CPC Definition - Subclass F16H

This place covers:

Gearings for conveying rotary motion:

- Toothed gearings;

- Friction gearings, e.g. gearings using endless flexible members;

- Fluid gearings;

- Change speed or reversing gearings;

- Differential gearings;

- Using intermittently-driving members;

- Gearings not limited to rotary motion;

- Mechanical gearings using levers, links or cams; or

- Using intermittently-driving members.

Combination of gearings.

General details of gearings.

Control of gearings.

Subclass F16H for gearings is a function-oriented place. Gearings or transmissions comprising general applicable inventions or intended for different applications are classified in this subclass. Specially adapted gearings for a particular purpose are classified in the related subclass for the application. Some examples where these gearings will be classified when specially adapted or for a particular purpose could be found in the following list of references.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Gearings in harvesters or mowers | |

Gearings in balers | |

Gearings in surgical tools | |

Gearings for toys | |

Toothed-wheel gearing for metal-rolling mills | |

Varying the speed ratio of driving or feeding mechanisms of machine tools | |

Gearings for portable rotary tools | |

Gearings for manipulators | |

Gearings in torque-transmitting axles | |

Conjoint control of drive units for vehicles | |

Transmissions for railway locomotives | |

Vehicle steering gears | |

Cycle transmissions | |

Marine propulsion | |

Transmissions for marine propulsion | |

Marine steering gears | |

Gearings for control surfaces in airplane and helicopters | |

Gearings for aircraft propellers or rotors | |

Gearings in dredging or soil shifting machines | |

Gearings in gas turbine plants | |

Transmission of mechanical power for wind motors | |

Gearings associated with fluid-actuated devices | |

Gearing used in indicating or recording apparatus in connection with measuring devices | |

Driving arrangements for tuning resonant circuits | |

Driving mechanisms for apparatus for transmission of coded digital information |

Attention is drawn to the following places, which may be of interest for search:

Arrangement of transmissions in vehicles | |

Fluid actuators | |

Couplings for transmitting rotation; Clutches |

The use of the available Indexing Codes in this subclass is mandatory and should be assigned for additional information to facilitate searching. The Indexing Codes under F16H 2700/00 are no longer used for classifying new documents.

In this place, the following terms or expressions are used with the meaning indicated:

gearing | mechanical, hydraulic, electric or other means for transmitting mechanical motion or force |

gearbox | housing of the gearing |

toothed gearing | includes worm gearing and other gearing involving at least one wheel or sector provided with teeth or the equivalent, except gearing with chains or toothed belts, which is treated as friction gearing |

conveying motion | includes transmitting energy, and means that the applied and resultant motions are of the same kind, though they may differ in, e.g. speed, direction or extent |

rotary motion | implies that the motion may continue indefinitely |

oscillating motion | moving about an axis to an extent which is limited by the construction of the gearing and which may exceed one revolution, the movement being alternately forwards and backwards during continued operation of the gearing |

reciprocating motion | moving substantially in a straight line, the movement being alternately forwards and backwards during continued operation of the gearing |

reversing or reversal | applied movement in one direction may produce a resultant movement in either of two opposed directions at will. Note: When reversing reciprocating motion, input rotary motion (which is defined as indefinitely continuous rotary motion) would cause an automatic reversal of the reciprocating motion. If the input rotational direction is changed in order to cause reversal of the reciprocating motion, the input motion is an oscillating motion (which is defined as alternately forward and backward rotary motion) |

central gears | includes any gears whose axis is the main axis of the gearing, e.g. sun or ring gear |

Ravigneaux set | a planetary gear set with at least three central gears, and conveying rotary motion between axially-spaced orbital gears. It comprises a long orbital gear consisting of two axially spaced orbital gears which are fixedly connected to each other. It comprises a further orbital gear which meshes with one of the orbital gears of the long orbital gear to form a pair of intermeshing orbital gears. All orbital gears are mounted on a common planet carrier and are considered as a single set of orbital gears. |

creeping | the vehicle has come to a stop, the engine is at idle (i.e., there is no request by the operator for a higher engine speed/torque), but due to the rotation of various transmission components, the vehicle starts to move, and the vehicle operator has some control over movement with a brake |

inching | the vehicle operator has some control, besides using a brake, over moving the vehicle by small degrees |

This place covers:

Gearing with fixed gear ratio using only gears with teeth.

This place does not cover:

Toothed gearing for conveying rotary motion with variable gear ratio of for reversing rotary motion |

Attention is drawn to the following places, which may be of interest for search:

Combinations of mechanical gearings | |

Gears associated with electric machines |

This place covers:

Toothed gearings for conveying rotary motion in which torque may be transmitted from the input to the output in only one input rotation direction, e.g. a clockwise input rotation is possible whereas a counter-clockwise input rotation is blocked.

Illustrative examples of subject matter classified in this place:

1a.

Figure 1a illustrates an example in which clockwise rotation is possible.

1b.

Figure 1b illustrates an example in which counter clockwise rotation is blocked.

2a.

2b.

Figures 2a and 2b illustrate an example in which rotation is allowed in only one direction.

Attention is drawn to the following places, which may be of interest for search:

Gearings or mechanisms preventing back-driving | |

Mechanically driven watches or clocks including devices allowing the motion of a rotatable part in only one direction |

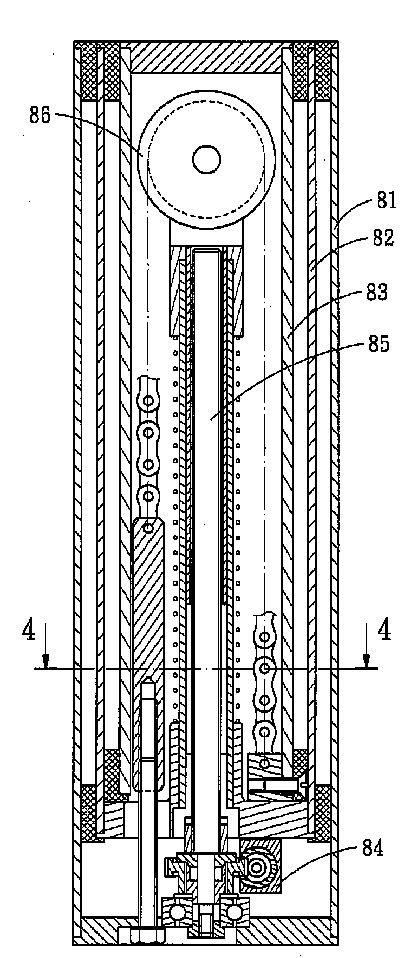

This place covers:

Illustrative examples of subject matter classified in this place:

1a.

1b.

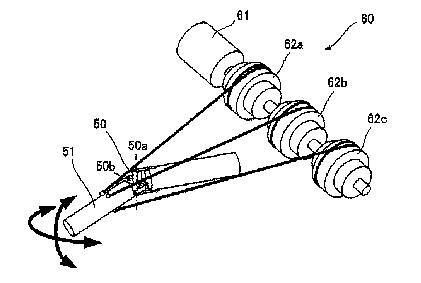

Figures 1a and 1b illustrate a worm drive shaft (a) and driven shaft (d) which may assume variable positions to one another, i.e. worm drive shaft (a) may pivot around driven shaft (d).

2.

Figure 2 illustrates a drive shaft (left outermost gear) and a driven shaft (right outermost gear) may assume variable positions to one another, i.e. gear train (252B) may pivot with respect to gear train (252A).

Attention is drawn to the following places, which may be of interest for search:

Angle drives for machine tools | |

Yielding couplings, i.e. with means permitting movement between the connected parts during the drive, e.g. universal joints |

This place covers:

Non-orbital toothed gearing wherein no more than a total of two intermeshing members are used to convey rotary motion.

Attention is drawn to the following places, which may be of interest for search:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving more than two intermeshing members |

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving only two intermeshing members, with parallel axes.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates a gearing having two parallel axes and involving only two intermeshing members (1) and (2). The latter are formed as spur gears.

2.

Figure 2 illustrates a gearing having two parallel axes and involving only two intermeshing members (1) and (2). The latter are formed as face gears.

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving only two intermeshing members, with parallel axes, the members having helical, herringbone or like teeth.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates a helical gearing having two parallel axes and involving only two intermeshing members (a) and (b). The latter having helical teeth.

2.

Figure 2 illustrates a double helical gearing having two parallel axes and involving only two intermeshing members (3) and (4). Each of the latter having two rows (1) and (2) of oppositely inclined helical teeth.

3.

Figure 3 illustrates a herringbone gearing having parallel axes (I) and (II) and involving only two intermeshing members (a1) and (a2). The latter having herringbone teeth.

Attention is drawn to the following places, which may be of interest for search:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving more than two intermeshing members, characterised by the driving or driven member being composed of two or more gear wheels |

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving only two intermeshing members, with parallel axes, one of the members being internally toothed.

Illustrative example of subject matter classified in this place:

The Figure illustrates a gearing having two parallel axes and involving only two intermeshing members (1) and (2). Member (1) is internally toothed.

Attention is drawn to the following places, which may be of interest for search:

Turntables, i.e. structure rotatable about 360°, e.g. slew drives |

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving only two intermeshing members, with non-parallel axes.

Illustrative example of subject matter classified in this place:

1a.

Figure 1a illustrates a crown gearing involving only two intermeshing members (1) and (2). Axes (3) and (4) are intersecting and non-parallel. Gears (1) and (2) are not conical.

1b.

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving only two intermeshing members, with non-parallel axes, comprising spiral gears.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates a gearing involving only two intermeshing members (4) and (8), with non-parallel axes (2) and (3). Intermeshing member (4) has spiral teeth. The gearing does not have conical gears.

2.

Figure 2 illustrates a gearing involving only two intermeshing members (20) and (52), with non-parallel and intersecting axes (F) and (P). Intermeshing members (20) and (52) have spiral teeth. The gearing does not have conical gears.

3.

Figure 3 illustrates a gearing involving only two intermeshing members (1) and (2), with non-parallel and non-intersecting axes. Intermeshing members (1) and (2) have spiral teeth. The gearing does not have conical gears.

Attention is drawn to the following places, which may be of interest for search:

Comprising conical gears only, with offset axes, e.g. hypoïd gearings |

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving only two intermeshing members, with non-parallel axes, comprising conical gears only.

Illustrative example of subject matter classified in this place:

The Figure illustrates a bevel gearing involving only two intermeshing members, i.e. bevel gears (2) and (4). The axes thereof are non-parallel.

Attention is drawn to the following places, which may be of interest for search:

Turntables, i.e. structure rotatable about 360°, e.g. slew drives |

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving only two intermeshing members, with non-parallel axes, comprising conical gears only, with offset axes, e.g. hypoïd gearings.

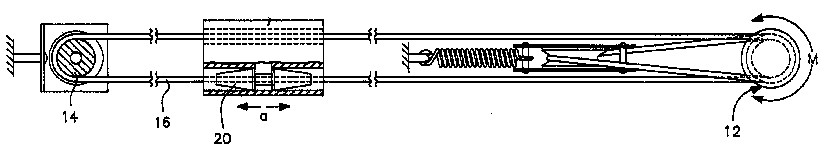

Illustrative example of subject matter classified in this place:

The Figure illustrates a hypoïd gearing involving only two intermeshing members, i.e. conical gears (12) and (14). Axes (Og) and (Op) are offset by a distance (E), i.e. they do not intersect.

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving only two intermeshing members, with non-parallel axes, comprising worm and worm-wheel.

Illustrative example of subject matter classified in this place:

The Figure illustrates a worm gearing involving only two intermeshing members, i.e. worm (2) and worm-wheel (5).

Attention is drawn to the following places, which may be of interest for search:

Special devices for taking up backlash for worms and worm gears | |

Support of worm gear shafts | |

Worm gears associated with electric machines |

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving only two intermeshing members, with non-parallel axes, comprising worm and worm-wheel, with balls between the co-operating parts.

Illustrative example of subject matter classified in this place:

The Figure illustrates a worm gearing involving only two intermeshing members, i.e. worm (4) and worm-wheel (8), with balls (5) between co-operating worm (4) and worm-wheel (8).

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving only two intermeshing members, with non-parallel axes, with members rotating around axes on the worm or worm-wheel.

Illustrative example of subject matter classified in this place:

1a.

1b.

Figures 1a and 1b illustrate a worm gearing involving only two intermeshing members, i.e. worm (12) and worm-wheel (10). Additionally, the worm gearing includes members, i.e. rollers (22), each rotating around an axis (24) on worm-wheel (10), which is perpendicular to axis (18) of worm wheel (10).

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving only two intermeshing members, with non-parallel axes, the members having helical, herringbone or like teeth.

This place does not cover:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving only two intermeshing members, with non-parallel axes, comprising conical gears only |

This place covers:

Non-orbital toothed gearing wherein the total number of intermeshing members used to convey rotary motion is greater than two intermeshing members.

Illustrative example of subject matter classified in this place:

The Figure illustrates a reduction gearing, with a fixed gear ratio, involving more than two intermeshing members, i.e. gears (2), (3), (4) and (5).

Attention is drawn to the following places, which may be of interest for search:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving only two intermeshing members | |

Combinations of toothed gearings only, not provided for in groups F16H 1/00 - F16H 35/00, for conveying rotary motion with constant gear ratio |

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving more than two intermeshing members, with non-parallel axes.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates a gearing with a fixed gear ratio involving four intermeshing members, i.e. spur gears (20) and (22) and hypoïd gears (30) and (31). The axis of gear (31) is not parallel with the axes of gears (20), (22) and (30).

2.

Figure 2 illustrates a gearing with a fixed gear ratio involving six intermeshing bevel gears. The gearing has four non-parallel axes of rotation.

3.

Figure 3 illustrates a gearing with a fixed gear ratio involving four intermeshing members, i.e. bevel gears (4) and (300) and spur gears (7) and (8). The axis of gear (300) is not parallel with the axes of gears (4), (7) and (8).

4.

Figure 4 illustrates a gearing with a fixed gear ratio involving four intermeshing members, i.e. worm (2), worm wheel (3), and spur gears (4) and (5). The axis of worm (2) is not parallel with the axes of gears (3), (4) and (5).

This place does not cover:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving more than two intermeshing members, with a plurality of driving or driven shafts or with arrangements for dividing torque between two or more intermediate shafts |

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving more than two intermeshing members, characterised by the driving or driven member being composed of two or more gear wheels.

Illustrative example of subject matter classified in this place:

The Figure illustrates a toothed gearing involving ten intermeshing members, i.e., gear pairs (11') and (13'), (12') and (14'), (15') and (16'), (17') and (19'), and (10') and (18'). The driving member, i.e. input shaft (1'), is composed of two gear wheels (11') and (12'). The driven member, i.e. output shaft (4'), is composed of two gear wheels (19') and (10').

Attention is drawn to the following places, which may be of interest for search:

Toothed gearings with gears having herringbone teeth, for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving only two intermeshing members, with parallel axes |

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving more than two intermeshing members, with a plurality of driving or driven shafts or with arrangements for dividing torque between two or more intermediate shafts.

Illustrative examples of subject matter classified in this place:

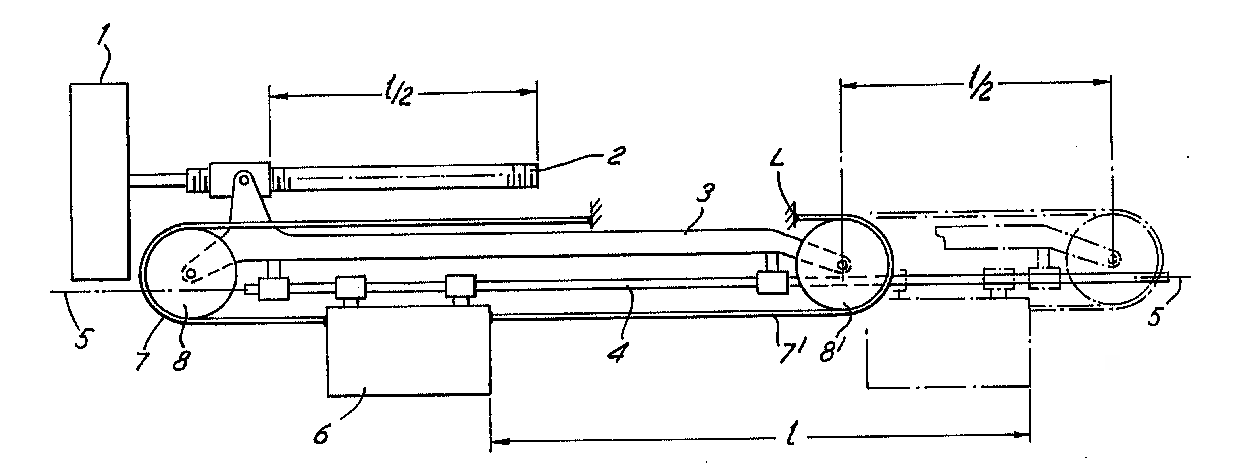

1.

Figure 1 illustrates a toothed gearing with a fixed gear ratio and fourteen intermeshing gears. The gearing has one driven shaft (27) and two driving shafts (13) and (13').

2.

Figure 2 illustrates a toothed gearing with a fixed gear ratio and four intermeshing gears. Torque from the driving shaft is divided between two intermediate shafts and summed at the driven shaft.

Attention is drawn to the following places, which may be of interest for search:

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion |

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without non-parallel axes, without gears having orbital motion, involving more than two intermeshing members, with a plurality of driving or driven shafts or with arrangements for dividing torque between two or more intermediate shafts, with non-parallel axes.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates a toothed gearing with a fixed gear ratio and intermeshing gears (1), (2), (3), (4), (1'), (2'), (3'), and (4'). The gearing includes a driving shaft 6 and two driven shafts (5) and (5'). Torque flows from driving shaft (6) via bevel gears (1) and (2), internal gear (3) and external gear (4) to driven shaft (5); and from driving shaft (6) via bevel gears (1') and (2'), internal gear (3') and external gear (4') to driven shaft (5').

2.

Figure 2 illustrates a toothed gearing with a fixed gear ratio and eight intermeshing gears. Torque from driving shaft (1) is divided between intermediate shafts (12) and (13) and summed at driven shaft (2).

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving more than two intermeshing members, with a plurality of driving or driven shafts or with arrangements for dividing torque between two or more intermediate shafts, with two or more worm and worm-wheel gearings.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates a toothed gearing with a fixed gear ratio and four intermeshing gears. The gearing includes a driven shaft (1) and three driving worm shafts (2), (3) and (7).

2.

Figure 2 illustrates a toothed gearing with a fixed gear ratio and seven intermeshing gears. Torque from the driving shaft, i.e. worm shaft (1), is divided between intermediate worm shafts (7) and (6) and summed at driven shaft (2).

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving more than two intermeshing members, with a plurality of driving or driven shafts or with arrangements for dividing torque between two or more intermediate shafts, comprising two or more gearwheels in mesh with the same internally toothed wheel.

1.

Figure 1 illustrates a toothed gearing with a fixed gear ratio and six intermeshing gears. The gearing includes two driving shafts (5) and a driven shaft (8). Both gearwheels (3) are in mesh with the same internally toothed wheel (2a).

2.

Figure 2 illustrates a toothed gearing with a fixed gear ratio and four intermeshing gears. Torque from driving shaft (16) is divided between intermediate shafts (36) and (37) and summed at internally toothed gear (21), which forms the driven shaft. Gearwheels (26) and (31) mesh with the same internally toothed wheel (21).

3.

Figure 3 illustrates a toothed gearing with a fixed gear ratio and four intermeshing gears. Torque from driving shaft (121) is divided between intermediate shafts (140) and summed at internally toothed gear (131), which forms the driven shaft. Gearwheels (132) mesh with the same internally toothed wheel (131).

Attention is drawn to the following places, which may be of interest for search:

Toothed gearings for conveying rotary motion with gears having orbital motion |

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving gears essentially having intermeshing elements other than involute or cycloidal teeth.

Illustrative example of subject matter classified in this place:

1a.

1b.

Figures 1a and 1b illustrate a gearing with a fixed gear ratio and without gears having orbital motion. Rollers (5) of gear (2) mesh with semi-circular grooves (4) of gear (1). In other words, the gearing includes intermeshing elements which are neither involute nor cycloidal teeth.

This place does not cover:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving only two intermeshing members, with non-parallel axes, comprising worm and worm-wheel |

This place covers:

Special means compensating for misalignment of axes of toothed gearings for conveying rotary motion, with fixed gear ratio, and without gears having orbital motion.

Illustrative example of subject matter classified in this place:

The Figure illustrates a toothed gearing comprising a pair of spur gears (6) and (10), driving shaft (6), and driven shaft (8). The gearing includes a spherical bearing formed on the drive shaft (8) in order to compensate for the misalignment of the axes associated with shafts (6) and (8), respectively.

Attention is drawn to the following places, which may be of interest for search:

Special means compensating for misalignment of axes of toothed gearings, with fixed gear ratio, comprising gears having orbital motion | |

Support of worm gear shafts in the gearbox |

This place covers:

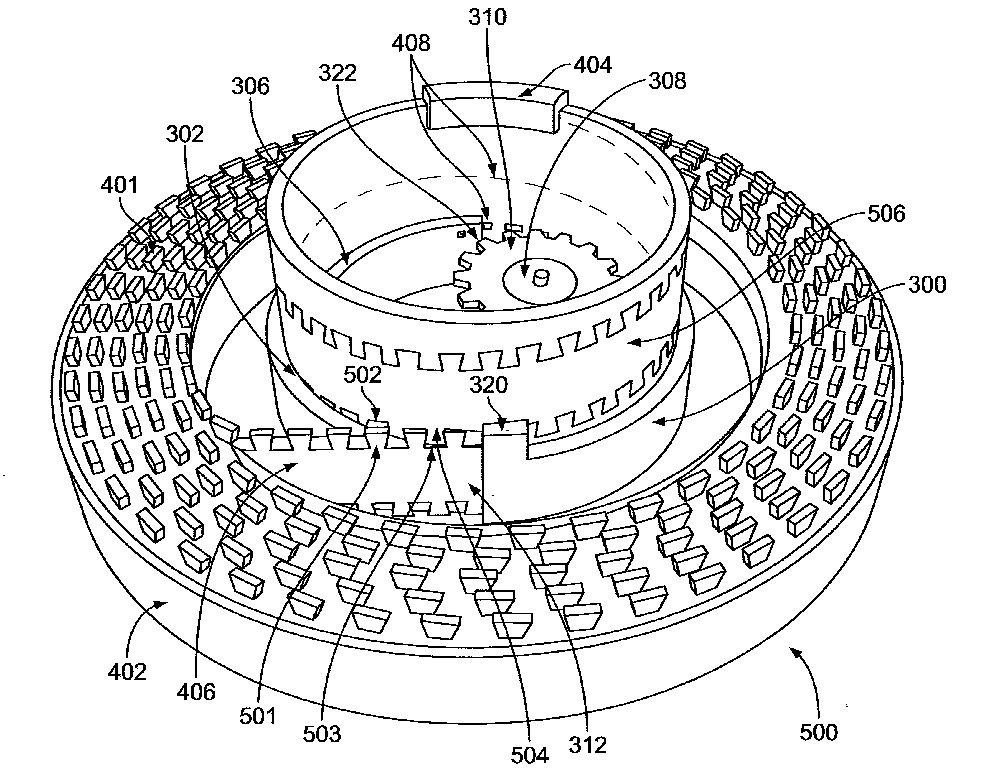

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion.

Illustrative example of subject matter classified in this place:

The Figure illustrates an orbital or planetary gearing comprising sun gear (4), orbital or planet gears (5), ring or internal gear (6) and planet carrier (7). Input shaft (1) is connected to sun gear (4), output shaft (2) is connected to planet carrier (7), and ring gear (6) is fixed to housing (3). Planet gears (5) rotate around their own axis. In addition, due to rotation of the planet carrier (7), planet gears (5) also orbit relative to and around rotating sun gear (4), i.e. they have orbital motion.

Attention is drawn to the following places, which may be of interest for search:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving more than two intermeshing members, with arrangements for dividing torque between two or more intermediate shafts | |

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving more than two intermeshing members, with arrangements for dividing torque between two or more intermediate shafts, comprising two or more gearwheels in mesh with the same internally toothed wheel | |

Differential gearing comprising bevel gears | |

Differential gearing comprising orbital spur gears | |

Transmission arrangements in gas turbine plants, or between the gas-turbine plant and the power user | |

Transmission of mechanical power in wind motors | |

Transmission of power in motors, machines or engines covered by subclasses F03B, F03D and F03G, e.g. in wind motors, by toothed gearing of the epicyclic, planetary or differential type |

In patent documents, the following words/expressions are often used as synonyms:

- "Planetary transmission" and "epicyclic transmission"

- "Gearing", "gear train" or "gear set"

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion, with means for equalising the distribution of load on the planet gears.

Attention is drawn to the following places, which may be of interest for search:

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion and with special means compensating for misalignment of axes, e.g. for equalising distribution of load on the face width of the teeth |

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion, with means for equalising the distribution of load on the planet-gears, by allowing limited movement of the ring gear relative to the casing or shaft.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates a planetary gearing with a ring gear (2) connected to casing (5) via an elastically deformable wave element (16). The latter allowing limited movement of ring gear (2) relative to casing (5).

2.

Figure 2 illustrates a planetary gearing with a ring gear (3) connected to casing (7) via pins (5) and roller elements (6a) and (6b), thereby allowing limited movement of ring gear (3) relative to casing (7).

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion, with means for equalising the distribution of load on the planet-gears, by allowing limited movement of the planet carrier, e.g. relative to its shaft.

Illustrative example of subject matter classified in this place:

The Figure illustrates a planetary gearing with planet carrier (13) connected to output shaft (17) by double-tooth clutch (15) which is axially biased by spring (18). This connection allows a limited axial movement of planet carrier (13) relative to output shaft (17).

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion, with means for equalising the distribution of load on the planet-gears, by allowing limited movement of the planet gears relative to the planet carrier or by using free floating planet gears.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates a planet gear (36) is rotatably mounted to planet carrier (38) via a planet bearing (63), a sleeve (56) and a flex-pin (40). Flex-pin (40) allows limited movement of planet gear (36) relative to planet carrier (38).

2a.

2b.

Figures 2a and 2b illustrates an example in which planet gears (6) are each rotatably mounted to planet carrier (3) by planet pins (12). Planet pins (12) may freely float within slits (11) in planet carrier (3).

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion, with means for equalising the distribution of load on the planet-gears, by allowing limited movement of the sun gear.

Illustrative example of subject matter classified in this place:

The Figure illustrates a planetary gearing including sun gear (9) connected to casing (10) via an elastically deformable wave element (24). The latter allowing limited movement of sun gear (9) relative to casing (10).

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion, involving conical gears.

Illustrative example of subject matter classified in this place:

The Figure illustrates a reduction gearing (40) including input shaft (31), output shaft (36), non-rotating housing (24) and bevel planet gear (42), i.e. a conical gear, having orbital motion.

Attention is drawn to the following places, which may be of interest for search:

Toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion, involving more than two intermeshing members, with arrangements for dividing torque between two or more intermediate shafts, with non-parallel axes, e.g. with bevel gears | |

Differential gearing with gears having orbital motion and comprising bevel gears |

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion, arrangements for adjusting or for taking-up backlash.

Illustrative example of subject matter classified in this place:

The Figure illustrates a planetary gearing including ring gear (5) having two parts (5') and (5''), which are rotated against each other to reduce the backlash between the teeth of the planet gears (3) and the teeth of the ring gear (5).

Attention is drawn to the following places, which may be of interest for search:

Special devices for taking up backlash for toothed bevel gears | |

Arrangements for adjusting or for taking-up backlash not provided for elsewhere |

This place covers:

Planetary gearing having a fixed gear ratio and including three central gears which are all engaged with the same planet gear, and the planet gear is mounted on an idling carrier.

Illustrative example of subject matter classified in this place:

The Figure illustrates a planetary gearing with a fixed gear ratio and including three central gears, i.e. sun gear (2) and two ring gears (3) and (4), which are all engaged by a common orbital gear (6) mounted on carrier (5). Carrier (5) is not connected to any shaft and therefore idles. In other words, carrier (5) constitutes an "idling carrier".

Attention is drawn to the following places, which may be of interest for search:

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion, comprising two axially spaced central gears, i.e. ring or sun gear, engaged by at least one common orbital gear wherein one of the central gears is forming the output |

This place covers:

Planetary gearing having a fixed gear ratio and including at least two axially spaced central gears which are both engaged with the same planet gear, and one of the at least two axially spaced central gears is the output for the gearing.

Illustrative example of subject matter classified in this place:

The Figure illustrates a planetary gearing with a fixed gear ratio and including two axially spaced central gears, i.e. ring gears (5) and (7), which are both engaged by a common orbital gear (3) and (3'). Ring gear (7) forms the output of the gearing.

Attention is drawn to the following places, which may be of interest for search:

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion, comprising three central gears, i.e. ring or sun gear, engaged by at least one common orbital gear mounted on an idling carrier |

Planetary gearings falling within the scope of both F16H 2001/2872 and F16H 2001/2881, are classified in F16H 2001/2872 only.

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion, comprising two or more coaxial and identical sets of orbital gears, e.g. for distributing torque between the coaxial sets.

Illustrative example of subject matter classified in this place:

The Figure illustrates a planetary gearing with a fixed gear ratio and comprising a first set of planet gears (25) and a second set of planet gears (25'). The two sets of planet gears (25) and (25') are coaxial and identical.

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion, in which an orbital gear is a worm; or in which the orbital gear has helical teeth and an axis crossing the main axis of the gearing.

This area also includes gearing in which the orbital gear has helical teeth and where the axis of the orbital gear is set at an angle relative to the main axis.

Illustrative examples of subject matter classified in this place:

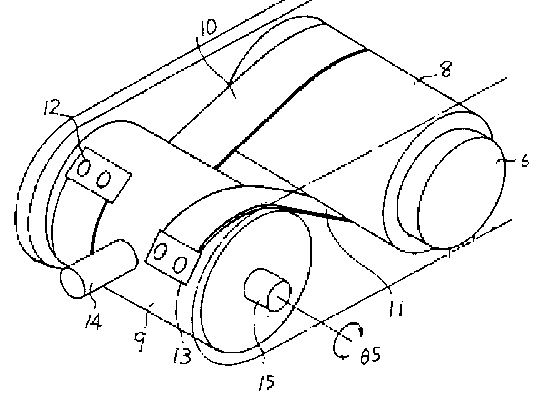

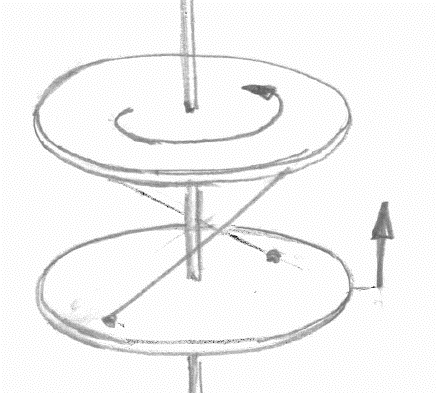

1a.

1b.

Figures 1a and 1b illustrate a planetary gearing, with a fixed gear ratio, comprising four orbital gears (9), each of which is a worm.

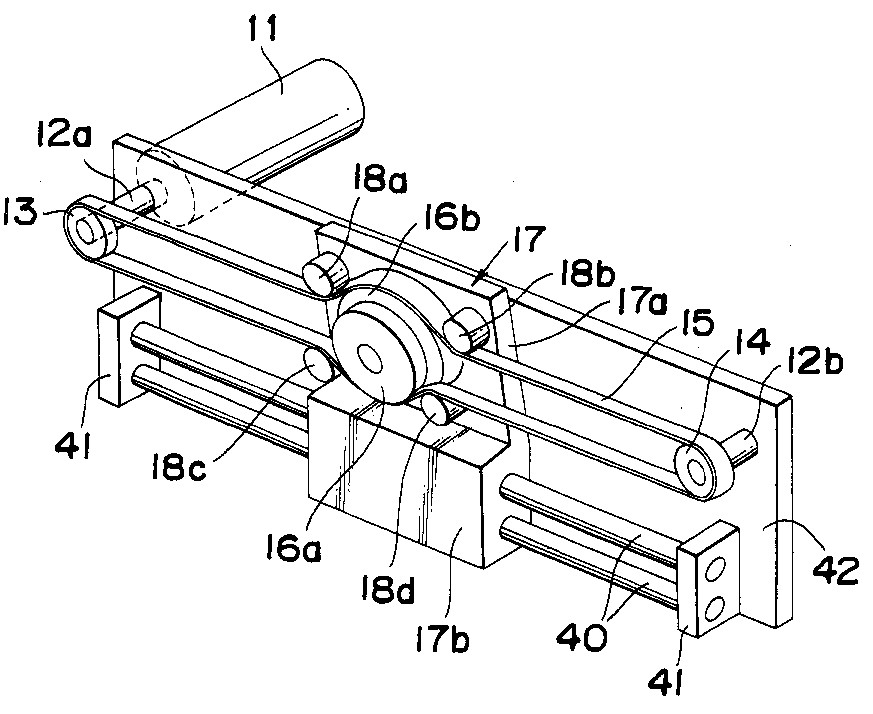

2a.

2b.

Figures 2a and 2b illustrate a planetary gearing comprising three orbital gears (16), each of which has helical teeth and an axis (17) set at an angle α relative to the main axis (18).

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion, in which the central axis of the gearing lies inside the periphery of an orbital gear, e.g. eccentric gearing or cycloidal gearing.

Attention is drawn to the following places, which may be of interest for search:

Gearings comprising cams for conveying rotary motion, with intermediate members guided along tracks on both rotary members | |

Wave gearings | |

Cycloidal or planetary mechanisms for adjustable back-rest in which the central axis of the gearing lies inside the periphery of an orbital gear, e.g. one gear without sun gear |

This place covers:

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates a planetary gear set in which orbital gears (9) and (9') are nutating.

2.

Figure 2 illustrates a planetary gear set in which orbital gears (9) and (11) are nutating.

This place covers:

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates a planetary gear set including an input crank (b), an output (f), an eccentric orbital gear (d) and a flexible coupling (g).

2.

Figure 2 illustrates a gearing including a planetary gear set having carrier (5) with mounted orbital gears (11) interacting with sun gear (3). The gearing further includes universal joints (28), (33) attached to the output of the planetary gear set.

This place covers:

Illustrative example of subject matter classified in this place:

1a.

1b.

Figures 1a and 1b illustrate a planetary gear set (1) includes an eccentric crankshaft (10) driven by input shaft (8), eccentric orbital gears (14a), (16a) driven by eccentric crankshaft (10) and output shaft (4).

This place covers:

Illustrative example of subject matter classified in this place:

The Figure illustrates a planetary gear set including eccentric input shaft (F), axially spaced and rigidly interconnected eccentric orbital gears (B), (D) and output shaft (C).

This place covers:

Orbital gearing in which the orbital movement of the orbital gears is transferred eccentrically around the main axis of the gearing by carrier pins interacting with circular holes, e.g. cycloid gearings.

Illustrative example of subject matter classified in this place:

1a.

1b.

Figures 1a and 1b illustrate a planetary gear set including input shaft (11), ring gear (20), eccentric orbital gears (30) and (40), carrier (50), sun gear (71) and output shaft (12). Pins (51) in carrier (50) guide orbital gears (30) and (40) in an eccentric motion via holes (32) and (42).

This place covers:

Orbital gearing in which the orbital movement of the orbital gears is transferred eccentrically about the main axis of the gearing by linear guiding means. The linear guiding means include means that allow radial movement in two orthogonal directions, e.g. an Oldham coupling.

Illustrative example of subject matter classified in this place:

1a.

Figure 1a illustrates a gearing comprising input crankshaft (10), output shaft (50) and orbital gears (30). The rotation of each of the orbital gears (30) around its own axis (30a), which is eccentric to center axis (40a), is converted into rotation of output shaft (50) around center axis (40a). Linear guiding means (70), in the form of a cross, allows radial movement in two orthogonal directions of orbital gears (30).

1b.

1c.

1d.

This place covers:

The eccentrically driven orbital gear has internal gear teeth.

Illustrative examples of subject matter classified in this place:

1a.

1b.

Figures 1a and 1b illustrate a planetary gear set (20) including input crankshaft (21), orbital gear (24), (25), reactionary ring gear (22) and output shaft (27). Orbital gear (24), (25) includes external teeth (24a) and internal teeth (25a).

2a.

2b.

2c.

Figures 2a, 2b and 2c illustrate a planetary gear set including input crankshaft (2a), orbital gear (6), sun gear (9) and output shaft (10). Orbital gear (6) has internal teeth (7).

Attention is drawn to the following places, which may be of interest for search:

Gearings comprising primarily only links or levers for conveying rotary motion by means of cranks, eccentrics, or like members fixed to one rotary member and guided along tracks on the other member |

This place covers:

Illustrative example of subject matter classified in this place:

1a.

1b.

Figures 1a and 1b illustrate a planetary gear set including a crankshaft (1) with balancing means (11), orbital gear (9), reactionary ring gear (10) and output (2).

Attention is drawn to the following places, which may be of interest for search:

Shape of crankshafts or eccentric-shafts having regard to balancing |

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion, involving gears essentially having intermeshing elements other than involute or cycloidal teeth.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates a planetary transmission, with fixed gear ratio, having intermeshing elements, i.e. teeth (7), (8) and (9), which are neither involute nor cycloidal teeth.

2a.

Figure 2a illustrates an eccentric gearing, with fixed gear ratio, having intermeshing elements, i.e. teeth in form of pins (36), which are neither involute nor cycloidal teeth.

2b.

This place does not cover:

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion, in which an orbital gear has an axis crossing the main axis of the gearing, either directly or in a projected plane, and has helical teeth or is a worm |

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion, with two central gears coupled by intermeshing orbital gears.

Illustrative example of subject matter classified in this place:

The Figure illustrates a planetary transmission, with fixed gear ratio, comprising two central gears, i.e. sun gear (2) and ring gear (3), coupled by two intermeshing orbital gears (4a) and (4b).

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion, consisting of a plurality of gear trains each with orbital gears and having three or more central gears.

Illustrative example of subject matter classified in this place:

1a.

1b.

Figures 1a and 1b illustrate a planetary transmission, with fixed gear ratio, comprising two gear trains (1) and (2) having altogether four central gears, i.e. sun gears (S1) and (S2) and ring gears (R1) and (R2). First gear train (1) has a single orbital gear (P1). Second gear train (2) has a pair of intermeshing orbital gears (P2) and (P3).

Attention is drawn to the following places, which may be of interest for search:

Combinations of toothed gearings only, not provided for in groups F16H 1/00 - F16H 35/00, for conveying rotary motion with constant gear ratio |

This place covers:

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion, e.g. eccentric gearing or cycloidal gearing, and with special means compensating for misalignment of axes, e.g. for equalising distribution of load on the face width of the teeth.

Illustrative example of subject matter classified in this place:

1a.

1b.

Figures 1a and 1b illustrate a planetary transmission, with a fixed gear ratio, comprising two gear trains (101) and (103), each respectively comprising one set of orbital gears (109) and (125). Figure 1a illustrates a misalignment of the main axes of gear trains (101) and (103). Sun gear (111), sun gear shaft (129) and planet carrier (123) of Figure 1a are replaced with sun gear (201), sun gear shaft (207) and planet carrier (213) in order to compensate for the misalignment which are illustrated in Figure 1b. This results in a more equally distributed load on the face width of the teeth of the sun gear (201), ring gear (105) and planet gears (109).

Attention is drawn to the following places, which may be of interest for search:

Special means compensating for misalignment of axes of toothed gearings for conveying rotary motion, with fixed gear ratio, without gears having orbital motion | |

Toothed gearings for conveying rotary motion, with fixed gear ratio, with gears having orbital motion, with means for equalising the distribution of load on the planet gears |

This place covers:

Gearings with variable gear ratio or reversing motion using only gears with teeth.

This place does not cover:

Speed-changing or reversing mechanisms |

Attention is drawn to the following places, which may be of interest for search:

Combinations of mechanical gearings |

This place covers:

Gearings which are convertible when not being operated such that, after the conversion, a different gear ratio is provided. In other words, convertible does not mean shiftable during operation.

Illustrative examples of subject matter classified in this place:

1a.

1b.

Figures 1a and 1b illustrate a gearing having an input shaft (21) and an output shaft (22). The gear ratio can be varied by converting the gearing outside of operation. This conversion is done by mounting output shaft (22) to a different one of gears (11-17). Thereby, different output gears are selected which result in different gear ratios.

2.

Figure 2 illustrates a gearing having an input shaft (5) and an output shaft (9). The gear ratio is varied from forward to reverse by converting the gearing as follows: the distance ring (13) is removed from its position between the casing body (1) and the lower lid (14) and is interposed between the casing body (1) and the upper lid (15). Thereby output shaft (9) is axially displaced so that input bevel gear (6) now meshes with lower output bevel gear (12) instead of upper output bevel gear (7) and the sense of rotation of the output shaft (8) being thereby reversed.

3.

Figure 3 illustrates a gearing including gear pair (56 and 58) which transfers torque during operation. Two replacement gear pairs (70 and 72) and (74 and 76) are stored in a chamber. When not in use, the gearing may be converted by substituting gear pair (56 and 58) with one of the two replacement gear pairs (70 and 72) and (74 and 76). This conversion varies the gear ratio.

Attention is drawn to the following places, which may be of interest for search:

Series transmissions of modular design, e.g. providing for different for different transmission ratios or power ranges |

In this place, the following terms or expressions are used with the meaning indicated:

convertible | an adaptation of the gearing when it is not in use. Convertible does not mean shiftable during operation of the gearing. |

This place covers:

Illustrative example of subject matter classified in this place:

1a.

Figure 1a illustrates a gearing with a variable gear ratio including conical ring gear (6) meshing with gears (24), (25), (26), (27) and (28). Each of gears (24), (25), (26), (27) and (28) has teeth (29) which are radially moveable in and out of mesh with the teeth of conical ring gear (6).

1b.

This place does not cover:

Toothed gearing without orbital motion with variable gear ratio or for reversing, essentially with both gears that can be put out of gear and continuously-meshing gears that can be disengaged from their shafts | |

Toothed gearing without orbital motion with variable gear ration or for reversing, exclusively or essentially using gears that can be moved out of gear | |

Toothed gearing without orbital motion with variable gear ration or for reversing, with gears having teeth formed or arranged for obtaining multiple gear ratios, e.g. nearly infinitely variable |

Attention is drawn to the following places, which may be of interest for search:

Cam gearings for conveying rotary motion, with intermediate members guided along tracks on both rotary members |

This place covers:

Toothed gearings in which the gear ratio is changed by inversion of torque, such that regardless of whether an input shaft changes rotation between clockwise and counter-clockwise, the output shaft always rotates in the same direction. For example, toothed gearing in which clockwise rotation of an input shaft results in clockwise rotation of an output shaft and a gear ratio of 1, and counter-clockwise rotation of the input shaft results in clockwise rotation of the output shaft and a gear ratio of -1.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates a gearing with a variable gear ratio including an input shaft (2000) and an output shaft (3000). When input shaft (2000) rotates clockwise, output shaft (3000) rotates clockwise. When input shaft (2000) rotates counter-clockwise and output shaft (3000) rotates clockwise.

2a.

2b.

Figures 2a and 2b illustrate a gearing with a variable gear ratio including an input shaft (131) and an output shaft (133). Due to freewheels (151) and (153) the flow path and, thus the gear ratio, is changed when the direction of rotation of input shaft (131) is changed. The direction of rotation of output shaft (133) remains the same.

This place covers:

Parallel selectable power or torque flow paths between the input and the output of the gearing, e.g. dual clutch transmissions.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates a toothed gearing including parallel torque flow paths selectively created between input (10a) and output (15a) by clutches (K1a) and (K2a).

2.

Figure 2 illustrates a toothed gearing including parallel torque flow paths selectively created between input (AN) and output (AB) by clutches (K1) and (K2).

Attention is drawn to the following places, which may be of interest for search:

Exclusively or essentially with continuously meshing gears that can be disengaged from their shafts, and with gear ratios in which power is transferred by axially coupling idle gears to each other | |

Exclusively or essentially with continuously meshing gears that can be disengaged from their shafts, and each of two or more countershafts having an output gear meshing with a single common gear on the output shaft | |

Exclusively or essentially with continuously meshing gears that can be disengaged from their shafts, and with coaxial countershafts | |

Combinations of toothed gearing having change gear transmissions in group arrangement |

In patent documents, the following abbreviations are often used:

DCT | dual-clutch transmission |

In patent documents, the following words/expressions are often used as synonyms:

- "Dual-clutch transmission", "twin-clutch transmission" and "double clutch transmission", "dual-coupling transmission", "twin-coupling transmission" and "double coupling transmission"

This place covers:

Illustrative example of subject matter classified in this place:

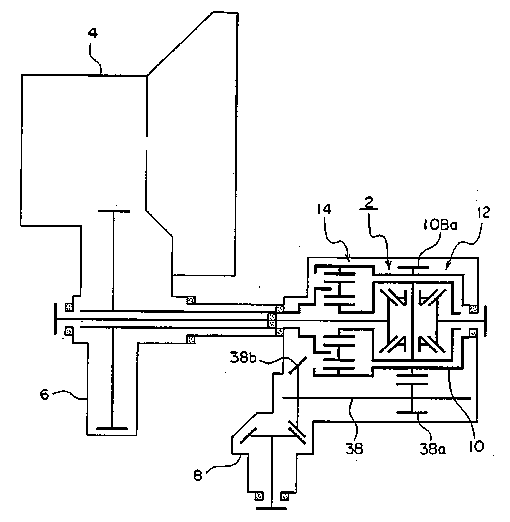

The Figure illustrates a six-speed transmission with two parallel flow path (10) and (12). Flow path (12) is directly connected to input (16) via first input shaft (14), and flow path (10) is connected to input (16) via clutch (27) and second input shaft (20).

This place covers:

Illustrative example of subject matter classified in this place:

1a.

1b.

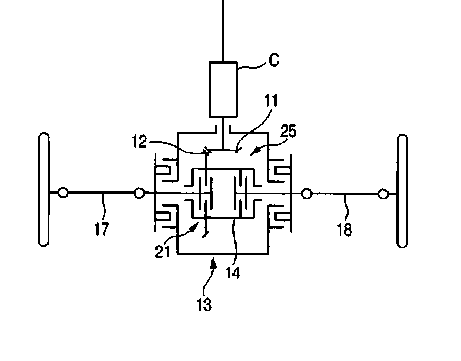

Figures 1a and 1b illustrate a transmission with two parallel flow paths via countershafts (CNT1) and (CNT2), and means (ST1) and (ST2) for selectively driving countershafts (CNT1) and (CNT2).

This place covers:

Illustrative example of subject matter classified in this place:

The Figure illustrates a multi-speed transmission, without gears having orbital motion, with internally toothed gears (6).

This place covers:

Illustrative example of subject matter classified in this place:

The Figure illustrates a transmission without gears having orbital motion, comprising three worms (4a), (4b) and (4c) with different pitches, which may be engaged with gear (2) by being axially moved on input shaft (3). Thereby two forward speeds and one reverse speed are provided for output shaft (1).

This place covers:

Illustrative example of subject matter classified in this place:

The Figure illustrates a transmission without gears having orbital motion with only continuously meshing gears, e.g. (G06) and (G16) always meshing. The gears of the transmission can be disengaged from their shafts, e.g. gear (G16) can be disengaged from shaft (PIS) via coupling (PS2).

In this group, gears which can be put out of mesh are not taken into consideration if they are used for reversal only.

This place covers:

Illustrative example of subject matter classified in this place:

The Figure illustrates a four-speed transmission having an input shaft (14) and an output shaft (16) as well as a countershaft (32) which is coaxial to input shaft (14).

Attention is drawn to the following places, which may be of interest for search:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion without gears having orbital motion exclusively or essentially with continuously meshing gears, that can be disengaged from their shafts with coaxial countershafts |

This place covers:

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates an eight-speed transmission without gears having orbital motion, comprising idle gears (5) and (6) which are axially couplable to each other by shift element (I), which changes the gear ratio.

2.

Figure 2 illustrates a multi-speed transmission without gears having orbital motion, including idle gears (33) and (34) which may be axially coupled to each other by engaging clutch (38), in order to transfer power.

In this place, the following terms or expressions are used with the meaning indicated:

winding transmission | a transmission including a gear ratio that is established by using multiple gear pairs in the transmission. For example, a transmission including a 1st gear ratio achieved by using more than one of the other existing gear pairs. In this 1st gear ratio, torque is wound through the transmission via the several gear pairs. Thereby, a separate gear plane for the 1st gear ratio is not necessary. This concept is often applied to the 1st gear and the reverse gear. These gears are usually used only during short periods, such that the reduced efficiency by using several gear pairs instead of only one gear pair can be neglected. |

winding gear ratio | a speed, e.g. 1st speed, which is achieved by winding torque through a winding transmission |

This place covers:

Illustrative example of subject matter classified in this place:

The Figure illustrates a four-speed transmission having an input shaft (1) and a coaxial output shaft (3). It uses unsynchronised clutches (9), (11) and (12).

Attention is drawn to the following places, which may be of interest for search:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears, that can be disengaged from their shafts, with means for synchronisation not incorporated in the clutches | |

Smoothing ratio shift by preventing or solving a tooth butt situation upon engagement failure due to misalignment of teeth | |

Smoothing ratio shift by smoothing engagement or release of positive clutches; Methods or means for shock free engagement of dog clutches |

This place covers:

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates a multi-speed transmission comprising means for power-shifting, by using bypass clutches (51) and (52).

2.

Figure 2 illustrates a multi-speed transmission comprising means for power-shifting, by using friction clutches (CT1) to (CT6).

Attention is drawn to the following places, which may be of interest for search:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears, that can be disengaged from their shafts, with means for synchronisation not incorporated in the clutches | |

Smoothing ratio shift by bridging torque interruption by torque supply with a clutch in parallel torque path |

This place covers:

Illustrative example of subject matter classified in this place:

The Figure illustrates a six-speed-transmission comprising a reverse shaft (48), two reverse gears (42) and (46) and a reverse clutch (44).

This place covers:

Illustrative example of subject matter classified in this place:

1a.

1b.

1c.

1d.

Figures 1a, 1b, 1c and 1d illustrate a multi-speed transmission without gears having orbital motion. Gear (Lo) on the output shaft is used for the (1st) and (3rd) forward speeds and gear (2) on the input shaft is used for the (2nd) and (6th) forward speeds.

Attention is drawn to the following places, which may be of interest for search:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears that can be disengaged from their shafts, with gear ratios in which power is transferred by axially coupling idle gears to each other | |

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears, that can be disengaged from their shafts, including a single countershaft, with coaxial input and output shafts | |

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears, that can be disengaged from their shafts, with two or more countershafts, each countershaft having an output gear meshing with a single common gear on the output shaft |

This place covers:

Illustrative example of subject matter classified in this place:

The Figure illustrates a three-speed transmission including balls (2) as radially acting clutching members. By axially moving sliding key (1), the three balls (2) are selectively radially moved into engagement with their respective idle gear.

Attention is drawn to the following places, which may be of interest for search:

Sliding keys as final output elements; Details thereof | |

Clutches per se with clutching members movable otherwise than only axially | |

Clutches per se with wedging balls or rollers or with other wedgeable separate clutching members | |

Systems of a plurality of actuated clutches per se |

This place covers:

Illustrative example of subject matter classified in this place:

The Figure illustrates a transmission without gears having orbital motion and including continuously meshing gears that can be disengaged from their shafts, e.g. gears (I), (II) and (III). The transmission comprises two output shafts (7) and (12). It is noted that differential casing (9) is not considered an output shaft.

Attention is drawn to the following places, which may be of interest for search:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears that can be disengaged from their shafts, with two or more countershafts, each countershaft having an output gear meshing with a single common gear on the output shaft | |

Combinations of mechanical gearings, comprising essentially only toothed or friction gearings, with differential gearing, with a plurality of driven shafts, with only one input shaft | |

Transmissions for multiple ratios comprising a power take off shaft | |

Arrangement or mounting of transmissions in vehicles, characterised by arrangement, location or type of power take-off | |

Arrangement or mounting of transmissions in vehicles, for driving both front and rear wheels, e.g. four wheel drive vehicles |

This place does not cover:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears that can be disengaged from their shafts, with radially acting and axially controlled clutching members, e.g. sliding keys | |

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears that can be disengaged from their shafts, with more than one output shaft |

When counting the countershafts, the reverse countershaft is not taken into consideration if it is used for reversal only.

This place covers:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears, that can be disengaged from their shafts, all of the meshing gears being supported by a pair of parallel shafts, one being the input shaft and the other the output shaft, there being no countershaft involved.

Illustrative example of subject matter classified in this place:

The Figure illustrates a multi-speed transmission without gears having orbital motion and including continuously meshing gears that can be disengaged from their shafts. The transmission comprises an input shaft (10) and an output shaft (20) which are parallel to each other. The transmission does not include a countershaft. It is noted that reverse countershaft (30), which is used for reversal only, is not counted as a countershaft, per the Note in F16H 3/087. It is further noted that differential casing (71) is not considered an output shaft, since the differential is not part of the multi-speed transmission.

This place covers:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears, that can be disengaged from their shafts, including a single countershaft.

Illustrative example of subject matter classified in this place:

The Figure illustrates a six-speed transmission without gears having orbital motion and including continuously meshing gears that can be disengaged from their shafts. The transmission comprises an input shaft (19) and an output shaft (22), which are parallel to each other, as well as a single countershaft (24). It is noted that reverse countershaft (40), which is used for reversal only, is not counted as a countershaft, per the Note in F16H 3/087. It is further noted that differential casing (15) is not considered an output shaft, since the differential is not part of the multi-speed transmission.

This place covers:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears, that can be disengaged from their shafts, including a single countershaft, with coaxial input and output shafts.

Illustrative example of subject matter classified in this place:

The Figure illustrates a four-speed transmission without gears having orbital motion and including continuously meshing gears that can be disengaged from their shafts. The transmission comprises an input shaft (15) and output shaft (16), which are coaxial to each other, as well as a single countershaft (17).

This place covers:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears, that can be disengaged from their shafts, with two or more countershafts.

Illustrative example of subject matter classified in this place:

The Figure illustrates a six-speed transmission without gears having orbital motion and including continuously meshing gears that can be disengaged from their shafts. The transmission comprises an input shaft (10), an output shaft (50) and two countershafts (20) and (30). It is noted that the differential housing (GFN) is not considered an output shaft, since the differential is not part of the multi-speed transmission.

This place covers:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears, that can be disengaged from their shafts, with two or more countershafts, each countershaft having an output gear meshing with a single common gear on the output shaft.

Illustrative example of subject matter classified in this place:

1a.

1b.

Figures 1a and 1b illustrate a multi-speed transmission without gears having orbital motion and including continuously meshing gears that can be disengaged from their shafts. The transmission comprises an input shaft (10), output shaft (11) and two countershafts (12) and (13). Countershafts (12) and (13) comprise output gears (26) and (33), respectively, meshing with a single common gear (27) on the output shaft.

Attention is drawn to the following places, which may be of interest for search:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears that can be disengaged from their shafts, with more than one output shaft |

This place covers:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears, that can be disengaged from their shafts, with two or more countershafts, with coaxial countershafts.

Illustrative example of subject matter classified in this place:

The Figure illustrates a five-speed transmission without gears having orbital motion and including continuously meshing gears that can be disengaged from their shafts. The transmission comprises an input shaft (1) and an output shaft (4) as well as two coaxial countershafts (2) and (5).

Attention is drawn to the following places, which may be of interest for search:

With countershafts coaxial with input or output shaft |

This place covers:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears, that can be disengaged from their shafts, with two or more countershafts, in which all or two or more of its countershafts comprising only one idle gear and one gear fixed to the respective countershaft.

Illustrative example of subject matter classified in this place:

The Figure illustrates a multi-speed transmission without gears having orbital motion and including continuously meshing gears that can be disengaged from their shafts. The transmission comprises four countershafts (28), (13), (17) and (22). Countershafts (28), (13) and (22) each include only one idle gear and one gear fixed to the respective countershaft. It is noted that reverse countershaft (R), which is used for reversal only, is not counted as a countershaft, per the Note in F16H 3/087.

This place covers:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears, that can be disengaged from their shafts, with two or more countershafts, in which all or two or more of its countershafts comprising only two idle gears and one gear fixed to the respective countershaft.

Illustrative example of subject matter classified in this place:

The Figure illustrates a multi-speed transmission without gears having orbital motion and including continuously meshing gears that can be disengaged from their shafts. The transmission comprises input shaft (15), output shaft (38), and five countershafts (16), (17), (18), (19) and (37), each of which comprises only two idle gears and one gear fixed to the respective countershaft. It is noted that reverse countershaft (39), which is used for reversal only, is not counted as a countershaft, per the Note in F16H 3/087.

This place covers:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears, that can be disengaged from their shafts, with two or more countershafts, with multiple gears on the input shaft directly meshing with respective gears on the output shaft.

Illustrative example of subject matter classified in this place:

The Figure illustrates a multi-speed transmission without gears having orbital motion and including continuously meshing gears that can be disengaged from their shafts. The transmission comprises an input shaft (Sm), an output shaft (Sc), and two countershafts (Ss1) and (Ss2). Gears (31), (48), and (50) on input shaft (Sm) are directly meshing with respective gears (32), (52), and (53) on output shaft (Sc). It is noted that differential casing (26) is not considered an output shaft.

This place covers:

Illustrative example of subject matter classified in this place:

The Figure illustrates a transmission without gears having orbital motion and including continuously meshing gears that can be disengaged from their shafts. Torque is simultaneously transmitted via both countershafts (14) and (16), i.e. torque is evenly distributed from the input shaft (32) to both countershafts (14) and (16).

This place covers:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears, that can be disengaged from their shafts, with two or more countershafts, the input and output shafts being aligned on the same axis.

Illustrative example of subject matter classified in this place:

The Figure illustrates a multi-speed transmission without gears having orbital motion and including continuously meshing gears that can be disengaged from their shafts. The transmission comprises two countershafts (4) and (6). It further comprises an input shaft (3) and an output shaft (1) which are coaxial.

This place covers:

Illustrative example of subject matter classified in this place:

The Figure illustrates a three-speed transmission without gears having orbital motion and including continuously meshing gears that can be disengaged from their shafts. The transmission comprises three one-way clutches (5a), (6a), and (7a) in addition to three friction clutches (5b), (6b) and (7b). During a shift of the transmission, the one-way clutches (5a), (6a), and (7a) allow an off-going friction clutch to remain engaged for a brief time while an on-coming friction clutch engages.

Attention is drawn to the following places, which may be of interest for search:

Gearings for conveying rotary motion with intermittently-driving members, e.g. with freewheel action | |

Other gearings with freewheeling members or other intermittently driving members | |

Freewheels or freewheel clutches per se |

Attention is drawn to the following places, which may be of interest for search:

Synchronised clutches |

This place covers:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears that can be disengaged from their shafts, with means for synchronisation not incorporated in the clutches, using a brake.

Illustrative example of subject matter classified in this place:

The Figure illustrates a multi-speed transmission without gears having orbital motion and including continuously meshing gears that can be disengaged from their shafts. The transmission comprises a brake (26) which is engaged during upshifts in order to reduce the speed of input shaft (2).

Attention is drawn to the following places, which may be of interest for search:

Synchronisation before shifting by control of shaft brakes |

This place covers:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially with continuously meshing gears, that can be disengaged from their shafts, with means for synchronisation not incorporated in the clutches, using an electric drive.

Illustrative example of subject matter classified in this place:

The Figure illustrates a six-speed transmission without gears having orbital motion and including continuously meshing gears that can be disengaged from their shafts. The transmission uses electric motor (29) as means for synchronisation.

Attention is drawn to the following places, which may be of interest for search:

Synchronisation before shifting by an electric machine, e.g. by accelerating or braking the input shaft |

This place covers:

Illustrative example of subject matter classified in this place:

The Figure illustrates a transmission without gears having orbital motion and including continuously meshing gears that can be disengaged from their shafts. The transmission includes one forward speed via meshing gears (3) and (4), and one reverse speed via meshing gears (7), (8) and (10).

Attention is drawn to the following places, which may be of interest for search:

Toothed gearings for reversal only, without gears having orbital motion, essentially with both gears that can be put out of gear and continuously-meshing gears that can be disengaged from their shafts | |

Toothed gearings for reversal only, without gears having orbital motion, exclusively or essentially using gears that can be moved out of gear | |

Combinations of toothed gearings only, with change gear transmissions in group arrangement, without gears having orbital motion, comprising a separate gearing unit for shifting between forward or reverse | |

Combinations of toothed gearings only, with forward-reverse units with forward and reverse gears for achieving multiple forward and reverse gears, e.g. for working machines |

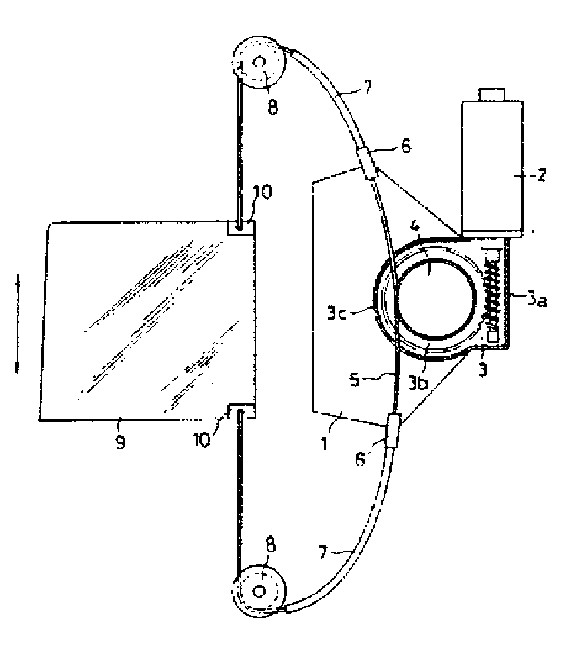

This place covers:

Illustrative example of subject matter classified in this place:

1a.

1b.

Figures 1a and 1b illustrate a transmission without gears having orbital motion. The transmission includes bevel gears (2) and (3) which are continuously meshing with gear (6). This allows bevel gears (2) and (3) to rotate in opposite directions. Bevel gears (2) and (3) can be disengaged from shafts (12a) and (12b), respectively, as shaft assembly (7) is moved axially.

Attention is drawn to the following places, which may be of interest for search:

Gearings for reversal only using gears having orbital motion |

In this group, gears which can be put out of mesh are not taken into consideration if they are used for reversal only.

In this group, gears which can be put out of mesh are not taken into consideration if they are used for reversal only.

This place covers:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially using gears that can be moved out of gear, with gears shiftable only axially, with driving and driven shafts coaxial.

Illustrative example of subject matter classified in this place:

The Figure illustrates a multi-speed transmission without gears having orbital motion. The transmission includes an input shaft (2) and an output shaft (3), which is coaxial to input shaft (2). Each of gears (19), (20) and (21) is axially shiftable such that they can be moved in and out of gear.

This place covers:

Toothed gearings for conveying rotary motion with variable gear ratio or for reversing rotary motion, without gears having orbital motion, exclusively or essentially using gears that can be moved out of gear, with gears shiftable only axially, with driving and driven shafts not coaxial.

Illustrative example of subject matter classified in this place:

The Figure illustrates a multi-speed transmission without gears having orbital motion. The transmission includes an input shaft (1) and an output shaft (2), which is not coaxial to input shaft (1). Each of gears (3), (4), (5), (6), (17), (18), (19) and (20) is axially shiftable such that they can be moved in and out of gear.

This place covers:

Illustrative example of subject matter classified in this place:

The Figure illustrates a multi-speed transmission without gears having orbital motion. The transmission includes an input shaft (3) and an output shaft (5). Each of gears (9) and (10) is shiftable in a circumferential direction such that they can be moved in and out of gear.

This place covers:

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates a multi-speed transmission without gears having orbital motion. The transmission includes coaxial gears (16a-16k) have conical teeth and are arranged on a surface of generally conical shape.

2.

Figure 2 illustrates a multi-speed transmission without gears having orbital motion. The transmission includes coaxial gears (18), which do not have conical teeth, but are arranged on a surface of generally conical shape.

This place covers:

Illustrative example of subject matter classified in this place:

The Figure illustrates a multi-speed transmission without gears having orbital motion. The transmission includes three coaxial gears arranged on flat disc-type surface (12) which engage with the gear on (16).

Attention is drawn to the following places, which may be of interest for search:

Constructional features of the final output mechanisms for reversing |

This place covers:

Illustrative example of subject matter classified in this place:

1a.

1b. Forward gear

1c. Reverse gear