CPC Definition - Subclass B60C

Attention is drawn to the following places, which may be of interest for search:

Manufacture, repairing |

This place covers:

Tyres including a chemical composition, i.e. a chemical substance or a combination of chemical substances, or a physical arrangement or mixture of the composition, exhibiting an essential or distinctive attribute to enhance the general structural characteristics of the tyre.

Examples of subject matter classified in this place:

1.

Composition | Parts by weight |

Rubber | 100 |

Carbon black | 45 |

Stearic acid | 3 |

Zinc oxide | 3 |

Antioxidant | 1.5 |

Softener | 5 |

Nickel dibutyl dithiocarbamate | 1.5 |

Mercaptobenzoate | 0.9 |

Sulfur | 2.75 |

Table above shows a composition of a rubber side wall stock.

The presence of the nickel dibutyl dithiocarbamate in the composition improves sidewall ozone checking resistance.

2.

A liner composition comprises a blend of a sulfur-vulcanisable elastomeric material with a partially-refined precured rubbery copolymer of a major proportion of an isoolefin having from four to seven carbon atoms with a minor proportion of an open-chain aliphatic conjugated diolefin having from four to eight carbon atoms. The liner of such composition provides excellent resistance to air diffusion and may be directly bonded to the rubbery body of the article merely by vulcanising the liner in contact with the rubbery body portion, thereby eliminating the necessity of using a tie gum or adhesive in adhering the liner to the rubbery body. Furthermore, the liner has an excellent resistance to chafing and may be manufactured in numerous colours.

Attention is drawn to the following places, which may be of interest for search:

Inflatable pneumatic tyres or inner tubes made from other material than rubber | |

Pneumatic tyres whose individual reinforcements, including any treatments thereon (e.g. adhesive treatment), are characterised by the chemical composition | |

Tyres whose individual bead reinforcements, including any treatments thereon (e.g. adhesive treatment), are characterised by the chemical composition | |

Tyres characterised by means enabling restricted operation in damaged or deflated condition whose internal lubrication is characterised by the lubricant chemical composition | |

Electric charge dissipating arrangements | |

Use of inorganic or non-macromolecular organic substance as compounding ingredients | |

Rubber compositions for general use |

Tyres characterised by physical properties, e.g. modulus, tan delta or dimensions of the tyre component made from the chemical composition are also classified elsewhere in B60C as appropriate:

Tread rubber | |

Carcass coating rubber | |

Belt coating rubber | |

Zero-degree belt coating rubber | |

Sidewall rubber | |

Bead reinforcing layer coating rubber | |

Run-flat sidewall insert rubber |

This place covers:

Subject matter wherein the chemical composition is provided as an inner liner, i.e. an integral layer or coating which has a relatively high resistance to the diffusion of inflation medium, e.g. air, at the inflation medium contacting surface of an inflatable pneumatic tyre.

Attention is drawn to the following places, which may be of interest for search:

Inflatable pneumatic tyres with impervious inner liner or coating structure or properties | |

Tyres having self-sealing layer | |

Sealing compositions per se |

Inflatable pneumatic tyres having a member performing the function of auto-repairing or self-sealing punctures characterised by the chemical composition are to be classified in B60C 19/12 unless the member is disclosed as also being the inner liner.

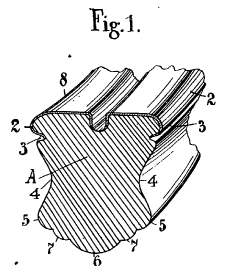

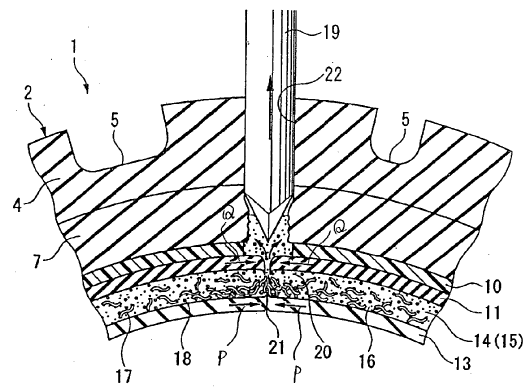

This place covers:

Subject matter wherein the chemical composition is located in a tread cap or tread base.

Tread is an outer part of a tyre that makes contact with the ground.

Attention is drawn to the following places, which may be of interest for search:

Tyre tread characterised by physical properties or dimensions |

This place covers:

Subject matter wherein the chemical composition is located in at least one of the sidewalls, i.e. external parts of the tyre extending between the tread and rim-engaging portions, e.g. beads, and covering the carcass.

Attention is drawn to the following places, which may be of interest for search:

Tyre sidewalls characterised by physical properties | |

Tyre sidewalls characterised by inlay, coating or different rubber layers |

This place covers:

Subject matter wherein the chemical composition is located in the sidewall insert, i.e. a reinforcement layer which enables restricted operation of a pneumatic tyre in damaged or deflated condition.

Attention is drawn to the following places, which may be of interest for search:

Tyres with sidewall rubber inserts |

This place covers:

Subject matter wherein the chemical composition is located in a carcass layer, i.e. a part of an inflatable pneumatic tyre exclusive of the tread, sidewalls and belts that forms the body of the tyre.

A carcass layer is usually made of reinforcement embedded in a matrix material, e.g. carcass coating rubber or topping rubber or skim rubber, and the chemical composition forms at least part of the matrix material.

Attention is drawn to the following places, which may be of interest for search:

Pneumatic tyres with carcass layer structure or properties |

This place covers:

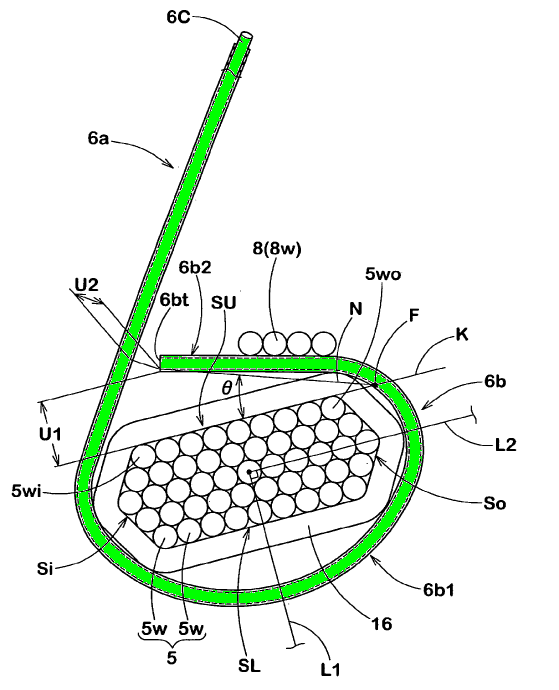

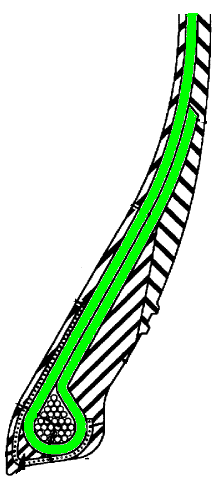

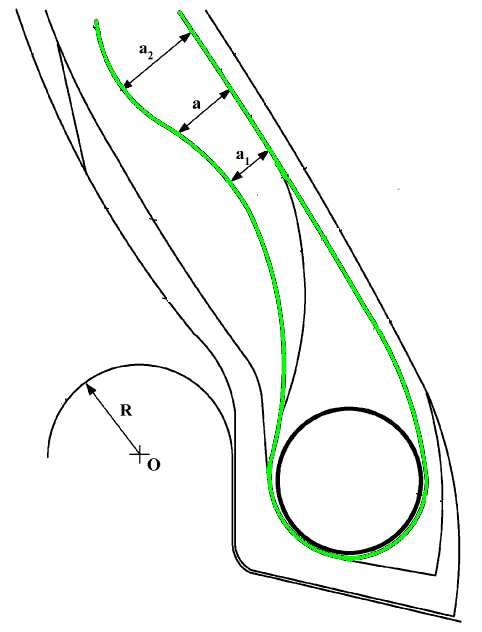

Tyres distinguished by a mathematical relationship, e.g. equation or ratio, or an absolute dimension, e.g. radius of curvature, which mathematical relationship or absolute dimension describes the cross-sectional profile or cross-sectional shape of the tyre.

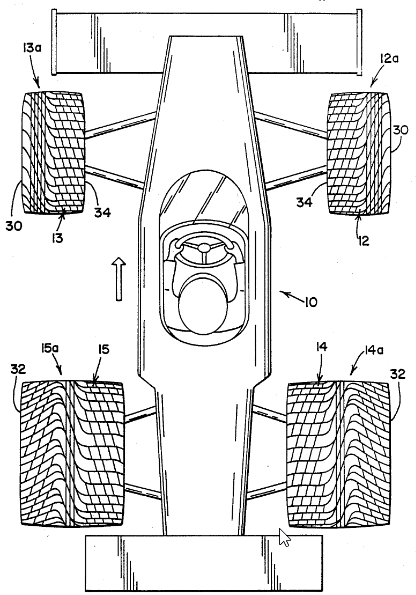

Illustrative examples of subject matter classified in this place:

1.

2.

3.

Attention is drawn to the following places, which may be of interest for search:

Wheels characterized by rail-engaging elements and having non-elastic tyres | |

Wheels characterized by rail-engaging elements and having elastic tyres |

Documents which nominally fit within B60C 3/00 but otherwise fit in any of the areas listed below should be classified in the appropriate area listed below:

Tyres whose transverse section is characterised only by carcass ply curvature | |

Tyres whose transverse section is characterised only by tyre tread radius of curvature | |

Tyres whose transverse section is characterised only by shape of the shoulders between tread and sidewall | |

Tyres whose transverse section is characterised only by sidewall radius of curvature | |

Tyres whose transverse section is characterised only by arrangement of sidewall grooves or ribs | |

Tyres whose transverse section is characterised only by shape of the tyre bead contour |

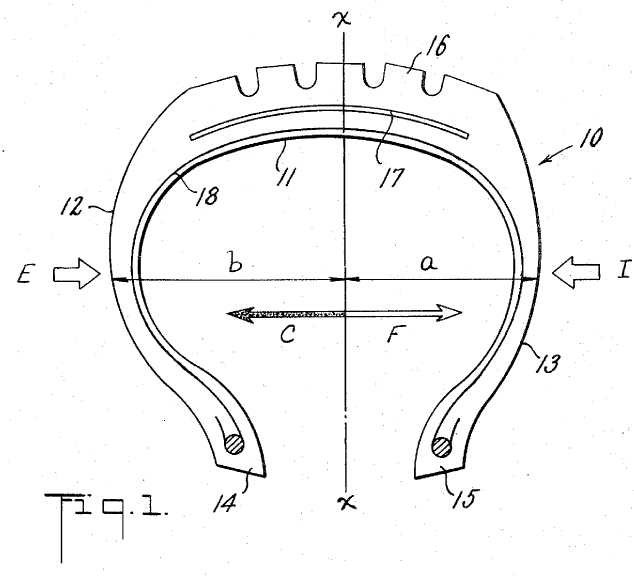

This place covers:

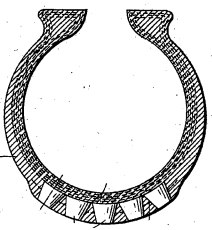

Subject matter under main group B60C 3/00 wherein a cross-section defined by a plane passing through the rotation axis of the tyre defines a continuous, circular-type configuration.

Example:

Attention is drawn to the following places, which may be of interest for search:

Securing tyres without beads; Securing closed torus or tubular tyres | |

Tyres with openings closeable by means other than the rim; Closing means therefor |

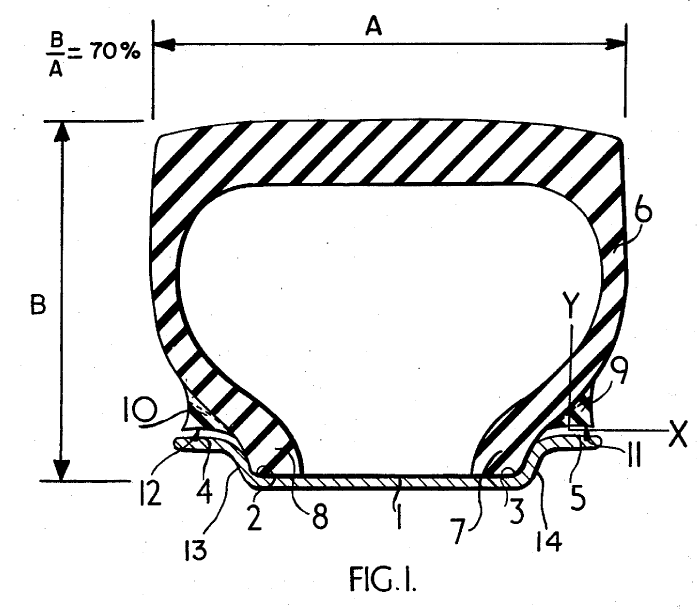

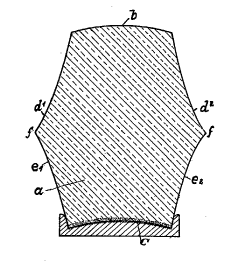

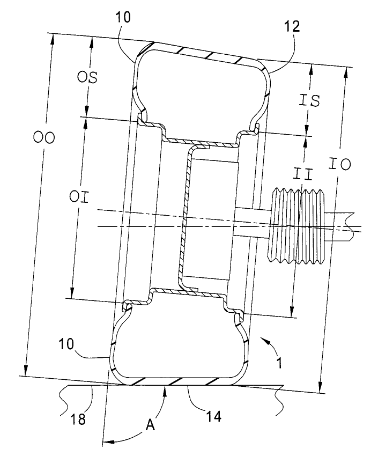

This place covers:

Subject matter under main group B60C 3/00 wherein the tyre is characterised by the relative dimensions of the section, e.g., section width, section height, and/or aspect ratio.

Example:

This place does not cover:

Tyre cross-section asymmetric about equatorial plane |

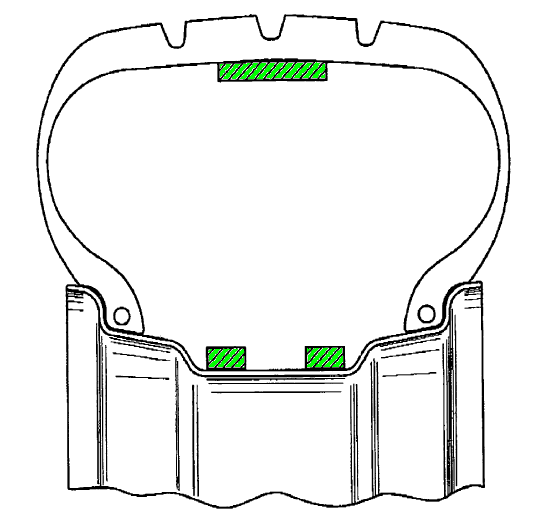

This place covers:

Subject matter under main group B60C 3/00 wherein the section does not have a plane longitudinally bisecting the section into mirror image halves, i.e. tyre equatorial plane or midcircumferential plane.

Example:

Attention is drawn to the following places, which may be of interest for search:

Asymmetric carcasses | |

Asymmetric belts | |

Asymmetric caps and base treads | |

Asymmetric tread patterns | |

Asymmetric bead seats | |

Asymmetric bead reinforcement | |

Tyres requiring asymmetric or special mounting |

This place covers:

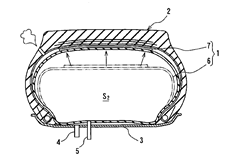

Example illustrating storage condition vs. inflated condition of a spare tyre:

Attention is drawn to the following places, which may be of interest for search:

Run-flat tyres |

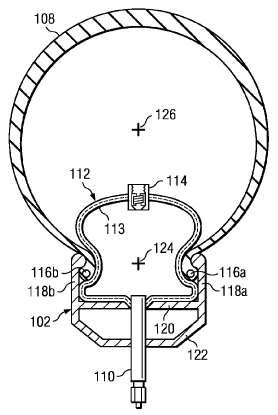

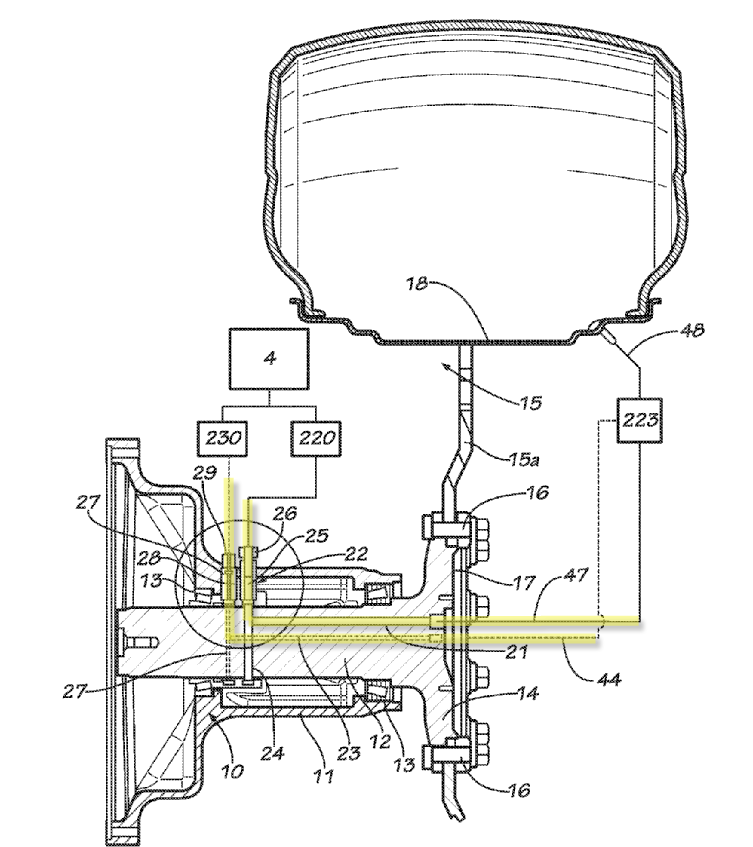

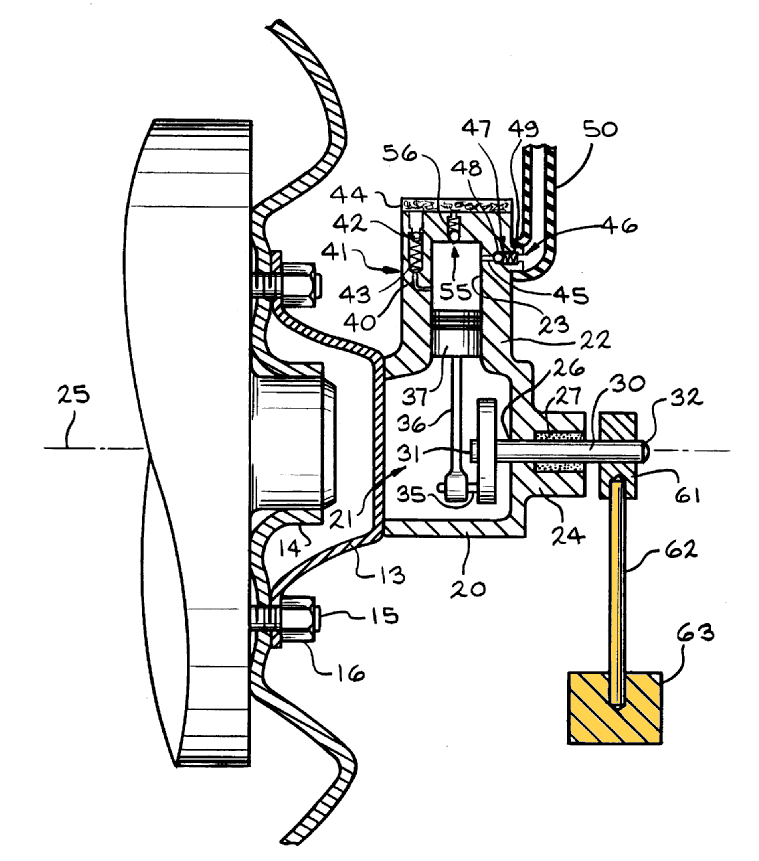

This place covers:

Subject matter wherein a tyre casing structure contains a chamber or chambers or a flexible closed annular element carried in said chamber whereby said chamber or annular element is filled with fluid under pressure greater than atmospheric pressure to sustain the tyre in inflated shape upon a hub or rim element.

This place does not cover:

Tyres characterised by the chemical composition or the physical arrangement or mixture of the composition | |

Reinforcements or ply arrangement of pneumatic tyres | |

Tyre tread bands; Tread patterns; Anti-skid inserts | |

Tyre sidewalls; Protecting, decorating, marking or the like | |

Tyre beads, e.g. ply turn-up or overlap | |

Tyres characterised by means enabling restricted operation in damaged or deflated condition; Accessories therefor |

Pneumatic tyres with an inner tube smaller than the tyre inner chamber provided for run-flat use are classified in B60C 17/01 only.

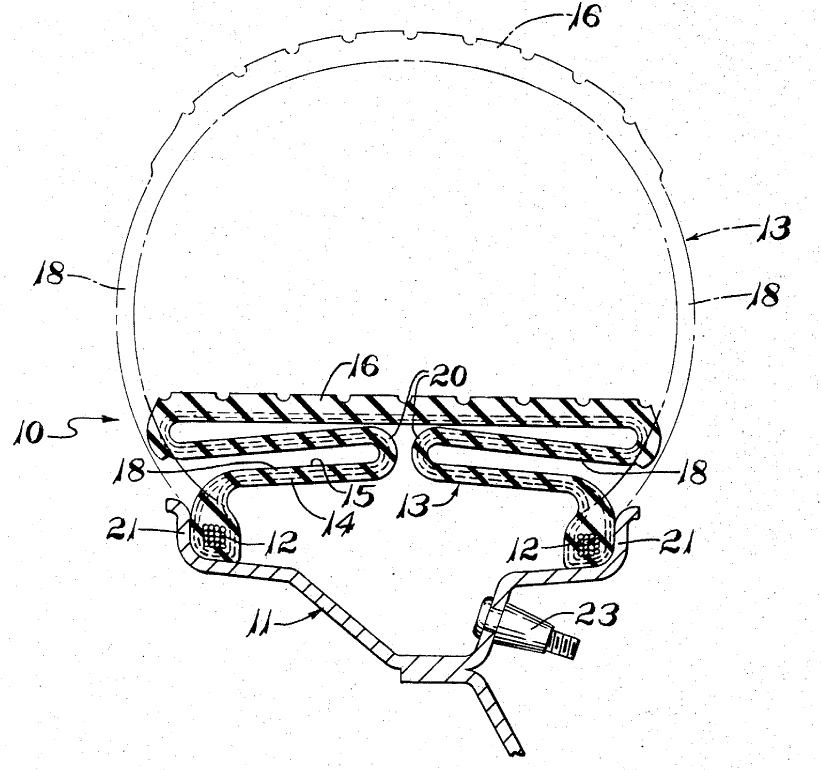

This place covers:

Subject matter wherein the tyre or inner tube is filled with a gas other than air.

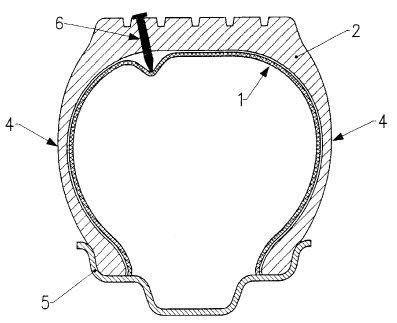

This place covers:

Subject matter wherein the pneumatic tyre is filled with foam material to absorb shock or support the tyre during normal operating condition.

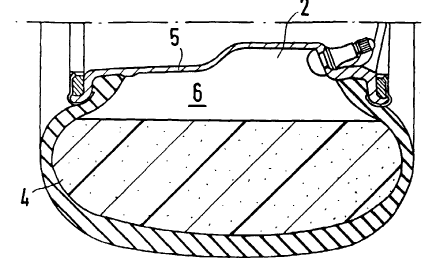

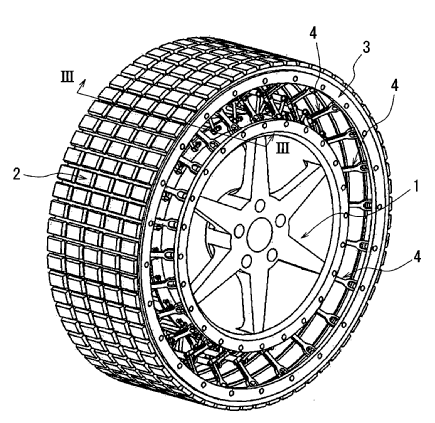

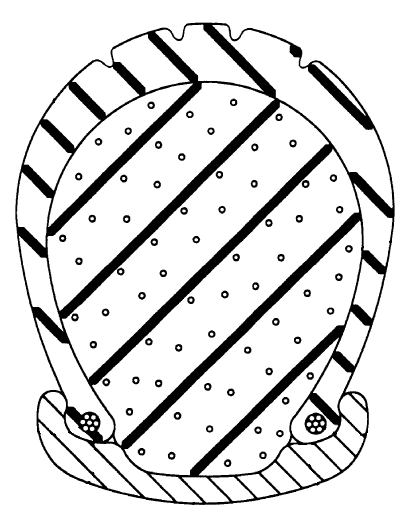

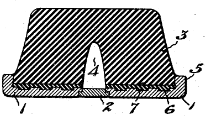

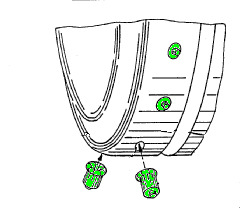

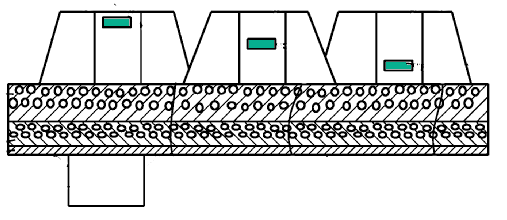

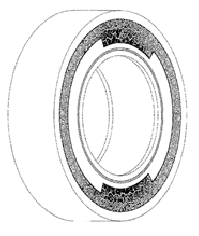

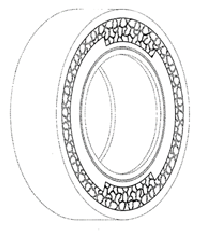

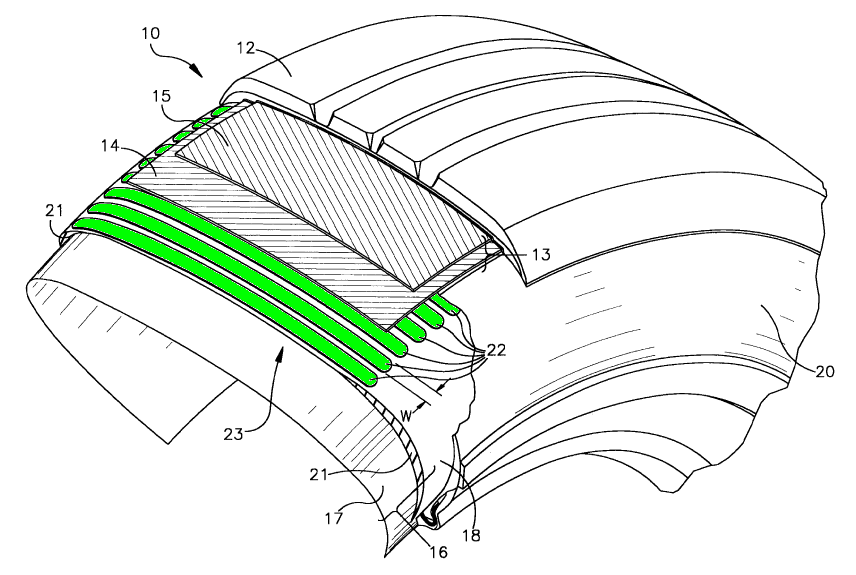

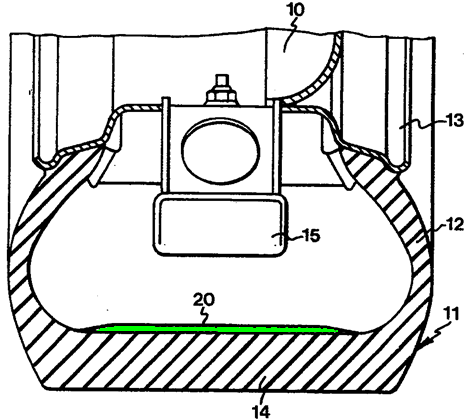

Illustrative example of subject matter classified in this place:

Pneumatic tyre filled with foam material (4).

Attention is drawn to the following places, which may be of interest for search:

Non-pneumatic tyre comprising foam cushioning means | |

Tyres comprising resilient foam means which become load supporting in a deflated or damage condition | |

Tyres comprising plural spherical elements provided in the tyre chamber and made up from a foam means which becomes load supporting in deflated or damaged condition | |

Tyres comprising foam noise damping means |

This place covers:

Subject matter wherein the tyre is filled at least partially with water or another liquid.

This place does not cover:

Tyre comprising flowable material for sealing punctures, i.e. sealant layer |

This place covers:

Subject matter wherein the liquid composition serves as a ballast to increase the weight of the tyre.

Attention is drawn to the following places, which may be of interest for search:

Valve arrangements for filling a tyre with liquid |

This place covers:

Subject matter wherein the tyre casing is made from a material other than natural or synthetic diene rubber, e.g. thermoplastic resin.

This place covers:

Subject matter wherein the tyre is configured for low pressure operation, e.g. tyre can flatten under load to facilitate movement of tyre over soft or irregular support surface.

Attention is drawn to the following places, which may be of interest for search:

Tyres characterised by means enabling restricted operation in damaged or deflated condition; Accessories therefor |

This place covers:

Subject matter wherein the pneumatic tyre lacks substantial cord reinforcement in the structure of the tyre casing, e.g. the tyre is formed without a carcass ply.

The use of bead reinforcements or belt reinforcement without carcass reinforcements constitutes a pneumatic tyre without substantial cord reinforcement for the purposes of this subgroup.

This place covers:

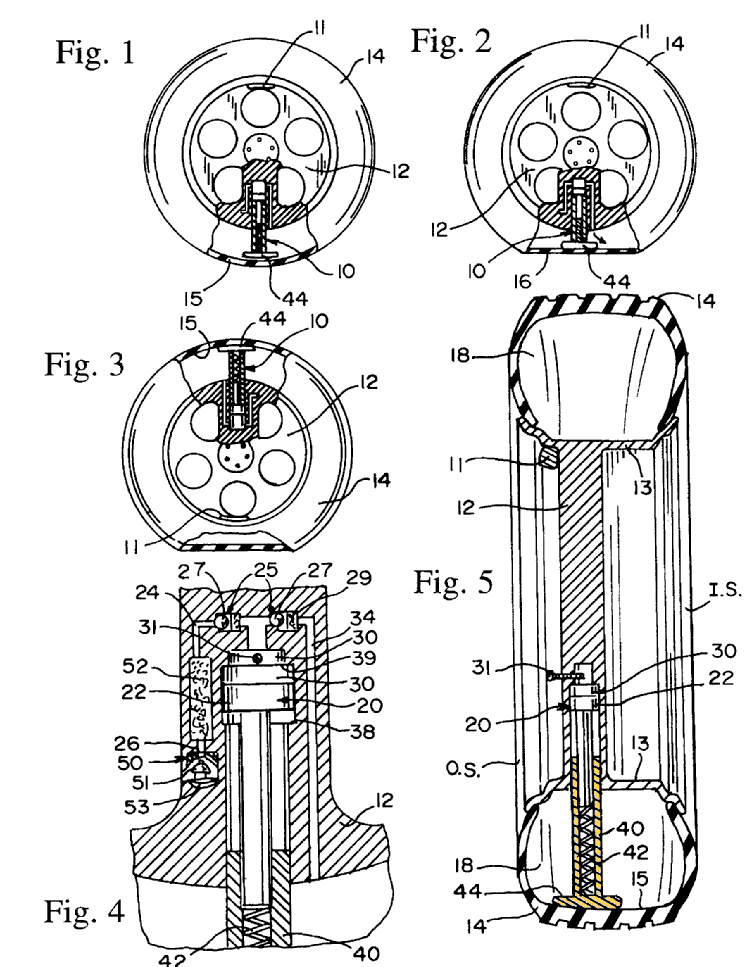

Subject matter wherein a closed annular element, e.g. inner tube, is carried within the chamber of the tyre and filled with fluid under pressure that is greater than atmospheric pressure.

This place does not cover:

Tyres or inner tubes with multiple separate inflating chambers |

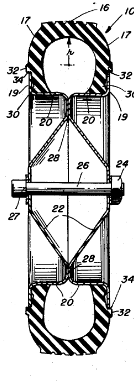

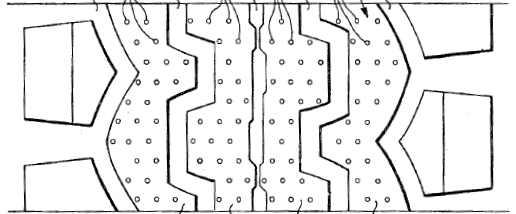

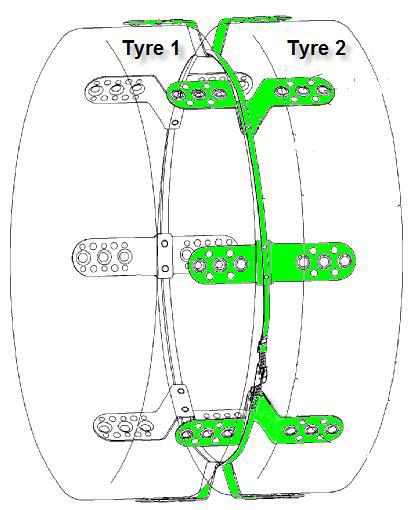

This place covers:

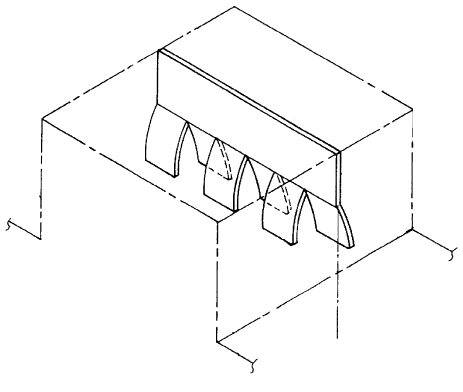

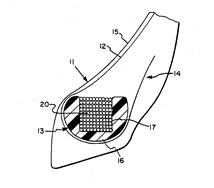

Subject matter with multiple chambers defined by the tyre casing, wherein each chamber possesses a separate inflatable insert.

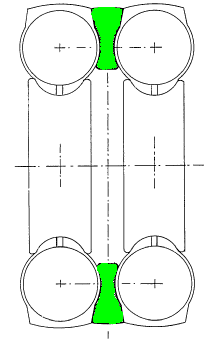

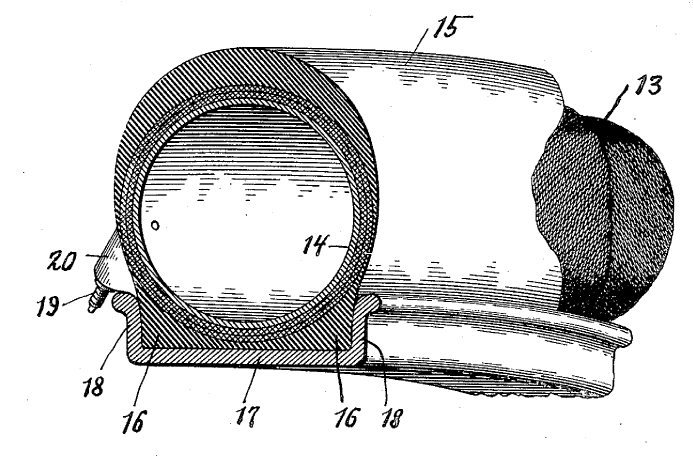

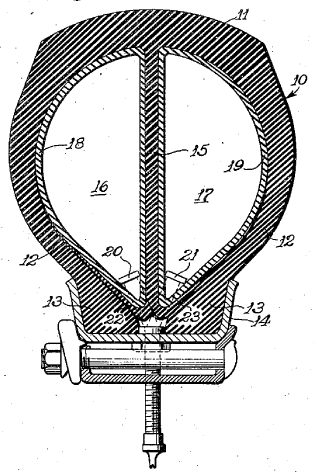

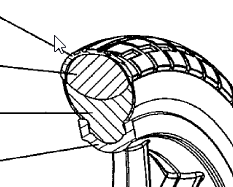

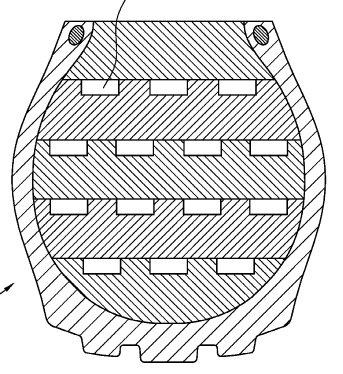

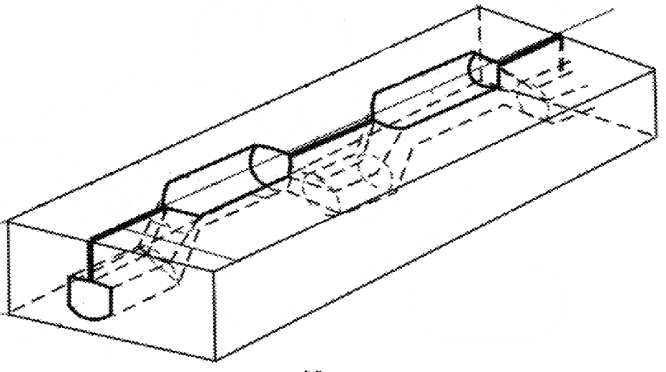

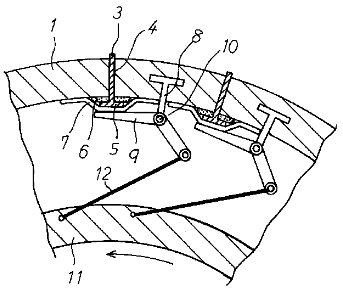

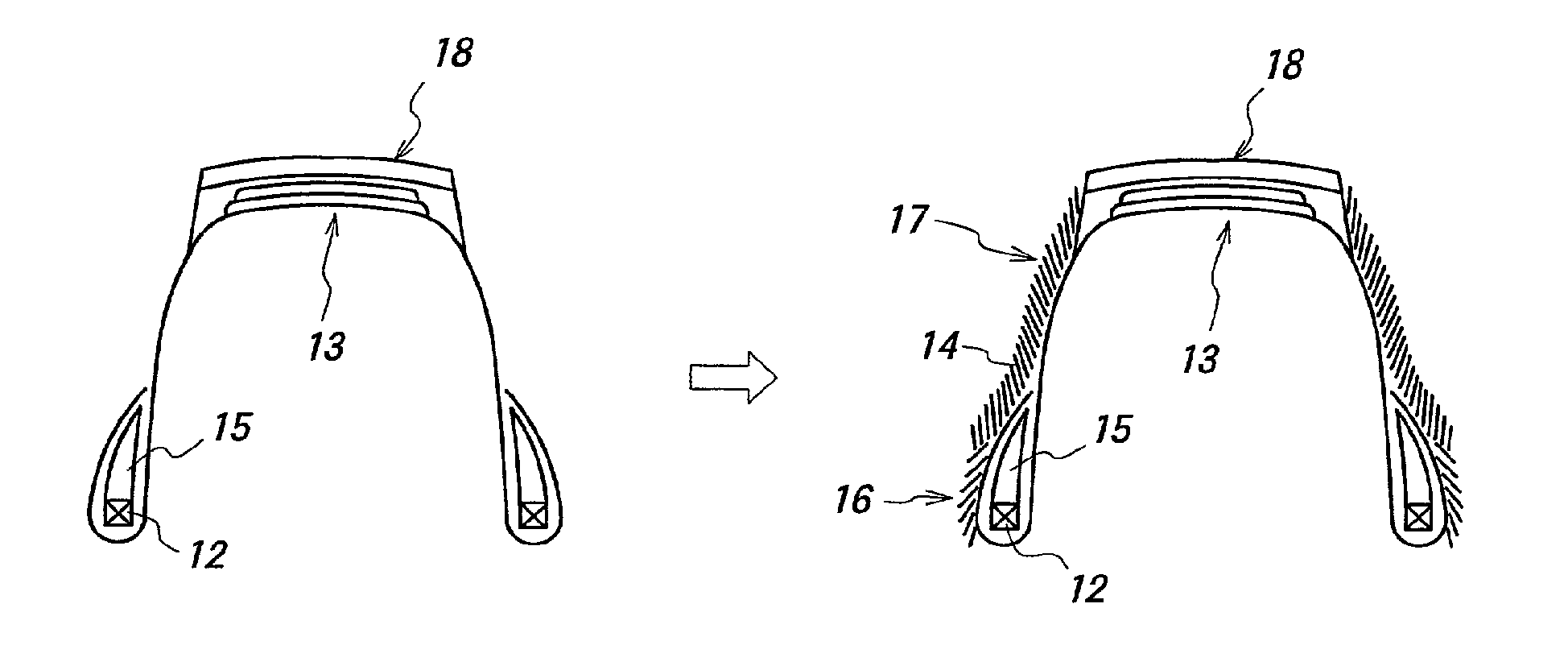

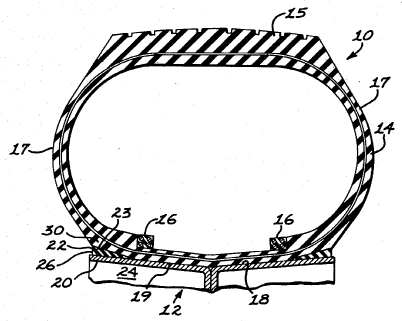

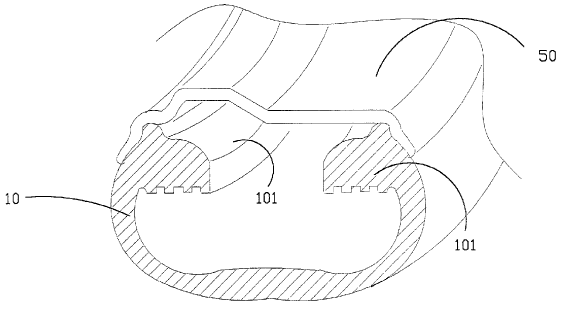

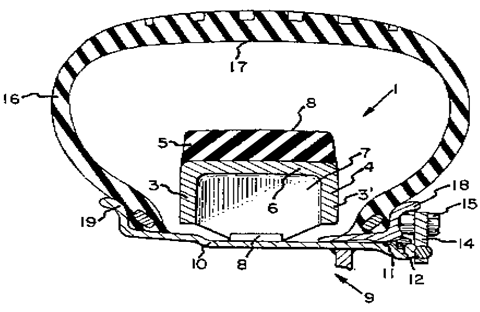

Illustrative example of subject matter classified in this place:

Multiple inflatable inserts (16 and 17) are shown.

This place does not cover:

Tyres or inner tubes with multiple separate inflating chambers |

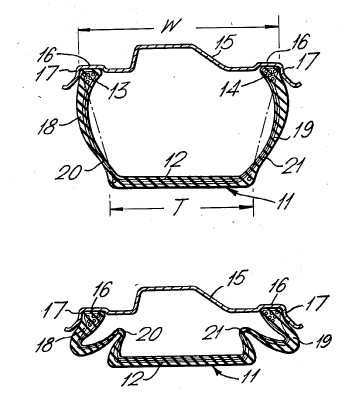

This place covers:

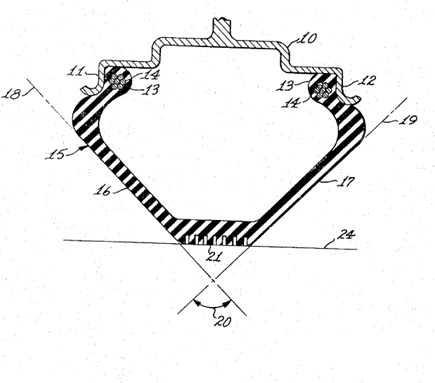

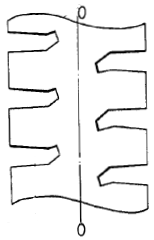

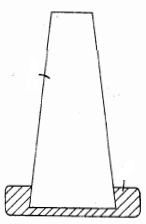

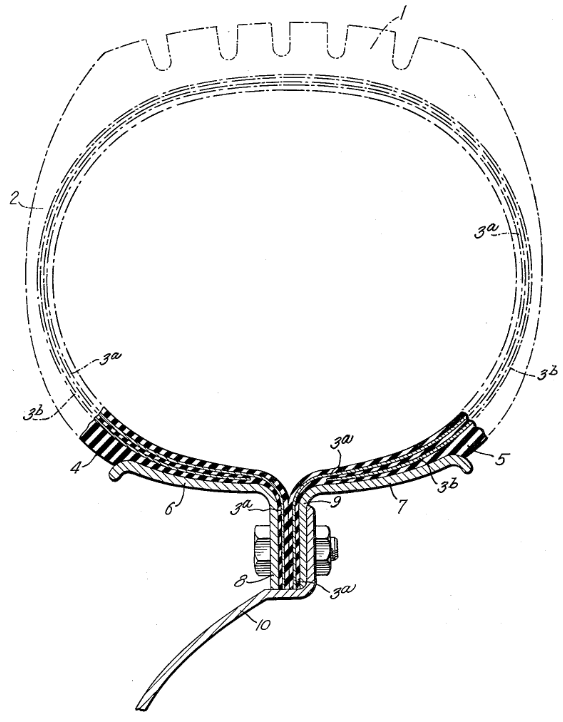

Illustrative example of subject matter classified in this place:

The figure shows an inner tube having a special shape.

This place does not cover:

Inflatable pneumatic tyres or inner tubes formed as a single discontinuous ring with contiguous ends which may be connected together |

This place covers:

Subject matter wherein the inner tube is strengthened throughout at least a portion of its extent.

This place covers:

Subject matter wherein the pneumatic tyre forms a discontinuous ring, the ends of which may connect together, overlap, or abut.

Example 1:

Example 2:

![]()

This place covers:

Subject matter wherein the pneumatic tyre is open to the rim and the tyre possesses an integral layer having relatively high resistance to diffusion of air.

This place does not cover:

Tyres or inner tubes with multiple separate inflating chambers |

This place covers:

Subject matter wherein the pneumatic tyre possesses an integral layer or coating of elastomeric material which has a relatively high resistance to the diffusion of air at its inner air contacting surfaces. The layer is commonly referred to as an inner liner.

Attention is drawn to the following places, which may be of interest for search:

Tyres characterised by sealant layer |

This place covers:

Subject matter wherein air impervious liner does not traverse the entire inner cavity surface of the tyre, i.e. it does not extend from one bead portion to another bead portion.

This place covers:

Subject matter wherein the impervious layer is characterised by the joints or splices between adjoining ends of the layer.

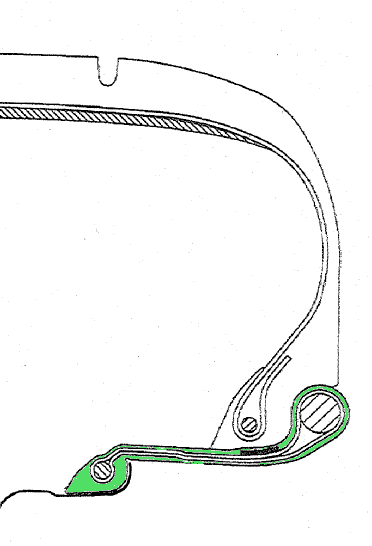

This place covers:

Subject matter characterised by sealing means between beads and rims of tubeless tyres.

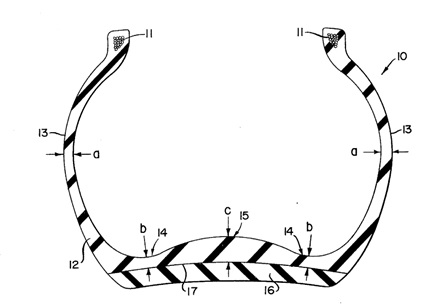

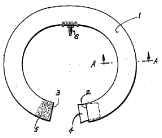

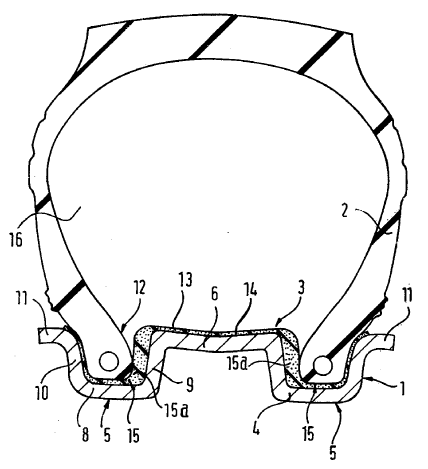

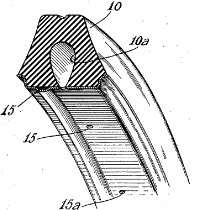

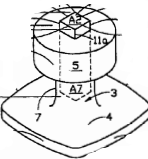

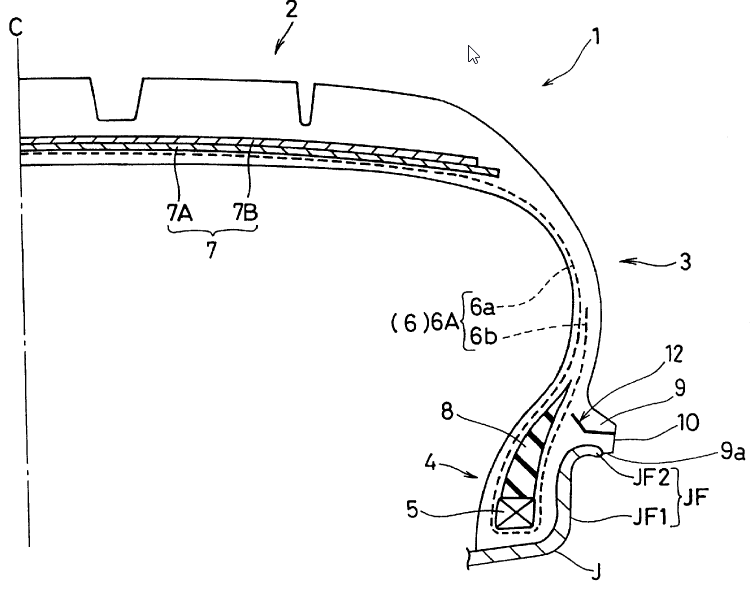

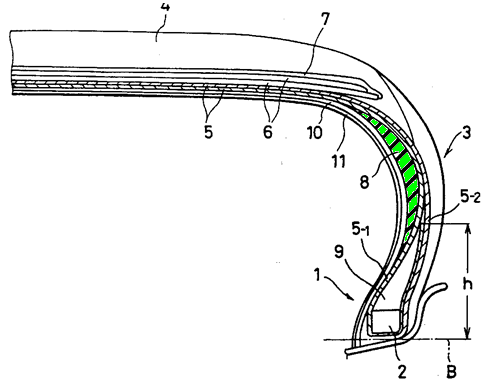

Illustrative example of subject matter classified in this place:

Sealing means (3) is provided between the bead and rim (5).

Attention is drawn to the following places, which may be of interest for search:

Rim appurtenances, e.g. lining bands |

This place covers:

Subject matter wherein the pneumatic tyre casing is composed of segments adapted to enclose an annular inner-tube.

This place covers:

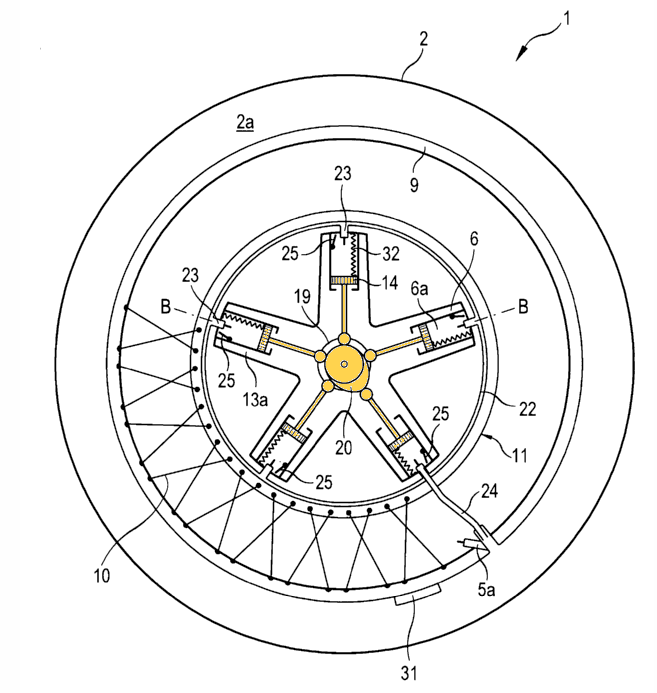

Subject matter wherein the tyre inner cavity or the inflatable insert is divided into multiple inflatable chambers.

Attention is drawn to the following places, which may be of interest for search:

Pneumatic tyre having additional inflatable supports which becomes load supporting when tyre is in deflated condition | |

Pneumatic tyre having inflatable chamber which becomes load supporting only when tyre is in deflated or damaged condition |

This place covers:

Subject matter wherein the multiple chambers are circular in form.

This place covers:

Subject matter wherein the multiple chambers are provided with walls that extend transversely of the tyre.

This place covers:

- non-inflatable tires of the solid rubber tyre type (e.g. sectional, casing enclosed core, integral) whether or not they include voids such as chamber openings

- non-inflatable tires made up of a tread band supported by a plurality of springs or spokes

- means for securing non-inflatable tyres to rims

Example:

This place does not cover:

Tyres characterised by the chemical composition or the physical arrangement or mixture of the composition |

Attention is drawn to the following places, which may be of interest for search:

Wheels characterised by rail-engaging elements | |

Castor wheels |

The precedential classification within B60C 1/00 should be given if the subject matter cannot to be classified within any subgroup of B60C 7/00. For example, disclosure which is related to the chemical composition of the tread but also discloses a solid tyre using foam material should be classified in both B60C 1/0016 as well as B60C 7/105.

This place covers:

Subject matter wherein there is provided means for absorbing road shocks other than the use of a pneumatic means (e.g. non-inflatable or solid tyre having a particular structure and/or composition).

Examples:

Attention is drawn to the following places, which may be of interest for search:

Highly resilient wheels |

This place covers:

Subject matter wherein the tyre consists of a casing enclosing a core where the core may be separate or integral with the casing. The core and casing must be distinct by reason of differing materials or arrangement.

Example:

This place does not cover:

Tyre casing enclosing a distinct core where the core has chambers therein |

Attention is drawn to the following places, which may be of interest for search:

Pneumatic tyre at least partially filled with foam material | |

Tyres comprising resilient foam means which become load supporting in deflated or damaged condition |

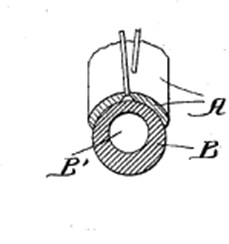

This place covers:

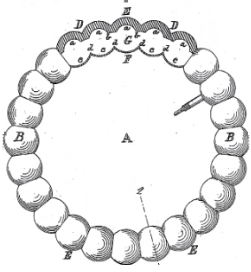

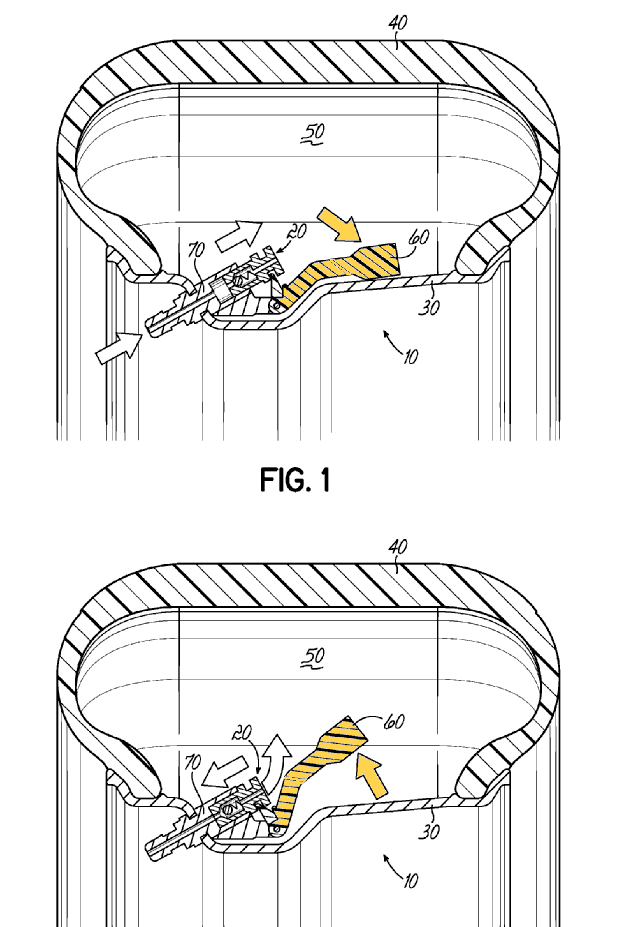

Subject matter where the tyres use enclosed chambers where the chambers are effectively empty, i.e. not filled with a solid material.

Illustrative example of subject matter classified in this place:

The figure shows enclosed chamber (B') surrounded by tyre (B).

Attention is drawn to the following places, which may be of interest for search:

Inflatable tyres |

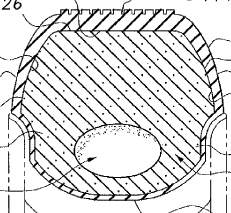

This place covers:

Subject matter wherein the tyre consists of a casing enclosing a core where the core may be separate or integral with the casing. The core and casing must be distinct by reason of differing materials or arrangement and include chambers within the core.

Example:

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

3.

Each figure above shows chambers formed by the tyre and rim.

This place covers:

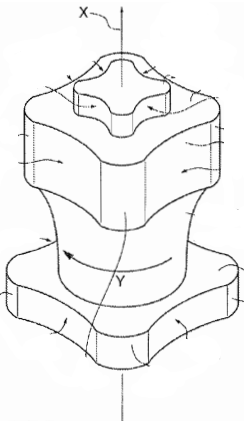

Subject matter that includes the structure and arrangement of reinforcing elements and cushioning layers which form a carcass/body ply or crown/belt reinforcement of the tyre.

This group also includes materials used in the reinforcement of a tyre which are not claimed as specific components of the belt, breaker, bead or carcass portions of a tyre.

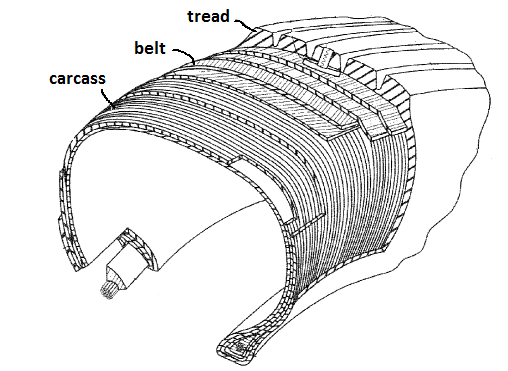

Illustrative example of subject matter classified in this place:

This place does not cover:

Inserts having reinforcing means | |

Bead structure, e.g. turnup or overlap construction |

Attention is drawn to the following places, which may be of interest for search:

Tyre characterised only by sidewall protection or reinforcing layer | |

Run-flat inserts | |

Textile tyre cords per se | |

Fabrics per se | |

Metal ropes or cables per se |

In this place, the following terms or expressions are used with the meaning indicated:

bias angle ply | layer that has reinforcing elements that are arranged generally at an angle of less than about 75° with respect to the mid-circumferential plane of the tyre. |

belt reinforcement | the arrangement of reinforcing material that is between the tread and carcass and generally extends between the shoulder regions of the tyre tread. |

carcass reinforcement | the arrangement of reinforcing material which forms the body of a tyre and which generally extends between the bead portions of the tyre. |

cords | threads, filaments, fibres, yarns or twisted assemblies thereof, which may be made of metal wire, glass or natural or synthetic fibres. |

geodesic cord path | the minimum length cord path. |

radial ply | layer that has reinforcing elements that are arranged generally at an angle of about 75° to 90° with respect to the mid-circumferential plane of the tyre, or arranged more specifically at an angle of 90°, i.e. parallel to the tyre axis. |

In patent documents, the following words/expressions are often used as synonyms:

- "carcass" and "body ply"

- "crown" and "belt reinforcement"

This place covers:

Tyre reinforcements which are made of metallic elements, strands, wires or cords.

Attention is drawn to the following places, which may be of interest for search:

Ropes or cables built-up from metal wires per se |

This place covers:

Subject matter wherein a means or chemical composition is applied to the metallic reinforcing element, commonly used to improve bonding with rubber coating, e.g. brass plating.

This place covers:

Subject matter directed towards rubber coating compositions of the cord or ply.

This place covers:

Reinforcements made from non-metallic, inorganic materials such as glass, carbon or asbestos.

This place covers:

Reinforcements made from synthetic materials such as polyester, nylon or aromatic polyamide, e.g. aramid.

This place covers:

Reinforcements which comprise different materials, e.g. cords formed by twisting together nylon and aramid yarns or yarns formed from nylon and aramid fibres.

This place covers:

Reinforcements that are preshaped prior to arrangement in the tyre.

This place covers:

Reinforcements wherein each reinforcing element is formed by a singular filament.

This place covers:

Reinforcements characterised by physical properties such as modulus, tensile strength or elongation at break.

This place covers:

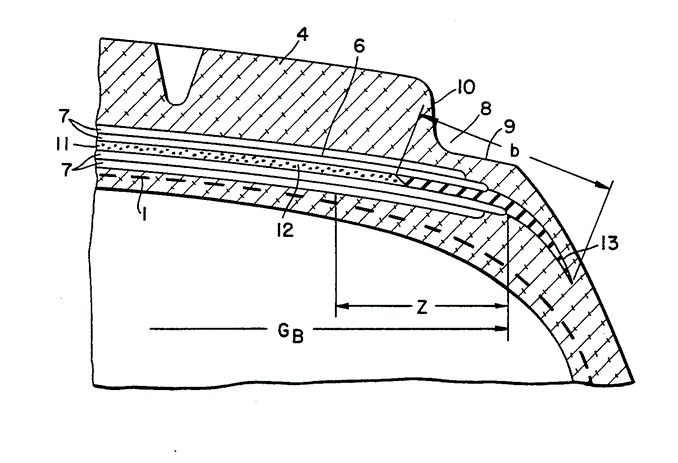

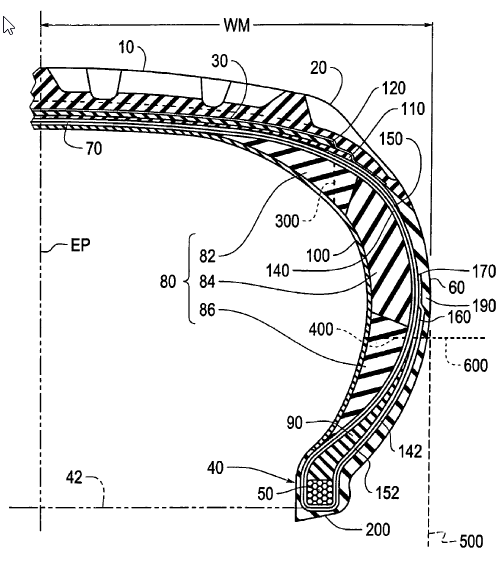

Subject matter directed towards the carcass of a tyre.

A carcass reinforcement refers to the arrangement of reinforcing material which forms the body of a tyre and which generally extends between the bead portions of the tyre.

Attention is drawn to the following places, which may be of interest for search:

Tyres with carcass without substantial cord reinforcement, e.g. cast tyres made up of polyurethane |

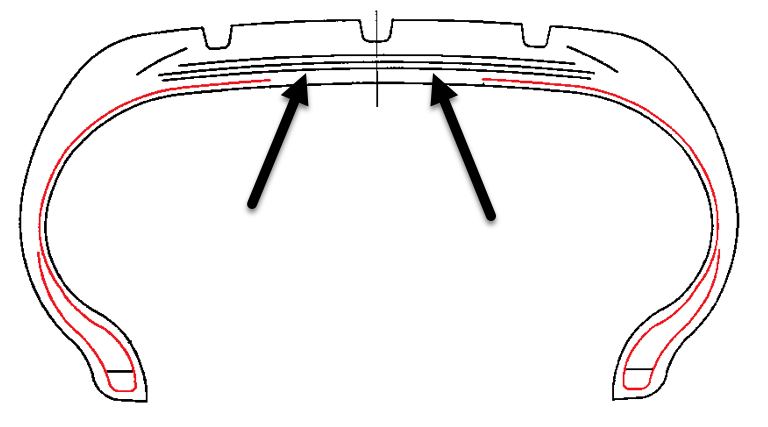

This place covers:

Subject matter wherein the carcass is characterised as an interrupted ply wherein the ply is discontinuous between bead portions.

Illustrative example of subject matter classified in this place:

Carcass is interrupted at the central portion of the crown as indicated by the arrows.

This place covers:

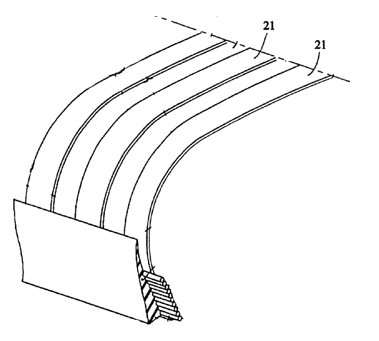

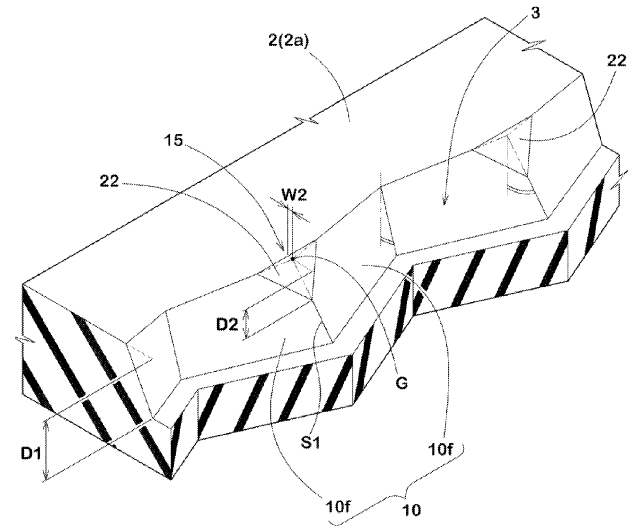

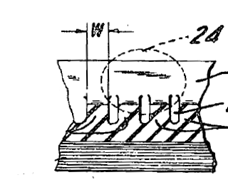

Subject matter wherein the carcass is formed by winding strips or individual cords instead of a continuous ply.

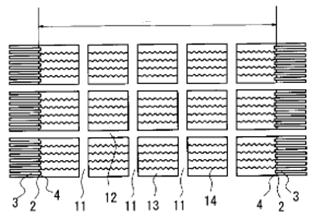

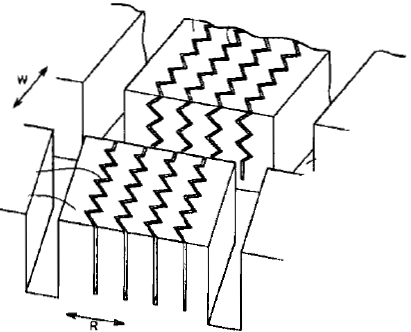

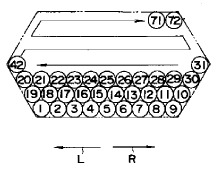

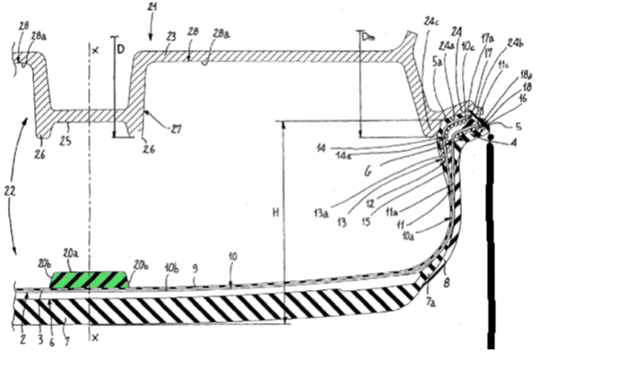

Illustrative examples of subject matter classified in this place:

1.

In figure 1, narrow strips (21) are used.

2.

In figure 2, individual cords or filaments are used.

This place covers:

Subject matter wherein the carcass ply is characterised by special physical properties of the ply as a whole, e.g. modulus or strength at break.

Attention is drawn to the following places, which may be of interest for search:

Physical properties or dimensions of carcass cords per se |

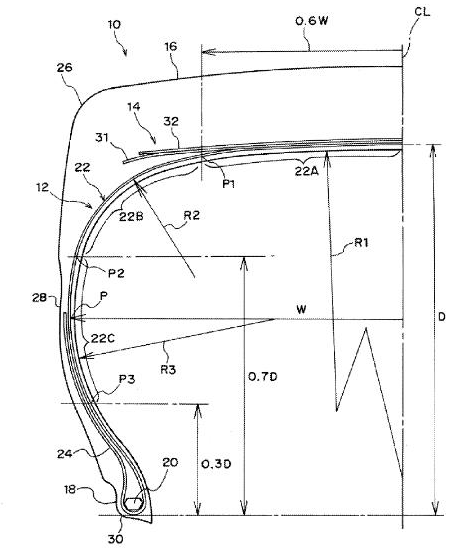

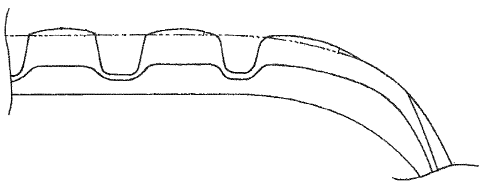

This place covers:

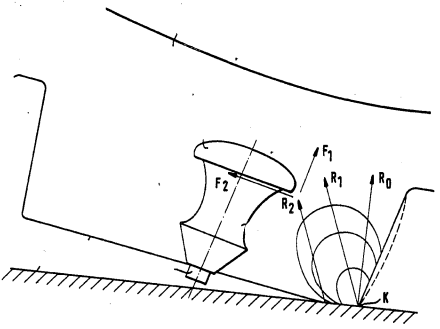

Subject matter wherein the carcass reinforcement is characterised by its curvature or cross-sectional shape.

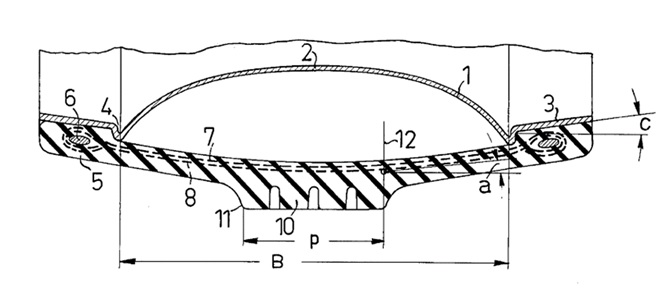

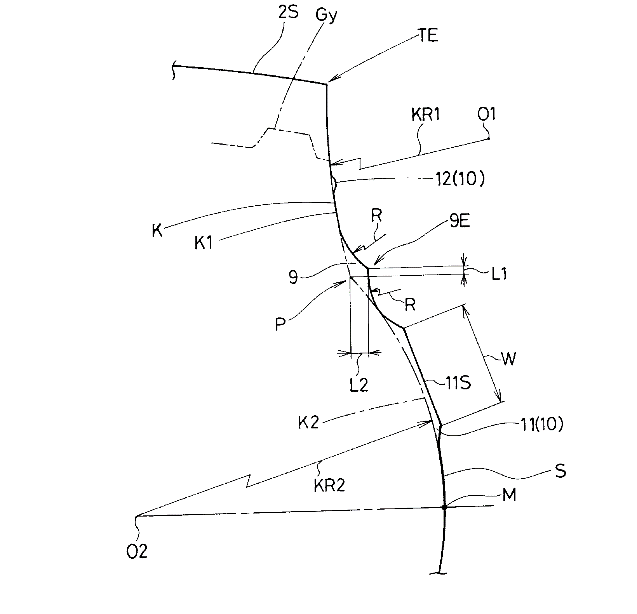

Illustrative example of subject matter classified in this place:

(R1), (R2) and (R3) are radii of curvature of different carcass ply portions.

This place does not cover:

Carcass ply curvature specifically relating to sidewall |

This place covers:

Subject matter wherein the carcass plies are composed of reinforcing materials which extend in the same direction substantially equidistant at all points without converging or diverging from one another.

This place covers:

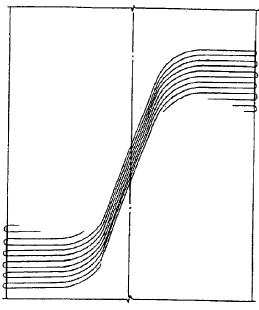

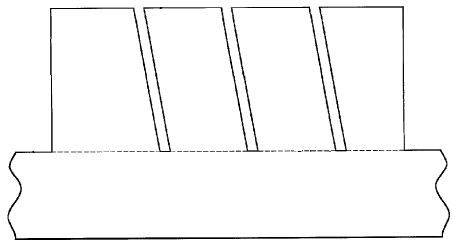

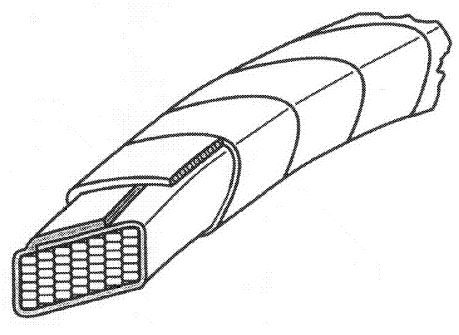

Subject matter wherein the carcass layer is characterised by the joints or splices between adjoining ends of the layer.

Illustrative example of subject matter classified in this place:

Figure shows an overlap splice.

Attention is drawn to the following places, which may be of interest for search:

General aspects of the joining methods |

This place covers:

Subject matter wherein the carcass ply is characterised by the physical properties of the carcass cords.

This place covers:

Subject matter wherein the carcass is characterised by the material or composition of the reinforcement elements.

This place covers:

Subject matter wherein the reinforcing materials of the carcass plies are of dissimilar materials or shape, e.g. different diameters.

This place covers:

Carcass reinforcements characterised by the path of the carcass cord along its extension direction, e.g. cords extend in radial direction with a localized undulating or sinusoidal shape.

Attention is drawn to the following places, which may be of interest for search:

Path characterised by an overall curved extension between beads, e.g. S-shaped or geodesic |

This place covers:

Subject matter wherein the carcass reinforcing materials in the carcass plies are so disposed that the reinforcing cords in adjacent carcass plies subtend (cross) each other such that they are in a superimposed angular relationship relative to one another.

This place does not cover:

In this place, the following terms or expressions are used with the meaning indicated:

bias ply | plies where the angular orientation of the reinforcing elements with respect to the mid-circumferential plane of the tyre is less than about 75° |

radial ply | plies where the angular orientation of the reinforcing elements with respect to the mid-circumferential plane of the tyre is about 90°, i.e. parallel to the tyre axis, and more generally from about 90° to about 75° |

This place covers:

Subject matter wherein the carcass reinforcing elements are disposed in the tyre casing such that an extension of the reinforcing elements from one bead portion to the other bead portion includes more than one angular orientation such that the carcass reinforcing elements in said ply do not lie along a single plane.

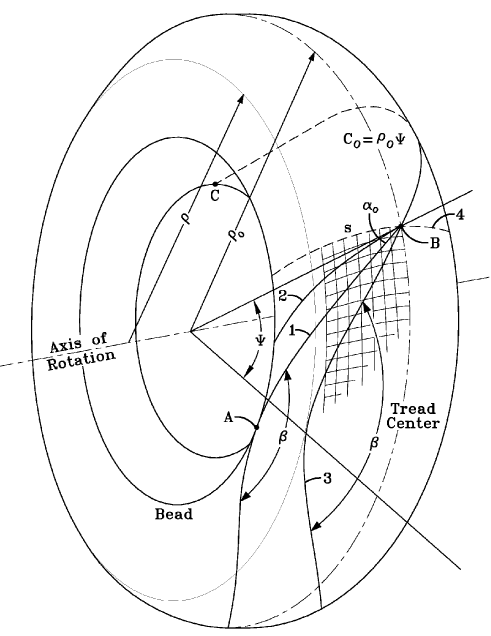

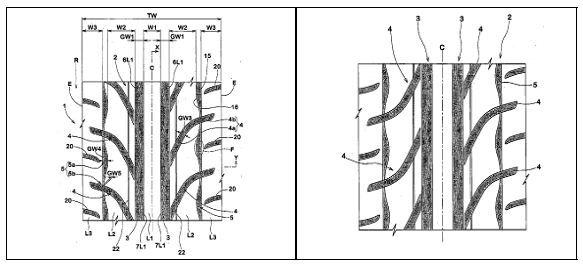

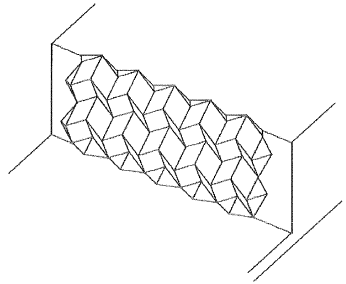

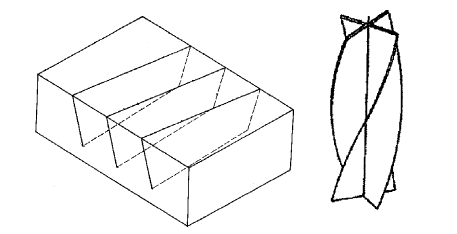

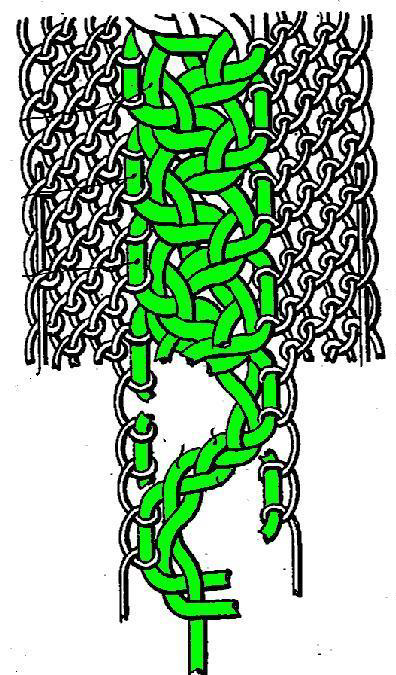

Illustrative examples of subject matter classified in this place:

1.

2.

Figures 1 and 2 include S-shaped cord paths and paths of minimum length along the curved surface of the tyre. The minimum length cord path is usually referred in the art as a geodesic cord path.

This place covers:

Subject matter wherein the carcass plies are composed of reinforcing materials which are substantially disposed in a radial plane, i.e. a plane that includes the axis of rotation.

This place does not cover:

Cords which curve from bead to bead in plural planes |

In this place, the following terms or expressions are used with the meaning indicated:

bias ply | plies where the angular orientation of the reinforcing elements with respect to the mid-circumferential plane of the tyre is less than about 75° |

radial ply | plies where the angular orientation of the reinforcing elements with respect to the mid-circumferential plane of the tyre is about 90°, i.e. parallel to the tyre axis, and more generally from about 90° to about 75° |

This place covers:

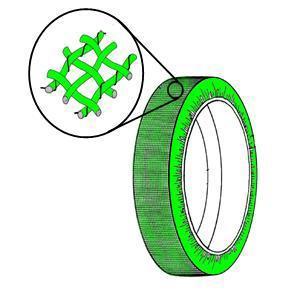

Carcass plies characterised by cords which extend in non-parallel directions such that the cords cross each other, e.g. plies are fabric, woven, non-woven or knitted.

This place covers:

Carcass plies characterised by reinforcement formed with woven i.e. interlaced warps/wefts, braided, or knitted textiles i.e. interlocking loops formed by continuous thread.

This place covers:

Carcass reinforcements which are characterised by discrete, non-continuous fibres or filaments, e.g. short fibres.

This place covers:

Subject matter wherein the carcass comprises a layer which can be characterised as a homogeneous sheet, web or film, e.g. unreinforced rubber layers rather than reinforced by discrete cords or woven fabrics.

This place covers:

Tyres comprising embedded metal armour as an element of the casing construction, e.g. metal plates, linked mats or woven fabrics.

This place covers:

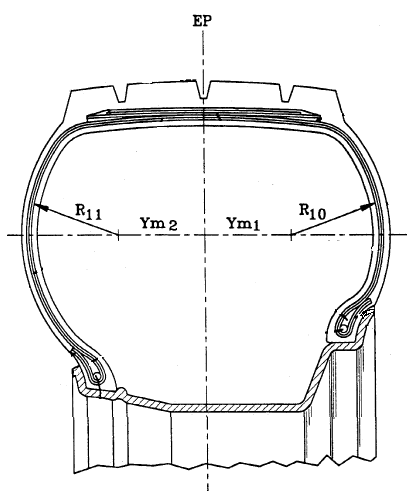

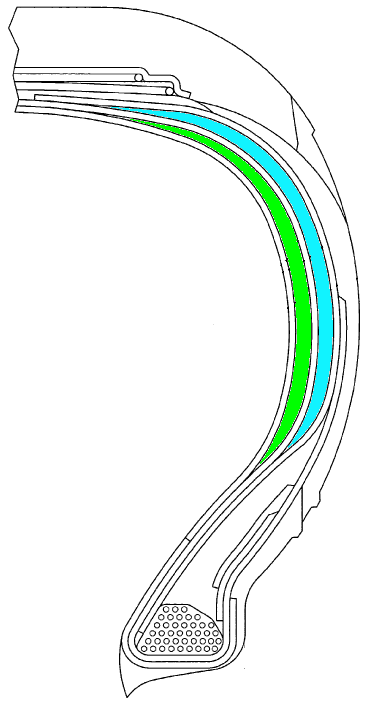

Subject matter wherein the carcass shape is asymmetrical to the centre plane of the tyre.

Illustrative example of subject matter classified in this place:

Asymmetric to mid circumferential plane (EP).

Attention is drawn to the following places, which may be of interest for search:

Tyres with asymmetric traverse section |

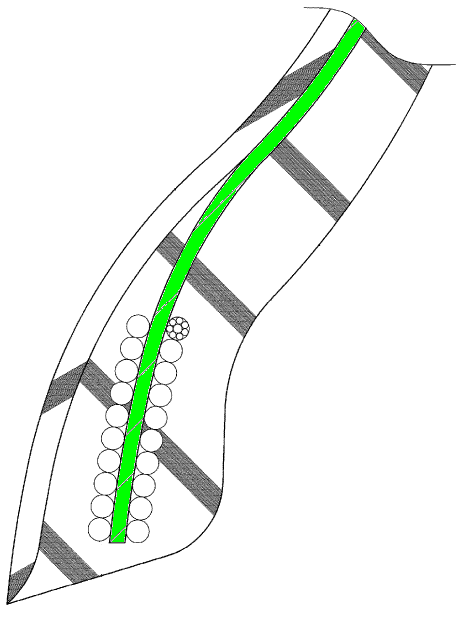

This place covers:

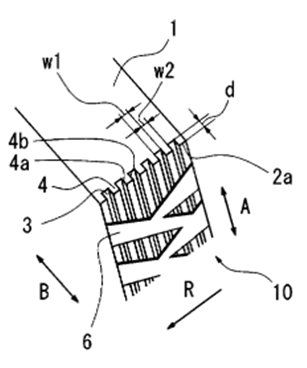

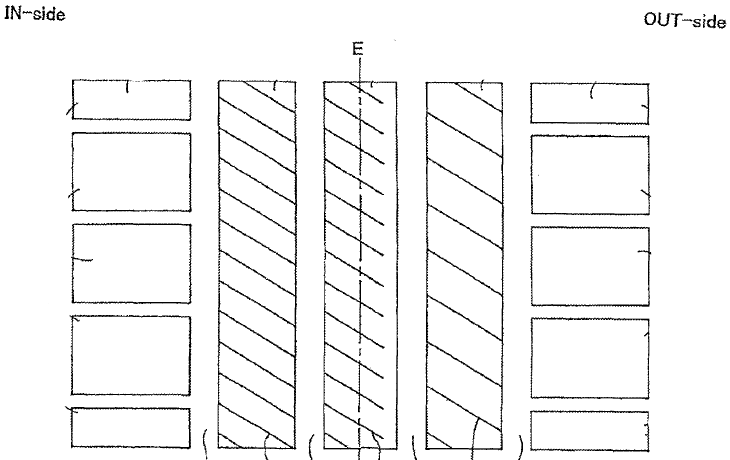

Subject matter which includes one or more relatively thin threads, filaments, yarns, wires, cables, bands, braids or the like formed into cords or reinforcing elements that are arranged to form a ply which annularly extends continuously at the radial outer side of the tyre casing substantially from shoulder region to shoulder region of a tyre tread to add strength to said tyre tread area or to protect the tyre casing in this region.

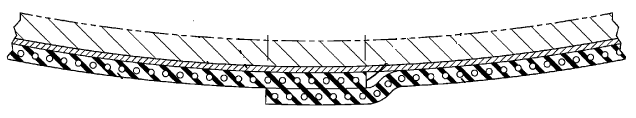

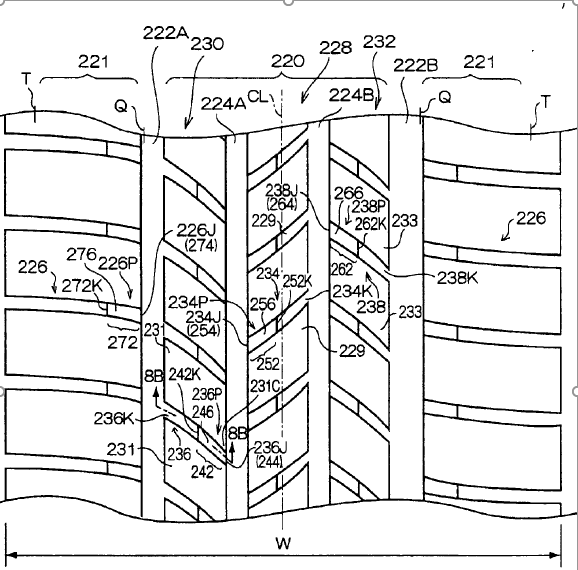

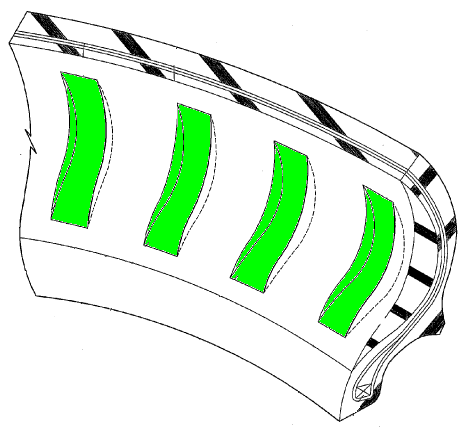

Illustrative examples of subject matter classified in this place:

1.

2.

3.

This place covers:

Subject matter wherein the belt layer comprises fabric material, e.g. woven, knitted or felted.

This place covers:

Subject matter wherein the belt layer comprises fabric material having a square or plain woven structure, i.e. threads cross at 90 degrees to each other.

This place covers:

Subject matter wherein the belt layer comprises discontinuous fibres or filaments, e.g. short fibres.

This place covers:

Subject matter wherein the belt layer is characterised by its physical properties, e.g. modulus of elasticity or tensile strength at break.

Attention is drawn to the following places, which may be of interest for search:

Compositions |

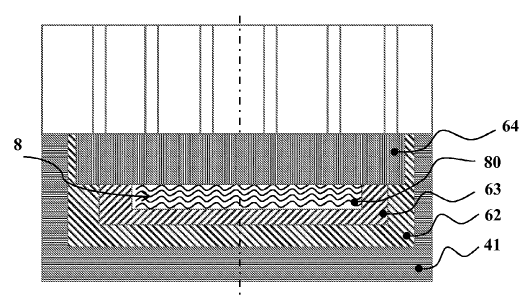

This place covers:

Subject matter wherein a discrete layer of elastomeric material is provided between belt layers and not limited to the belt edge region.

This place covers:

Subject matter wherein a discrete layer of elastomeric material is provided between a belt layer and carcass layer and not limited to the belt edge region.

This place covers:

Subject matter wherein the tyre comprises multiple carcass plies and a belt layer is arranged between at least two of the carcass plies.

This place covers:

Subject matter wherein a belt layer is arranged radially inwards of the carcass reinforcement layers.

This place covers:

Subject matter wherein the belt layer structure comprises a plurality of reinforcement cords, yarns, threads, wires, filaments or the like having a parallel arrangement and which are coated with an elastomer layer to form a ply.

This place covers:

Subject matter wherein the belt layer is characterised by the material or composition of the reinforcing elements.

Attention is drawn to the following places, which may be of interest for search:

Tyre reinforcements made of metallic elements | |

Tyre reinforcements made of mineral fibres | |

Tyre reinforcements made of organic materials | |

Tyre reinforcements made of synthetic materials | |

Tyre reinforcements made of different materials |

This place covers:

Subject matter where the entire belt package consists solely of steel cord plies, e.g. construction vehicle tyres where the working plies and the protection plies are made of steel – such structure is usually provided for light truck tyres, heavy duty tyres or construction vehicle tyres.

This place covers:

Subject matter wherein the tyre comprises multiple plies wherein one ply has reinforcing elements of different material from that of another ply – such structure is usually provided in passenger car tyres, e.g. two steel plies and one nylon cap ply.

Attention is drawn to the following places, which may be of interest for search:

Different cords in the same layer |

This place covers:

Subject matter wherein the belt reinforcing elements are disposed such that an extension of the reinforcing elements from lateral edge to the other lateral edge of the belt includes more than one angular orientation such that the reinforcing elements in said ply do not lie along a single plane.

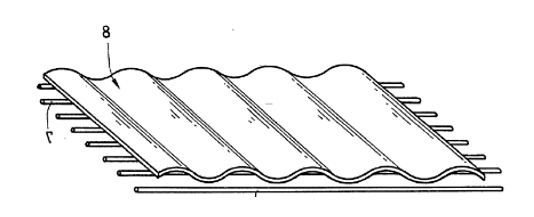

This place covers:

Subject matter wherein a belt ply comprises cords having different materials, dimensions or constructions.

This place covers:

Subject matter wherein the belt reinforcing elements are characterised by a special path of the reinforcing element along its extension direction, e.g. cords extend with an undulating or sinusoidal shape.

Illustrative example of subject matter classified in this place:

Layer (8) has cords (80) that are undulated.

Belt plies having a folded or zigzag configuration wherein the reinforcement bends back onto itself at the lateral edges of the ply should be classified under B60C 9/26 or B60C 9/263.

This place covers:

Subject matter wherein the belt ply is comprised of material formed into thin strips or bands.

This place covers:

Subject matter wherein the disposition of a ply having cords inclined or 90 degrees to the circumferential direction is limited to an axially outer edge of a belt reinforcement layer.

Attention is drawn to the following places, which may be of interest for search:

Belts with an interrupted belt ply, e.g. using two or more portions of the same ply |

This place covers:

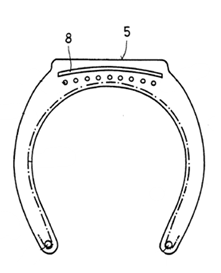

Subject matter wherein the tyre comprises at least one belt ply having cords that define an angle of substantially zero degrees relative to a median equatorial plane of the tyre.

Tyres having a single ply of substantially zero-degree cords.

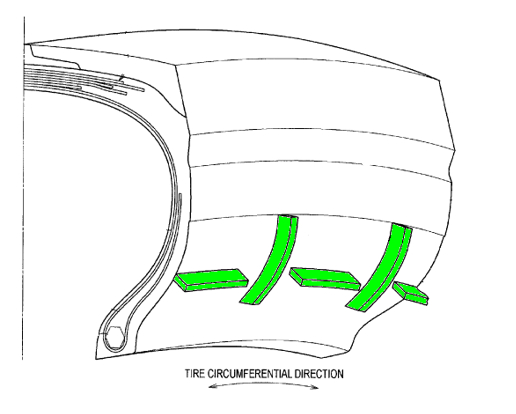

This place covers:

Subject matter wherein the belt ply is comprised of material formed into thin strips or bands which are wrapped around the carcass in the crown region according to a predetermined pattern, e.g. helically wound band strip.

Attention is drawn to the following places, which may be of interest for search:

Building a tyre on a round core wherein a continuous band is applied by winding it spirally | |

Building a tyre on a round core wherein a continuous band is applied by winding it helically | |

Building a tyre on a round core wherein a continuous band is applied by back and forth (zigzag) movement | |

Building a tyre on a drum wherein a continuous band is applied by winding it spirally | |

Building a tyre on a drum wherein a continuous band is applied by winding it helically | |

Building a tyre on a drum wherein a continuous band is applied by back and forth (zigzag) movement |

This place covers:

Subject matter wherein the disposition of a zero-degree ply is limited to an axially outer edge of a belt reinforcement layer.

Attention is drawn to the following places, which may be of interest for search:

Zero-degree plies that are interrupted, i.e. plies using two or more portions for the same ply |

This place covers:

Subject matter wherein the lateral end of a belt ply is folded or bent to extend back in the opposite inclination direction at the lateral edges of the ply.

Illustrative example of subject matter classified in this place:

This place covers:

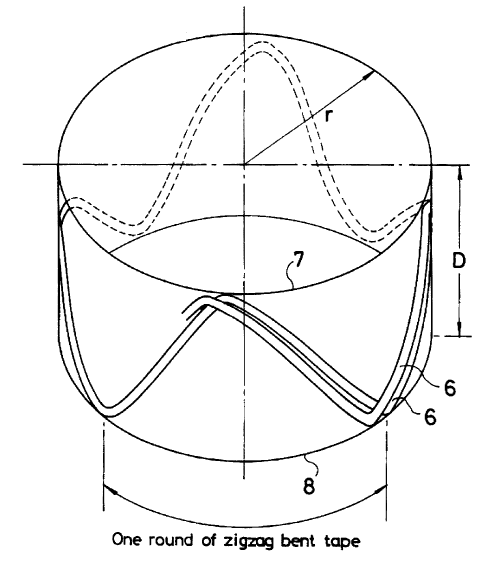

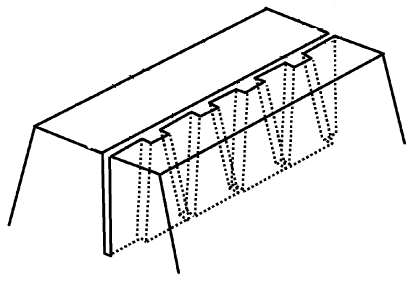

Subject matter wherein the belt ply comprises a continuous reinforcement strip or cord which extends at an inclination across the ply and then bends back in the opposite inclination direction at the lateral edges of the ply so as to form an endless zigzag configuration.

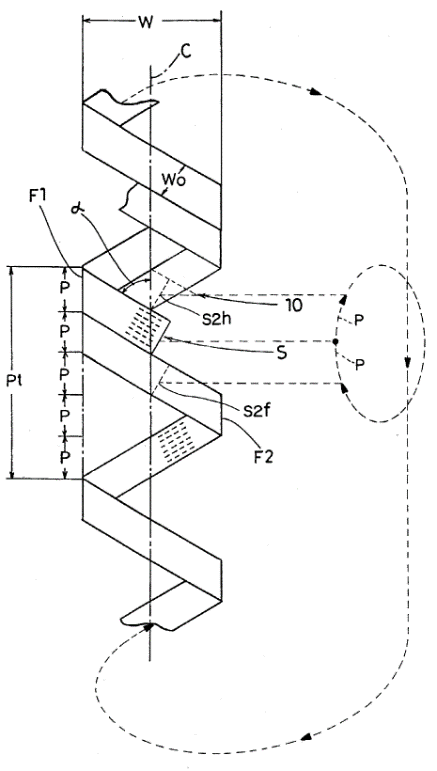

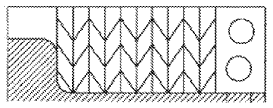

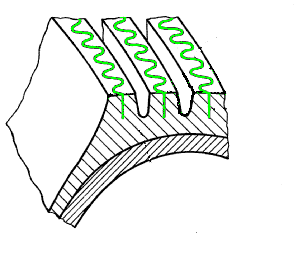

Illustrative examples of subject matter classified in this place:

1.

Figure 1 shows a strip being folded upon itself at the edges and forming a zigzag configuration.

2.

Figure 2 shows a strip that is bent at the edges to form a zigzag configuration without being folded upon itself.

This place covers:

Subject matter wherein significance is attributed to the size or the curvilinear profile of the belt or breaker.

This place does not cover:

Belts and breakers asymmetric to the midcircumferential plane |

This place covers:

Subject matter wherein the crown reinforcement or cushioning layers are asymmetric about the midcircumferential plane of the tyre.

This place covers:

Tyre tread bands characterised by physical properties, dimensions and the like as well as tyre tread bands characterised by at least two different tread sections, e.g. cap section-base section or side-by-side tread sections, wherein at least one of the tread sections has a specified chemical composition or physical properties.

Tread patterns characterised by tread elements, e.g. blocks, ribs, grooves, channels, sipes, incisions, voids, recesses, notches, slits, slots or holes.

In general grooves remain open in the footprint whereas sipes close in the footprint.

Anti-skid inserts characterised by inserts, short fibres, spikes or studs for improving anti-skid.

Attention is drawn to the following places, which may be of interest for search:

Rubber compositions for treads | |

Soles for shoes | |

Producing tyre treads | |

Tracks for endless track vehicles | |

Tracks of continuously flexible type, e.g. rubber belts |

Non-skid devices temporarily attachable to tyre treads are only classified in B60C 27/00.

In this place, the following terms or expressions are used with the meaning indicated:

NTG | net to gross; contact area ratio; land ratio; total contact area/total tread area; 100% - GA [negative ratio] |

GA | groove area ratio; negative ratio; sea ratio; total groove area/total tread area; 100% - NTG |

L/S | land sea ratio; total contact area/total groove area |

S/L | sea land ratio; total groove area/total contact area |

open in footprint | when the mounted tyre is contacting the road, the walls of material delimiting a void do not contact one another |

closed in footprint | when the mounted tyre is contacting the road, the walls of material delimiting a void at least partially come into contact with one another |

This place covers:

Tyre treads characterised by physical properties, dimensions or the like of the tread rubber.

Attention is drawn to the following places, which may be of interest for search:

Tyre treads characterised by chemical composition |

This place covers:

Tread characterised by physical properties including hardness, modulus, tan delta, i.e. hysteresis, snow traction index and the like.

Treads characterised by dimensions including tread thickness, e.g. having specified units such as millimetres.

This place covers:

Treads when the modulus is described numerically, e.g. modulus = 10 MPa; and when the tan delta is described numerically, e.g. tan delta = 0.10.

This place covers:

Treads when the thickness of the tread is described absolutely, e.g. tread thickness = 8 mm to 10 mm, or thickness is described relatively, e.g. tread thickness at equatorial plane is less than tread thickness at tread edge, or tread thickness = 6% tread width.

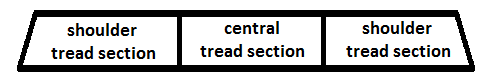

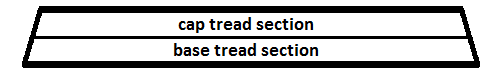

This place covers:

Tyre treads characterised by at least two different tread sections, e.g. cap and base sections or side by side tread sections, wherein at least one of the tread sections has specified chemical composition and/or physical properties different from the other section.

Illustrative example of subject matter classified in this place:

Side-by-side tread section

Attention is drawn to the following places, which may be of interest for search:

Tread having different rubber for tread wings | |

Tread grooves covered by a rubber different from the tread rubber | |

Tread having rubber anti-skid inserts |

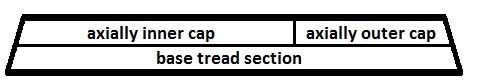

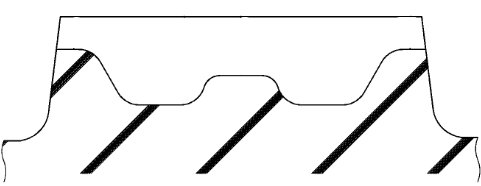

This place covers:

Treads characterised by tread rubber layers disposed adjacent in the radial direction.

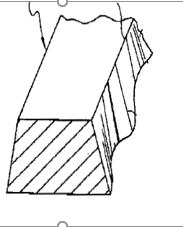

Illustrative example of subject matter classified in this place:

This place covers:

Treads characterised by different cap rubber layers in the axial direction.

Illustrative example of subject matter classified in this place:

This place covers:

Treads characterised by cap layers having asymmetric arrangement about the tyre equator.

Illustrative example of subject matter classified in this place:

This place covers:

Treads characterised by different base rubber layers in the axial direction.

Illustrative example of subject matter classified in this place:

This place covers:

Subject matter wherein the curvature of tread between tread edges is described numerically by using equations or by plural radii, e.g. tread has radius R1 = 500 mm or radius R1 > radius R2.

This place covers:

Treads made by winding narrow strips.

This place covers:

Subject matter wherein the shoulder is provided with at least one recess.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 illustrates recesses (4) in the shoulder.

2.

Figure 2 illustrates recesses (6) in the shoulder.

This place covers:

Replaceable treads including treads which are bonded or secured mechanically to a cured tyre carcass, e.g. precured treads for retreading a used tyre.

This place covers:

Treads characterised by tread elements:

- blocks or ribs;

- grooves or channels, open in footprint;

- sipes or incisions, closed in footprint;

- voids, e.g. recesses, notches, slits, slots, holes.

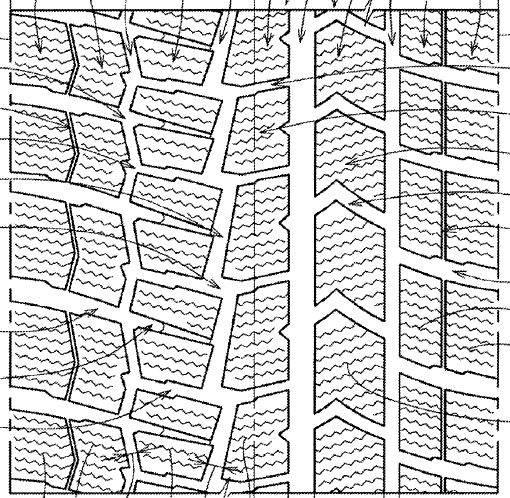

This place covers:

Directional tread patterns.

A directional pattern commonly has lateral grooves on each side of the tyre equator which converge at an angle to form a "V" shape.

A tyre having directional pattern has an intended rotational direction whereas a tyre having non-directional pattern can be mounted in either direction on a vehicle and retain the same pattern arrangement.

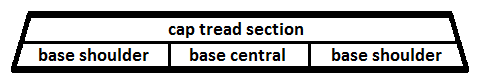

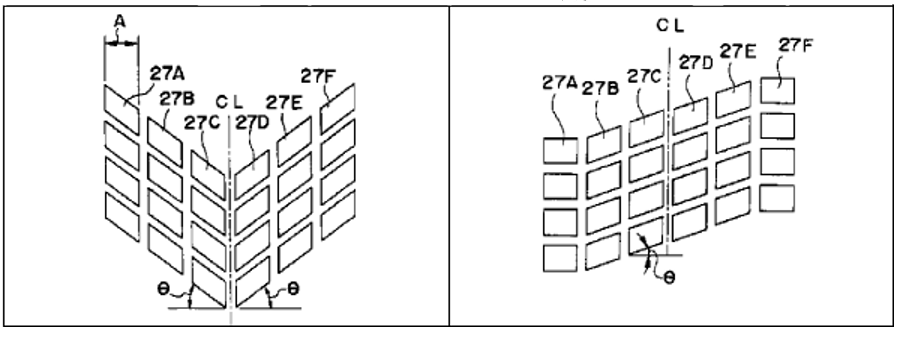

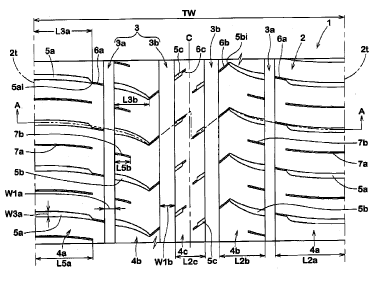

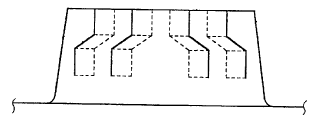

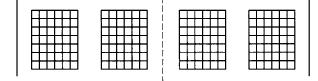

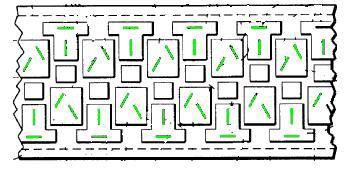

Illustrative examples of subject matter classified in this place:

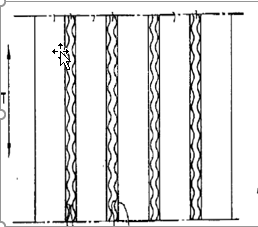

1.

2.

3.

In figures 1, 2 and 3, the left columns illustrate directional tread patterns in contrast to the right columns which illustrate non-directional tread patterns.

Attention is drawn to the following places, which may be of interest for search:

Asymmetric patterns having no rotational direction | |

Directional patterns comprising tread lugs arranged parallel or oblique to the axis of rotation |

This place covers:

Tread patterns whereby one side of tread centreline is not a mirror image or does not have symmetry with a tread pattern on other side of tread centreline. Asymmetric tread patterns are generally characterised by a specified mounting direction in relation to the vehicle, e.g. inboard vs. outboard or inner vs. outer side.

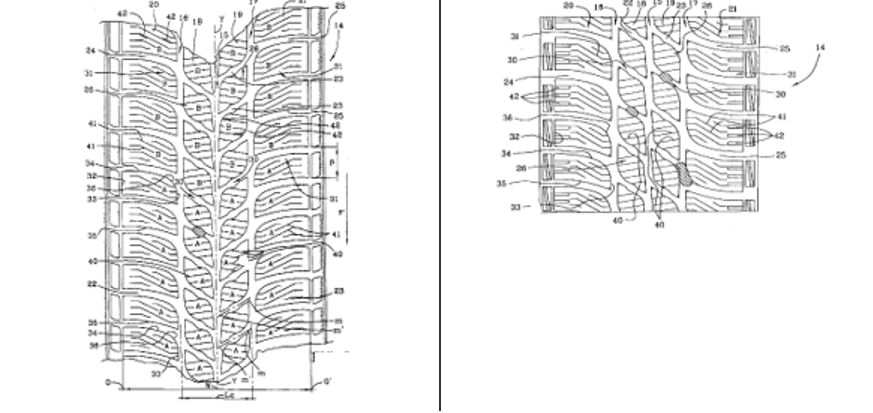

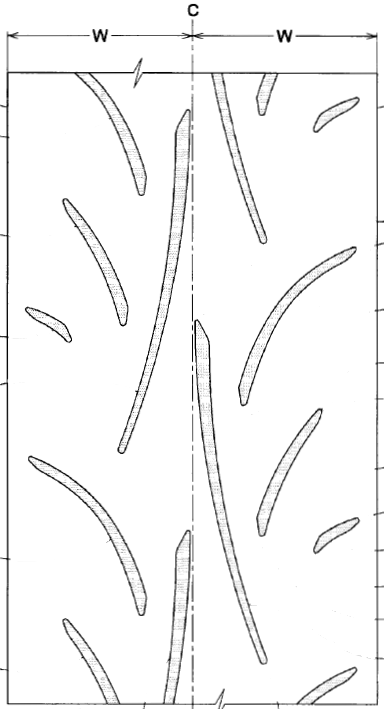

Illustrative examples of subject matter classified in this place:

1.

2.

3.

These figures illustrate an asymmetric tread pattern having at least one tread feature on one half of the tread that is not the same as the other half of the tread.

A tread pattern that has line-symmetry or point-symmetry about the tread centreline, i.e. non-directional, is not considered to be an asymmetric tread pattern.

A tread pattern wherein the patterns on either side of the centreline are circumferentially off-set mirror images is not considered to be an asymmetric tread pattern.

This place covers:

Treads including at least one row of blocks separated by width direction grooves and that may include at least one rib.

Attention is drawn to the following places, which may be of interest for search:

Tread pattern consists only of isolated elements, e.g. blocks |

This place covers:

Treads comprising at least one block row and further characterised by a special shape of the groove cross-section of the circumferential grooves.

Attention is drawn to the following places, which may be of interest for search:

Tread characterised by the groove cross-section |

Treads having grooves characterised by the groove cross-section should also receive classification under B60C 11/13.

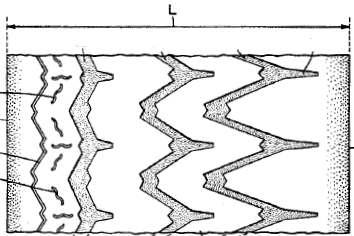

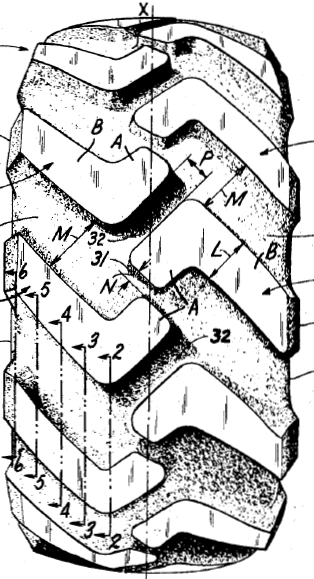

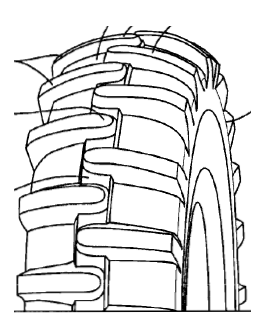

This place covers:

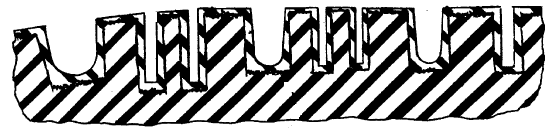

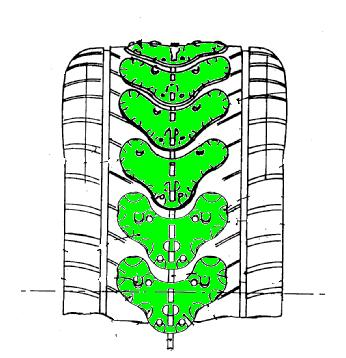

Treads comprising large tread lugs for agricultural tyre or construction tyre or treads comprising large lug grooves extending from tread edge to centre rib and defining large tread lug elements connected to the centre rib.

Illustrative examples of subject matter classified in this place:

1.

2.

Figure 2 shows an off-road tyre having two rows of large lugs.

3.

Figure 3 shows a construction tyre having three rows of large lugs. Right figure shows a construction tyre having two rows of large lug grooves.

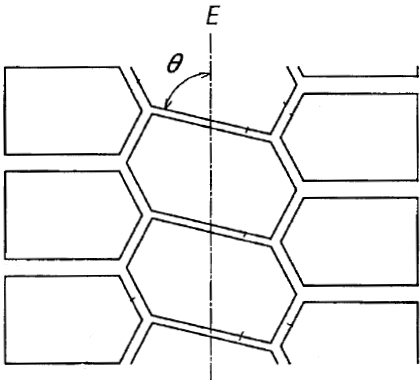

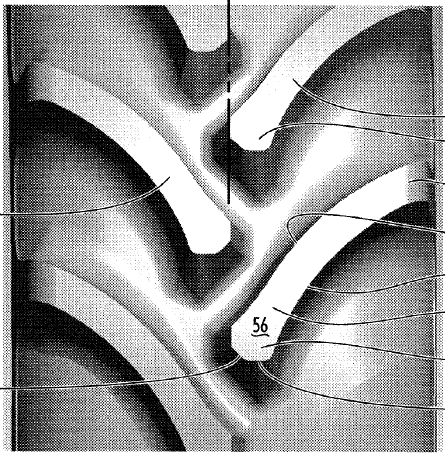

This place covers:

Treads comprising large tread lugs and further characterised by a directional pattern.

Illustrative example of subject matter classified in this place:

Figure shows an agricultural tyre having two rows of large lugs (56) arranged to define a directional tread patter.

Attention is drawn to the following places, which may be of interest for search:

Treads characterised by directional pattern |

This place covers:

Treads further characterised by the shape of the groove cross-section.

Attention is drawn to the following places, which may be of interest for search:

Treads characterised by the groove cross-section |

Treads having grooves characterised by the groove cross-section should also receive classification under B60C 11/13.

This place covers:

Treads comprising repeating geometric features having different pitch lengths usually for reducing noise, e.g. a row of blocks comprising blocks having large length L, blocks having medium length M and blocks having small length S arranged in a sequence such as SMLMSML ... or random sequence of S, M, L.

This place covers:

Tread patterns that include isolated recesses e.g. holes or both end closed grooves.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 shows a tread having ribs, each comprising small holes.

2.

Figure 2 shows a tread having isolated grooves.

Attention is drawn to the following places, which may be of interest for search:

Treads comprising channels under the tread surface |

This place covers:

Treads comprising sunken cavities that appear at the tread surface after the tyre is worn. The sunken cavities may or may not be connected to the tread surface by a sipe or incision.

Illustrative example of subject matter classified in this place:

Figure shows sunken cavities each connected to the tread surface by a sipe.

This place covers:

Tyres characterised by the properties of the tread pattern such as groove area ratio, shape of the footprint or stiffness of the tread.

Attention is drawn to the following places, which may be of interest for search:

Physical properties or dimensions of tread rubber | |

Modulus or tan delta of the tread rubber |

This place covers:

Net-to-gross ratios, groove area ratios, volume ratios or the like of tread patterns being described numerically or net-to-gross ratio, groove area ratio, volume ratio, or the like of one region of tread pattern being compared to another region of the tread pattern, e.g. net to gross of central region is less than net to gross of shoulder region.

In this place, the following terms or expressions are used with the meaning indicated:

NTG | net to gross = contact area ratio = land ratio |

NTG | total contact area/total tread area |

NTG | [net to gross] = 100% ‐ GA [negative ratio] |

GA | groove area ratio = negative ratio = sea ratio |

GA | total groove area/total tread area |

GA | [groove area ratio] = 100% ‐ NTG [net to gross] |

L/S | land sea ratio |

L/S | total contact area/total groove area |

S/L | sea land ratio |

S/L | total groove area/total contact area |

This place covers:

Tyres characterised by the footprint or contact patch of the tread, including:

- overall shape of the footprint, e.g. rectangular or oval-shaped;

- leading or trailing edge of the footprint;

- dimensions of the footprint, e.g. ratio of the length of the footprint at centreline to length of the footprint at shoulder or width of the footprint at different loads.

This place covers:

Design features of the pattern including circumferential grooves, lateral grooves, slant grooves or continuous ribs.

This place covers:

Tread patterns having at least one groove.

This place covers:

Tread patterns having at least one circumferential groove.

This place covers:

Circumferential grooves having undulating traces.

This place covers:

Circumferential grooves described as having a width less than 4 mm.

A figure showing a circumferential groove but no circumferential sipes having significantly smaller width than typical full width main circumferential grooves should be placed in B60C 2011/0348 regardless of whether the exact width is numerically specified.

This place covers:

Tread patterns whereby at least one circumferential groove has a depth of less than 50% of at least one other groove.

This place covers:

Tread patterns whereby the width of circumferential groove is described numerically.

This place covers:

Tread patterns whereby the depth of circumferential groove is described numerically.

This place covers:

Tread patterns whereby the angle of lateral groove is illustrated or described numerically as being 45 to 90 degrees with respect to the equatorial plane.

This place covers:

Tread patterns whereby the lateral groove is a shallow lateral groove having a depth less than 50% of at least one other groove.

This place covers:

Tread patterns whereby the width of lateral groove is described numerically.

This place covers:

Tread patterns whereby the depth of lateral groove is described numerically.

This place covers:

Tread patterns whereby the depth of lateral grooves changes along length of lateral groove or along width of lateral groove. The varying depth may be defined by a tie bar.

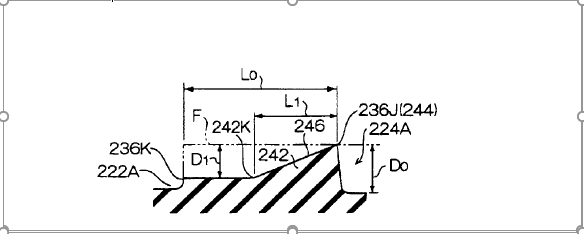

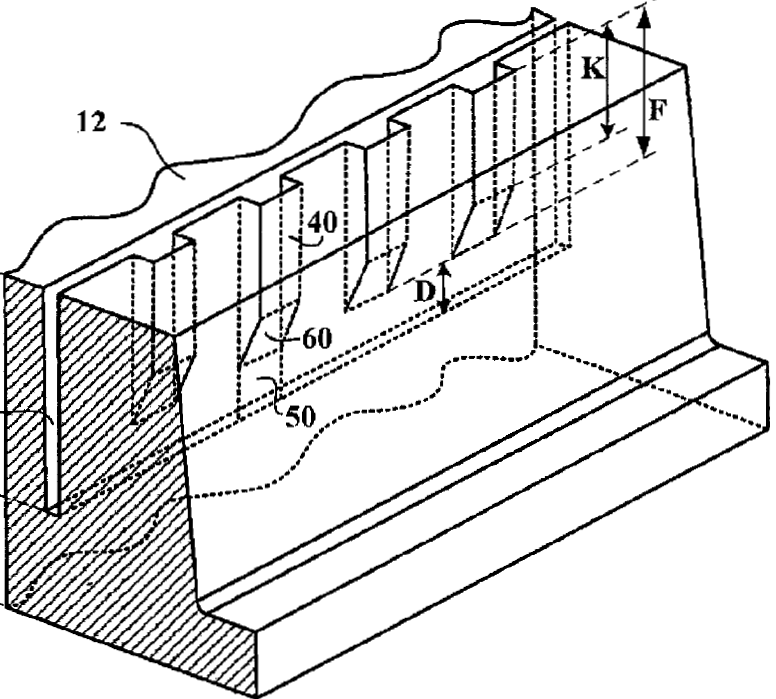

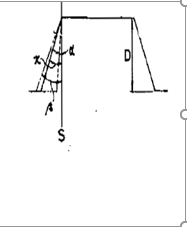

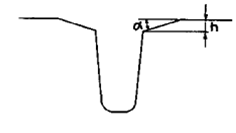

Illustrative example of subject matter classified in this place:

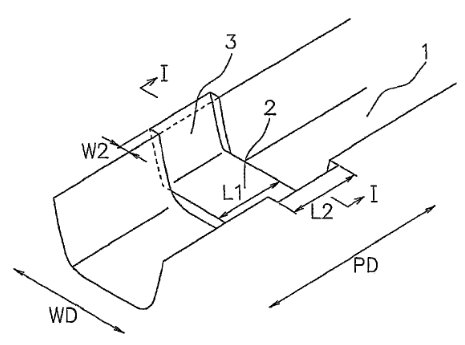

1a.

1b.

Above figures 1a and 1b show a lateral groove having a depth varying over length (L1).

Attention is drawn to the following places, which may be of interest for search:

Tie bars for linking block elements and bridging the groove |

This place covers:

Tread patterns whereby the angle of lateral groove is described numerically.

This place covers:

Tread patterns whereby the angle of slant groove is illustrated or described numerically as being 5 to 35 degrees with respect to the equatorial plane or angle.

This place covers:

Tread patterns whereby the width of slant groove is described numerically.

This place covers:

Tread patterns whereby the depth of slant groove is described numerically.

This place covers:

Treads comprising one end open grooves, i.e. one end of the groove is open to another groove and the other end of the groove terminates in a tread element such that the other end of the groove is closed.

Attention is drawn to the following places, which may be of interest for search:

Both end closed grooves |

In this place, the following terms or expressions are used with the meaning indicated:

one end open groove | one end of the groove is open to another groove and the other end of the groove terminates in a tread element such that the other end of the groove is closed |

This place covers:

Tread patterns whereby one end open grooves are formed in land portion at equatorial plane.

This place covers:

Tread patterns whereby the continuous rib is a continuous shoulder rib including lateral grooves having one end terminating in rib and the other end open to the tread end. The continuous rib may be divided by both end open sipes.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 shows a shoulder rib (2) comprising a narrow rib divided by short sipes (6a) that are connected to shoulder lateral grooves (5a).

2.

Figure 2 shows a shoulder rib comprising an undivided narrow rib and one end opening lateral grooves.

This place covers:

Treads including continuous ribs offset from the tread surface.

This place covers:

Tread patterns whereby all tread elements in the tread pattern are continuous circumferential ribs, i.e. circumferentially extending ribs that may be divided by both end open sipes, such that the tread pattern is exclusive of blocks.

This place does not cover:

Tread patterns characterised by narrow slits or incisions | |

Tread patterns characterised by groove cross-section |

This place covers:

Subject matter wherein all tread elements in the tread pattern are blocks such that the tread pattern is exclusive of ribs.

The subject-matter of this place refers in particular to irregularly arranged blocks which are not provided in simple block rows – such tread patterns may be found, for example, on off-road tyres.

This place does not cover:

Characterised by the use of narrow slits or incisions, e.g. sipes | |

Characterised by the groove cross-section, e.g. for buttressing or preventing stone-trapping |

This place covers:

Tread patterns whereby the sipes are characterised by the two-dimensional, i.e. planar, or three-dimensional shape of the sipe walls or by a particular shape formed in the tread, e.g. crank-shaped, zigzag, circular or polygonal.

Sipes having variable depth or width within the same sipe should include further classifications in B60C 11/1263 or B60C 11/1281, respectively.

This place covers:

Tread patterns whereby in the plan view of the tread surface, the sipe has a rectilinear trace instead of curved.

This place covers:

Tread patterns whereby, in the plan view of the tread surface, the sipe has a sinusoidal, zigzag or wavy shape.

This place covers:

Tread patterns whereby sipes have three-dimensional shape, e.g. varying shape or undulating width in both the depth direction and extending directions or having a shape which splits in the depth direction, e.g. inverted Y-shape. Sipes which vary in only extension direction or depth direction are generally not considered to be three-dimensional sipes.

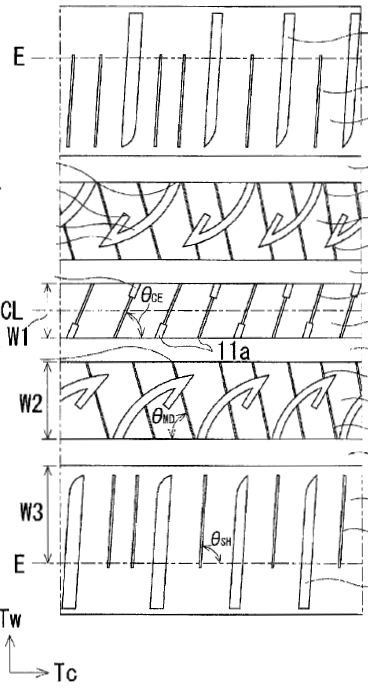

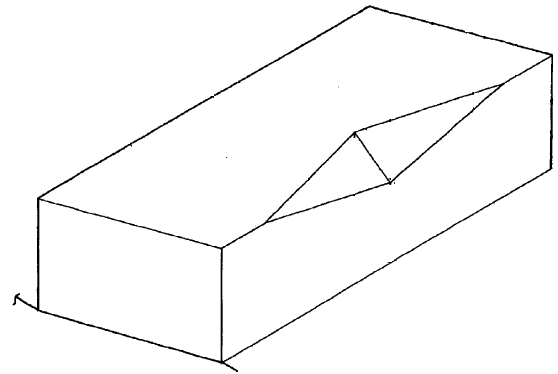

Illustrative examples of subject matter classified in this place:

1.

Figure 1 shows a three-dimensional sipe being zigzag along its length and being zigzag along its depth.

2.

Figure 2 shows a three-dimensional sipe having wide portions varying along the depth of the sipe.

3.

Figure 3 shows a three-dimensional sipe having lower branched portions.

This place covers:

Tread patterns whereby the shape of the sipe twists or warps along the extension of the sipe.

Illustrative example of subject matter classified in this place:

Above figures show sipes being twisted in the depth direction.

This place covers:

Tread patterns having sipes with different shapes or individual sipes having portions with different shapes, e.g. linear at ends and zigzag in middle.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 shows one type of sipes having a step portion facing left and another type of sipes having a step portion facing right.

2

Figure 2 shows a sipe having a left flat region, a middle region having zigzag traces and a right region having circular protrusions.

3.

Figure 3 shows one block having a first sipe type being zigzag along its length and straight along its depth, and another block having a second sipe type being zigzag along its length and zigzag along its depth.

Attention is drawn to the following places, which may be of interest for search:

Sipes characterised only by variable depth | |

Sipes characterised only by variable width |

This place covers:

Tread patterns whereby the sipes or fine grooves have shallow depths.

This place covers:

Tread patterns whereby the sipes are characterised by their location, orientation, or inclination in the tread pattern.

Attention is drawn to the following places, which may be of interest for search:

Sipes characterised by pitch or density |

This place covers:

Tread patterns with sipes whose depth-wise extension is inclined with respect to the radial direction of the tyre.

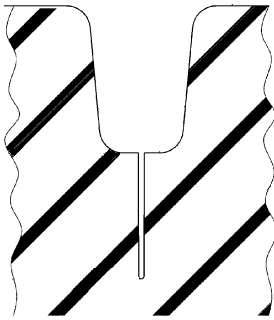

Illustrative example of subject matter classified in this place:

Figure shows sipes extending inward from the tread surface and being inclined with respect to the radial direction.

This place covers:

Tread patterns wherein sipes are arranged as a network of intersecting sipes, e.g. pattern forming a mesh.

Illustrative example of subject matter classified in this place:

Figure shows circumferentially extending sipes intersecting axially extending sipes in a surface of a block to form a mesh.

This place covers:

Tread patterns with sipes extending from bottom of a groove.

Illustrative example of subject matter classified in this place:

Figure shows a sipe extending radially inward from a bottom of a groove.

This place covers:

Tread patterns whereby the sipes can be identified as closed or blind, i.e. both ends of the sipe do not open to a groove.

This place covers:

Tread patterns whereby the sipes are characterised by variable depth or specified depth dimensions.

This place covers:

Tread patterns with sipes comprising portions having different depths.

Illustrative example of subject matter classified in this place:

Figure shows a sipe having shallow end portions and a shallow middle portion.

This place covers:

Treads comprising sipes having different depths.

This place covers:

Treads comprising sipes characterised by variable width or specified width dimensions.

This place covers:

Tread patterns whereby the sipes comprise portions having different widths, e.g. enlarged bottom or enlarged or chamfered openings.

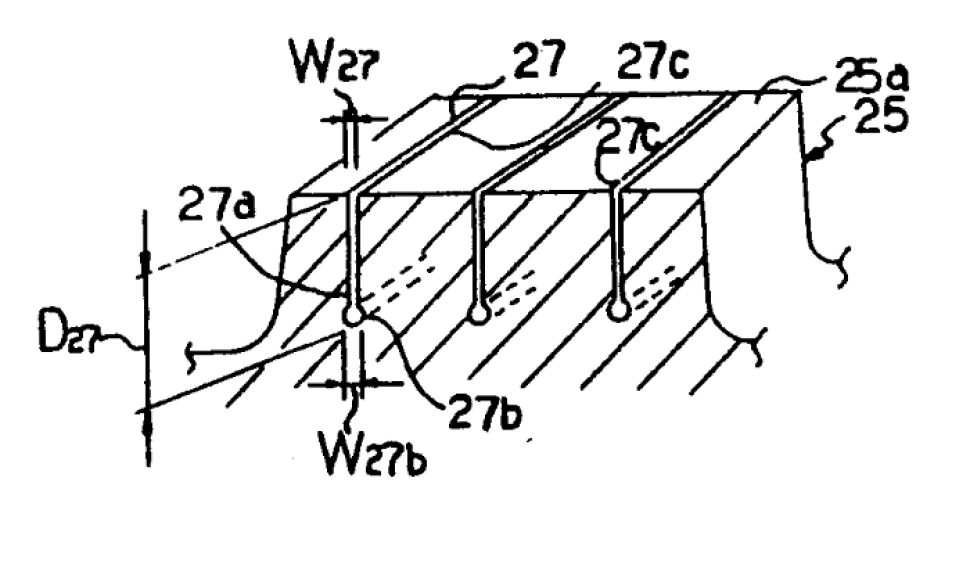

Illustrative examples of subject matter classified in this place:

1.

Figure 1 shows a sipe having a width varying along the length of the sipe.

2.

Figure 2 shows sipes, each having an enlarged bottom portion (27b).

Attention is drawn to the following places, which may be of interest for search:

Sipes formed at the bottom of a groove |

This place covers:

Treads comprising sipes having different widths.

This place covers:

Treads comprising sipes characterised by their density, their pitch or the distance between adjacent sipes.

This place covers:

Tread patterns comprising portions having different sipe densities, e.g. high sipe density in the central tread region and low sipe density in the shoulder tread regions.

Attention is drawn to the following places, which may be of interest for search:

Tread patterns comprising block rows or discontinuous ribs and further characterised by the groove cross-section | |

Tread patterns comprising tread lugs and further characterised by the groove cross-section | |

Pattern characterised by grooves | |

Tread patterns comprising ribs and further characterised by the groove cross-section |

Subject matter classified in B60C 11/0309, B60C 11/0316 or B60C 11/042 – B60C 11/047 should also include a classification in B60C 11/13 or its subgroups.

This place covers:

Treads comprising grooves that are characterised by the shape of groove walls, e.g. inclination angles, protrusions or recesses.

Attention is drawn to the following places, which may be of interest for search:

Groove walls having a three-dimensional shape |

This place covers:

Treads comprising grooves having at least one wall defined by varying inclination angles along its extension direction.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 shows the angle of the sidewall of a groove with respect to the radial direction varying along the length of the groove.

2a.

2b.

2c.

Above figures 2a, 2b and 2c show four circumferential grooves, each having a straight trace at the tread surface and undulating trace at the groove bottom, where these traces are joined by a sidewall having an angle with respect to the radial direction that varies along the length of the groove.

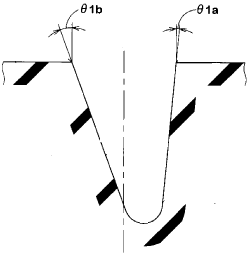

This place covers:

Treads comprising grooves defined by opposing walls having shapes that are asymmetric to the groove centreline, e.g. groove walls defined by different inclination angles.

Illustrative example of subject matter classified in this place:

Figure shows a groove having a left sidewall inclined at a large angle (theta 1b) with respect to the radial direction and a right sidewall inclined at a small angle (theta 1a) with respect to the radial direction.

This place covers:

Treads whereby the groove wall surface is concave or recessed relative to the extension direction of the wall.

Illustrative example of subject matter classified in this place:

Figure shows a groove having a recess in each sidewall of the groove.

This place covers:

Treads whereby the groove wall has an element projecting from one wall and spaced from the bottom and opposing wall of the groove.

Illustrative example of subject matter classified in this place:

Figure shows a groove having a protrusion projecting from each sidewall of the groove.

This place covers:

Treads whereby the grooves having a thin layer of rubber that covers the surface of the groove.

Illustrative example of subject matter classified in this place:

Figure shows thin rubber layer following contour of tread surface and grooves.

Attention is drawn to the following places, which may be of interest for search:

Tread characterised by cap and base sections |

This place covers:

Treads whereby the grooves are characterised by the shape of the groove bottom, e.g. recesses, protrusions or undulating.

Attention is drawn to the following places, which may be of interest for search:

Sipes formed at the bottom of a groove | |

Protrusion from groove bottom linking tread elements, i.e. tie bars |

This place covers:

Grooves having a protrusion from the bottom of the groove and spaced from one or both walls of the groove.

Attention is drawn to the following places, which may be of interest for search:

Groove bottom comprising trapping protection elements, e.g. stone ejectors |

This place covers:

Treads having an element projecting from one wall, extending laterally and connecting to the opposing wall of the groove.

Illustrative examples of subject matter classified in this place:

1a.

Figure 1a is an axial cross-section showing a tie bar in a groove.

1b.

Figure 1b is a circumferential cross-section showing tie bars in a groove.

Attention is drawn to the following places, which may be of interest for search:

Groove cross-sections characterised by special features of the groove bottom |

This place covers:

Tread elements having tread contact surface which departs from the general tread contour, e.g. tread elements have a concave, convex or rounded shape relative to the general tread contour.

Illustrative example of subject matter classified in this place:

Figure shows land portions, each having a curved convex upper surface.

This place covers:

Tread elements having a chamfer only at the corner of the element.

Illustrative example of subject matter classified in this place:

Figure shows a chamfer at a corner of a tread element.

Attention is drawn to the following places, which may be of interest for search:

Chamfer extends substantially along edge of the tread element |

This place covers:

Tread elements having chamfer which extends along the length of the edge of the tread element.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 shows a chamfer along an edge of a block.

2.

Figure 2 shows edges of blocks and ribs having a chamfer.

3.

Figure 3 shows a cross-section of a groove including a chamfer having a height (h).

This place covers:

Treads wherein the tyre constitutes an anti-skid device by virtue of anti-skid elements embedded therein.

Anti-skid elements, per se, when it is disclosed that they are for use in a tyre.

Studs for snow mobiles are only classified in B62D 55/286.

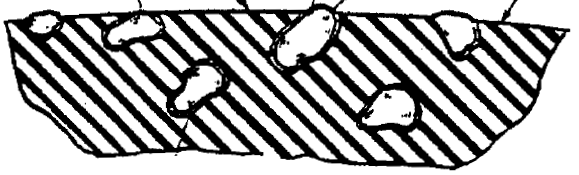

This place covers:

Anti-skid elements characterised by scattered particles embedded in the tread surface.

Illustrative example of subject matter classified in this place:

Figure shows particles embedded in the tread surface.

This place covers:

Anti-skid elements characterised by discontinuous fibres, cords, wires or fabric embedded in the tread surface.

This place covers:

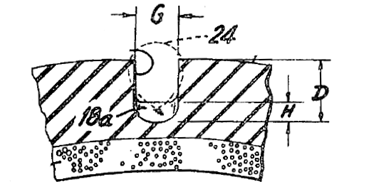

Anti-skid element characterised by a discrete piece of metal or textile that projects from the surface of the tread, e.g. a stud or spike.

Illustrative example of subject matter classified in this place:

Figure shows studs and a tyre comprising studs.

This place covers:

Subject matter wherein the tyre or plug has means to actuate the extension or retraction of the plug from the tread contact surface.

Illustrative example of subject matter classified in this place:

Figure shows retractable plugs 3.

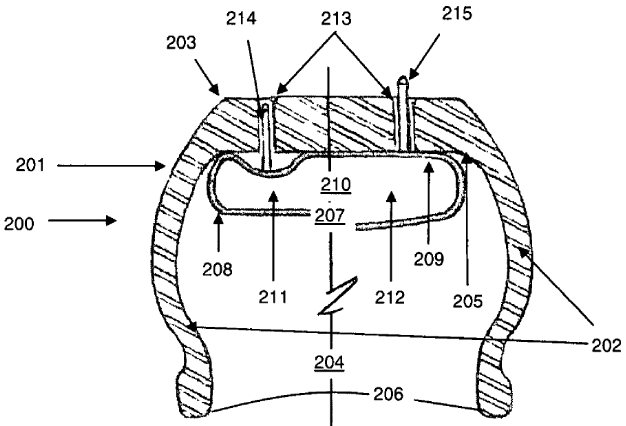

This place covers:

Subject matter wherein the extension or retraction of the plug actuated by fluid, e.g. air.

Illustrative example of subject matter classified in this place:

Figure shows plugs (214) and (215) actuated by inflation of chamber (210).

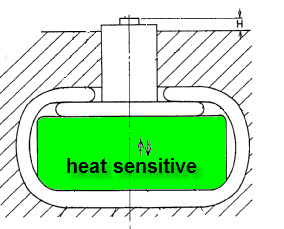

This place covers:

Subject matter wherein the extension or retraction of the plug actuated by temperature sensitive elements.

Illustrative example of subject matter classified in this place:

Figure shows a stud which extends or retracts depending on temperature.

This place covers:

Treads characterised by the arrangement of the plug within the tread pattern, e.g. different orientation to each other, arranged at different depths, arranged in relation to a groove.

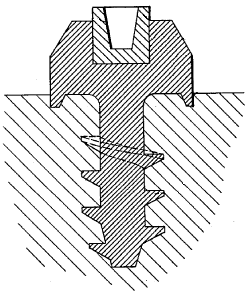

This place covers:

Tyres or plugs characterised by the specific means of attachment of the plug into the tread.

Illustrative example of subject matter classified in this place:

Figure shows a stud having means for attachment in the form of a helical thread for attaching the stud to the tread.

This place covers:

Plugs characterised by the shape of the plug body portion. The body portion is generally the portion of the plug which is embedded in the tread.

This place covers:

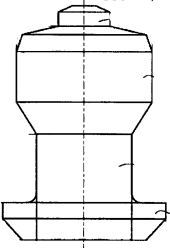

Illustrative examples of subject matter classified in this place:

1.

2.

Figures 1 and 2 show stud having conical shaped body.

This place covers:

Illustrative examples of subject matter classified in this place:

1.

Figure 1 shows stud comprising body having concave surface.

2.

Figure 2 shows stud comprising upper body portion having convex and concave portions, and shows lower body portion that is the bottom flange having convex and concave portions.

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

Above figures 1 and 2 show studs having helical shaped body.

This place covers:

Illustrative examples of subject matter classified in this place:

1.

2.

![]()

3.

Figures 1, 2 and 3 each show a stud comprising a body having an upper collar and a bottom flange.

This place covers:

Plugs characterised by the shape of the plug tip portion which engages with the ground contact surface.

This place covers:

Plug tips having a circular cross-section, e.g. hemispherical top.

This place covers:

Plugs whereby each plug comprises multiple tips.

This place covers:

Plugs characterised by the means by which the plug-tip is secured to the plug-body.

This place covers:

Anti-skid inserts characterised by thin, elongate structure.

Illustrative example of subject matter classified in this place:

Figure shows thin rectangular studs.

This place does not cover:

Anti-skid inserts in coiled form |

This place covers:

Subject matter wherein the anti-skid insert is made of metal and has a strip form.

Illustrative examples of subject matter classified in this place:

1.

2.

Figures 1 and 2 show anti-skid strip having blade-like form.

This place covers:

Subject matter wherein the anti-skid insert has a coiled, wound or spiral shape.

Illustrative examples of subject matter classified in this place:

1.

2.

Figures 1 and 2 show an anti-skid insert comprising a coiled form.

This place covers:

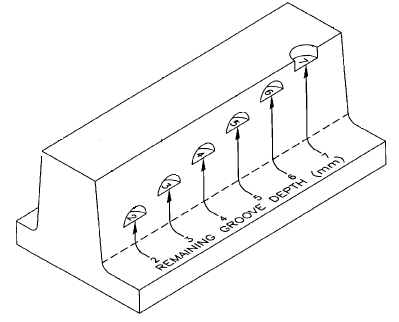

Treads having tread wear indicators, e.g. protrusions, recesses, markings, coloured layers or systems for visually indicating tread wear.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 shows wear indicator comprising recesses in a tread element.

2.

Figure 2 shows wear indicator 2 in the form of a tie bar.

Attention is drawn to the following places, which may be of interest for search:

Warning devices, e.g. devices generating noise due to flat or worn tyres |

This place covers:

Tyres with sensor arrangements for determining tyre wear.

Illustrative example of subject matter classified in this place:

Figure shows an arrangement of sensors for determining wear in the tread.

This place covers:

Systems or computer models that monitor or predict tyre wear.

Attention is drawn to the following places, which may be of interest for search:

Signalling devices actuated by tyre pressure | |

Signalling devices actuated by deformation of the tyre |

This place covers:

Subject matter which includes structure that corresponds with the part of the tyre between the shoulder of the tread and the rim.

Illustrative examples of subject matter classified in this place:

1.

2.

Figures 1 and 2 generally show tyre sidewall features.

This place does not cover:

Shape of the shoulders between tread and sidewall | |

Means facilitating folding of sidewalls, e.g. run-flat sidewalls | |

Removable tyre sidewall trim rings |

Attention is drawn to the following places, which may be of interest for search:

Sidewall rubber compositions | |

Tyre transverse section | |

Production of the tyre sidewall |

Carcass or bead reinforcements are only classified in groups B60C 9/00 and B60C 15/00 respectively.

Sidewall reinforcing inserts for run-flat use are classified in group B60C 17/00 only.

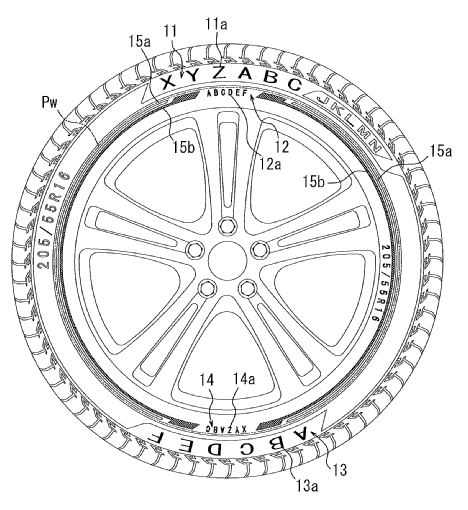

This place covers:

Subject matter wherein the tyre sidewall is provided with decorative markings, patterns or lettering.

Illustrative examples of subject matter classified in this place:

1.

2.

This place covers:

Elements in the side wall which increase the resistance to cutting or cracking.

Illustrative examples of subject matter classified in this place:

1.

Figure 1 shows embedded pucture prevention layer within the sidewall of the tyre.

2.

Figure 2 shows weather resistant coating provided to the tyre outer surface.

This place covers:

Tyres characterised by the curvature of the sidewall, e.g. radius of curvature.

Illustrative example of subject matter classified in this place:

Figure shows a tyre having a sidewall with specified curvature (i.e. KR2).

Attention is drawn to the following places, which may be of interest for search:

Carcass ply curvature |

This place covers:

Illustrative example of subject matter classified in this place:

This place covers:

Subject matter wherein additional bead cores are provided in the sidewall portion of the tyre.

Illustrative example of subject matter classified in this place:

Figure shows bead cores used in a tyre sidewall.

Attention is drawn to the following places, which may be of interest for search:

Tyre characterised by multiple bead cores in the bead portion of the tyre |

This place covers:

Subject matter wherein the sidewall comprises raised projections or recessed portions.

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Sidewall characterised by decorative features | |

Sidewall rubber inserts for run-flat purposes comprising grooves or ribs |

This place covers:

Subject matter wherein the sidewall comprises structure for preventing the tyre from splashing mud or water.

This place covers:

Subject matter wherein grooves or projections are provided on the interior surface of the tyre sidewall.

This place covers:

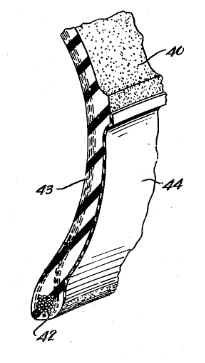

Subject matter wherein the sidewall structure comprises a filled section or an applique of material in a colour other than black or a protective coating layer.

Illustrative example of subject matter classified in this place:

Figure shows a tyre with annular white sidewall veneer (44) covering the lower portion of black sidewall (40).

This place covers:

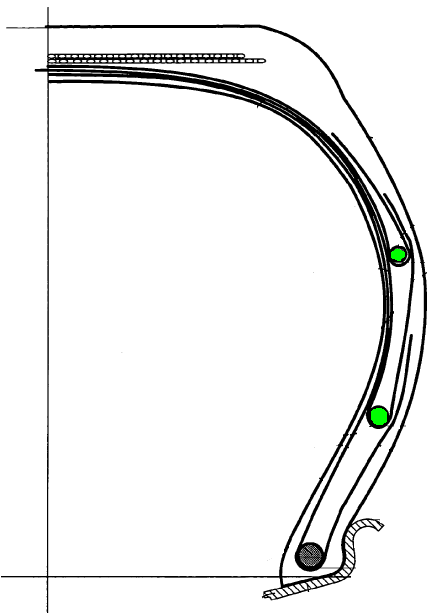

Subject matter wherein the side wall is made of different rubber layers.

Illustrative example of subject matter classified in this place:

Figure shows a tyre with sidewall rubber layers (10) and (11).

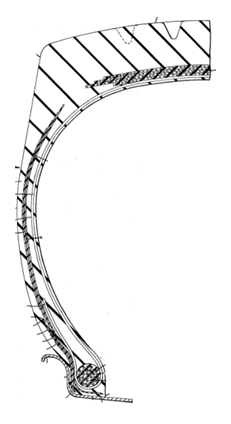

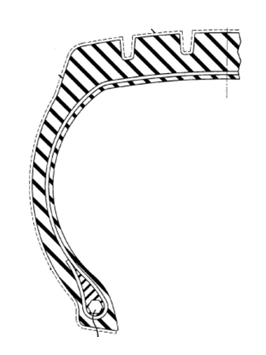

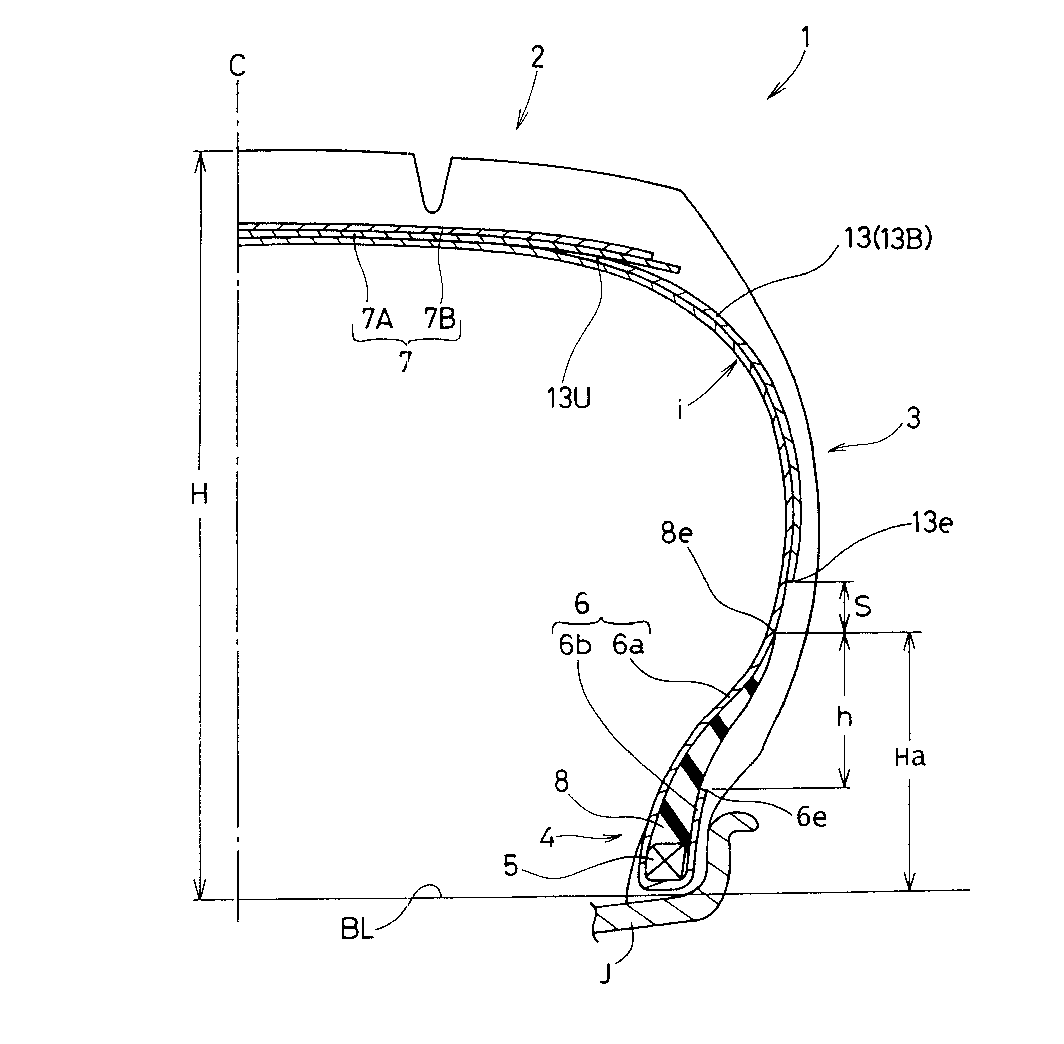

This place covers:

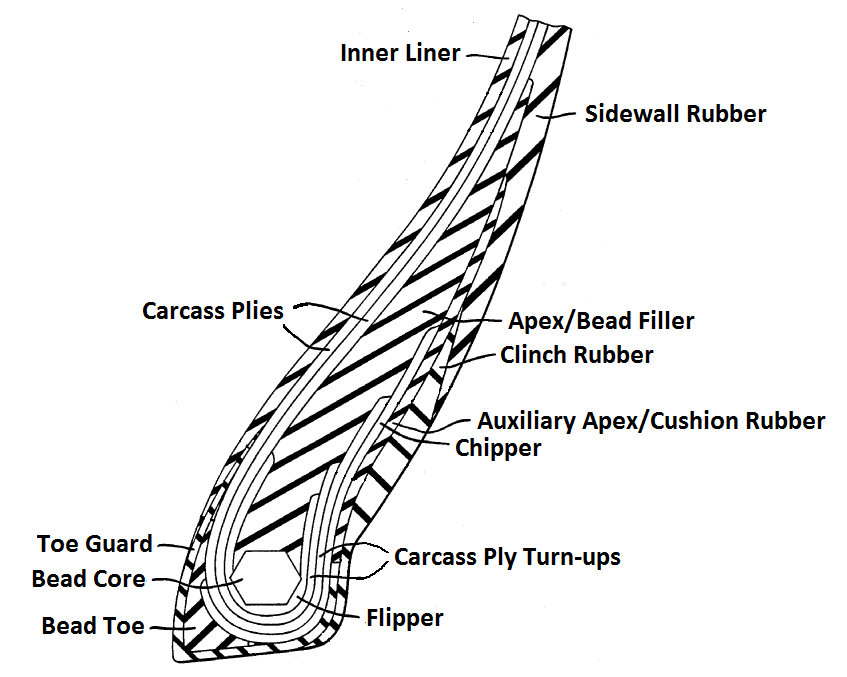

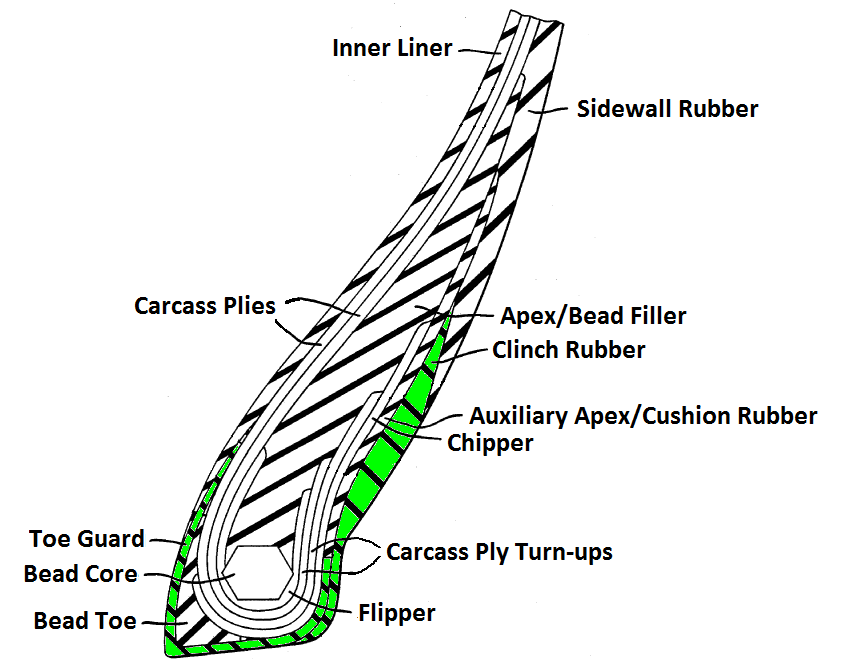

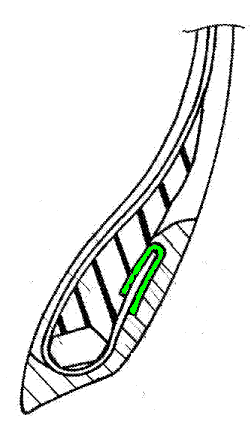

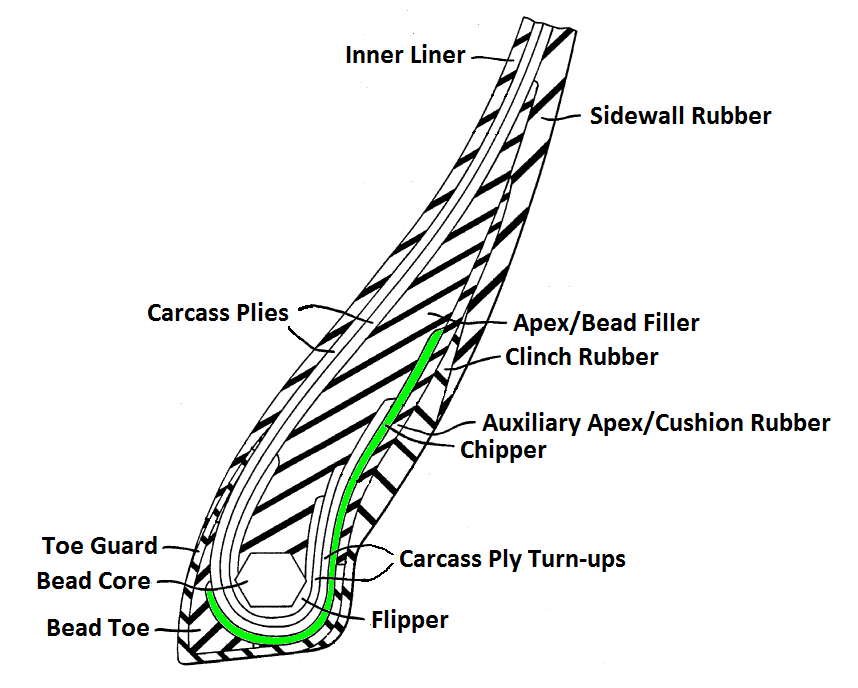

Subject matter that includes the structure of the annular edge of a pneumatic tyre that opens at the rim zone and includes annular reinforcing elements to anchor the tyre or the tyre carcass material to the rim.

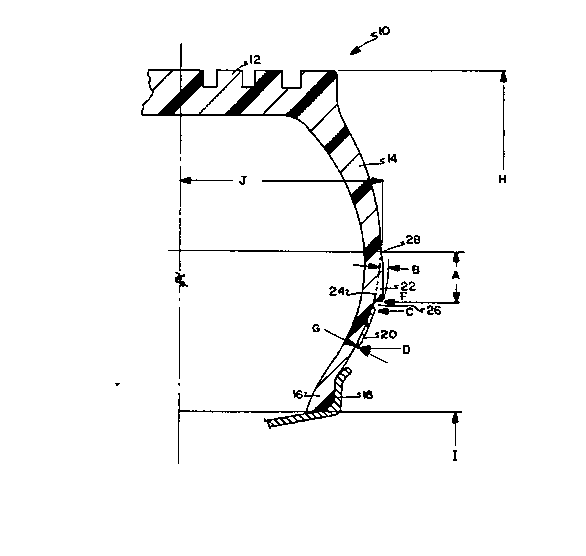

Illustrative example of subject matter classified in this place:

Attention is drawn to the following places, which may be of interest for search:

Transverse section of the rim | |

Rims characterised by the form of tyre-seat or flange |

Carcass reinforcements per se are classified under B60C 9/00.

In this place, the following terms or expressions are used with the meaning indicated:

tyre beads | the annular edges of the tyre |

bead cores or bead wires | the annular reinforcing elements of the beads |

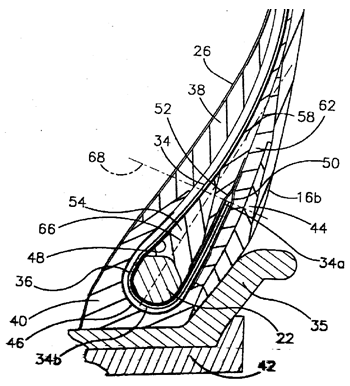

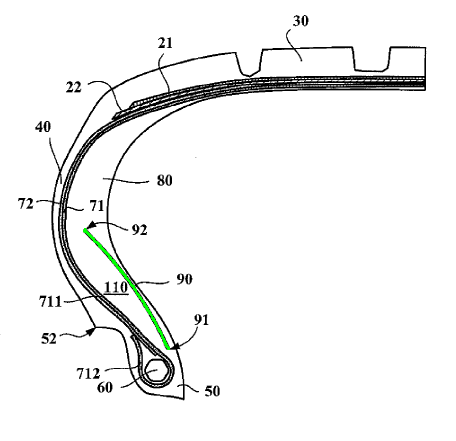

This place covers:

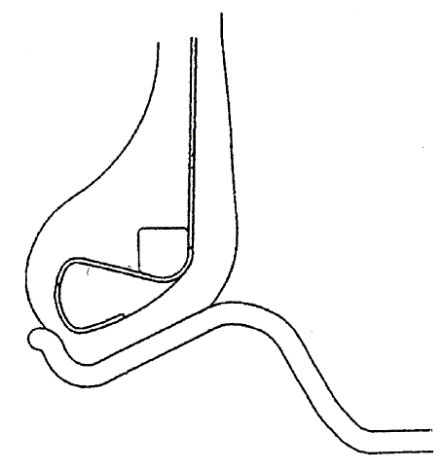

Subject matter wherein the tyre is characterised by the carcass ply terminal portion, e.g. the shape of the terminal portion, the terminating location of the carcass ply turn-up, or the manner in which the carcass ply folds around or interfaces with annular reinforcing elements in the bead.

Illustrative example of subject matter classified in this place:

Figure shows carcass terminal portion (6b) having end (6e).

This place covers:

Subject matter wherein the bead portion of the tyre includes annular reinforcing elements to anchor the tyre or the tyre carcass layers, wherein the carcass layers terminate within the bead portion without being folded around any annular reinforcing element.

Illustrative example of subject matter classified in this place:

This place covers:

Subject matter wherein the carcass ply folds around and terminates at an annular reinforcing element.

Illustrative example of subject matter classified in this place:

This place covers:

Subject matter wherein the carcass ply folds around an annular reinforcing element and a terminal end of said ply extends radially outwards of the maximum section width of the tyre.

This place covers:

Subject matter wherein the carcass ply folds around an annular reinforcing element and a terminal end of said ply extends at least as far as the edge of a belt reinforcing layer.

This place covers:

Subject matter wherein the carcass ply folds around an annular reinforcing element and a terminal end of said ply extends parallel and adjacent to the carcass main portion.

Illustrative example of subject matter classified in this place:

This place covers:

Subject matter wherein the carcass ply folds around an annular reinforcing element and the terminal ends of said ply diverge from the carcass main portion.

Illustrative example of subject matter classified in this place:

This place covers:

Subject matter wherein the carcass plies are turned about an annular reinforcing element in a direction from the axial outer wall of the bead portion of the tyre to the inner wall of the bead portion of the tyre. This direction is the reverse of the more conventional disposition of carcass plies about the annular reinforcing elements.

This place covers:

Subject matter wherein the carcass plies are folded around or between multiple annular reinforcing elements.

Attention is drawn to the following places, which may be of interest for search:

Tyre bead containing multiple bead cores |

This place covers:

Subject matter wherein the carcass ply turned about the annular reinforcing element is of such length as to extend along the side portion of the carcass a specified absolute extent or an extent that is relative to other tyre dimensions, e.g. the maximum height of the tyre.

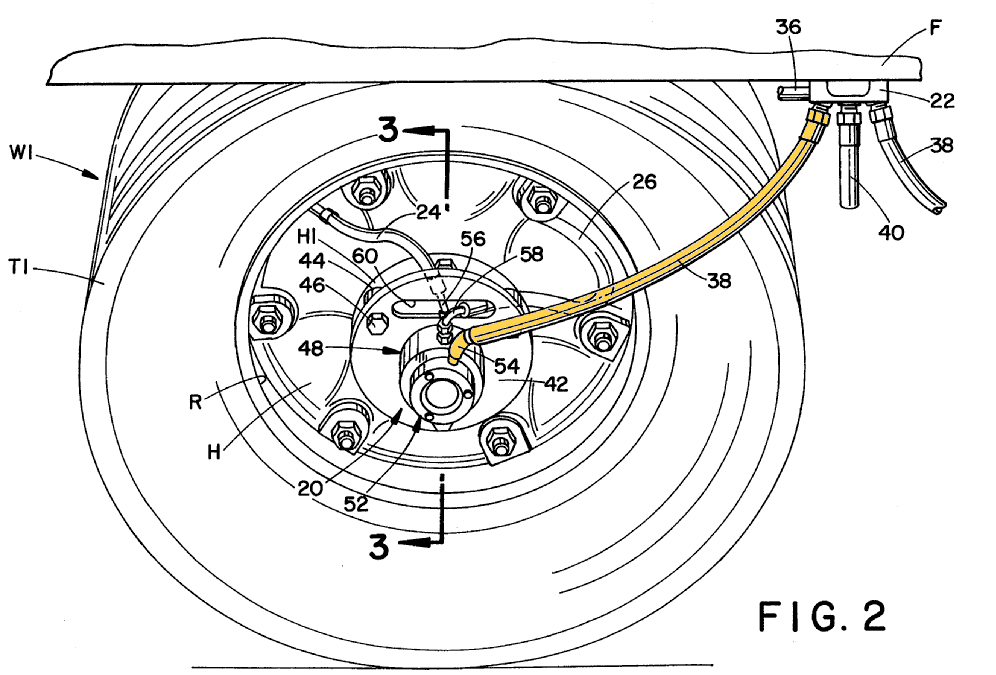

This place covers:

Subject matter whereby resilient tyres are held secured to vehicle wheels or rims.

This place does not cover:

Attention is drawn to the following places, which may be of interest for search:

Rims | |

Rims characterised by the form of tyre-seat or flange |

This place covers:

Subject matter wherein the rim or tyre bead comprises additional means engageable with a corresponding tyre bead or rim to secure the tyre to a bead flange on the rim.

Attention is drawn to the following places, which may be of interest for search:

Rim comprising appurtenances, e.g. lining bands |

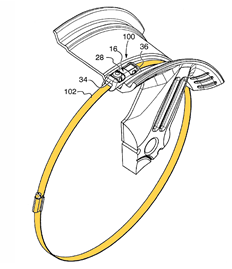

This place covers:

Subject matter wherein supplementary means has projections that wrap around and engage with the rim flange.

Illustrative example of subject matter classified in this place:

This place covers: