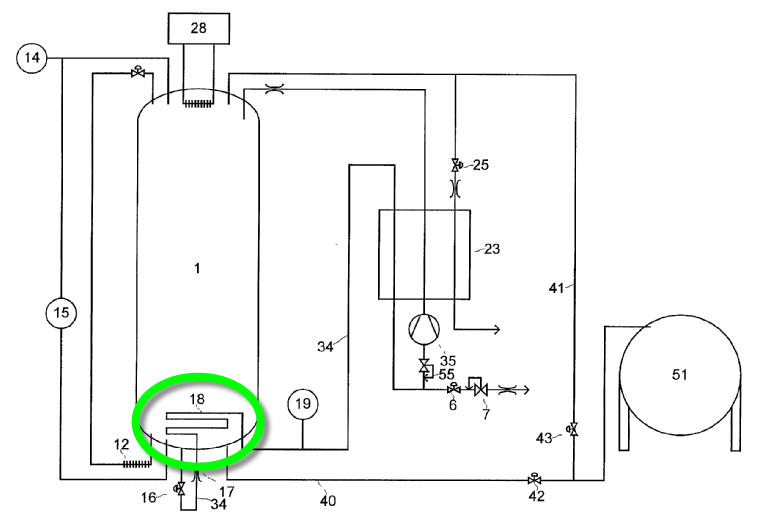

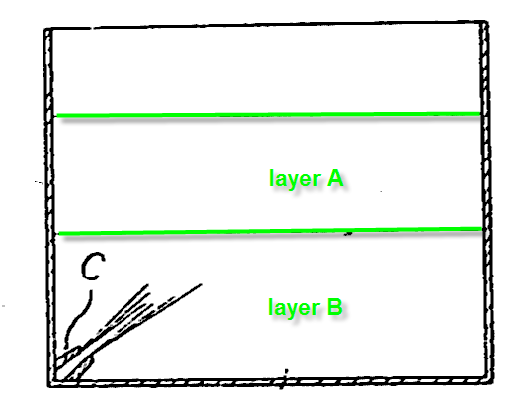

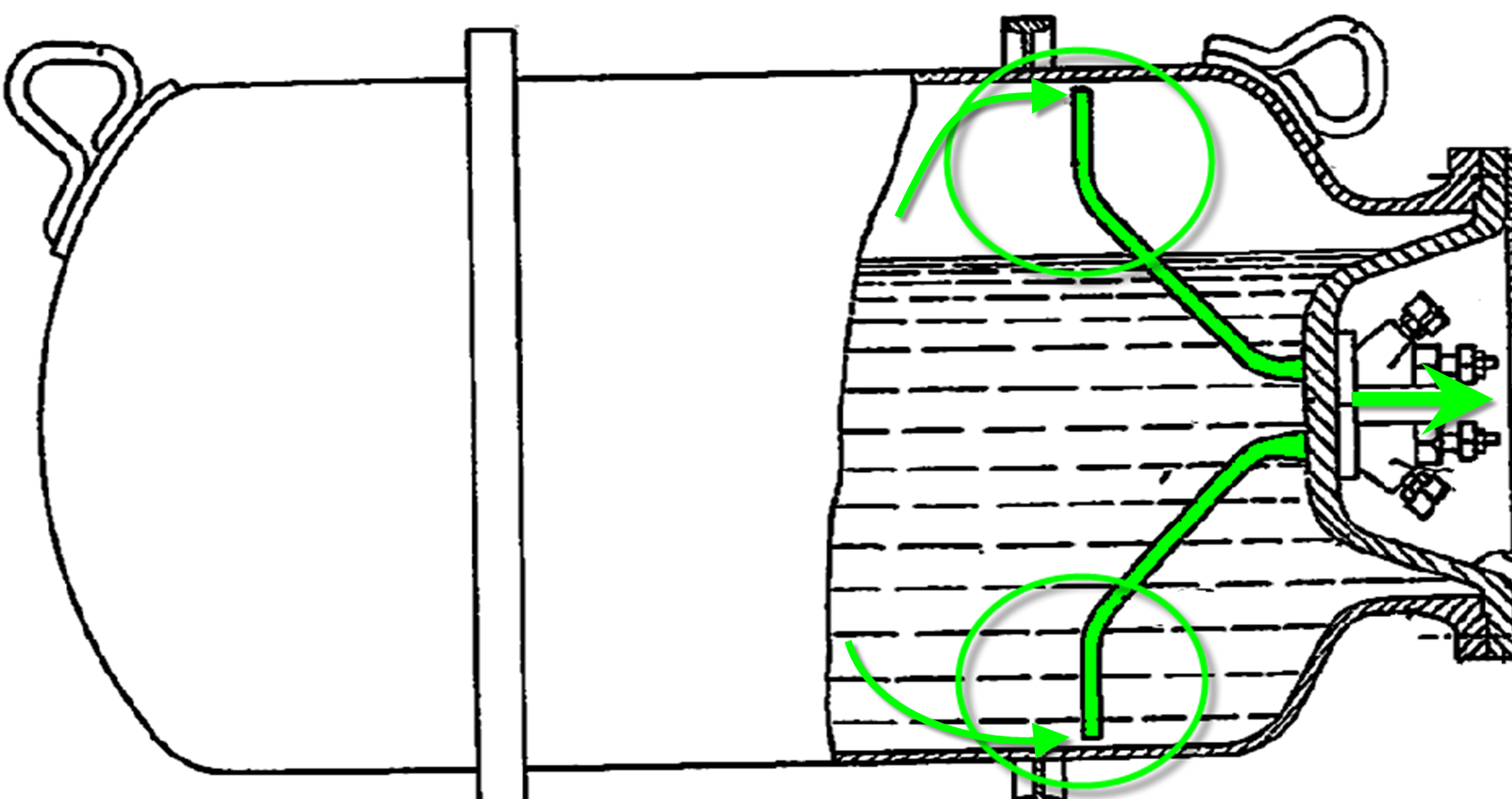

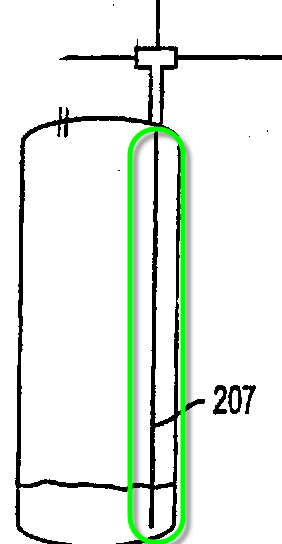

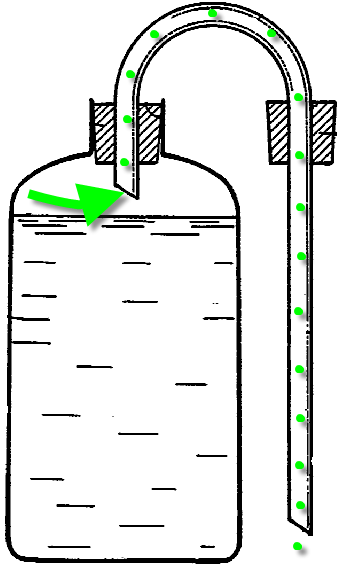

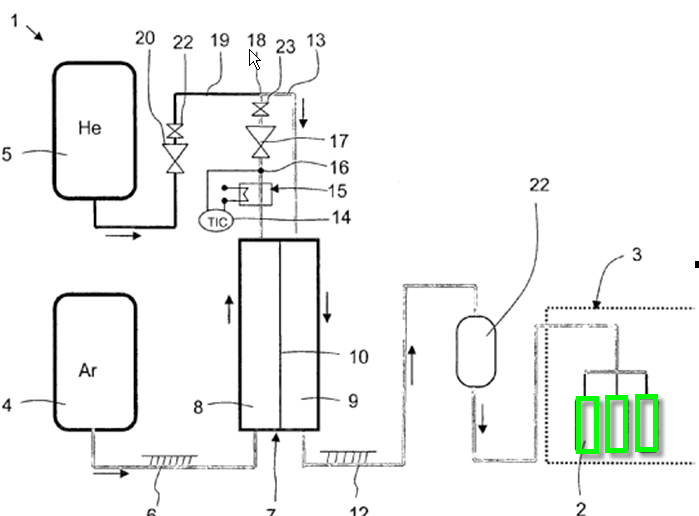

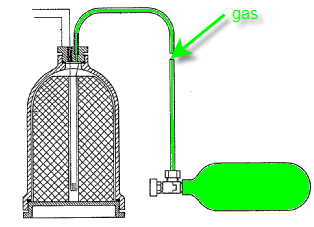

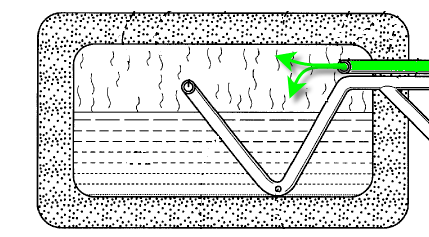

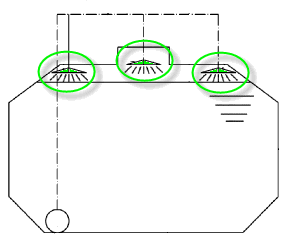

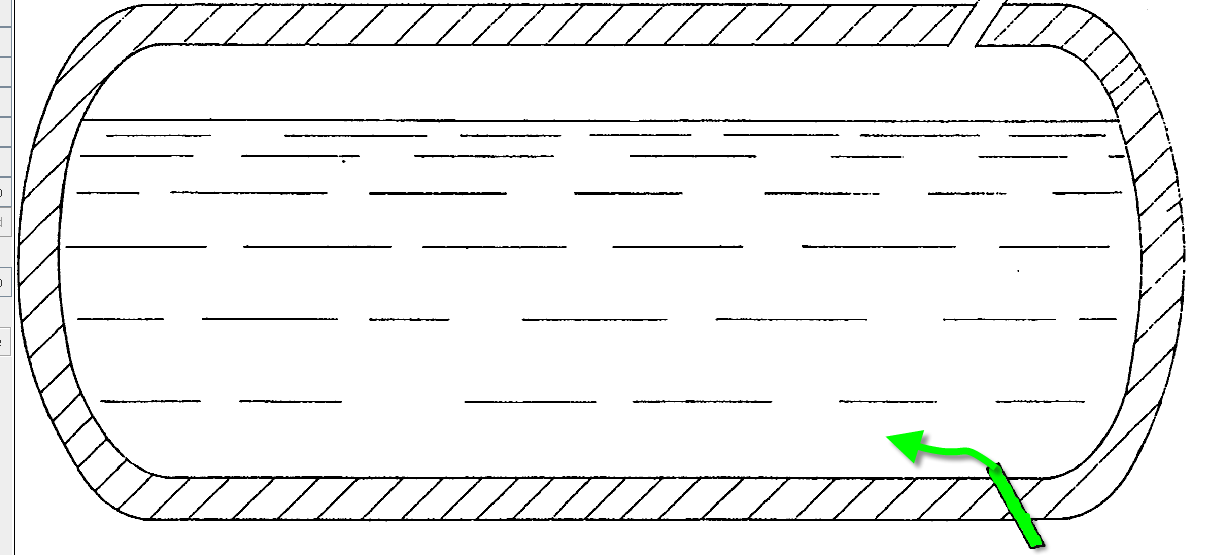

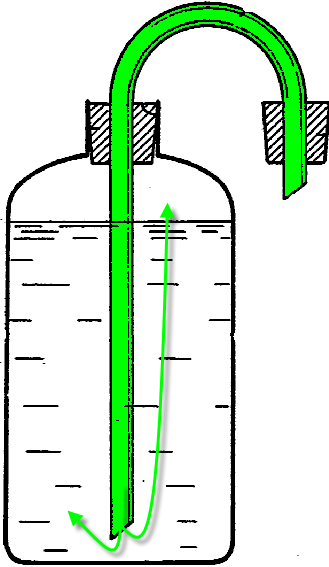

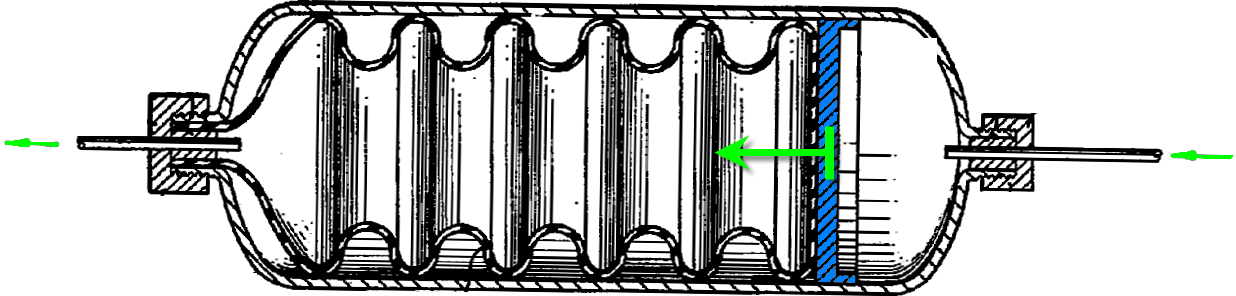

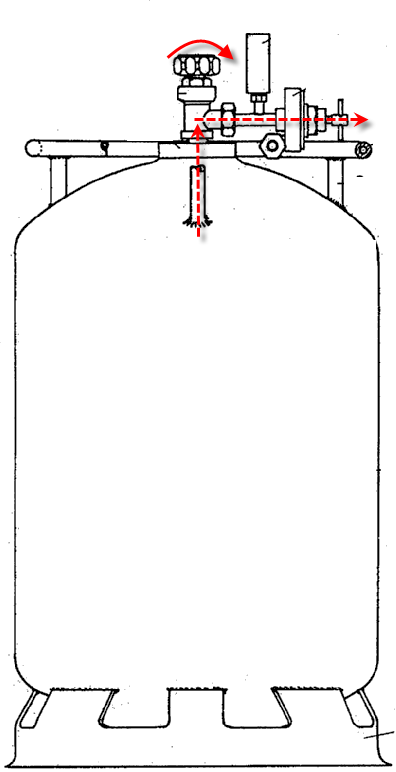

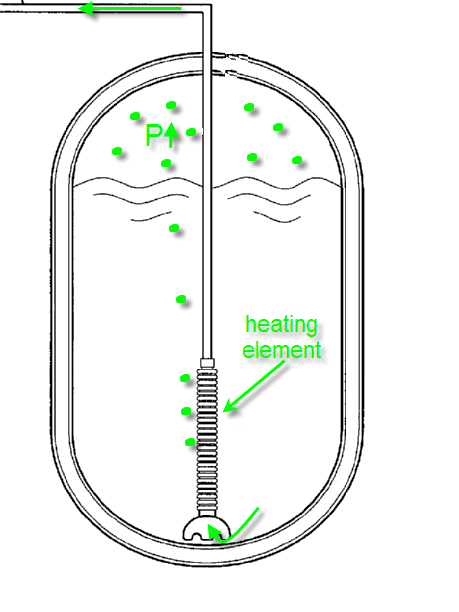

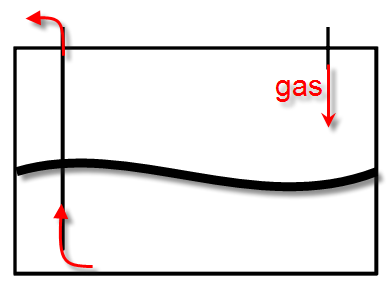

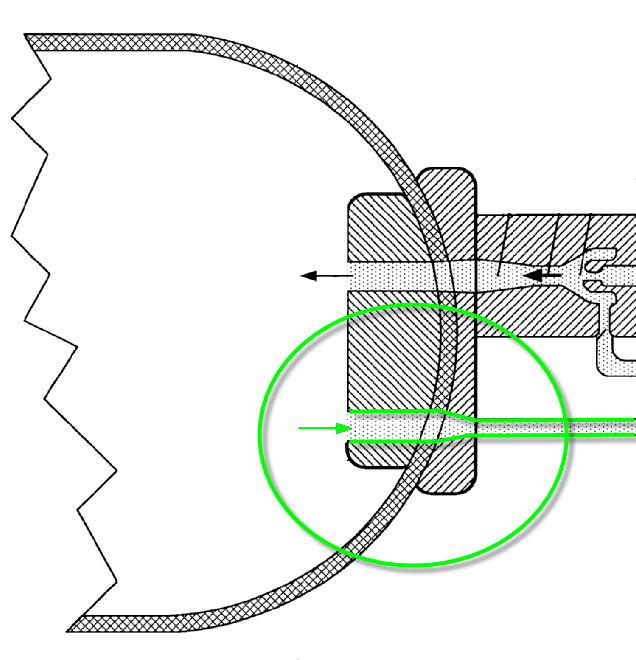

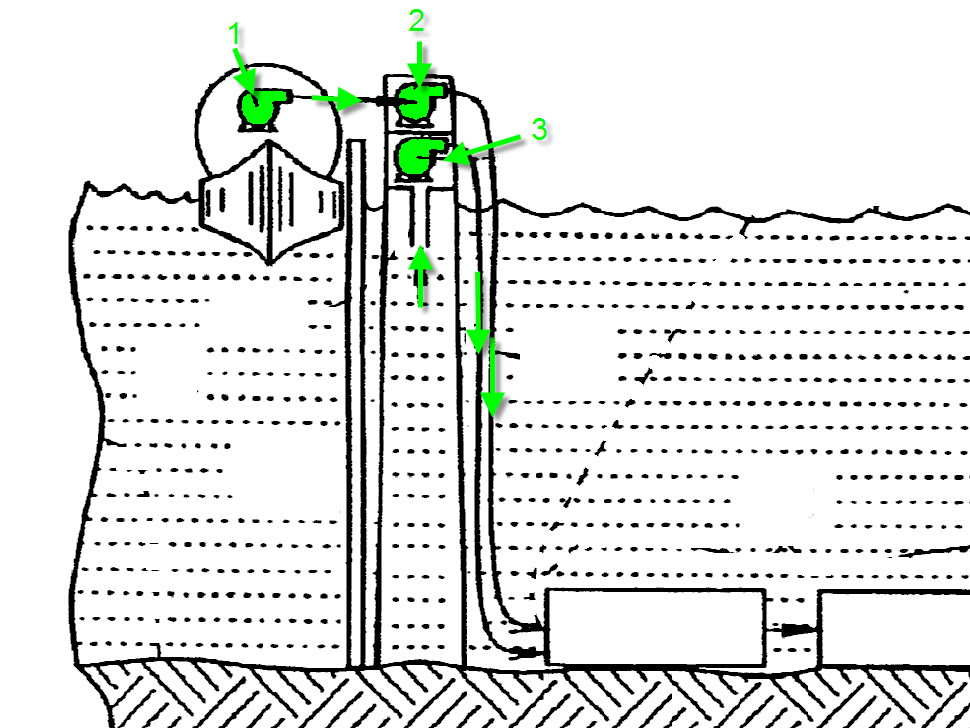

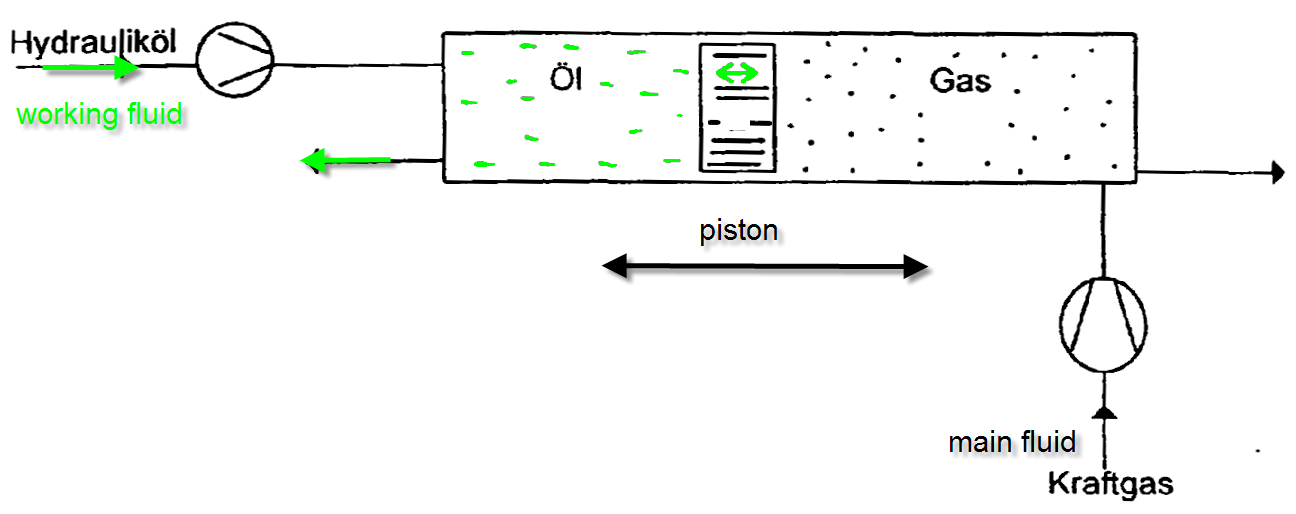

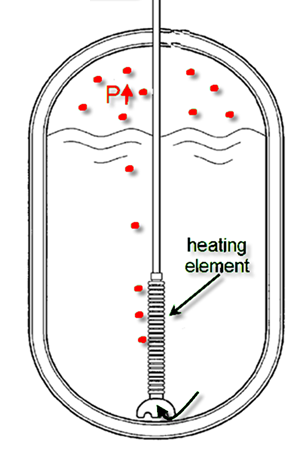

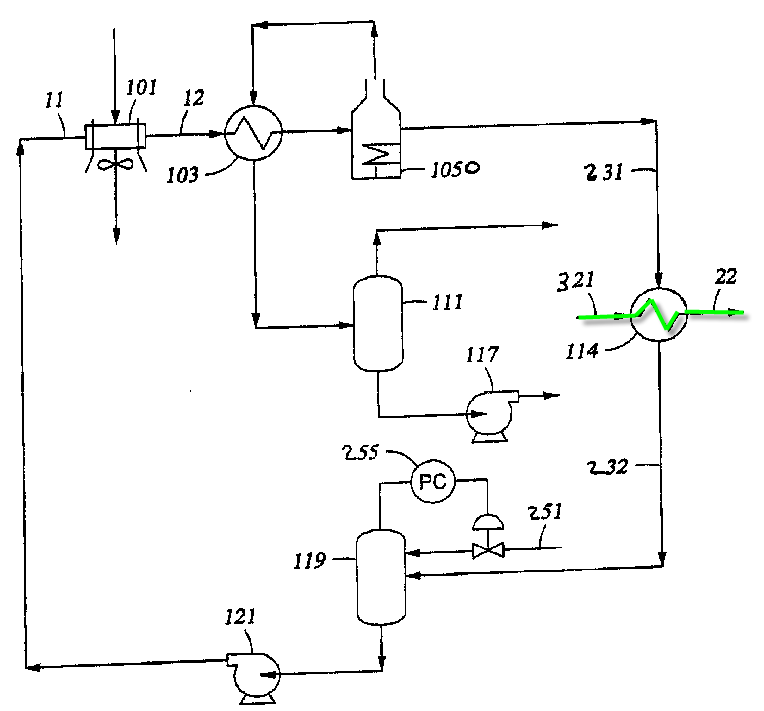

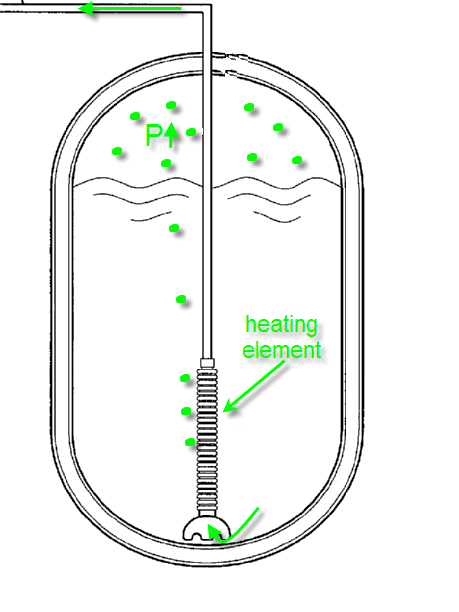

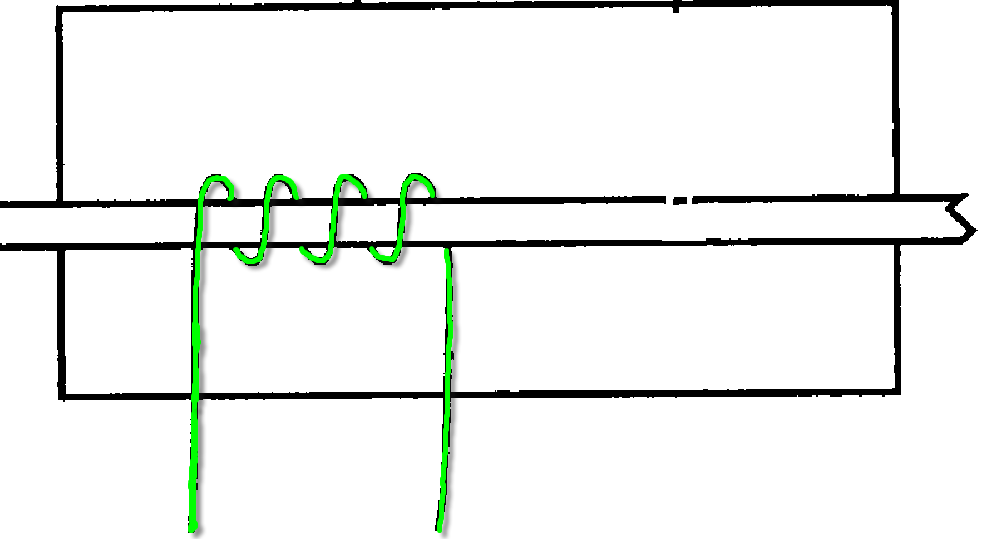

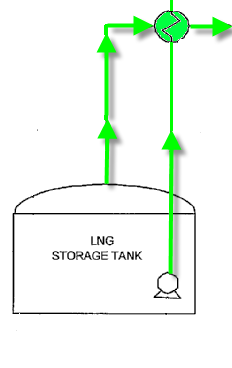

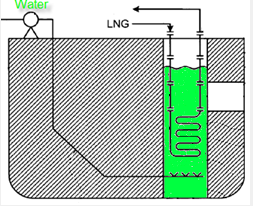

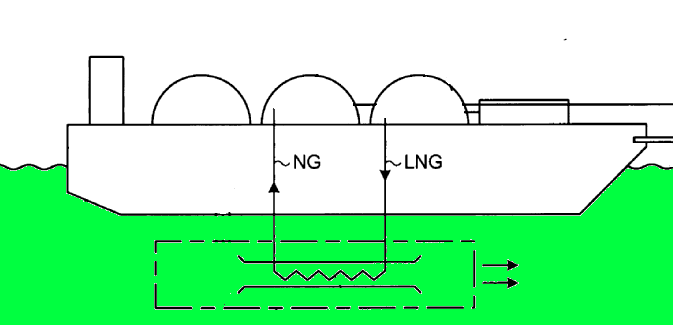

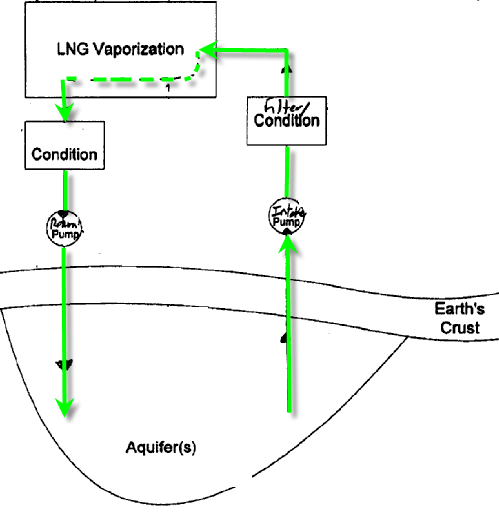

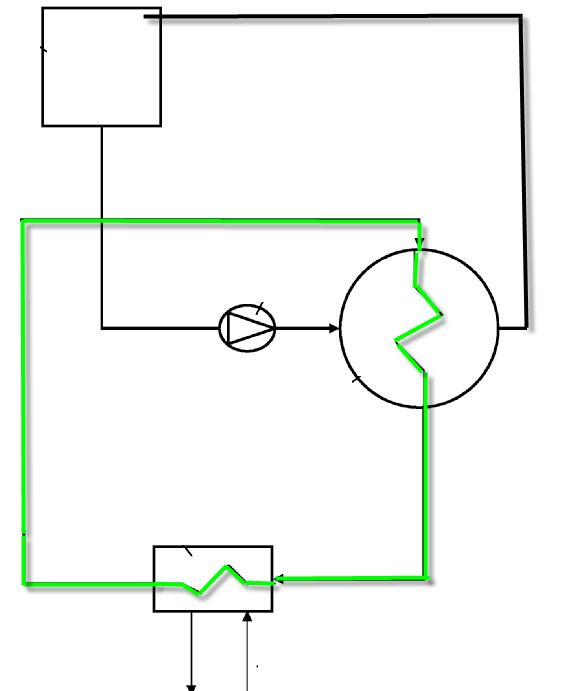

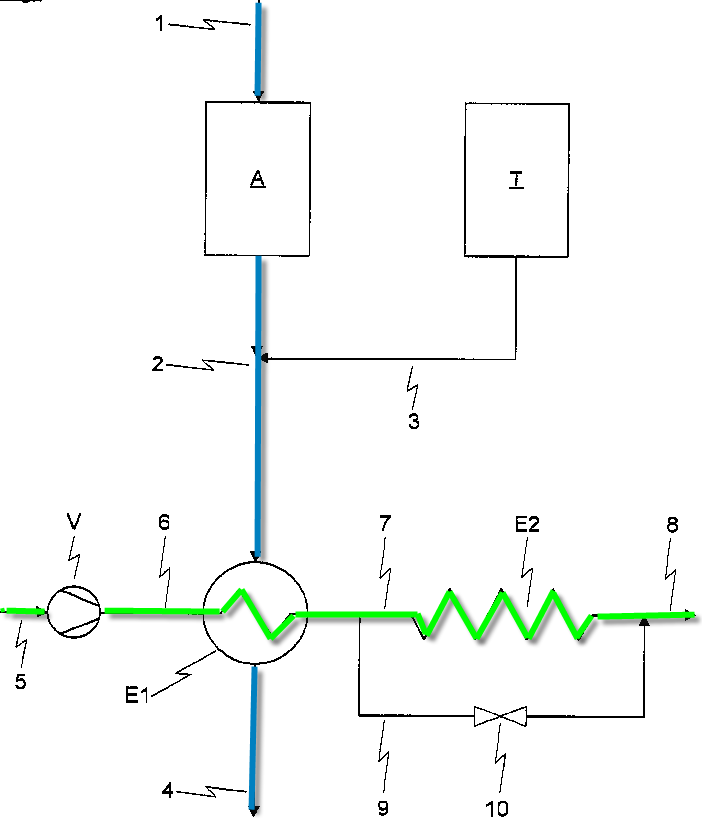

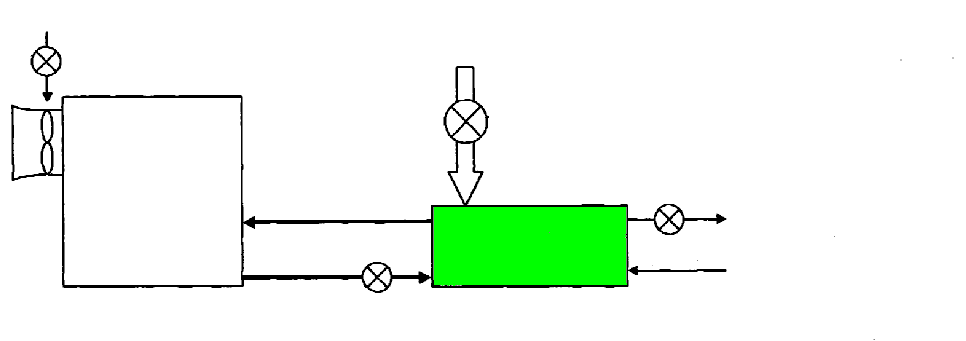

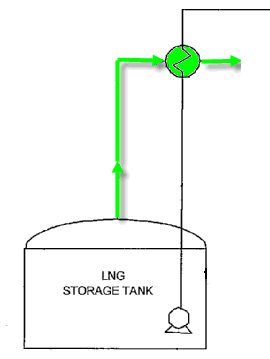

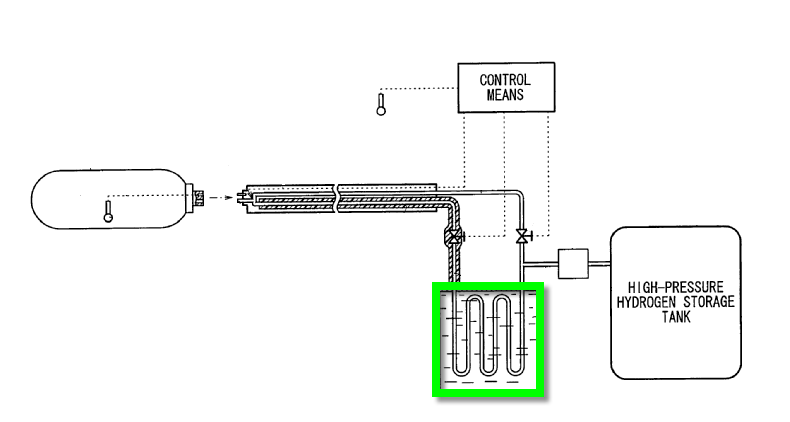

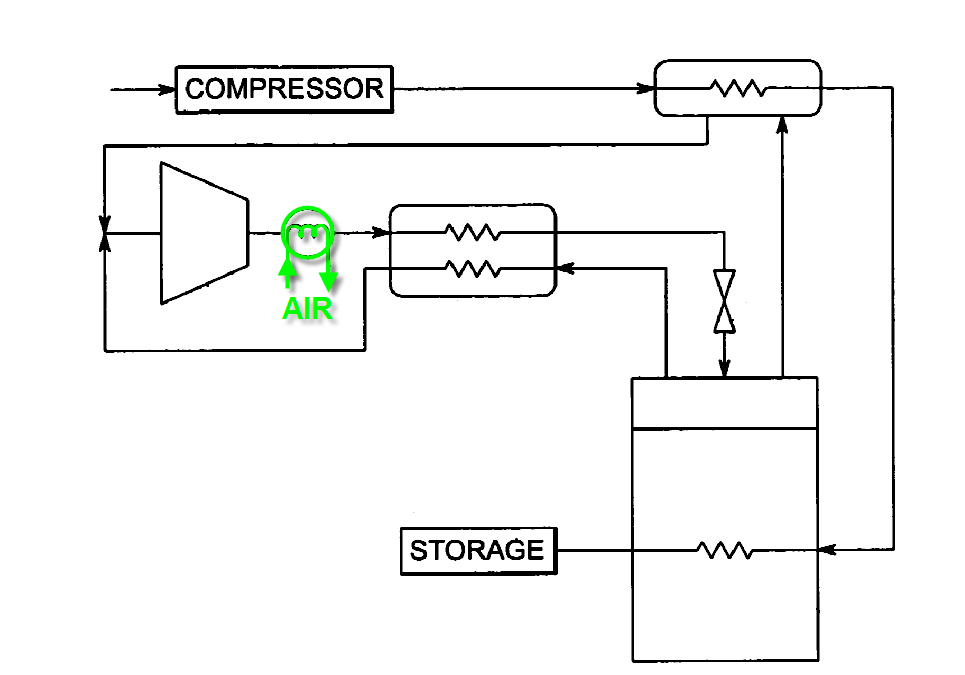

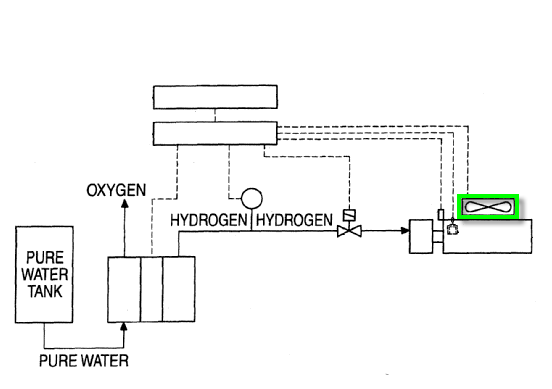

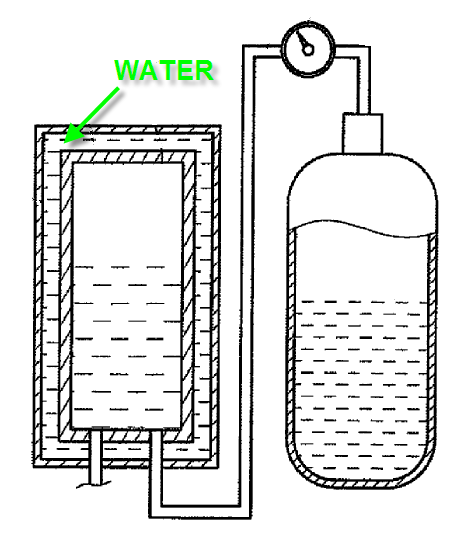

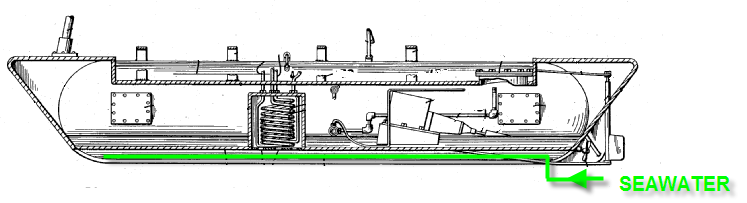

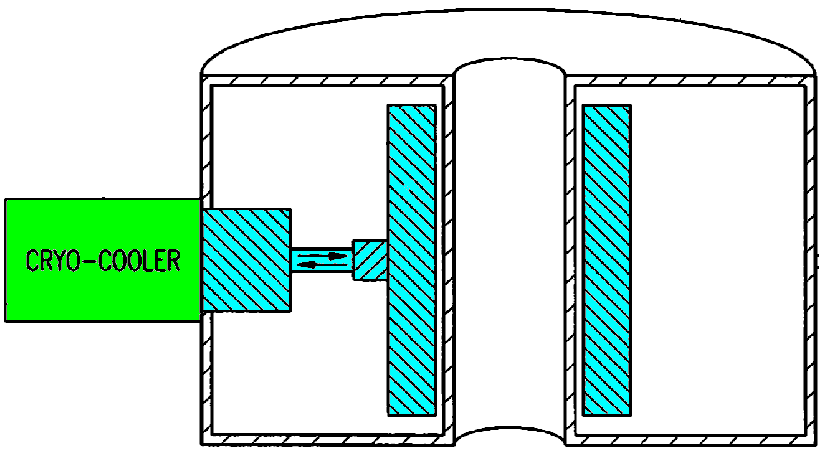

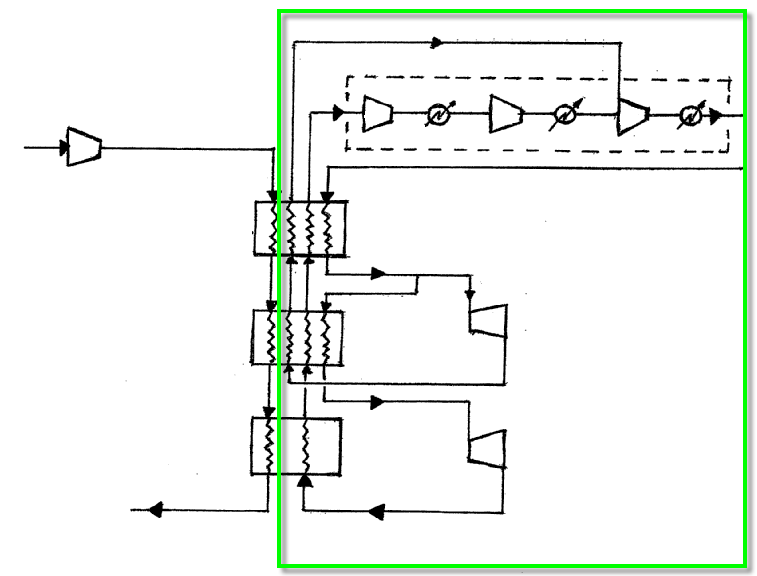

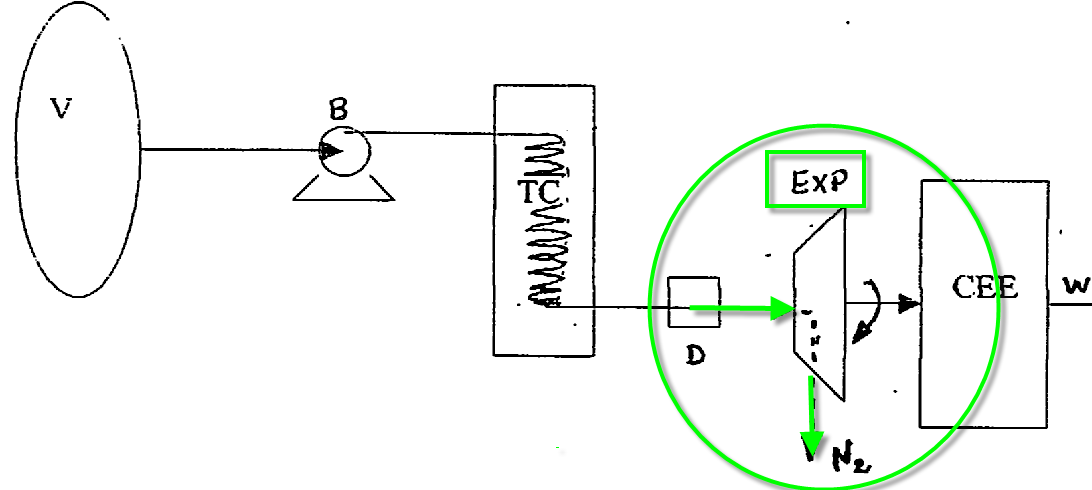

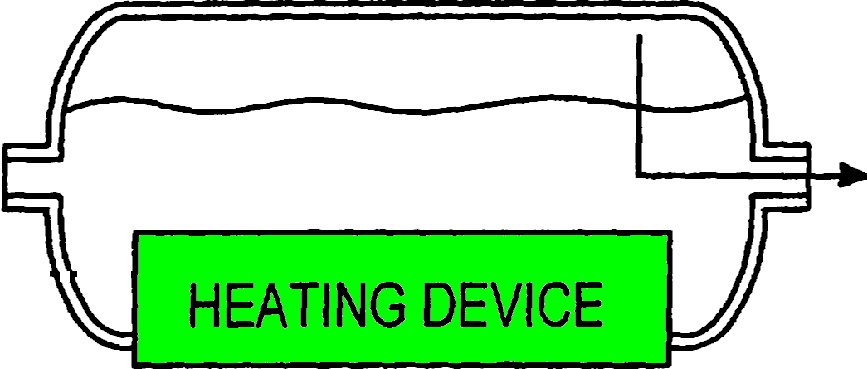

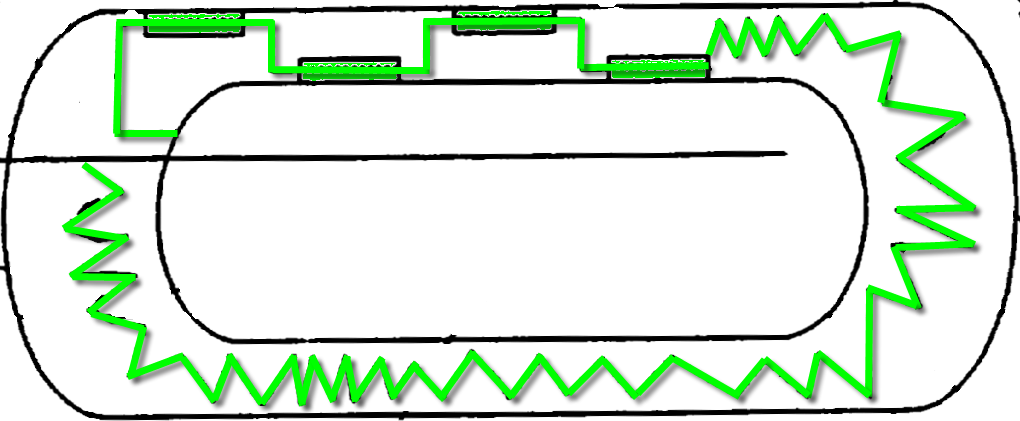

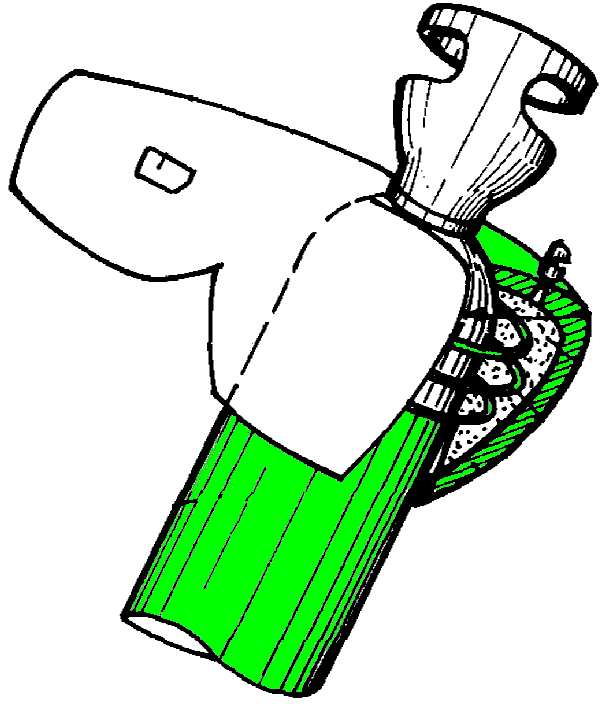

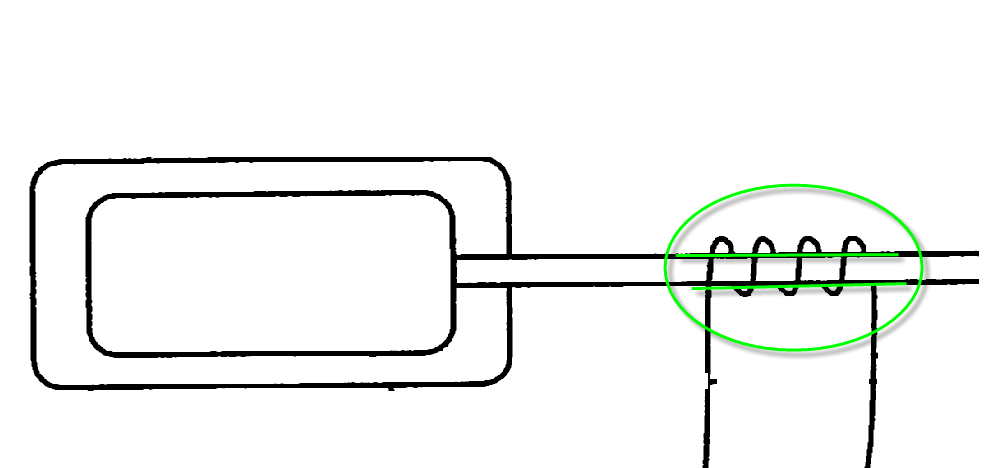

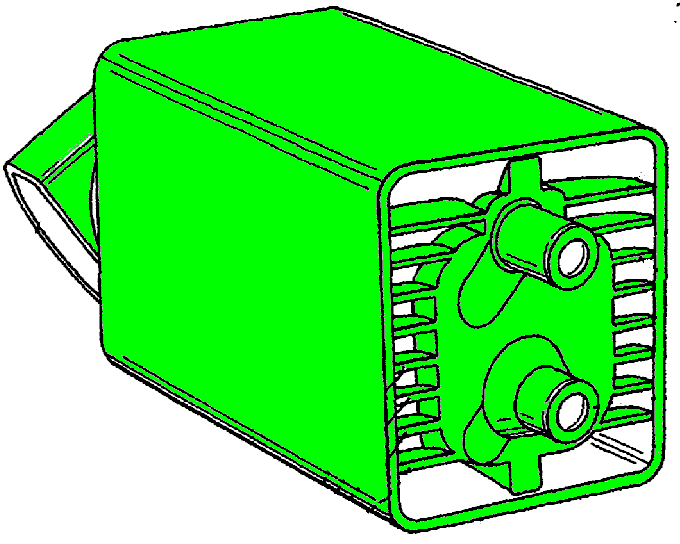

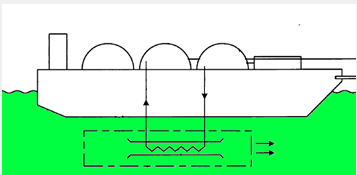

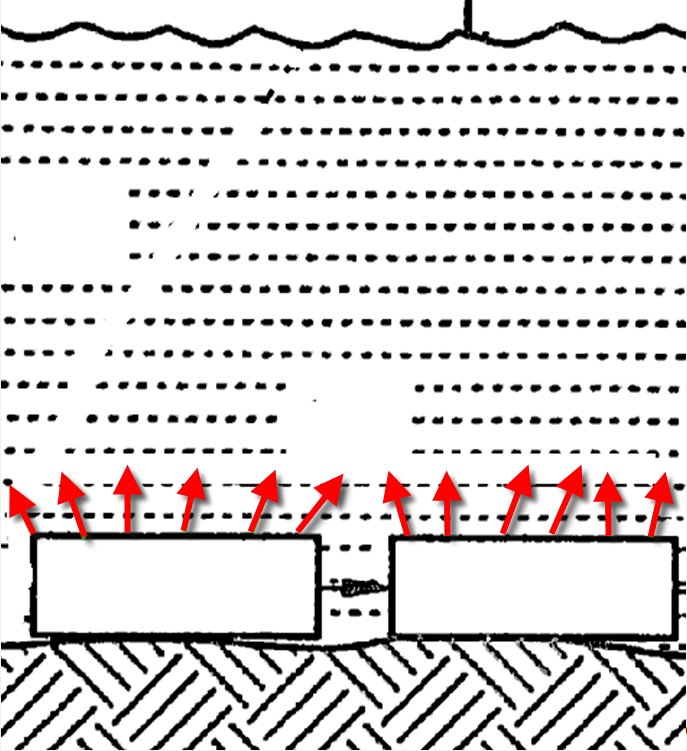

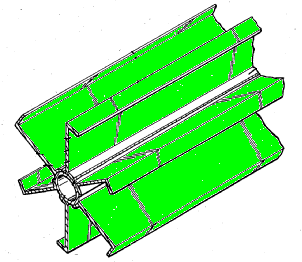

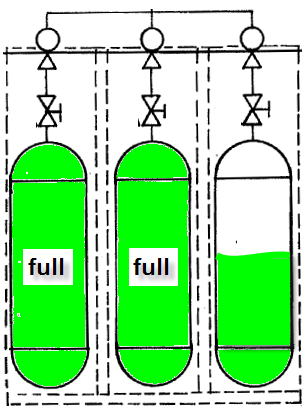

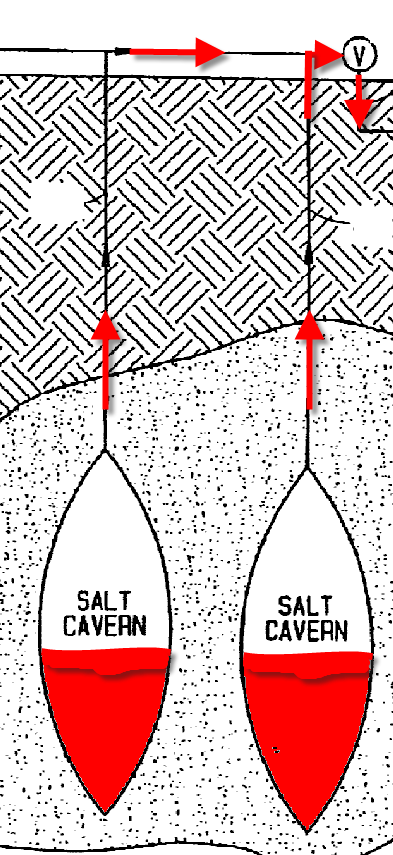

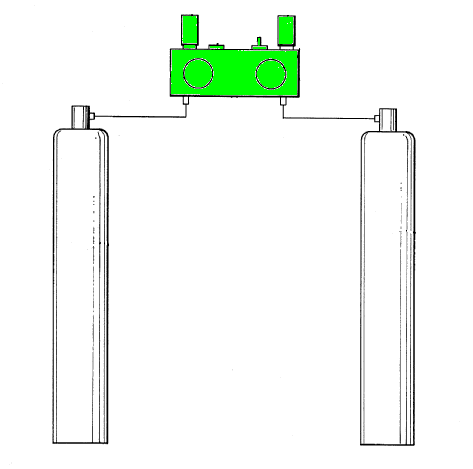

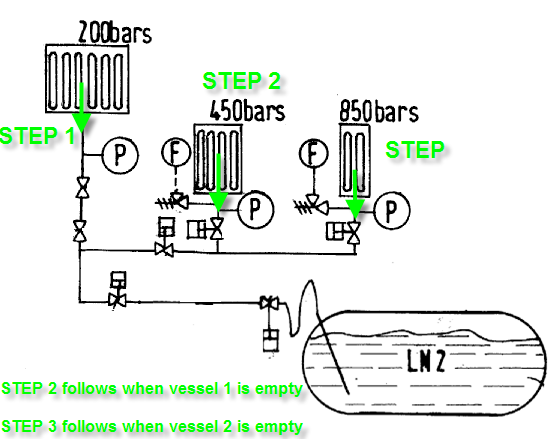

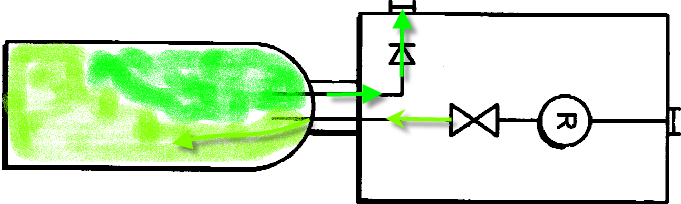

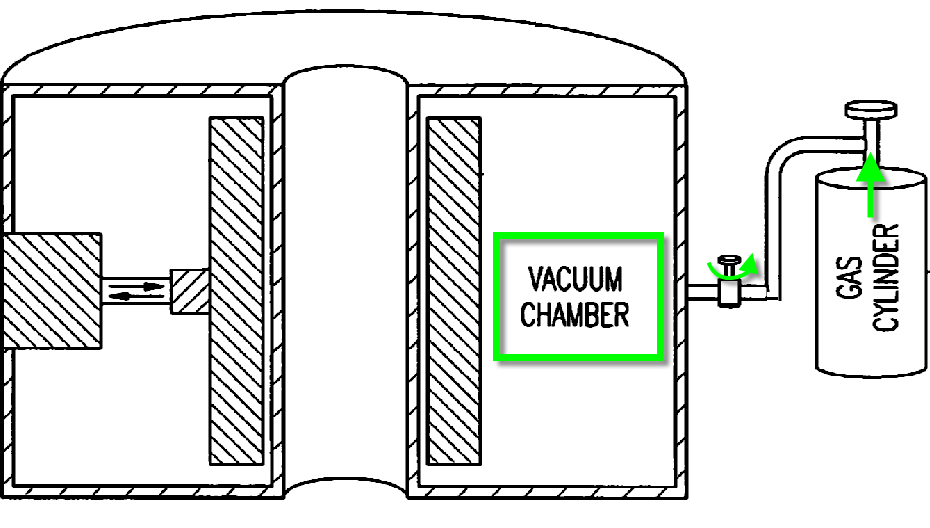

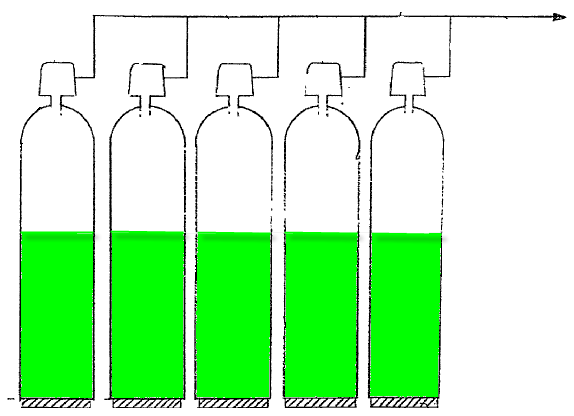

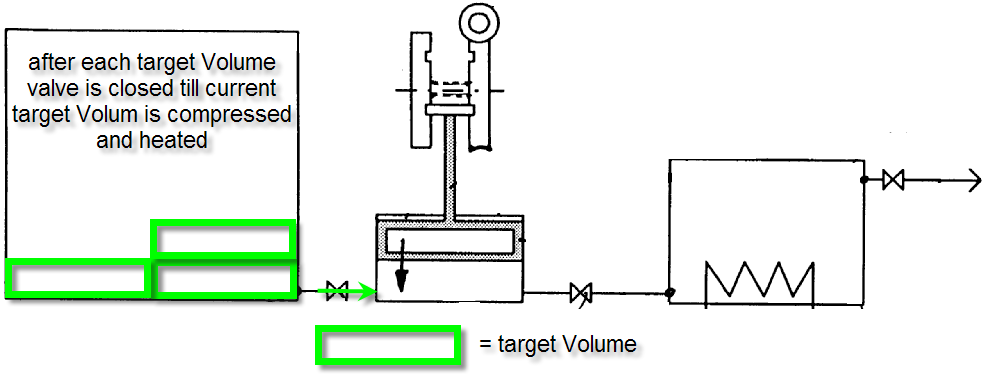

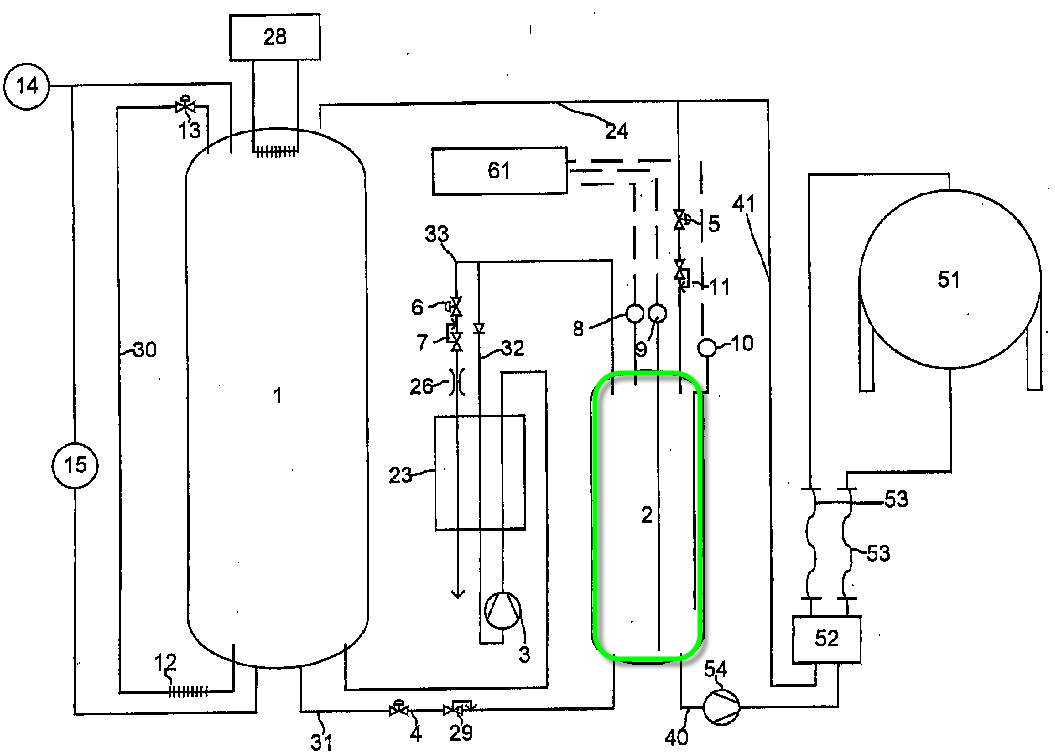

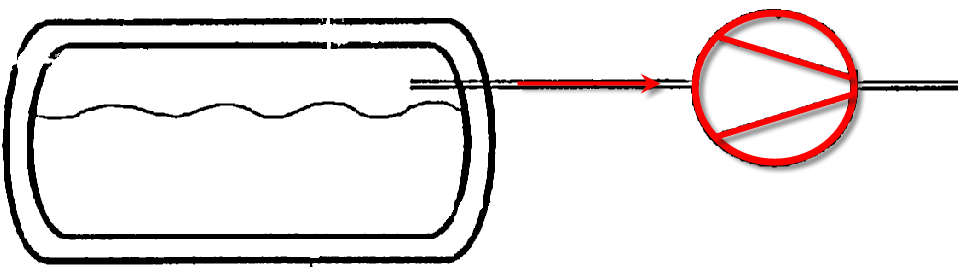

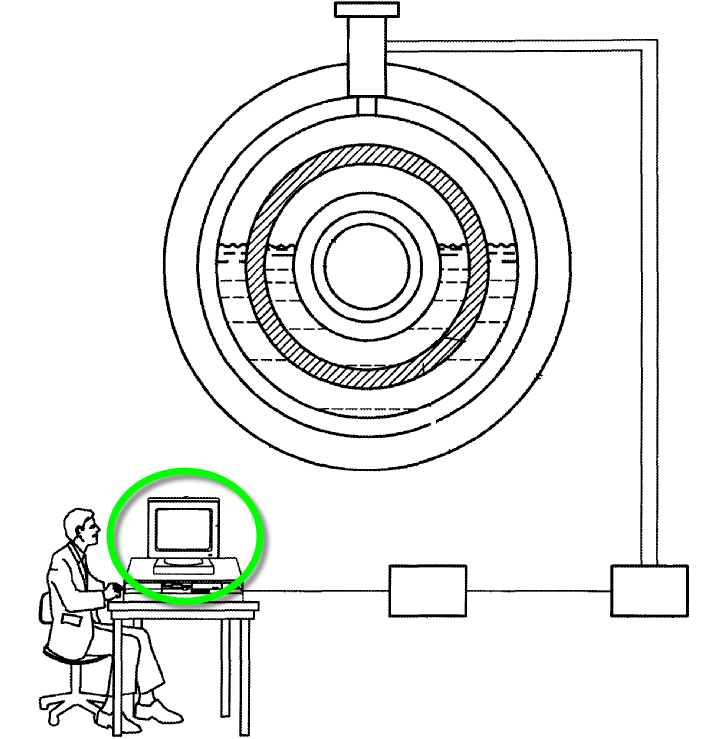

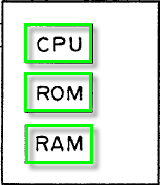

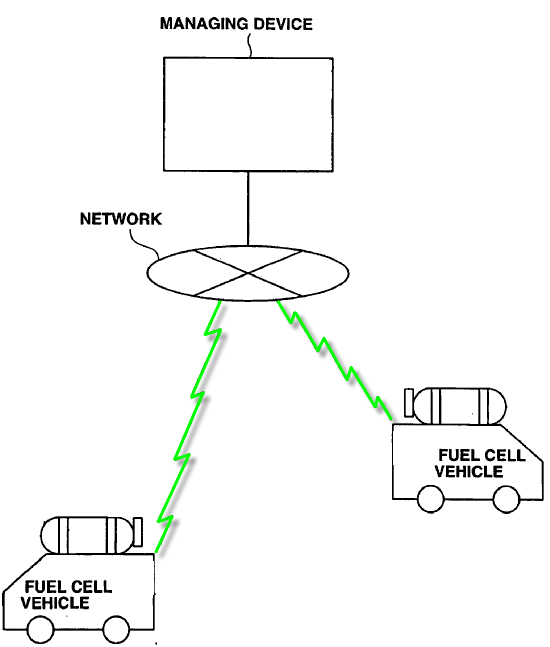

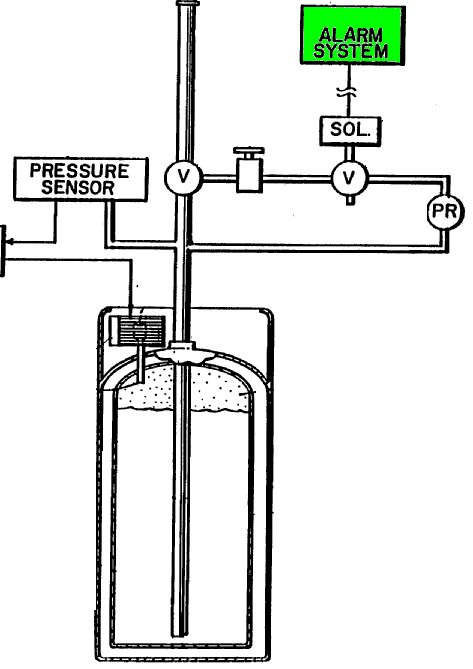

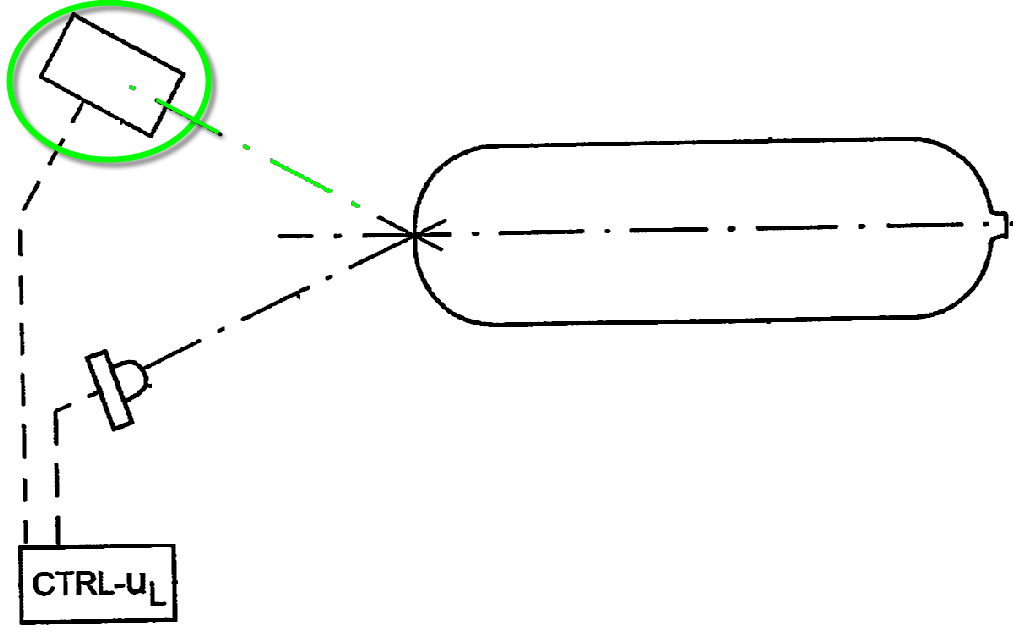

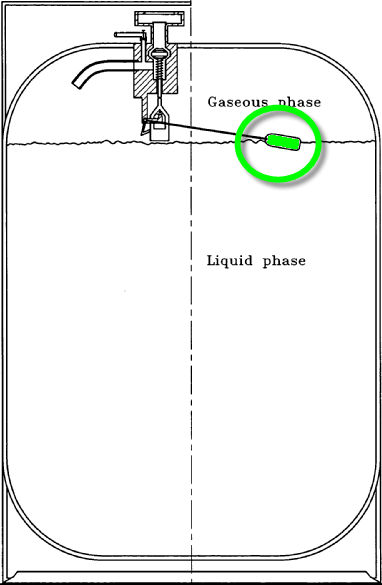

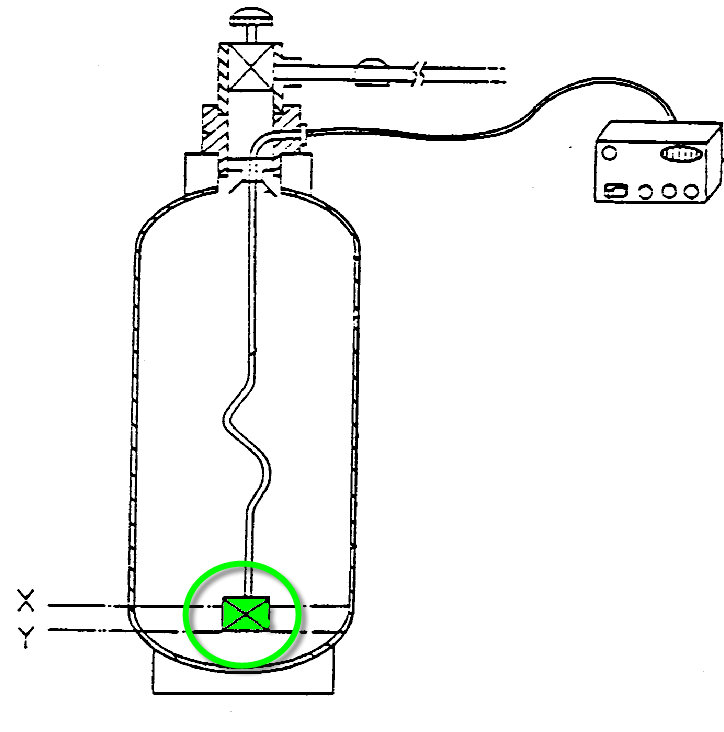

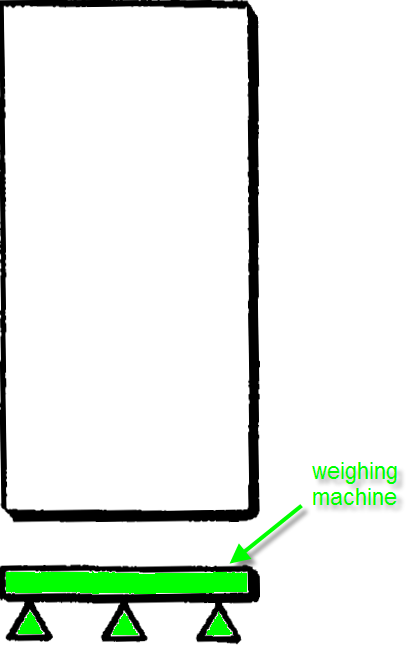

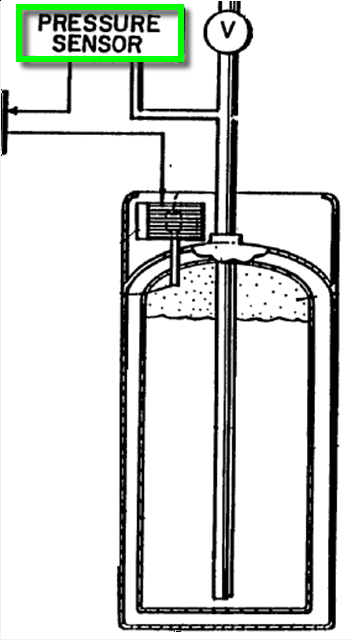

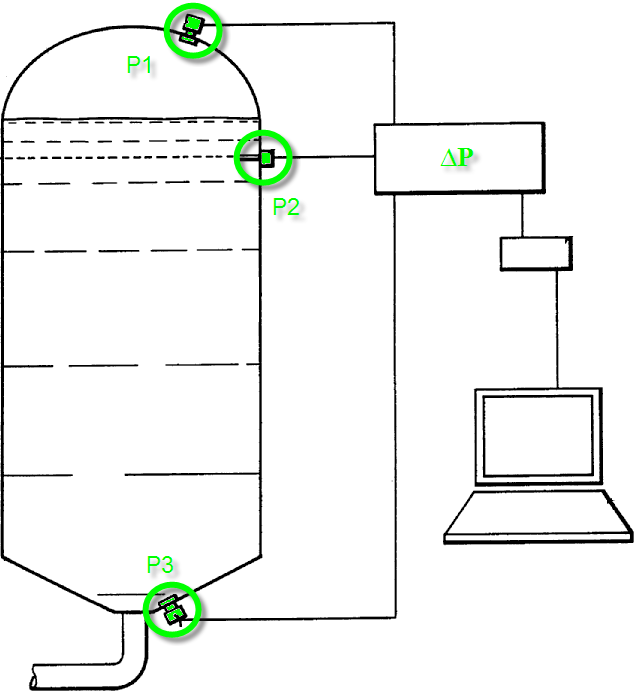

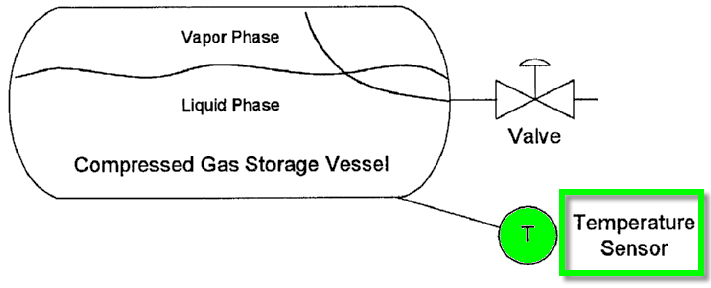

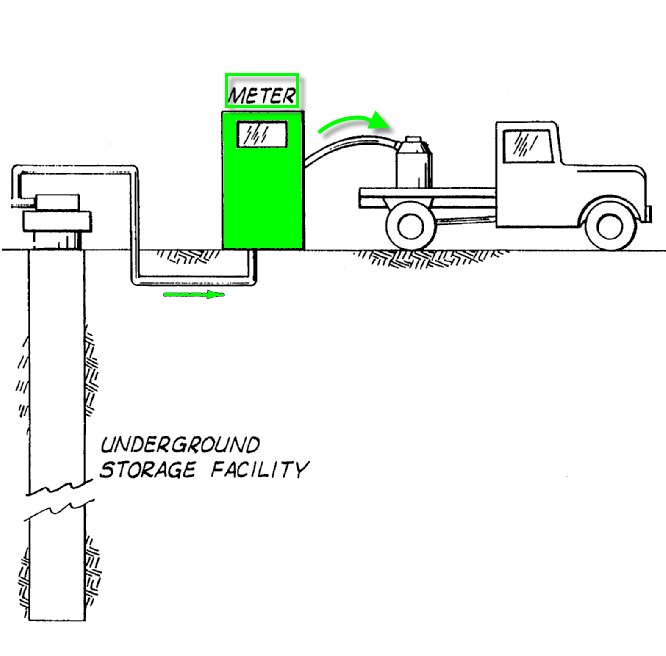

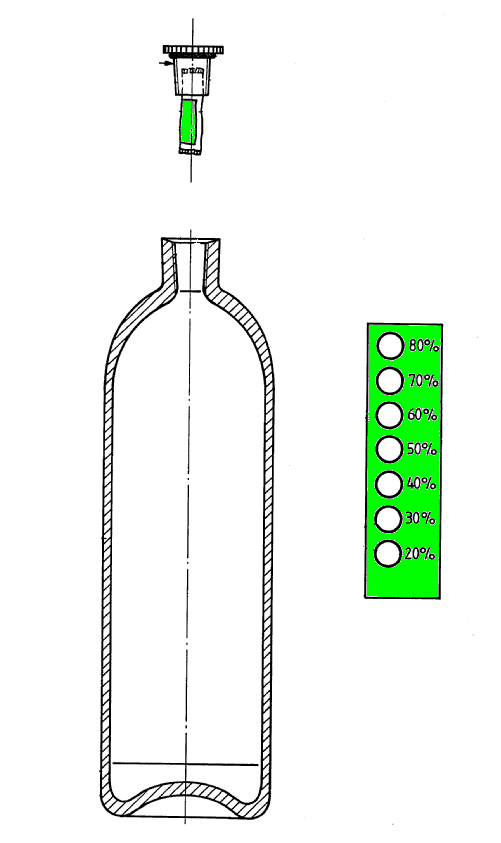

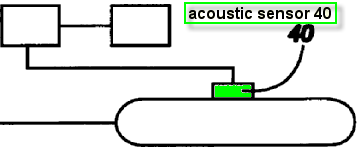

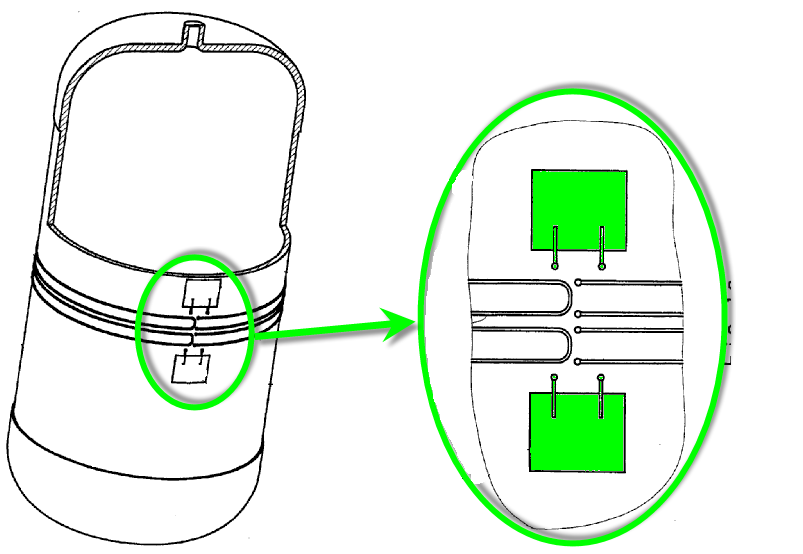

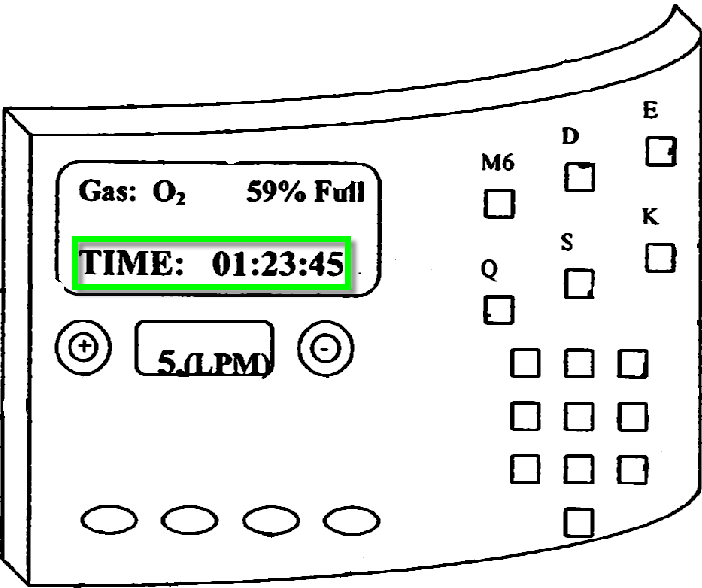

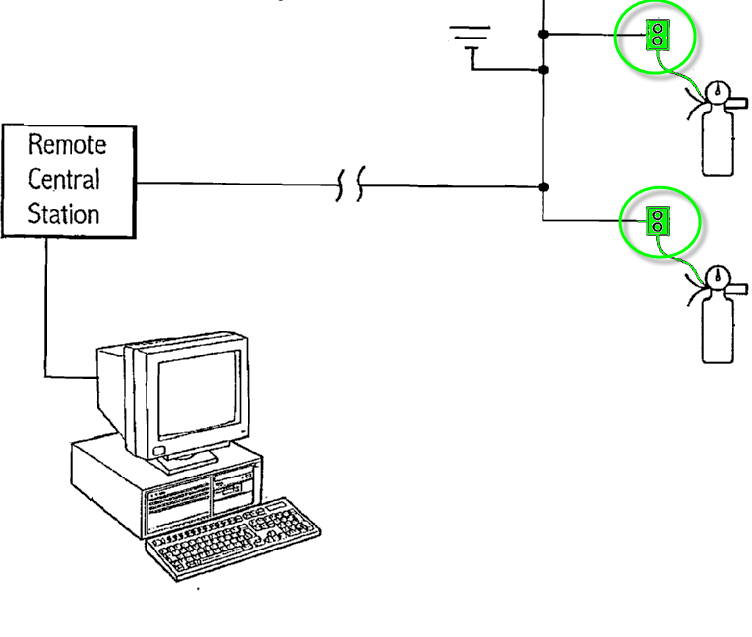

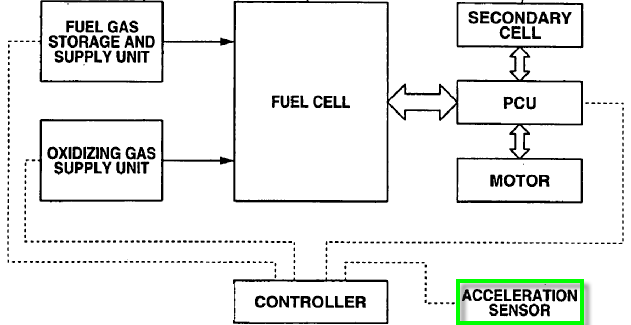

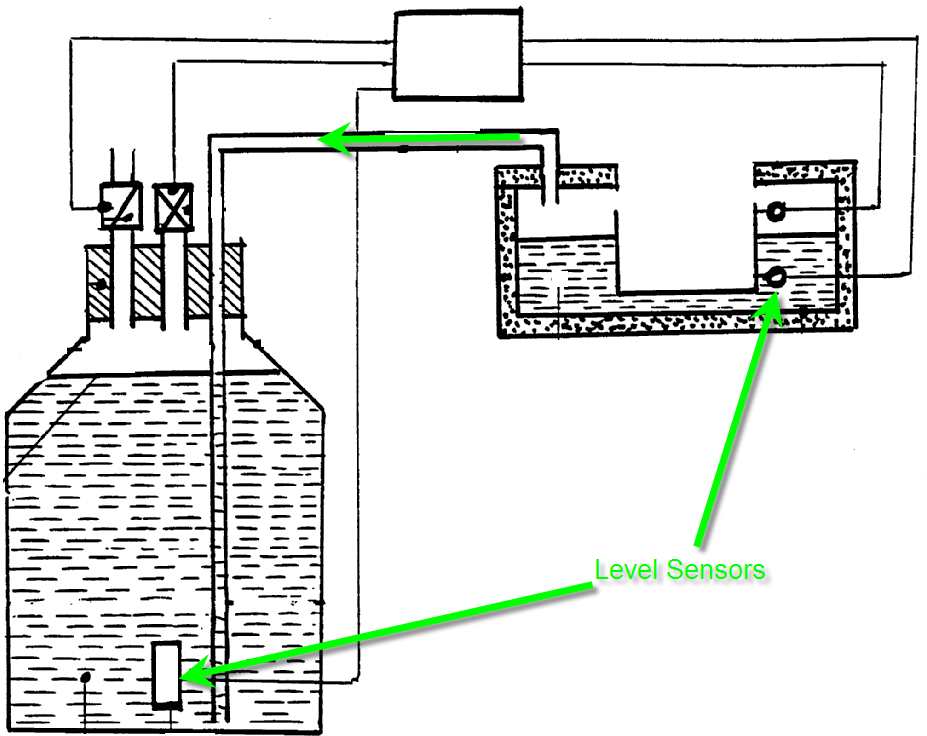

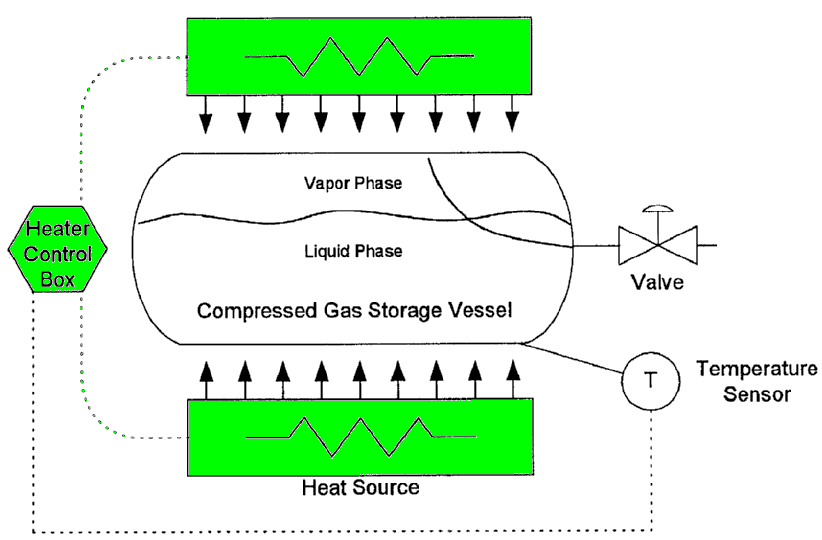

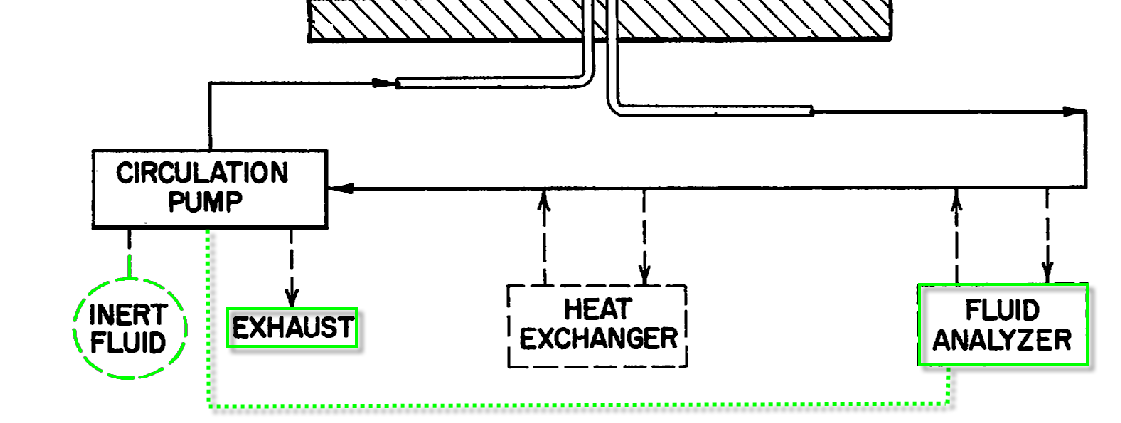

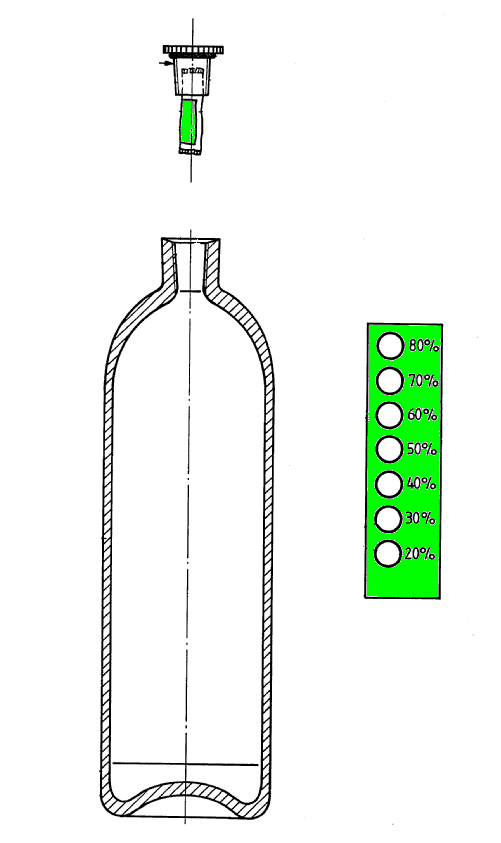

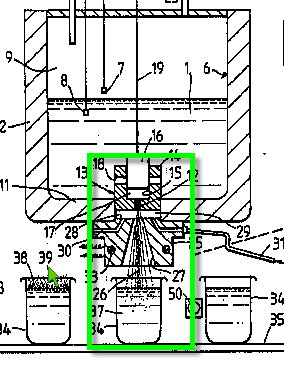

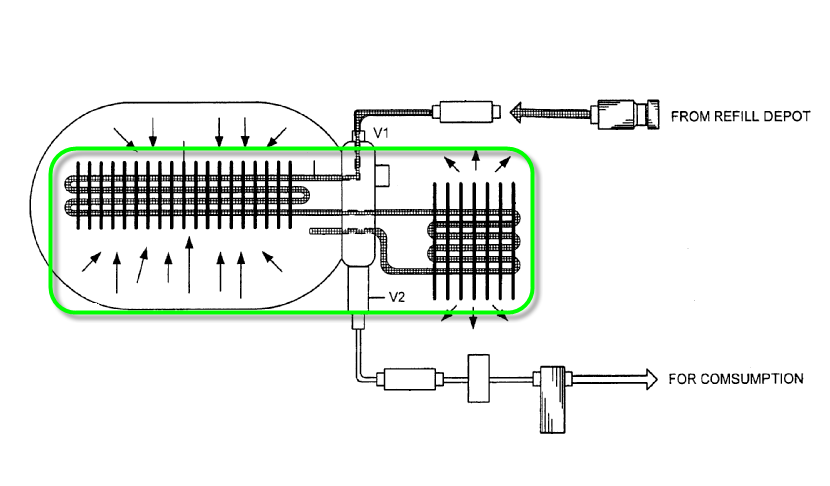

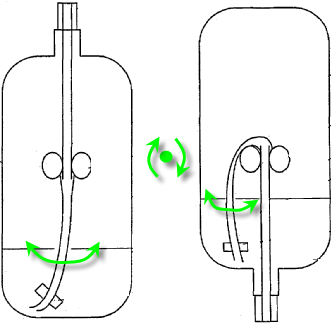

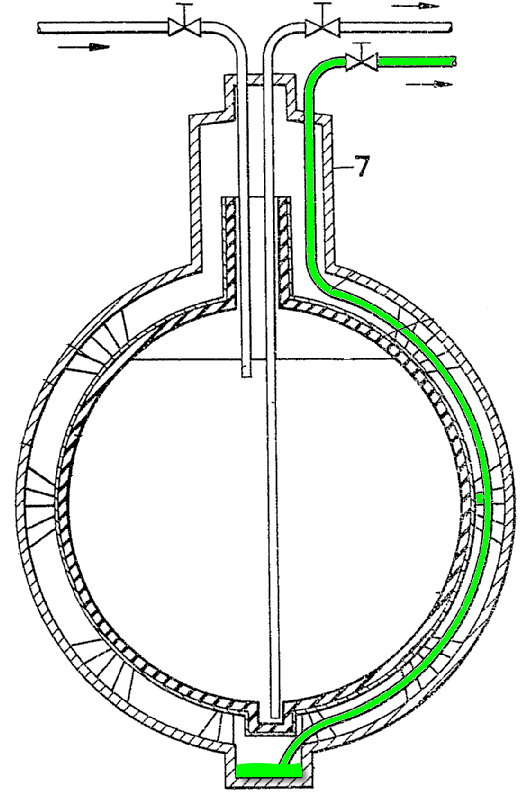

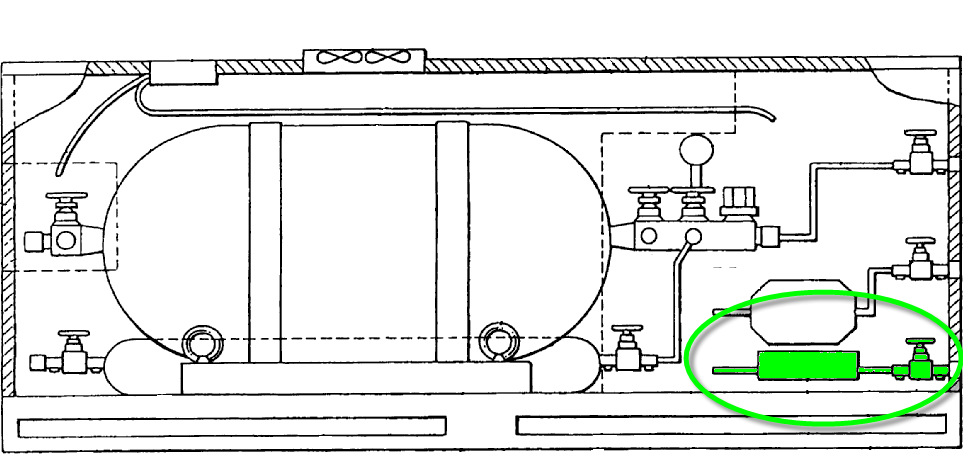

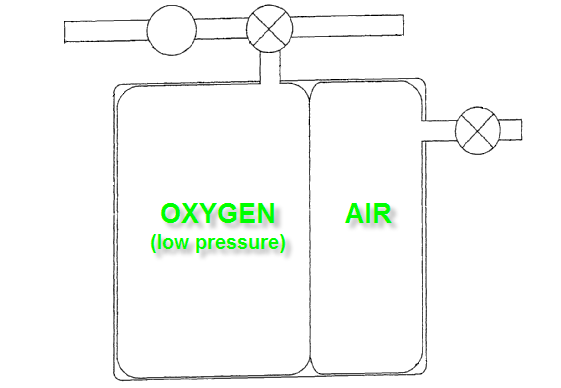

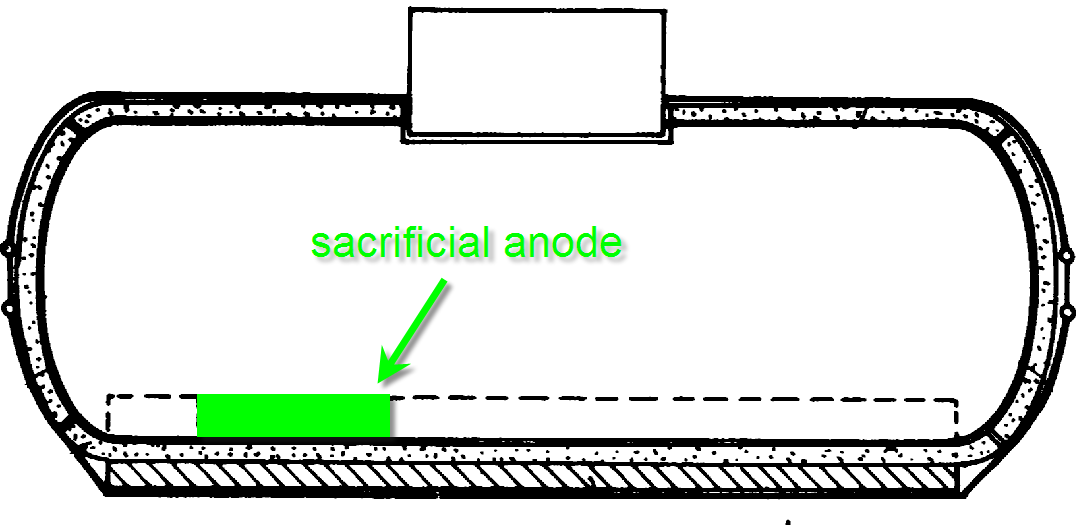

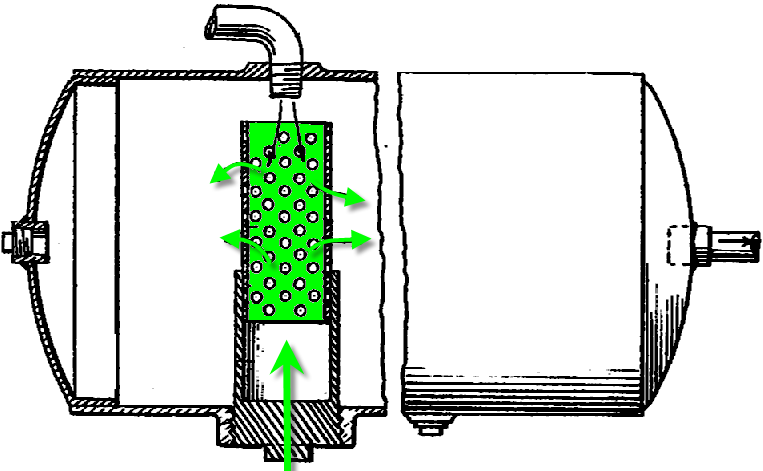

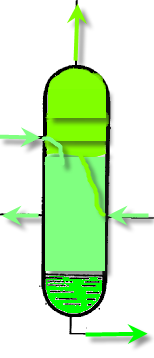

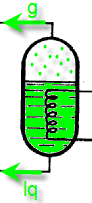

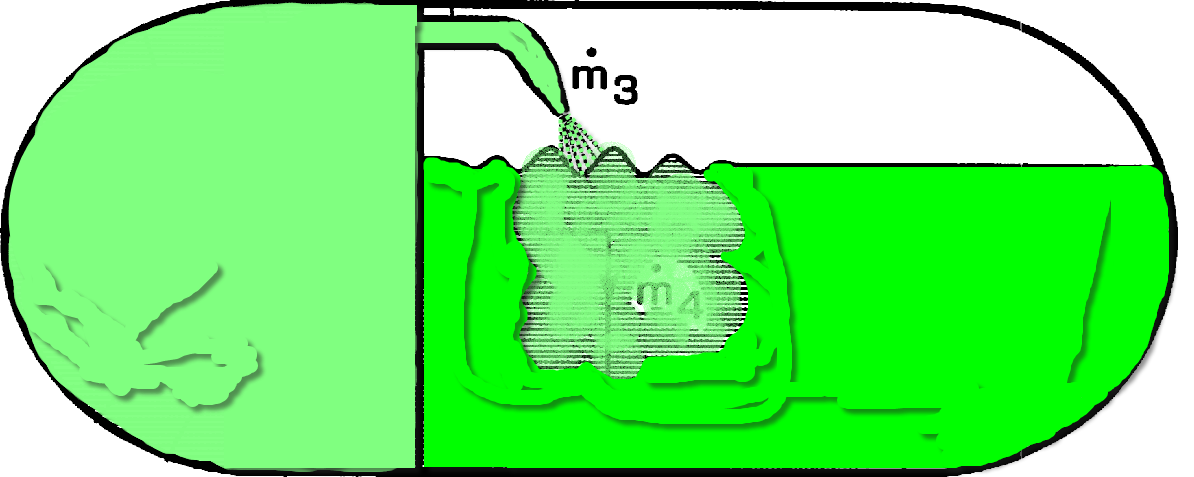

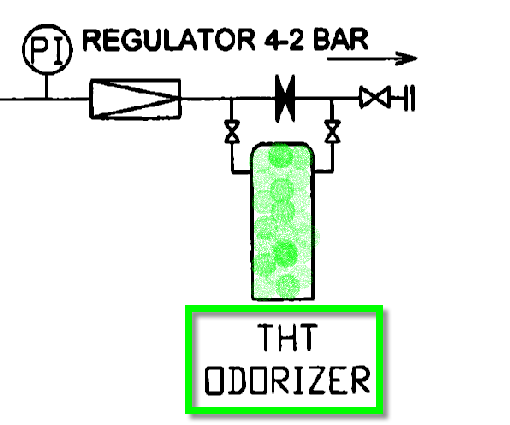

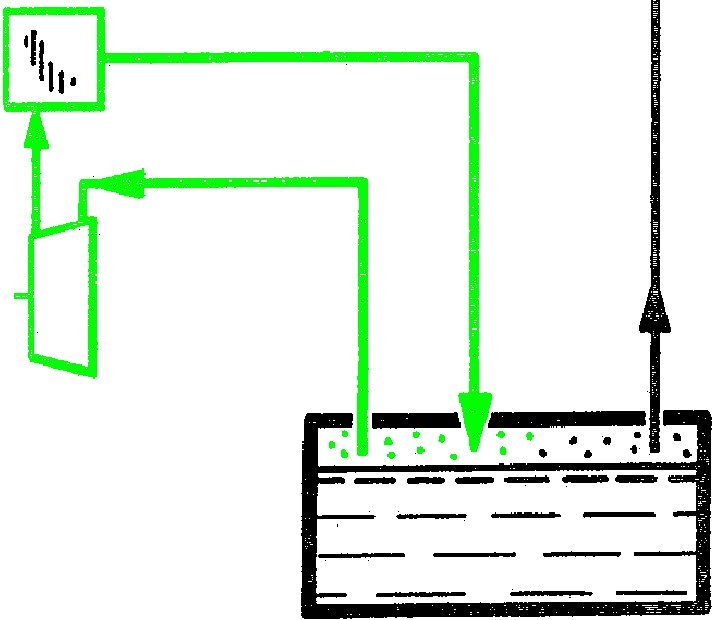

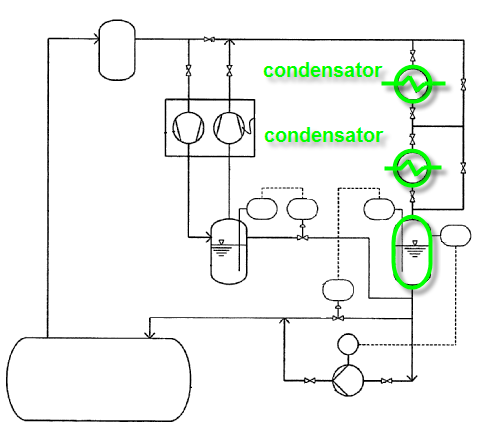

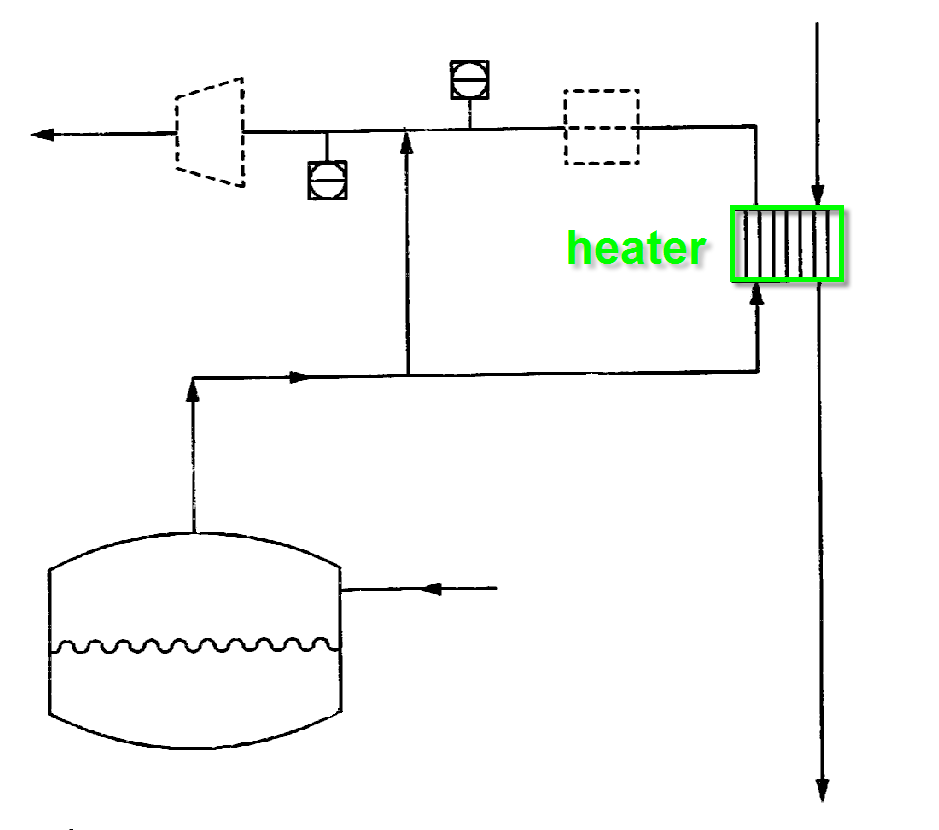

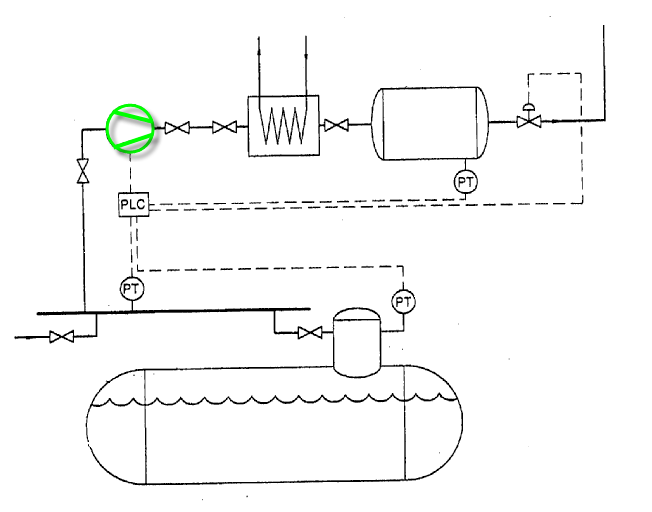

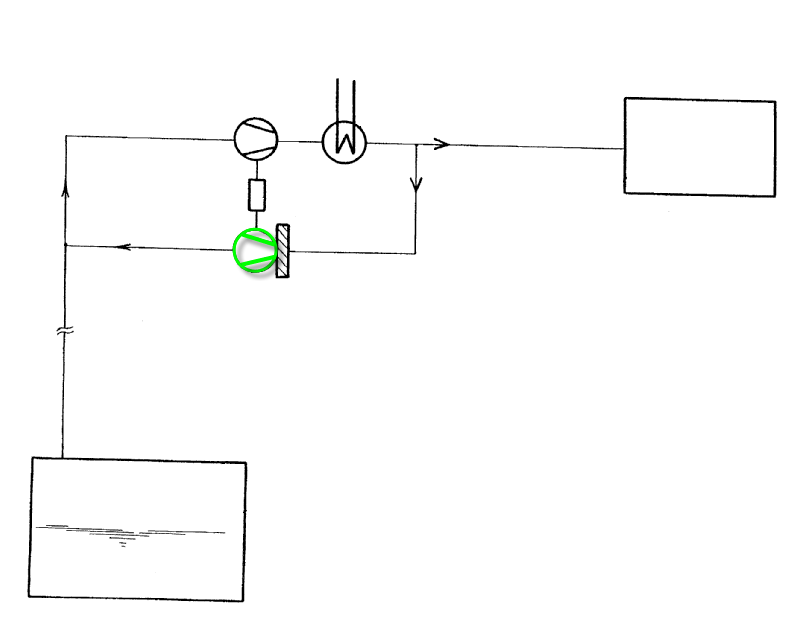

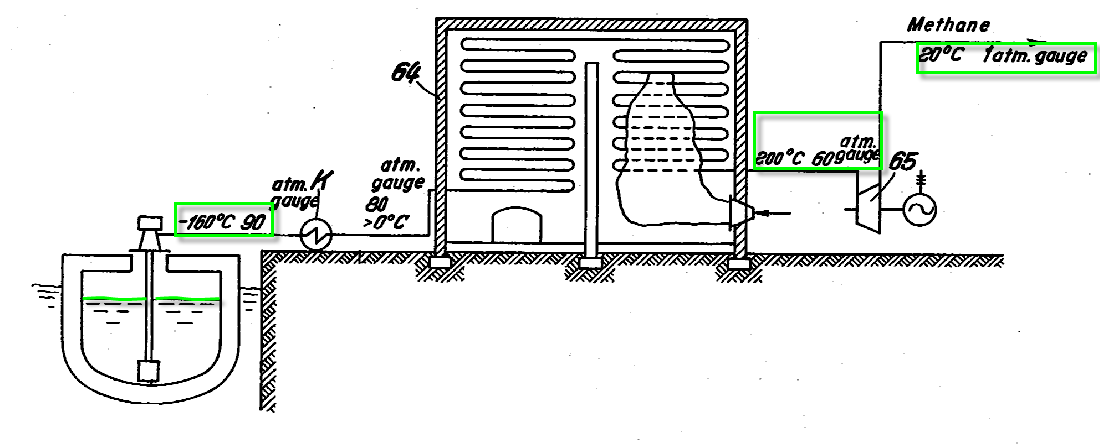

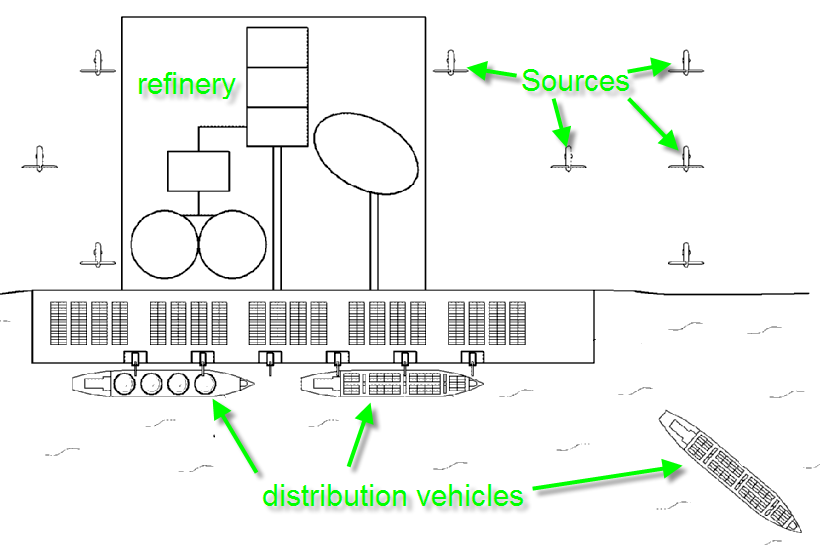

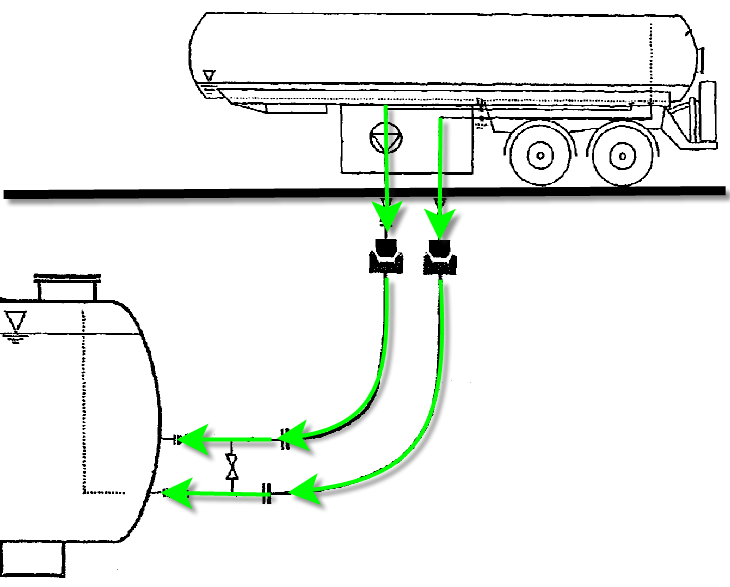

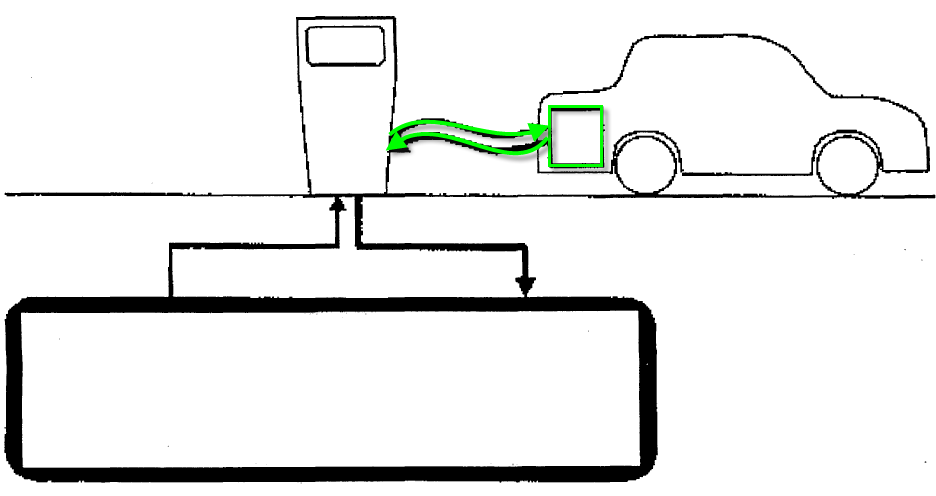

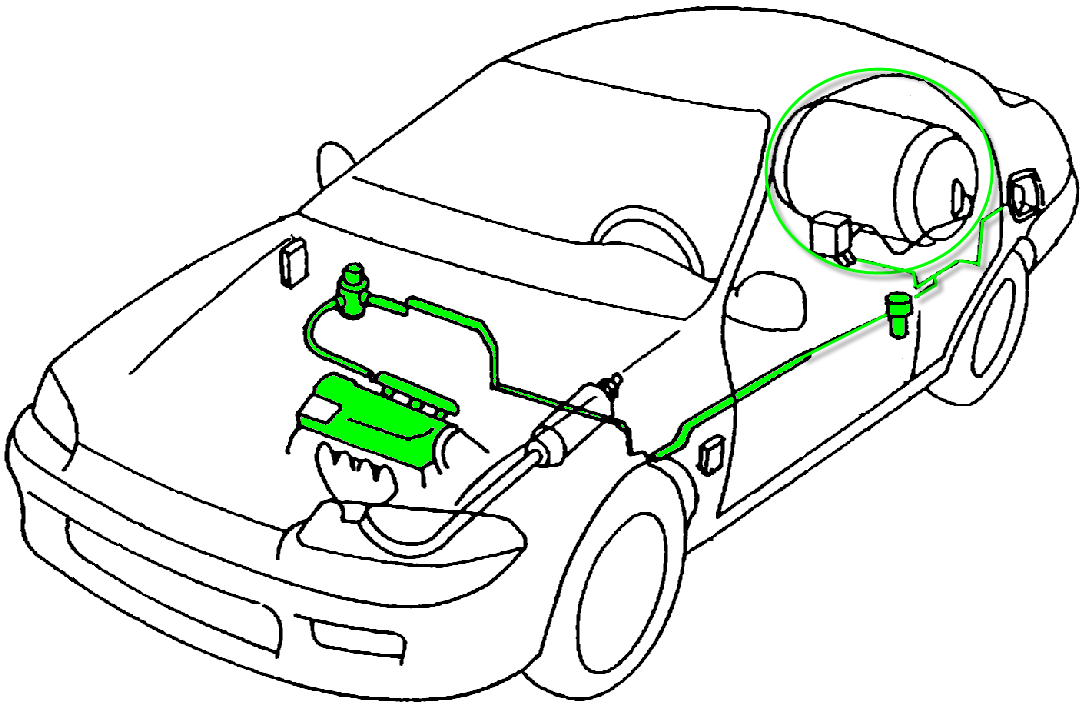

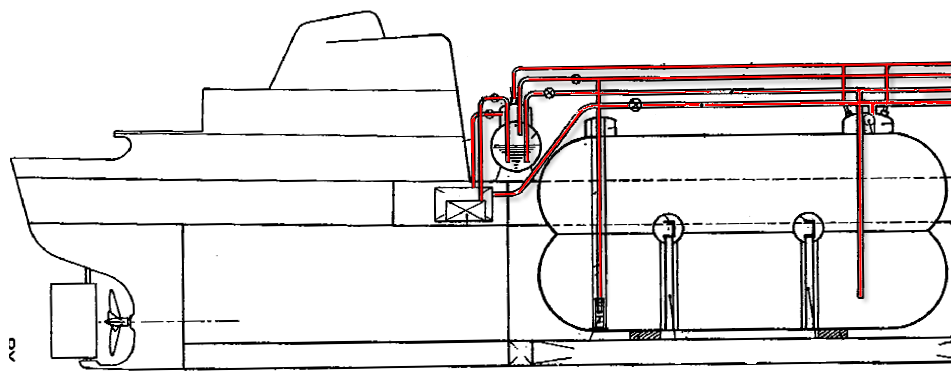

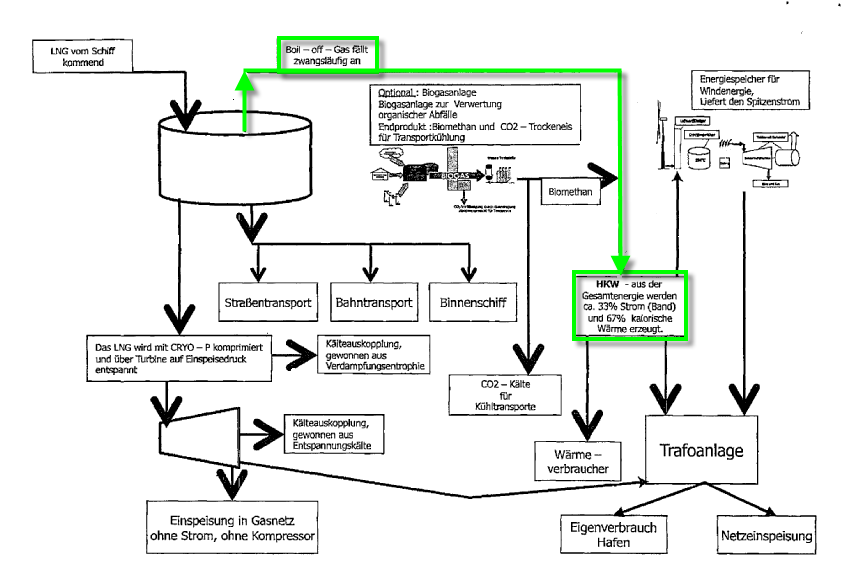

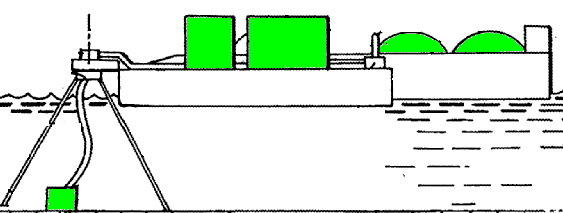

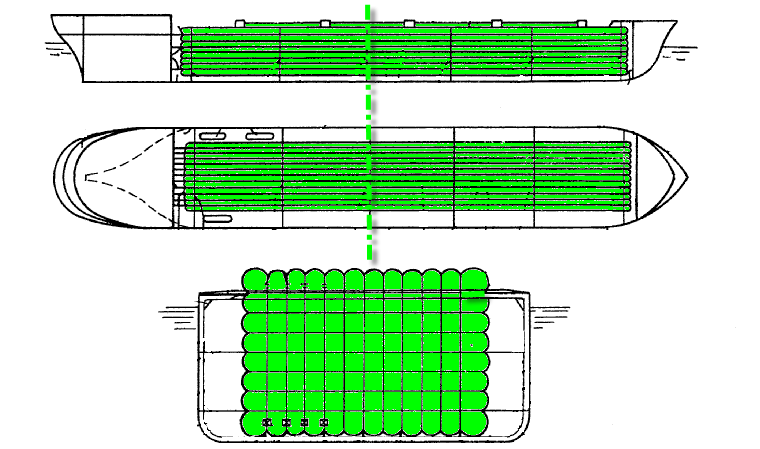

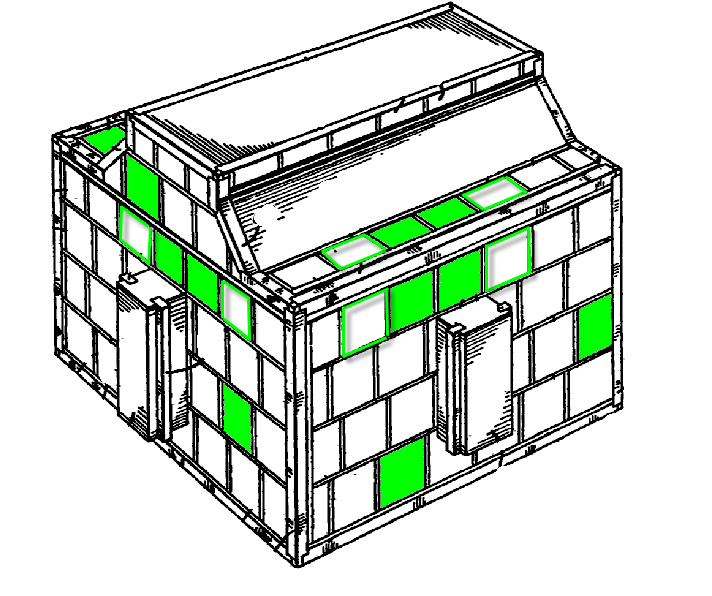

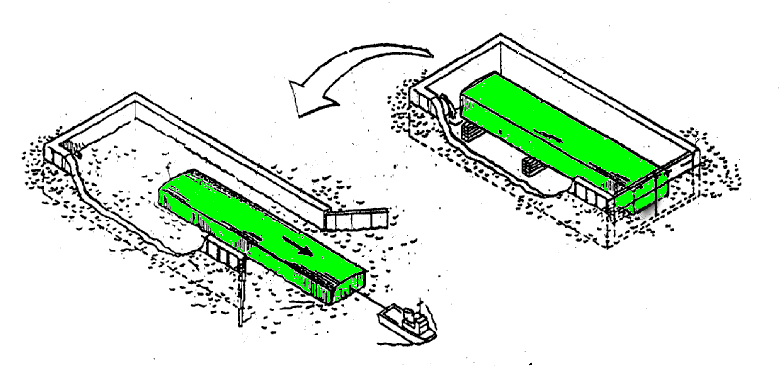

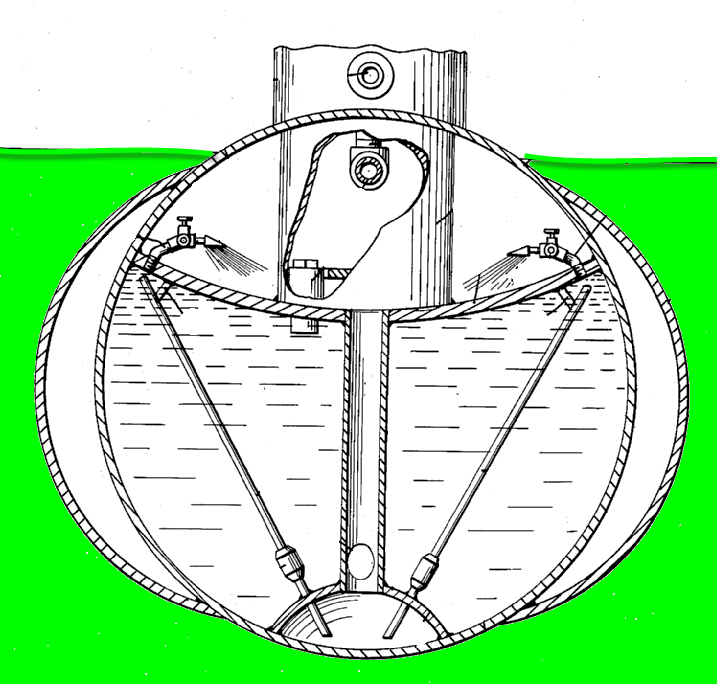

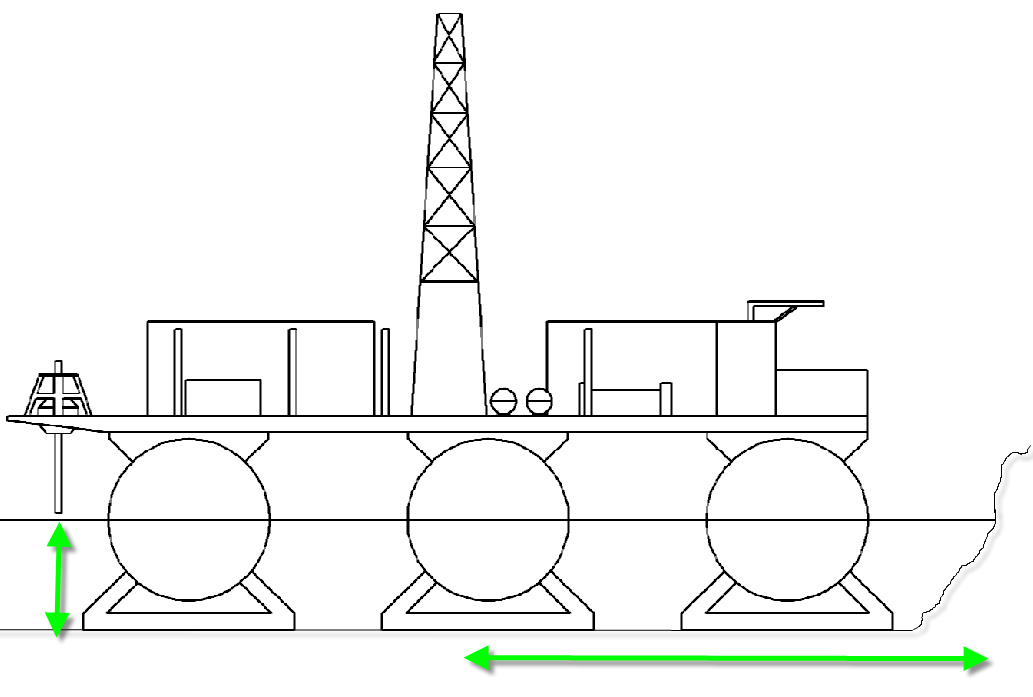

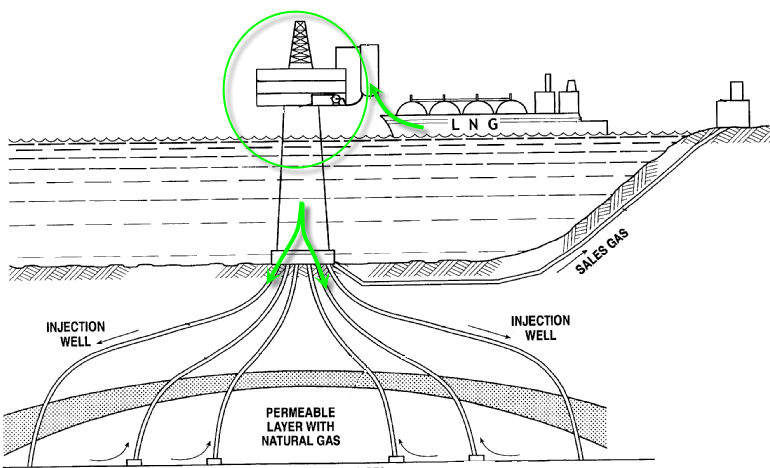

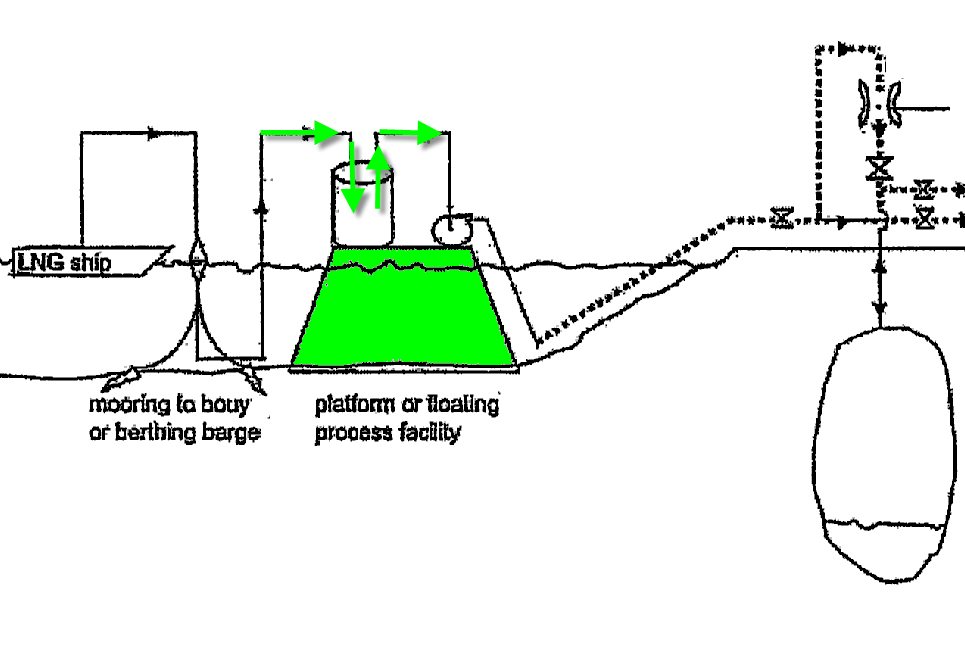

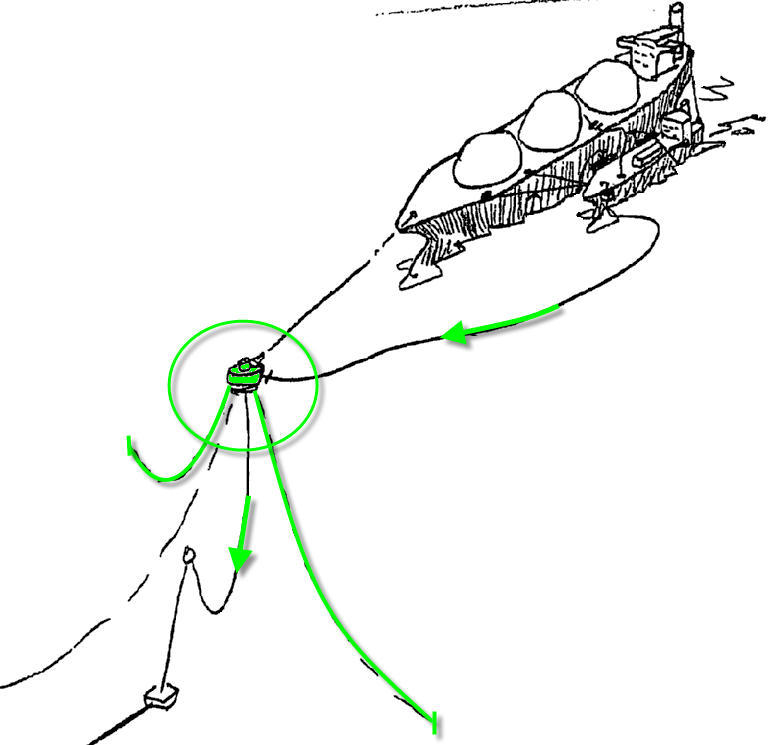

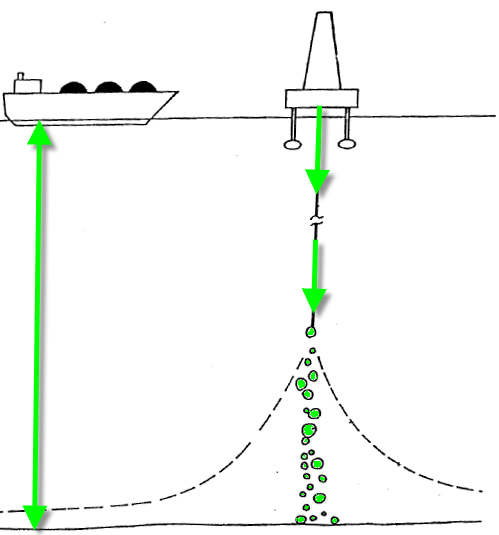

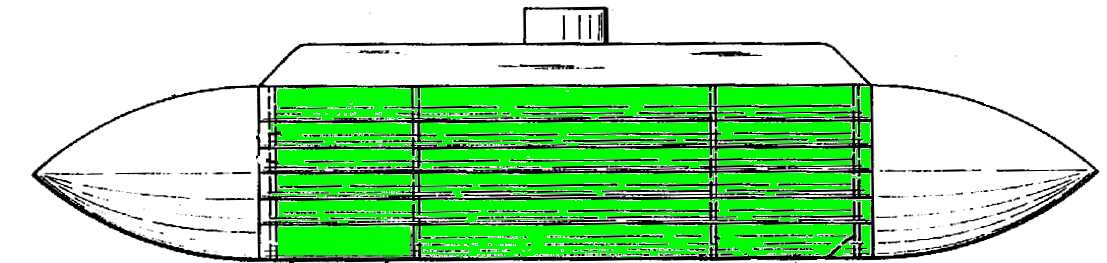

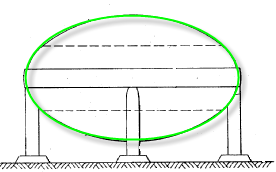

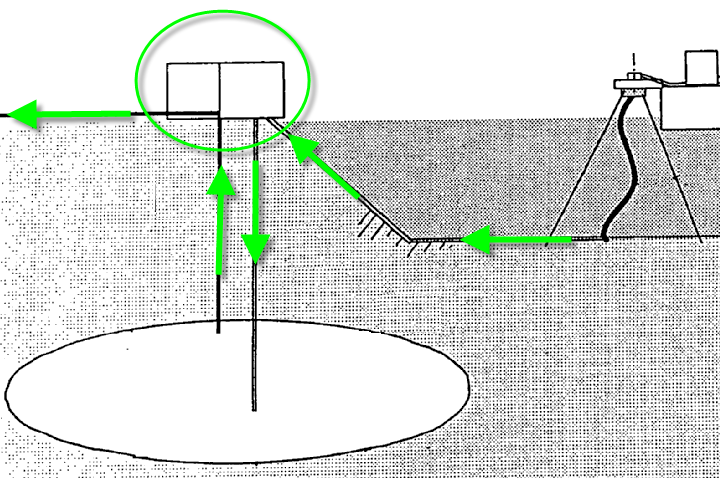

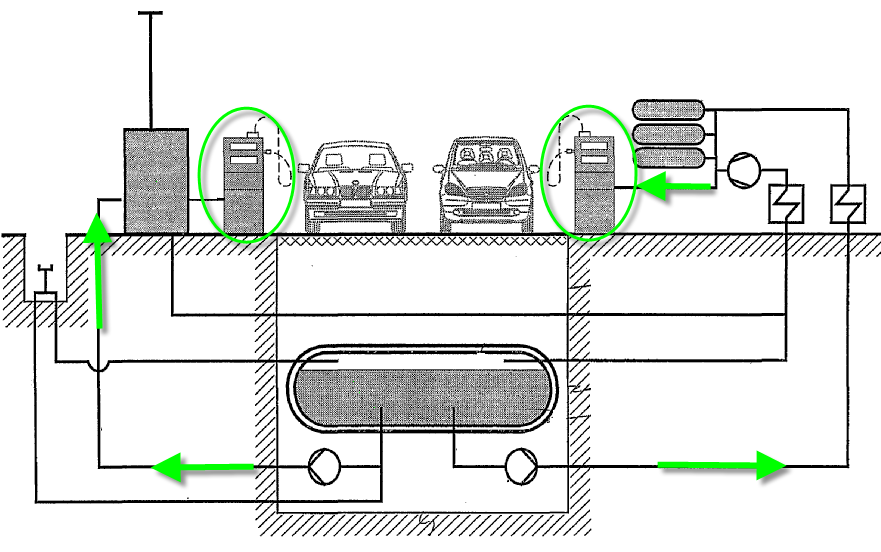

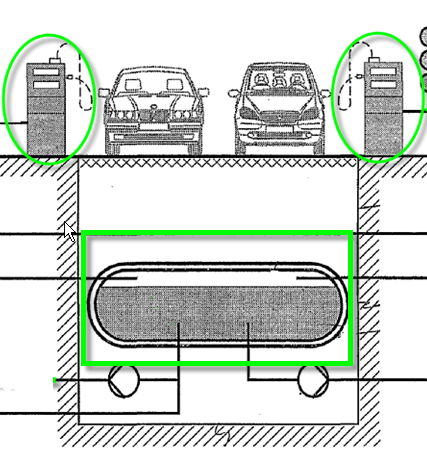

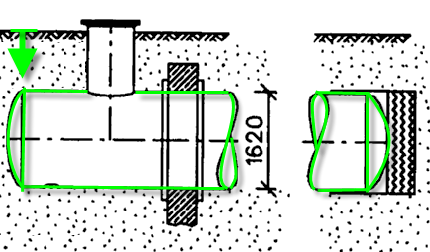

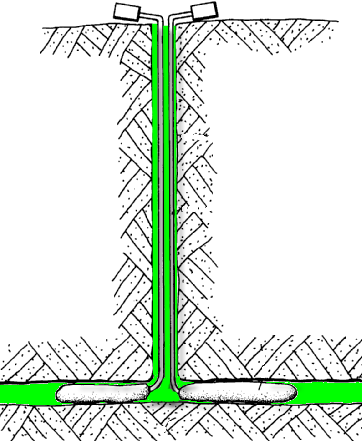

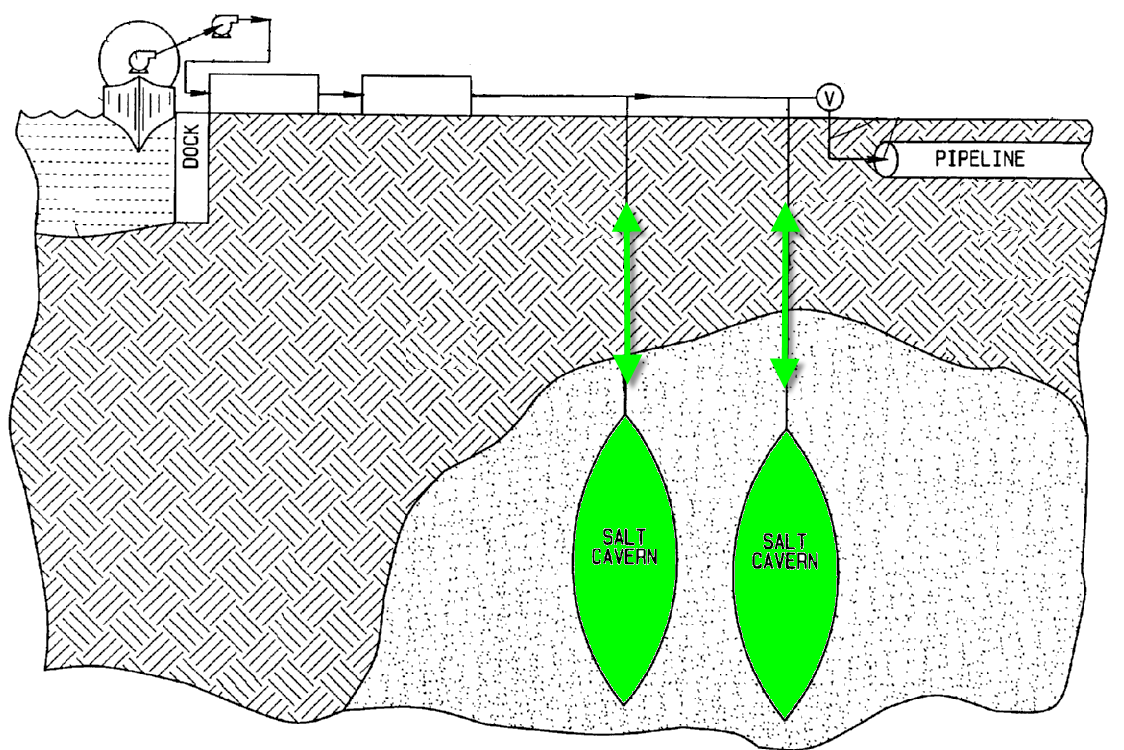

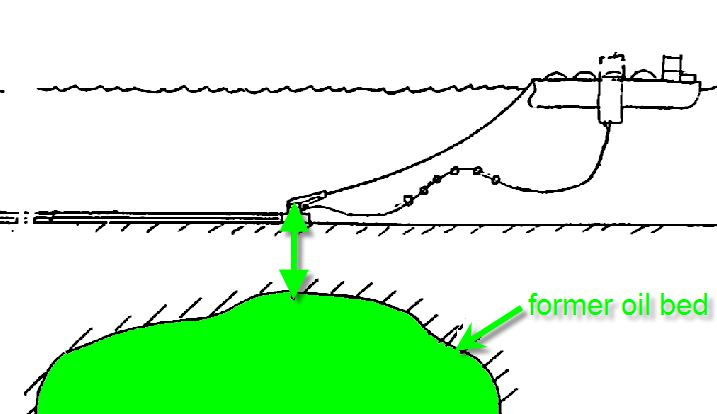

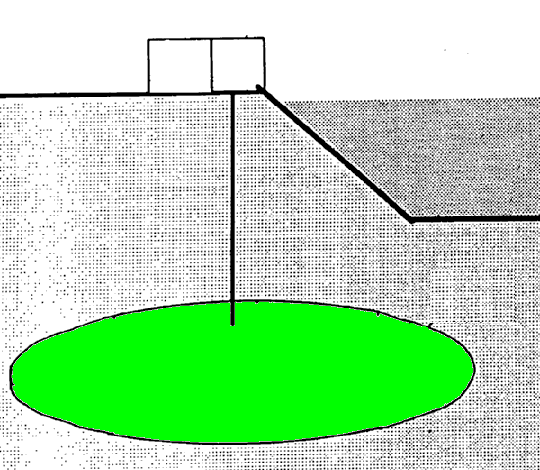

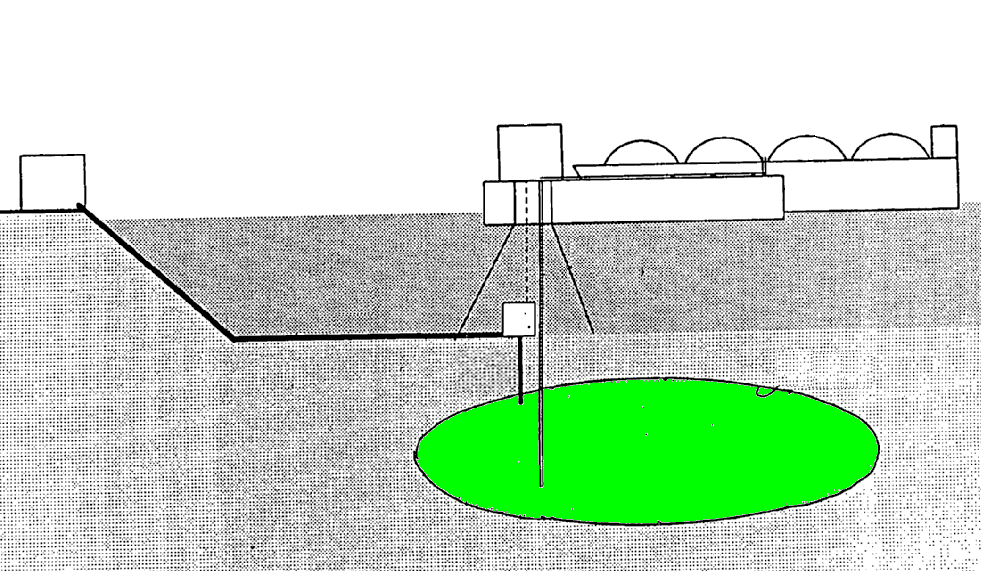

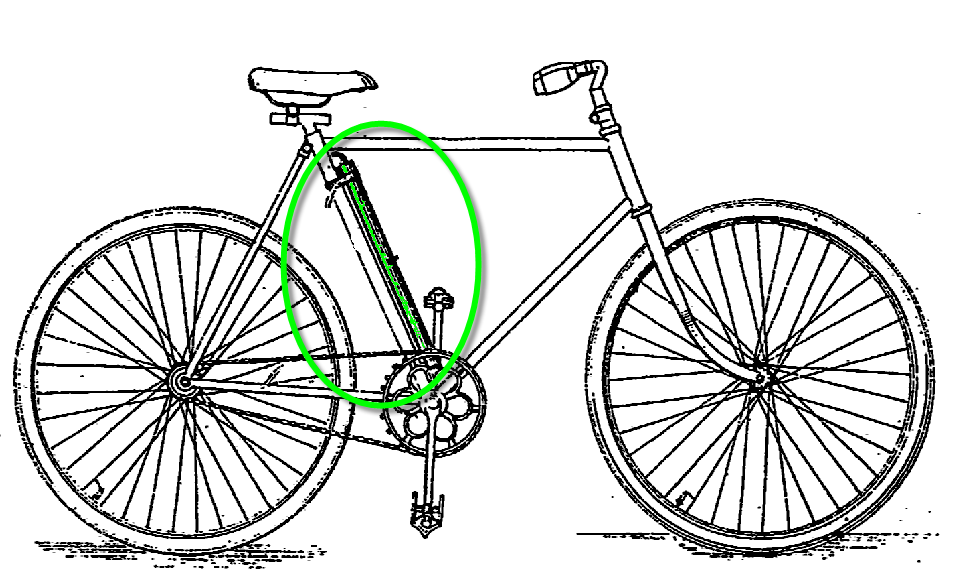

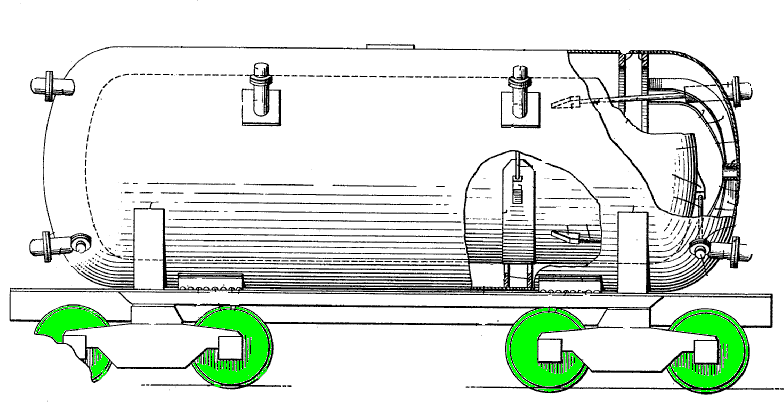

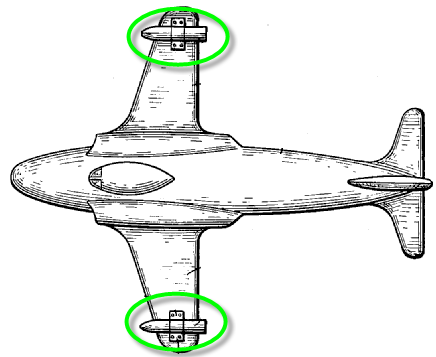

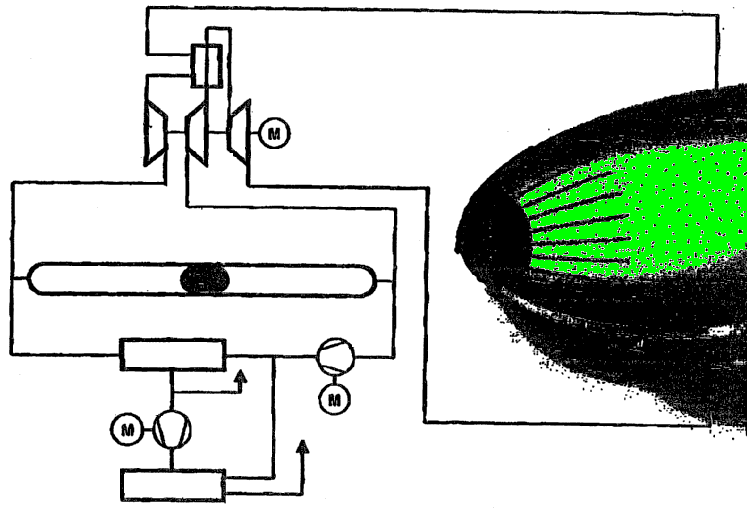

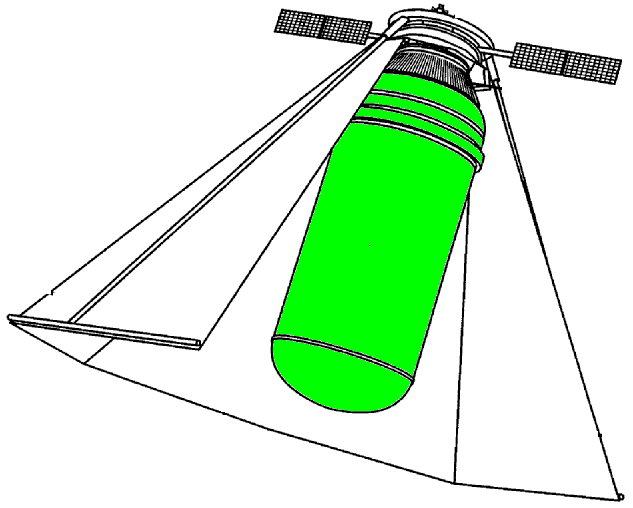

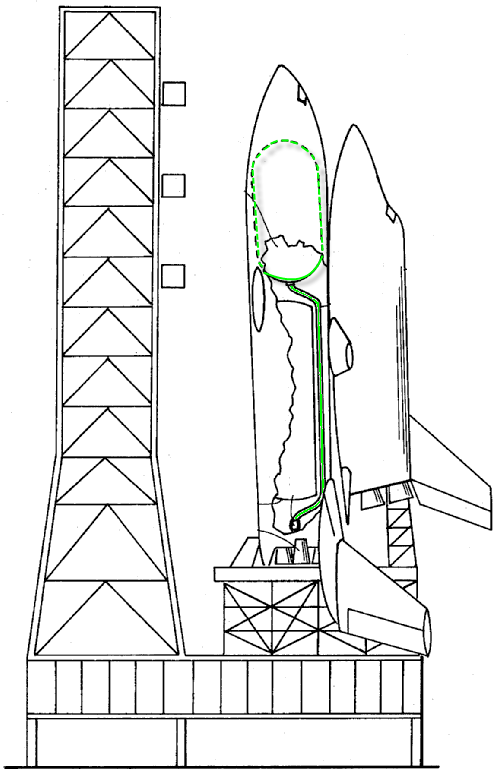

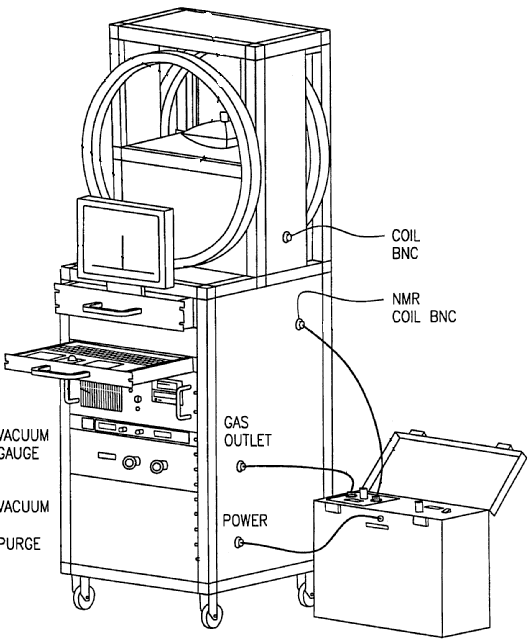

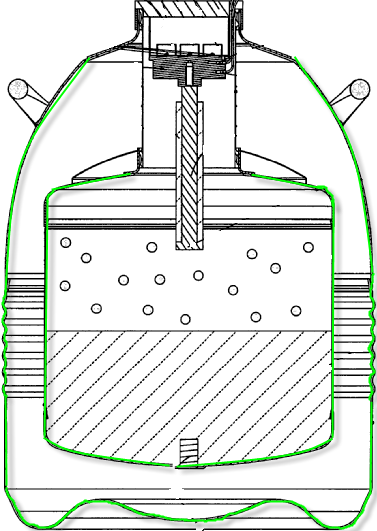

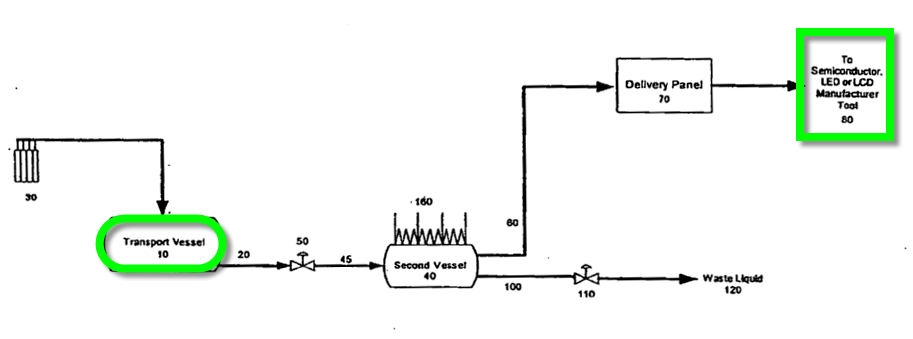

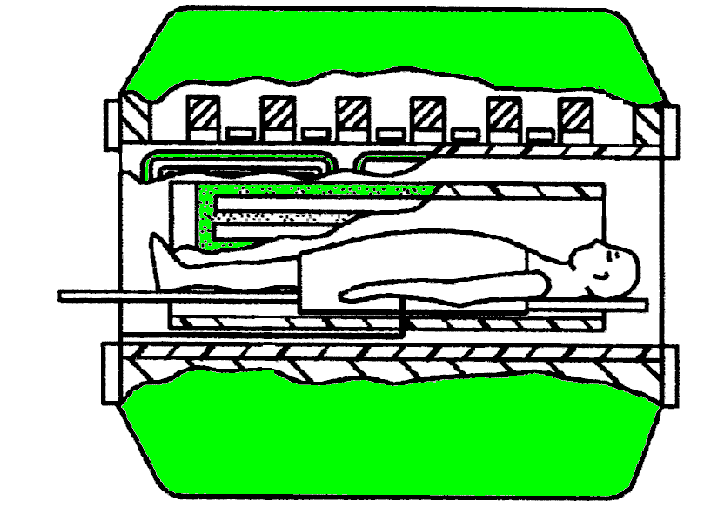

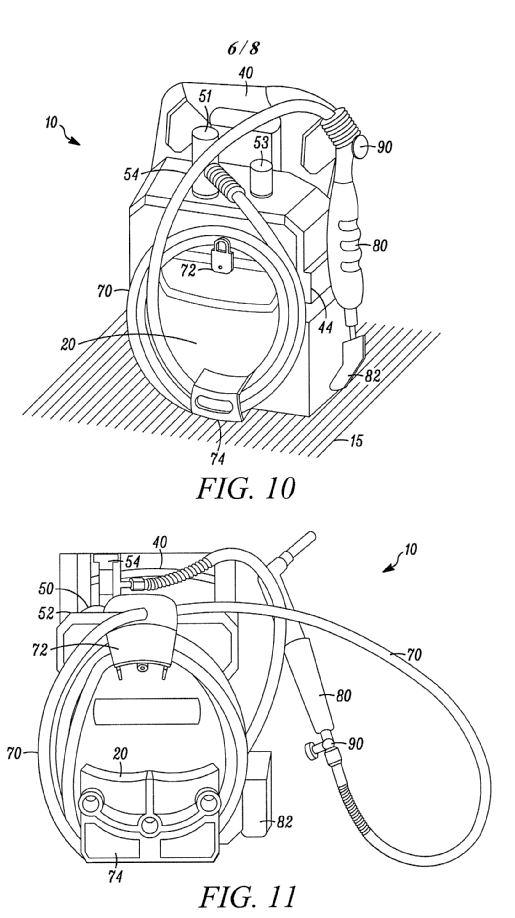

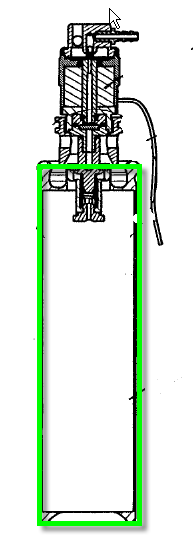

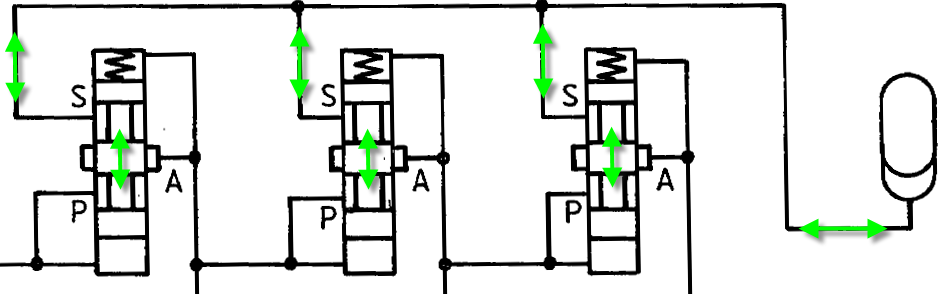

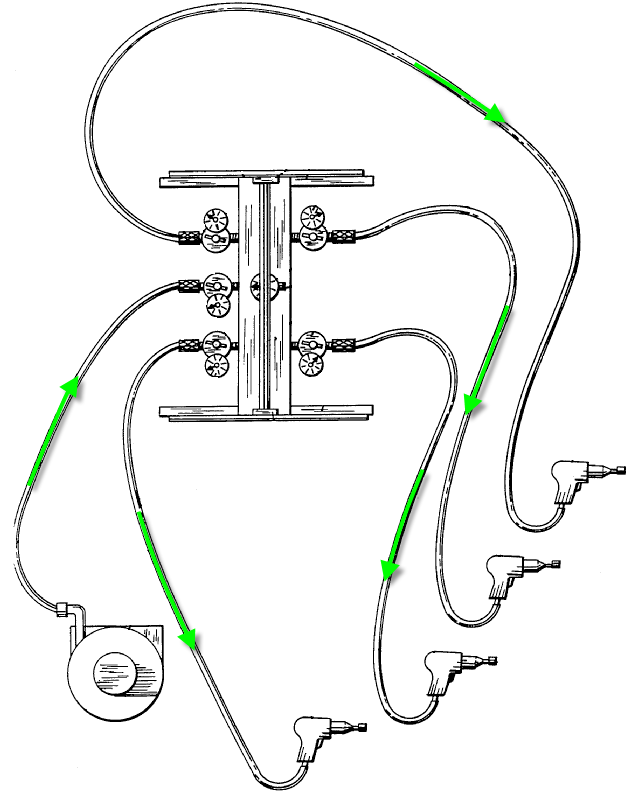

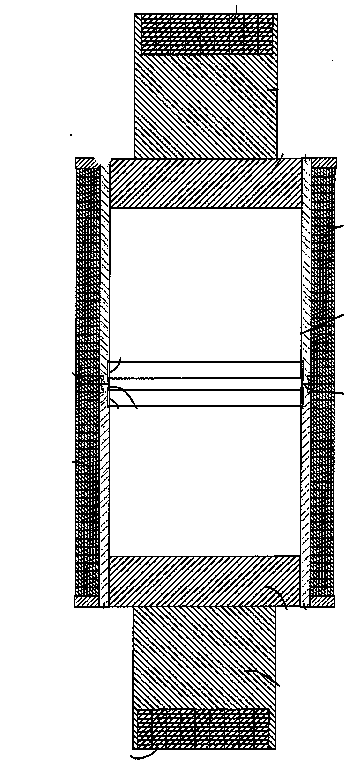

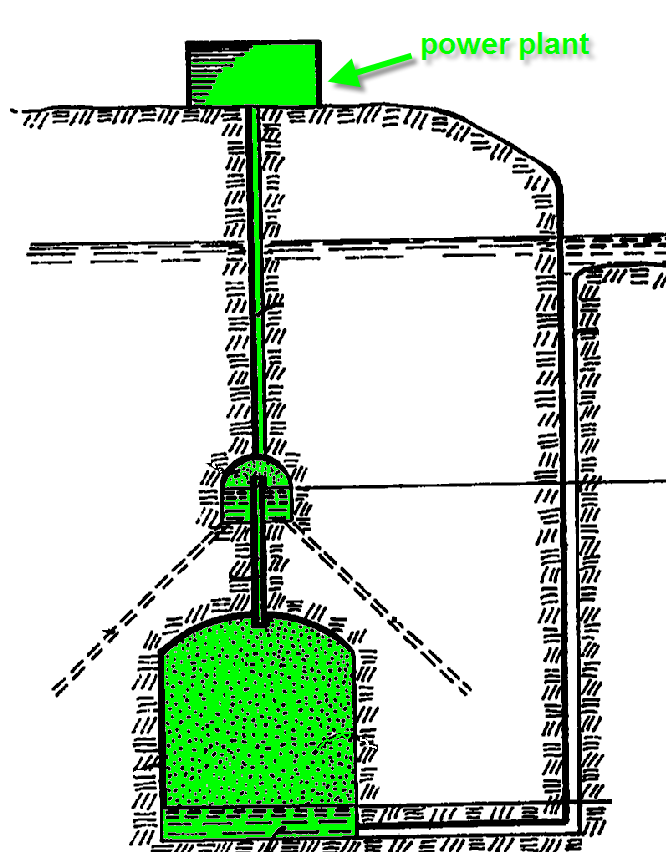

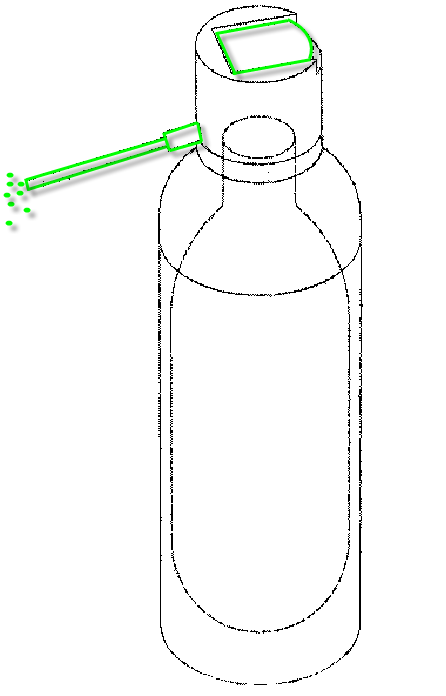

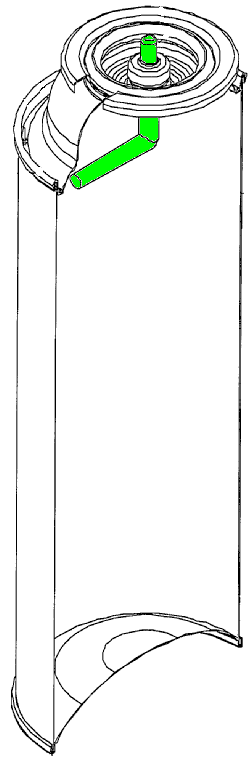

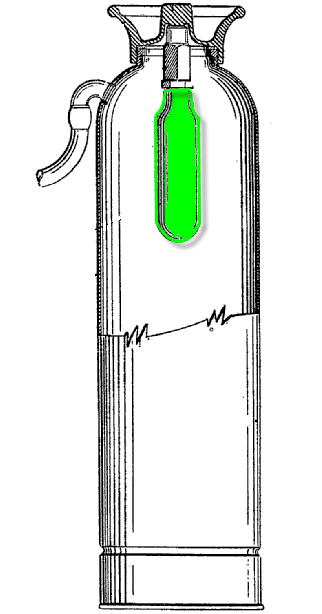

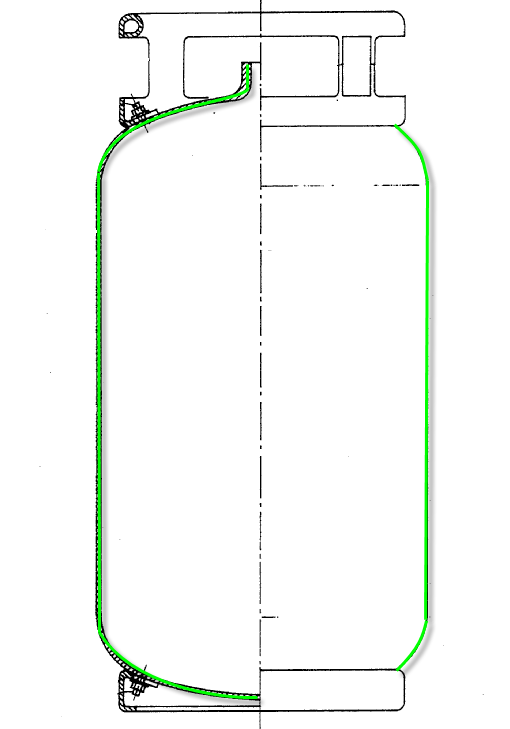

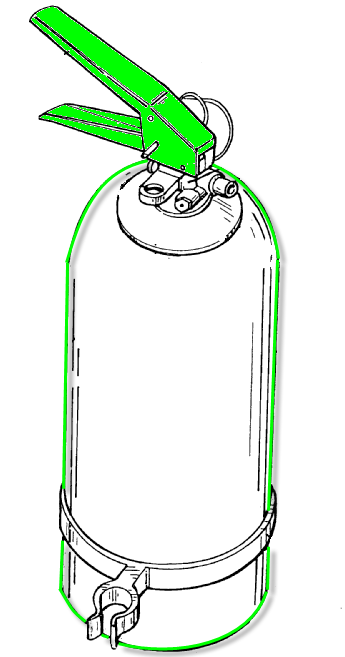

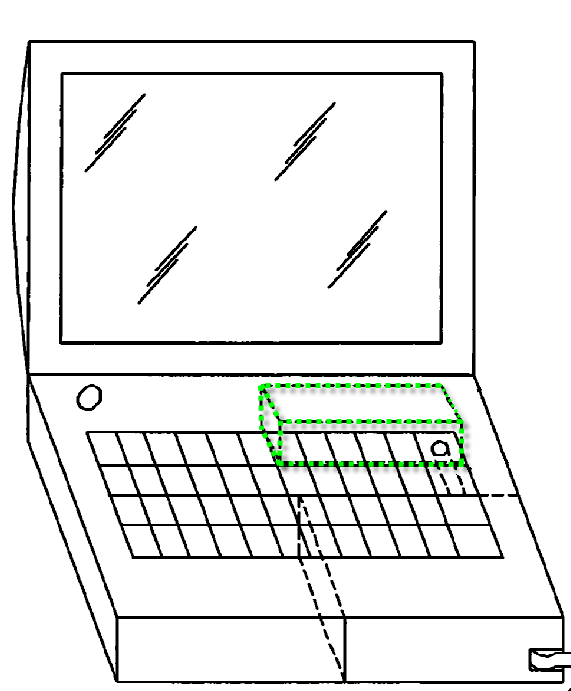

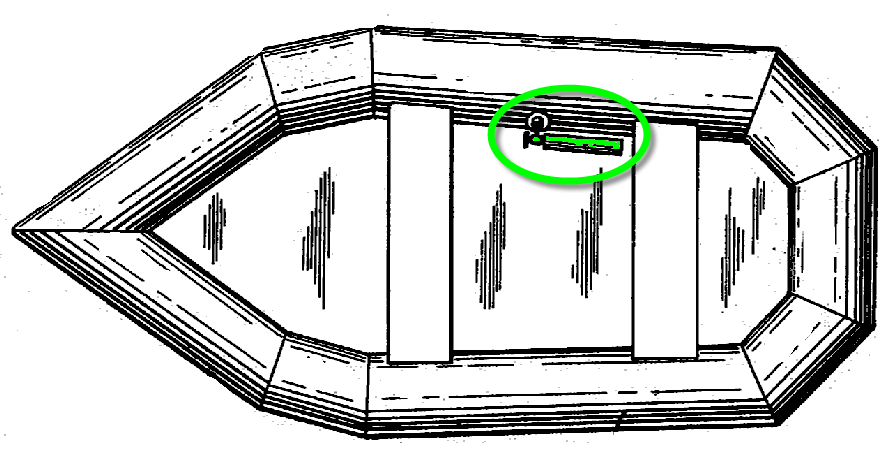

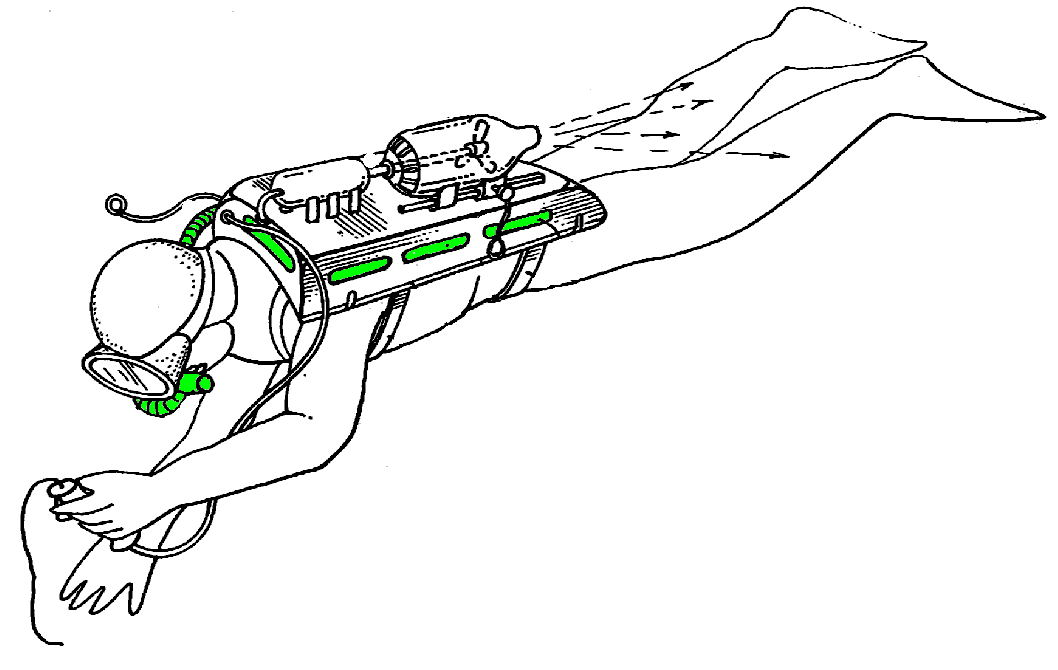

"Positive" examples have been chosen among patents to illustrate the definition statement and what is to be classified in the groups of the 2000 range. The qualifying features are marked in green in these drawings.

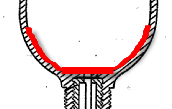

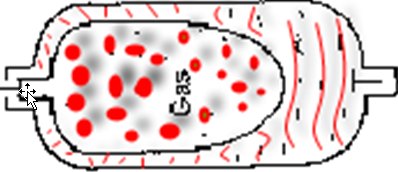

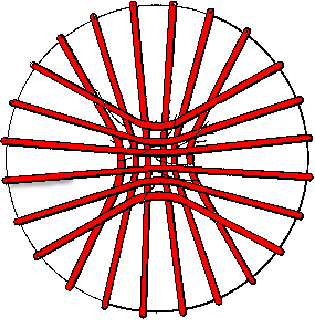

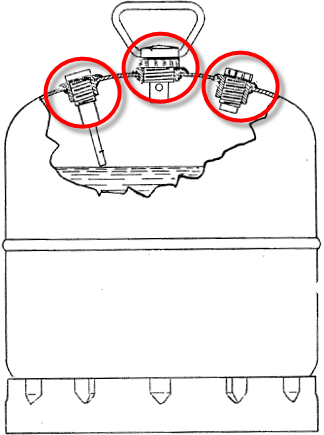

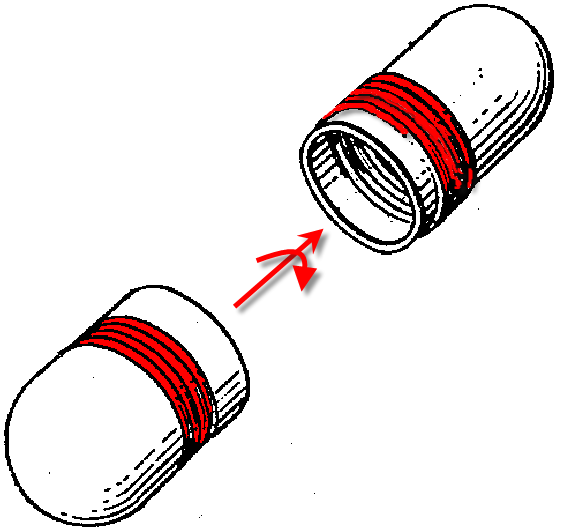

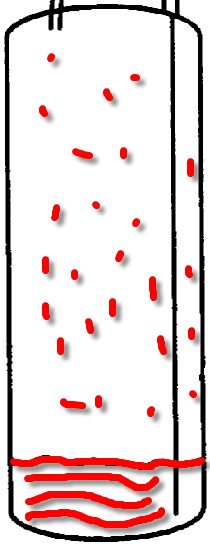

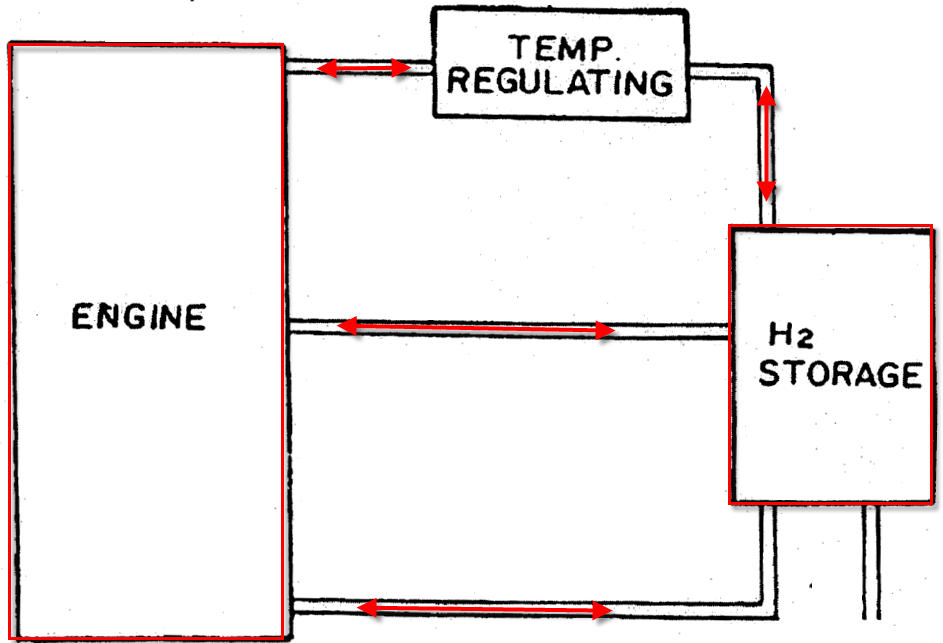

To illustrate the boundaries of the definition statement, "negative" examples have been chosen among patents to illustrate what would not lead to or even disqualify from a classification in a group. The corresponding features are marked in red in these drawings.

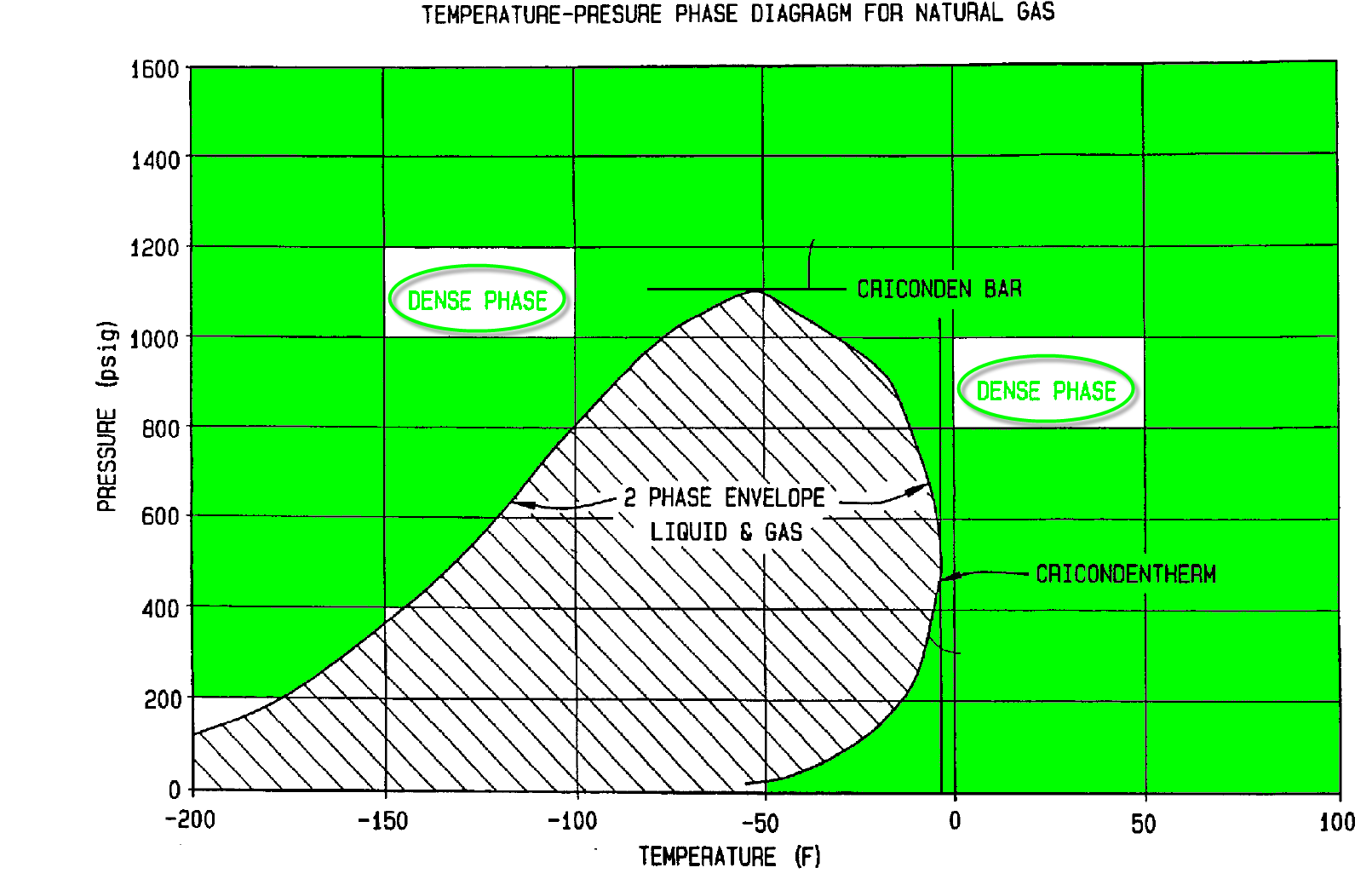

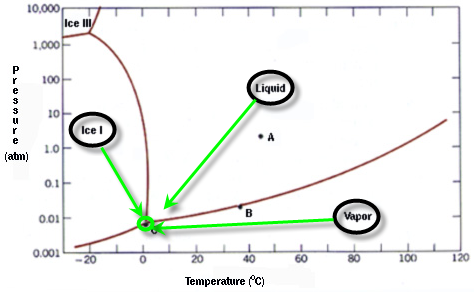

The fluid contained in the vessel according to F17C should be a gas. It is stored in a gaseous, mostly compressed, or in a liquefied or solidified state of matter in the pressure vessel.

Vessels that contain other substances than gases are classified in B65D.

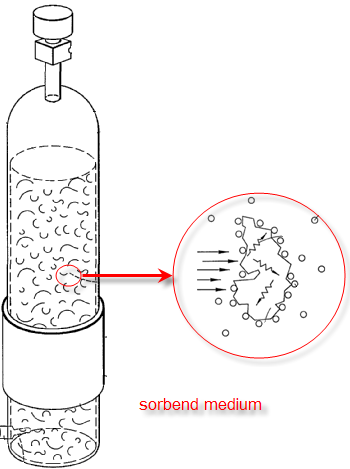

Gas that is stored in solved or adsorbed form are classified in F17C 11/00.

Liquefaction, solidification or separation of gases or gaseous mixtures by pressure and cold treatment are classified in F25J.

Vessels in which processes take place, like chemical reactions, nuclear reactions, gas mixing or liquefaction, are classified in corresponding subclasses, like B01F 23/00 for mixing, e.g. dispersing, emulsifying, according to the phases to be mixed.

Processes involving gas, but for which the focus is on the process external to the pressure vessel and not on the pressure vessel itself, should be classified in subclasses relevant to the process.

Pressure vessel containing additionally to the gas another product or apparatus for which the gas serves as a carrier or a means for achieving another effect than storage, are to be classified in subclasses relevant to the application.

This place does not cover:

- Pressure vessels in which processes, besides sublimation or vaporisation, take place

- Pressure vessels for chemical or nuclear reactions

- Pressure vessels in which gas flows are mixed

- Pressure vessels in which the gas serves purposes other than being stored, like being a vector for another substance

- Pressure vessel containing another product or apparatus for which the gas serves as containment

Attention is drawn to the following places, which may be of interest for search:

Autoclaves | |

Construction or assembling of bulk storage containers employing civil engineering techniques | |

Accumulators for supplying fluid under pressure | |

Methods or means for influencing the flow of gases or liquids | |

Methods or apparatus for combustion using only solid fuel | |

Stoves for gaseous fuels | |

Domestic or central heating systems | |

Fluid heaters | |

Liquefaction or refrigeration machines, plants or systems |

Documents classified in F17C should also get classifications in the 2000 series of this subclass. Classification in those Indexing Codes is mandatory.

Each technical feature in line with a definition should get this classification. There is theoretically no limitation to the quantity of symbols that can be attributed to one single document.

A document contains a technical feature when either this feature is explicitly mentioned in the text or undoubtedly visible in the drawings (e.g.: a weld seam symbol in a drawing has to be classified). Features that are implicit but not mentioned should generally not be considered. Exceptionally, when a feature is not explicitly mentioned but there is no doubt that this particular feature is meant, it may be classified too.

All embodiments have to be considered individually and their features separately identified and classified.

In the exceptional case that one feature reasonably fits into more than one definition, it can be classified in all of them.

Documents should, be classified within this 2000 series completely or not at all, to identify easily if complete classification of all features have been given. Simply attributing e.g. a single classification in that range to a document and not classifying all the other technical features should be avoided.

If the text contains a term which is very specific in the art of "pressure vessels for gas storage and transport" (e.g. "liner" or "LNG"), but its definition or use in the document seems to be in contradiction with the definition herein or the general knowledge of person skilled in the art, the term should in any case be considered and a classification code related to the term should be attributed.

When prior art (e.g. in form of patent numbers, summaries or drawings about prior art) is specifically mentioned in the document, its technical features are NOT considered for classification.

Warning about reorganisation!

Only a part of the documents classified in main groups F17C 1/00 - F17C 9/00 and F17C 13/00 have been coded completely in the 2000 series.

In this place, the following terms or expressions are used with the meaning indicated:

Gas | substance that is in gaseous state of matter at normal conditions (atmospheric pressure and normal ambient temperature. Substances that are in a gaseous state of matter but would not be gaseous at normal conditions are not considered in this subclass. Gas can be put in liquid (liquefied gas), or solidified state of matter, for transport and storage |

Pressure vessel | container containing gas for storage and/or transport |

Fluid or handled fluid | fluid contained in, charged into or discharged out of the pressure vessel |

In patent documents, the following words/expressions are often used as synonyms:

- "reservoirs", "bottles", "cartridges" and "containers"

This place covers:

Constructional aspects of vessel for containing gas under high pressure.

This place does not cover:

Autoclaves |

Attention is drawn to the following places, which may be of interest for search:

Pressurised apparatus for purposes other than storage | |

Pressurised apparatus for purposes other than storage associated with vehicles | |

Tank vehicles | |

Railway tank wagons for carrying fluent materials | |

Accumulators for supplying fluid under pressure | |

Pressure vessels in general | |

Liquefied gas stoves |

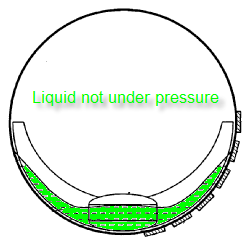

This place covers:

Constructional aspects of vessel for containing liquefied gas or cryogenic fluid which is not under high pressure such as details about the insulation or about the suspension of an inner vessel within an outer vessel.

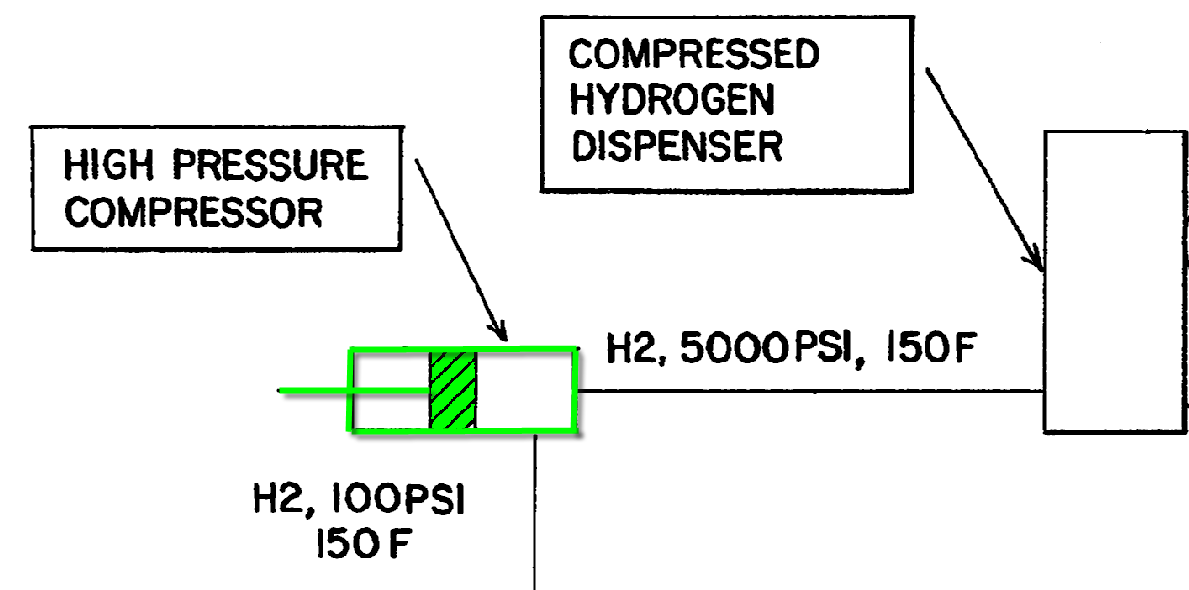

This place covers:

The filling of a receiver vessel with a gas at a high pressure.

This place does not cover:

Methods or apparatus for adding propellants to aerosol containers |

This place covers:

The filling a vessel with a low pressure as for liquefied gas or cryogenic fluid.

This place covers:

The discharging of a vessel comprising a gas stored with a high pressure therein.

This place covers:

The discharging of a vessel comprising a gas stored with a low pressure therein as for liquefied gas or cryogenic fluid.

This place does not cover:

Absorbing compositions for hydrogen | |

Absorbing compositions for acetylene |

This place covers:

Means for coding or identifying vessels or their content, special adaptations of indicating, measuring, monitoring and regulating, mounting arrangements of vessels, it means their integration in their area of use, arrangement or mounting devices for preventing or minimising the effect of explosion, arrangement of valves, and closures.

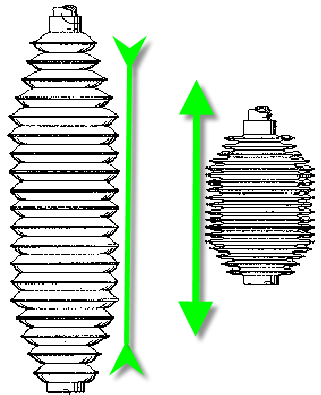

This place covers:

Pressure vessels for which either the shape or axis orientation can be determined or the size either determined or estimated.

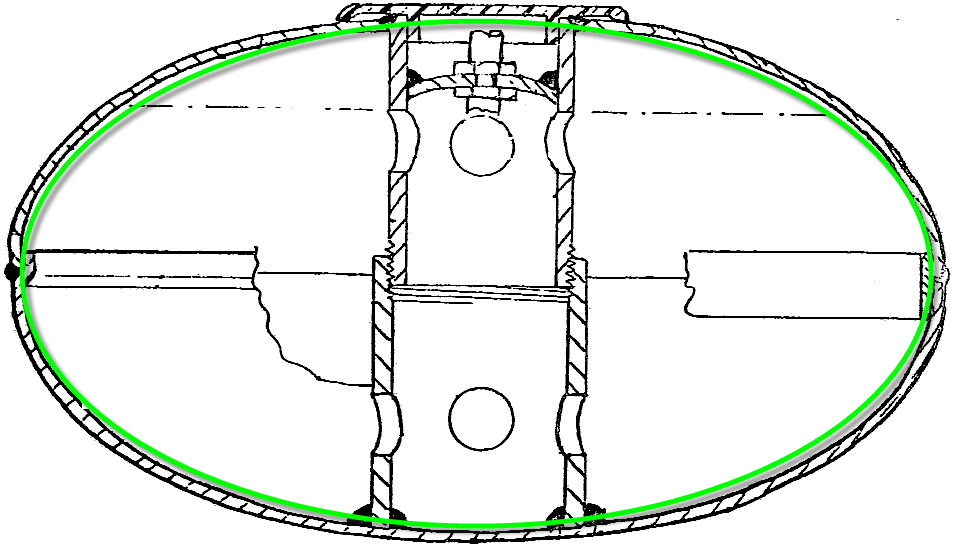

This place covers:

Pressure vessels the shape of which can be identified. For grouped vessel, the shape of the single vessel has to be considered individually, not the shape of the group per se.

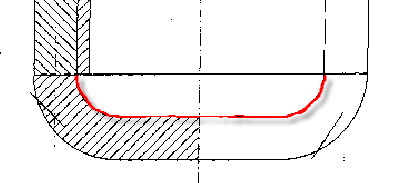

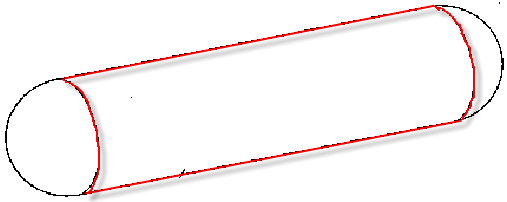

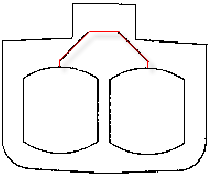

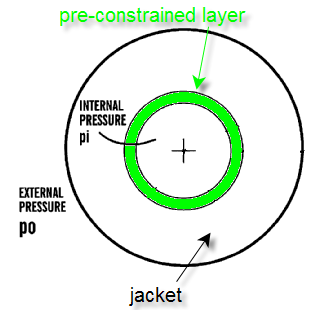

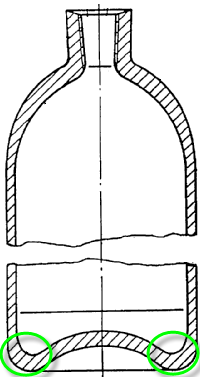

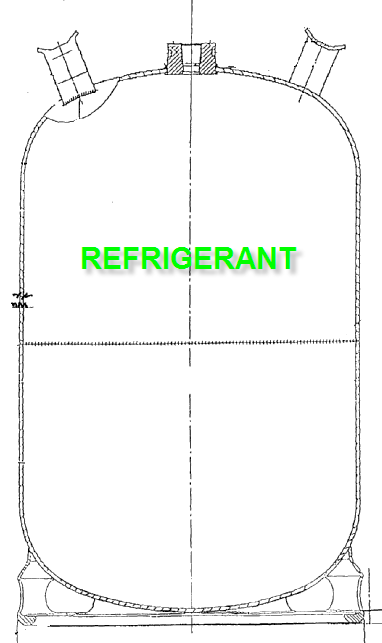

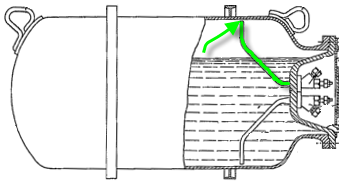

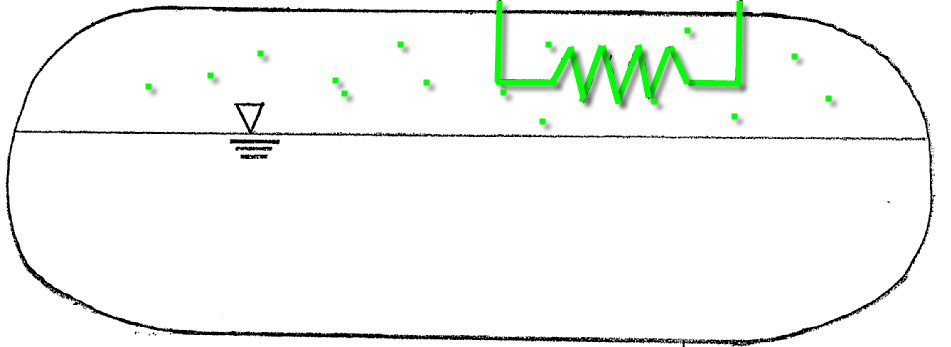

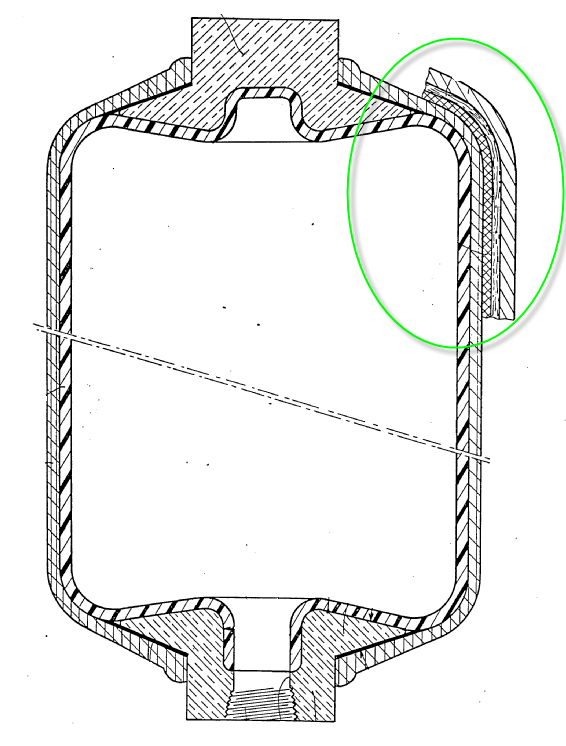

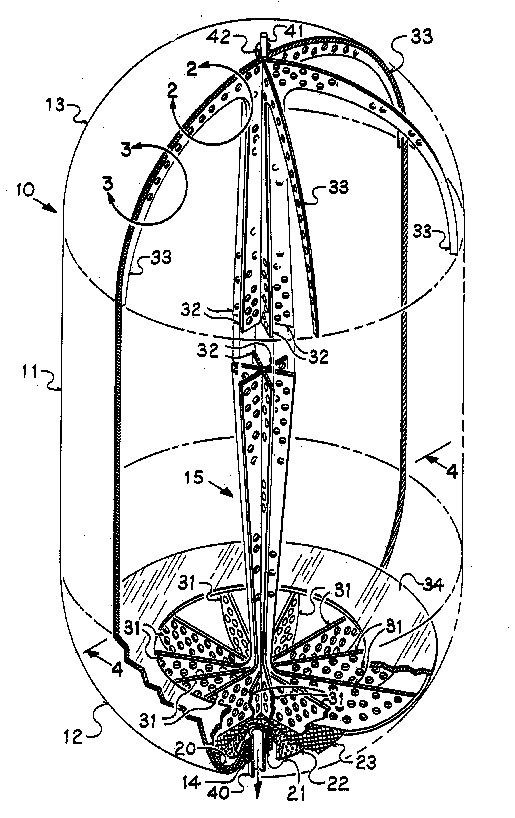

In this positive example from GB818073: the shape of the vessel is the shape of the inner vessel.

In this negative example from GB818073, the outer jacket shape is NOT to be considered, as the definition of "shape" excludes the contour of external frames, covers, boxes etc...

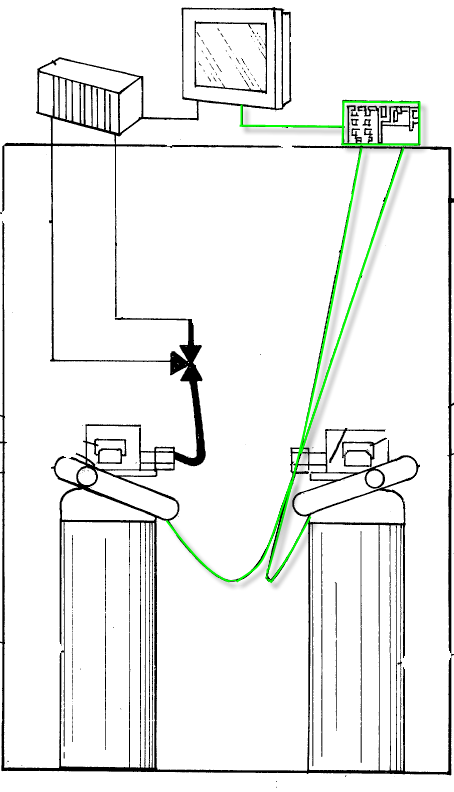

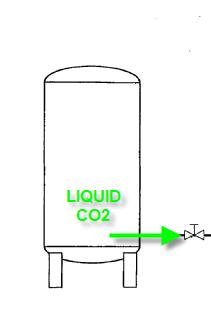

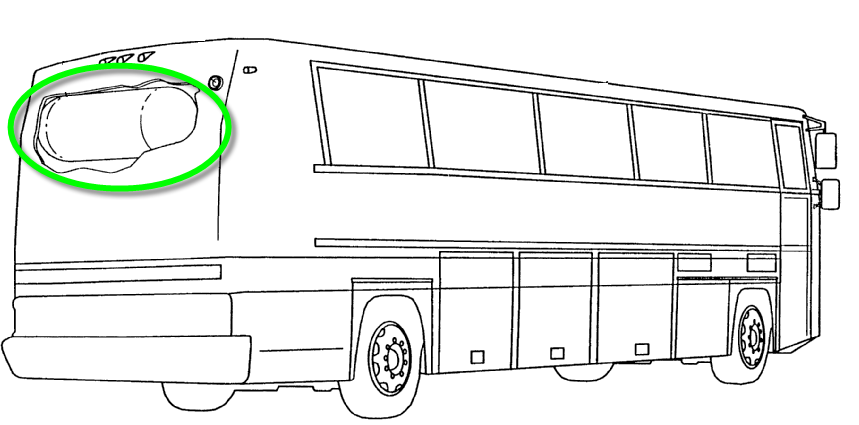

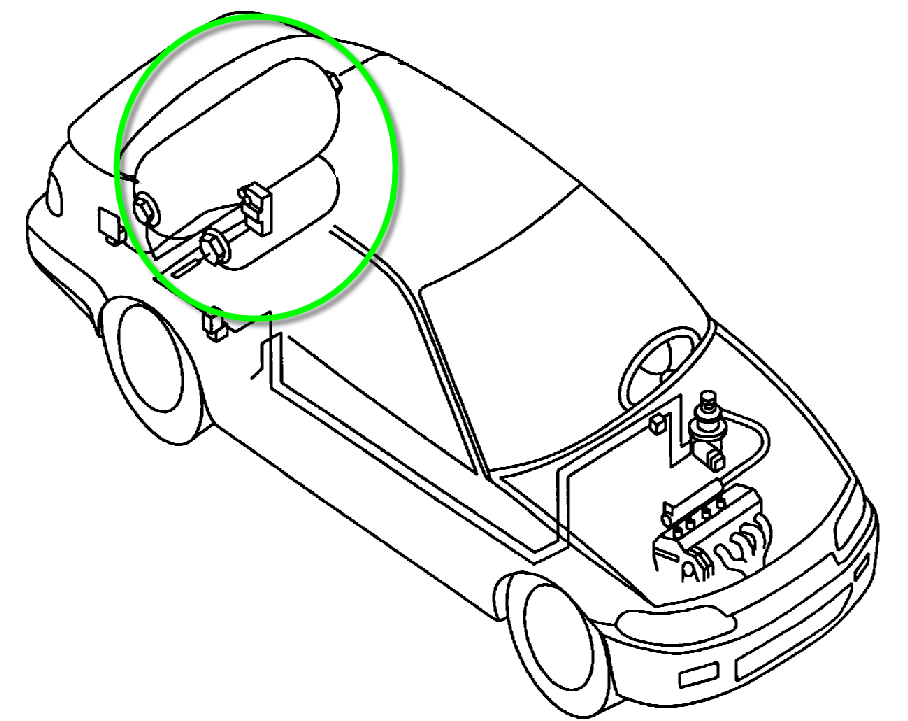

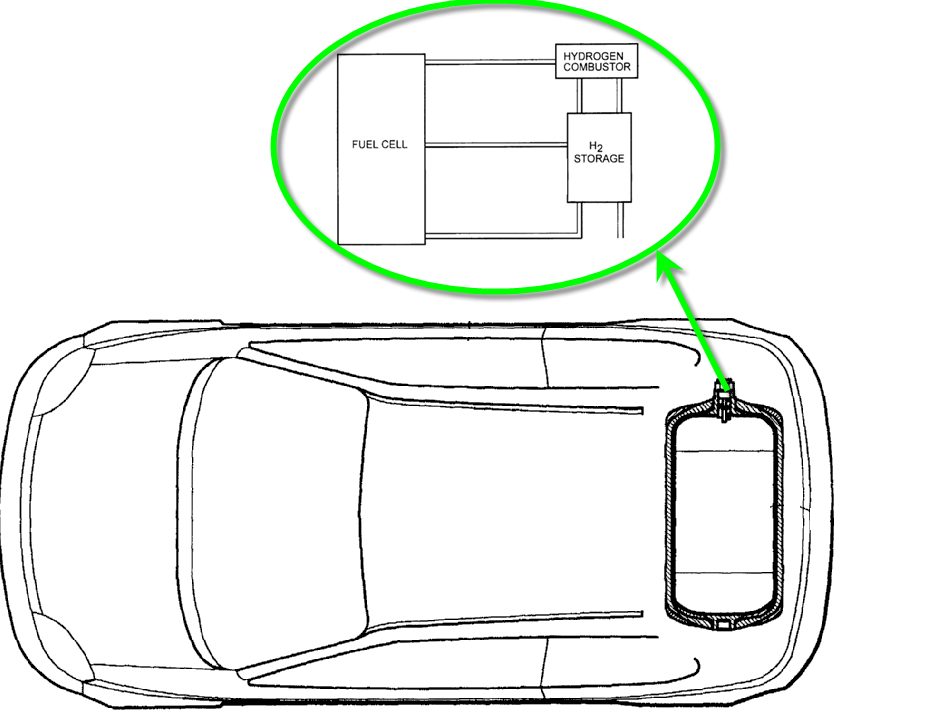

In this negative example from US20080178611, the shape is not classified, as in this purely functional drawings, the vessels is represented symbolically. Symbolic information is generally not considered sufficient to determine a shape, unless the drawing is explicit and realistic, which is not the case here.

In most cases, the exterior shape of a vessel is identical to the interior shape of the vessel. It may though happen that a pressure vessel discloses a visible exterior shape that is different from the interior contour. In these exceptional cases, the classification codes of both shapes have to be allocated.

In this place, the following terms or expressions are used with the meaning indicated:

Shape | the shape of a pressure vessel is the visible external form of the pressure vessel when reduced to its core. The core comprises only the layers that contribute to the structural integrity of the vessel and enable it to withstand the pressure of the contained fluid. |

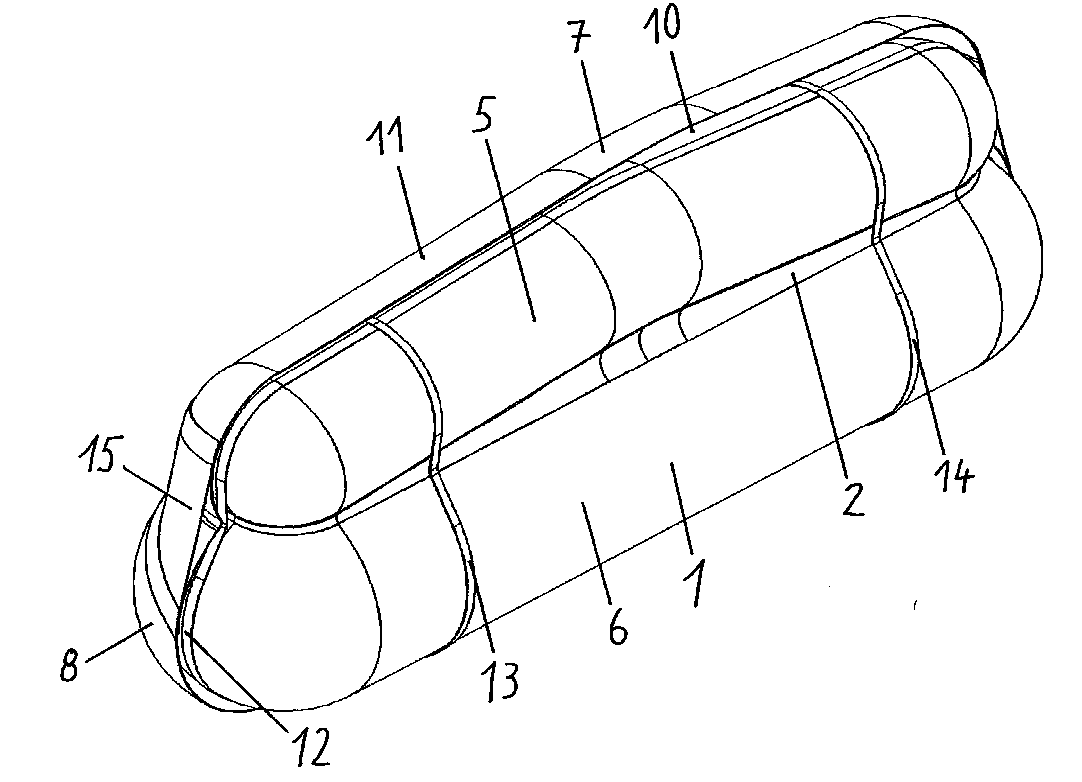

This place covers:

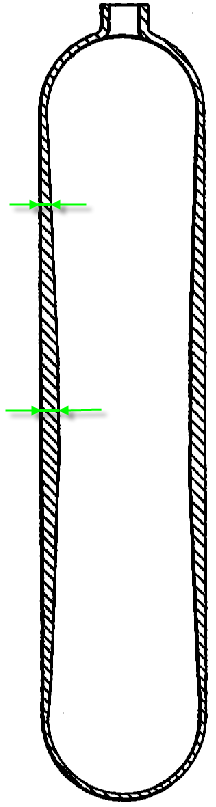

Pressure vessels with an axis and a cylindrical form with circular sections

In this place, the following terms or expressions are used with the meaning indicated:

End-piece | end parts of a cylindrical pressure vessel, complementary to the middle part. End-pieces and middle part form the whole vessel. |

Middle part | part of a cylindrical pressure vessel between the end-pieces. End-pieces and middle part form the whole vessel. |

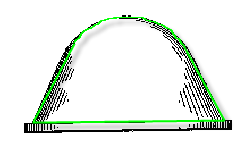

This place covers:

Cylindrical pressure vessels with at least one exteriorly curved end-piece. The form of the end-piece is convex when considered from the outside and this convex form has to be dominant.

In this positive example from DE8619754U, the shape is a half-globe.

In this positive example from WO2053966, the shape has a flat bottom, but is dominantly exteriorly curved.

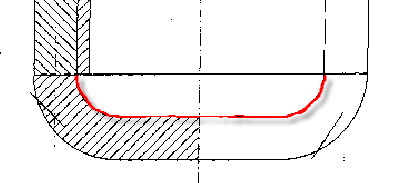

In this negative example from DE19952611, the round corners seem related to the manufacturing of the vessel. The flat bottom is dominant: the vessel is classified as having flat end-pieces.

This place covers:

Cylindrical pressure vessels with at least one interiorly curved end-piece. The form of the end-piece is concave when considered from the outside and this concave form has to be dominant.

In this positive example from DE877461, the shape of the vessel is interiorly curved.

This place covers:

Cylindrical pressure vessels with at least one flat end-piece. The flat form has to be dominant.

In this positive example from CH1480971, the shape of the vessel is flat.

In this negative example from DE490791, the curved portion is dominant upon the flat one: the vessel is classified as having exteriorly curved end-pieces.

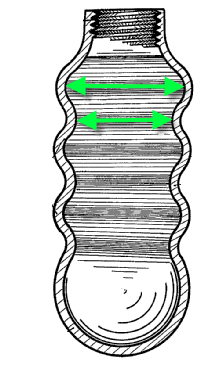

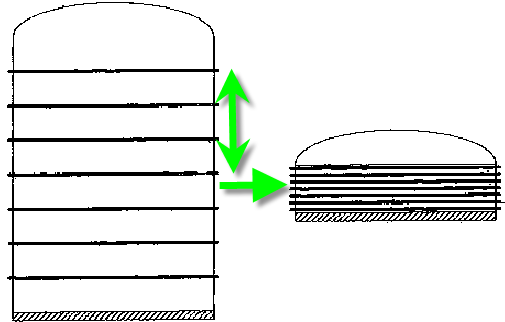

This place covers:

Cylindrical pressure vessels for which in the middle part, the cross section has not a constant surface along the axis.

Cylindrical pressure vessels for which the wall thickness in the middle part is not constant along the axis.

The variations in thickness or diameter can be the result of a variable wall thickness along the axis, but also the result of e.g. rings added externally on the middle part.

In this positive example from US2280501, the thickness of the wall is not constant.

In this positive example from BE405843, the thickness of the wall is constant, but not the surface of the section.

In this negative example from DE10325598, the wall of the end piece, but not of the middle part, has a variable thickness.

This place covers:

Pressure vessels with a spherical or elliptical shape.

In this positive example from DE3131040, the shape is elliptical .

In this positive example from WO9612914, the shape is spherical.

In this negative example from DE800230, the shape seems elliptical but from the text indicated that the vessel is cylindrical (cross sections may be misleading).

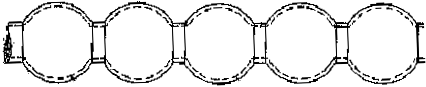

This place covers:

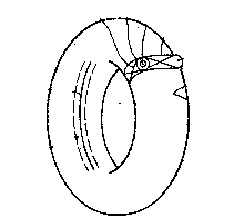

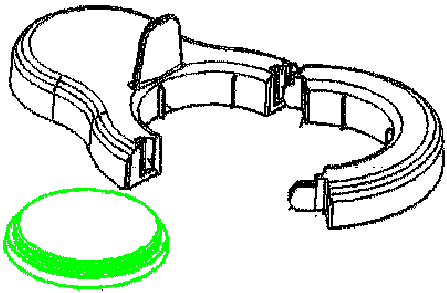

Pressure vessels with toroidal form, like a hoop or a tyre, that actually often replace spare tyres in cars.

In this positive example from DE3316539, the shape is a tore.

In patent documents, the following words/expressions are often used as synonyms:

- "tore and "donut"

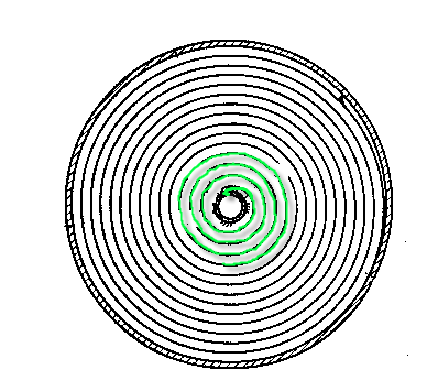

This place covers:

Pressure vessels in form of a tube or a hose. The diameter of the tube is small in comparison with the extended length of the tube.

In this positive example from DE2305840 , the shape is tubular, even if the entire construction may look like a cylinder.

In this positive example from DE19547752, the shape is tubular.

In this negative example from US2008256960, the middle part is tubular, but the vessel is actually cylindrical.

This place covers:

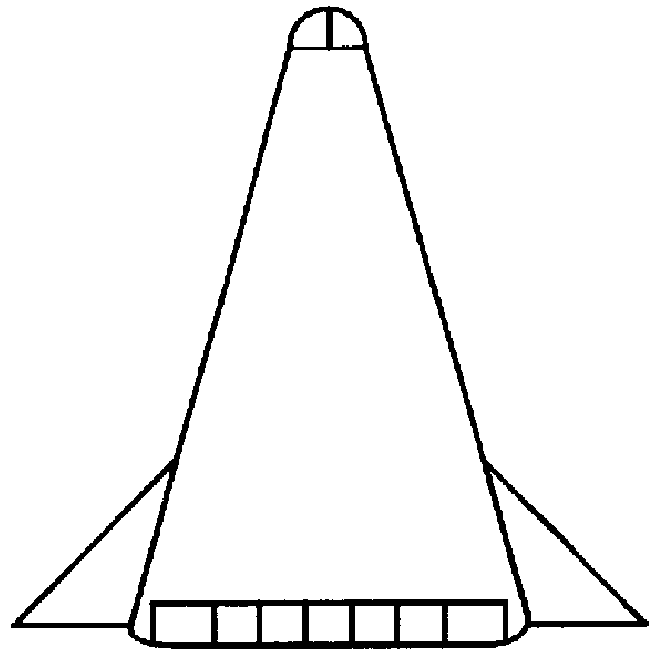

Pressure vessels in a general conical form, i.e. cylindrical with an increasing and/or decreasing cross section.

In this positive example from WO2004005790, the shape is conical.

In this positive example from DE19747907 the shape is conical.

In this negative example from GB521979, the vessel is cylindrical, with an intermediate conical connection to the end-piece.

This place covers:

Pressure vessels the shape of which is not covered by the groups above, i.e. not cylindrical, spherical, elliptical, tubular or conical.

Pressure vessels the shape of which is not an association of fluidly connected shapes covered by the groups above, not cylindrical, spherical, elliptical, tubular or conical.

In this positive example from DE2931947, the shape is simple, but compliant with the definition of complex.

In this negative example from WO0049330, two cylindrical pressure vessel are bundled. This vessel "cylindrical with exteriorly curved end pieces" (F17C 2201/0109) and the bundle is considered as "two or more vessels " (F17C 2205/013).

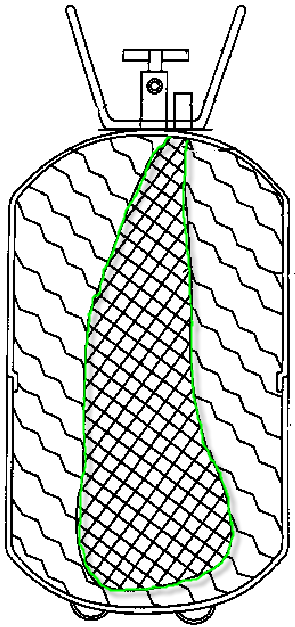

This place covers:

Pressure vessels with the shape of connected curved wall segments.

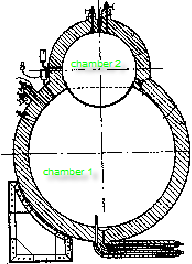

In this positive example from DE1944315, the external shape consists of lobes, with an single internal volume.

In this positive example from EP1355105, the external shape consists of lobes, with several distinct internal volumes.

This place covers:

Pressure vessels with the shape of connected flat wall segments with generally sharp edges.

In this positive example from FR2781555, the external shape is polygonal, with several distinct internal volumes.

In this negative example from CH148097, the shape seems polygonal, but the pressure vessel is actually cylindrical (cross sections may be misleading).

This place covers:

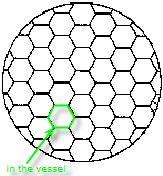

Pressure vessels with a honeycomb structure (6 edges) inside the vessel, in contact with the stored fluid.

In this positive example from FR1268538, the honeycomb structure is in contact with the fluid.

In this negative example from NL7414082, the honeycomb structure is located in the insulation layer and is thus not in contact with the stored fluid.

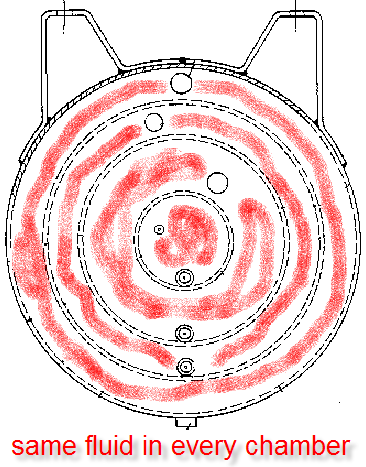

This place covers:

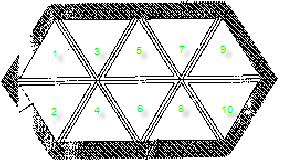

Pressure vessels with the inner storage volume subdivided in individual volumes. These volumes are separated by common walls.

In this positive example from FR2781555 , 10 chambers are visible.

In this positive example from GB412814, 2 chambers are visible.

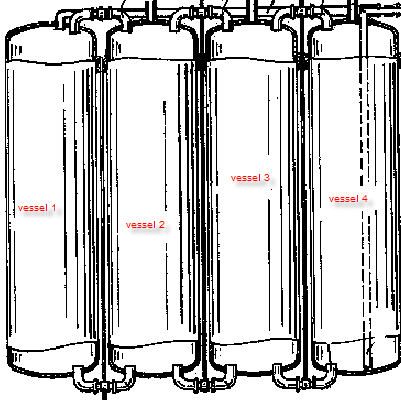

In this negative example from DE1946465, several distinct cylindrical vessels are fluidly connected and arranged in a bundle (F17C 2205/0134).

In this negative example from US1692670, two clearly distinguishable cylindrical vessels are mounted one inside the other (F17C 2205/0149).

This place covers:

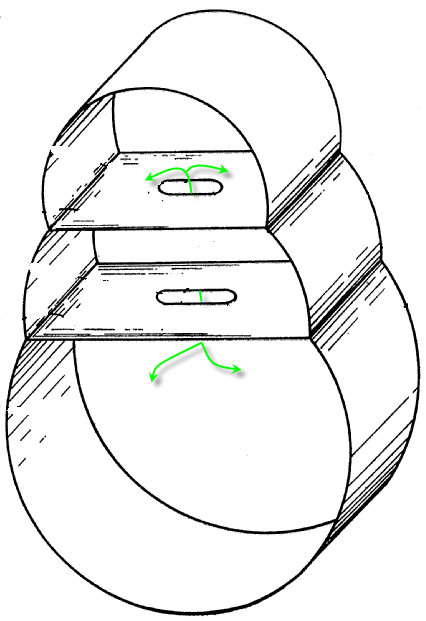

Pressure vessel forming a single vessel wherein pressure balance between several distinct chambers is obtained via a permanent open hole between these chambers. For "pressure vessels divided in several chambers", the permanent open hole is situated in the common wall.

In this positive example from DE63206430, the 3 chambers of the " pressure vessel divided in several chambers" are connected by two permanent holes.

In this positive example from FR783241, a single vessel, materialized by its common external hull and its common fittings, is created by connecting cylindrical chambers via a permanent connection. This connection can be assimilated to holes as the cylindrical chambers are close to each other.

In this negative example from GB693156, two strictly separated vessels are simply connected by a pipe. No common vessel is created and the pipe is too long to be considered a hole.

In this negative example from DE531720, a hole connects two chambers of the vessel, but an inserted valve allows no pressure balance.

This place covers:

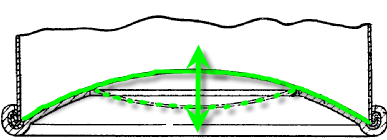

Pressure vessel with a non-constant or variable shape or with a non-constant or variable inner or outer volume.

In this positive example from DE102009017650, the shape is constant, but the volume changes.

Attention is drawn to the following places, which may be of interest for search:

Large flexible containers | |

Gas holders with variable capacity, with flexible walls |

Warning about pending reorganisation: Documents from F17B that will be deep-indexed with be classified herein.

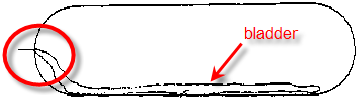

This place covers:

Pressure vessel with an inflatable bag located in the vessel to retain the fluid.

In this positive example from US6234352, the bladder is attached on top.

When counting the number of layers in the group F17C 2203/0612, a bladder is not counted.

In patent documents, the following words/expressions are often used as synonyms:

- "bag (English)bladder" and "bag"

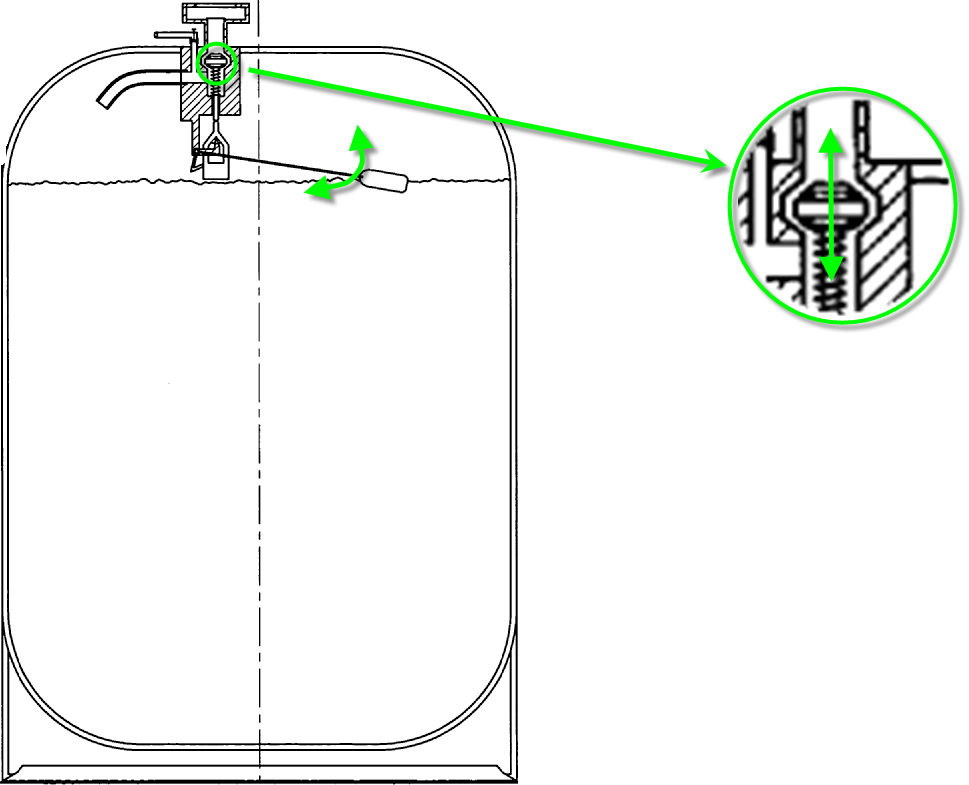

This place covers:

Pressure vessel with volume separating membrane attached to the inner wall of the vessel along a line.

In this positive example from GB80450, a membrane separates the vessel in two.

In this negative example from DE29816811U, a bladder separates the vessel in two.

Attention is drawn to the following places, which may be of interest for search:

Shape flexible with bladders |

Bladders have the function of a separating membrane, but are only classified in F17C 2201/018.

This place covers:

Pressure vessel with a volume separating piston.

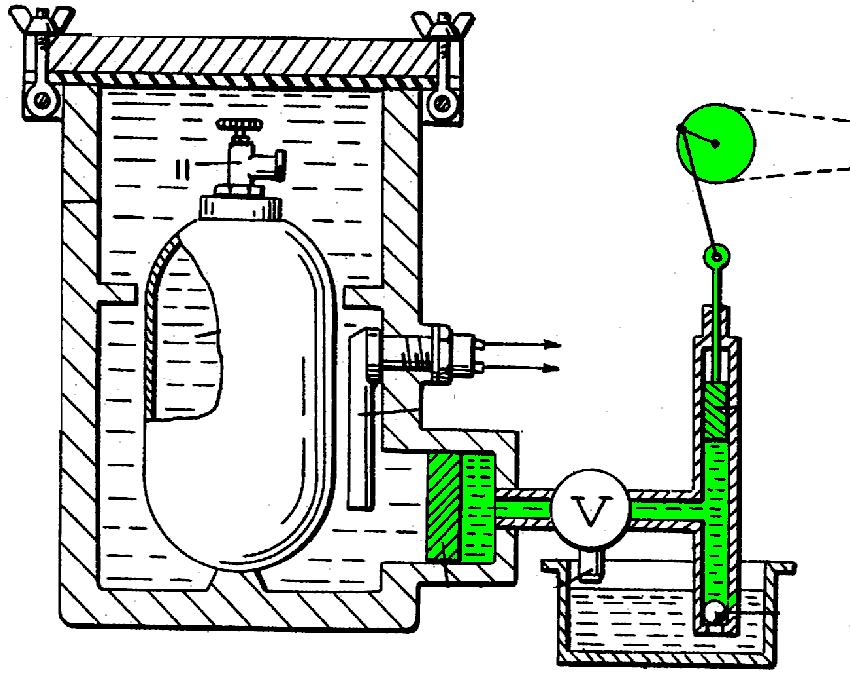

In this positive example from US5253682, a free piston in the vessel helps discharging.

In this negative example from US3426545, the piston is part of a pump.

Attention is drawn to the following places, which may be of interest for search:

Positive displacement machines for liquids; pumps: |

This place covers:

Pressure vessel in form of a bellows.

In this positive example from US3270905, the whole pressure vessel is a bellows.

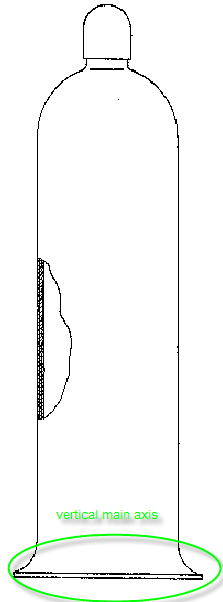

This place covers:

Pressure vessels for which an axis can be defined and for which this axis has a defined orientation when mounted or in use. The orientation is mostly suggested by a device that allows or constrains the pressure vessel to be oriented a certain way. Such devices can be supporting feet, hanging up devices, frames etc.

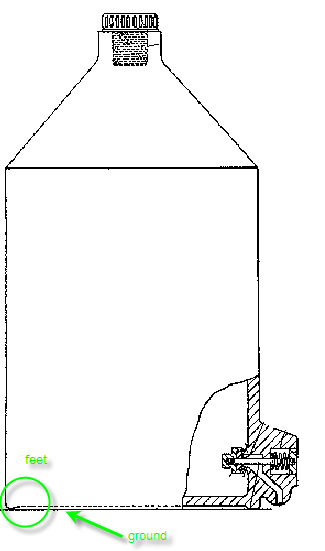

In this positive example from GB494426, the pressure vessel has a vertical orientation due to its flat bottom acting as a mounting foot.

In this negative example from DE19934851, the vessel is a cylindrical bottle that can be turned upside down or oriented in any direction, without any preferred direction.

In this negative example from US3468264, no main axis of the vessel on the ship is identifiable.

This place covers:

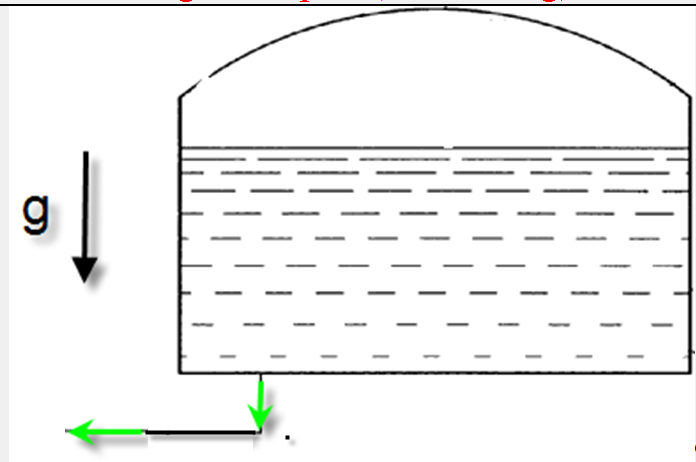

Pressure vessels for which the axis has a vertical orientation.

In this positive example from DE199106, the pressure vessel is cylindrical and has a flat bottom.

Pressure vessels with toroidal shape are classified herein, their axis passing through the middle of the hole.

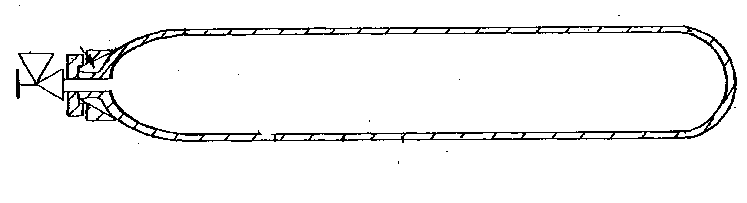

This place covers:

Pressure vessels for which the axis has a horizontal orientation

In this positive example from DE10022741, the cylindrical vessel rests on mounting feet.

This place covers:

Pressure vessels for which the axis is neither horizontal nor vertical.

In this positive example from EP2312196, the pressure vessel is mounted on an inclined frame.

This place covers:

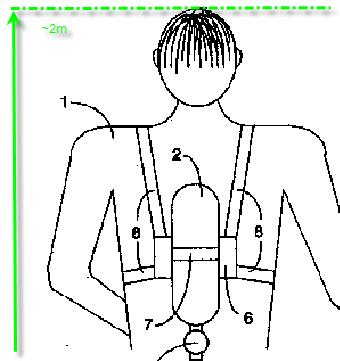

Pressure vessels for which the inner storage volume can be determined.

Pressure vessels for which the inner storage volume can be estimated. The volume can be suggested by any hint, like objects in the drawings or knowledge from the context the pressure vessel is used in.

In this positive example from US20040003743, the size of the human allows to estimate the size of the vessel.

In this negative example from BE427219, the pressure vessel "looks" small, but there is no hint about the size.

In this negative example from NL7314739, the storage capacity of the whole ship is certainly large, but not to be considered as the vessels are probably bundled, and the size of the individual vessel is difficult to estimate.

In case of bundled pressures vessels from F17C 2205/0134, the volume of the individual pressure vessel has to be classified, not the resulting overall volume.

The rule of classification, according to which a technical feature has to be explicitly mentioned, is not strictly applicable here: the size is a technical feature that can be estimated.

The boundaries indicated in the groups (30 liters, 1 m³, 1000 m³) are merely to be understood as an indication and an order of magnitude. They are not binding or strict.

In doubt, it is recommended to classify into two adjacent classes (portable and small, or small and medium, or medium and large) simultaneously.

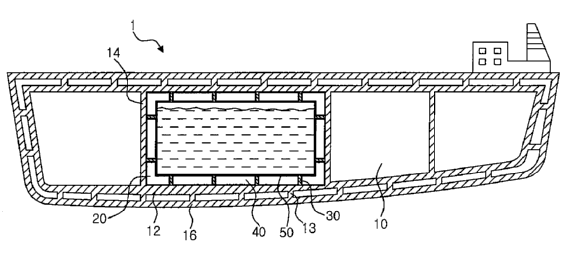

This place covers:

Pressure vessels of large size, an order of magnitude being 1000 m³. Such pressure vessels often appear in terminals, on subterranean caverns, on maritime gas carriers or sewage plants and hints that suggest a large size are often houses or ships.

In this positive example from WO9962794, the large size of the vessel is suggested by the building.

Attention is drawn to the following places, which may be of interest for search:

Large containers | |

Component parts, details or accessories for large containers |

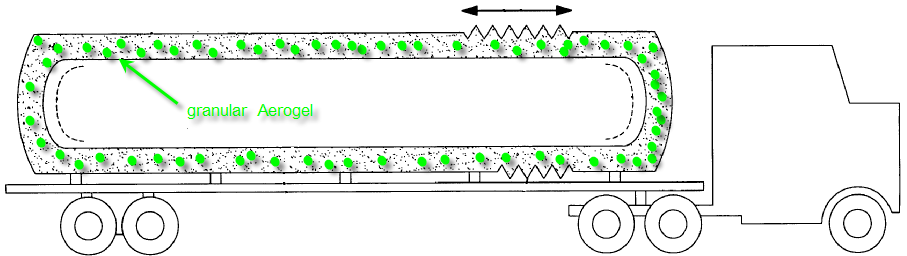

This place covers:

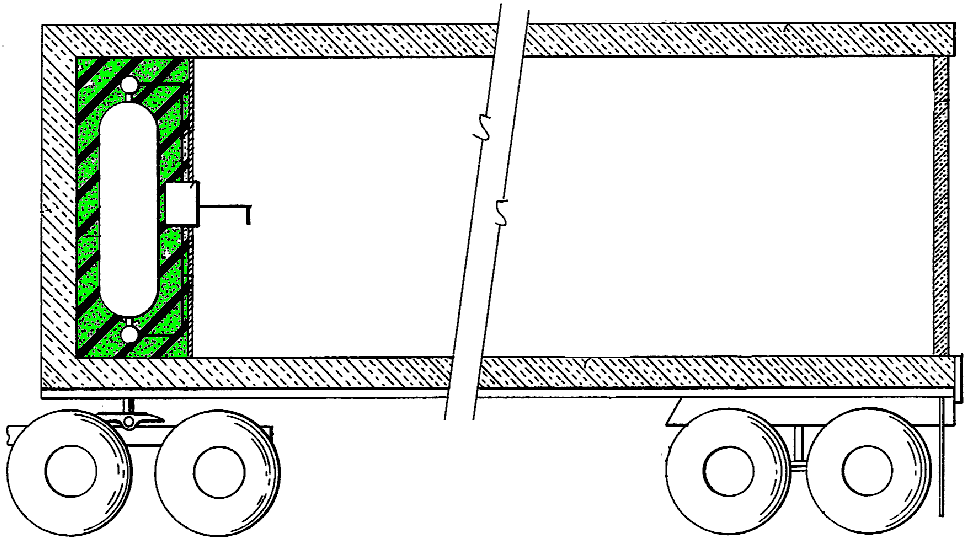

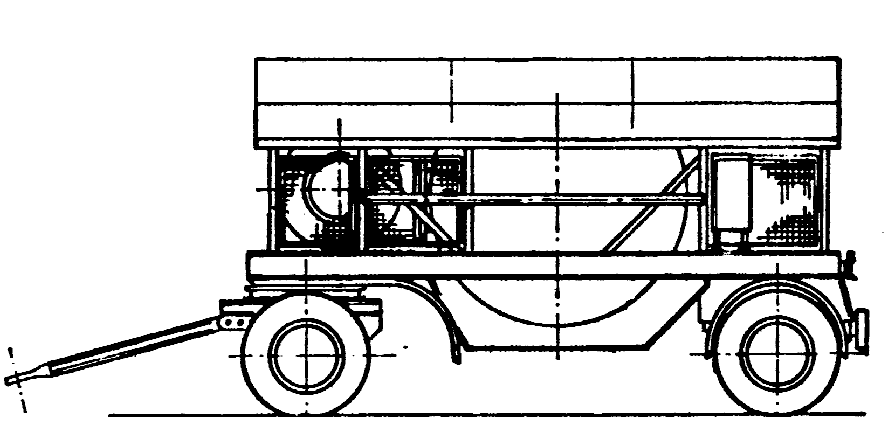

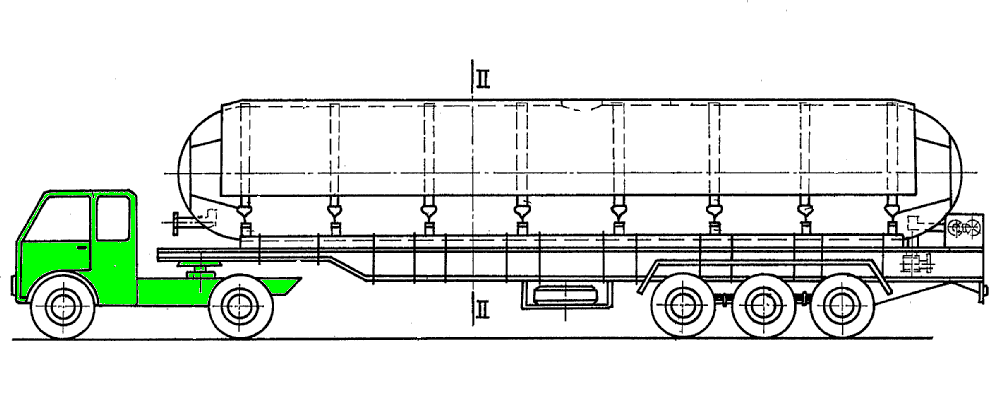

Pressure vessels of medium size (between 1 m³ and 1000 m³), often appearing e.g. on trailers supplying fuel stations, in installations for gas supply or in domestic use, e.g. buried LPG tanks.

In this positive example from DE10027619, the vessel is mounted on a trailer.

This place covers:

Pressure vessels of small size (between 0,03 m³ and 1 m³), often appearing on cars, in domestic use or with transporting means on wheels.

In this positive example from US2005183425, the pressure vessel stores gas fuel in a car.

This place covers:

Pressure vessels of small size (up to 30 liters), like gas bottles or cartridges, which are typically portable or liftable by a single human by muscular force.

In this positive example from NL7708523, the pressure vessel is a gas cartridge.

This place covers:

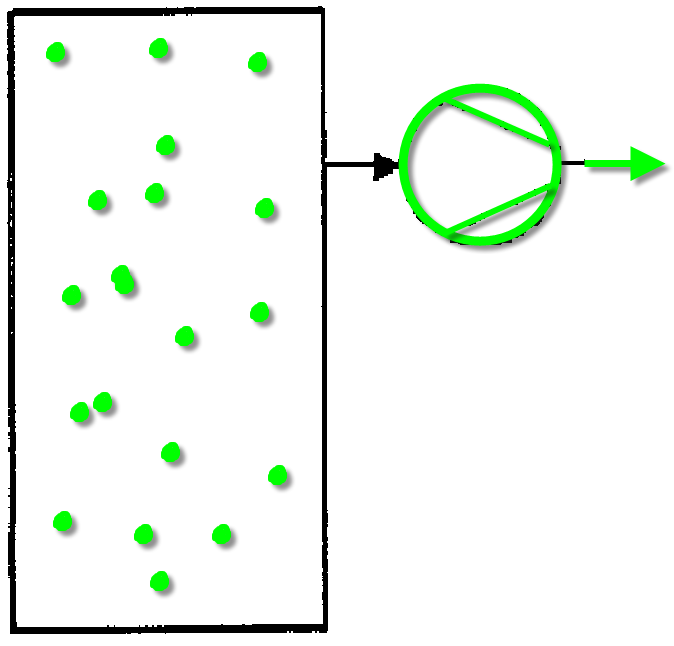

Pressure vessels containing floating elements in the liquid, which have only a physical and no chemical interaction with the fluid. Such elements are for instance microspheres or open spheres that prevent slosh.

In this positive example from US2008272130, spheres fill the whole container.

In this negative example from WO0211860, the pressure vessel is filled with an adsorbing medium, allowing adsorption and desorption of the fluid (F17C 11/00)

Attention is drawn to the following places, which may be of interest for search:

Use of gas-solvents or gas-sorbents in vessels |

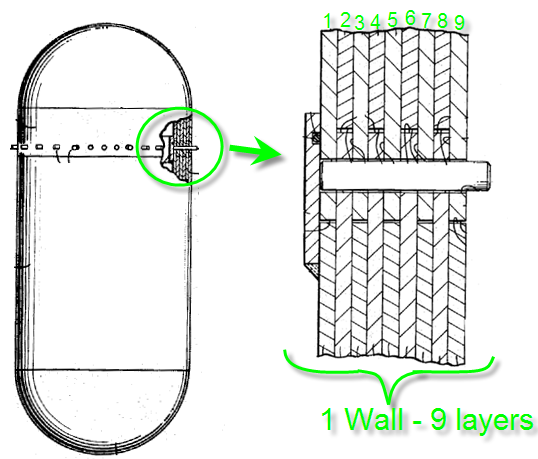

This place covers:

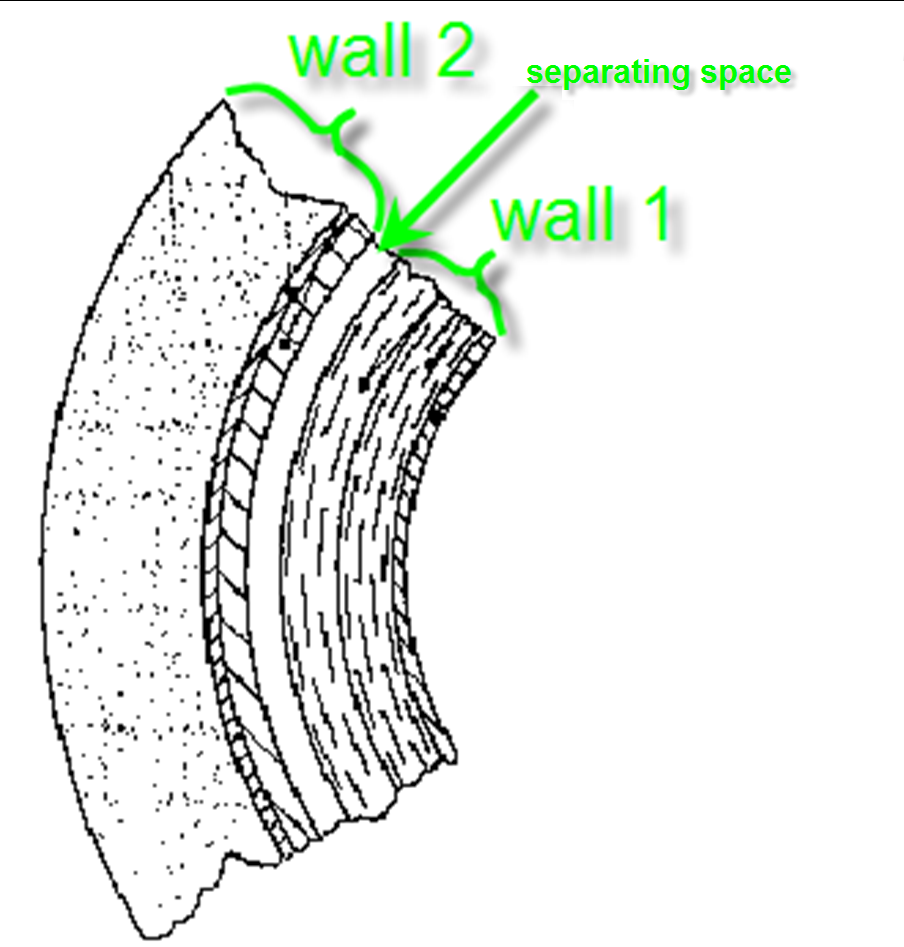

Pressure vessels for which technical features of the vessel wall and its structure can be determined.

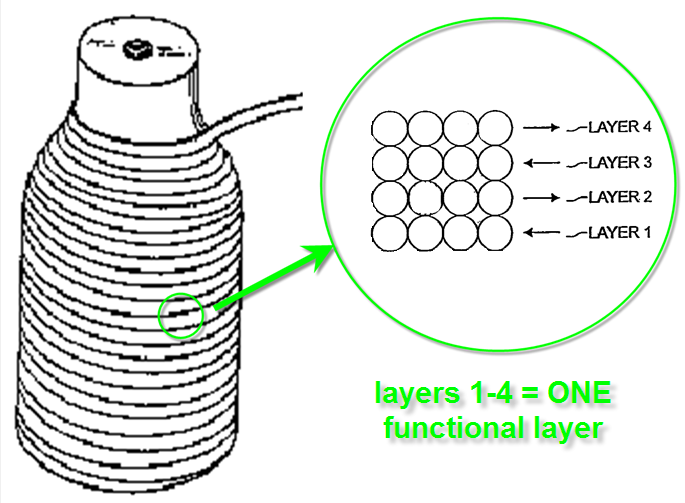

Overlapping filament wraps are considered as one layer, as long as they form a functional envelope. They are often manufactured in one single process step.

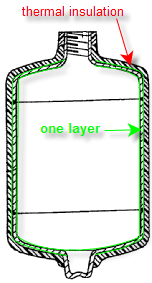

The following items are not counted as wall or layer (convention for counting walls and layers): a thermal insulation envelope, a bladder, a coating.

In this place, the following terms or expressions are used with the meaning indicated:

Wall | Envelope that forms the vessel and creates a structure capable of withholding the inner fluid pressure. A wall can be discerned from other functional envelopes around the vessel by answering the question: would the structural integrity of the pressure vessel be threatened if this wall was absent? |

Layer | Single functional sub-envelope, and must be clearly distinguishable from other layers, e.g. by its function or method of manufacturing. |

This place covers:

Pressure vessels for which means, additionally to the wall, are provided, to strengthen the wall.

This place covers:

Pressure vessels in which the means to strengthen the wall are integrated in the wall or placed on the wall, e.g. in form of ribs or bars.

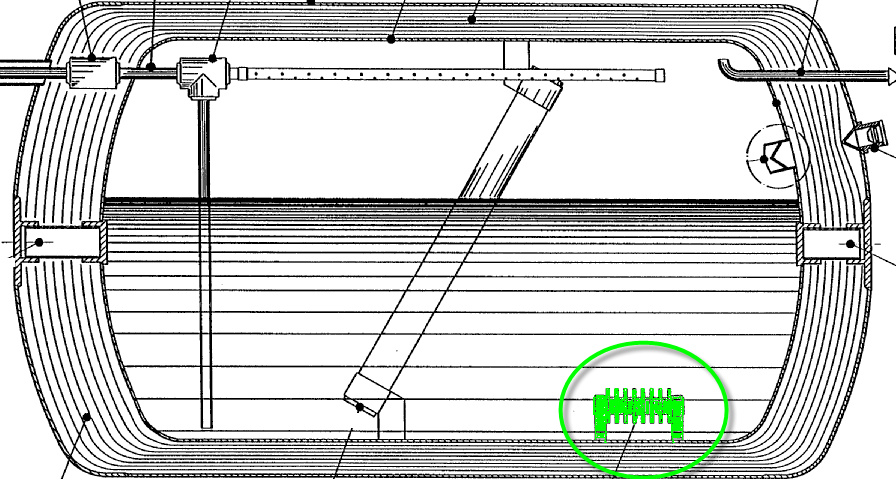

In this positive example from GB476713, circumferential reinforcing rings are mounted on the middle part.

In this positive example from FR2799526, a reinforcing bar is mounted in the inner separation wall, in particular in a column inside the vessel.

In this negative example from US5822838, the wall is made of wound filament. This filament is no additional means to reinforce the wall, but defines the wall itself.

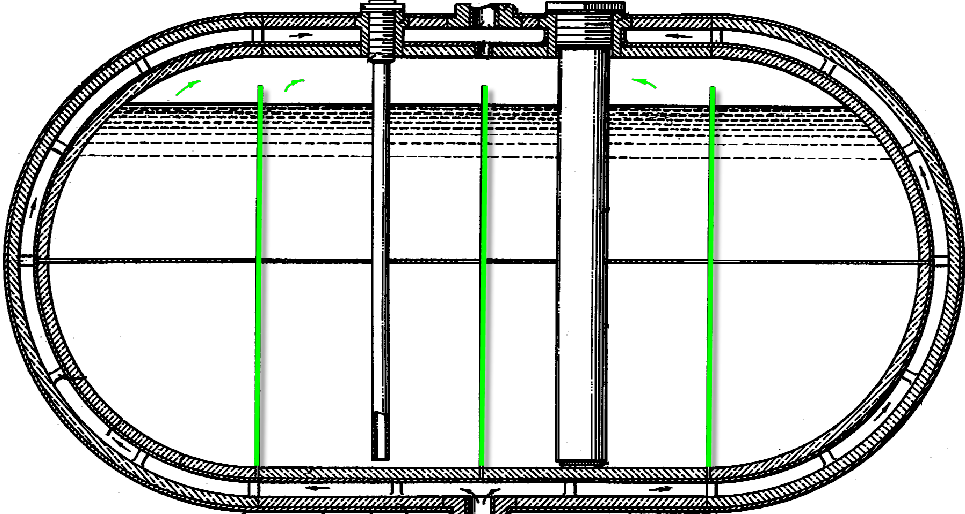

This place covers:

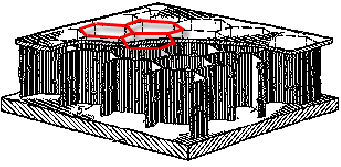

Pressure vessels in which the means to strengthen the wall are wall-to-wall bars, columns or rods in the interior of the pressure vessel.

In this positive example from EP0166492, wall-to-wall columns connect and support the two upper and lower flat walls.

In this negative example from DE4300484, the reinforcing means on the inner wall do not have a wall-to-wall column structure.

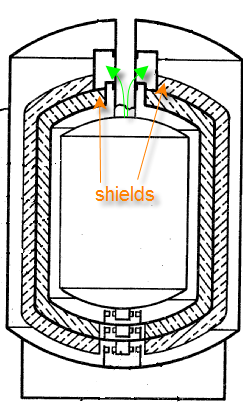

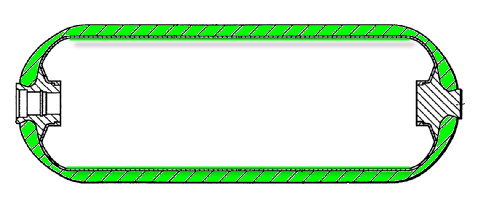

This place covers:

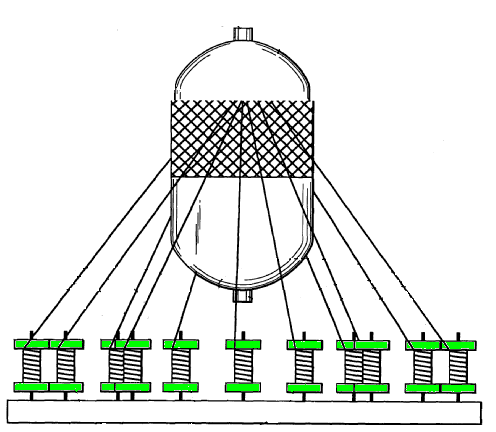

Pressure vessels with an inner and a separate outer vessel wall, the inner vessel wall being held in the outer vessel wall by suspensions means, which are mostly designed to minimize thermal transfer.

In this negative example from DE101347733, the whole vessel is mounted in a frame.

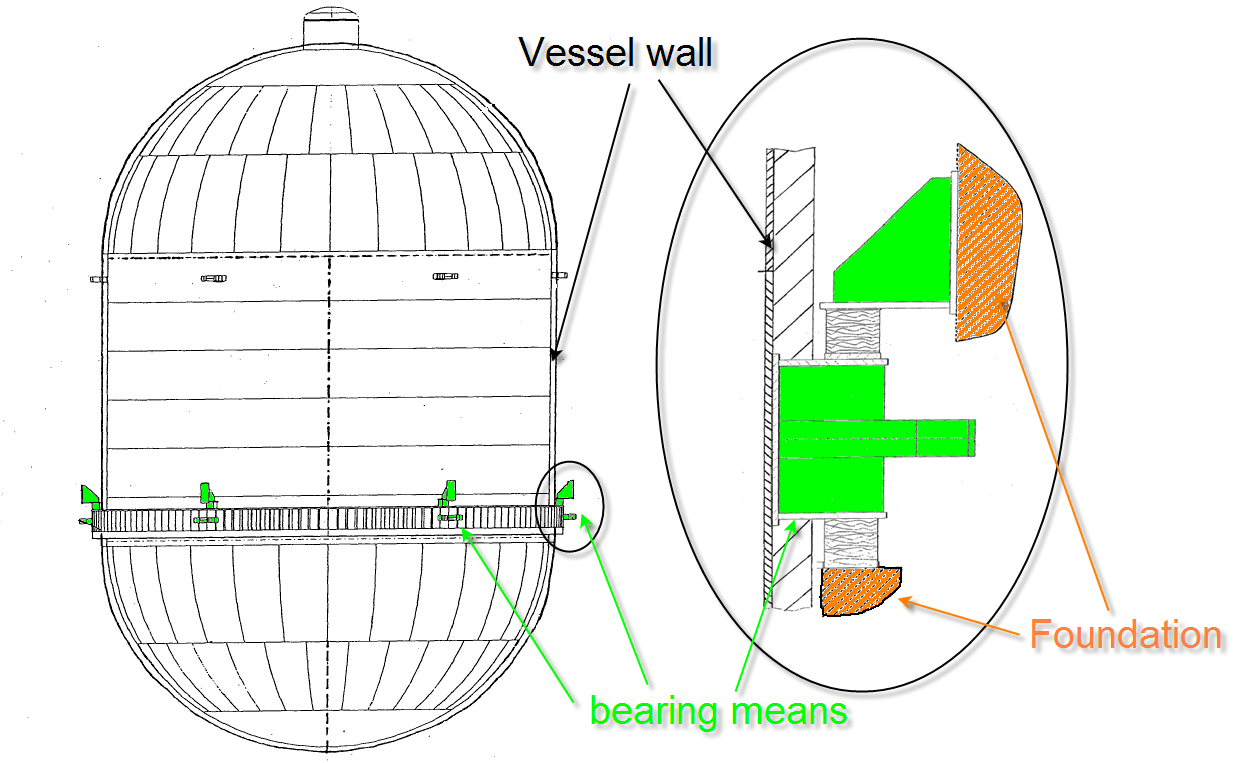

In this negative example from WO2010020431, circumferential bearing means (F17C 2205/0192) are no suspension means, as they hold the entire vessel upright from the outside.

.

.

Bearing means for the vessel itself are classified in F17C 2205/0192.

This place covers:

Pressure vessels in which the suspension means are in form of stiff bars, that can be submitted to traction or compression.

In this positive example from WO9859195, bars hold the inner tank.

In patent documents, the following words/expressions are often used as synonyms:

- "bar" and "rod"

This place covers:

Pressure vessels in which the suspension means are in form of cords, submitted to traction only.

In this positive example from DE603062, the inner vessel is held by a cord.

In this negative example from US6345933, cords attach the entire vessel to the ground (F17C 2205/0184).

This place covers:

Pressure vessels in which the suspension means are in form of magnetic means, avoiding contact between the vessel walls.

In this positive example from WO2006034521, the inner vessel is held in place by magnets.

This place covers:

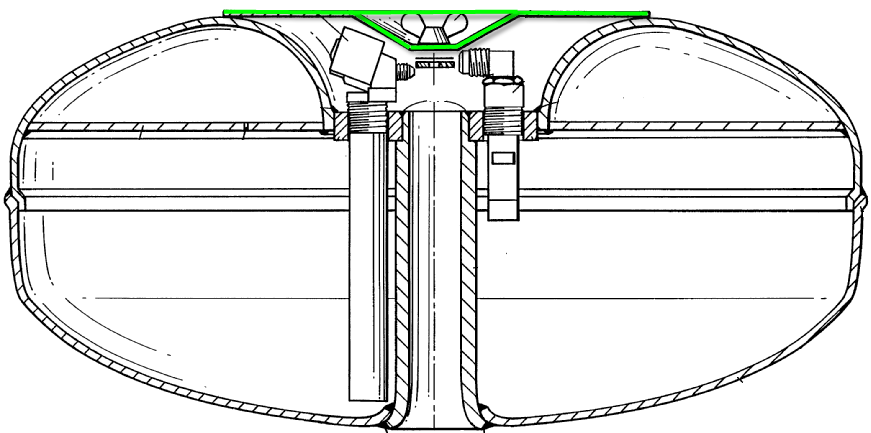

Pressure vessels in which the inner vessel is attached at its neck to the outer vessel.

In this positive example from US4218892, the inner vessel of the vertical pressure vessel is attached at the neck only.

In this negative example from EP1041337, a bladder is attached at the neck.

Bladders F17C 2201/018 are usually attached at the neck, but they are not to be classified here.

This place covers:

Pressure vessels in which insulating means are provided to avoid or reduce thermal transfer between the fluid in the pressure vessel and the environment.

Attention is drawn to the following places, which may be of interest for search:

Thermal insulation in general |

When counting the number of layers in the group F17C 2203/0612, the thermal insulation layer is not counted.

Any material surrounding a pressure vessel has some thermal insulating effect, but only those documents should be considered having a thermal insulation in which the function of thermal insulation is explicitly mentioned.

This place covers:

Pressure vessels in which the insulating means have a solid consistency.

This place covers:

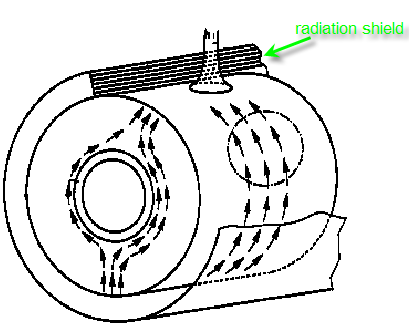

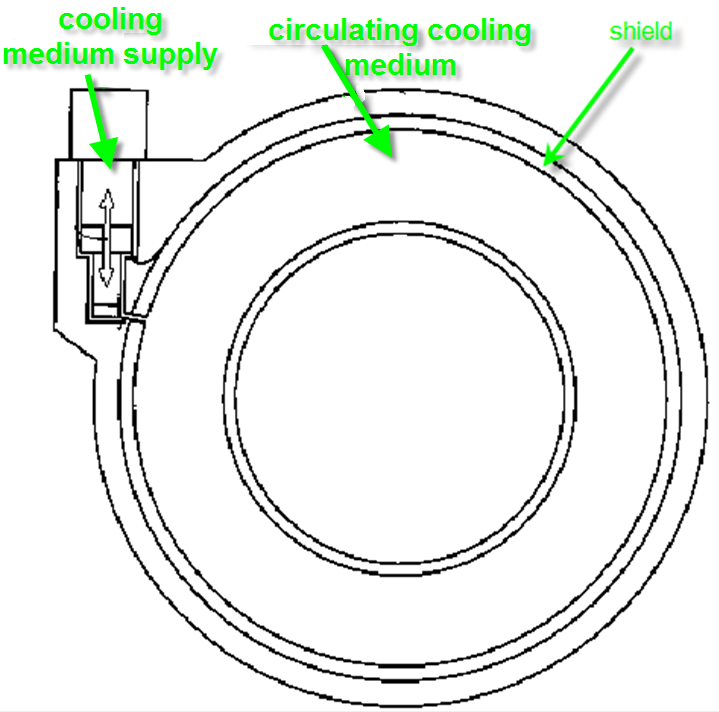

Pressure vessels in which the insulating means prevent radiation thermal transfer, like e.g. aluminum coating.

In this positive example from GB2454475, a radiation shield is wrapped around the vessel.

This place covers:

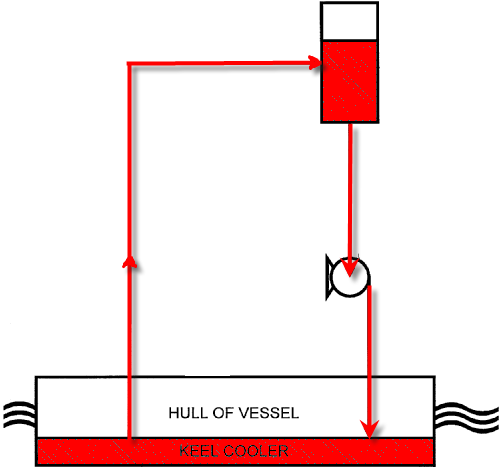

Pressure vessels in which the radiation shield is cooled and the heat is transferred by external means.

In this positive example from GB2414539, a cooling medium in form of a fluid is circulated and in contact with the shield.

This place covers:

Pressure vessels containing gas in a liquefied phase and in which the radiation shield is cooled by the gas in vaporized form. Usually, the gas has a cooling effect because of its discharge.

In this positive example from GB2025029, a constant flow of very cold vaporised helium serves as coolant for the shield.

This place covers:

Pressure vessels comprising a layer made of several thin reflective foils, sometimes in form of pads.

In this positive example from US6521077, multi-sheet blankets form insulation pads.

In this negative example from US3133659 a thicker ribbon is wrapped around the vessel in an overlapping helical scheme.

In this negative example from US3092148, a thicker sheet is wrapped several times around the vessel.

This place covers:

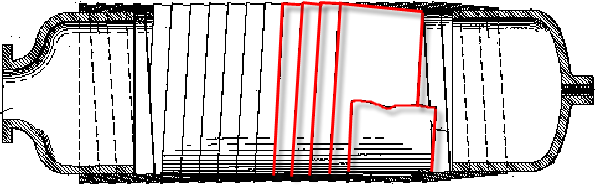

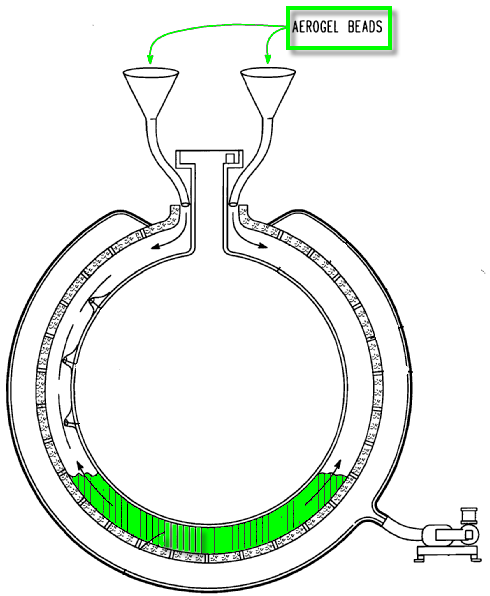

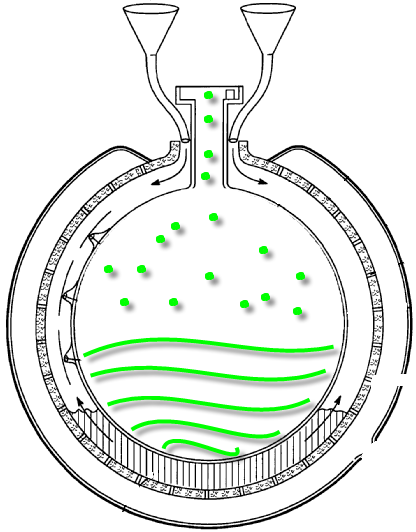

Pressure vessels in which the insulating means is made of aerogel, a material comprising about 99% pores.

In this positive example from US2010146992, granular aerogel surrounds the inner vessel.

This place covers:

Pressure vessels in which the insulating means is made of foam

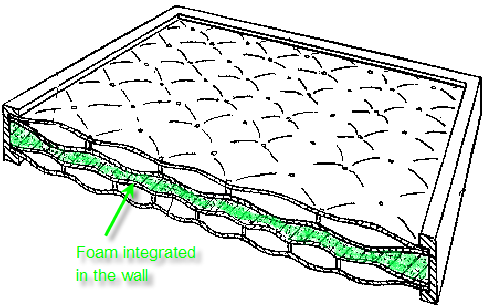

In this positive example from EP0166492, foam is integrated in the wall.

This place covers:

Pressure vessel in which the foam is made of polyurethane.

This place covers:

Pressure vessels in which the insulating means is in granular form.

In this positive example from AU439960, ceramic balls are integrated in the wall.

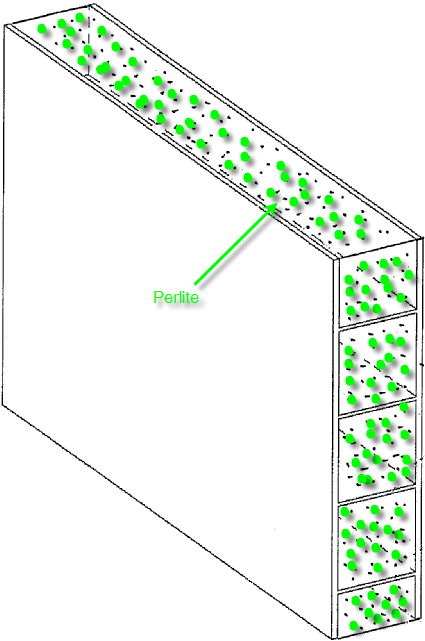

This place covers:

Pressure vessels in which the insulating means is perlite in granular form.

In this positive example from WO2006001711, perlite is integrated in the wall.

This place covers:

Pressure vessels in which the insulating means is in fiber form.

In this positive example from US2004256395, fibers fulfill the explicit task of thermal insulation.

In this negative example from DE3103646, insulation is not mentioned in relation with the fibers.

This place covers:

Pressure vessels in which the fibers are glass wool.

In this positive example from US4366917, two glass wool fiber layers are used.

In this positive example from US3583351, a single glass wool fibre layer is used.

This place covers:

Pressure vessels in which the insulating means is wood.

In this positive example from DE2349100, wooden heat insulation is used on a ship.

This place covers:

Pressure vessels in which the insulating means is in form of panels, usually placed next to each other.

In this positive example from EP0543686, insulation on a ship is in form of panels.

Attention is drawn to the following places, which may be of interest for search:

Panels into ships |

This place covers:

Pressure vessels in which the insulating means is in liquid form.

In this positive example from US2507778, a liquid serves as insulating means.

This place covers:

Pressure vessels in which the liquid insulating means is a cryogen.

In this positive example from WO2007026332, liquefied cryogenic gas at its boiling point is used for insulation

This place covers:

Pressure vessels in which the liquid insulating means is water.

In this positive example from US2009114290, water is the insulating means.

This place covers:

Pressure vessels in which the insulating means is gaseous.

In this positive example from WO2009147162, an insulating cavity is filled with gas.

This place covers:

Pressure vessels in which the gaseous insulating means is an inert, non-reactive gas.

In this positive example from US3319431, an insulating cavity is filled with a non-combustible gas.

This place covers:

Pressure vessels in which the gaseous insulating means is air.

In this positive example from GB832880, air surrounds the vessel.

This place covers:

Pressure vessels in which the gaseous insulating means is a cryogen.

This place covers:

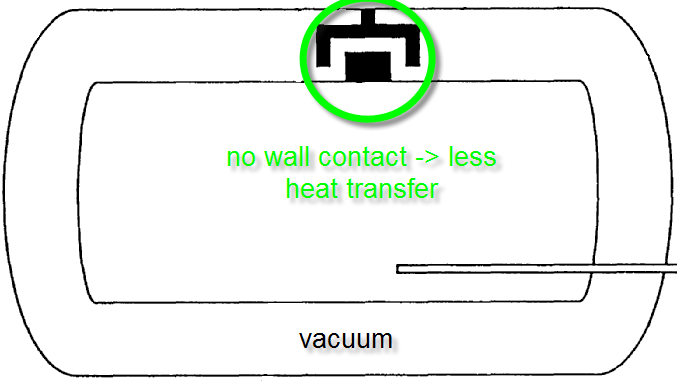

Pressure vessels in which the insulation is reached by evacuating an insulating cavity.

In this positive example from WO03018344, a vacuum cavity surrounds the vessel.

This place covers:

Pressure vessels in which the vacuum is maintained at a desired level by a getter, a reactive material used to remove traces of gas. The getter can be in form of a specific coating applied to the surface within the evacuated chamber.

In this positive example from WO9325843, the getter is placed in the intermediate evacuated space.

This place covers:

Pressure vessels for which the wall composition and layer structure and properties of these layers can be determined.

This place covers:

Pressure vessels comprising a liner, a solid layer located on the inner side of the vessel that prevents diffusion of the fluid and thus contact of the fluid with other layers and eventually corrosion. Liners are usually thin, and only moderately contribute to the mechanical resistance of the vessel.

In this positive example of EP0343098, a liner made of stainless steel is mounted in a pressure vessel for high-purity fluid. The term "liner" does not appear in the text.

In this negative example from EP2166260 coating for corrosion protection is sprayed on the vessel surface.

A liner is counted as a layer.

A layer fulfilling all the requirements of a liner (solid layer on the inner side to prevent diffusion) is to be classified herein too, even if the word "liner" does not explicitly appear.

If the word "liner" appears in the document, but the functionality of this "liner" differs from the requirements of a liner (solid layer on the inner side to prevent diffusion), the document is to be classified herein too.

If the word "liner" appears in the document without any further explanation, the document is to be classified herein too.

Simple coatings for corrosion protection are not to be considered as a liner.

This place covers:

Pressure vessels comprising a coating, a very thin painted or sprayed protection, usually against corrosion.

In this positive example from US2004089440, a coating is sprayed on the outside.

A coating is not is counted as a layer.

A layer fulfilling all the requirements of a coating (very thin, painted or sprayed) is to be classified here too, even if the word "coating" does not explicitly appear.

If the word "coating" appears in the document, like for cement coating, but the functionality of this "coating" differs from the requirements of a coating (very thin, painted or sprayed), the document is to be classified here too,

If the word "coating" appears in the document without any further explanation, the document is to be classified here too.

In patent documents, the following words/expressions are often used as synonyms:

- "paint and "fabric"

This place covers:

Pressure vessels comprising a layer made of usually adjacently wrapped bands, straps or ribbons.

In this positive example from NL6413265, ribbons are wrapped around a cylindrical vessel.

In this negative example from GB1518156, filaments, which have no ribbon form, are wrapped around a vessel.

Straps, bands or ribbons are counted as a layer.

This place covers:

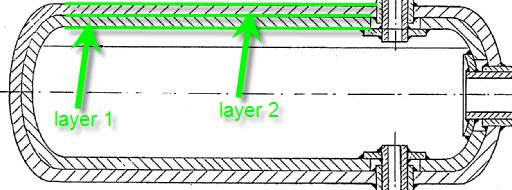

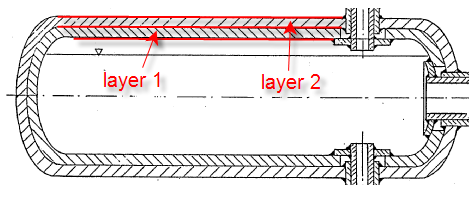

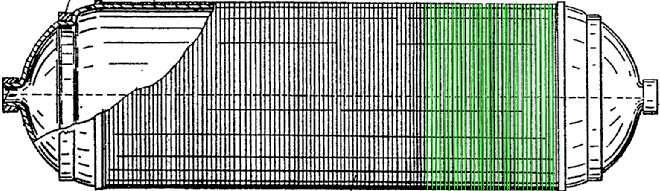

Pressure vessels for which the number of walls and/or layers can be counted.

In this positive example from WO02074616, the drawing indicates 4 layers (layers 1-4), but from the definition of "layer", these 4 filament wraps are counted as one single layer.

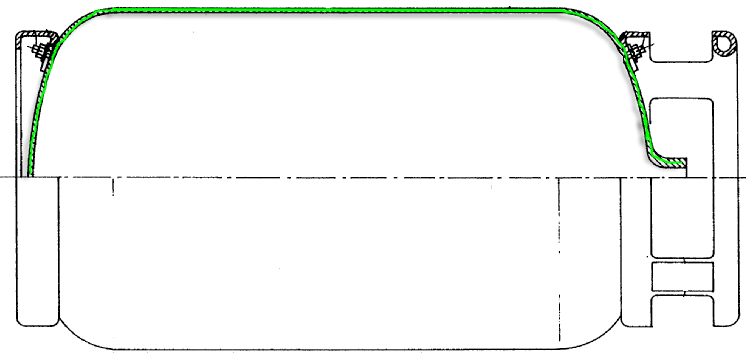

In this positive example from GB1150131, the vessel comprises an inner envelope, and an outer envelope for thermal insulation. The inner envelope counts for a single wall (with one layer). Thermal insulation is per convention not counted as wall or layer.

This place covers:

Pressure vessels comprising only one wall made of one or several layers.

In this negative example from GB2440350, thermal insulation cavities separate and thus create 3 walls.

This place covers:

Pressure vessels, for which the single wall comprises only one layer.

In this positive example from NL7906614, the metallic vessel has the simplest construction with one single layered wall.

This place covers:

Pressure vessels, for which the single wall comprises two layers.

In this positive example from DE3716426, two layers are visible.

This place covers:

Pressure vessels, for which the single wall comprises three layers.

In this positive example from US3140006, three layers are visible.

This place covers:

Pressure vessels, for which the single wall comprises four or more layers.

In this positive example from US3372828, the single wall is made of 9 layers.

This place covers:

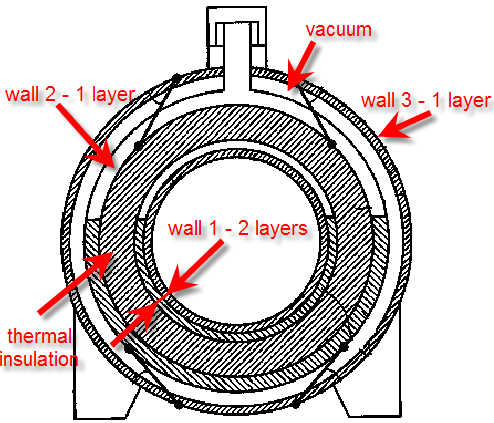

Pressure vessels comprising two or more walls. Usually, thermal insulating envelopes or cavities filled with a different fluid than the fluid stored, generate walls.

In this negative example from GB2249377, the stored fluid fills the cavities between of the pressure vessel: only one wall is counted.

For pressure vessels with two or more walls, no layers are counted.

This place covers:

Pressure vessels comprising two walls

In general the two structural walls are separated by thermal insulation.

In this positive example from WO0031459, two separated packages of layers defining two walls are separated by a space.

This negative example from DE3716426, one single wall with two layers is visible, without any separating space.

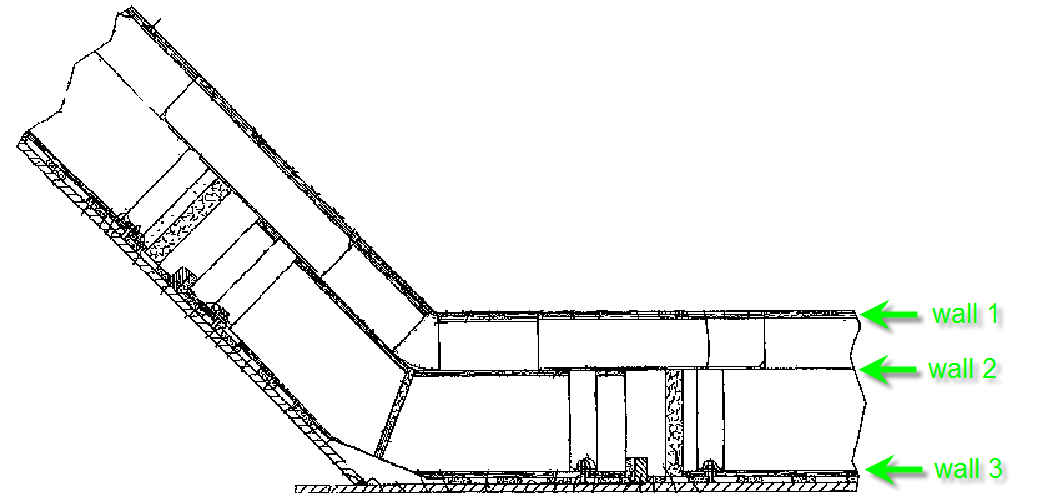

This place covers:

Pressure vessels comprising three or more walls.

In this positive example from US2002023926, three walls are counted.

This place covers:

Pressure vessels for which the wall's or layer's material is defined.

Material of exterior arrangement, insulation, assembling means, connecting components etc. are not considered.

This place covers:

Pressure vessels for which the wall's or layer's material comprises metal.

This place covers:

Pressure vessels for which the wall's or layer's metal comprises steel, that consists mostly of iron and has a carbon content between 0.2% and 2.1% by weight.

This place covers:

Pressure vessels for which the wall's or layer's material comprises non-magnetic steel.

This place covers:

Pressure vessels for which the wall's or layer's material comprises stainless steel.

This place covers:

Pressure vessels for which the wall's or layer's material comprises aluminium.

This place covers:

Pressure vessels for which the wall's or layer's material comprises an alloy, or for which a composition of the metal is disclosed.

Only alloys for which another groups are not foreseen are classified here.

Metals designated as "alloy" in the text, without revealing the exact composition, are classified here.

Alloys, for which the composition is revealed, are classified here, and in the group of the composing metal. Example: Al3Cr2Mg is classified as alloy and as aluminum.

The revelation of the composition of an alloy can be in any form: chemical formulae, by volume, by weight etc.

This place covers:

Pressure vessels for which the wall's or layer's material comprises FeNi36 or 64FeNi (US), known as Invar, a nickel steel alloy notable for its uniquely low coefficient of thermal expansion and resistance to cryogenic temperatures.

This place covers:

Pressure vessels for which the wall's or layer's material comprises lead (Pb).

This place covers:

Pressure vessels for which the wall's or layer's material is made of metal filaments.

In this positive example from GB48534, a metal filament winding forms a layer.

In this negative example from GB1518156, individual metal filaments do not form a layer.

This place covers:

Pressure vessels for which the wall's or layer's material is synthetic

This place covers:

Pressure vessels for which the wall's or layer's synthetic material comprises plastics.

This place covers:

Pressure vessels for which the wall's or layer's synthetic material is made of fibers or filaments.

In this positive example from EP0744274, a synthetic filament winding forms a layer.

In patent documents, the following words/expressions are often used as synonyms:

- "radial" and "circumferential"

This place covers:

Pressure vessels on which fibers or filaments are wound at right angle to the main axis of the vessel.

In this positive example from GB48534, filaments are radially wound around the middle part of the cylinder.

In patent documents, the following words/expressions are often used as synonyms:

- "radial" and "circumferential"

This place covers:

Pressure vessels on which fibers or filaments are wound in a way aligned with the main axis of the vessel.

In this positive example from US2009308874, filaments are axially wound around the middle part of the cylinder.

In this positive example from WO0157429, filaments are axially and radially wound.

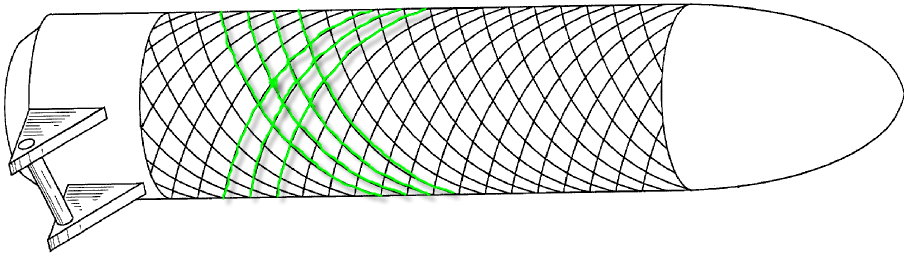

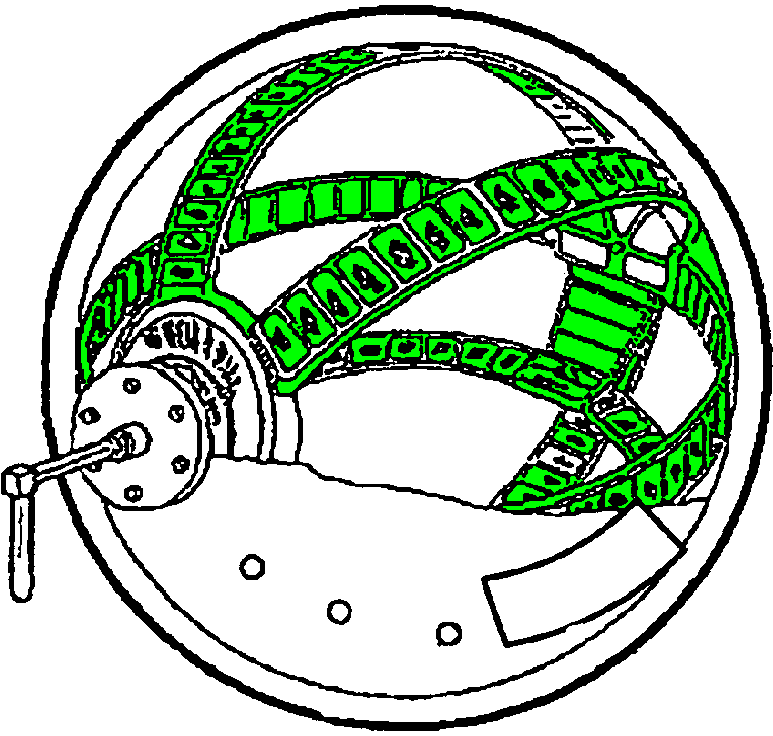

This place covers:

Pressure vessels on which fibers or filaments are helically wound.

In this positive example from GB2253041, filaments are helically wound.

This place covers:

Pressure vessels on which fibers or filaments are embedded in a polymer.

In this positive example from WO03016777, fiber are embedded in a resin matrix.

In this place, the following terms or expressions are used with the meaning indicated:

FRM | composite (fiber reinforced resin matrix) |

FRM | Fibre reinforced resin |

In patent documents the following words "FRM" and "composite" are often used as synonyms.

This place covers:

Pressure vessels for which the composition of the wall's or layer's synthetic material is disclosed.

The revelation of the composition can be in any form: chemical formulae, by volume, by weight etc.

This place covers:

Pressure vessels for which the wall's or layer's material comprises concrete or cementitious materials.

Attention is drawn to the following places, which may be of interest for search:

Foundations, excavations, embankments, underground or underwater |

This place covers:

Pressure vessels for which the wall's or layer's material is made of a fluid in liquid or gaseous form.

In this positive example from GB1343187, a pressurized liquid fills the free space.

In this negative example from EP0624752, a gaseous thermal insulation surrounds the vessel.

This is no load-bearing layer in the sense of the definition of "layer".

This place covers:

Pressure vessels for which the wall's or layer's material is flexible.

In this positive example from GB2435505, the whole vessel is flexible.

In this negative example from US4982870, the shape of the vessel is flexible, but not the material.

This place does not cover:

Bladders |

This place covers:

Pressure vessels for which the wall's or layer's material is superconducting.

This place covers:

Pressure vessels for which the wall's or layer's material comprises a break point, i.e. an intentionally weakened section supposed to break first at overpressure or when punctured.

In this positive example from GB2080436, a weakened tab member is located at the bottom section.

In this positive example from WO2004113787, a weakened part is located at the top section.

This place covers:

Pressure vessels for which the wall's or layer's material is transparent.

In this positive example from US4589562, a transparent layer allows to consult the label underneath.

This place covers:

Pressure vessels for which the wall's or layer's material is pre-constrained.

In this positive example from WO9935036, the inner layer is pre-constrained.

This place covers:

Pressure vessels for which the wall's or layer's material comprises nanoparticles, usually sized between 1 and 100 nanometers.

Attention is drawn to the following places, which may be of interest for search:

Nanotechnology |

This place covers:

Means related to the stand or mounting of pressure vessels, to devices attached to it or in fluid connection with it, and to identification means.

This place covers:

Mounting arrangements allow the mounting of the pressure vessel but are not necessary for the structural integrity of the vessel, i.e. to avoid its bursting.

This place covers:

Mounting arrangements external to the pressure vessels.

This place covers:

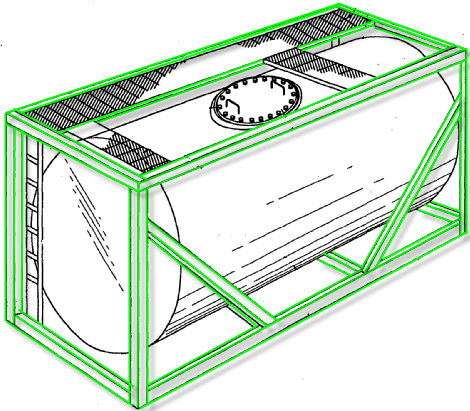

Exterior arrangement in form of an external frame, usually for protection or transport.

In this positive example from EP1522786, a frame surrounds the vessel.

This place covers:

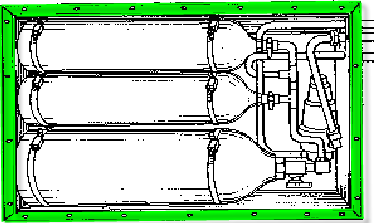

Exterior arrangement in form of an box in which the pressure vessel is contained, usually for protection or transport.

In this positive example from US4523548, 3 pressure vessels are mounted inside a common box.

Attention is drawn to the following places, which may be of interest for search:

Enclosures; Chambers |

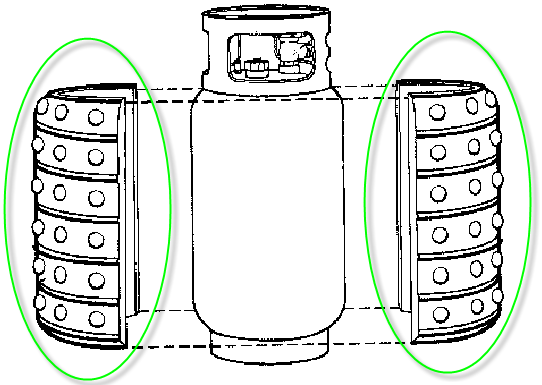

This place covers:

Exterior arrangement in form of a dismountable hull to protect the vessel e.g. made out of neoprene, to protect from impacts.

In this positive example from US2001037549, two sections of composite fiber protect the vessel from bumps.

In this positive example from DE102007006047, the hull is welded and thus not dismountable.

This place covers:

Exterior arrangement which is also part of the vessel, the vessel wall itself fulfilling a double function: containing the fluid and constituting the external structure in which the vessel is mounted, e.g. a wing of a plane being at the same time the liquefied fuel tank.

In this positive example from EP1431096, the car frame is a vessel wall.

In this positive example from US3640237, the ship hull is a vessel wall.

This place covers:

Count of the number of pressure vessels and their external arrangements

This place covers:

Count of one single pressure vessel and its external arrangement.

In this positive example from EP1150059, a single spherical vessel is held in a frame.

In this negative example from BE471532, there is no exterior arrangement.

This place covers:

Count of two or more pressure vessels and their external arrangements.

In this positive example from US4523548, 3 pressure vessels are mounted inside a common box.

This place covers:

Count of two or more pressure vessels comprising at least one fluid connection.

In this positive example from US2005205137, several cylindrical pressure vessels are connected by several fluid connections.

In this negative example from EP1150059, no fluid connection is established.

In this negative example from DE4009248, the aligned cartridges are not in fluid connection.

This place covers:

Two or more pressure vessels in which the fluid connection is a serial fluid connection.

In this positive example from FR1222726, fluid from the right vessel needs to pass into the first vessel.

In most cases, there is no clear serial connection, so that generally, only the word "series" in the text can trigger classification in this group.

In this place, the following terms or expressions are used with the meaning indicated:

In series | Per analogy to an electrical connection in series, vessels are in fluid connection in a row, so that when fluid is removed, it has to pass through the vessel next in the row. |

This place covers:

Two or more pressure vessels in which the fluid connection is a fluid connection in parallel.

In this positive example from DE3024251, fluid can be filled into or emptied from each vessel independently.

In most cases, there is no clear parallel connection, so that mainly the word "parallel" in the text triggers classification in this group.

In this place, the following terms or expressions are used with the meaning indicated:

In parallel | Per analogy to an electrical connection in parallel, fluid connection in which vessels have an individual fluid connection, so that when fluid is removed, it has not to pass through another vessel. |

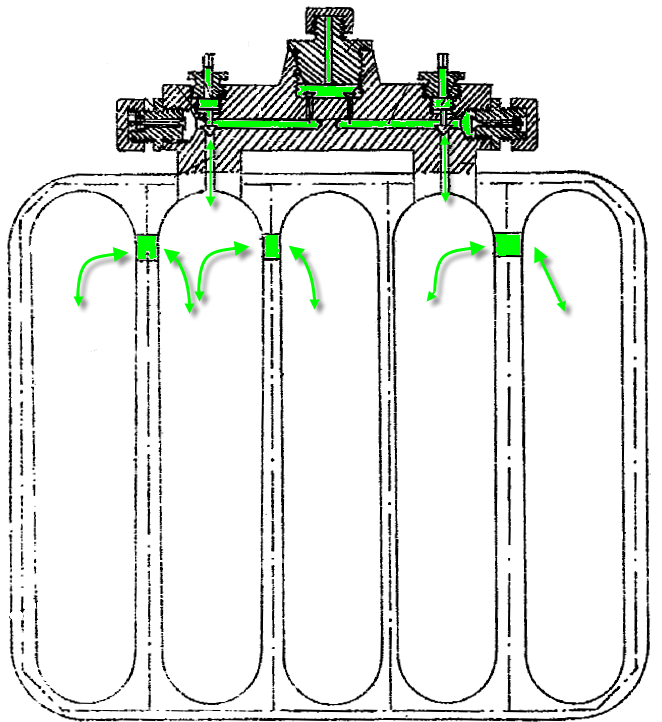

This place covers:

Fluid connection between several vessels with a manifold, wherein details of the manifold (e.g. single valves, detailed connections, way of distributing fluid) are visible or explained.

In this positive example from US2007215209, the inner structure of the manifold is defined.

In this place, the following terms or expressions are used with the meaning indicated:

Manifold | Fluid connection which is common to several vessels. |

This place covers:

Arrangement of two distinct pressure vessels, in which one vessel is mounted inside the other and in which each vessel could have be operated as an independent vessel in terms of withholding the internal pressure. Each vessel contains fluid to be stored, and not a fluid for another purpose like insulation. The fluid contained in the different vessels can be different.

In this positive example from US1692670, two clearly distinguishable cylindrical vessels are mounted one inside the other.

In this negative example from GB2249377, the same fluid occupies a single vessel separated in several chambers. There are no independent vessels.

In this negative example from GB412814, the common wall of both chambers is dominant.

Each independent vessel has to be considered separately with regard to its wall structure (number of layers, material etc...).

Vessels that share a common wall have to be considered individually: if the common wall is dominant, than a classification herein is not necessary; if the common wall is not extended, an independent vessel can be defined and classified herein.

This place covers:

A device that indicate a specific way of transporting the vessel.

In this positive example from FR1281179, cavities for forks or for a forklift are foreseen.

In this positive example EP1643182, it is explained that the form is ergonomic so as to easily lift the vessel by hand.

In this negative example from EP0034555, a small cartridge is, by its size, easy to lift by human force and easy to transport, but there is not specific device that suggests a certain mode of transport.

This place covers:

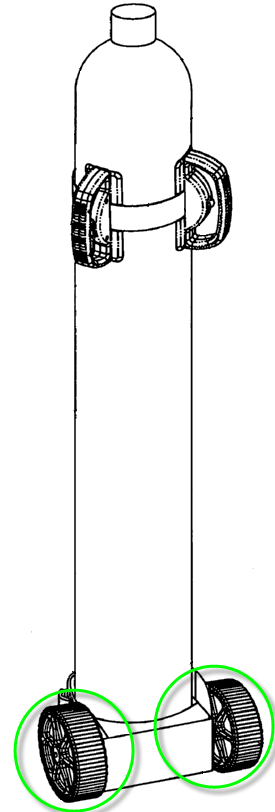

The device for transport comprising wheels

In this positive example from US2006261567, wheels can be attached to the vessel.

Attention is drawn to the following places, which may be of interest for search:

Hand carts having only one axis carrying one or more transport wheels | |

Hand carts having more than one axis carrying transport wheels | |

Gas bottles for domestic use |

Specific vehicles with wheels like e.g. trailers and trucks transporting pressure vessels are classified in groups in F17C 2270/0165.

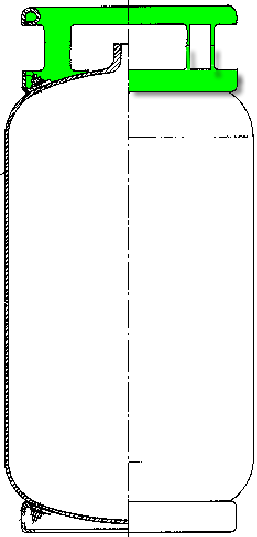

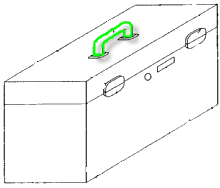

This place covers:

The device for transport comprising a handgrip.

In this positive example from NL7906614, the handgrip is on the vessel.

In this positive example from WO0111285, the handgrip is mounted on a transporting box.

This place covers:

A device allowing to stack vessels or groups of vessel upon each other.

In this positive example from US2010186426, a specific frame allows to stack groups of vessel.

In this positive example from DE20010514U, a stacking device is mounted on the protection cap and fits with the mounting feet at the bottom of the vessel.

In this negative example from US4846088, the pressure vessels are piled on a ship, but without any detailed indication about a stacking device.

In patent documents, the following words/expressions are often used as synonyms:

- "nestable and "stackable"

This place covers:

A device, e.g. a lock, preventing access to or removal of one or several vessels.

In this positive example from GB2171785, a safety lock holds a protective cap on the vessel.

In this positive example from US2007109068, access to the vessel is prevented by a lock on a box.

Attention is drawn to the following places, which may be of interest for search:

Signalling or calling systems, Alarm systems |

This place covers:

A device, e.g. a ventilator or ventilation openings, that support ventilation of the room or box in which the pressure vessel is stored.

In this positive example from EP1037269, two ventilators are mounted in the box wall.

In this negative example from WO2007048953 a vent valve is mounted on the vessel, but not on a room or box in which the pressure vessel is stored.

This place covers:

A device directly on the pressure vessel allowing an upright or lying fixed stable position.

In this positive example from GB412814, mounting feet are placed below a spherical vessel.

In this positive example from EP0826433, the bottom of the pressure vessel is formed so as to allow a stable upright position.

In this negative example from DE19952611, the flat bottom of the pressure vessel would allow an upright position, but there is no form that suggests mounting feet.

This place covers:

A device allowing not only positioning of the pressure vessel to the ground but an attaching, mooring or anchoring.

In this positive example from DE2447246, the vessel is attached to the sea ground.

In this positive example from US6345933, the vessel is attached to the ground by ropes

In this negative example from DE2633607, the supporting elements are not anchored to the ground.

This place covers:

A device allowing hanging up and lifting of the vessel.

In this positive example from DE20204336U, the vessel is hung up with crooks.

In this negative example from GB2440350, the inner vessel is hung in the outer vessel by suspension means.

Hanging up one vessel inside another is dealt with in F17C 2203/014, "suspension means".

This place covers:

A device allowing to maintain the vessel in an external structure.

In this positive example from EP1060936, the vessel can be attached into a vehicle by screws.

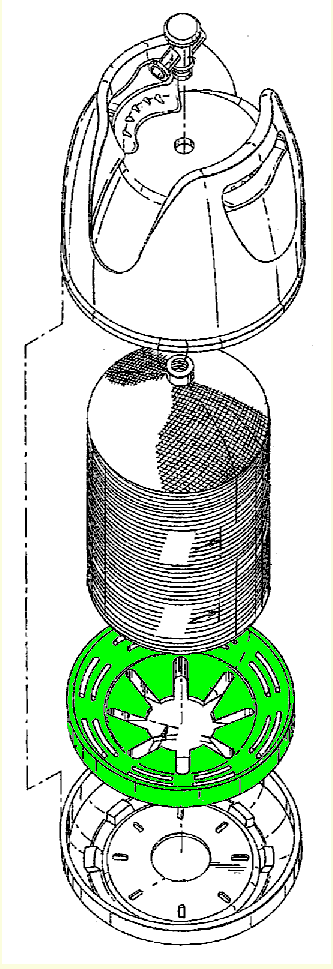

In this positive example from WO2010020431, circumferential bearing means hold the vessel upright.

This place covers:

A device comprising means absorbing shocks.

In this positive example from US2011147390, a shock absorbing padding is placed at the bottom of the tank.

This place covers:

Devices through which the fluid contained in the vessel flows or may flow.

Attention is drawn to the following places, which may be of interest for search:

Filling nozzles |

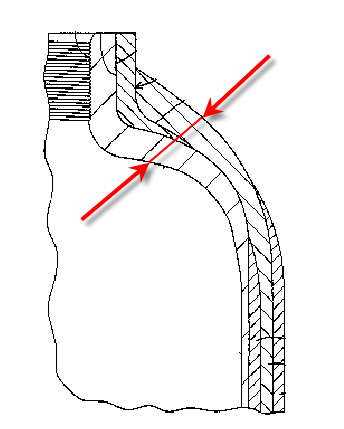

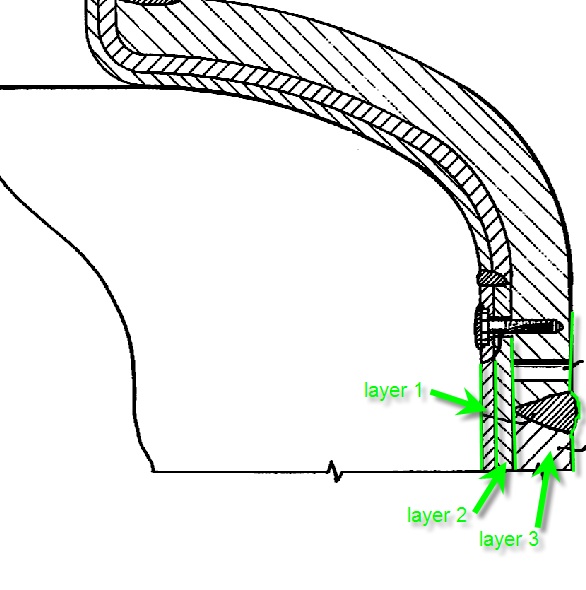

This place covers:

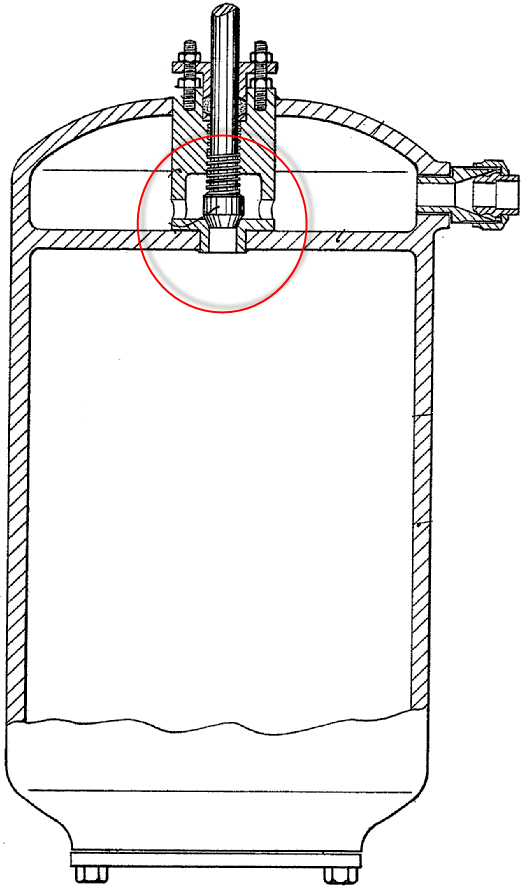

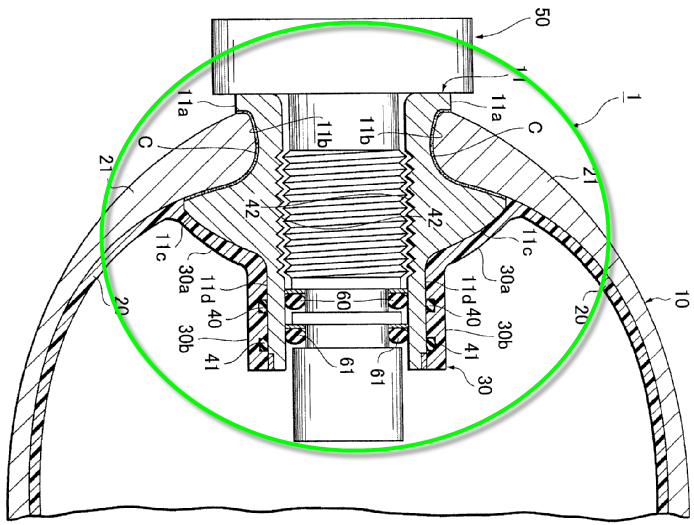

Bosses and boss collars for which details related to the mounting, the sealing or the attachment to the vessel are available.

In this positive example from US2010072209, boss and boss collar are detailed.

In this place, the following terms or expressions are used with the meaning indicated:

Boss | The zone around a circulate opening of the pressure vessel. |

Boss collar | Particular zone of the boss, at which the boss is in contact with the vessel body |

This place covers:

Device for protecting the boss of a pressure vessel, and the valves mounted thereon, from impact. This device can be a prolonged part of the vessel wall.

In this positive example from BE1006503, the protection is flat.

In this positive example from FR1120882, the protection surrounds the valve.

Attention is drawn to the following places, which may be of interest for search:

Pressure vessels | |

Covers or similar closure members for pressure vessels in general | |

Covers with safety devices, e.g. to prevent opening prior to pressure release | |

Sealings | |

Covers for housings |

This place covers:

Device for permanently closing the vessel openings, allowing only exceptionally an opening

In this positive example from FR1435928, a closure device is mounted on the vessel.

In this positive example from GB291061, a closure device is screwed on the vessel.

This place does not cover:

Valves | |

Pressure regulators |

This place covers:

Closure means with a weakened zone bursting when a limit pressure is reached.

In this positive example from US4219126, the closure mean ruptures at a thinner weak zone

This place does not cover:

Weakened zones in the vessel wall itself |

In patent documents, the following words/expressions are often used as synonyms:

- "rupture" and "burst"

This place covers:

Closure means with a heat sensitive zone fusing or melting when a limit temperature is reached.

In this positive example from US2004159352, a melting device is placed in a manifold.

This place covers:

Closure means with a weakened zone to be easily pierced or punctured.

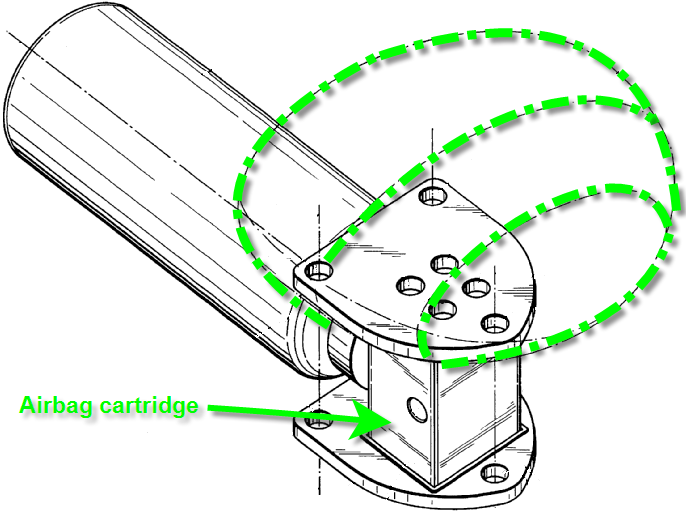

In this positive example from EP0155407, the cartridge discloses a zone to be punctured by a needle.

In patent documents, the following words/expressions are often used as synonyms:

- "pierce" and "puncture"

This place covers:

Valves through which the fluid contained in the vessel flows or may flow.

Attention is drawn to the following places, which may be of interest for search:

Valves for pressure vessels |

Valves related to other processes, like the cooling process, are not classified.

This place covers:

Valves with electrical actuation, usually a solenoid.

In this positive example from EP1990568, a solenoid valve is disclosed.

This place covers:

Valves with a manual actuation.

In this positive example from BE716158, the manual actuation is materialized by a handle on top.

This place covers:

Valves the opening of which is triggered by dangerous state of the fluid, usually overpressure.

In this positive example from EP1318347, gas is evacuated at overfilling.

Attention is drawn to the following places, which may be of interest for search:

Safety valves |

PRV | pressure relief valves |

SV | Safety valves |

In patent documents the following words "PRV", "SV" and "venting valve" are often used as synonyms.

This place covers:

Valves that prevents fluid flow in a certain direction.

In this positive example from US2004123735, the fluid can only flow out through the branch with the check-valve.

Attention is drawn to the following places, which may be of interest for search:

Check valves |

NRV | Non-return valves |

In patent documents the following words "NRV" and "back pressure valve" are often used as synonyms.

This place covers:

Regulators for pressure with a set point and means to stay at it.

In this positive example from WO0201306, a pressure regulator is mounted inside the vessel.

Attention is drawn to the following places, which may be of interest for search:

Systems for controlling and regulating non-electrical variables |

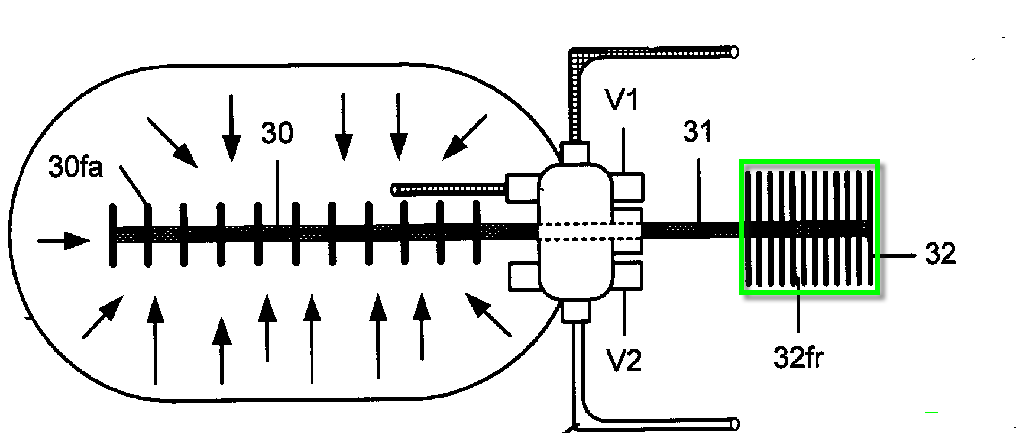

This place covers:

Filters for purifying the stored fluid.

In this positive example from US4111661, a filter is mounted inside the vessel.

This place covers:

Filters of the sintered type, like sintered bronze, often used in applications requiring high temperatures resistance.

This place covers:

Filters of the active carbon type with extremely porous activated carbon for absorption or chemical reaction to enable high quality filtering.

This place covers:

Devices to reduce flow of the fluid, like restrictors or throttles.

In this positive example from US2005028536, flow is reduced.

In this positive example from EP1445622, a capillary stem restricts the flow of hyperpolarized gas.

This place covers:

Pipes for which details are available.

In this positive example from US2006254676, details of the pipes are visible, in particular the bending and the parts located in the vessel and at the pressure vessel inlet.

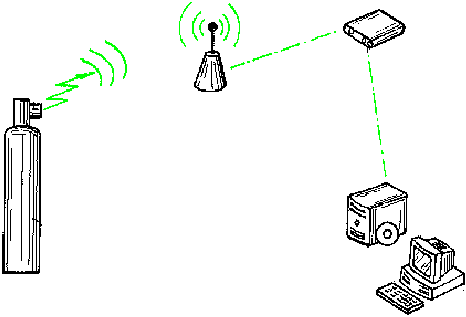

In this negative example from EP0908665, no details about the pipe are visible. In purely functional drawings, pipes are often represented symbolically as a line between two points, without any details.

Attention is drawn to the following places, which may be of interest for search:

Loading unloading fluids for ships | |

Pipes, joints or fitting for pipes |

This place covers:

Pipes with a thermal insulation.

In this positive example from US2235424, the pipe is insulated.

In this negative example from US2005211711, the pipes run through the vessel and insulate the fluid inside the vessel.

The convenient subclass is "Thermal insulation by liquid means (F17C 2203/037)".

This place covers:

Pipes mounted inside another one

In this positive example from US3355893, several coaxial pipes reach into an underground vessel.

This place covers:

Pipes with a ripped outer or inner surface.

In this positive example from US2007186925, a ripped pipe is directly mounted on the vessel.

This place covers:

Pipes which, in use, can take several locations due to the flexibility of the material or due to articulations.

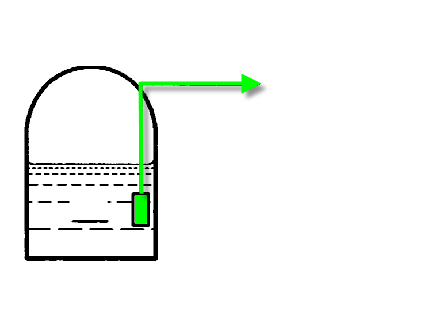

In this positive example from DE19910894, the pipe follows the fluid level in the vessel.

In this positive example from WO2005032942, the pipe adapts to the movement between ship and mooring buoy.

Attention is drawn to the following places, which may be of interest for search:

Hose |

This place covers:

Pipes functioning in parallel, one being an inflow (usually liquefied gas), the other a backflow line (usually gas).

In this positive example from EP0889274, a liquefied fluid pipe and a gas pipe run in parallel and are located in parallel.

In this positive example from WO2006008299, a liquid hose and a vapor hose run in parallel.

In this positive example from EP2236904, a LNG pipe and a gas pipe run in parallel.

This place covers:

Means to quickly connect two devices so as to transfer fluid.

In this positive example from DE29711842U, a coupling allows to branch to a pipe.

In this negative example from EP1099664, the coupling has the form of dispensing pistols.

Attention is drawn to the following places, which may be of interest for search:

Couplings of the quick-acting type |

Quick connecting means in form of a dispensing coupling are classified with "Dispensing pistols" in F17C 2205/0376

This place covers:

Adapter to be located between means to connect two coupling devices, these means being for example a quick coupling means or a dispensing pistol.

In this positive example from EP1099664, an adapter is mounted on a dispensing pistol.

This place covers:

Means to quickly connect two devices so as to transfer fluid, the means having the form of a pistol, with the typical pistol bend.

In this positive example from EP1669663, the dispensing pistol is for liquefied gas.

Quick connecting means in form of a dispensing coupling which have not the typical pistol bend are classified with "quick connecting means" in F17C 2205/037

This place covers:

Pressure vessels comprising an access to the inner space for maintenance or inspection, no matter whether the access is dimensioned for a whole person or for a hand.

In this positive example from EP1522786, a manhole is situated on top of the vessel.

In this negative example from DE69723389T2, a manhole provides access to the protective concrete surrounding, not the vessel itself.

All vessels have an access to the inside. Those accesses that justify a classification herein should explicitly be designed for that purpose, e.g. maintenance or inspection should be mentioned in the text, or a ladder should be placed next to the access.

This place covers:

Valves or regulators for which details of the internal mechanisms are visible, which are thus not represented as functional drawings, but rather as workshop drawings or cut views.

In this positive example from FR847127, the valve seat, the spring, and a solenoid are visible.

In this negative example from US2003010395, valves are only represented as symbol.

This place covers:

Compact unit comprising several valves or regulators mounted en bloc.

In this positive example from FR2798450, one single body holds 5 types or valves.

In this negative example from EP1726869, a sequence of valves seems mounted close to the vessel, but there is no single unit.

Attention is drawn to the following places, which may be of interest for search:

Construction of housing formed from a plurality of the same valve elements |

This place covers:

Localisation of valves, regulators or filters in the gas storage or handling process.

This place covers:

Localisation of valves, regulators or filters at least partially inside the pressure vessel.

In this positive example from US5197710, the insertion of the valve is partial.

In this positive example from WO0181822, the pressure regulator is mounted entirely inside the vessel

This place covers:

Localisation of valves, regulators or filters on or in direct contact with the pressure vessel.

In this positive example from BE471532, the valve is mounted on the vessel.

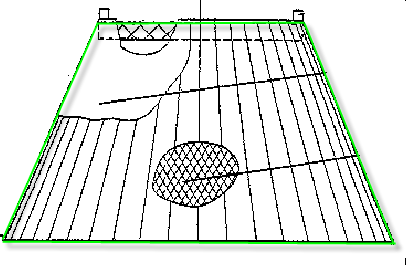

In this negative example from DE10058496, the valves marked in red are placed on the pipe, only one valve directly mounted on the pressure vessel could be classified here.

This place covers:

Localisation of valves, regulators on two opposed or distant sides of the pressure vessel.

In this positive example from EP0753700, two openings are situated at opposite locations on the vessel.

In this positive example from DE19937470, openings are situated at opposite locations on the vessel and on the middle part

In this negative example from FR2067600, the main opening is flanked by two secondary openings.

The presence of appropriate openings, within the explicit presence of valves or regulators, is sufficient to allow a classification here.

An opening which is not on an opposed or at least distant localisation on the vessel is not classified herein.

This place covers:

Devices carrying information about the content of the vessel or the vessel itself.

In this positive example from FR2849606, a maintenance report is attached to vessel.

Attention is drawn to the following places, which may be of interest for search:

Labeling or tagging machines, apparatus, or processes | |

Logistics for storage, shipping, distribution, loading | |

Inventory or stock management |

This place covers:

Devices using coating to carry the information.

In this positive example from US2007164040, the gas type is marked on the vessel.

Coating which has not role in carrying information like e.g. coating that serves for protection against mechanical impact, is not classified here, but only under F17C 2203/0607

This place covers:

Devices using a sticker to carry the information.

In this positive example from WO8504380, a label is placed between two layers.

This place covers:

Devices using bar codes to carry the information.

In this positive example from EP0515184, a bar code is attached to the valve.

This place covers:

Devices using magnetic means to carry the information.

In this positive example from WO2007042879, an electromagnetic tag is attached at the neck of the vessel.

This place covers:

Devices using electronic chips to carry the information.

In this positive example from FR2868186, information carried on chips can be transmitted.

This place covers:

Devices using RFID to carry the information.

In this positive example from EP1988327, RFID allows transmitting information over longer distances.

This place covers:

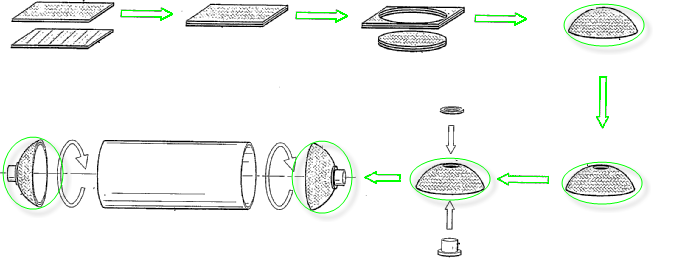

Manufacturing steps or manufacturing method for pressure vessels.

In this positive example from WO03031860, several manufacturing steps of a cylindrical vessel are illustrated.

In this negative example from GB2096299, round corners appear, but are not sufficient to deduct any manufacturing method like moulding.

Attention is drawn to the following places, which may be of interest for search:

Processing sheet of metal or metal tubes or rods without removing material | |

Processing metal and making hollow objects | |

Turning, boring | |

Polishing | |

Shaping or joining of plastics | |

Presses | |

Non mechanical removal of metallic material from surface, inhibiting corrosion of metallic material |

Ideally, manufacturing steps or methods are explicitly disclosed. Alternatively the vessel must be described in a way indicating how it has been manufactured e.g. "blow-moulded vessel".

This place covers:

Manufacturing steps or manufacturing method for pressure vessels during which material is put into a certain shape.

This place covers:

Manufacturing steps or manufacturing method for pressure vessels comprising moulding, e.g. applied to plastics or metal.

This place covers:

Manufacturing steps or manufacturing method for pressure vessels comprising injection moulding, during which heated material is forced into a mould cavity where it cools and hardens.

This place covers:

Pressure vessel for which blow moulding is disclosed as manufacturing step, usually to form hollow elements, consisting in forcing heated material into a mould cavity where it cools to form hollow parts.

Attention is drawn to the following places, which may be of interest for search:

Blow moulding of plastics |

In patent documents, the following words/expressions are often used as synonyms:

- "Extrusion blow moulding", "injection blow moulding", and "stretch blow moulding"

This place covers:

Manufacturing steps or manufacturing method for pressure vessels using wax moulds, which are lost after the process.

In patent documents, the following words/expressions are often used as synonyms:

- In the patent documents the following words "die cast" and "wax moulding" are often as used as synonyms.

This place covers:

Manufacturing steps or manufacturing method for pressure vessels comprising rotation moulding, causing the material to disperse and stick to the mould walls.

In patent documents, the following words/expressions are often used as synonyms:

- "roto casting" and "spin casting"

This place covers:

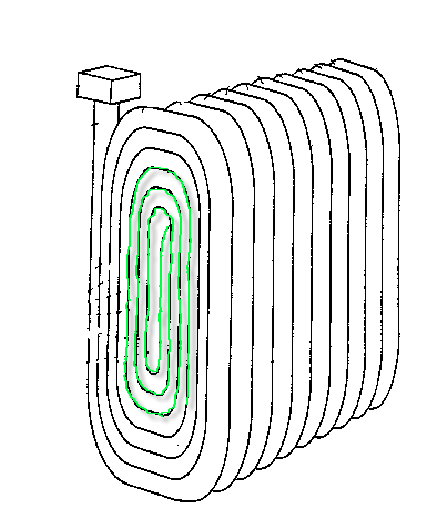

Manufacturing steps or manufacturing method for pressure vessels comprising winding

In this positive example from US5202165, details of the winding step are visible.

In this negative example from US2011210131, a wound pressure vessel is disclosed without details of the manufacturing process.

Attention is drawn to the following places, which may be of interest for search:

Winding | |

Shaping composites |

The term "wound" or "winding" is per se not sufficient to materialize a manufacturing step. A wound pressure vessel is classified under

F17C 2203/0663. Manufacturing steps or a manufacturing method details how the pressure vessel is wound is required to classify herein.

This place covers:

Manufacturing steps or manufacturing method for pressure vessels comprising winding with a mandrel, which is removed after the process.

In this positive example from US6189723, the removable mandrel is visible.

In this negative example from FR2575966, the winding takes place around a liner, which is not removed afterwards.

This place covers:

Manufacturing steps or manufacturing method for pressure vessels comprising a form of polishing, e.g. by sand blasting.

This place covers:

Manufacturing steps or manufacturing method for pressure vessels comprising a metal working process, like deep drawing, stamping or cutting.

In this positive example from US4023696, a punch forms metal into a vessel.

Attention is drawn to the following places, which may be of interest for search:

Making hollow objects for high pressure containers |

This place covers:

Manufacturing steps or manufacturing method for pressure vessels comprising a non-metal working process, like extruding.

In this positive example from WO0236333, a polymeric vessel is formed by extruding.

Attention is drawn to the following places, which may be of interest for search:

Shaping or joining of plastics |

This place covers:

Manufacturing steps or manufacturing method for pressure vessels during which material parts are assembled to complete the vessel.

Unless particularly interesting and exceptional assembling steps are detailed, the mounting of valves on the vessel should not be classified herein.

This place covers:

Manufacturing steps or manufacturing method for pressure vessels during which material parts are assembled by welding

In this positive example from WO8900658 weld spots are visible in a drawing.

Attention is drawn to the following places, which may be of interest for search:

Soldering, welding |

As there is no other classification entry related to welding, an explicit welding manufacturing step is not necessary, so that the term "welded" or the presence of welding spots on drawings are sufficient for classification in this group.

This place covers:

Manufacturing steps or manufacturing method for pressure vessels during which material parts are assembled by friction welding.

In this positive example from WO2004096459, several parts are assembled by friction welding at the same time.

This place covers:

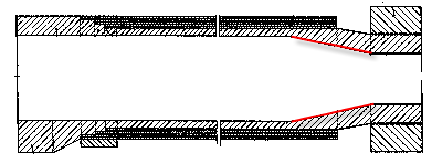

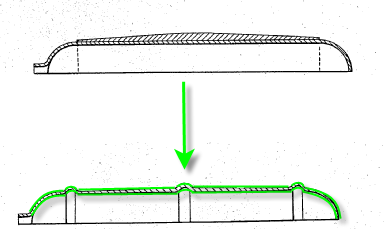

Manufacturing steps or manufacturing method for pressure vessels during which material parts are assembled by press- or shrink-fitting.

In this positive example DE8619754U, fitted parts of the middle part are slightly conical.

This place covers:

Manufacturing steps or manufacturing method for pressure vessels during which material parts are sprayed.

In this positive example from US2004089440, glue is sprayed.

This place covers:

Manufacturing steps or manufacturing method for pressure vessels during which material parts are assembled by adhesive means like glue.

In this positive example from WO02088593, layers are glued together.

In this negative example from WO0148418, fibers in a layer are adhered by a matrix material, but this is not considered an assembling step.

This place covers:

Manufacturing steps or manufacturing method for pressure vessels during which material parts are assembled by screws or bolts or rivets.

In this positive example from DE671013, a screw holds parts of the vessel together.

In this negative example from US2372800, two parts of a vessel are screwed together. This example is classified in "assembling processes"

This place covers:

Particular details or locations in relation with manufacturing steps or manufacturing method for pressure vessels.

Any details related to a way of assembling walls or layers, like the presence of welding spots, the placing of an O-ring or a way to fold metal in the contact zone, are classified herein.

A manufacturing process step does not need to be explicitly mentioned, in most cases, a drawing with a detail is sufficient.

This place covers:

Details in relation with the assembling of walls or layers.

In this positive example from WO9220954, a layer is assembled with a certain angle.

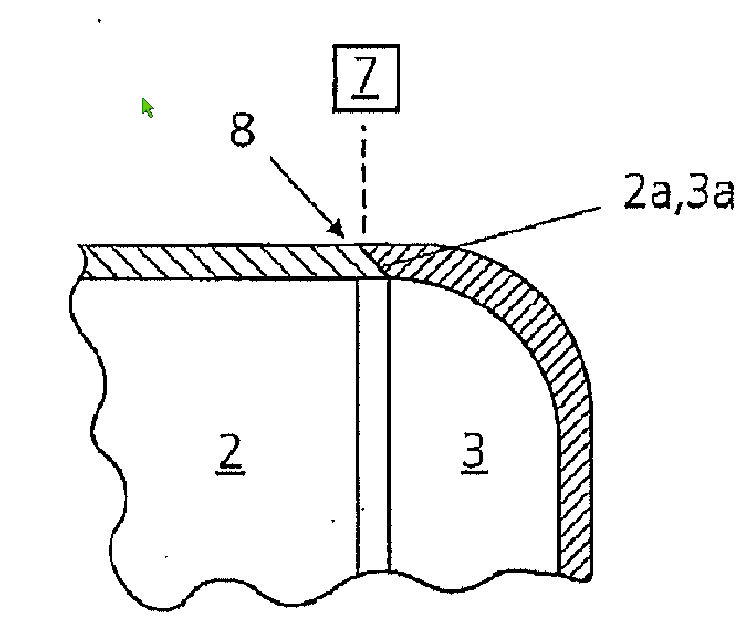

![]()

![]()