CPC Definition - Subclass B21C

This place covers:

The methods and devices for working metal as follows:

- Metal drawing (covered by B21C 1/00 - B21C 19/00);

- Metal extrusion (covered by B21C 23/00 - B21C 35/00);

- Methods for manufacturing metal sheets, rods, wires, tubes or the like, not otherwise provided for (covered by B21C 37/00);

- Devices for cleaning metal products adapted for use with machines of this subclass (covered by B21C 43/00);

- Separating mandrels from work (covered by B21C 45/00);

- Winding-up, coiling, winding-off metal wire or metal band (covered by B21C 47/00);

- Devices for temporarily accumulating material (covered by B21C 49/00);

- Measuring, gauging, indicating, counting or marking devices adapted for use with subclasses B21B - B21F (covered by B21C 51/00);

- Other subject-matter concerning the manufacture of metal sheets, wire, rods, tubes or profiles otherwise than by rolling as well as other subject-matter concerning auxiliary operations used in connection with metal-working without essentially removing material (covered by B21C 99/00).

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Attention is drawn to the following places, which may be of interest for search:

Devices for cleaning in general | |

Rolling of metal | |

Working or processing of sheet metal or metal tubes, rods or profiles without essentially removing material; Punching metal | |

Making forged or pressed metal products | |

Continuous casting | |

Soldering, welding, flame-cutting | |

Pressure welding by means of a rolling mill | |

Metal-working not otherwise provided for; Combined operations | |

Transport or storage devices, e.g. conveyors for loading | |

Handling thin or filamentary material, e.g. sheets, webs, cables |

This place covers:

Methods, devices and drives for metal drawing of metal sheets, metal wire, metal rods, metal bars, metal tubes or like semi-manufactured products.

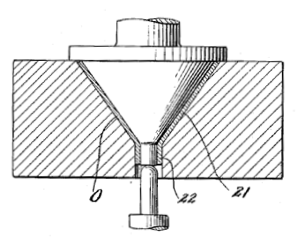

Metal drawing consists in reducing the cross-section of a work piece (e.g. reducing the diameter of a metal rod or wire) by forcing it through a die. Metal drawing differs from extrusion by the lower rate of reduction.

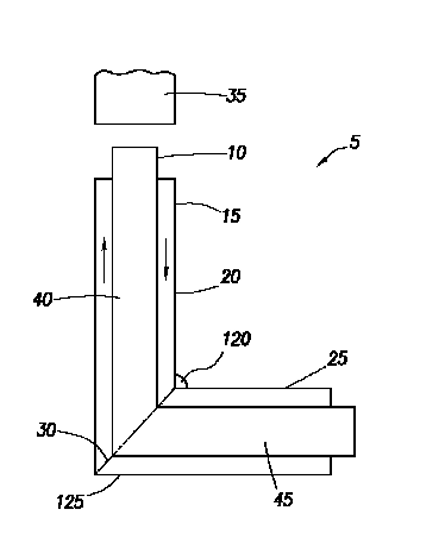

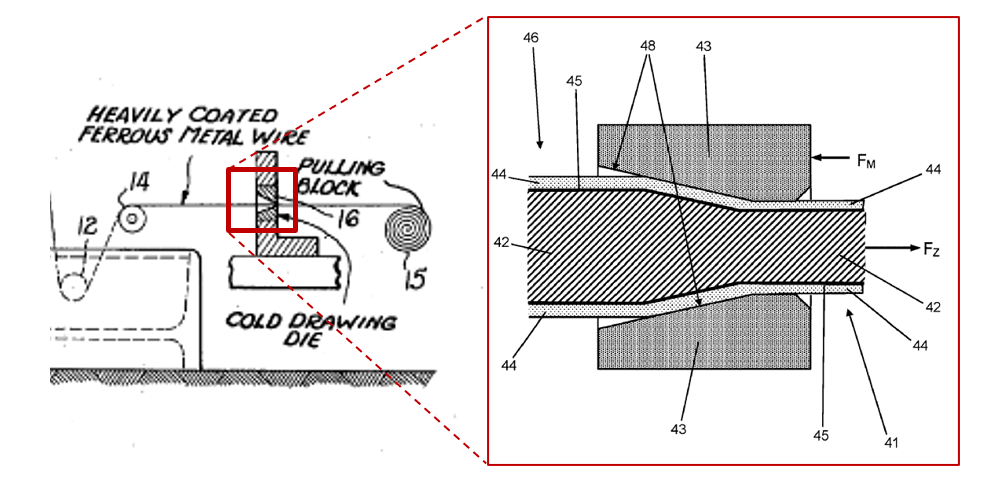

Illustrative example of subject matter classified in this place:

This place covers:

Drawing special alloys with the purpose, for example, of modifying the physical properties of such alloys, and all special drawing methods therefor.

Illustrative example of subject matter classified in this place:

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Attention is drawn to the following places, which may be of interest for search:

Ropes or cables built-up from metal wires, e.g. of section wires around a hemp core, the wires being characterised by an anti-corrosive or adhesion promoting coating |

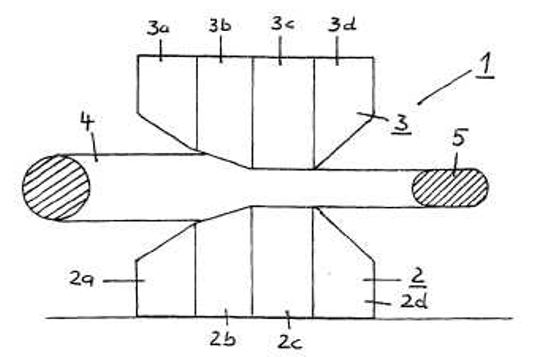

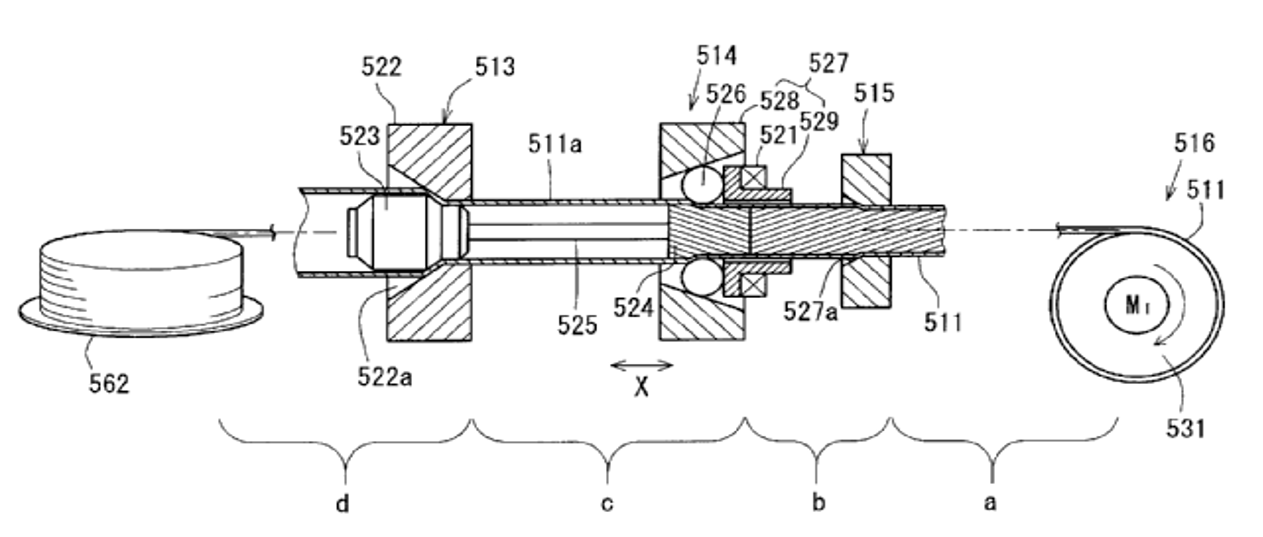

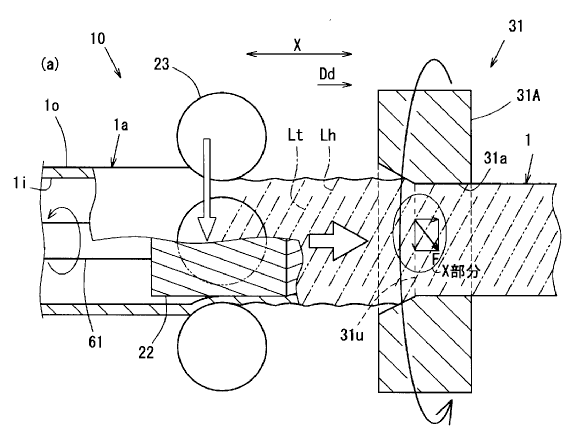

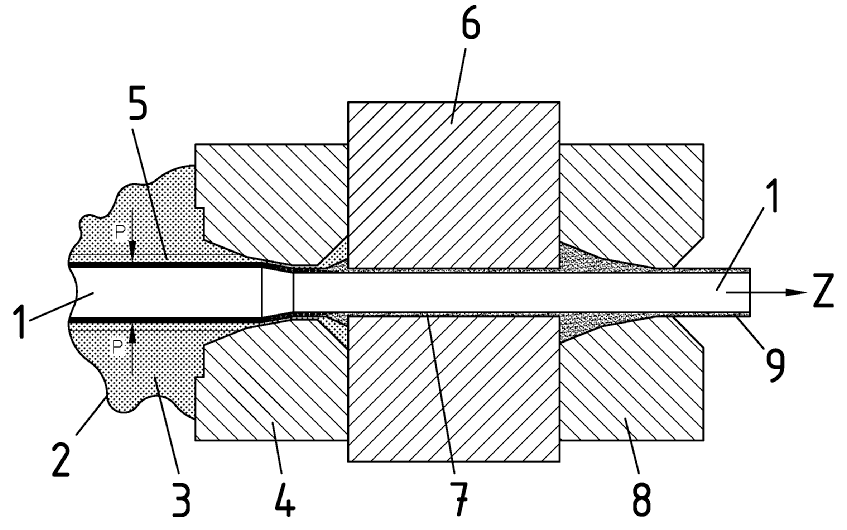

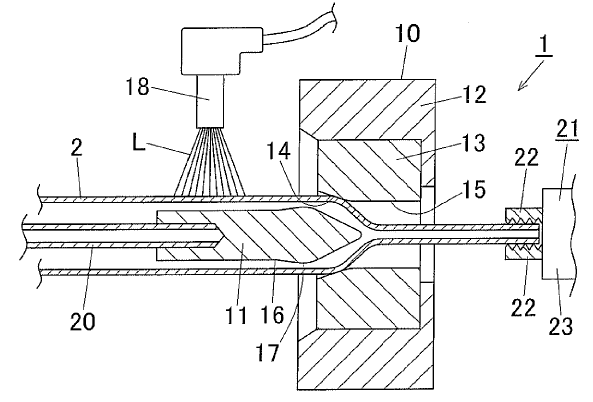

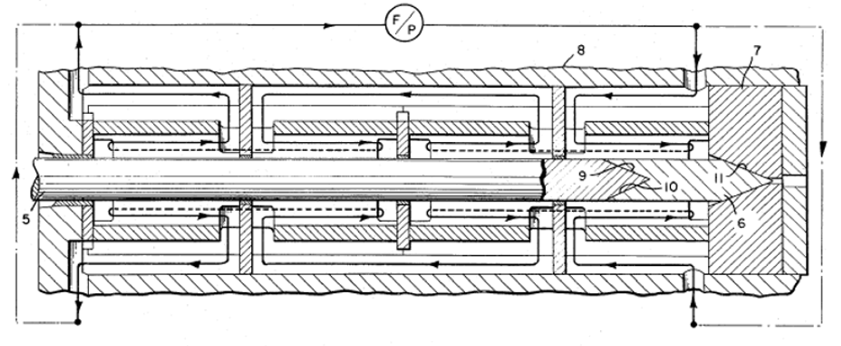

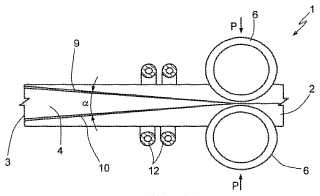

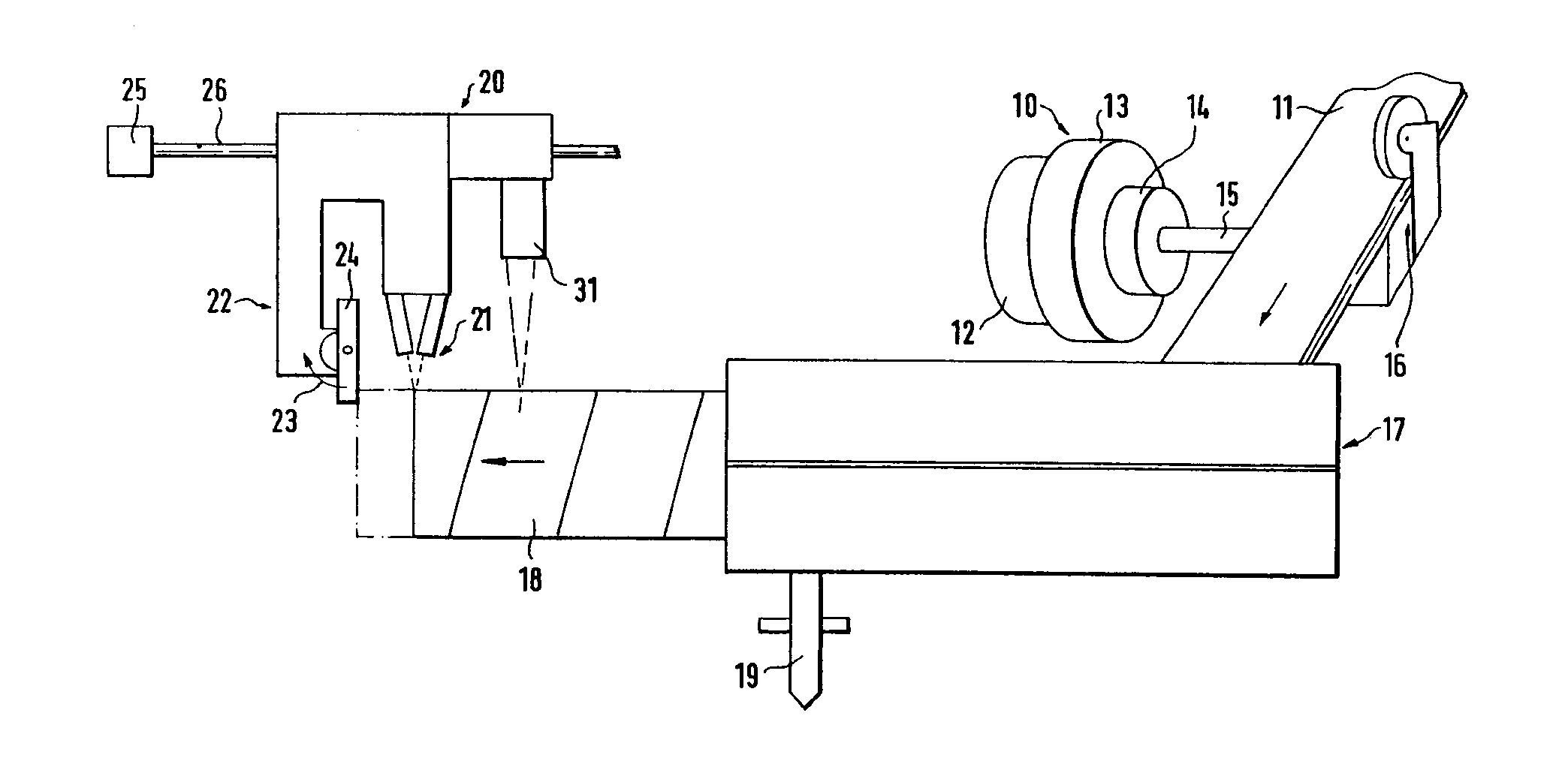

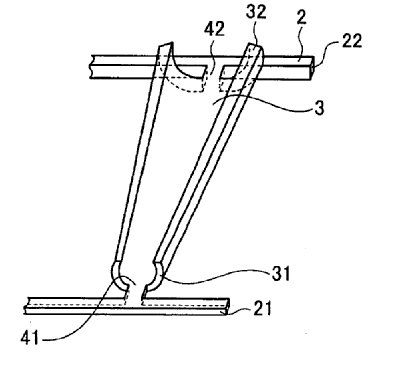

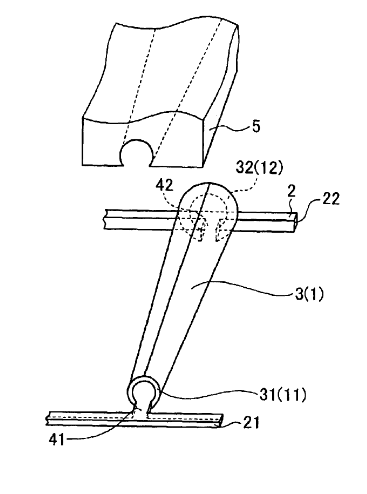

This place covers:

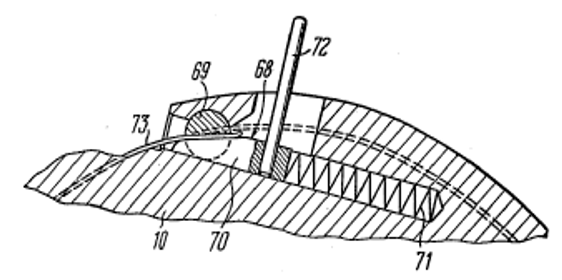

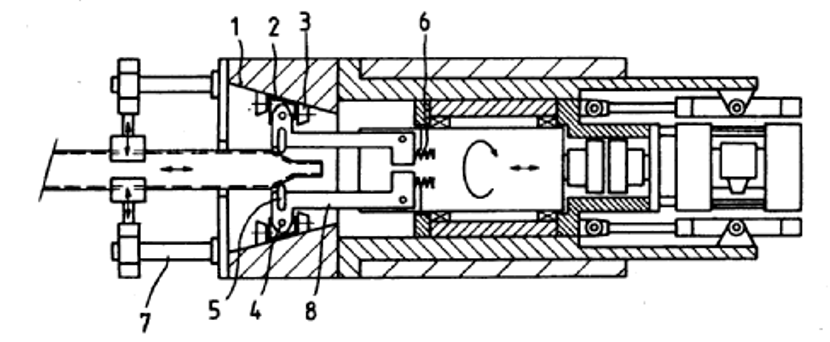

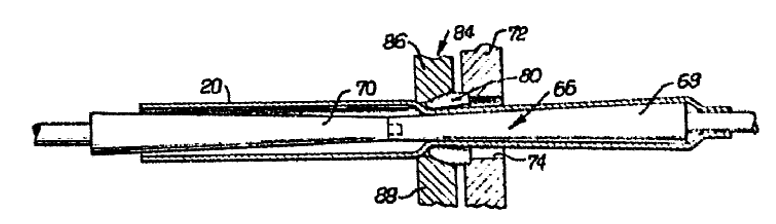

Drawing metal sheets, metal wire, metal rods, metal tubes applying vibratory energy, for example, to the mandrel or the dies.

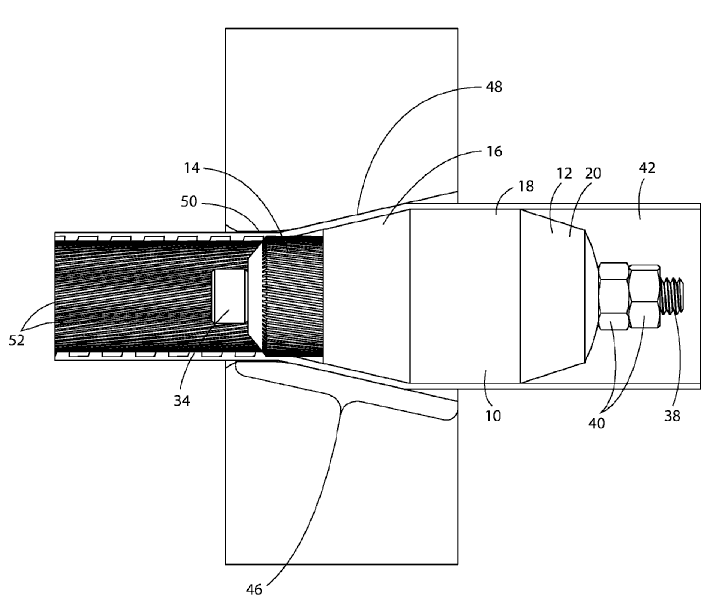

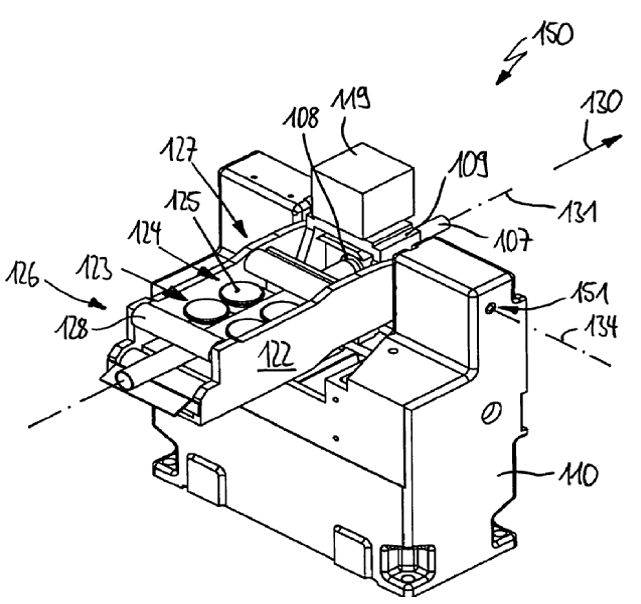

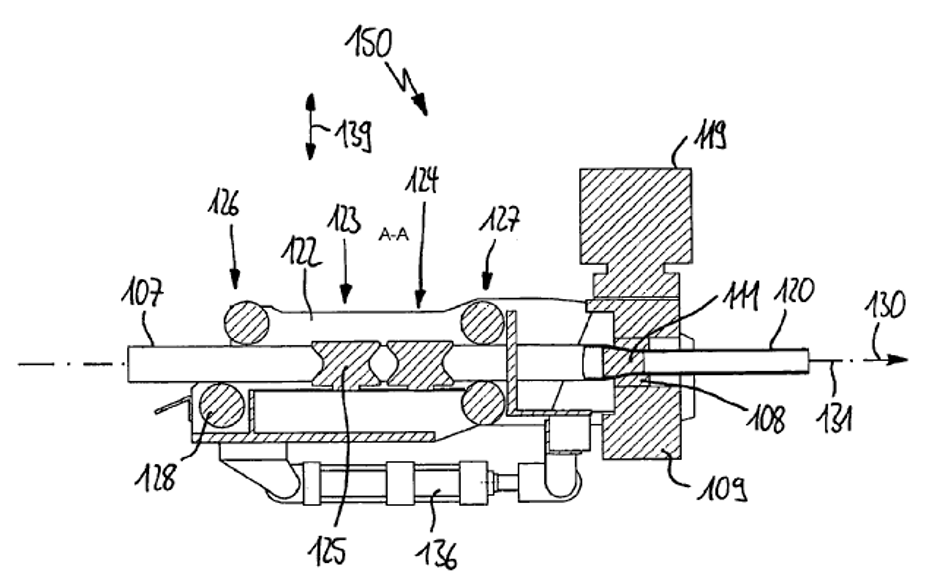

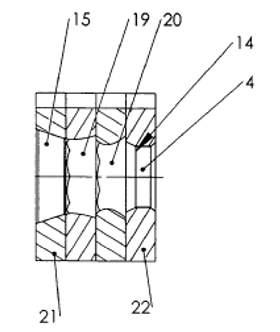

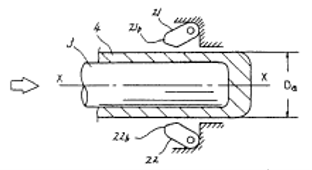

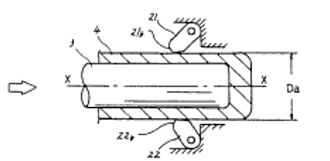

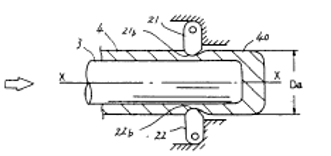

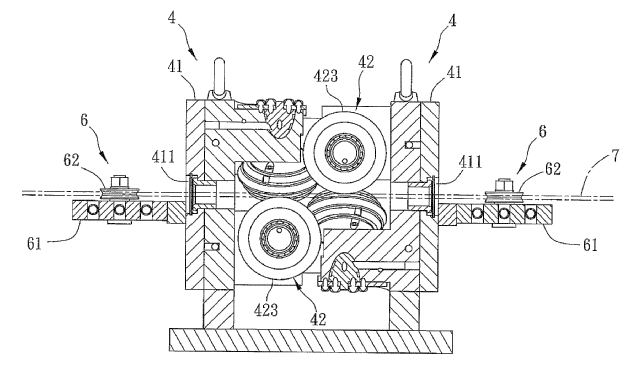

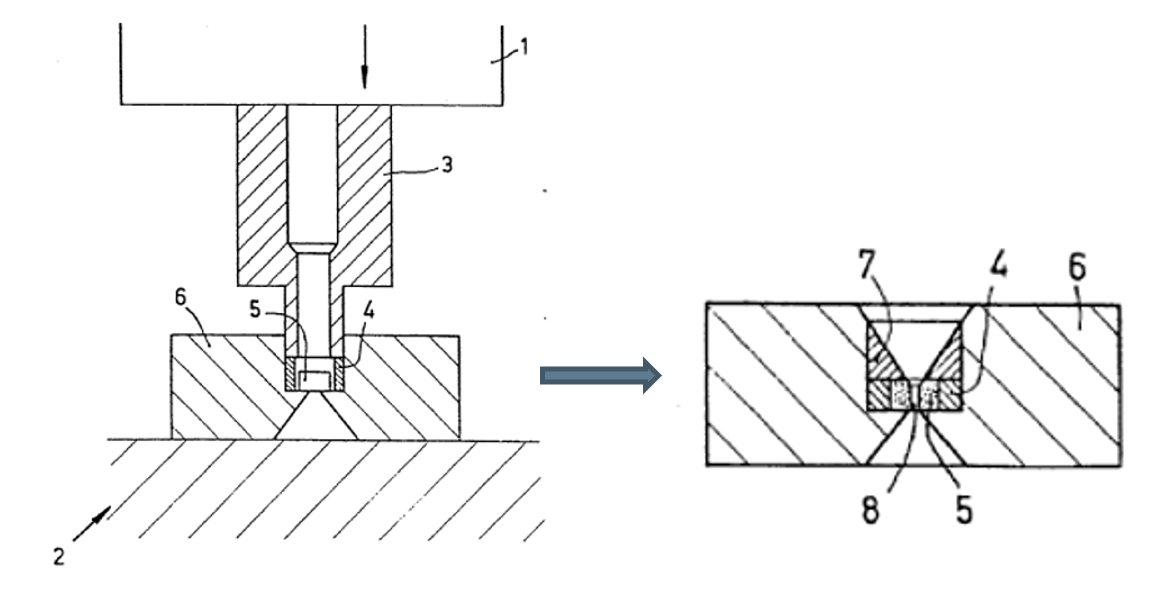

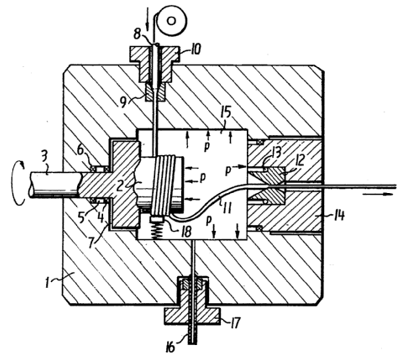

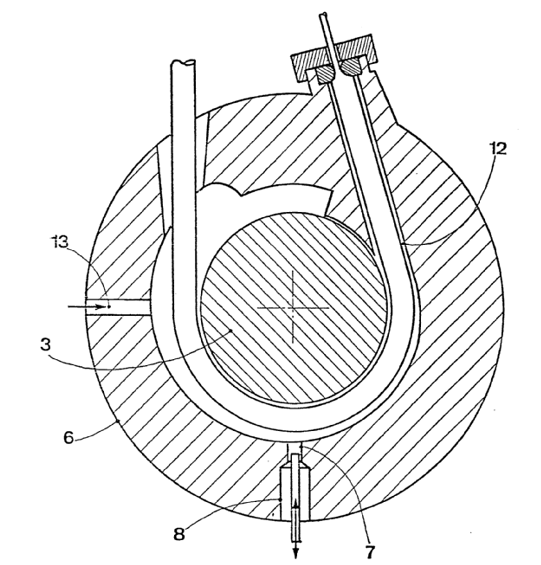

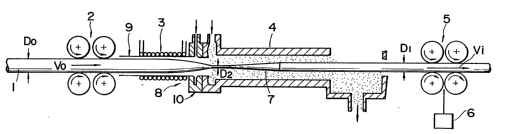

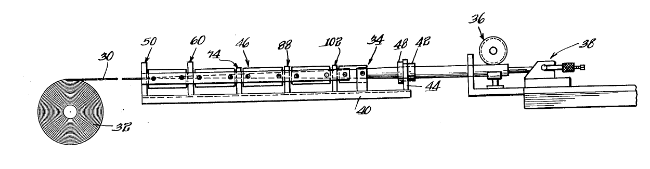

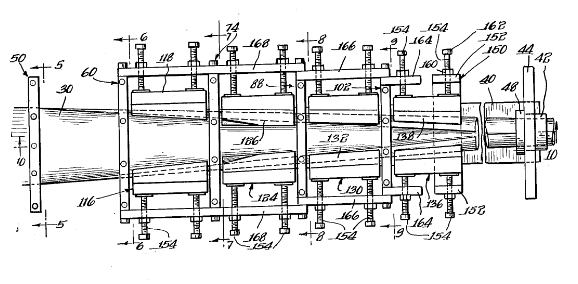

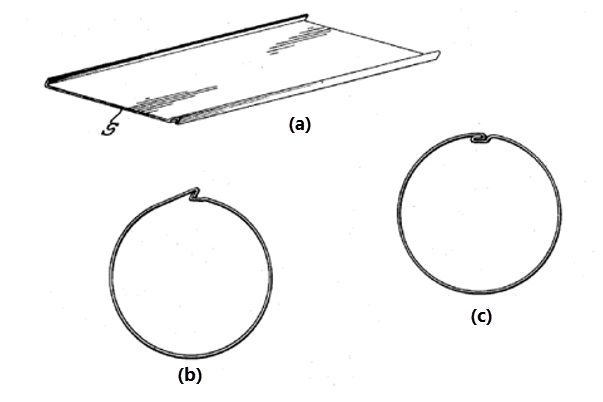

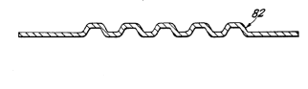

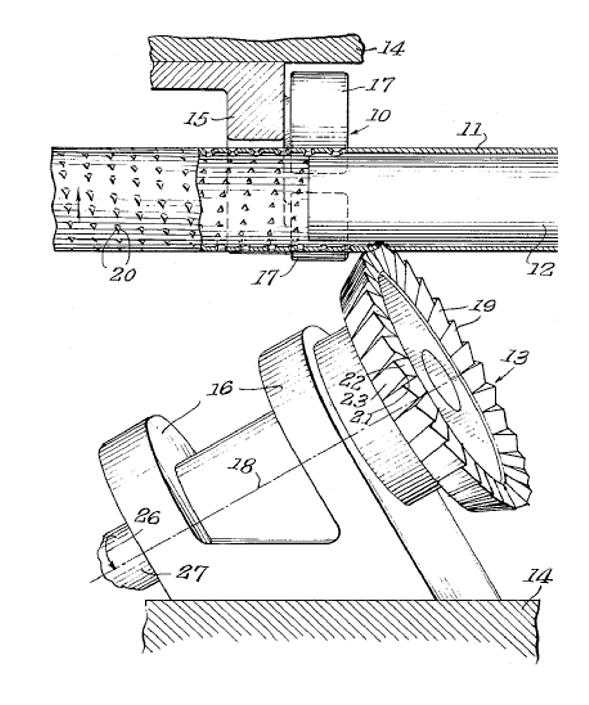

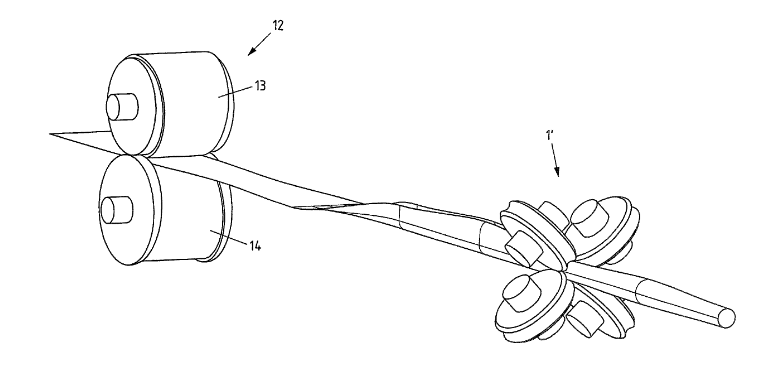

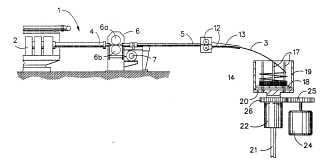

Illustrative examples of subject matter classified in this place:

1.

2.

This place covers:

Illustrative examples of subject matter classified in this place:

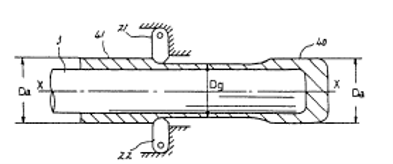

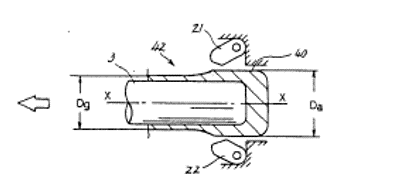

1.

2.

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

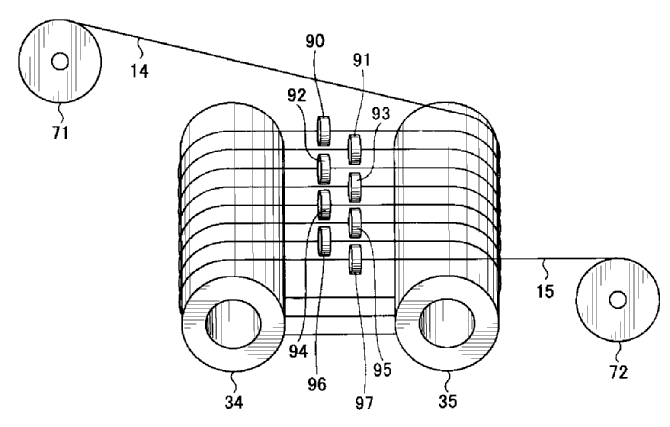

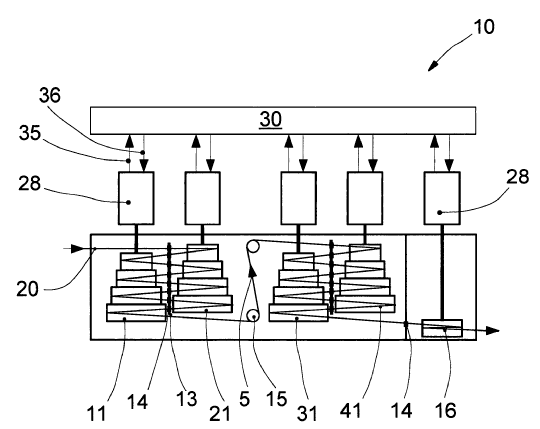

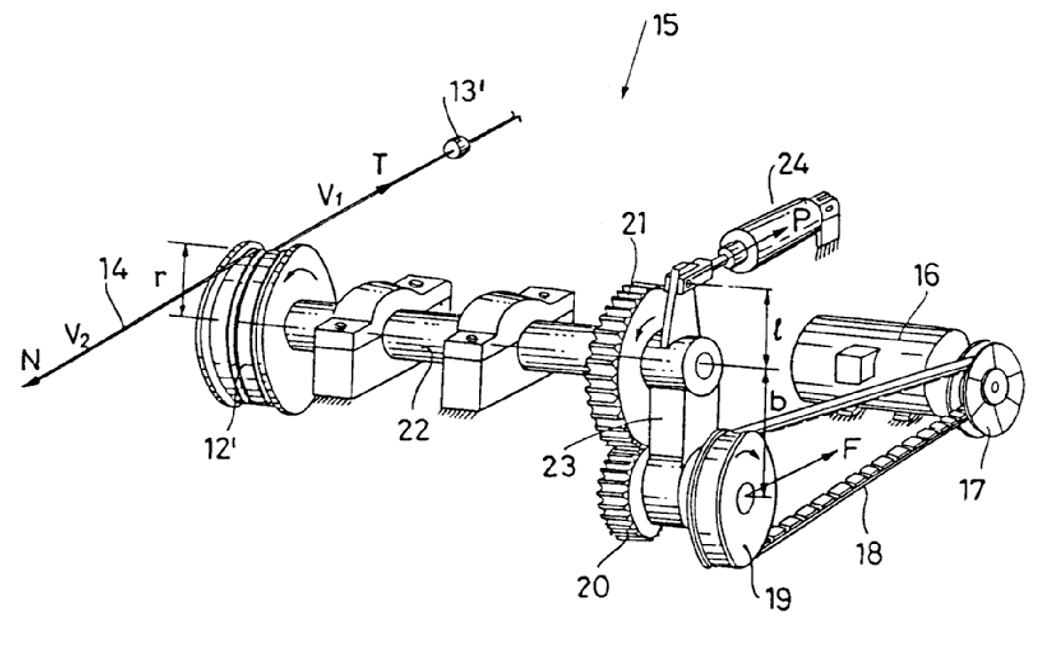

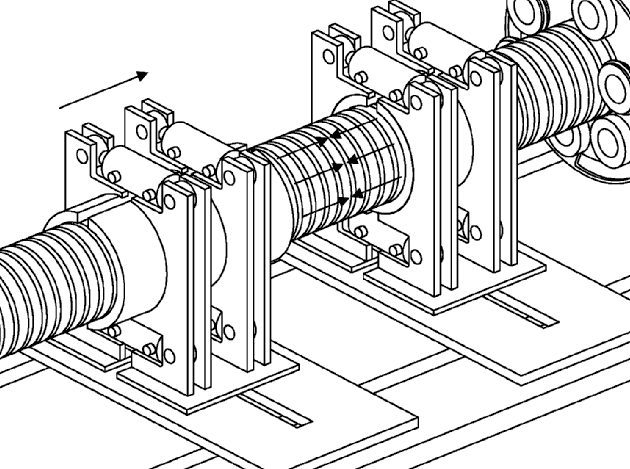

This place covers:

Wire drawing devices and methods whereby positive slip ensures that all portions of the wire are taut and that there is adequate frictional force exerted on the wire by the drums to pull the wire through the dies.

Illustrative example of subject matter classified in this place:

This place covers:

Wire drawing devices and methods whereby wire slips on the drawing drums are eliminated.

Illustrative example of subject matter classified in this place:

This place covers:

Wire drawing devices and methods whereby a certain amount of wire is accumulated in order, for example, to allow steady operation of the machine, even though the speeds of the various drums are not in exact proportion to the elongation of the wire.

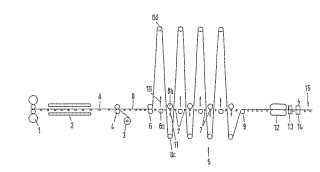

Illustrative examples of subject matter classified in this place:

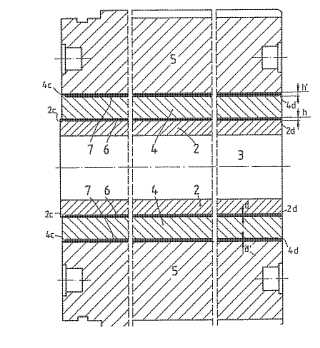

1.

2.

Attention is drawn to the following places, which may be of interest for search:

Devices for temporarily storing filamentary material during forwarding, e.g. for buffer storage |

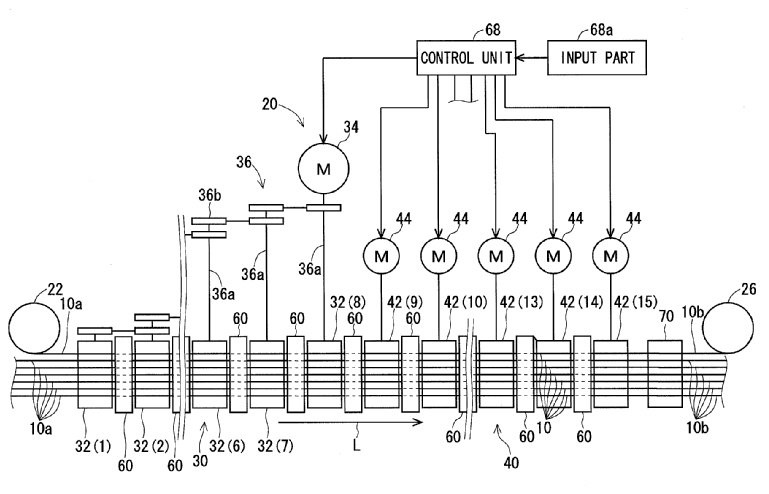

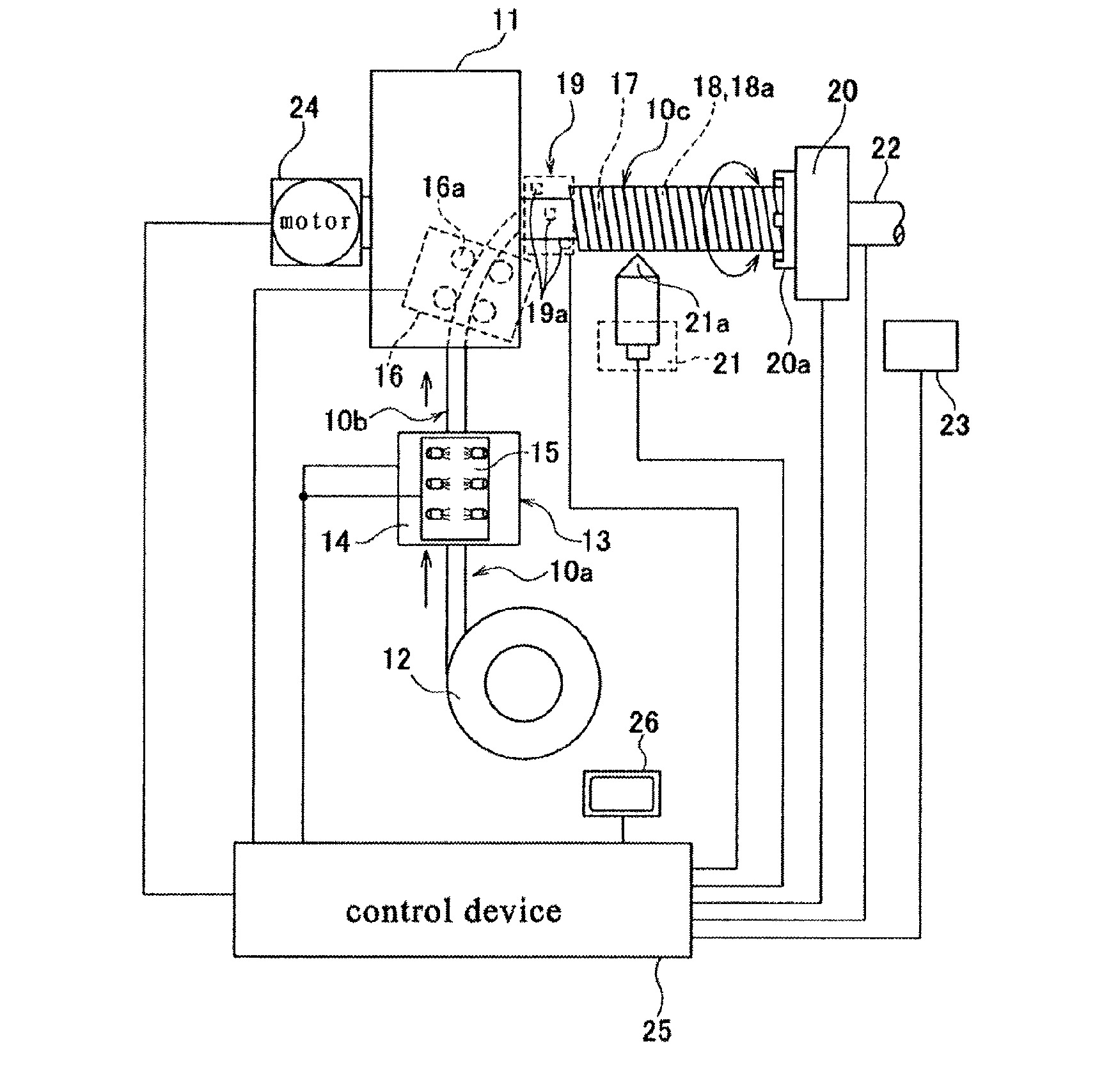

This place covers:

- Wire drawing devices and methods, whereby drums are controlled to apply the correct tension on the wire;

- Details of drives for drums; and

- Stop or relief mechanisms.

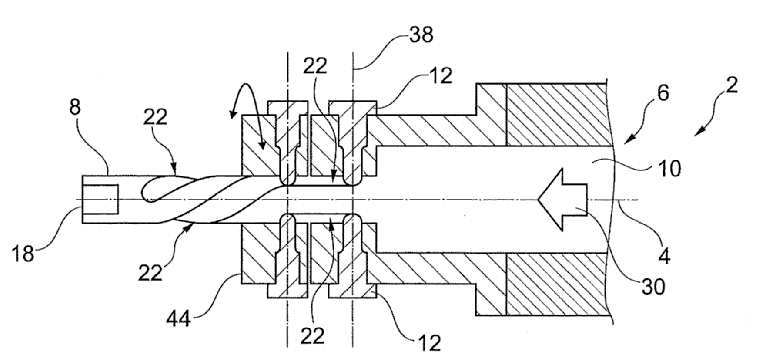

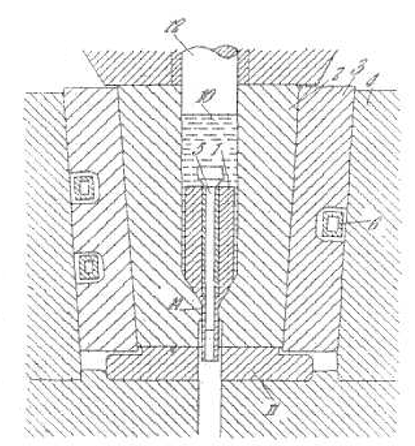

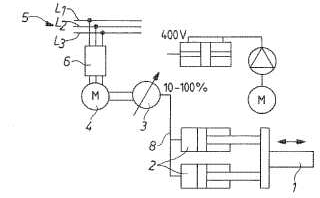

Illustrative examples of subject matter classified in this place:

1.

2.

Attention is drawn to the following places, which may be of interest for search:

Couplings for drums |

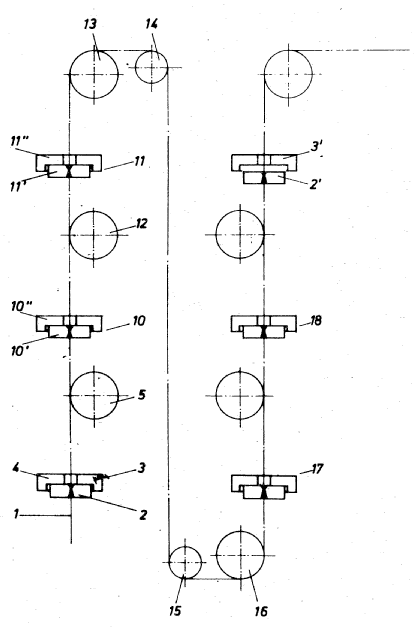

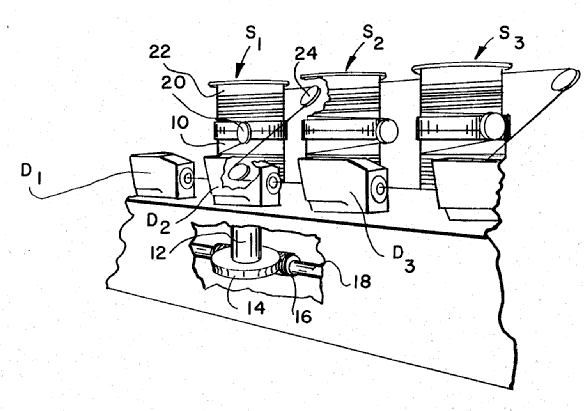

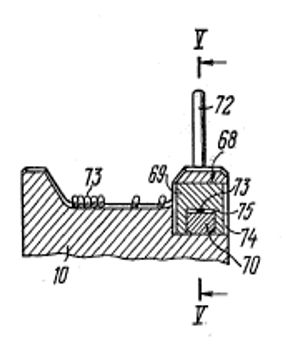

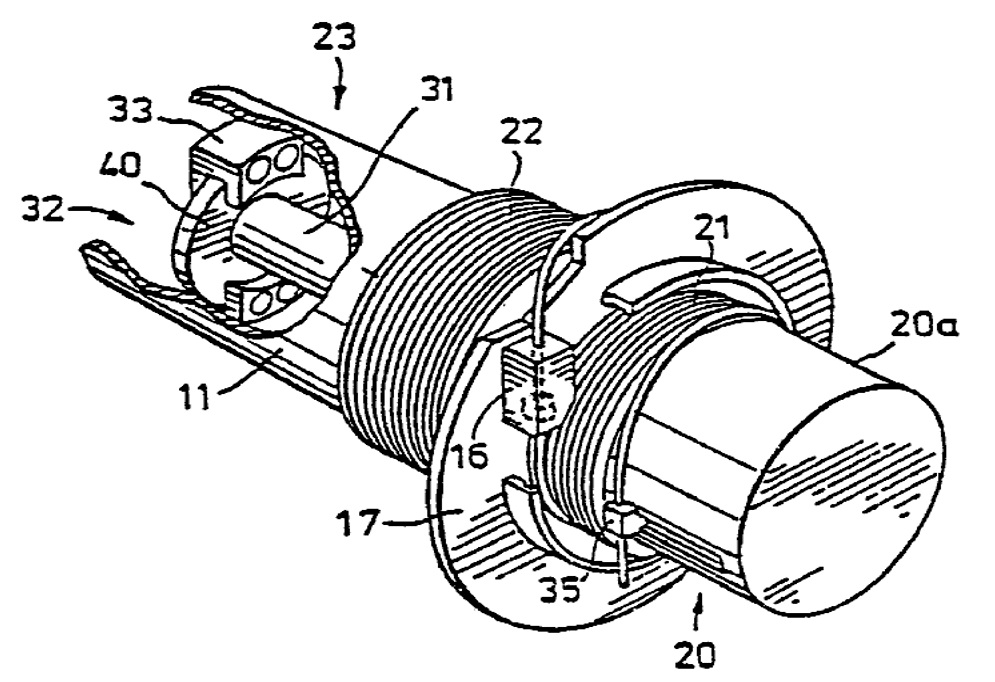

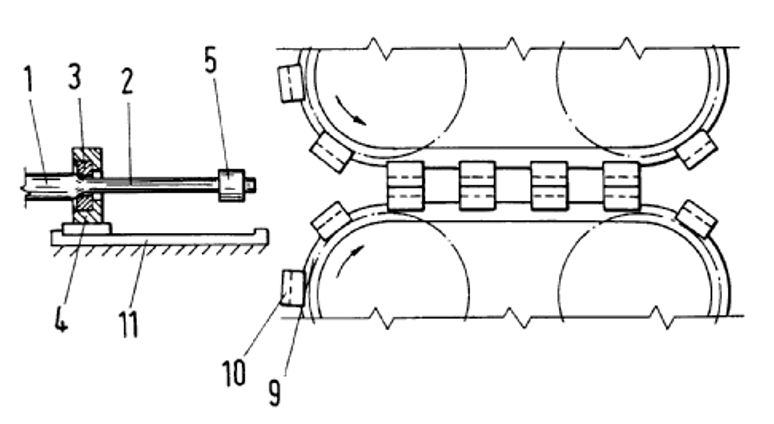

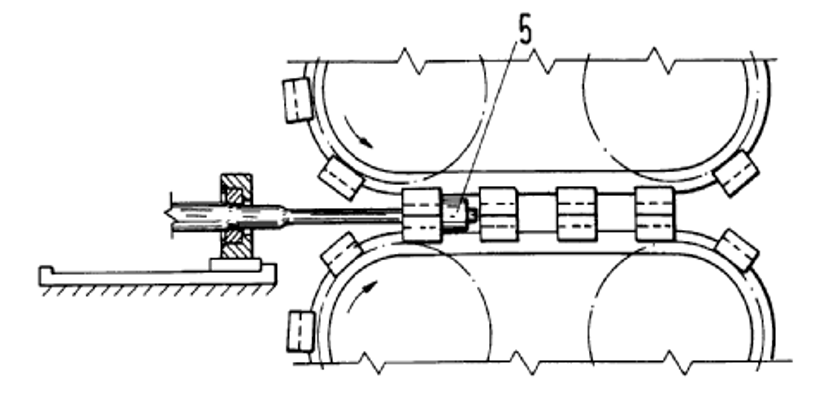

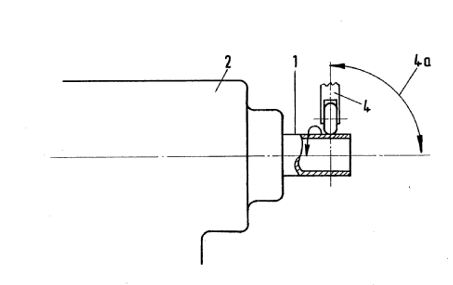

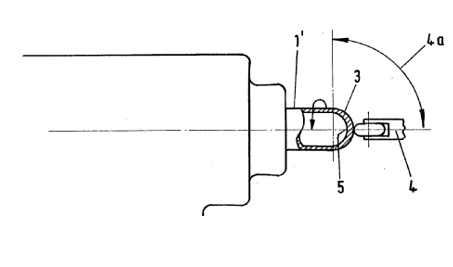

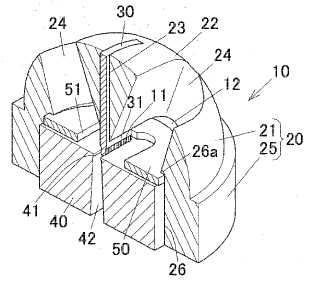

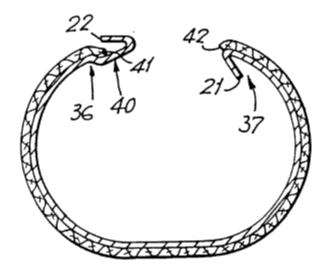

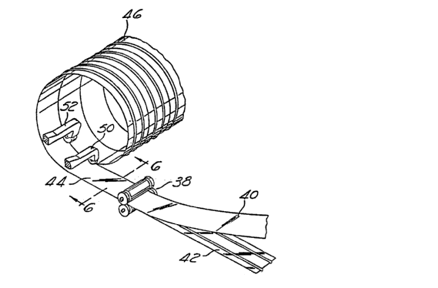

This place covers:

Wire drawing capstans and gripping means cooperating with said capstans.

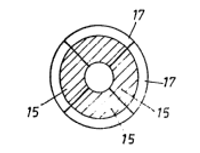

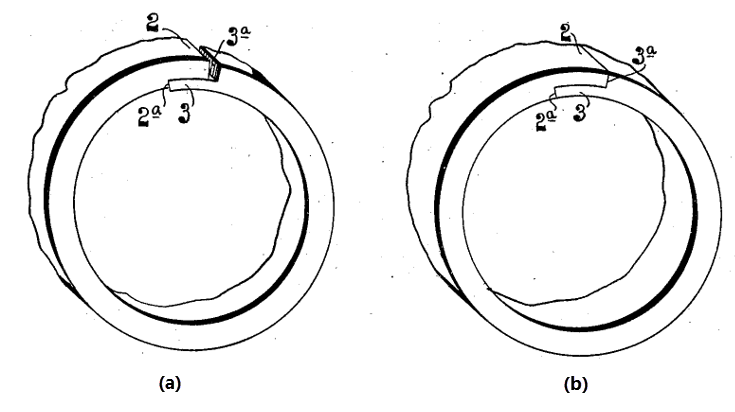

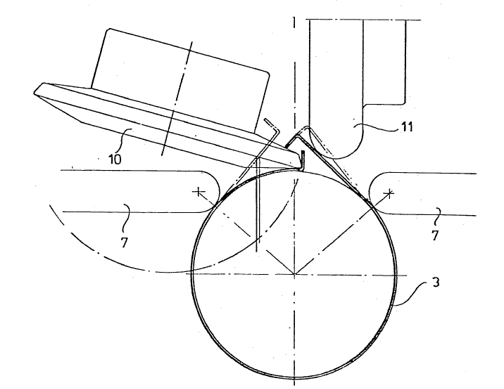

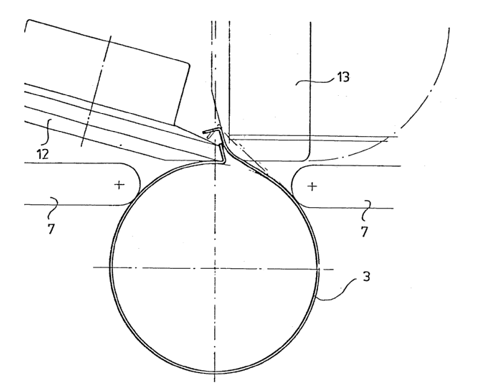

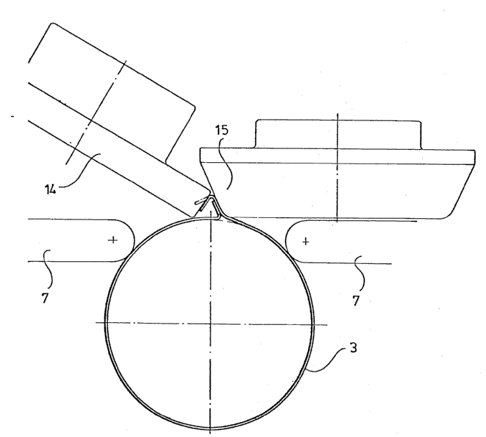

Illustrative examples of subject matter classified in this place:

1.

2a.

2b.

3.

Attention is drawn to the following places, which may be of interest for search:

Capstans or winches in general |

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

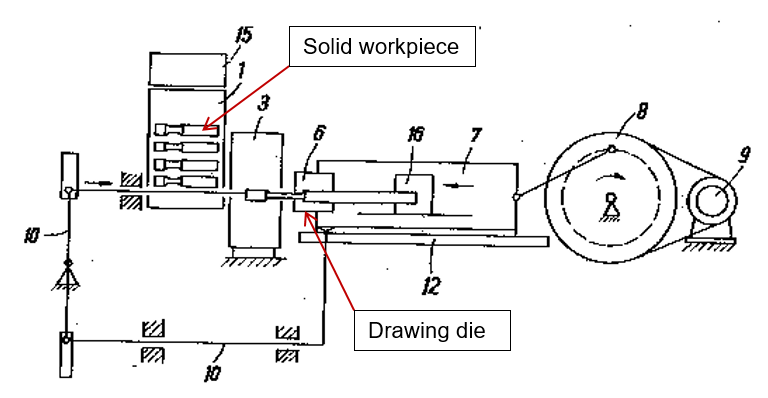

This place covers:

Drawing devices and methods from solid stocks of limited length.

Illustrative example of subject matter classified in this place:

This place does not cover:

Metal drawing by machines specially adapted for making tubular articles |

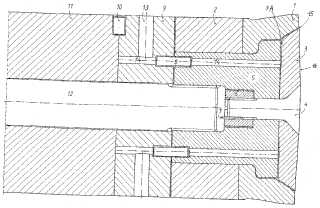

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

This place does not cover:

Metal drawing by machines specially adapted for making tubular articles |

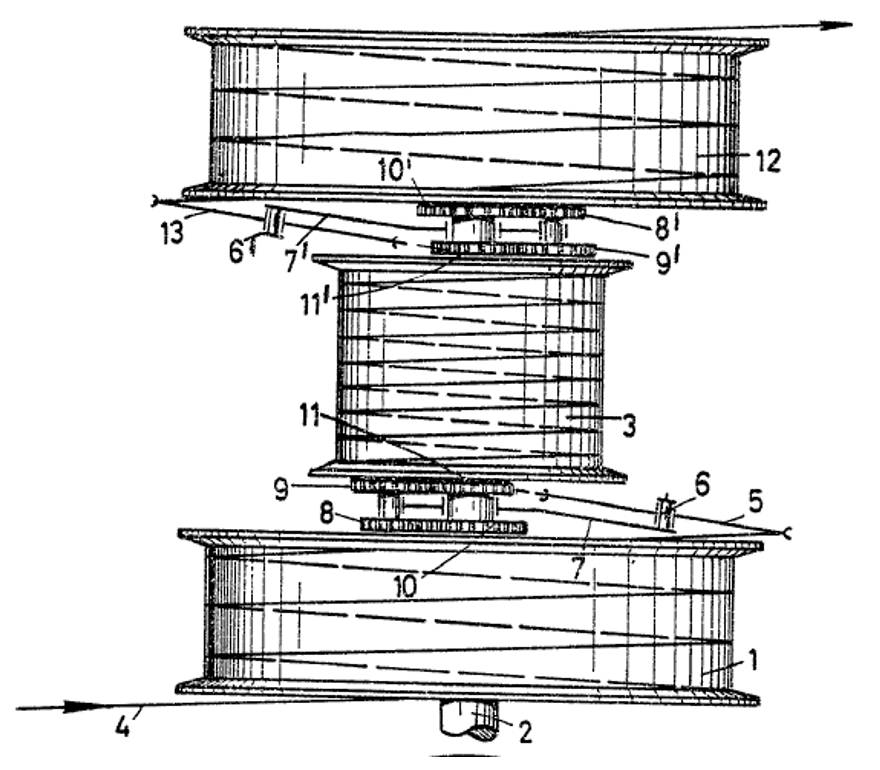

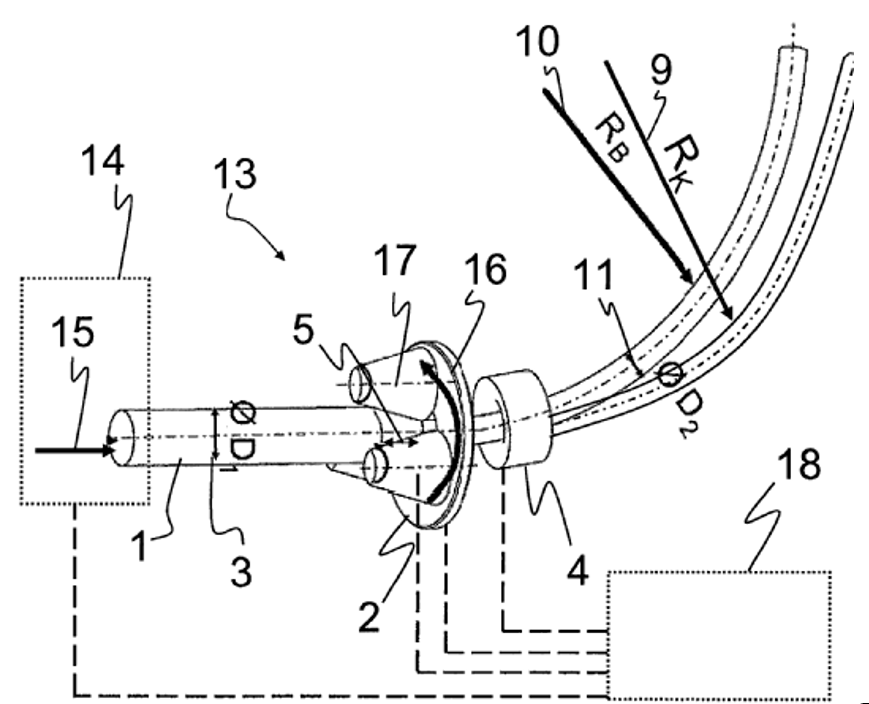

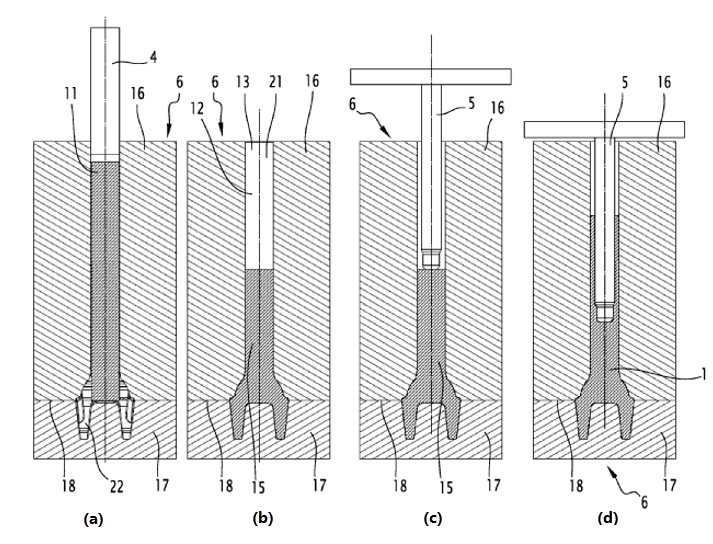

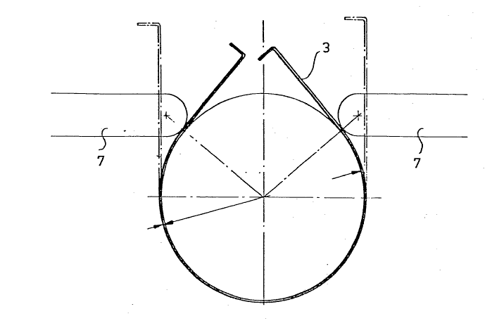

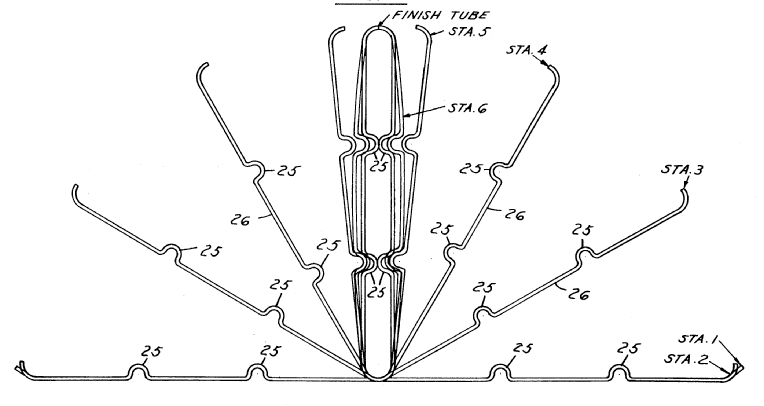

This place covers:

Drawing devices and methods specially adapted for making tubular articles, also starting from stock of limited length.

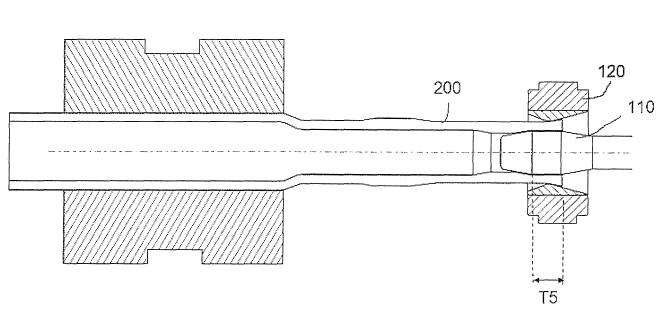

Illustrative example of subject matter classified in this place:

This place does not cover:

Bending sheet metal into tubular form by drawing |

Attention is drawn to the following places, which may be of interest for search:

Metal tube-rolling not restricted to methods provided for in only one of groups B21B 17/00, B21B 19/00, B21B 21/00, e.g. combined processes | |

Rigid pipes wound from sheets or strips, with or without reinforcement, made of metal |

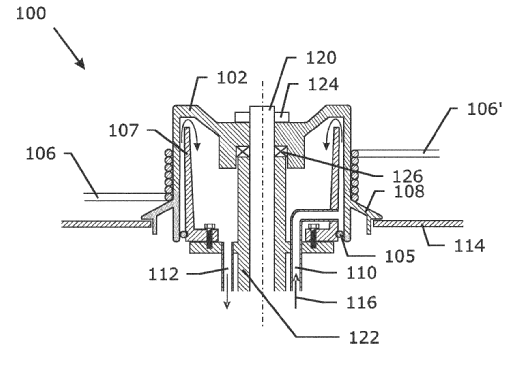

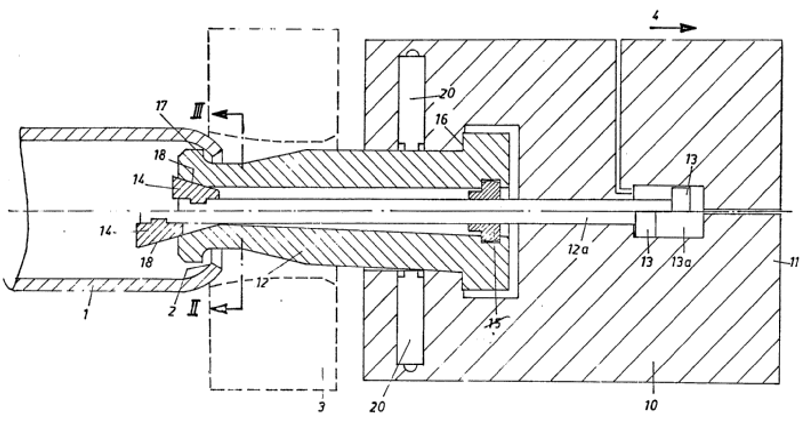

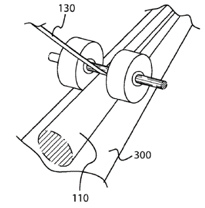

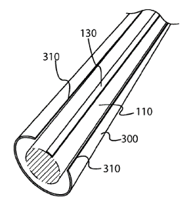

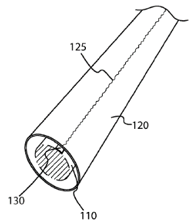

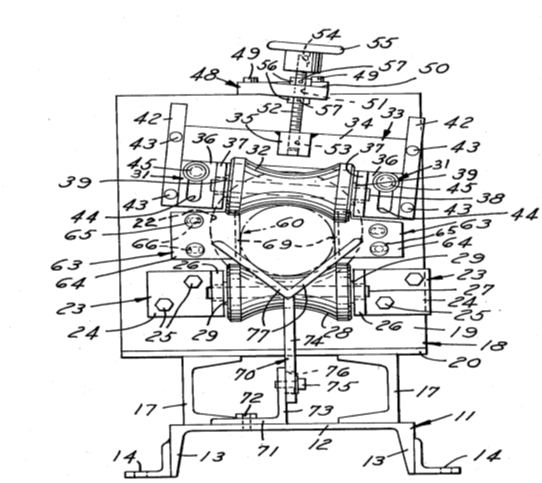

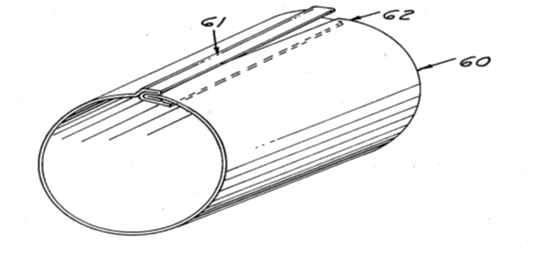

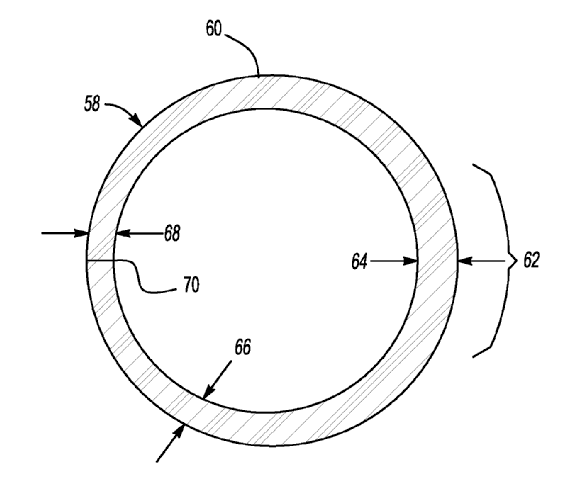

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2a.

2b.

Attention is drawn to the following places, which may be of interest for search:

Mandrels | |

Making helical or similar guides in or on tubes without removing material, e.g. by drawing same over mandrels, by pushing same through dies; Making tubes with angled walls, ribbed tubes or tubes with decorated walls |

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

Attention is drawn to the following places, which may be of interest for search:

Mandrels; Mounting or adjusting same | |

Metal tube-rolling not restricted to methods provided for in only one of groups B21B 17/00, B21B 19/00, B21B 21/00, e.g. combined processes | |

Shaping metal without cutting, by deep-drawing |

This place covers:

Illustrative example of subject matter classified in this place:

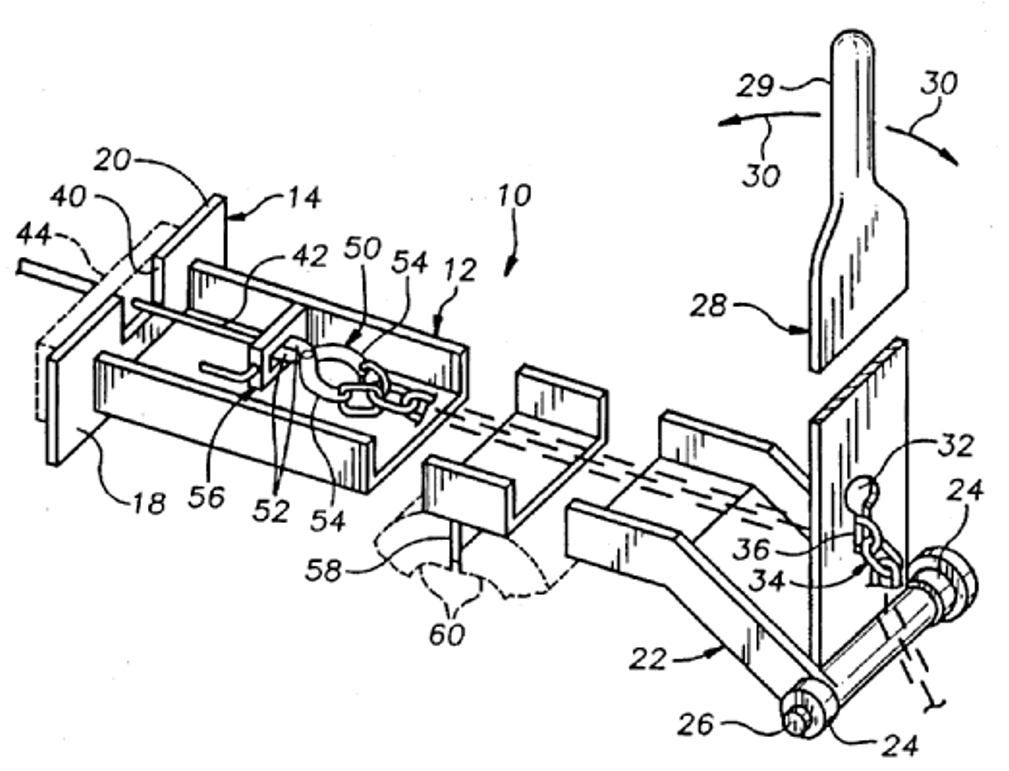

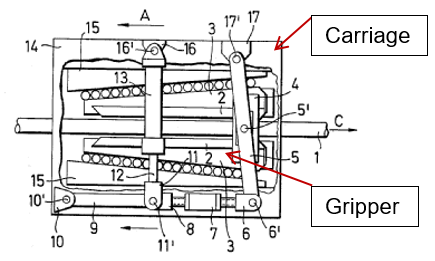

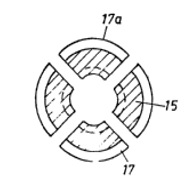

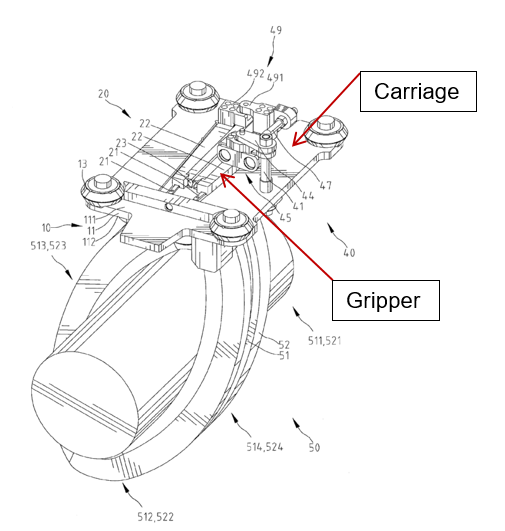

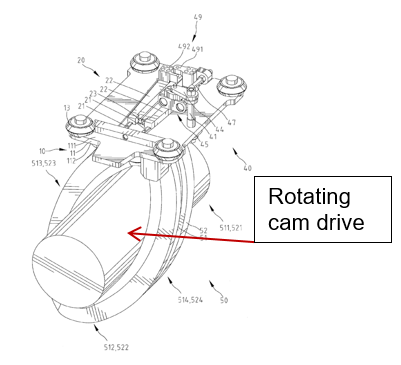

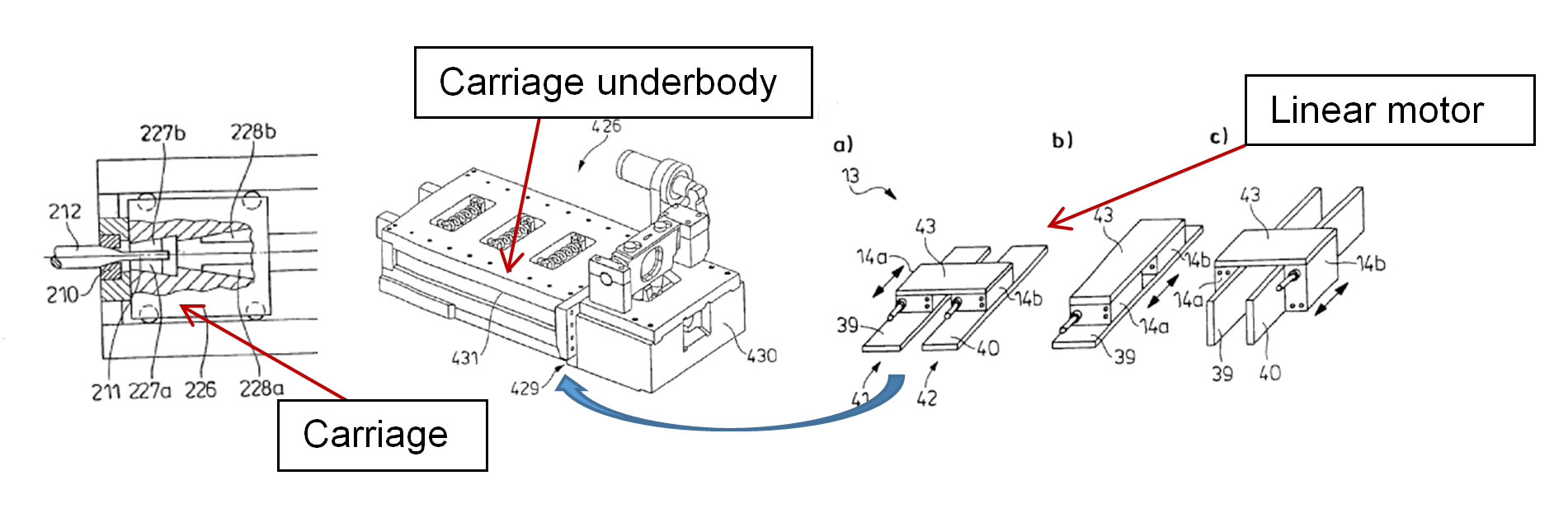

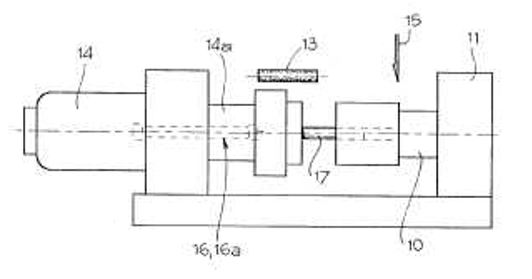

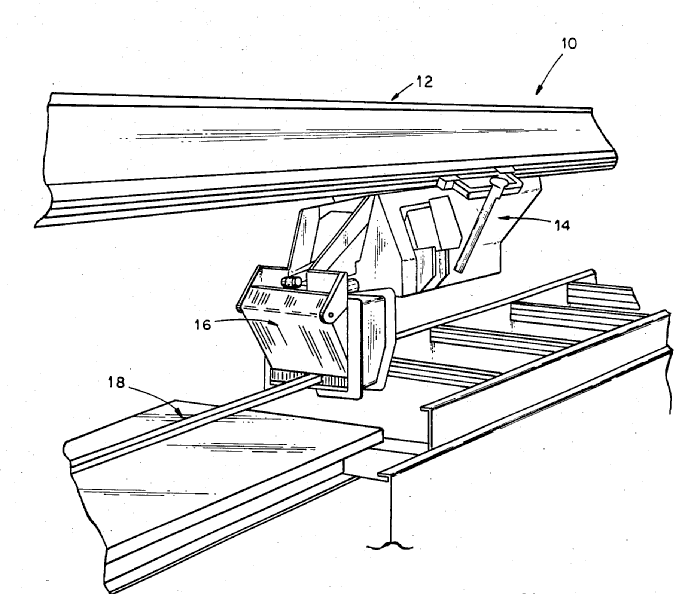

This place covers:

Illustrative examples of subject matter classified in this place:

1.

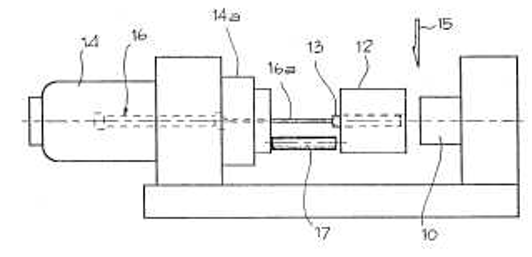

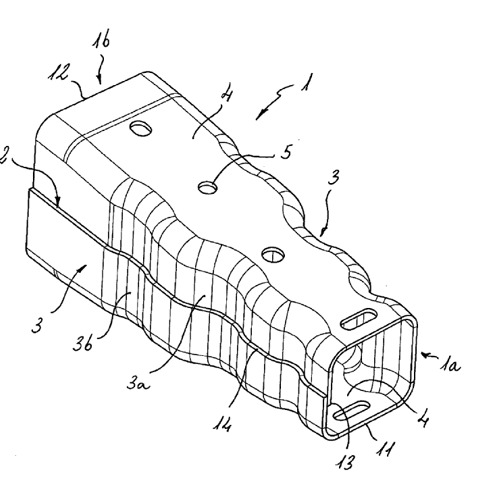

Figure 1 illustrates a carriage (14) and grippers (3).

2a.

2b.

2c.

3.

Attention is drawn to the following places, which may be of interest for search:

Grippers for drawing machines of the drum type |

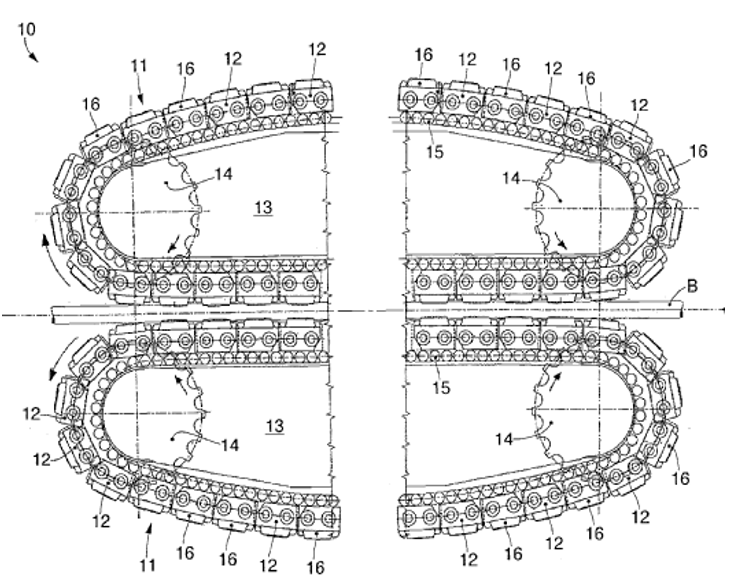

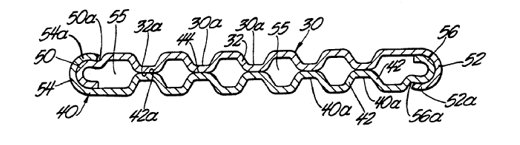

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

Attention is drawn to the following places, which may be of interest for search:

Removing work from metal extruding presses; Drawing-off metal extruded work | |

Endlessly revolving chain systems for metal coiling | |

Aprons, endless belts, lattices or like driven elements for forwarding filamentary material |

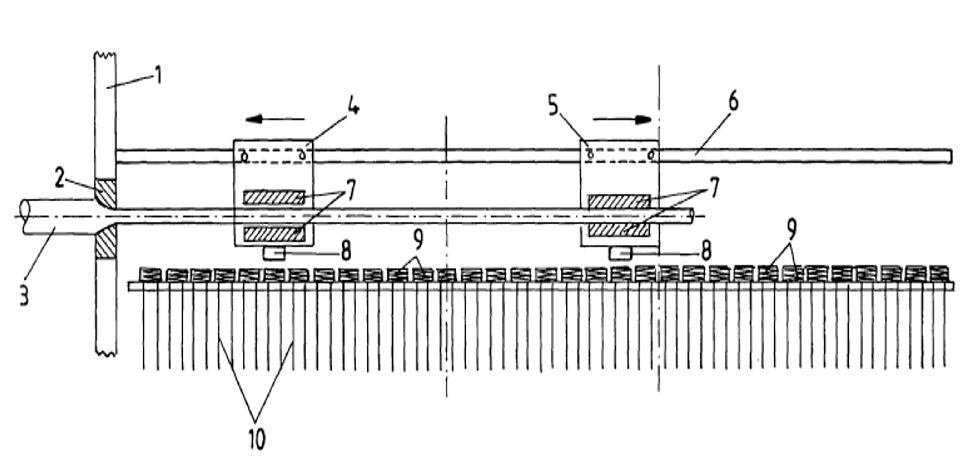

This place covers:

Electric linear motors for drawing.

Illustrative examples of subject matter classified in this place:

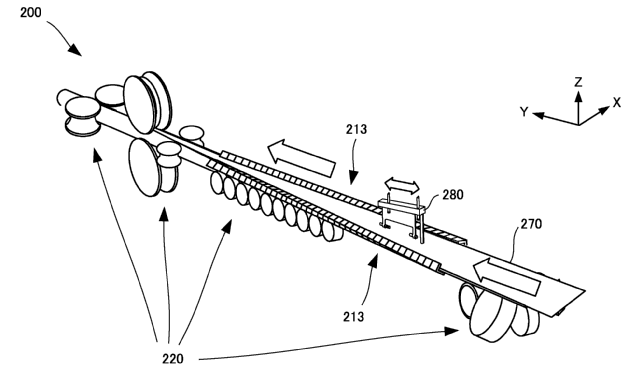

1.

2.

3.

Attention is drawn to the following places, which may be of interest for search:

Linear or sectional motors for propulsion systems in which a rigid body is moved along a path due to dynamo-electric interaction between the body and a magnetic field travelling along the path |

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

3a.

3b.

This place covers:

Illustrative examples of subject matter classified in this place:

1a.

1b.

2.

This place covers:

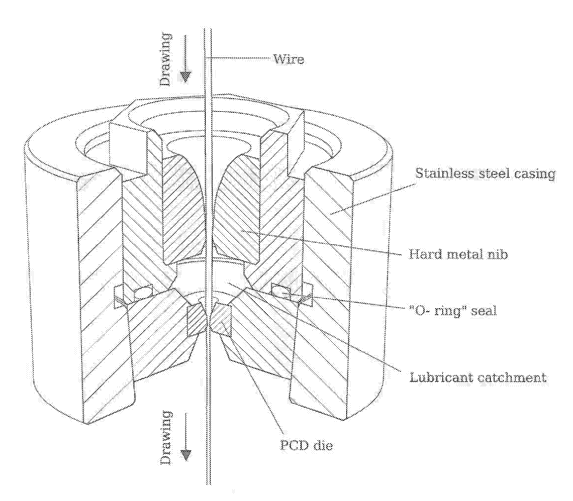

Metal drawing tools, e.g. dies, die holders, mandrels.

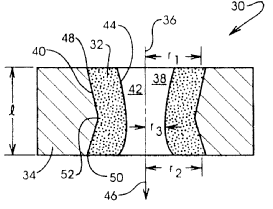

Illustrative example of subject matter classified in this place:

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

Attention is drawn to the following places, which may be of interest for search:

Alloys based on carbides, oxides, nitrides, silicides or other metal compounds |

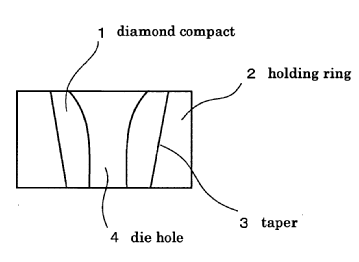

This place covers:

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

High-pressure synthesis processing of diamond | |

High-pressure synthesis production of diamond | |

Alloys containing diamond |

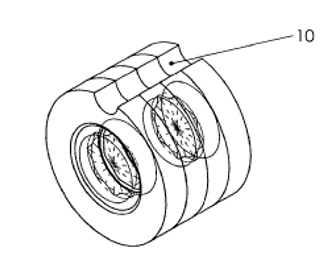

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

This place does not cover:

Profiling dies for metal drawing with section defined by rollers, balls or the like |

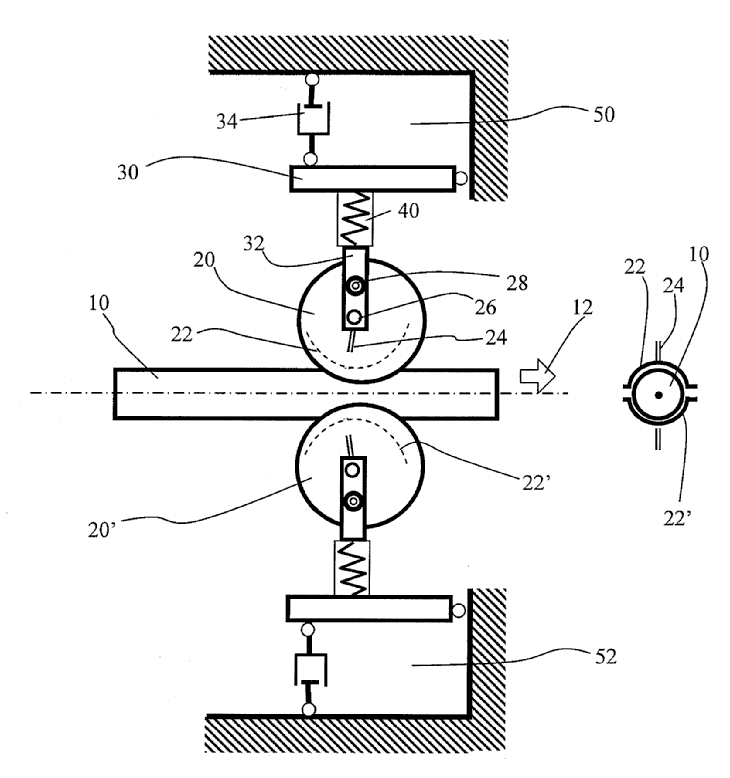

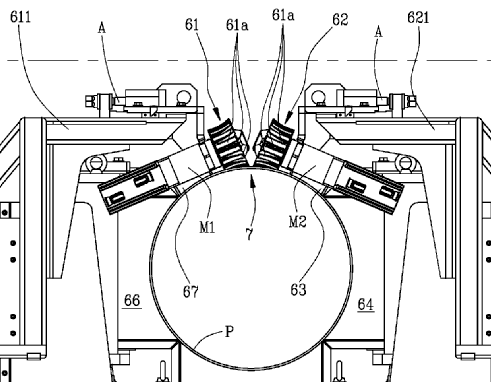

This place covers:

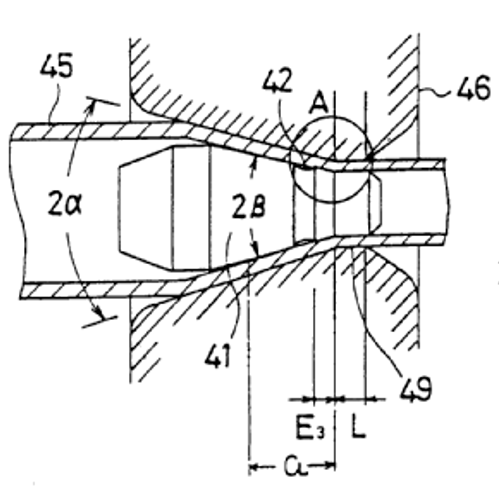

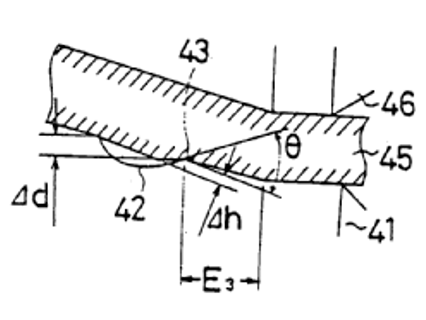

Illustrative examples of subject matter classified in this place:

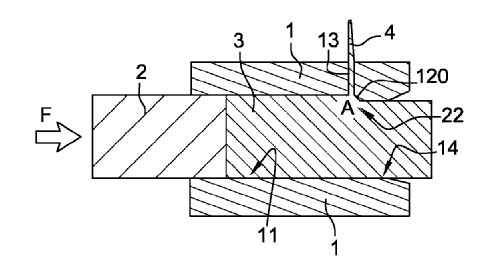

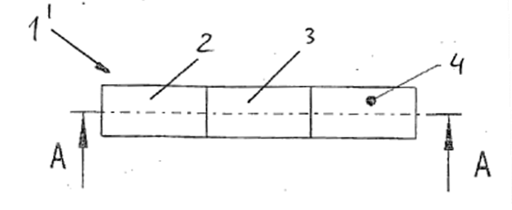

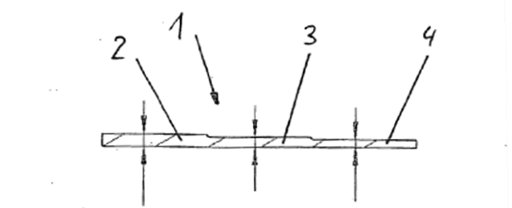

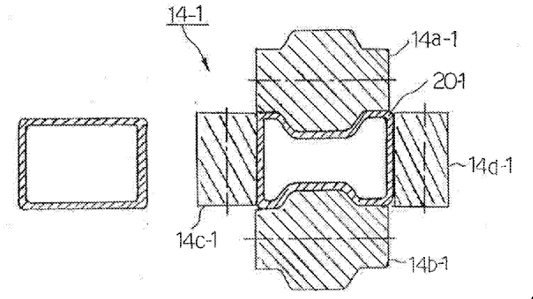

1a.

1b.

1c.

1d.

1e.

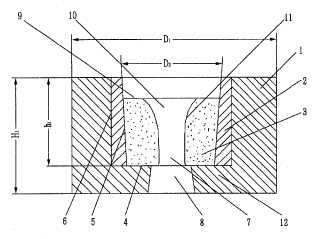

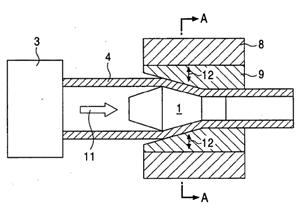

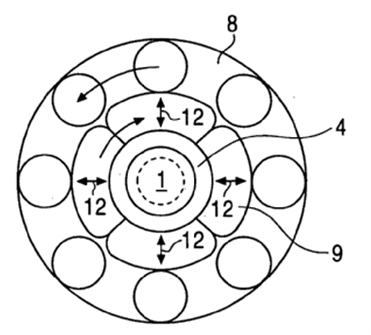

2a.

2b.

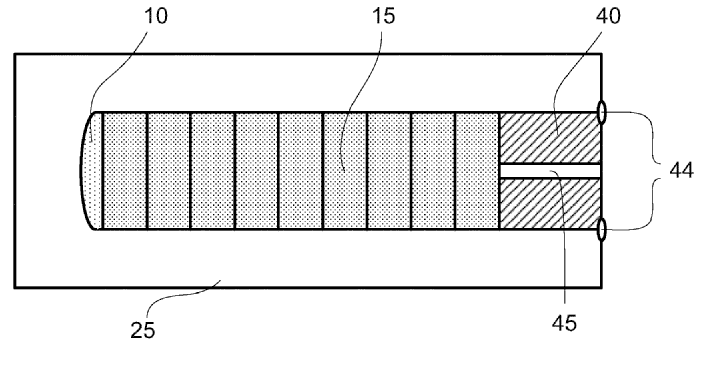

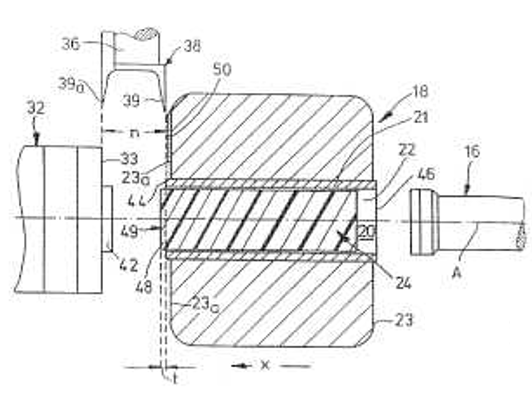

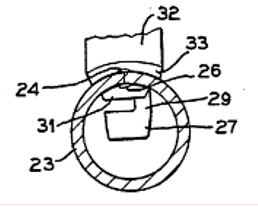

Figure 2b illustrates a cross-sectional view along line A-A of Figure 2a.

This place does not cover:

Profiling dies for metal drawing with section defined by rollers, balls or the like |

Attention is drawn to the following places, which may be of interest for search:

Rolling metal wire | |

Drawing combined with metal-rolling mills |

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

Attention is drawn to the following places, which may be of interest for search:

Rolling metal wire | |

Drawing combined with metal-rolling mills | |

Metal die making not otherwise provided for |

This place covers:

Illustrative example of subject matter classified in this place:

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

Attention is drawn to the following places, which may be of interest for search:

Rolling metal wire | |

Drawing combined with metal-rolling mills |

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2a.

2b.

Attention is drawn to the following places, which may be of interest for search:

Cooling, heating or lubricating drawing material |

Attention is drawn to the following places, which may be of interest for search:

Separating mandrels from work |

This place covers:

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Making working faces of dies, either recessed or outstanding | |

Metal die making not otherwise provided for |

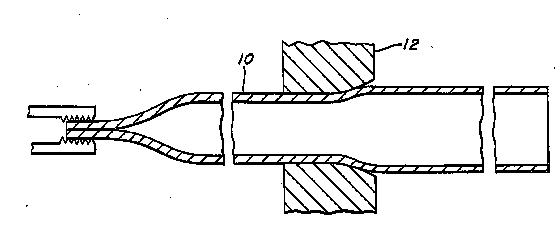

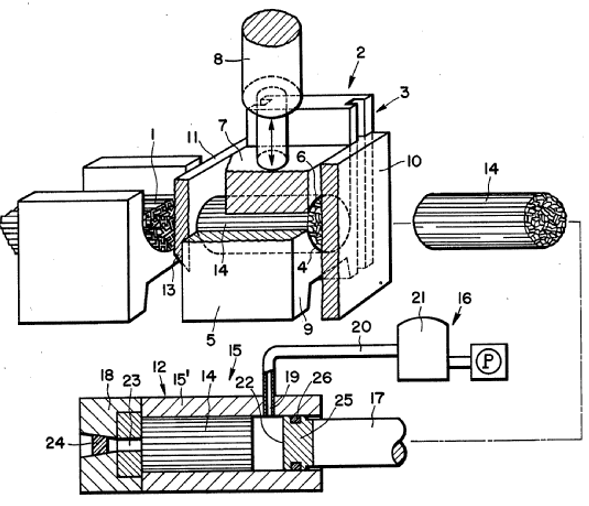

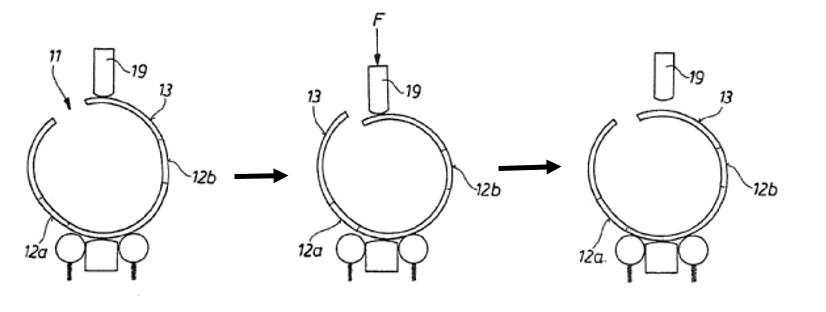

This place covers:

Reducing the cross-section of the material's leading end for easing its insertion into the drawing die prior to drawing.

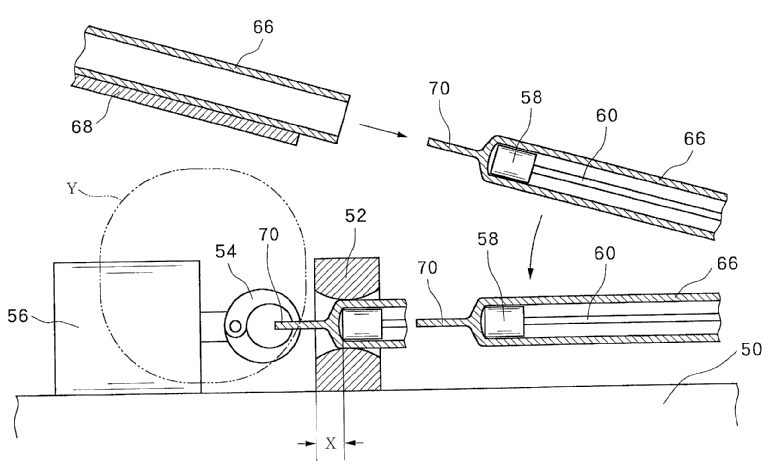

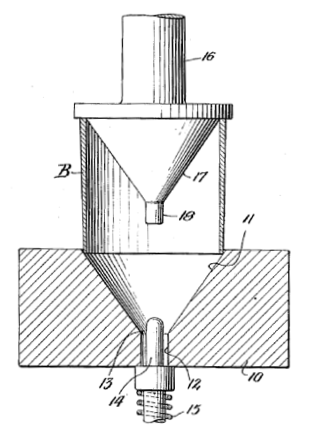

Illustrative example of subject matter classified in this place:

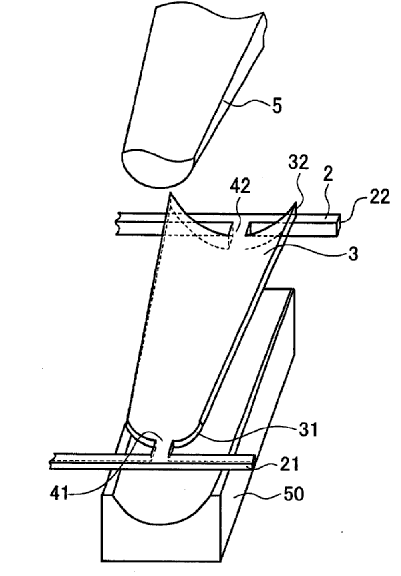

This place covers:

Reducing the cross-section of the hollow material's leading end for easing its insertion into the drawing die prior to drawing.

Illustrative examples of subject matter classified in this place:

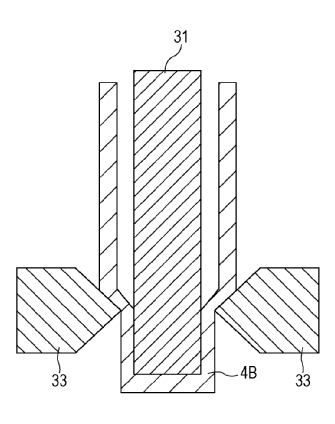

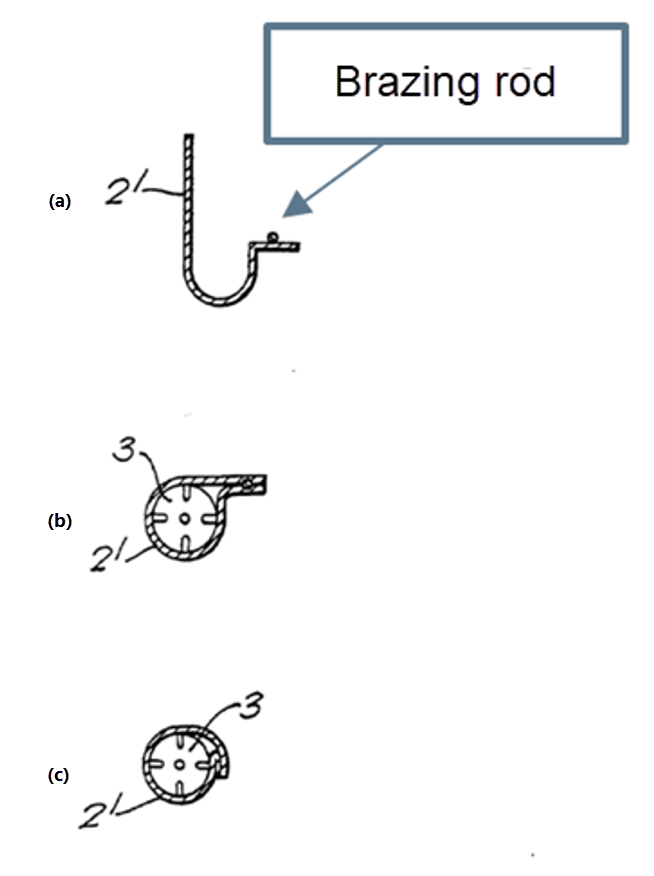

1a.

1b.

2.

Attention is drawn to the following places, which may be of interest for search:

Application of procedures in order to reduce or close the diameter of metal tube ends | |

Forging or pressing end portions of hollow metal articles |

This place covers:

Reducing the cross-section of the solid material's leading end for easing its insertion into the drawing die prior to drawing.

Illustrative examples of subject matter classified in this place:

1.

2.

Attention is drawn to the following places, which may be of interest for search:

Pointing of pins, nails or the like, with or without cutting |

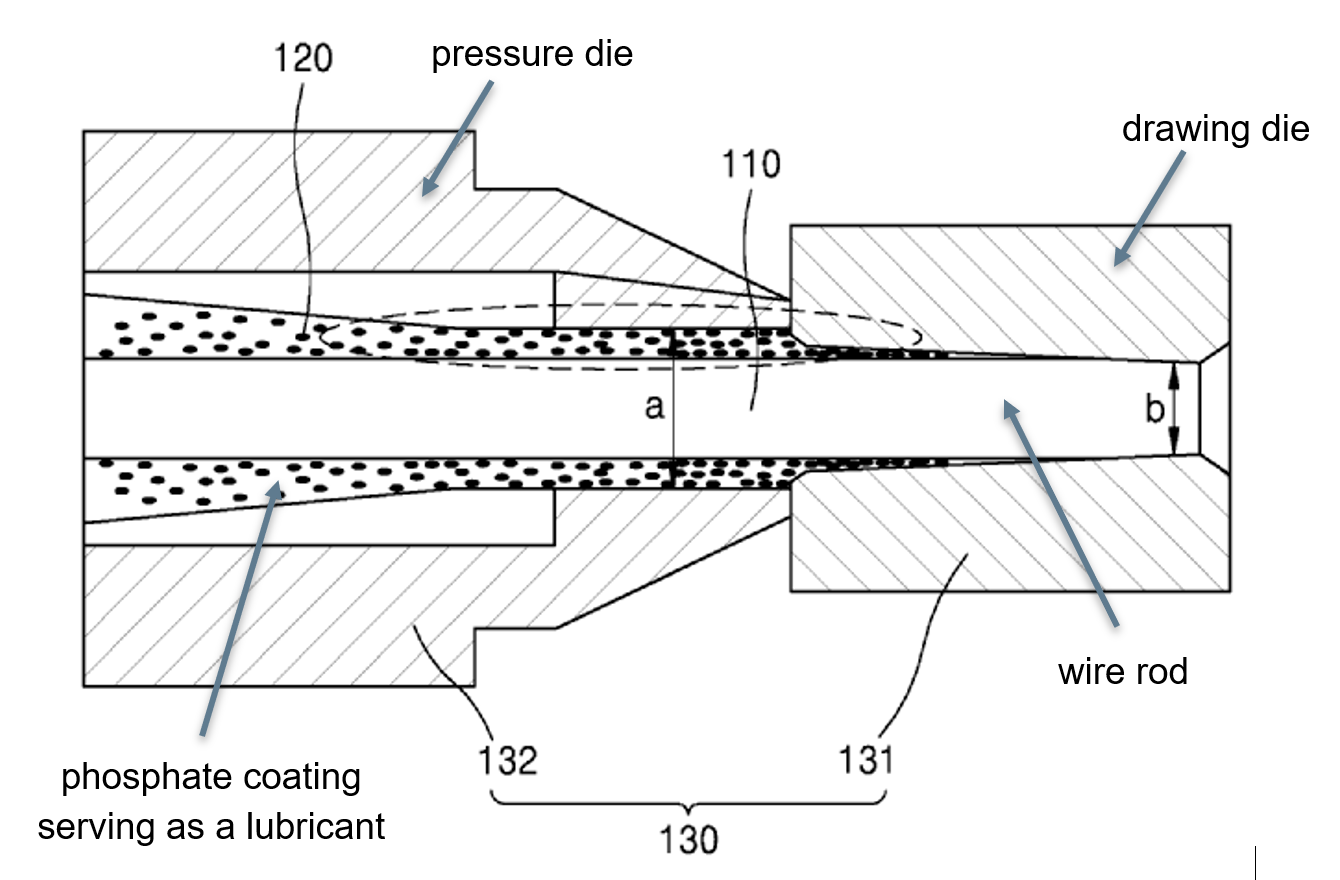

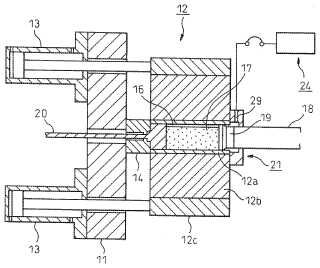

This place covers:

Cooling, heating or lubricating the drawing material or the drawing devices or dies.

Illustrative examples of subject matter classified in this place:

1.

2.

3.

This place does not cover:

Die holders combined with devices for guiding the drawing material or combined with devices for cooling, heating or lubricating |

Attention is drawn to the following places, which may be of interest for search:

Metal drawing machines, methods or drives | |

Lubricating workpieces for deep-drawing | |

Lubrication of tool and workpiece | |

Lubricating during forging or pressing | |

Lubricants in general | |

Lubricating compositions for metal working |

This place covers:

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Lubricating compositions for metal working |

This place covers:

Devices either:

- for straightening wire, wherein the straightening action is realized by using drawing dies, or

- for straightening wire, which devices are used in combination with wire drawing or winding machines (e.g. straightening prior to drawing).

Attention is drawn to the following places, which may be of interest for search:

Winding, coiling | |

Straightening or restoring form of metal rods, metal tubes, metal profiles or specific articles made therefrom, whether or not in combination with sheet metal parts | |

Working of metal wire by straightening |

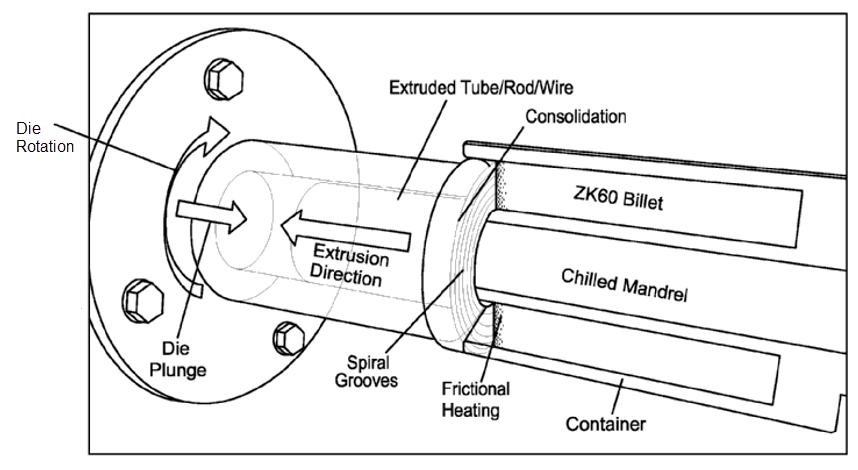

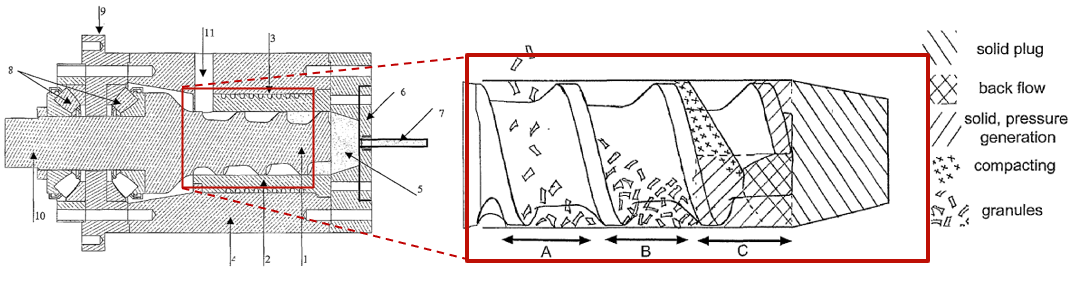

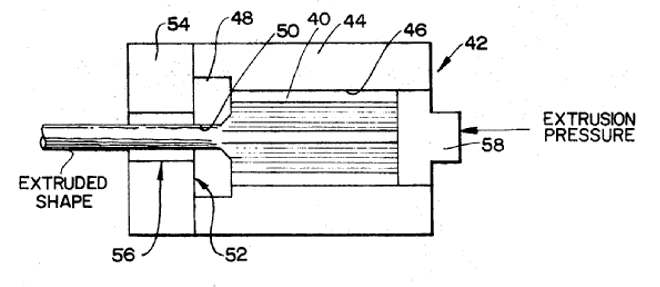

This place covers:

Methods and devices for metal extrusion including impact extrusion, products obtained by metal extrusion as well as lubrication aspects.

Metal extrusion consists in forcing solid metal through a suitably shaped orifice using compressive forces. Metal extrusion differs from metal drawing by the higher rate of reduction.

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Profiling tools for metal extrusion, e.g. mandrels or dies | |

Rams or plungers for metal extrusion; Disks therefor | |

Containers for metal to be extruded | |

Cooling or heating extruded work or parts of the extrusion press | |

Control or measuring devices in relation with metal extrusion | |

Feeding extrusion presses with metal to be extruded | |

Removing work or waste from extrusion presses; Cleaning dies, ducts, containers or mandrels for metal extruding | |

Continuous casting | |

Extrusion of plastic material |

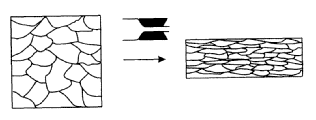

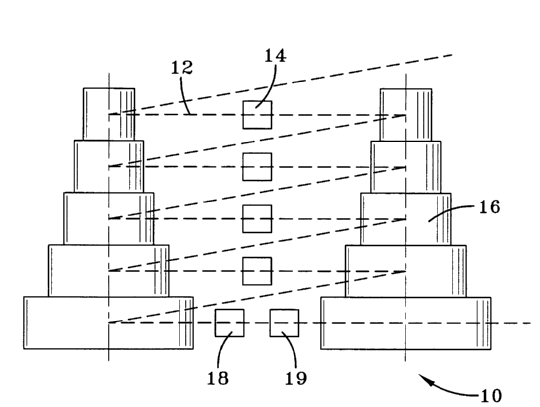

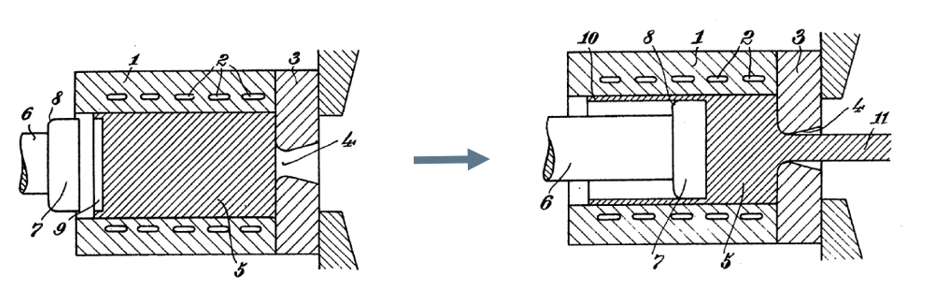

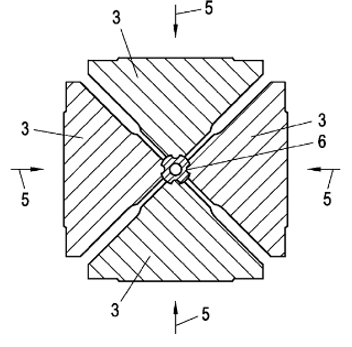

This place covers:

All aspects relating to the extrusion of metals with the purpose of improving the physical properties of such metals, for example, through severe plastic deformation such as equal channel angular pressing [ECAP] or equal channel angular extrusion [ECAE].

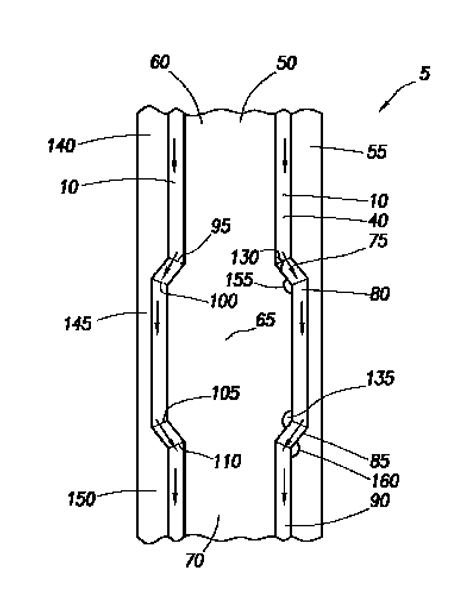

Illustrative examples of subject matter classified in this place:

1.

2.

3.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Attention is drawn to the following places, which may be of interest for search:

Extruding metal starting from material of particular form or shape, e.g. mechanically pre-treated | |

Preliminary treatment of metal stock without particular shaping affecting grain orientation, e.g. salvaging segregated zones, forging or pressing in the rough |

In patent documents, the following abbreviations are often used:

ECAP | equal channel angular pressing |

ECAE | equal channel angular extrusion |

This place covers:

Illustrative example of subject matter classified in this place:

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working |

Attention is drawn to the following places, which may be of interest for search:

Manufacture of workpieces or articles from metallic powder characterised by extrusion as the manner of compacting or sintering | |

Alloys based on aluminium |

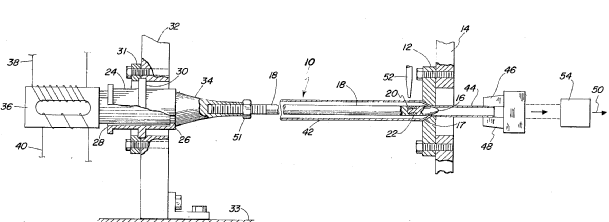

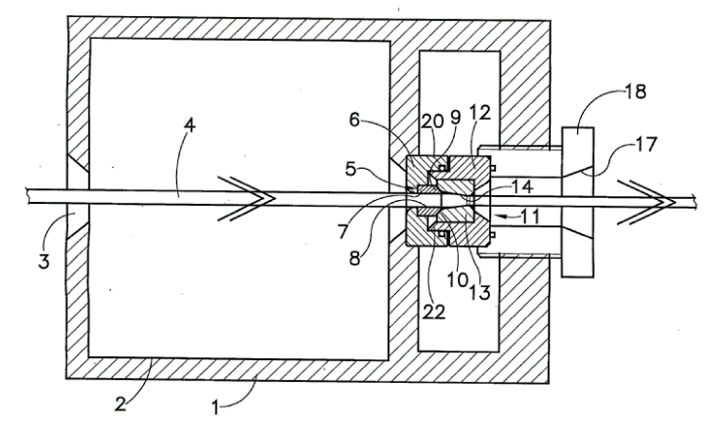

This place covers:

Extruding metal using vibratory sequences.

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Methods or apparatus for generating mechanical vibrations of infrasonic, sonic or ultrasonic frequency |

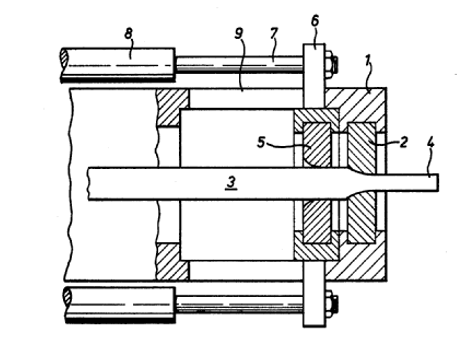

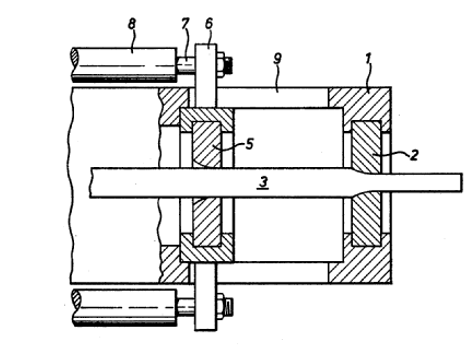

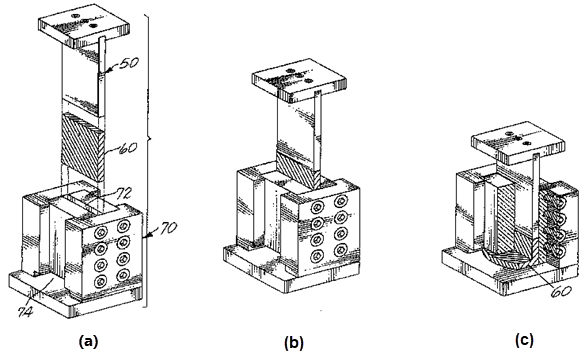

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

This place does not cover:

Continuous hydrostatic extrusion of metal |

Attention is drawn to the following places, which may be of interest for search:

Pressure die casting or injection die casting | |

Manufacture of workpieces or articles from metallic powder characterised by extrusion as the manner of compacting or sintering |

This place covers:

Illustrative example of subject matter classified in this place:

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

3.

This place covers:

Gas treatment of work, e.g. to prevent oxidation or to create surface effects.

This place does not cover:

Gas treatment of work for heating or cooling only |

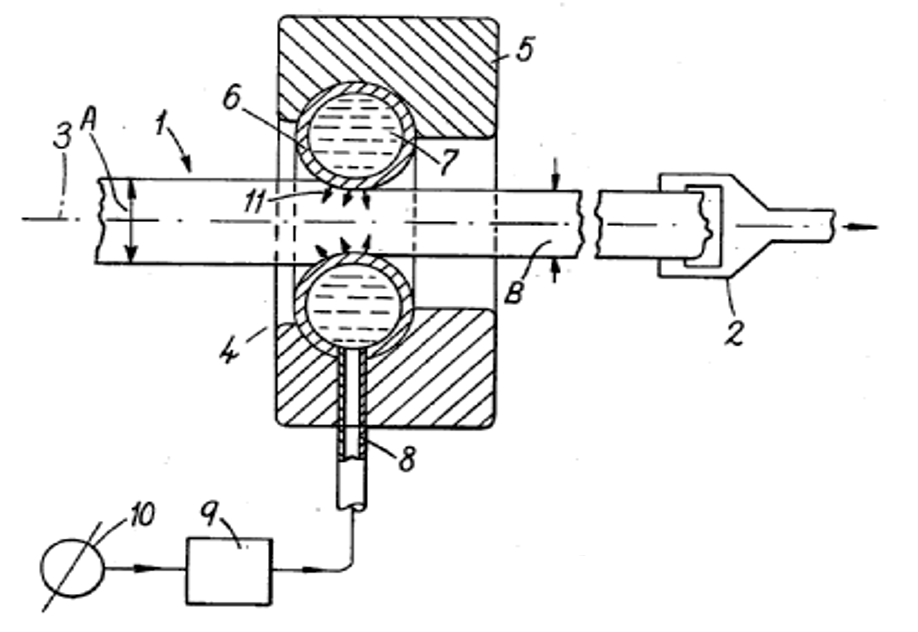

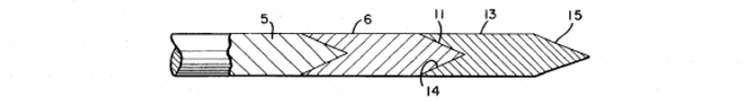

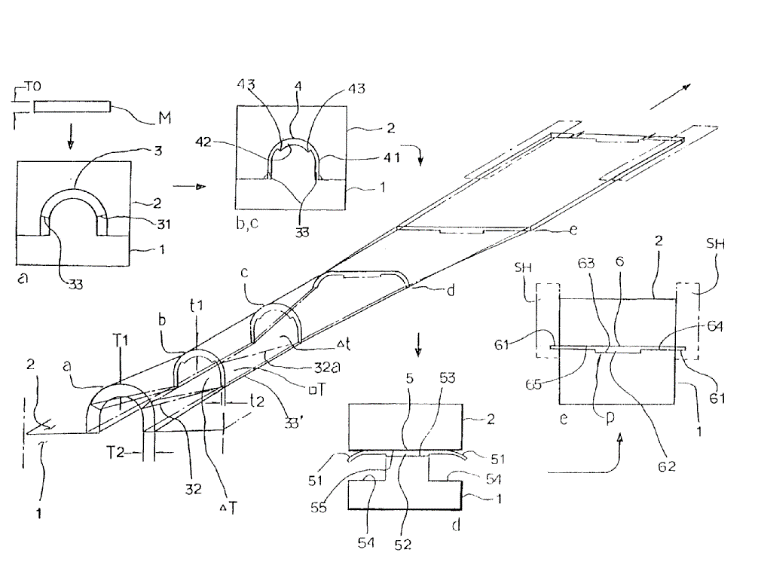

This place covers:

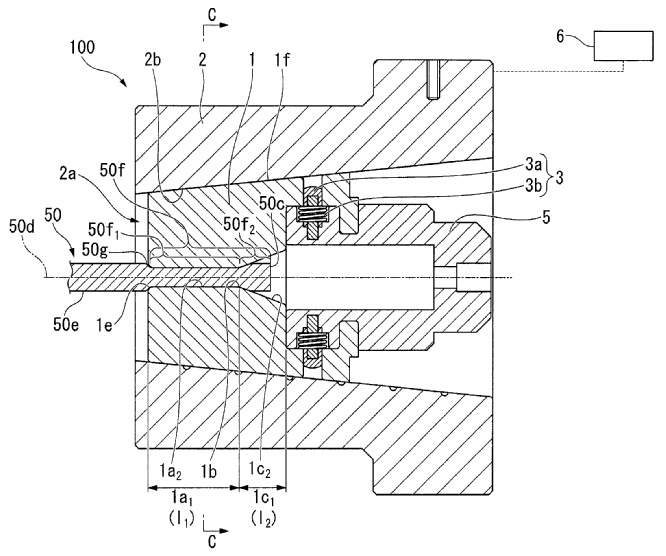

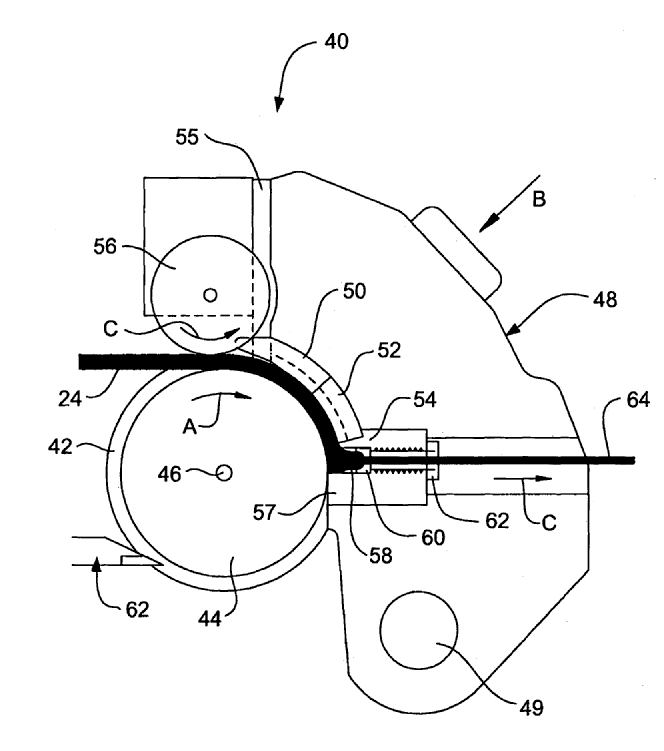

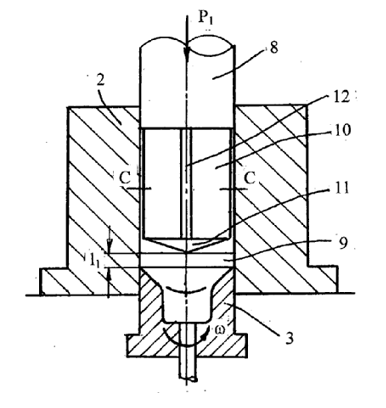

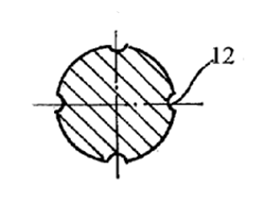

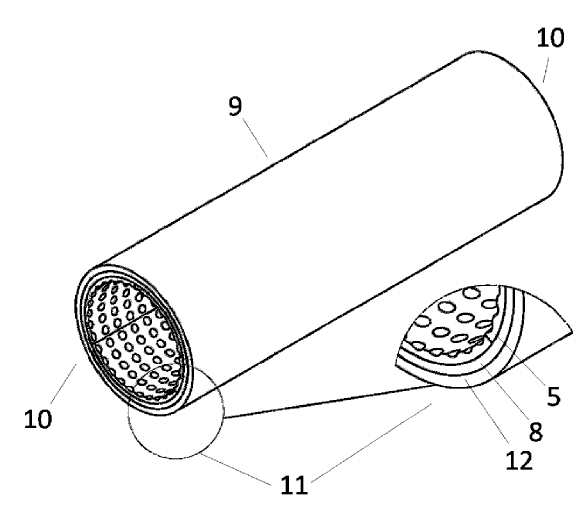

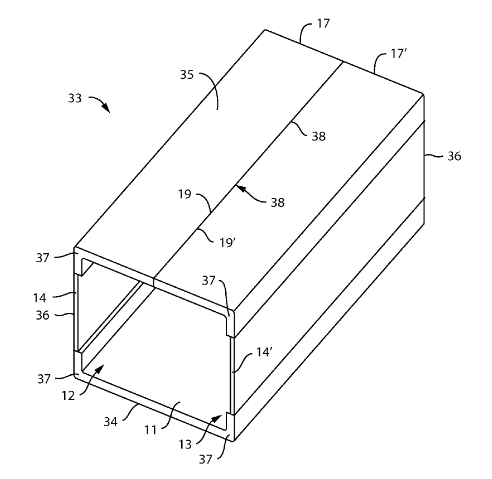

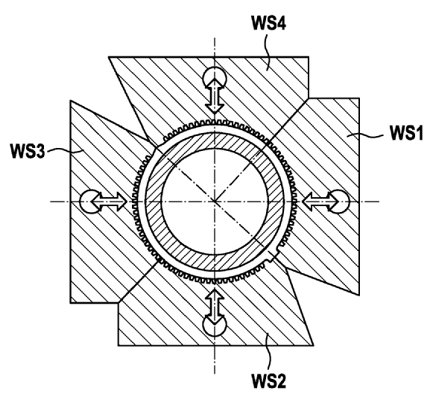

Illustrative examples of subject matter classified in this place:

1a.

1b.

Figure 1b illustrates the cross-section along line C-C of Figure 1a.

2a.

2b.

3.

4.

5.

6.

This place does not cover:

Making metal-coated products by extrusion; Making products from two or more metals by extrusion |

Attention is drawn to the following places, which may be of interest for search:

Extruding metal to improve the material properties, e.g. lateral extrusion | |

Feeding extrusion presses with metal to be extruded | |

Manufacture of workpieces or articles from metallic powder characterised by extrusion as the manner of compacting or sintering |

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

Attention is drawn to the following places, which may be of interest for search:

Making uncoated products by impact extrusion | |

Making uncoated products by backward extrusion |

This place covers:

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Making uncoated products of generally elongated shape by backward extrusion |

This place covers:

Illustrative example of subject matter classified in this place:

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

3.

Attention is drawn to the following places, which may be of interest for search:

Manufacture of metal sheets |

This place covers:

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Making twist-drills |

Attention is drawn to the following places, which may be of interest for search:

Extrusion presses in general |

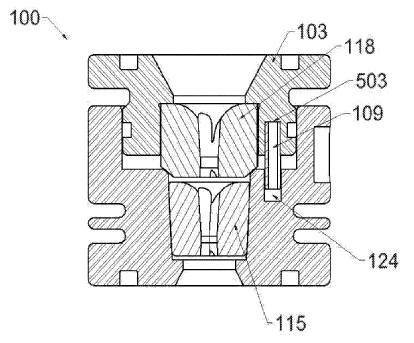

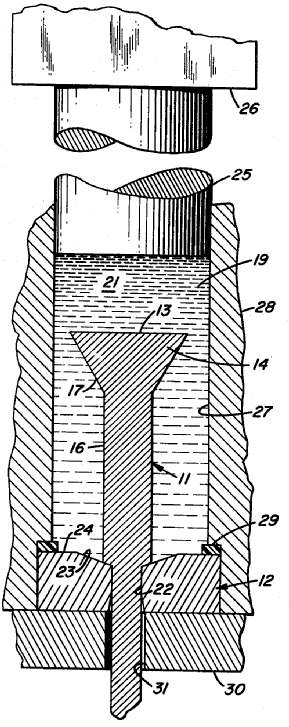

This place covers:

Dies and mandrels for metal extrusion, including dies and mandrels for coating work by extrusion or having a section variable during extruding.

The extrusion die and/or mandrel define/s the section through which the billet is forced, thereby defining the cross-sectional shape of the extruded product.

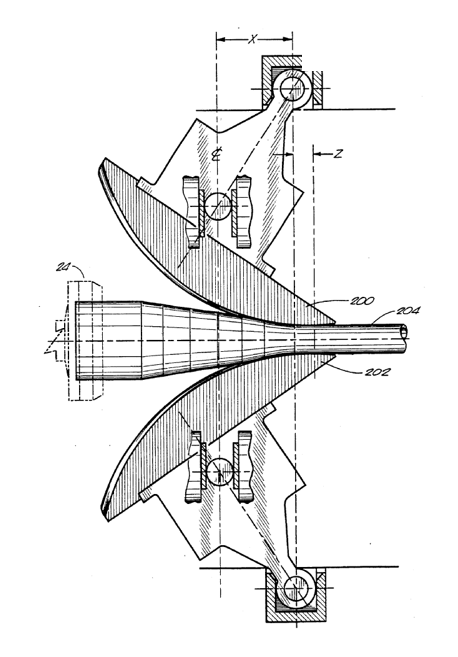

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Metal extrusion devices and methods | |

Rams or plungers for metal extrusion; Disks therefor | |

Containers for metal to be extruded | |

Cooling or heating extruded work or parts of the extrusion press | |

Control or measuring devices in relation with metal extrusion | |

Feeding extrusion presses with metal to be extruded | |

Removing work or waste from extrusion presses; Cleaning dies, ducts, containers or mandrels for metal extruding |

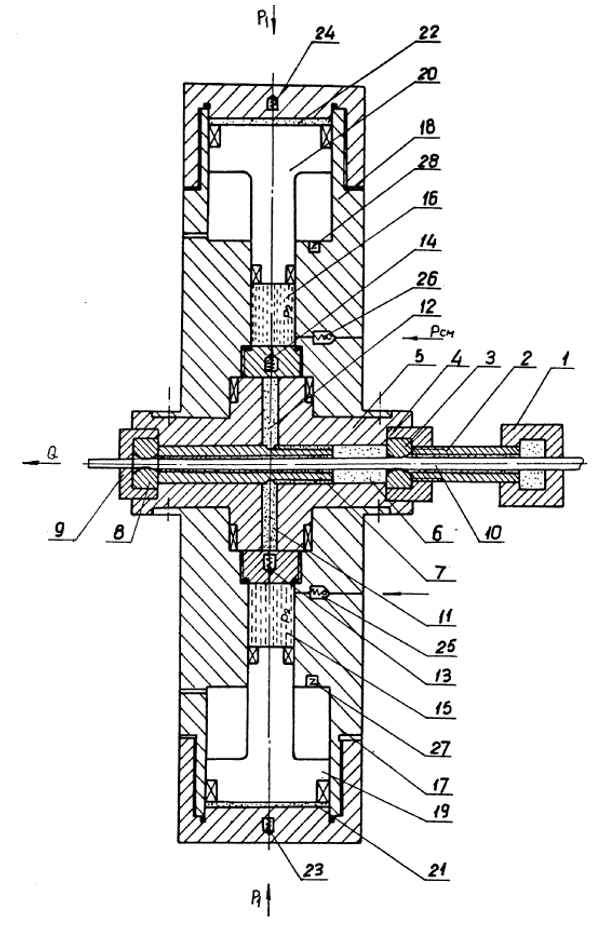

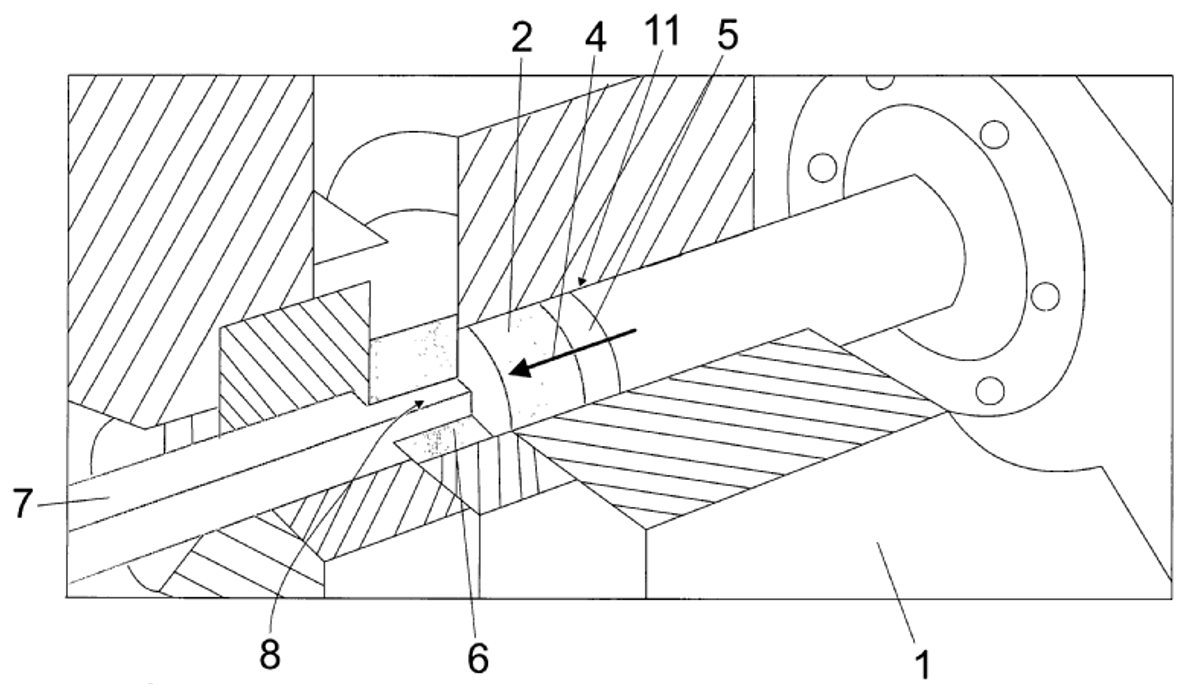

This place covers:

Rams or plungers for metal extrusion; the disks therefor as well as the dummy blocks.

The extrusion ram or plunger is normally the element applying the extrusion pressure to the billet to be extruded.

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Metal extrusion devices and methods | |

Profiling tools for metal extrusion, e.g. mandrels or dies | |

Containers for metal to be extruded | |

Cooling or heating extruded work or parts of the extrusion press | |

Control or measuring devices in relation with metal extrusion | |

Feeding extrusion presses with metal to be extruded | |

Removing work or waste from extruding presses; Cleaning dies, ducts, containers or mandrels for metal extruding |

This place covers:

Containers into which the billet is placed and pressurised for extrusion.

Illustrative example of subject matter classified in this place:

This place does not cover:

Cooling or heating of containers for metal to be extruded |

Attention is drawn to the following places, which may be of interest for search:

Metal extrusion devices and methods | |

Profiling tools for metal extrusion, e.g. mandrels or dies | |

Rams or plungers for metal extrusion; Disks therefor | |

Cooling or heating extruded work or parts of the extrusion press | |

Control or measuring devices in relation with metal extrusion | |

Feeding extrusion presses with metal to be extruded | |

Removing work or waste from extrusion presses; Cleaning dies, ducts, containers or mandrels for metal extruding |

This place covers:

Heating or cooling in combination with metal extrusion.

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Metal extrusion devices and methods | |

Profiling tools for metal extrusion, e.g. mandrels or dies | |

Rams or plungers for metal extrusion; Disks therefor | |

Containers for metal to be extruded | |

Control or measuring devices in relation with metal extrusion | |

Feeding extrusion presses with metal to be extruded | |

Removing work or waste from extruding presses; Cleaning dies, ducts, containers or mandrels for metal extruding |

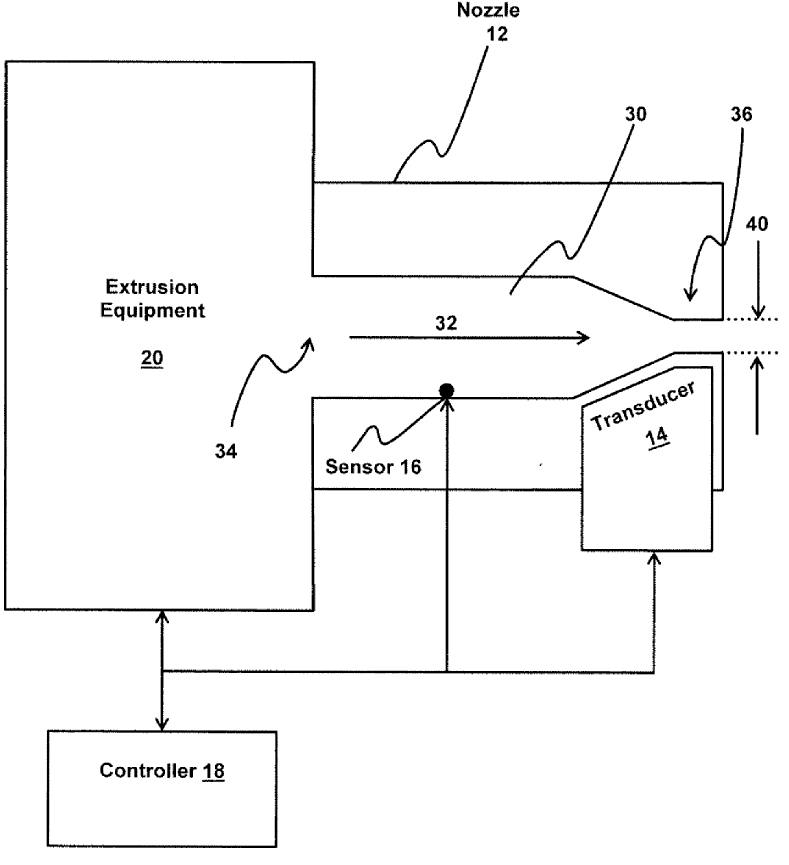

This place covers:

Illustrative example of subject matter classified in this place:

This place does not cover:

Controlling variation of section with dies or mandrels during extruding |

Attention is drawn to the following places, which may be of interest for search:

Metal extrusion devices and methods | |

Rams or plungers for metal extrusion; Disks therefor | |

Containers for metal to be extruded | |

Cooling or heating extruded work or parts of the extrusion press | |

Feeding extrusion presses with metal to be extruded | |

Removing work or waste from extruding presses; Cleaning dies, ducts, containers or mandrels for metal extruding | |

Measuring devices specially adapted for use in the production or manipulation of material in accordance with subclasses B21B - B21F |

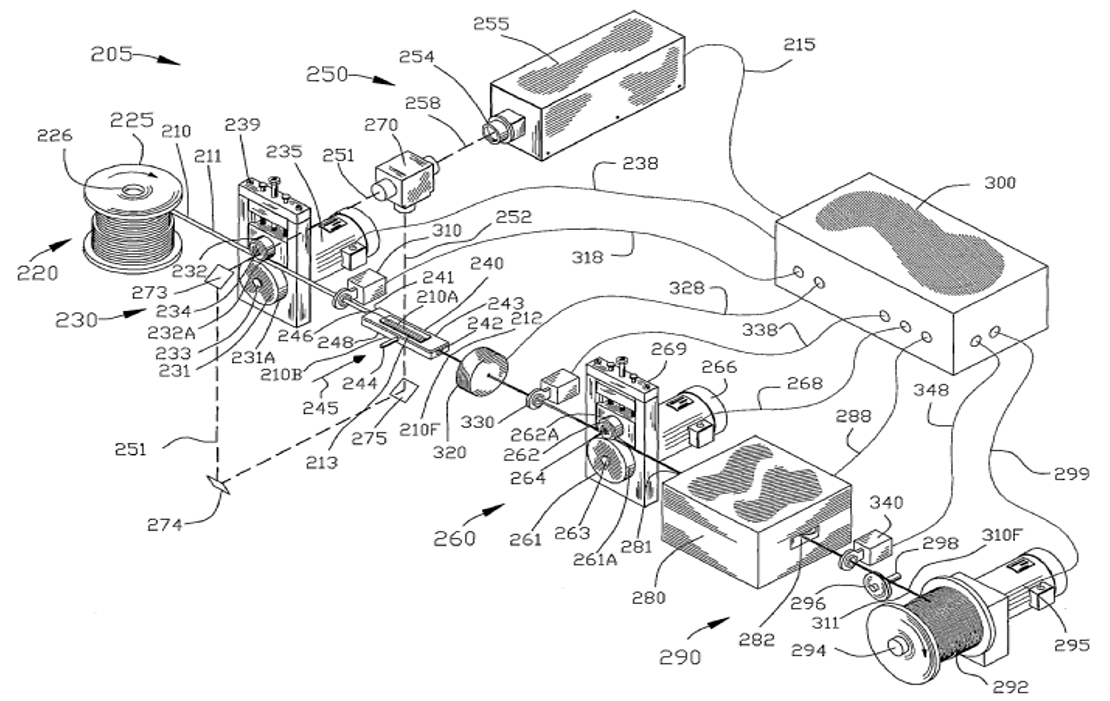

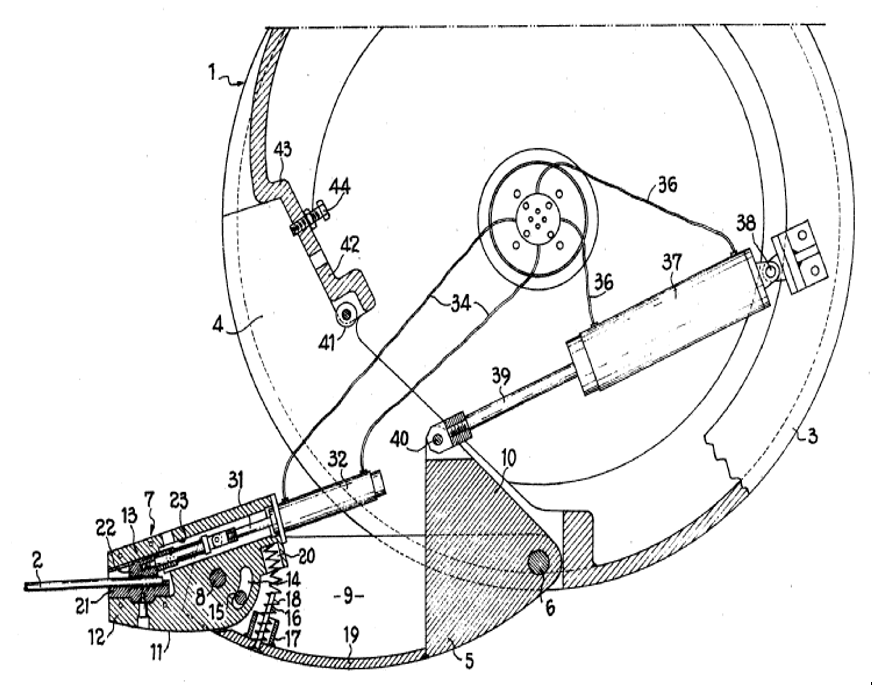

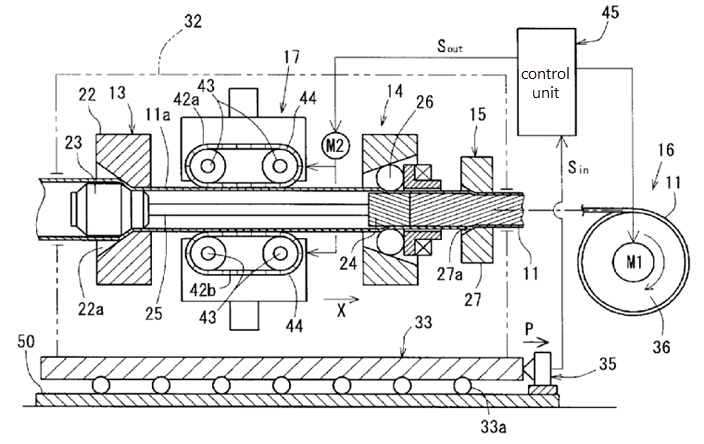

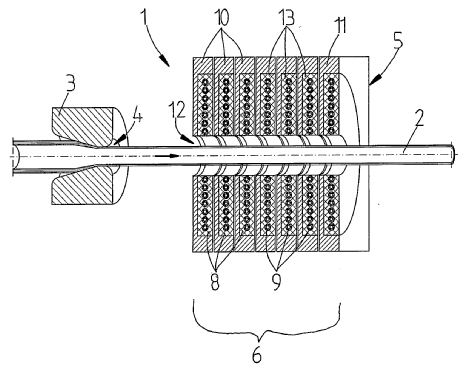

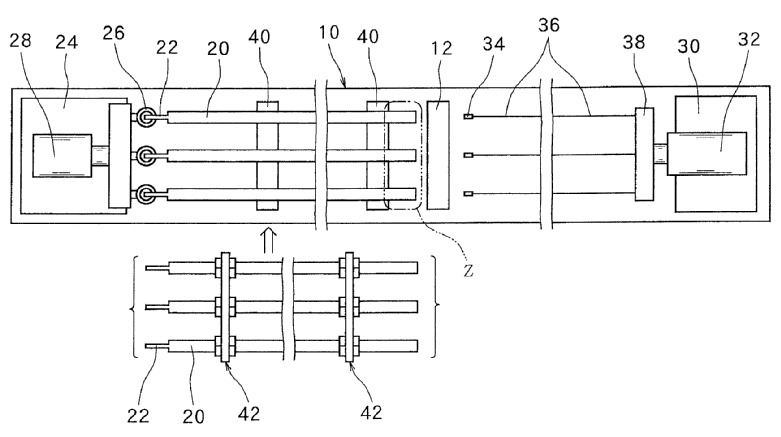

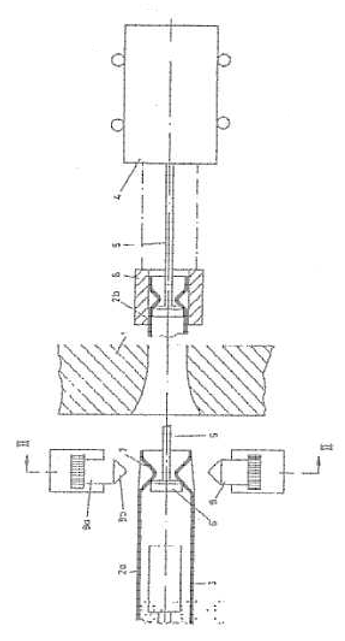

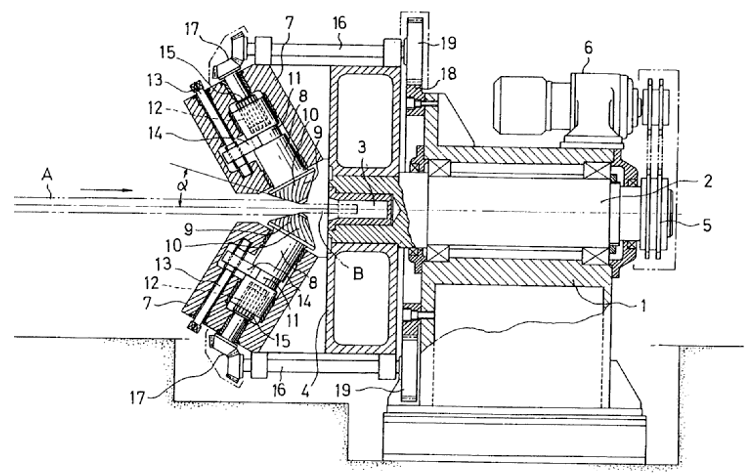

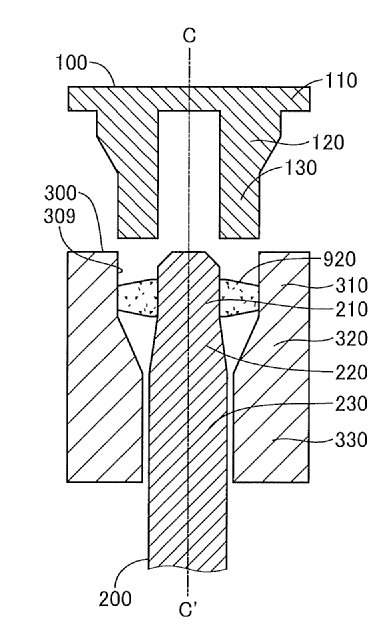

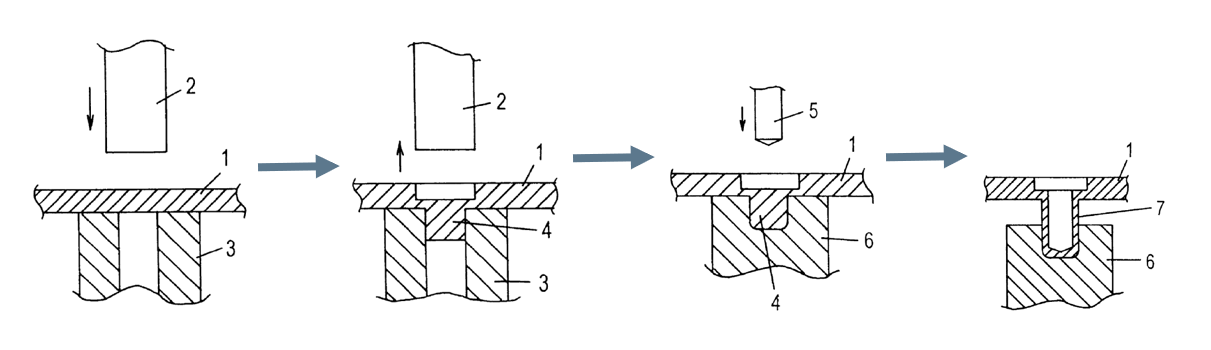

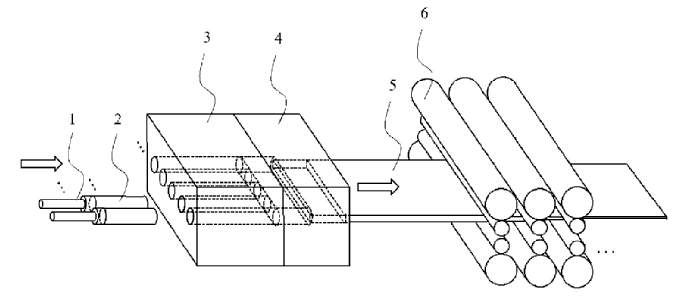

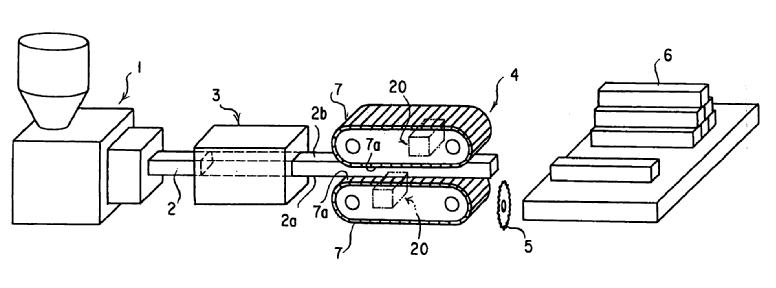

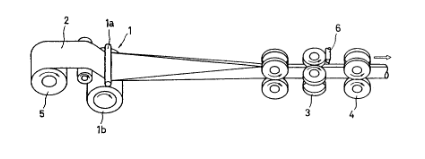

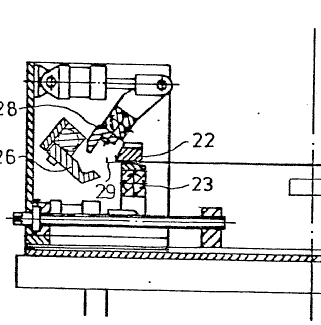

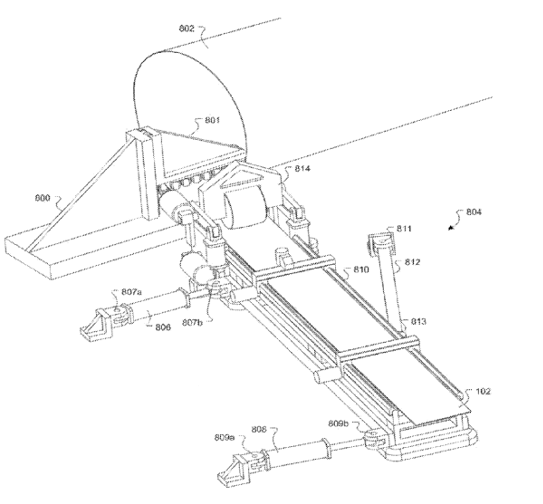

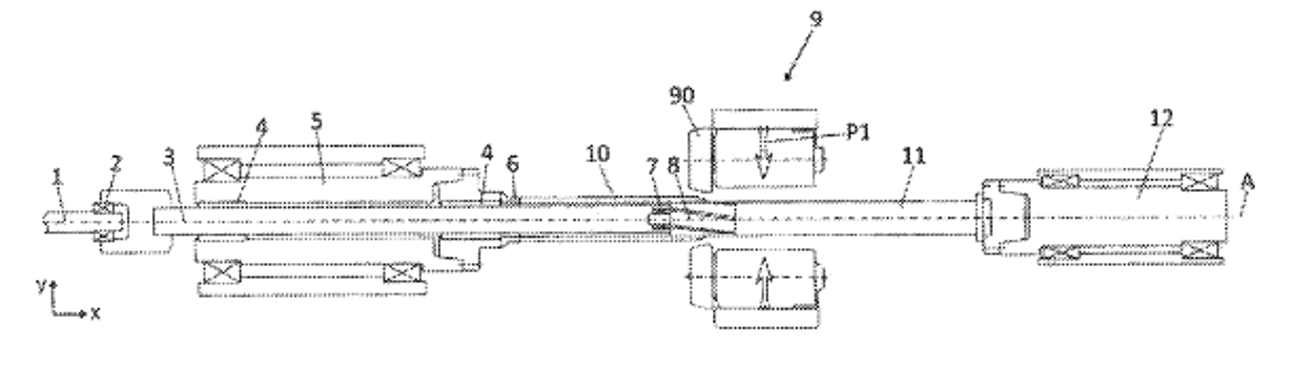

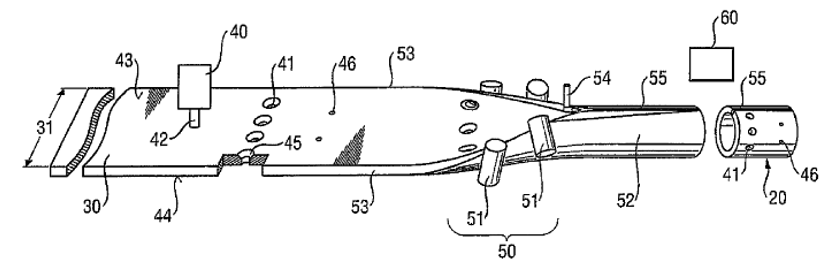

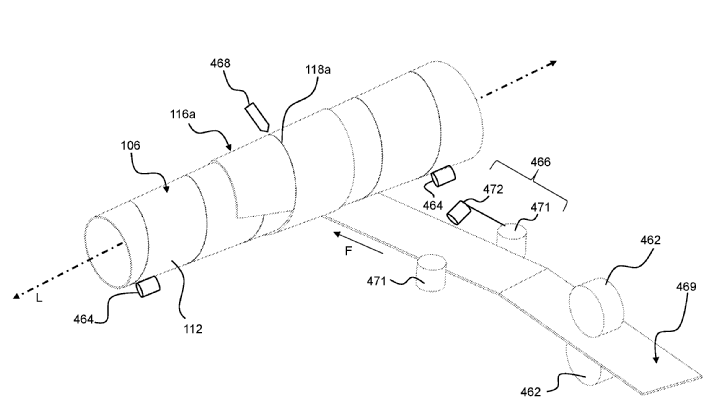

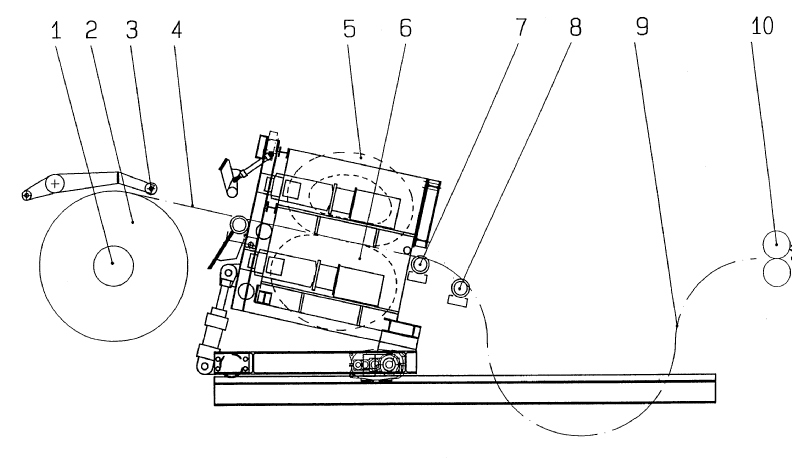

This place covers:

Operations or devices upstream of the extrusion press or extrusion process, and specifically linked to it, including, e.g. feeding conveyors and grippers used to provide a workpiece to an extrusion press.

Illustrative example of subject matter classified in this place:

1a.

1b.

Attention is drawn to the following places, which may be of interest for search:

Metal extrusion devices and methods | |

Profiling tools for metal extrusion, e.g. mandrels or dies | |

Rams or plungers for metal extrusion; Disks therefor | |

Containers for metal to be extruded | |

Cooling or heating extruded work or parts of the extrusion press | |

Control or measuring devices in relation with metal extrusion | |

Removing work or waste from extrusion presses; Cleaning dies, ducts, containers or mandrels for metal extruding |

This place covers:

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Manufacture of metal wires with particular section or properties | |

Manufacture of metal fine wires |

This place covers:

Operations or devices downstream of the extrusion press or extrusion process, and specifically linked to it, including, e.g.:

- Removing work or waste from extruding presses;

- Drawing off extruded work;

- Cleaning dies, ducts, containers or mandrels;

- Scrapers and scraping knives for cutting-off or removing the waste or for removing sections from the extruded work, e.g. removing a strip to create an open profile.

Illustrative example of subject matter classified in this place:

This place does not cover:

Removing work or waste from extruding presses in connection with the extruding of bent tubes or rods; Drawing-off extruded work in connection with the extruding of bent tubes or rods |

Attention is drawn to the following places, which may be of interest for search:

Profiling tools for metal extrusion, e.g. mandrels or dies) | |

Rams or plungers for metal extrusion; Disks therefor | |

Containers for metal to be extruded | |

Cooling or heating extruded work or parts of the extrusion press | |

Control or measuring devices in relation with metal extrusion | |

Feeding extrusion presses with metal to be extruded |

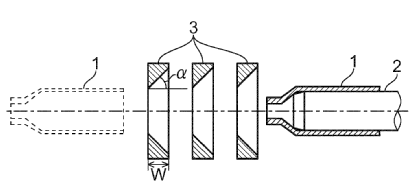

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

Attention is drawn to the following places, which may be of interest for search:

Linear motor pulling devices in machines for drawing metal |

This place covers:

Illustrative example of subject matter classified in this place:

Examples of places in relation to which this place is residual:

Manufacture of metal sheets, rods, wire, tubes, profiles or like semi-manufactured products by metal extrusion | |

Manufacture by working or processing of semi-finished sheet metal or metal tubes, rods or profiles without essentially removing material | |

Manufacture of metal rods, profiles or tubes by bending | |

Manufacture by working or processing metal wire | |

Manufacture by casting of metals | |

Manufacture by electroforming | |

Manufacture of tubes by electroforming | |

Manufacture of wires by electroforming |

Attention is drawn to the following places, which may be of interest for search:

Rolling of metal | |

Manufacture by material-removing machine tools | |

Welding; Cladding or plating by welding | |

Making steel wool or the like | |

Grinding; Polishing |

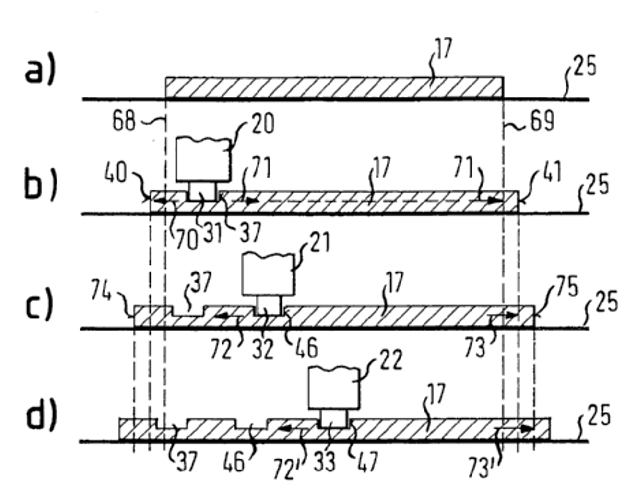

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

Figure 2 illustrates the pressing of a heated blank to form varying thicknesses.

3a.

3b.

Figure 3b illustrates a cross-sectional view along line A-A of Figure 3a.

Examples of places in relation to which this place is residual:

Making metal sheets by extrusion |

Attention is drawn to the following places, which may be of interest for search:

Rolling metal sheets of indefinite length | |

Rolling metal sheets of limited length | |

Embossing metal sheets or rolls by rolling |

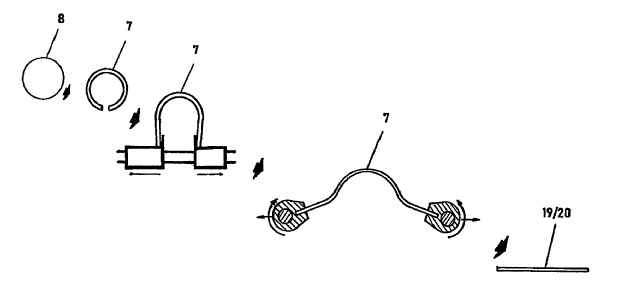

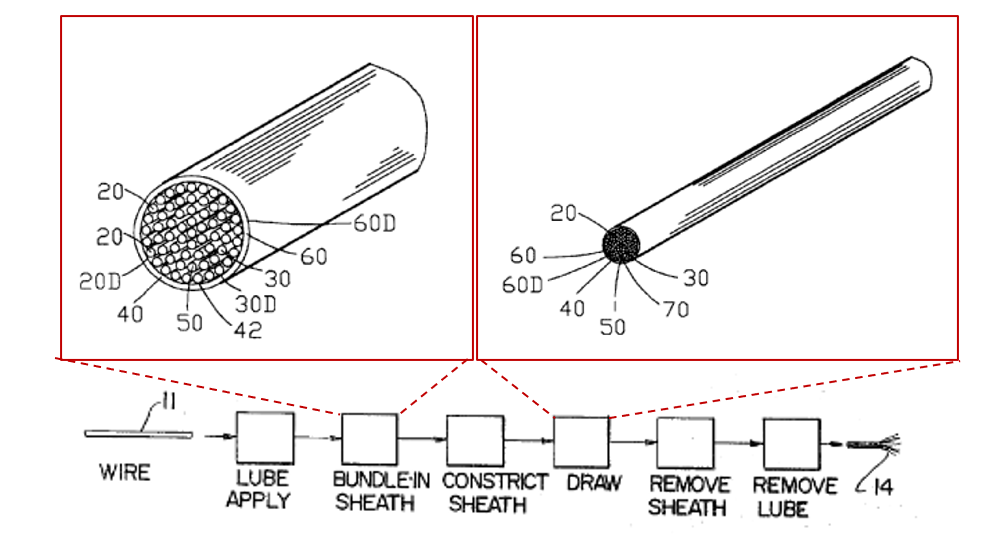

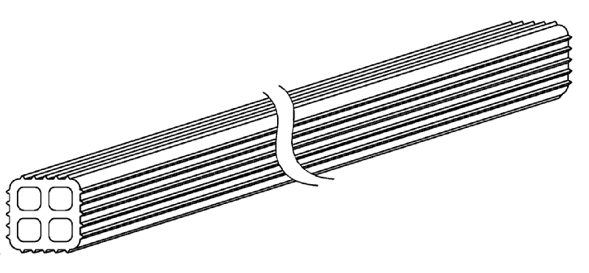

This place covers:

Manufacture of metal rods, bars or wire by metal working not otherwise provided for.

Illustrative examples of subject matter classified in this place:

1.

2a.

2b.

3.

4.

Modifying the physical properties by deformation combined with, or followed by, heat treatment during the manufacture of wires is classified in C21D 8/06. Manufacture of rods or wire not otherwise provided for is classified in B21C 37/04.

Examples of places in relation to which this place is residual:

Manufacture of metal wire by drawing | |

Making uncoated wire by direct extrusion | |

Working or processing of metal wire |

Attention is drawn to the following places, which may be of interest for search:

Rolling metal wire | |

Wire electrical connectors in or for semiconductor devices; Manufacturing methods related thereto |

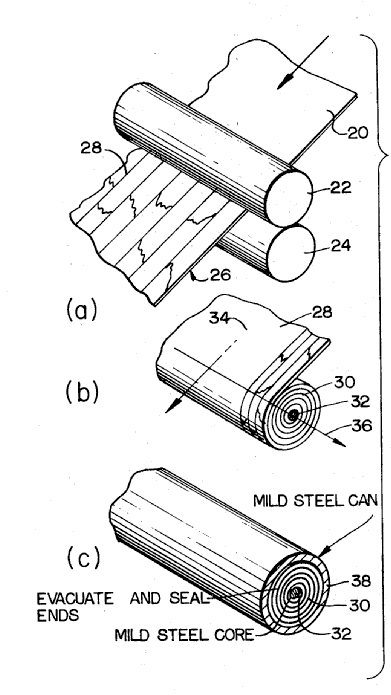

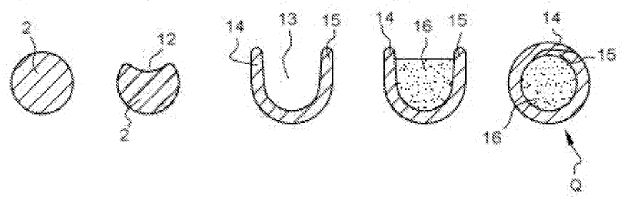

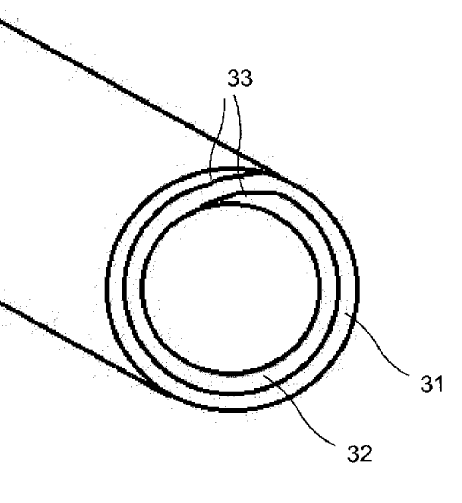

This place covers:

Manufacture of coated wire, rods or bars not otherwise provided for.

Illustrative examples of subject matter classified in this place:

1a.

1b.

1c.

2.

Examples of places in relation to which this place is residual:

Covering indefinite lengths of metal or non-metal wires or rods with a metal coating by extrusion | |

Metallic coating of wire | |

Coating by spraying wires | |

Electroplating of wires |

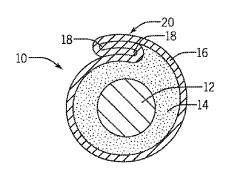

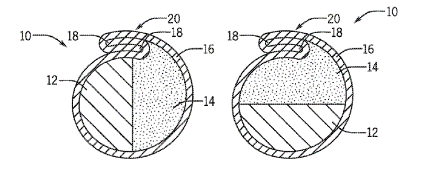

This place covers:

Manufacture of wire, rods or bars with particular section or properties not otherwise provided for.

Illustrative examples of subject matter classified in this place:

1.

2.

3.

4.

5.

Modifying the physical properties by deformation combined with, or followed by, heat treatment during the manufacture of wires is classified in C21D 8/06. Heat treatment for wire is classified in C21D 9/525. Manufacture of rods or wire with particular section or properties not otherwise provided for is classified in B21C 37/045.

Examples of places in relation to which this place is residual:

Drawing materials of special alloys for manufacture of metal wires or rods |

This place covers:

Illustrative example of subject matter classified in this place:

Examples of places in relation to which this place is residual:

Drawing materials of special alloys for manufacture of metal wires | |

Cooling, heating or lubricating drawing material for manufacture of metal wires | |

Continuous casting of metal wire | |

Drawing fibres reinforced with a metal wire |

Examples of places in relation to which this place is residual:

Bending sheets for making tubes | |

Bending sheet metal along straight lines between rams and anvils or abutments for making tubes | |

Bending sheet metal along straight lines by drawing procedure making use of dies or forming-rollers for making tubes | |

Seaming by folding, e.g. connecting edges of a metal sheet to form a cylinder |

This place covers:

Illustrative example of subject matter classified in this place:

Examples of places in relation to which this place is residual:

Combined processes according to methods of straightening, restoring form, bending, corrugating or flanging used in manufacture of tubes and starting from blanks having varying thickness |

This place does not cover:

Making metal tubes or metal hoses with welded or soldered helically arranged seams |

Attention is drawn to the following places, which may be of interest for search:

Involving only a soldering or welding operation |

This place covers:

Illustrative example of subject matter classified in this place:

Examples of places in relation to which this place is residual:

Deforming metal tubular bodies by applying fluid pressure |

Attention is drawn to the following places, which may be of interest for search:

Making metal tubes with non-circular section |

This place covers:

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Finishing metal tubes, e.g. sizing, burnishing | |

Machines for cutting tubes |

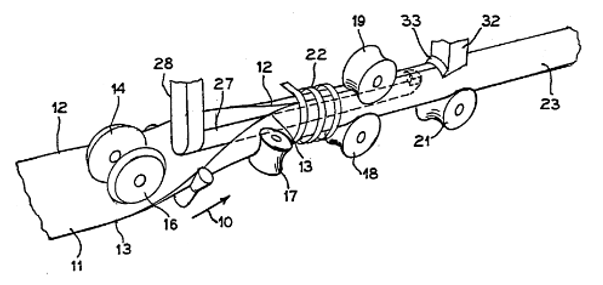

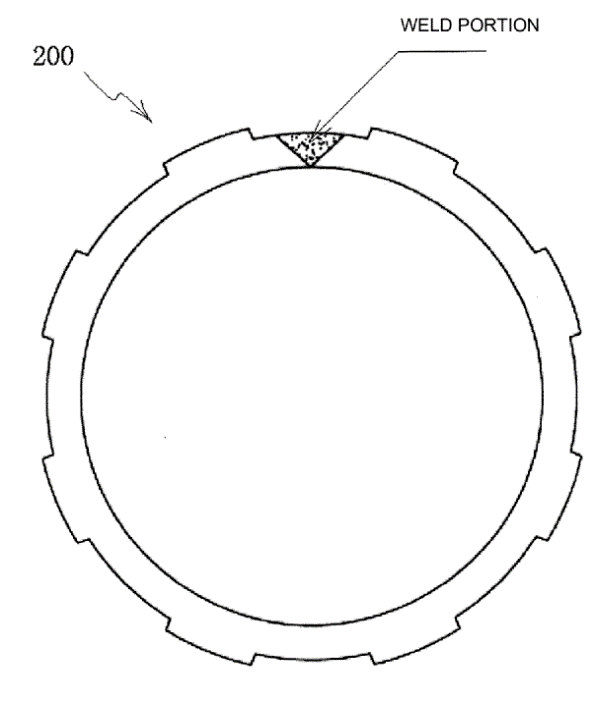

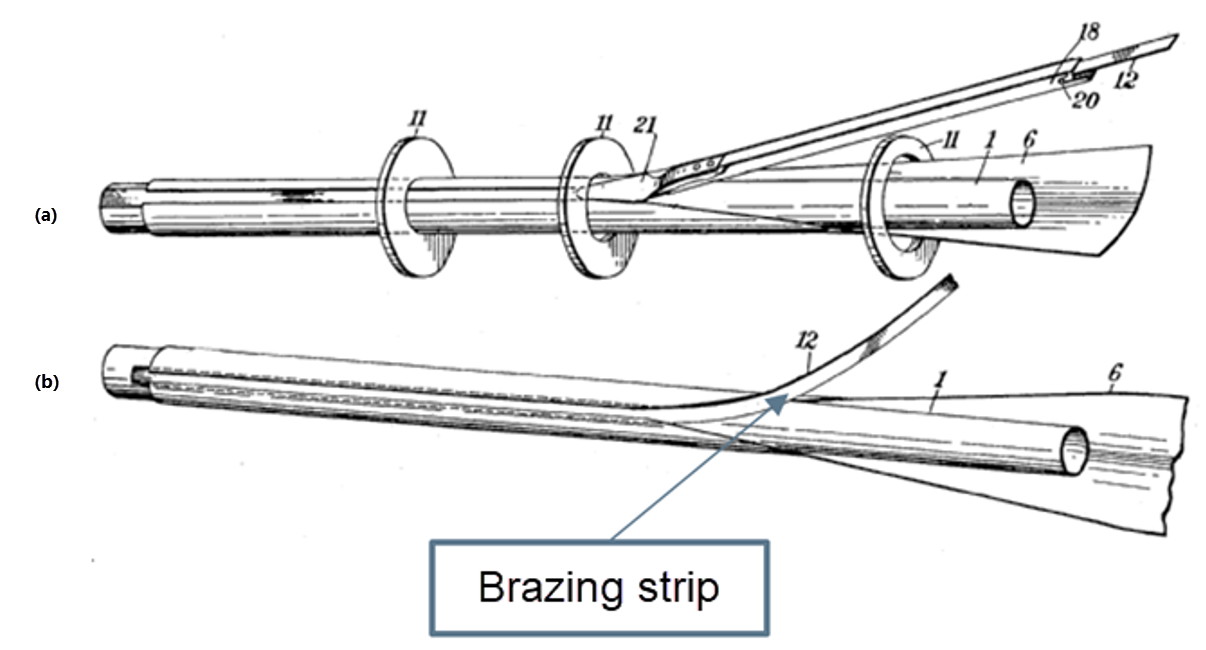

This place covers:

Illustrative example of subject matter classified in this place:

1a.

1b.

Heat treatment for metal welded joints is classified in C21D 9/50.

Examples of places in relation to which this place is residual:

Machines or devices for removing welding, brazing or soldering burrs on pipes |

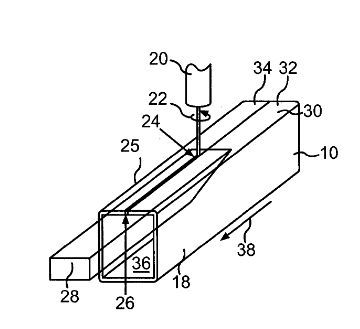

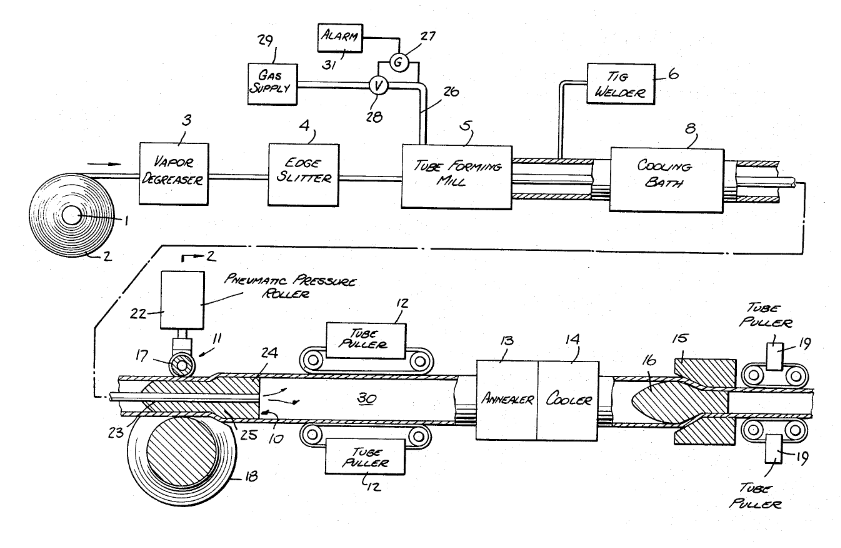

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

Attention is drawn to the following places, which may be of interest for search:

Arc welding longitudinal seam of metal tubes | |

Resistance welding using roller electrodes for welding longitudinal seams of metal tubes | |

Seam welding metal tubes by induction heating | |

Seam welding metal tubes by conduction heating | |

Laser welding of longitudinal seams of metal tubes |

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

3.

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

Attention is drawn to the following places, which may be of interest for search:

Making metal tubes by soldering or welding, but not covered by any single one of main groups B23K 1/00 - B23K 28/00 | |

Tubular or hollow metal articles made by soldering, welding or cutting |

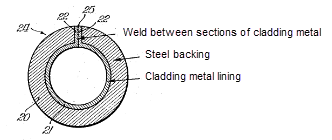

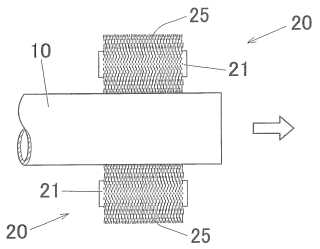

This place covers:

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates a weld (25) between sections of cladding metal comprising a steel backing (20) and a cladding metal lining (21).

2.

Attention is drawn to the following places, which may be of interest for search:

Making multi-wall metal tubes |

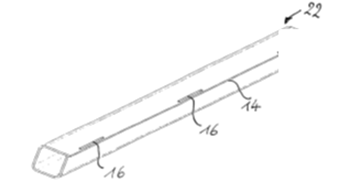

This place covers:

Manufacture of tubes or pipes with seams being neither welded nor soldered, e.g. riveted or folded seams.

Illustrative examples of subject matter classified in this place:

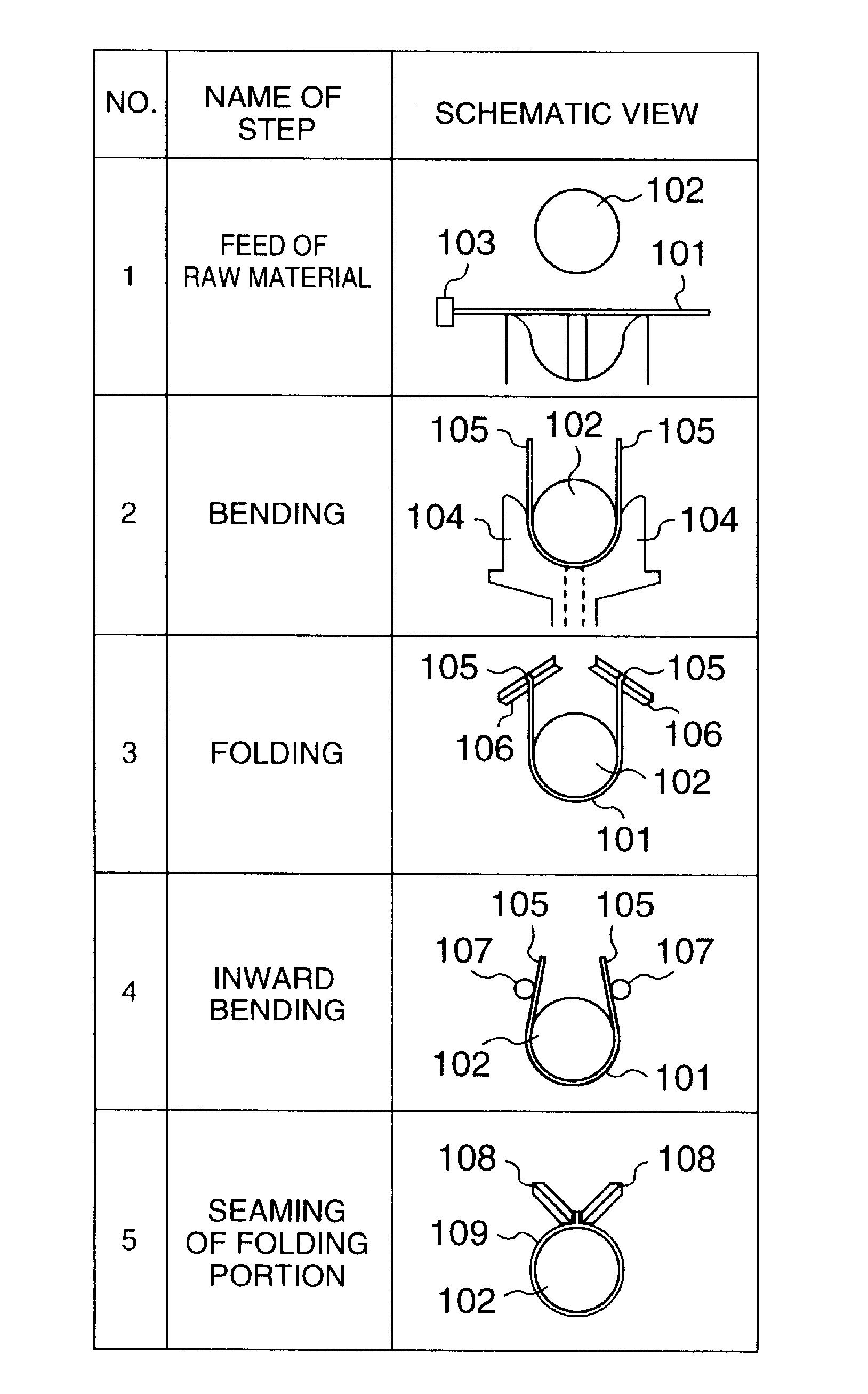

1a.

Figure 1a illustrates the manufacture of a pipe (22) with riveted seams (16).

1b.

Figure 1b illustrates a cross-sectional view of Figure 1a.

2.

3.

Figure 3 illustrates the manufacture of a pipe with a folded seam.

This place does not cover:

Making metal tubes or metal hoses with helically arranged seams being neither welded nor soldered |

Examples of places in relation to which this place is residual:

Bending sheet metal along straight lines by drawing procedure for making tubes | |

Folding sheet metal to form a cylinder by connecting edges |

This place covers:

Illustrative example of subject matter classified in this place:

1a.

1b.

Examples of places in relation to which this place is residual:

Folding sheet metal to form a cylinder by connecting edges | |

Folding of longitudinal seam of cans or tins |

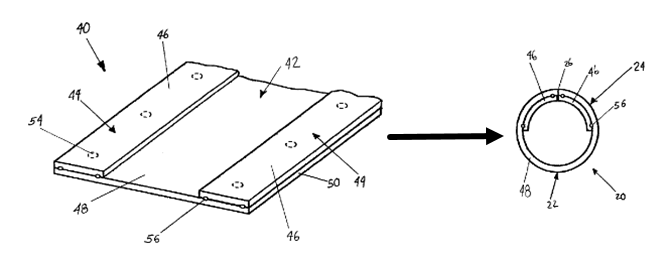

This place covers:

Manufacture of non-welded and non-soldered tubes or pipes with coated strip material or multi-wall material.

Illustrative example of subject matter classified in this place:

1a.

1b.

Examples of places in relation to which this place is residual:

Sheathing of hollow metal objects |

Attention is drawn to the following places, which may be of interest for search:

Making multi-walled metal tubes |

This place covers:

Making non-cylindrical or polygonal tubes having riveted or folded seams.

Illustrative example of subject matter classified in this place:

Examples of places in relation to which this place is residual:

Making non-cylindrical shape cans or tins, e.g. conical, rectangular, polygonal, bulged |

Attention is drawn to the following places, which may be of interest for search:

Making metal tubes with non-circular section |

This place covers:

Supply or operations combined with the supply of strip material for forming of tubes or pipes with riveted or folded seams.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates the supply of a blank and a preliminary bending operation.

2a.

2b.

2c.

2d.

Figures 2a-2d illustrate the forming of a folded seam.

Attention is drawn to the following places, which may be of interest for search:

Supply or operations combined with the supply of strip material for making metal tubes with welded or soldered seams | |

Unwinding or uncoiling metal strip material from reels or drums | |

Guiding of metal strip material from or to a coiler |

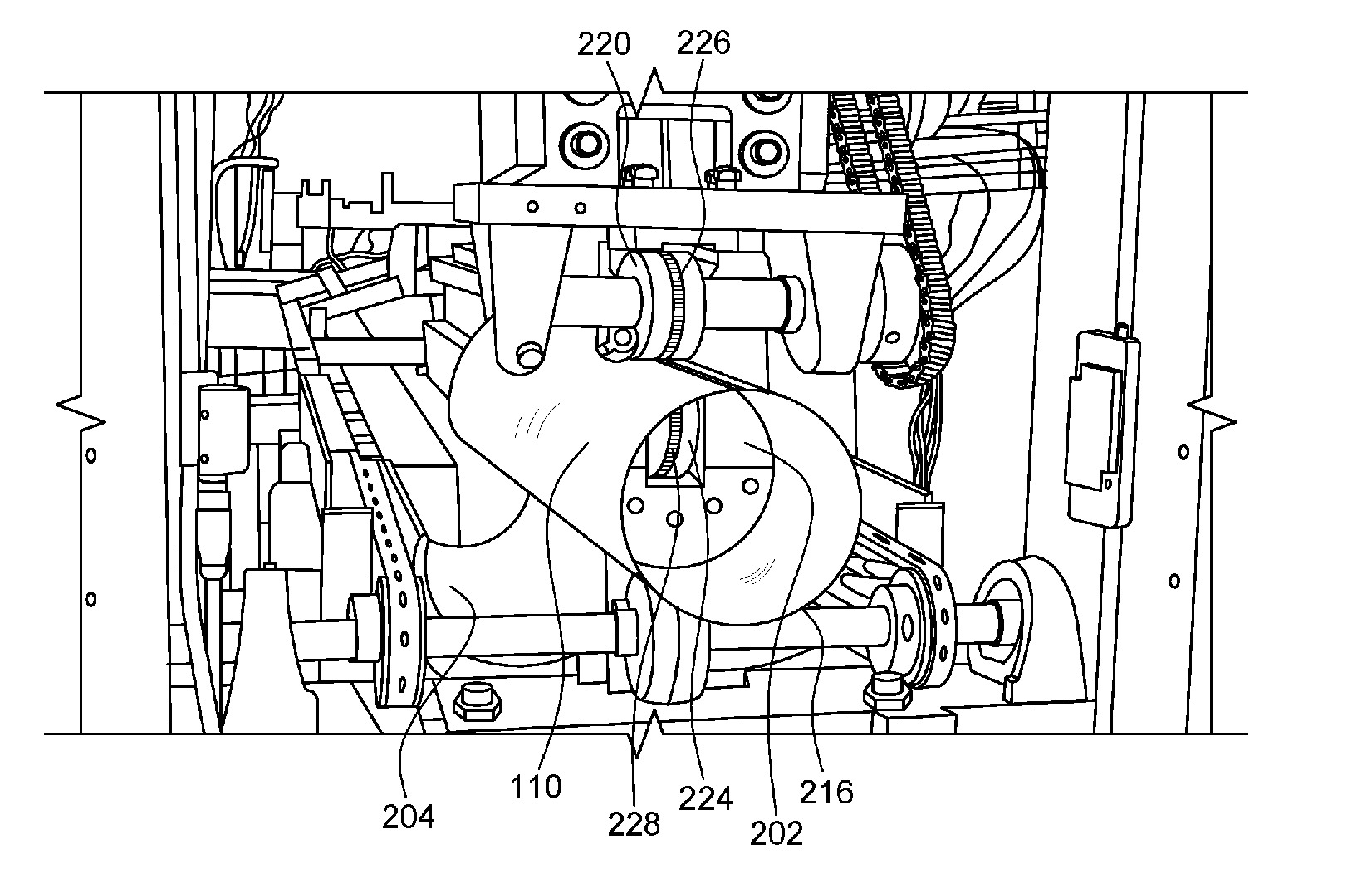

This place covers:

Treating, manipulating or cutting of tubes in combination with tube making machines for tubes with riveted or folded seams.

Illustrative example of subject matter classified in this place:

The Figure illustrates knurling wheels (226, 228) for treating an overlapped pipe seam.

Attention is drawn to the following places, which may be of interest for search:

Finishing metal tubes, e.g. sizing, burnishing | |

Transversely cutting tubes |

This place covers:

Illustrative example of subject matter classified in this place:

Examples of places in relation to which this place is residual:

Bending sheet metal along straight lines between rams and anvils or abutments for making tubes | |

Bending sheet metal along straight lines by drawing procedure making use of dies or forming-rollers for making tubes | |

Bending metal tubes using a mandrel in a press | |

Round bending of sheet metal |

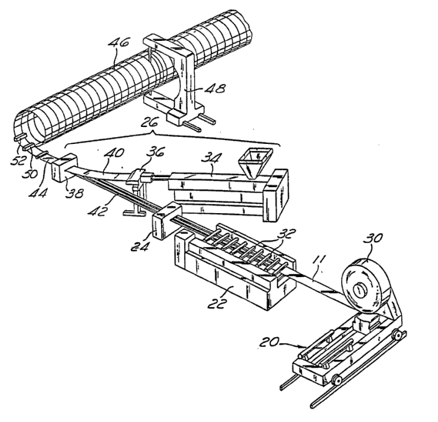

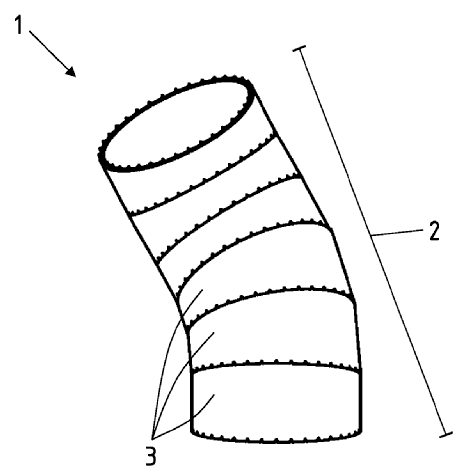

This place covers:

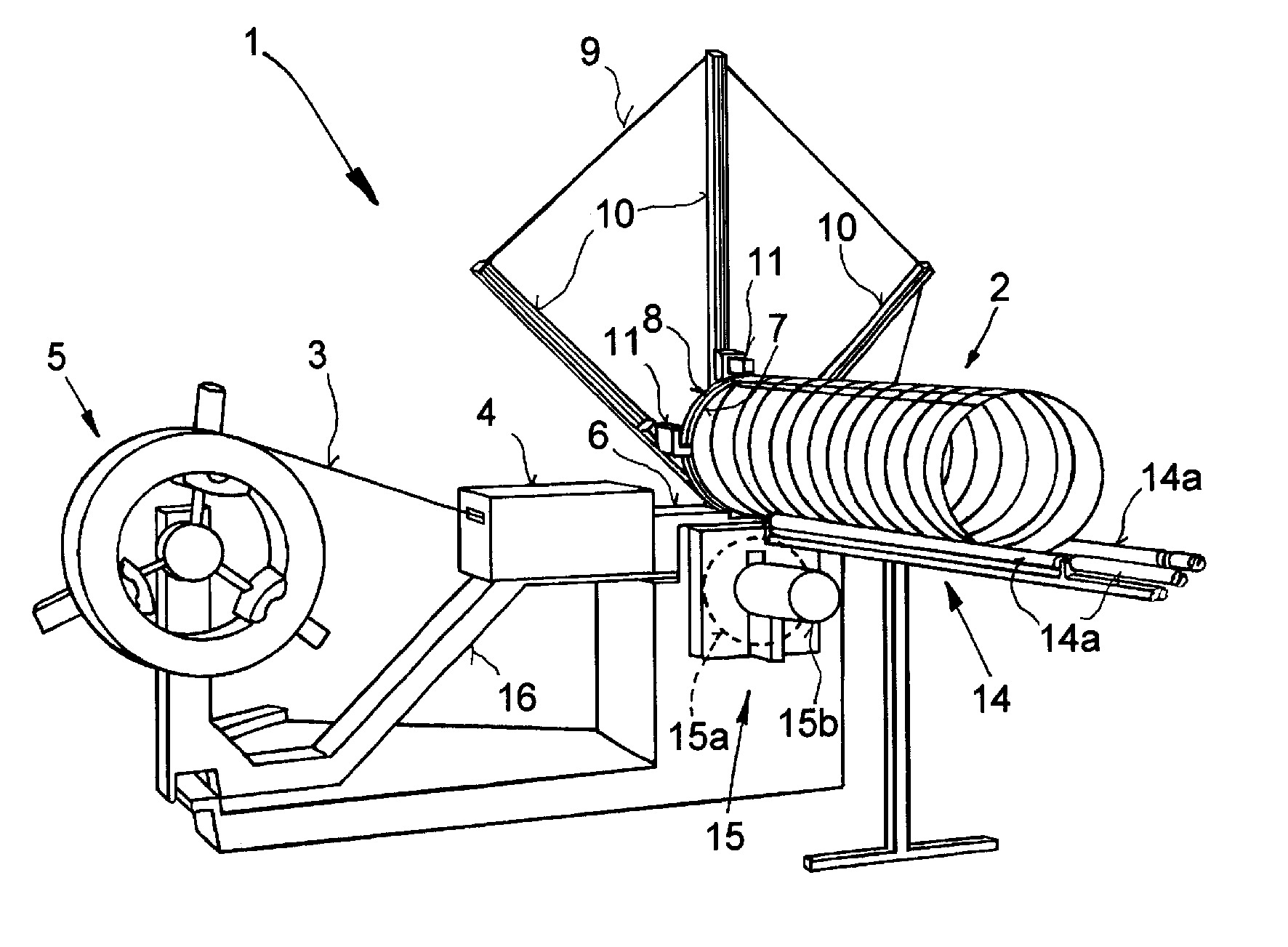

Manufacture of tubes or hoses with helical seams from a strip of material.

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Making metal tubes with helical guides without removing material | |

Making helically-ribbed metal tubes by fixing strip material to tubes |

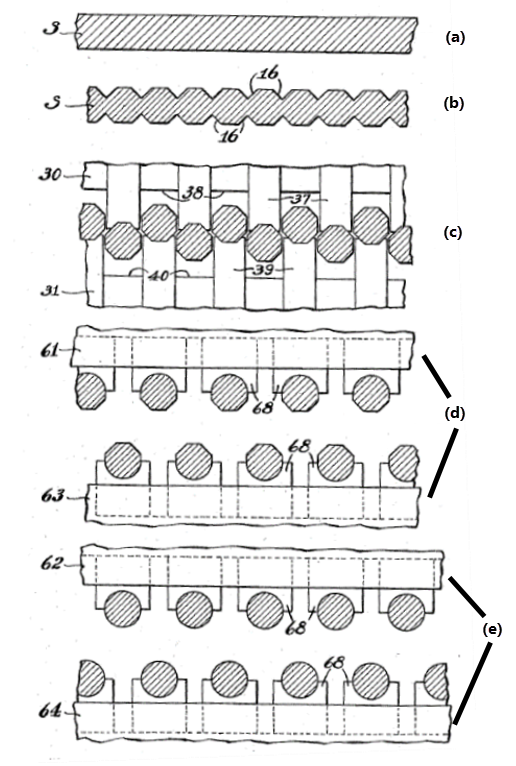

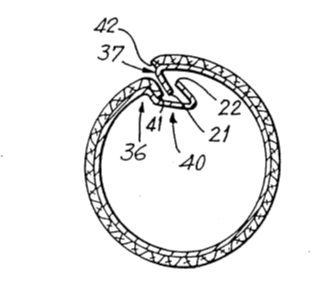

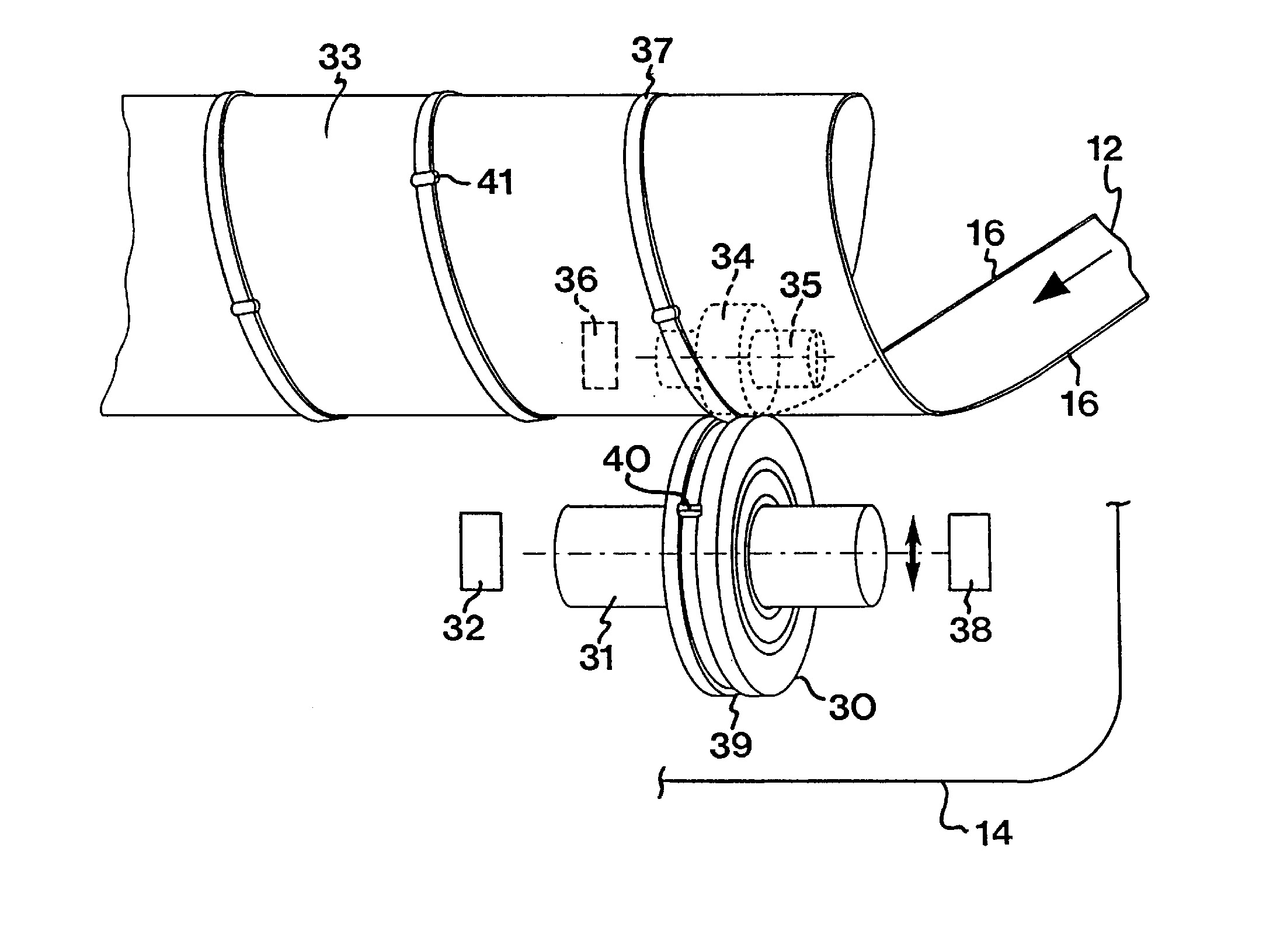

This place covers:

Illustrative example of subject matter classified in this place:

The Figure illustrates roller (30) providing lock seam deformation (41) to seal helical seam (37).

Examples of places in relation to which this place is residual:

Helical winding of elongated heat exchanger elements |

Attention is drawn to the following places, which may be of interest for search:

Hoses made of rigid metal material wound from profiled strips or bands |

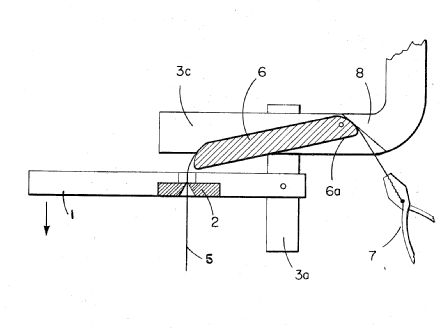

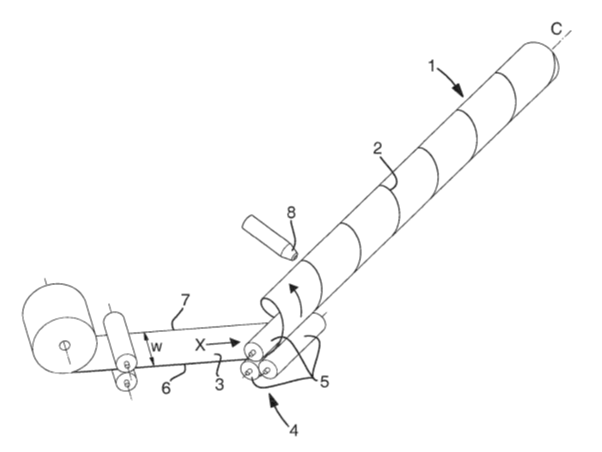

This place covers:

Illustrative example of subject matter classified in this place:

The Figure illustrates a welding electrode (8) for welding a helical seam (2).

Examples of places in relation to which this place is residual:

Helical winding of elongated heat exchanger elements |

Attention is drawn to the following places, which may be of interest for search:

Gas flame welding of helicoidal seams | |

Arc welding of helicoidal seams | |

Resistance welding of helicoidal seams using roller electrodes | |

Resistance welding of helicoidal seams | |

Laser beam welding of helicoidal seams | |

Tubes made by welding |

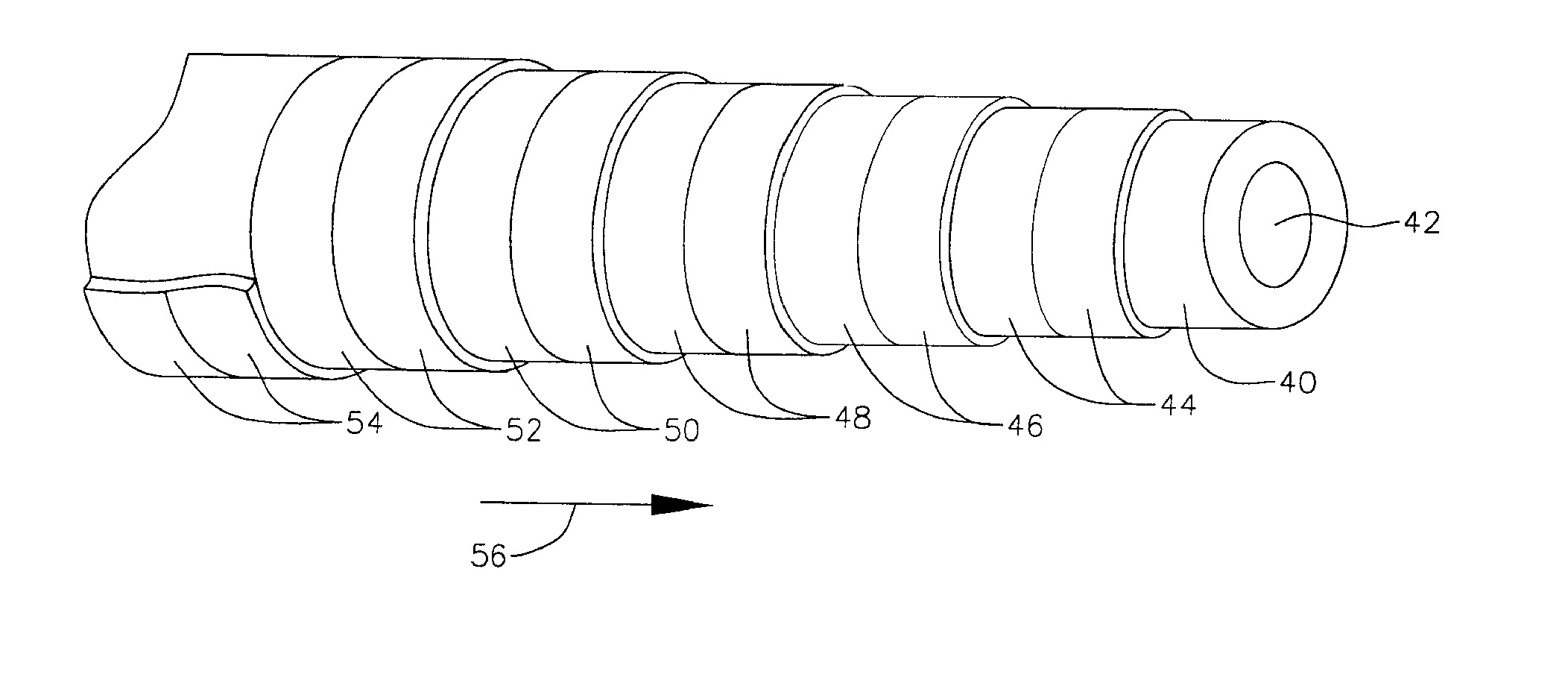

This place covers:

Illustrative example of subject matter classified in this place:

The Figure illustrates steel strip material (44, 48, 52) being helically wound with intermediate lining layers (46, 50) and a cover layer (54) to form a helically seamed coated tube.

Attention is drawn to the following places, which may be of interest for search:

Making multi-wall metal tubes | |

Rigid pipes wound from metal sheets with reinforcement | |

Hoses made of rigid metal material wound from profiled strips or bands |

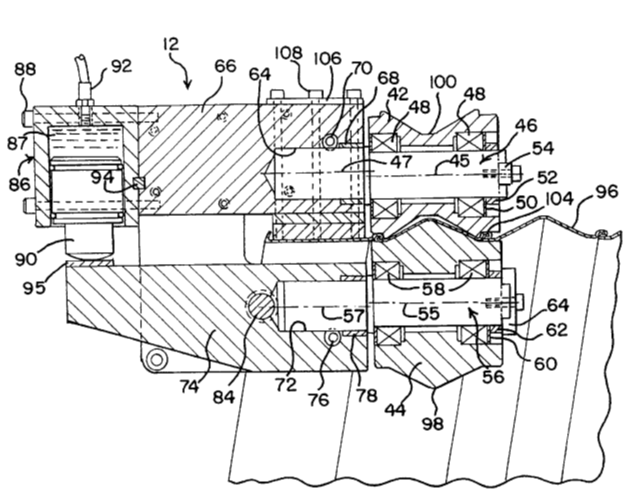

This place covers:

Manufacture of helically seamed tubes or hoses having a special shape.

Illustrative examples of subject matter classified in this place:

1.

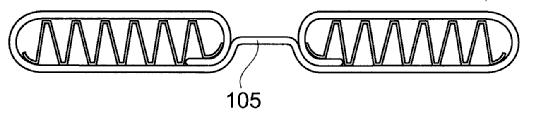

Figure 1 illustrates corrugating surfaces (98, 100) on rollers (42, 44) for creating a helically wound lock seam (104).

2.

Examples of places in relation to which this place is residual:

Corrugating metal tubes transversely, e.g. helically |

Attention is drawn to the following places, which may be of interest for search:

Making metal tubes with non-circular section | |

Making conical metal tubes |

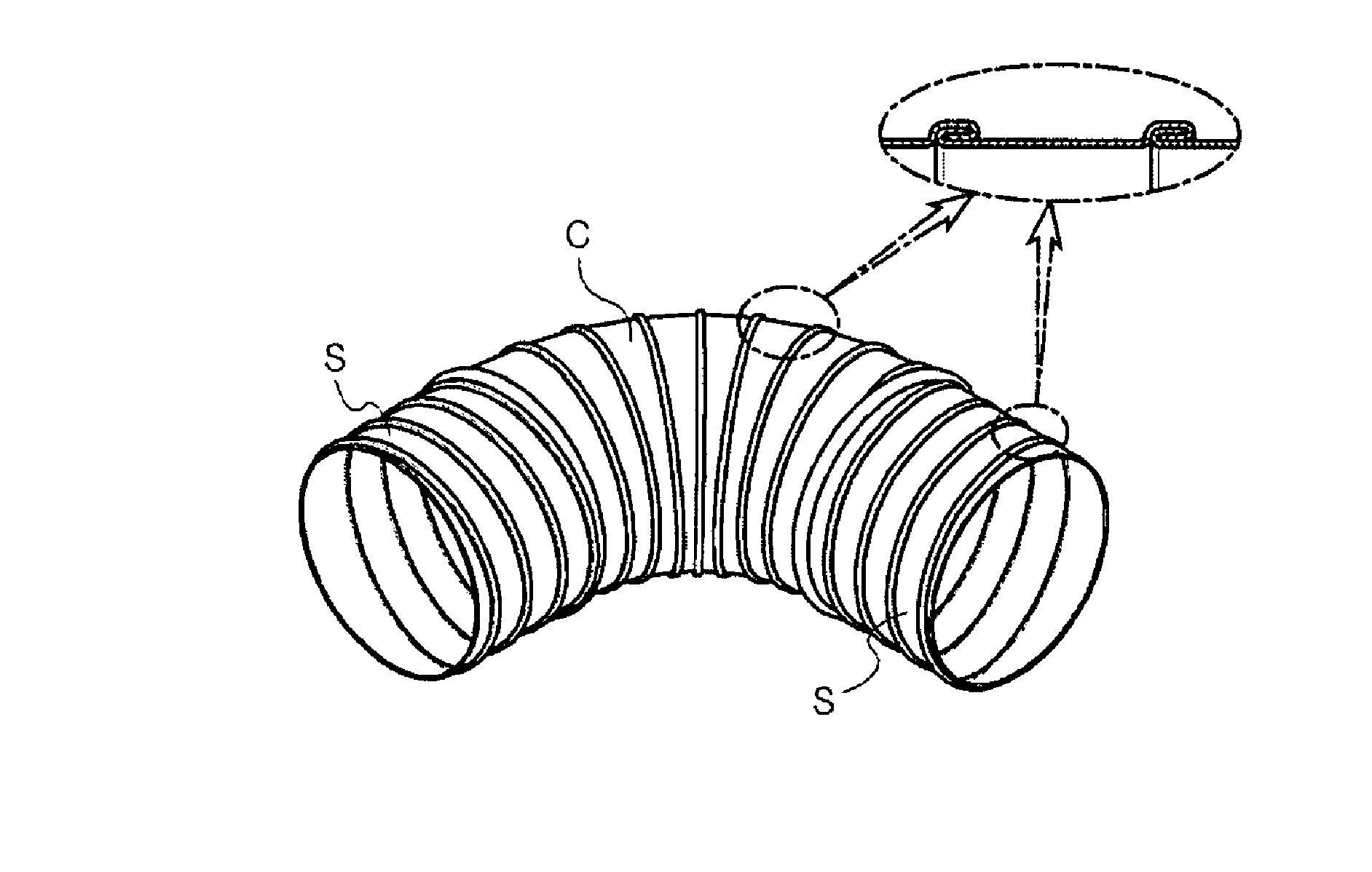

This place covers:

Illustrative example of subject matter classified in this place:

Examples of places in relation to which this place is residual:

Bending metal tubes |

Attention is drawn to the following places, which may be of interest for search:

Making tube fittings for connecting pipes |

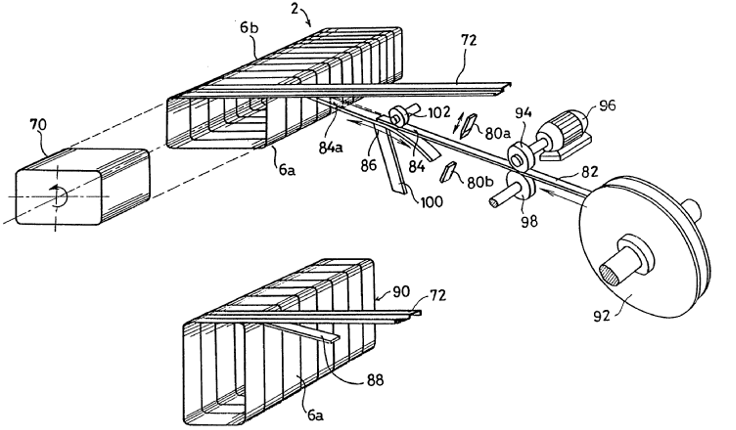

This place covers:

Supply of strip material in combination with a machine for helical winding of tubes or hoses and operations combined with supply.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates a flanging device (16) for flanging a strip (11) prior to tube winding in a tube forming tool (17).

2.

3.

4a.

4b.

Attention is drawn to the following places, which may be of interest for search:

Manufacturing metal tubes or metal hoses starting from specific blank | |

Unwinding or uncoiling metal strip material from reels or drums |

This place covers:

Helical tube or pipe treating, manipulating or cutting in combination with a helical tube making machine.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates the cutting of holes (25, 28) in a helically formed tube.

2a.

2b.

2c.

3.

Figure 3 illustrates setting the pitch value of a winding.

Attention is drawn to the following places, which may be of interest for search:

Finishing metal tubes, e.g. sizing, burnishing | |

Transversely cutting tubes |

This place covers:

Control devices for controlling helical tube or hose winding machines.

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Control devices or methods specially adapted for tube rolling in metal-rolling mills |

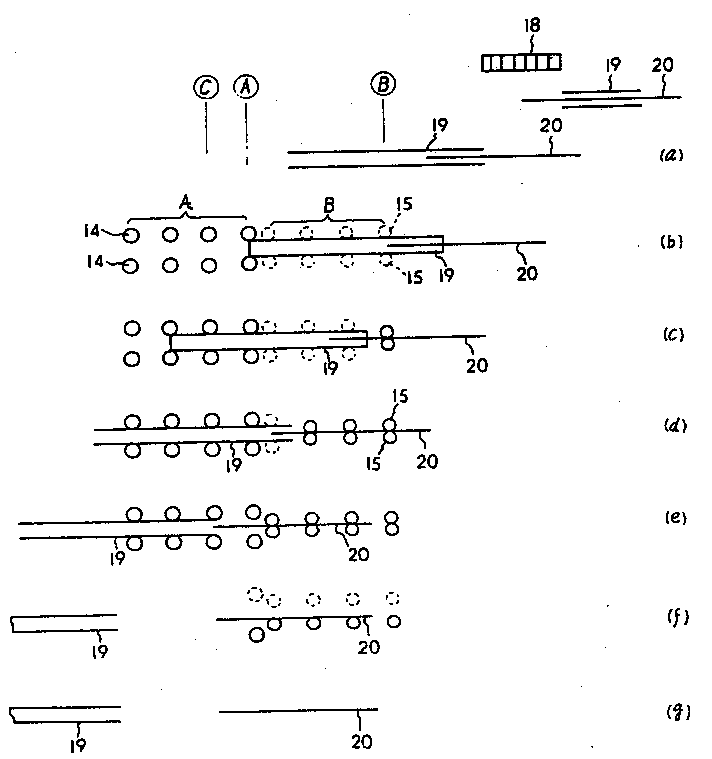

This place covers:

Manufacture of tubes or pipes from double flat material.

Illustrative examples of subject matter classified in this place:

1.

2a.

2b.

2c.

3a.

3b.

3c.

3d.

4.

Examples of places in relation to which this place is residual:

Making heat exchangers by inflating partially united sheet metal plates |

Attention is drawn to the following places, which may be of interest for search:

Making metal heat exchangers not otherwise provided for | |

Heat-exchange apparatus with plate-like conduits wherein a single plate is bent to form one or more conduits |

This place covers:

Making tubes or pipes of special shape and making tube fittings.

Illustrative examples of subject matter classified in this place:

1.

2.

This place does not cover:

Making metal tubes having a special shape, e.g. polygonal tubes, with welded or soldered seams | |

Making metal tubes having a special shape, e.g. polygonal tubes, with riveted seams | |

Making metal tubes having a special shape, with helically arranged seams |

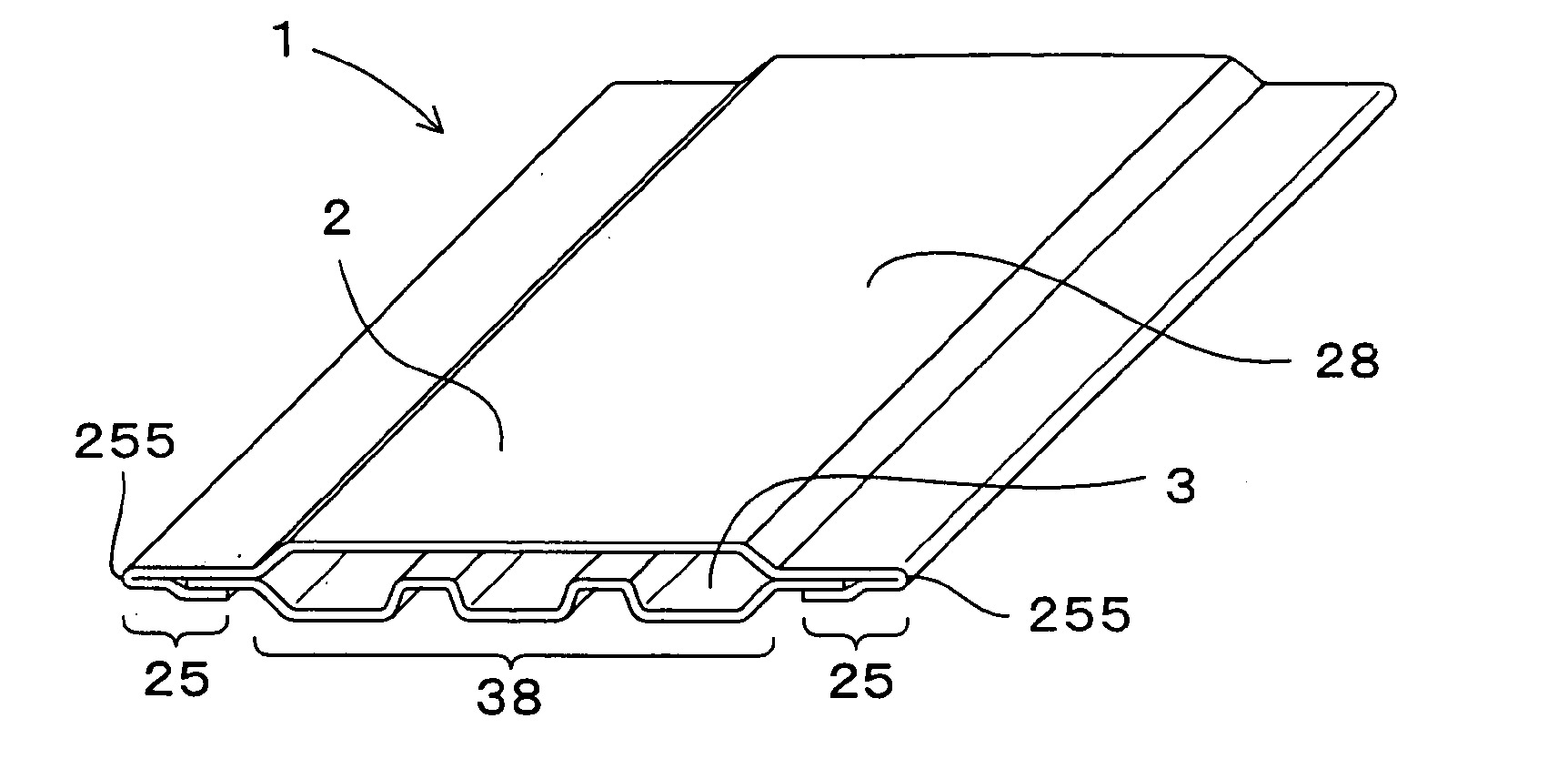

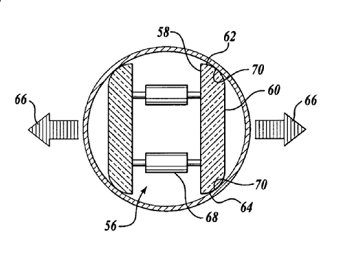

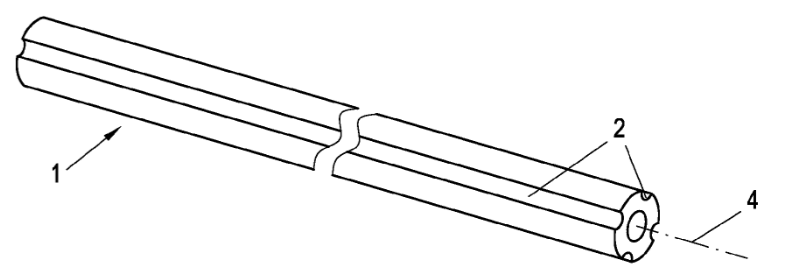

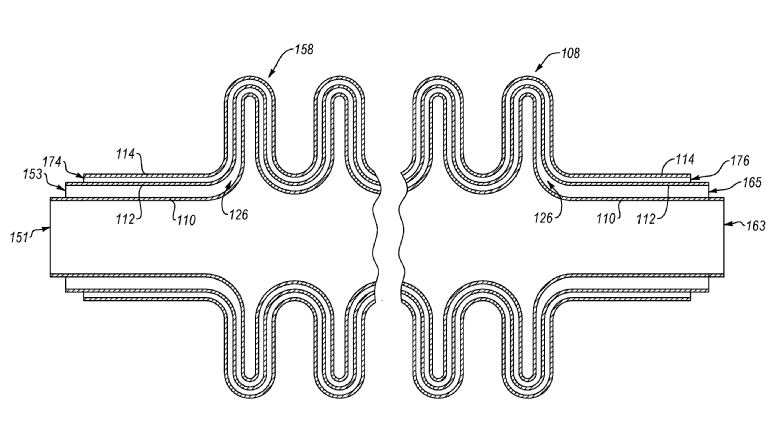

This place covers:

Making tubes or pipes with multiple passages.

Illustrative examples of subject matter classified in this place:

1.

2.

Examples of places in relation to which this place is residual:

Making uncoated tubes by direct extrusion | |

Deforming metal tubular bodies by applying fluid pressure | |

Making heat exchanger metal tubes |

Attention is drawn to the following places, which may be of interest for search:

Making metal heat exchangers not otherwise provided for | |

Heat exchange apparatus with plate-like conduits wherein a single plate is bent to form one or more conduits | |

Heat-exchange tubular elements with non-circular cross-section and with multiple channels |

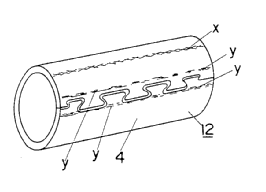

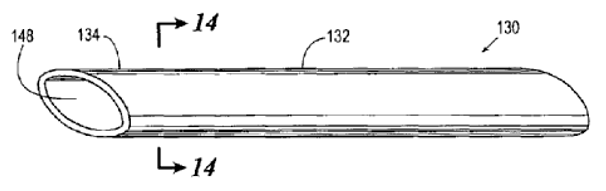

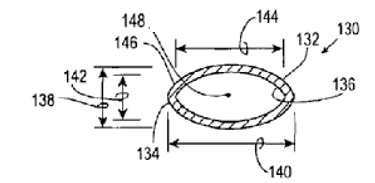

This place covers:

Illustrative example of subject matter classified in this place:

1a.

1b.

Examples of places in relation to which this place is residual:

Corrugating metal tubes longitudinally by applying fluid pressure | |

Deforming metal tubular bodies by applying fluid pressure |

Attention is drawn to the following places, which may be of interest for search:

Treating surfaces mechanically with or without calibrating | |

Barrels or gun tubes with grooves or rifling |

This place covers:

Illustrative example of subject matter classified in this place:

The Figure illustrates a rotating mandrel (7) with grooves (8) for forming the interior of a barrel.

Examples of places in relation to which this place is residual:

Corrugating metal tubes longitudinally by applying fluid pressure | |

Deforming metal tubular bodies by applying fluid pressure |

Attention is drawn to the following places, which may be of interest for search:

Making helical or similar guides in or on metal tubes without removing material | |

Forming profiles on internal or external surfaces by forging, hammering or pressing | |

Barrels or gun tubes with grooves or rifling |

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

3.

Examples of places in relation to which this place is residual:

Making metal-coated tubes by extrusion | |

Deforming metal double-walled bodies by applying fluid pressure | |

Assembling of tubes with tubes |

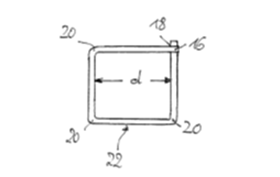

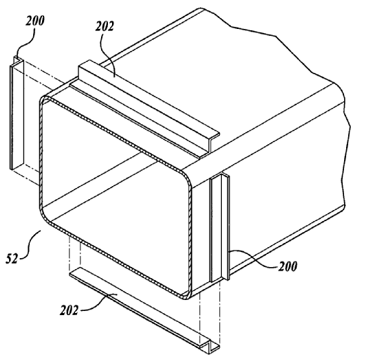

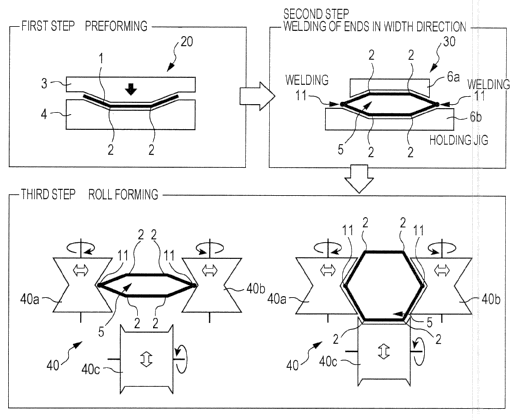

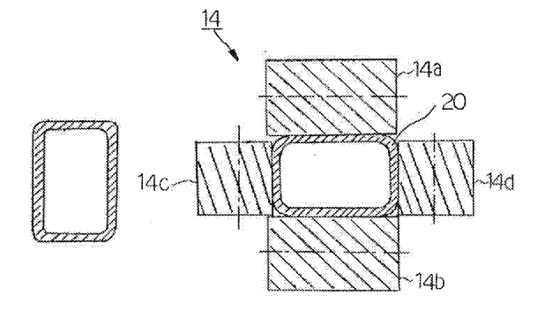

This place covers:

Making polygonal or other non-circular cross-section tubes.

Illustrative examples of subject matter classified in this place:

1a.

1b.

2a.

2b.

This place does not cover:

Making metal tubes with multiple passages | |

Making multi-wall metal tubes |

Examples of places in relation to which this place is residual:

Deforming metal tubular bodies by applying fluid pressure | |

Making non-circular cans or tins |

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

This place does not cover:

Making helical or similar guides in or on metal tubes without removing material | |

Making finned or ribbed metal tubes by fixing strip or like material to tubes |

Examples of places in relation to which this place is residual:

Locally embossing the walls of formed can bodies |

Attention is drawn to the following places, which may be of interest for search:

Forming profiles on internal or external surfaces by forging, hammering or pressing | |

Making hollow metal racks |

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

Examples of places in relation to which this place is residual:

Perforating metal sheet bodies by applying fluid pressure | |

Perforating metal tubular bodies by applying fluid pressure | |

Perforating, i.e. punching holes, in tubes |

Attention is drawn to the following places, which may be of interest for search:

Flow drilling during friction heat forging |

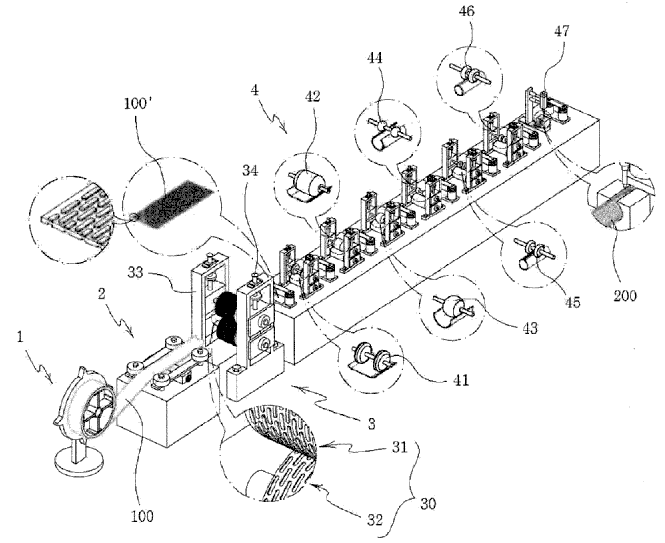

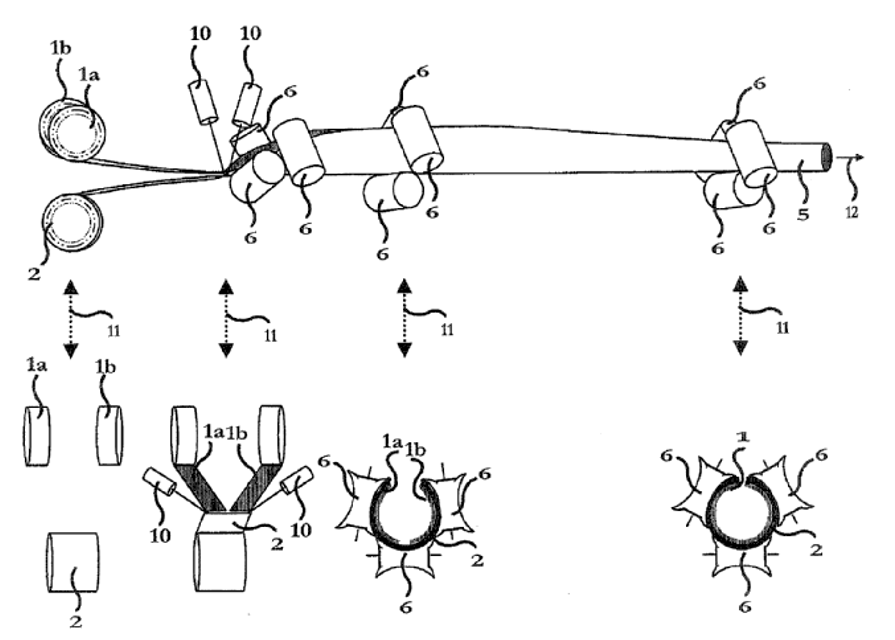

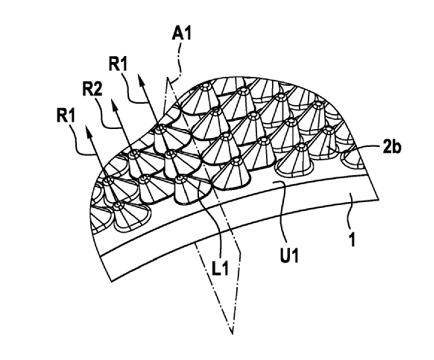

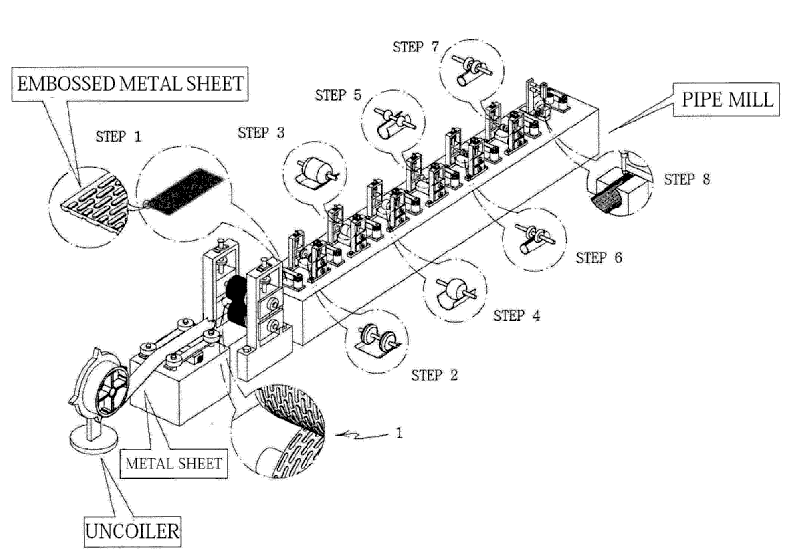

This place covers:

Forming dimples in or protrusions on a tube.

Illustrative examples of subject matter classified in this place:

1a.

1b.

2.

Figure 2 illustrates a pipe mill that uncoils a metal sheet and embosses (1) the metal sheet in step 1 and then advances the metal sheet in successive steps to seam and bend the embossed metal sheet into a tube/pipe.

Examples of places in relation to which this place is residual:

Corrugating metal tubes | |

Making hollow metal objects with corrugated walls |

Attention is drawn to the following places, which may be of interest for search:

Embossing metal sheets or rolls by rolling | |

Tubular elements with means for increasing heat-transfer area, e.g. with fins, with projections or recesses | |

Plate-like elements with means for increasing heat-transfer area, the means being integral punctual deformations of the element, e.g. dimples |

This place covers:

Making tubes with varying cross-sectional diameter.

Illustrative examples of subject matter classified in this place:

1.

2.

Examples of places in relation to which this place is residual:

Drawing metal tubular articles by means of mandrels | |

Pointing of metal tubes | |

Metal extrusion profiling tools for making tapered tubes | |

Procedures to alter the diameter of metal tube ends |

Attention is drawn to the following places, which may be of interest for search:

Shaping hollow metal articles with different cross-section by forging | |

Forging or pressing end portions of hollow metal articles |

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2a.

2b.

3.

Examples of places in relation to which this place is residual:

Procedures to alter the diameter of metal tube ends | |

Making conically shaped hollow metal objects |

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

Attention is drawn to the following places, which may be of interest for search:

Metal towers |

Examples of places in relation to which this place is residual:

Making heat exchangers |

Attention is drawn to the following places, which may be of interest for search:

Flow drilling during friction heat forging |

This place covers:

Cleaning metal products, wherein the cleaning action is realised by using machines of B21C or wherein the cleaning action is used in combination with machines of B21C.

This group includes in particular, cleaning metal products, especially descaling, by metal drawing, or with methods associated to metal drawing or winding processes.

Illustrative example of subject matter classified in this place:

Devices for de-scaling metal sheet in combination with rolling are classified in B21B 45/04.

Devices for de-scaling wire or like flexible work are classified in B21C 43/04.

This place covers:

Illustrative example of subject matter classified in this place:

This place covers:

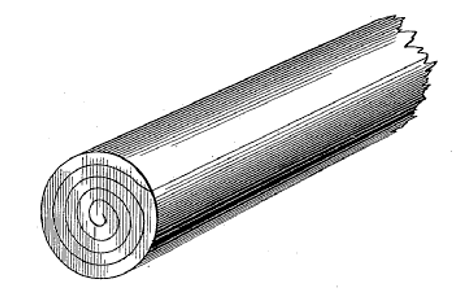

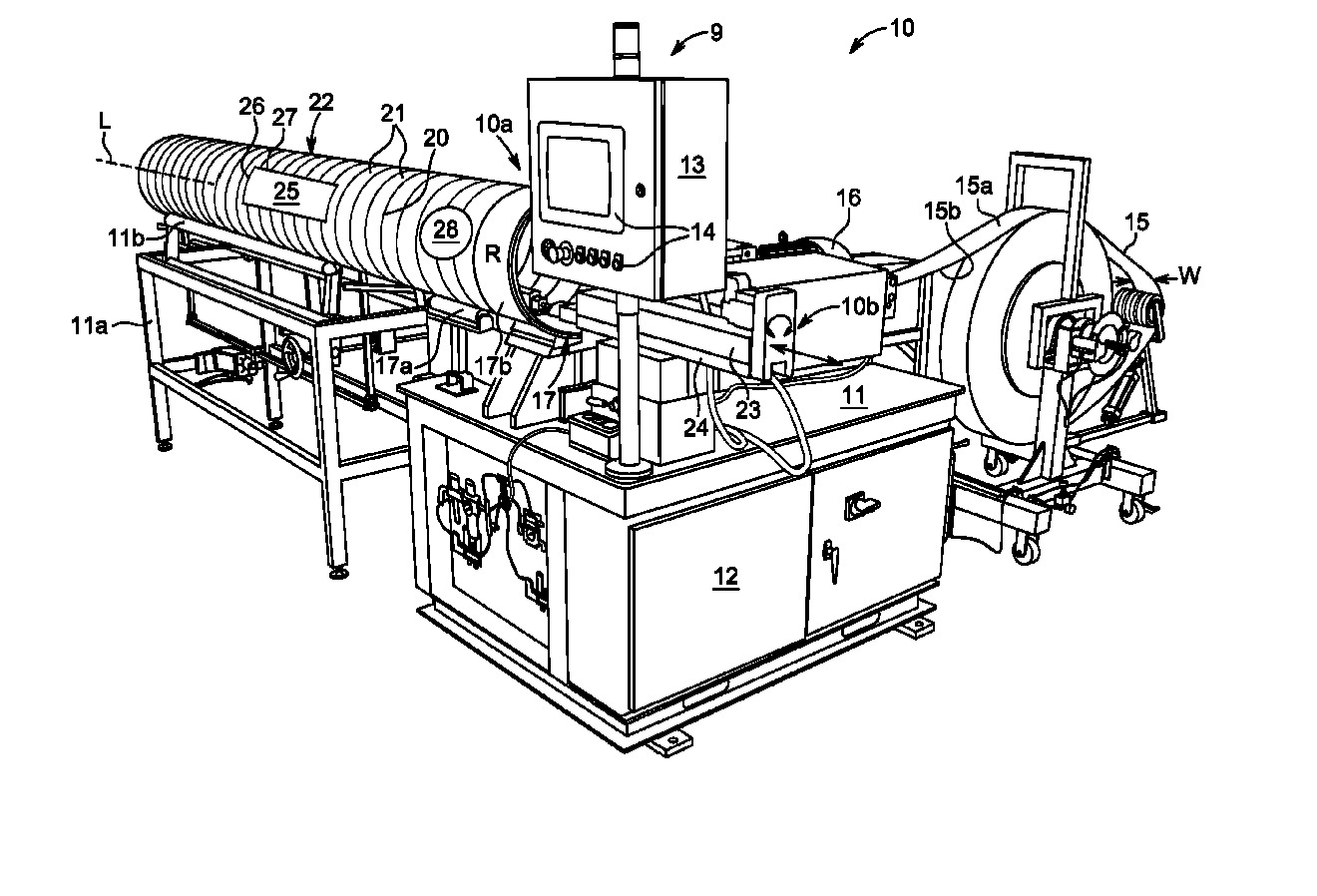

Methods and devices for coiling (winding) and uncoiling (unwinding) of metal wire, band or similar metal product.

Associated operations, like feeding or guiding the material, transferring coils, joining wire or band ends, treating the material, holding on drums or coil holders.

Illustrative example of subject matter classified in this place:

This place does not cover:

Coiling metal wire into particular form |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Hot coilers in connection with heat-treatment apparatus for metal strips or wire |

Attention is drawn to the following places, which may be of interest for search:

Joining ends of material to continuous strip, bar or sheet in metal-rolling mills |

Attention is drawn to the following places, which may be of interest for search:

Reels or drums |

Attention is drawn to the following places, which may be of interest for search:

Joining ends of material to continuous strip, bar or sheets in metal-rolling mills |

Attention is drawn to the following places, which may be of interest for search:

Gripping means |

This place covers:

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Metal drawing chains |

This place covers:

Devices for temporarily accumulating metallic material, e.g. metal bands or wires.

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Accumulating easily-flexible work, e.g. wire, sheet metal bands, in loops or curves | |

Advancing webs in general |

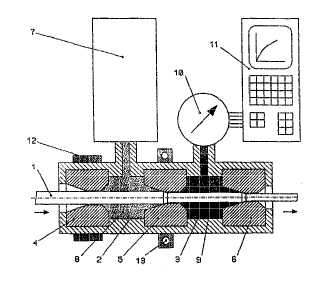

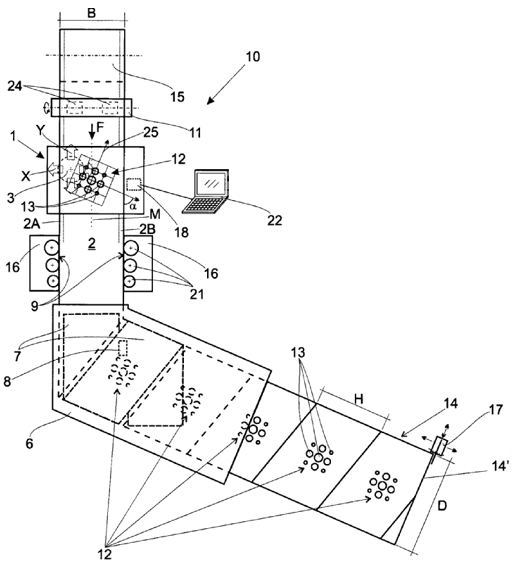

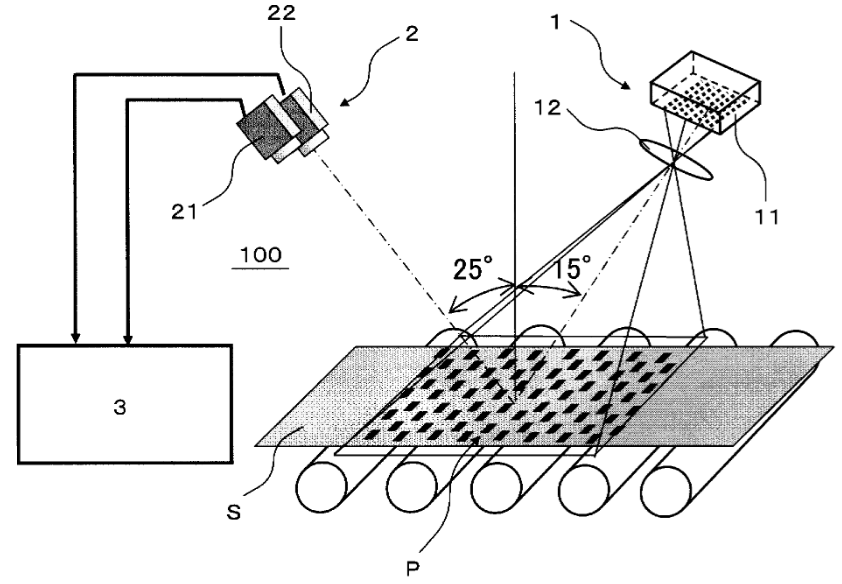

This place covers:

Mainly detecting flaws of metal sheets and positioning or marking said flaws.

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Machines or apparatus for embossing decorations or marks |

This place covers:

Subject-matter not provided for in other groups of this subclass concerning the manufacture of metal sheets, wire, rods, tubes or profiles otherwise than by rolling

Subject-matter not provided for in other groups of this subclass concerning auxiliary operations used in connection with metal-working without essentially removing material.