CPC Definition - Subclass H01R

This place covers:

all kinds of contact-making disconnectible and non-disconnectible electric line connectors, coupling devices, lamp or similar holders or current collectors for all kinds of electric lines, cables or apparatus;

non-printed means for electric connections to or between printed circuits.

This subclass does not cover mounting of connections in or on specified apparatus. Such mounting is covered by the relevant subclass for such apparatus, e.g. mounting in junction or distribution boxes is covered by subclass H02B or H02G, high-temperature connections for heating elements is covered by group H05B 3/08. Structural association of one part of a coupling device with specific electric apparatus is classified with the apparatus, e.g. association of cap with incandescent lamp is covered by subclass H01K.

Attention is drawn to the following places, which may be of interest for search:

Switches, fuses | |

Coupling devices of the waveguide type | |

Switching arrangements for the supply or distribution of electric power | |

Installations of electric lines, cables or auxiliary apparatus | |

Printed means for providing electric connections to or between printed | |

Semiconductor devices |

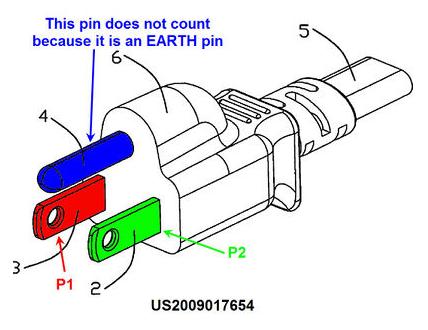

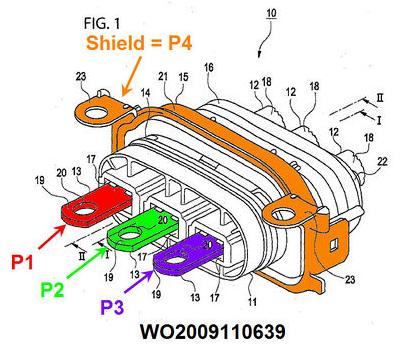

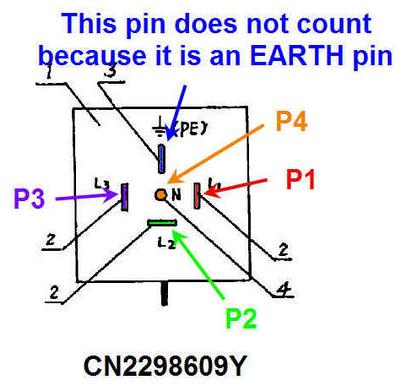

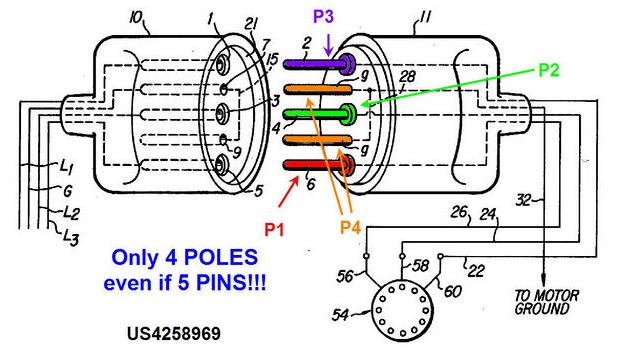

In this subclass, a contact in a coupling device is only regarded as an additional earth contact if this contact is clearly designed for that purpose. General details are classified in groups H01R 4/00, H01R 9/00, H01R 11/00.

In this place, the following terms or expressions are used with the meaning indicated:

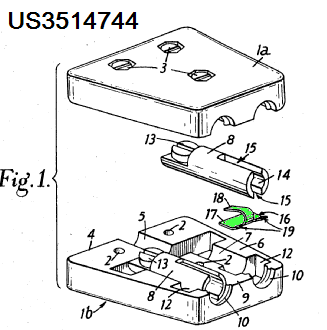

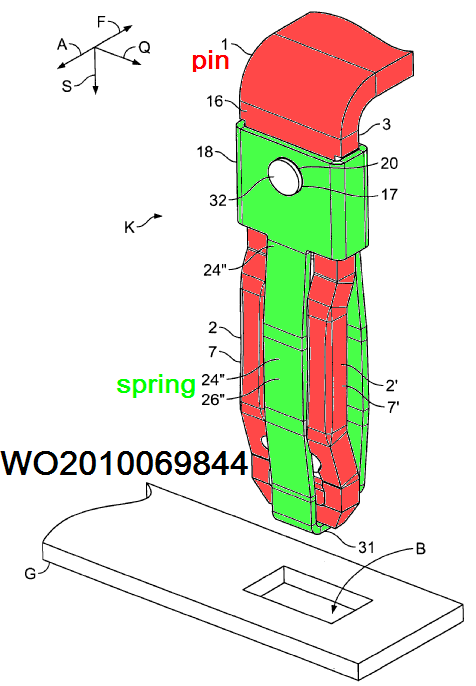

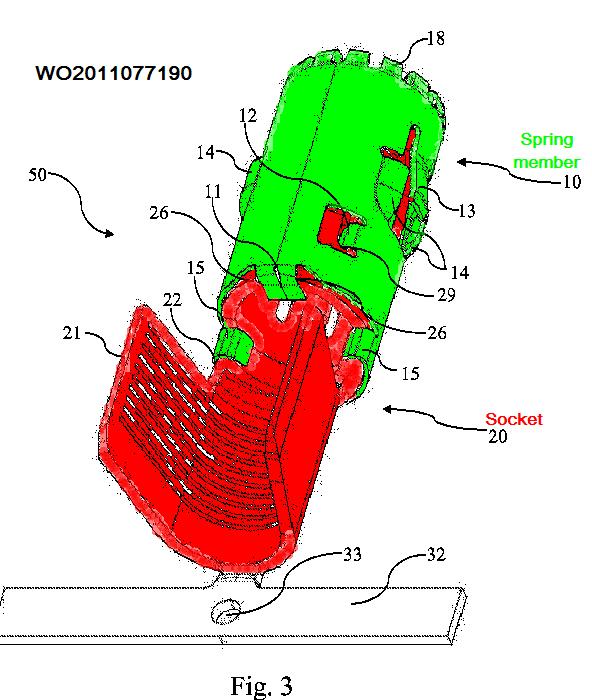

Pin | rigid or flexible conductor for engagement with an appropriately shaped socket to establish contact therewith |

Socket | rigid or flexible conductor for receiving an appropriate pin to establish electrical contact therewith |

Coupling devices | devices having two or more parts specially adapted so as to be capable of ready and repeated physical engagement or disengagement, without the use of a tool, for the purpose of establishing or breaking an electrical path. Examples of such devices having more than two parts are: a) adapters for linking two coupling parts; and b) rails or bus-bars provided with a plurality of discrete connecting locations for counterparts |

This place does not cover:

Slip rings with liquid contacts |

Attention is drawn to the following places, which may be of interest for search:

Electrodes for batteries or accumulators |

This place covers:

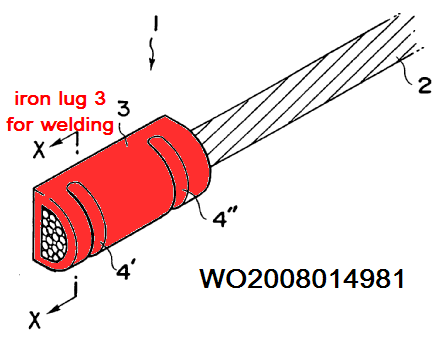

Fixed connections, e.g. soldered, welded, spliced;

Direct connections between conductors and conductive members of coupling; Insulation-penetrating

Attention is drawn to the following places, which may be of interest for search:

Two-part coupling devices | |

Details of disengageable contacts of two-part coupling devices | |

Flexible or turnable line connectors | |

Non rotary current collectors |

This place does not cover:

Soldered or welded connections between conductors of different materials | |

Making a soldered electrical connection simultaneously with the heat shrinking | |

Flexible printed circuits, flat or ribbon cables or like structures |

This place does not cover:

Soldered or welded connections between two or more cables or wires | |

Soldered or welded connections between cables or wires and terminal | |

Soldered or welded connections with built-in heat generating elements | |

Soldered or welded connections comprising means for eliminating an insulative layer prior to soldering or welding | |

Soldered or welded connections comprising means for positioning or holding the parts to be soldered or welded | |

Soldered or welded connections comprising means for preventing flowing or wicking of solder or flux in parts not desired |

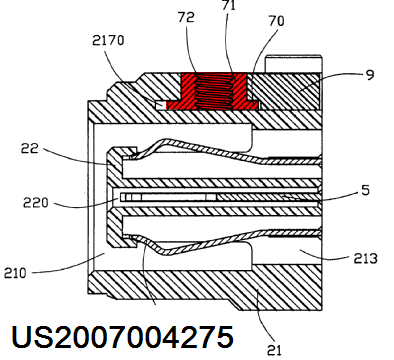

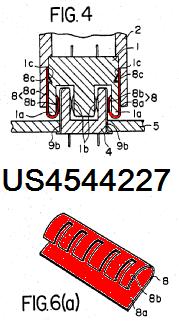

This place covers:

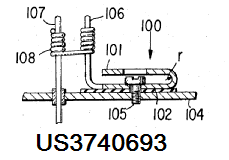

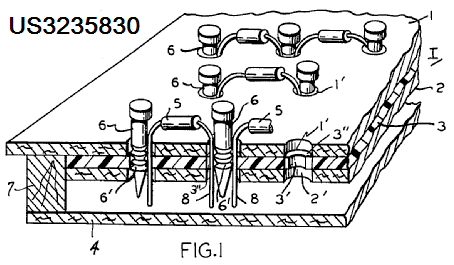

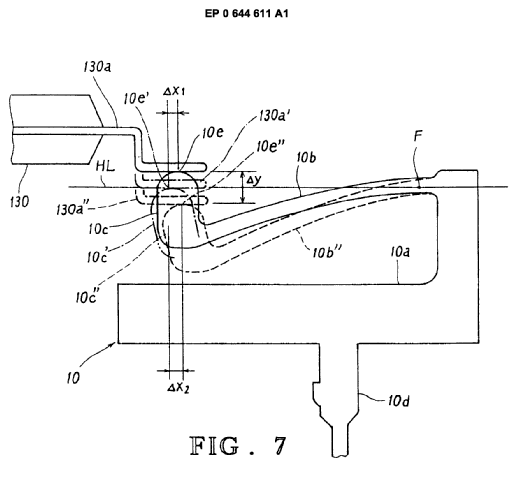

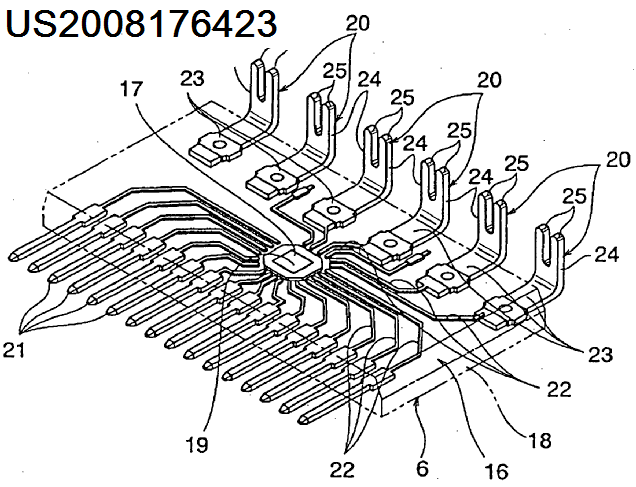

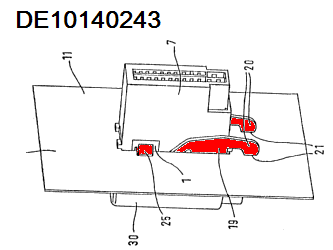

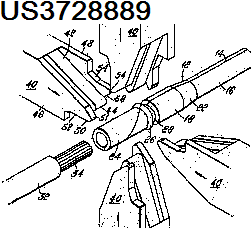

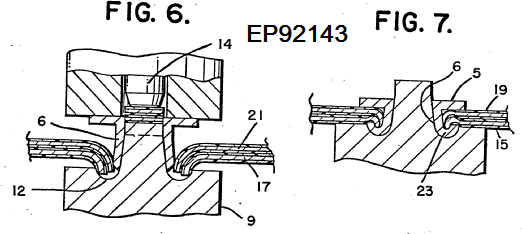

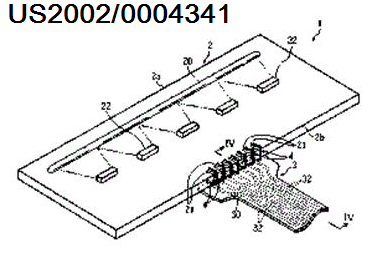

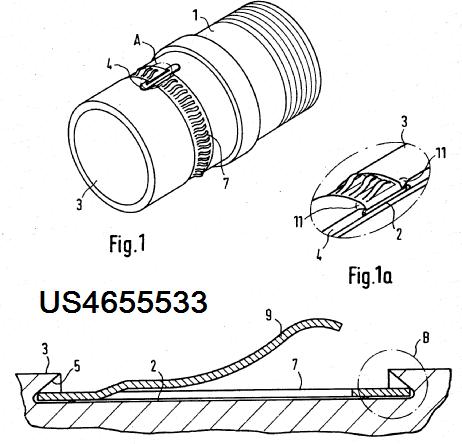

Illustrative example of subject matter classified in H01R 4/06: flatconductor cable (21,17) is connected to conductive member (9) via riveted structure (5):

This place does not cover:

Riveted connections by explosion |

This place does not cover:

Connections using shape memory materials | |

Insulation penetration combined with permanent deformation of contact member | |

Crimping for coaxial cables |

This place does not cover:

Connections using shape memory materials |

This place does not cover:

Connections using shape memory materials |

Attention is drawn to the following places, which may be of interest for search:

For multiphase cables | |

For coaxial cables | |

For flat cables |

Attention is drawn to the following places, which may be of interest for search:

Penetration into a wire end in axial direction |

Attention is drawn to the following places, which may be of interest for search:

Clamped connection using a screw |

This place does not cover:

Using shape memory materials |

This place does not cover:

Connections made by means of terminals specially adapted for contact with, or insertion into, printed circuits |

This place does not cover:

Utilising a clamping member acted on by screw or nut | |

Clamped connections, spring connections utilising a cam, wedge, cone or ball, also combined with a screw | |

For coaxial cables |

Attention is drawn to the following places, which may be of interest for search:

Locking of screw or nut in general |

Attention is drawn to the following places, which may be of interest for search:

Shapes of thread, special thread forms |

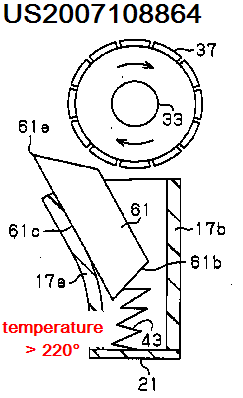

This place covers:

Leaf springs that can be latched in a position (usually open or biased position). This latching should not be due to the spring activating arrangement but to the spring itself.

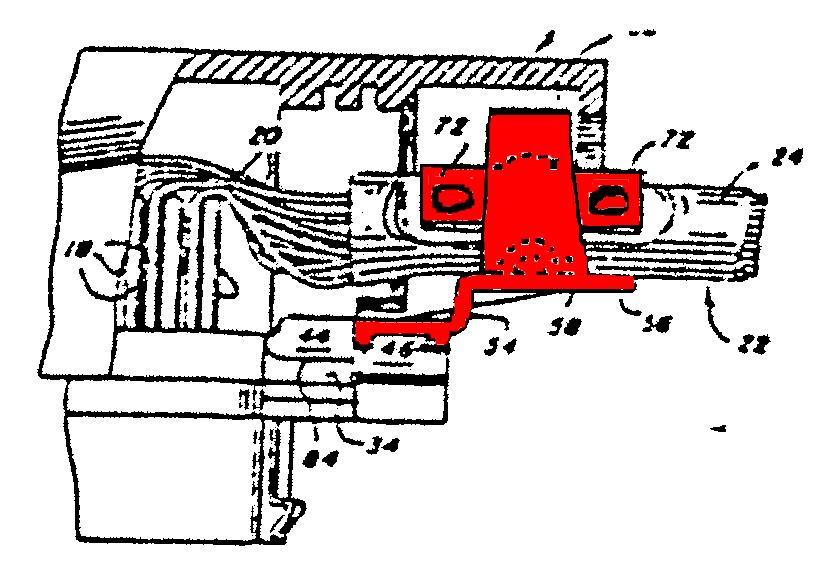

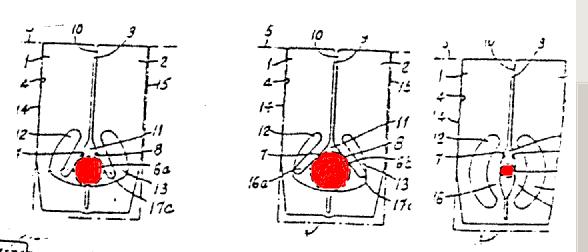

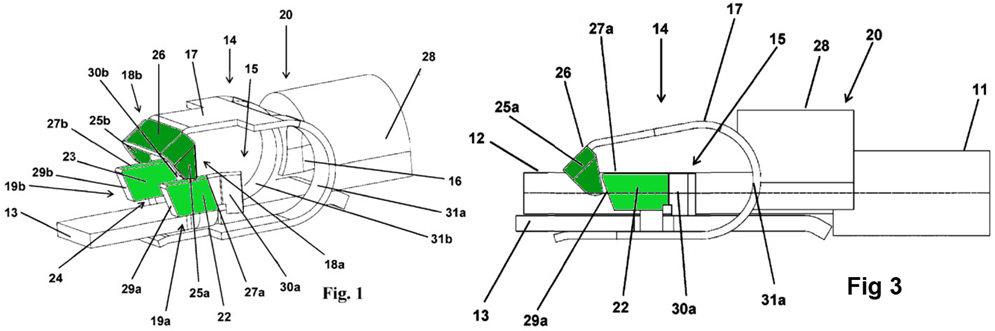

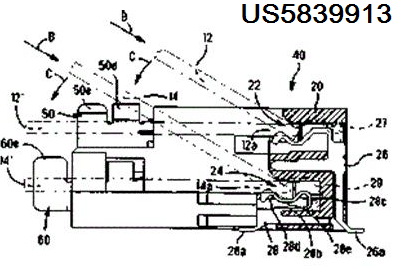

The following figures show a leaf spring (14). On figure 1, the leaf spring is latched in the biased open position. The greyed-out portions (25a) and (25b) of the spring are resting on the greyed-out surface (27a) and (27b) of the spring itself. On figure 3 the latching configuration is removed and the spring is biasing the core (12) of the wire (11).

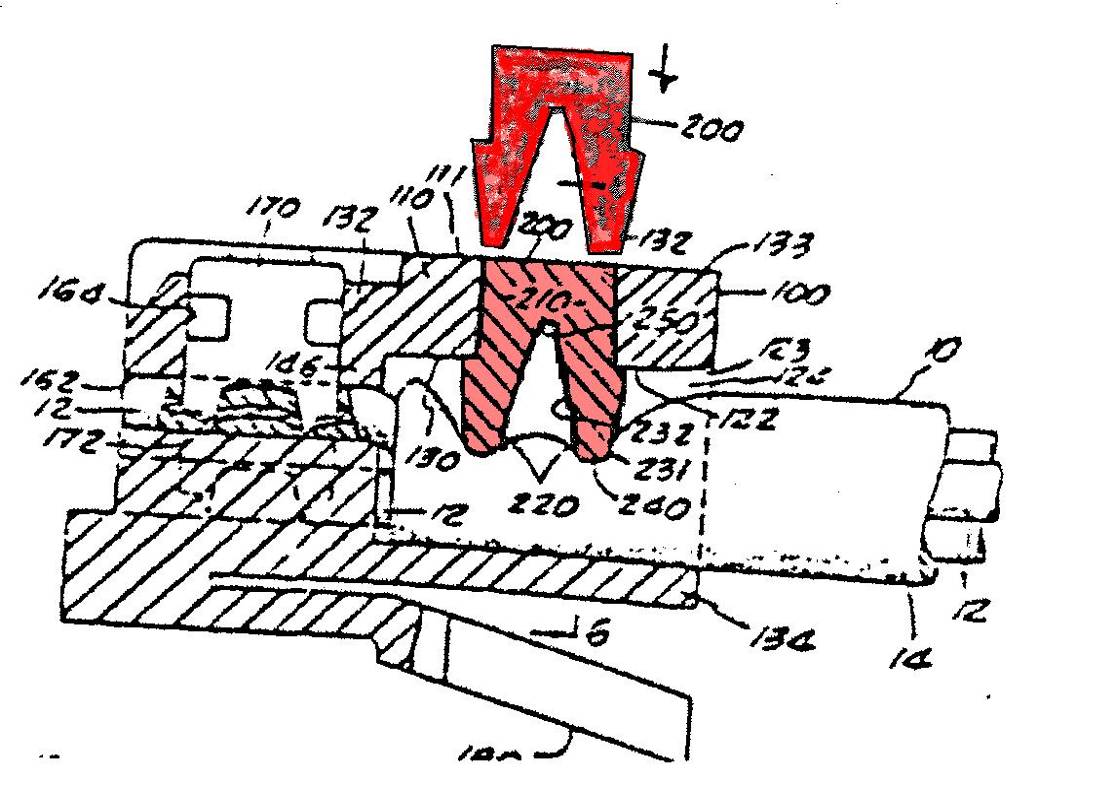

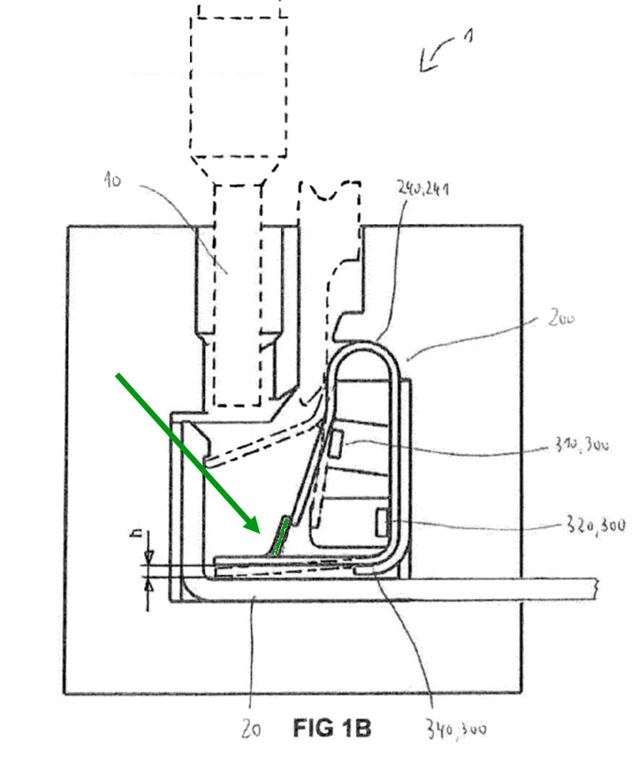

The following figure shows a leaf spring (200) which is coiled on itself and latched in a biased position by the part of the spring itself highlighted in grey and pointed out by the arrow. Insertion of a wire (1a) will push down the bottom left end of the spring thereby releasing the cantilevered lance.

Leaf springs latched by the spring activating arrangement are covered by group H01R 4/4835.

This place covers:

Spring clamped connections requesting an opening of the spring before being able to insert the wire. In its un-biased position, the spring prevents the conductor to be inserted in the connection area of the spring e.g. by presenting a flat portion blocking the insertion channel of the conductor or by guiding the wire away from the spring.

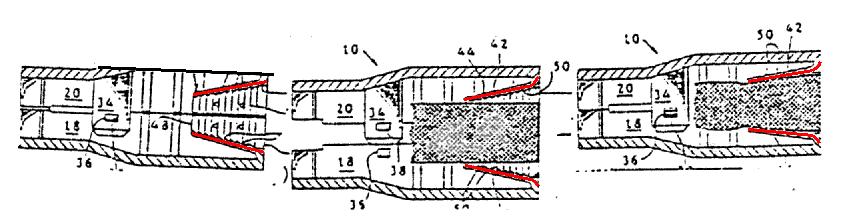

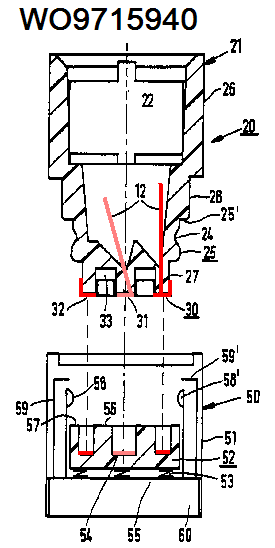

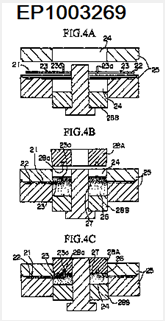

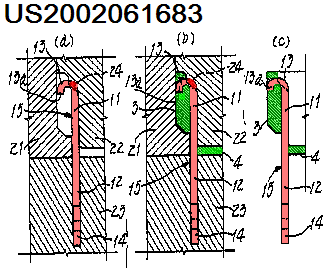

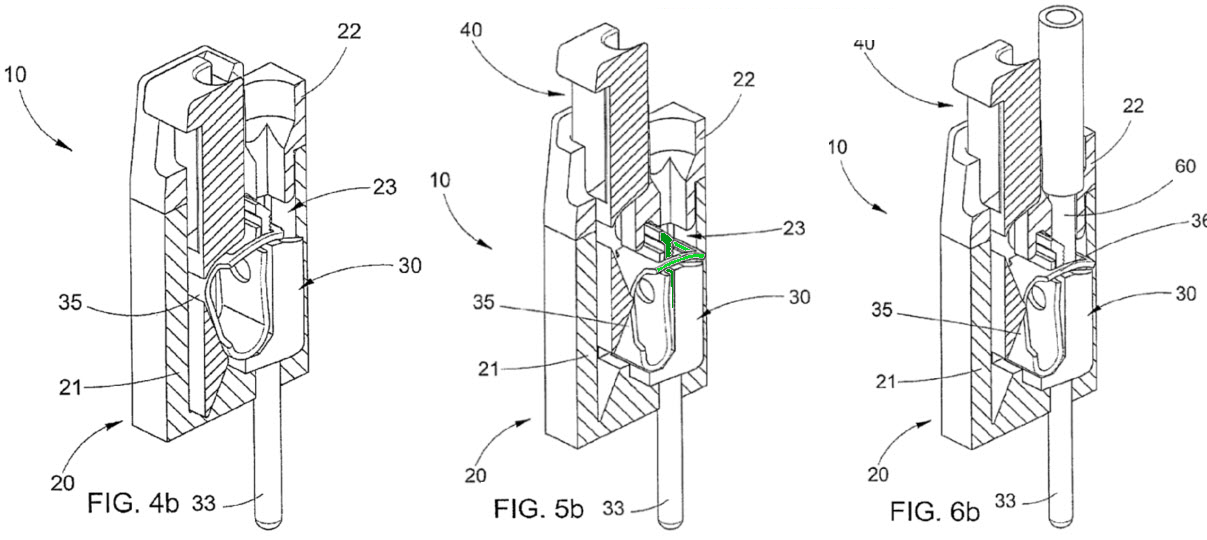

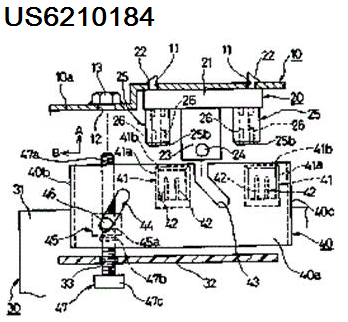

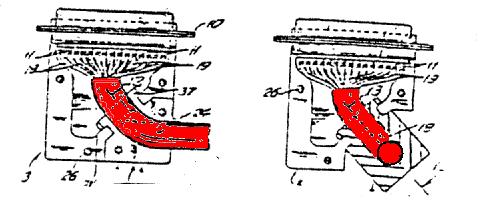

The following figures show a busbar (31), a leaf spring (32) and a wire (60) that cannot be connected to the spring without previously opening it. The wire connecting site is greyed-out on figure 5b below between the vertical part of the busbar and the moving horizontal edge of the spring. On figure 4b the leaf spring is abutting on the busbar and the end of the leaf spring obstructs the connecting site suitable for receiving the wire. On figure 5b, as the spring is biased by the element (40), then the connection site for the wire (60) is opened between the busbar and the spring.

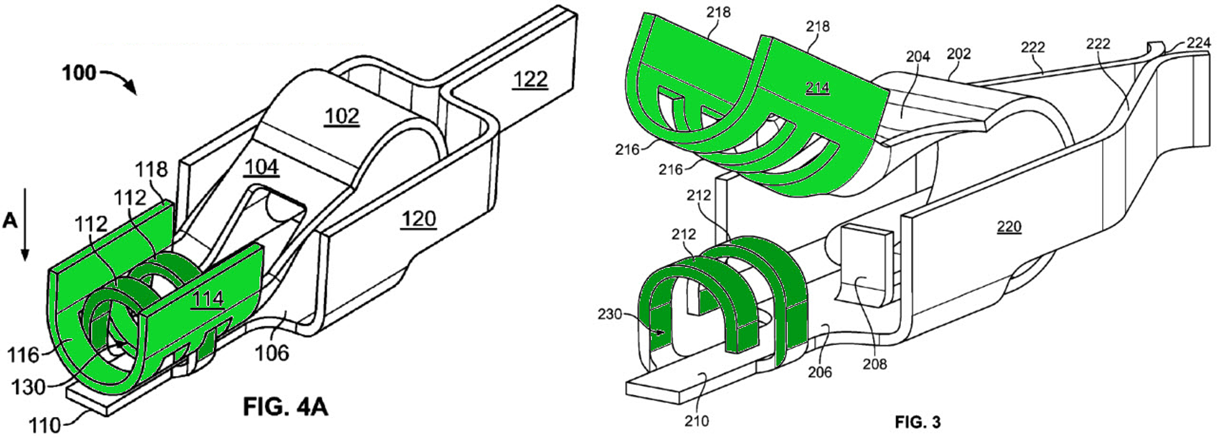

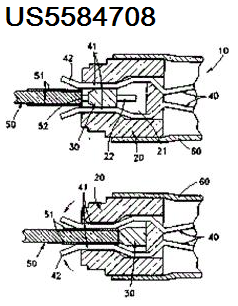

The following figures show a leaf spring (102). On figure 3, the leaf spring is in the unbiased position and the connection site between (214) and (230) is not available because the two ends of the spring are not aligned and are not forming the insertion site for the wire. On the contrary, after biasing the spring (pushing the movable greyed-out part down) as visible on figure 4a, the connection site for the wire is available.

This place covers:

Electrical connections established by a leaf spring. The insertion of the wire will push the spring away from the busbar. Said otherwise, the spring is shaped to allow the insertion of the wire even if it is not pre-biased.

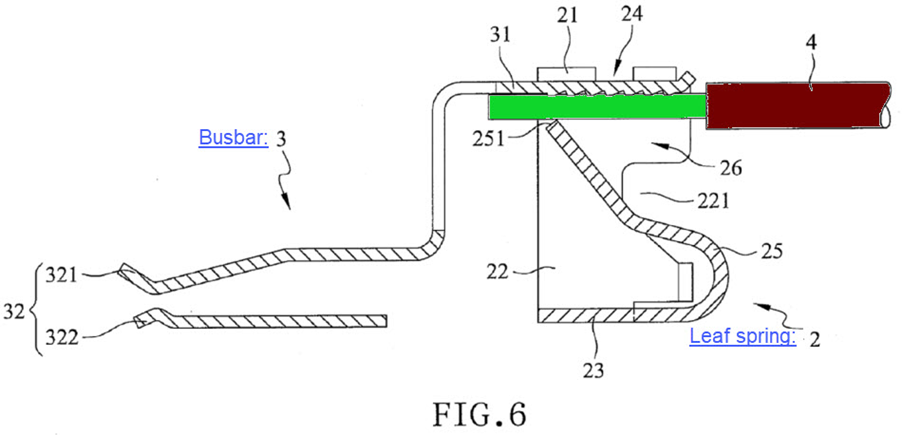

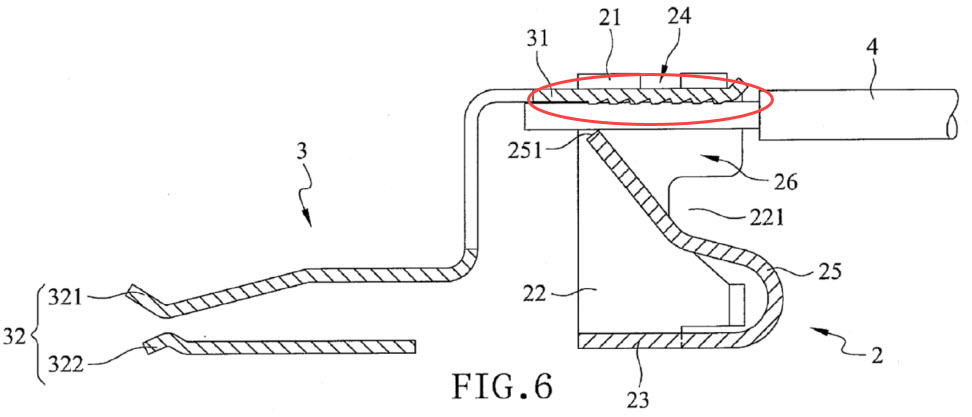

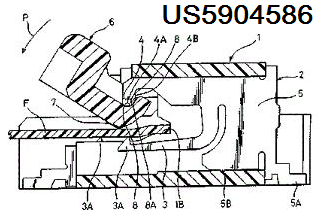

The following figure shows a busbar (3), a leaf spring (2) and the wire (4) that can be inserted without previously opening the spring because the spring presents an orientation allowing it.

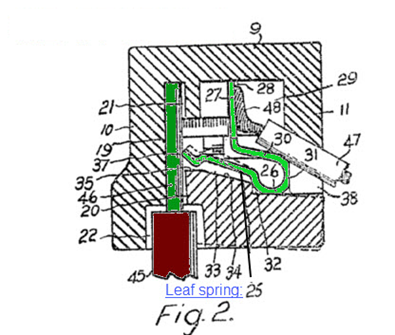

The following figure shows a leaf spring (25) shaped to allow the insertion of the wire (45) without pre-opening of the spring. It is mentioned that in the present case, no busbar is provided in the housing. The leaf spring is the only electrical element electrically connecting the wire (45) to the other wire (47).

This place covers:

Leaf springs with the resilient part biasing the core of the wire, where the resilient part is made of a single resilient arm.

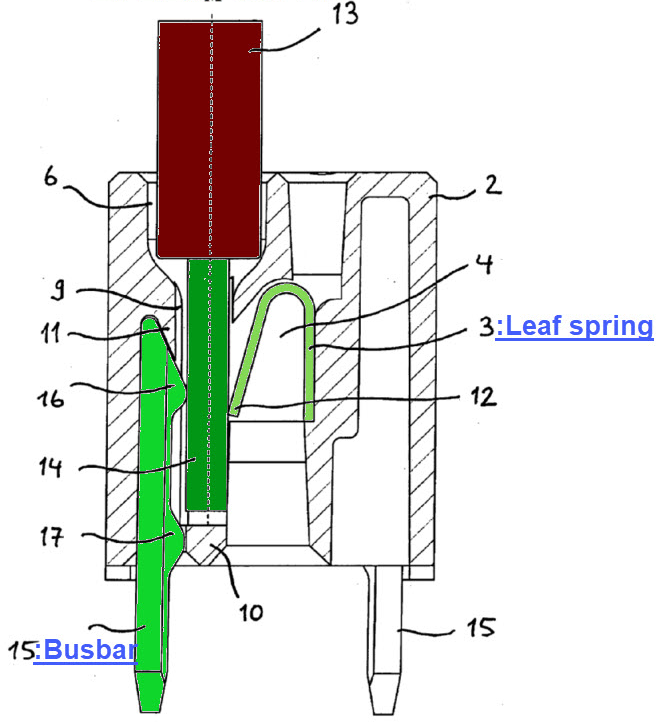

The following figure shows a leaf spring (3) biasing the core (14) of the wire (13) towards the busbar (15). The leaf spring has a single resilient arm biasing the wire.

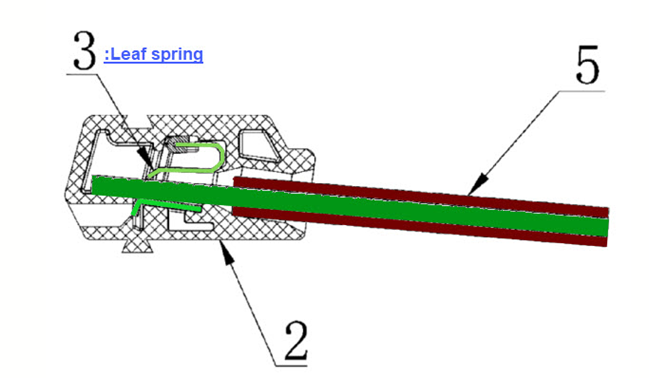

The following figure shows a leaf spring (3) biasing the wire (5) towards the busbar. The leaf spring is made of a single resilient arm.

This place covers:

Leaf springs with the resilient part biasing the core of the wire, where the resilient part is made of a at least two resilient arms.

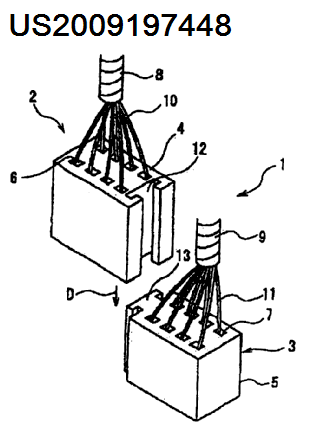

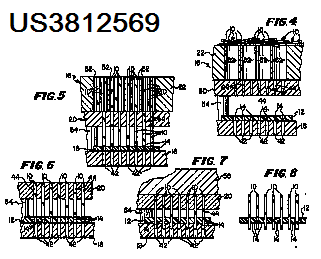

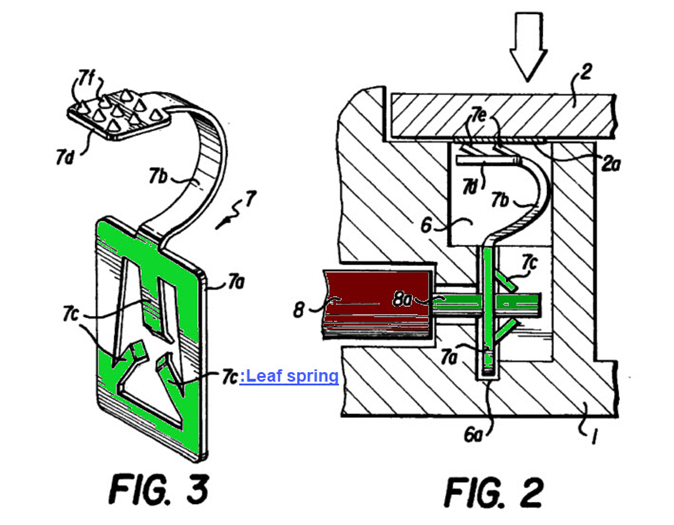

The following figures show a leaf spring (7) comprising three resilient arms (7c) clamping the wire between them.

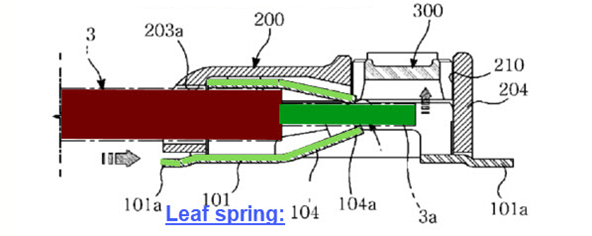

The following figure shows a leaf spring (101) comprising two different elastic members (104 and 105) both biasing the core of the wire.

Leaf springs with the same blade having two opposite ends acting on two different wires are classified in groups H01R 4/4821 and H01R 11/09 (if different connecting locations are present).

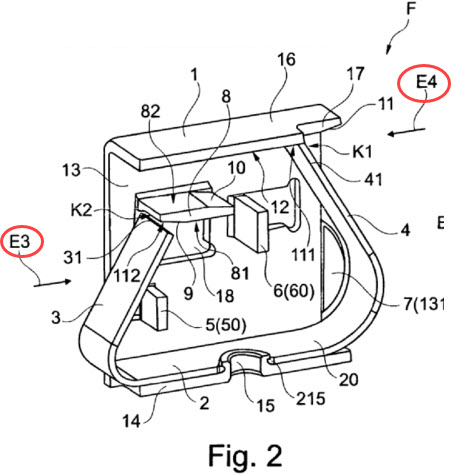

In the following example, E3 and E4 are made for insertion of two different wires. Even if 3 and 4 are part of the same blade, each connection is using a single resilient blade 3 or 4. Each blade establishes a galvanic connection in the sense of H01R. Therefore the device establishes two different galvanic connections with two different wires.

This place covers:

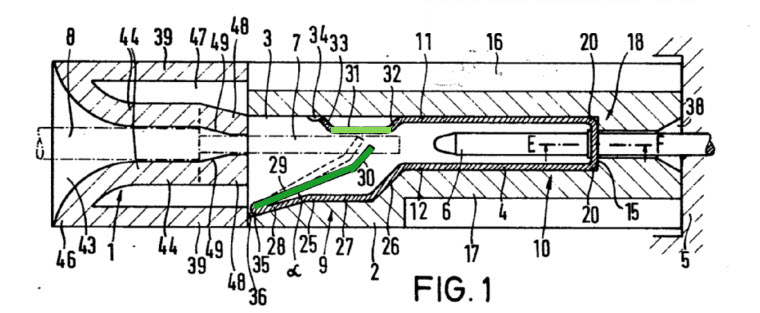

Configurations where the wire is inserted into the electrical connection by a hole in the spring. For example, the spring usually starts parallel to the wire in a direction opposite to the insertion direction of the wire and then loops back to create a free end used for biasing the wire. In this case the hole is usually located in the part of the spring looping back.

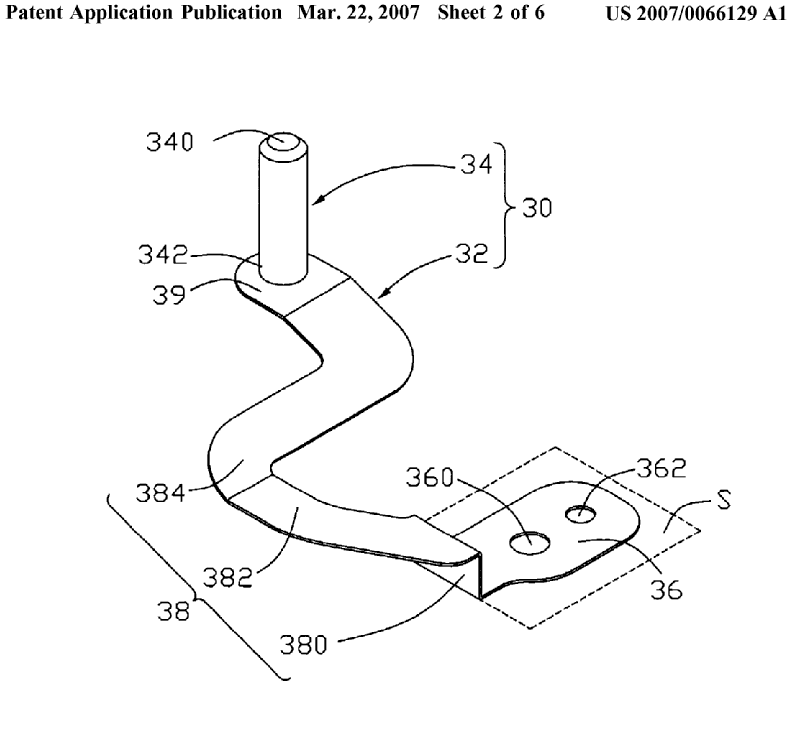

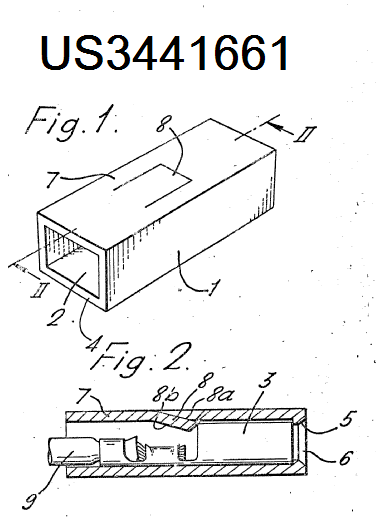

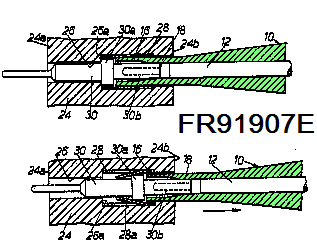

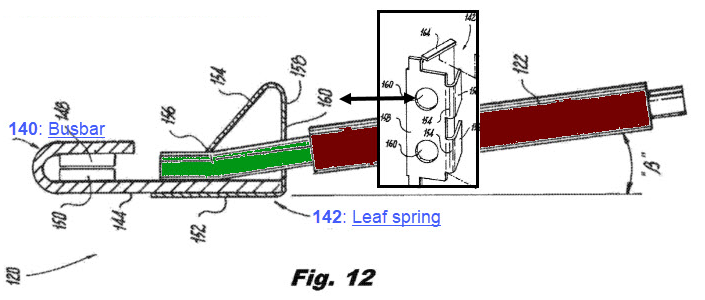

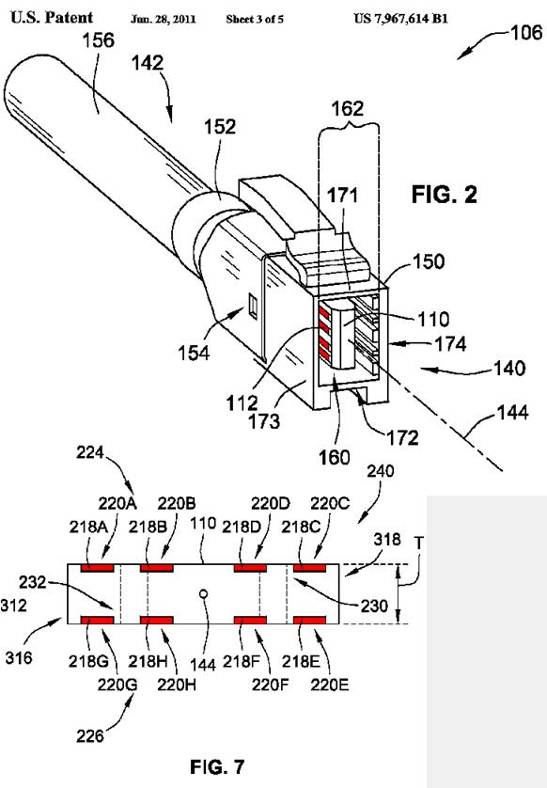

The following figure shows a busbar (140), a leaf spring (142) and the wire (122) is inserted from the back of the leaf spring (142) at the position is loops back toward the left of the figure. The spring comprises a hole (160) receiving the wire (122).

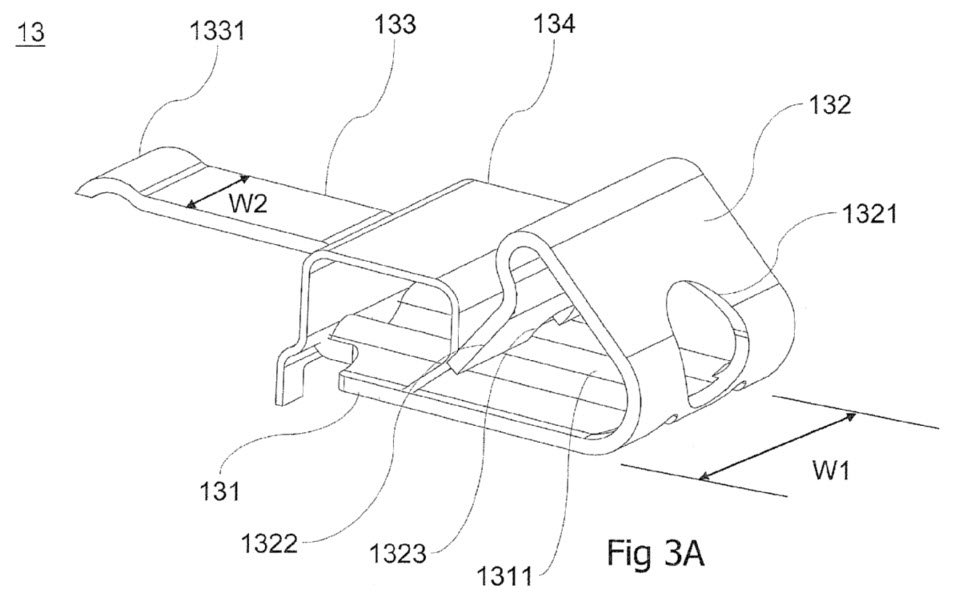

The following figure shows a leaf spring (131) and the wire is inserted from the back of the leaf spring (131) inside the hole (1321).

This place covers:

Details of the leaf spring activating arrangements that cannot be classified in the subgroups of the present group.

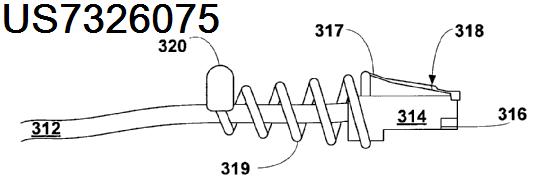

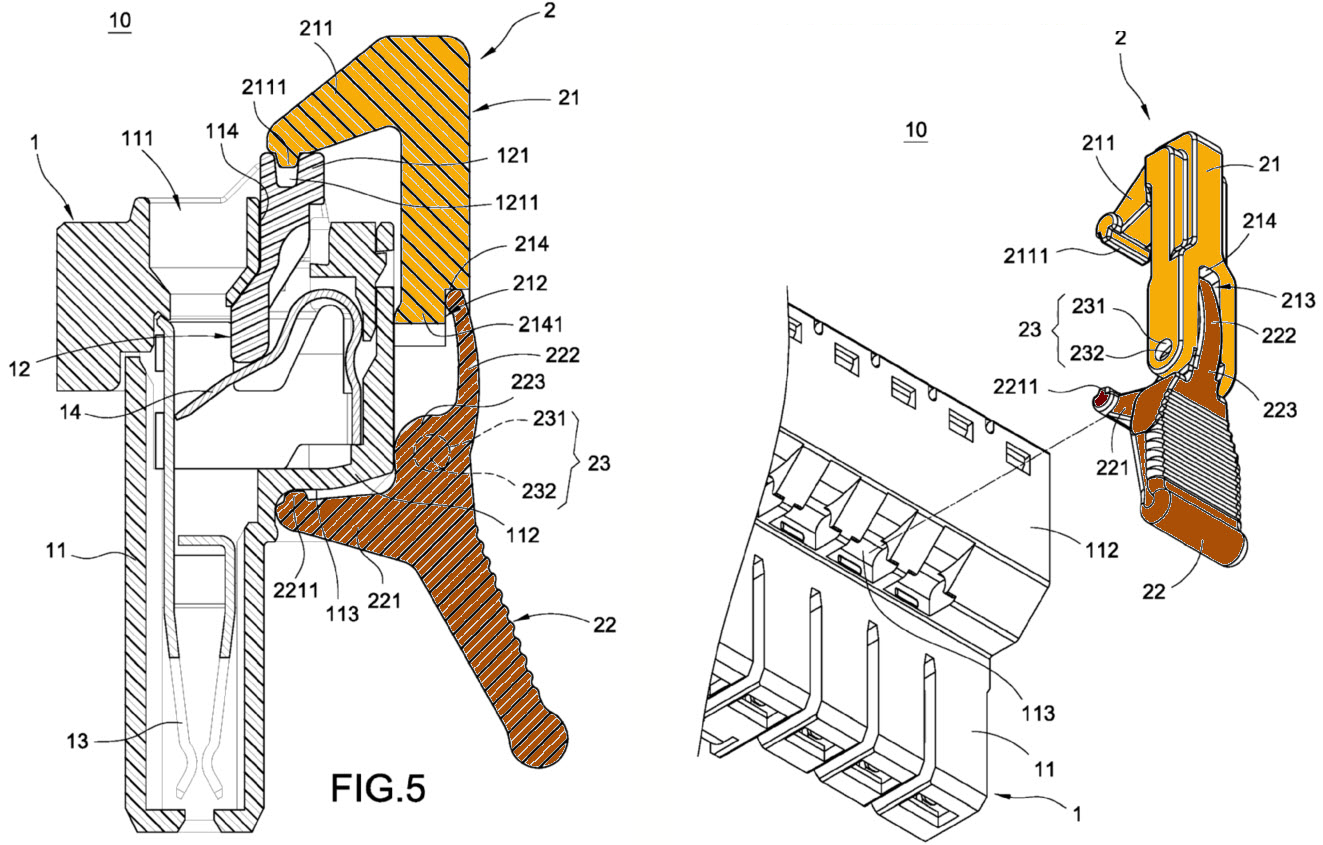

The following figures show a handle (2) mounted on the housing and used to indirectly actuate the leaf spring. This handle does not have a simple sliding or rotating movement.

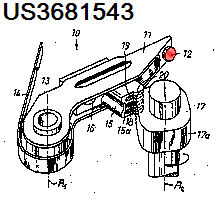

This place covers:

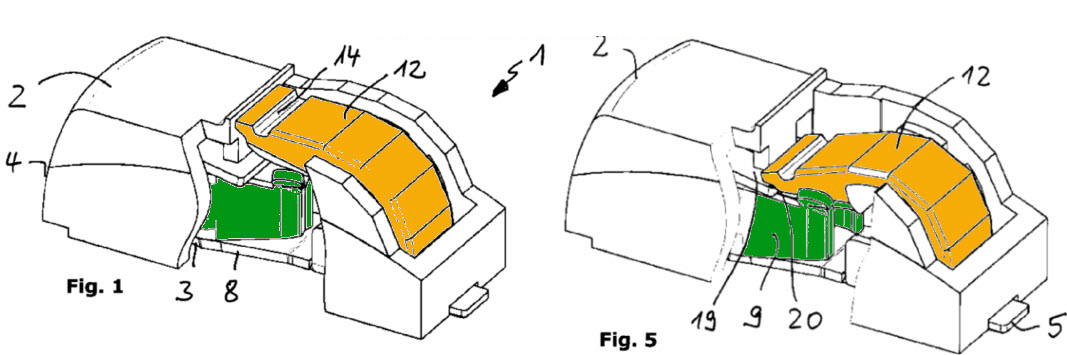

Leaf springs are activated by an arrangement pivoting with respect to the spring or the housing.

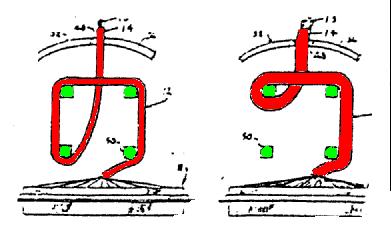

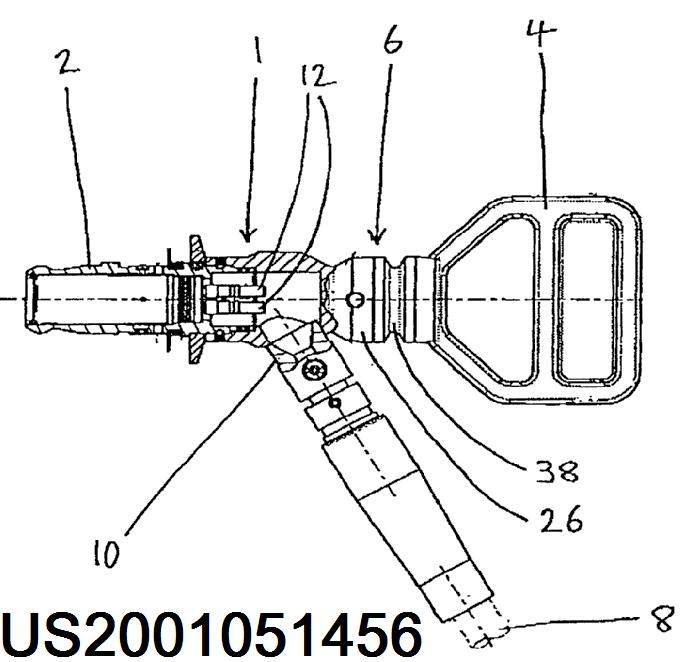

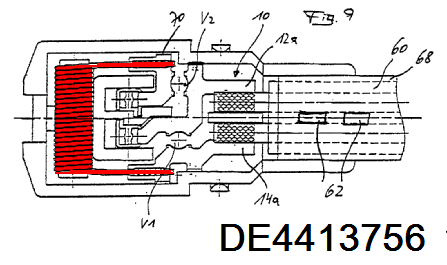

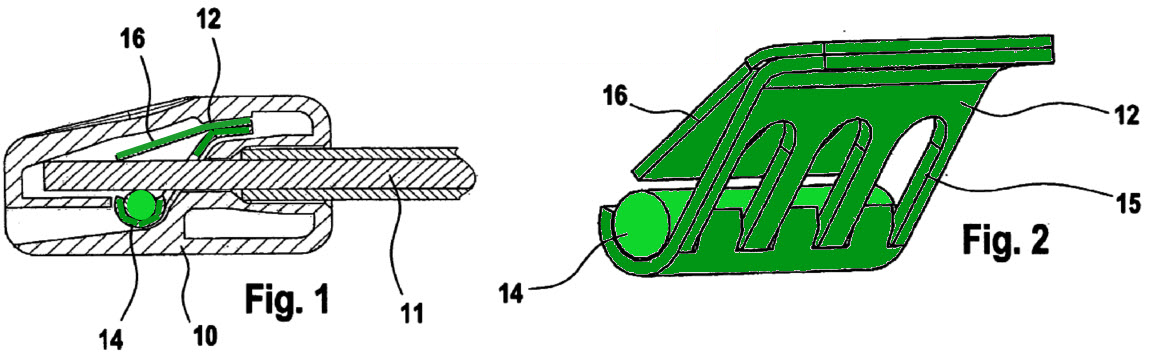

The following figures show a leaf spring (1) actuated by a lever (22). Further the lever biasing the leaf spring is rotating with respect to the housing (8) or the leaf spring (1).

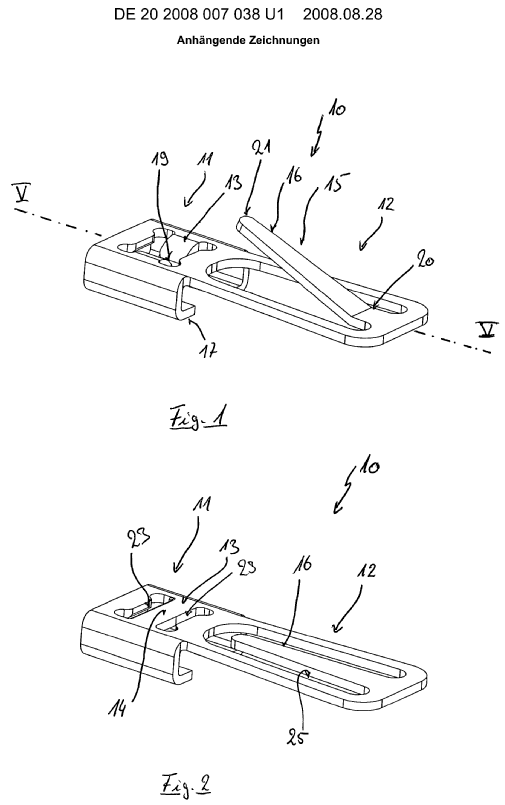

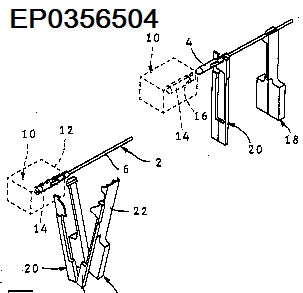

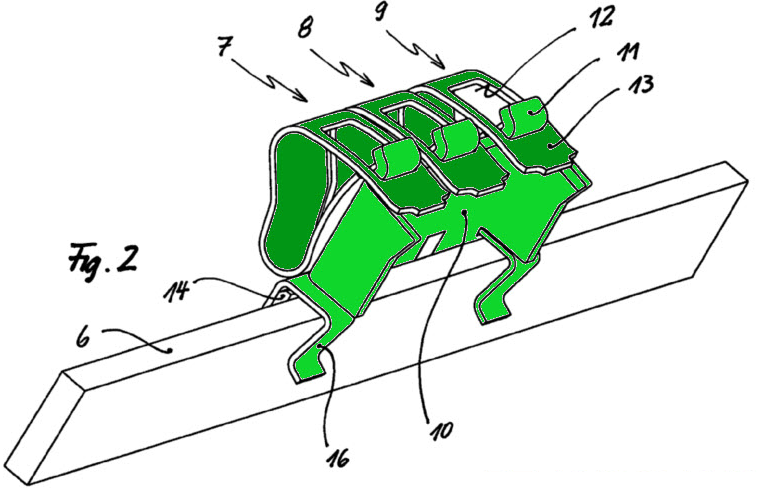

The following figures show a housing (2) comprising an integral rotating lever (12). This lever 12 is used for biasing opened both arms (9) of the leaf spring (3). Closed position of the spring is visible on Fig.1 and opened or biased position is visible on Fig.5.

This place covers:

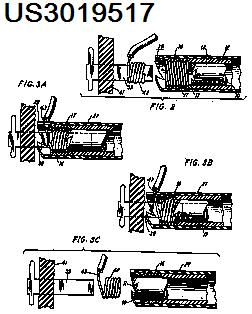

Leaf springs activated by an arrangement sliding with respect to the spring or the housing.

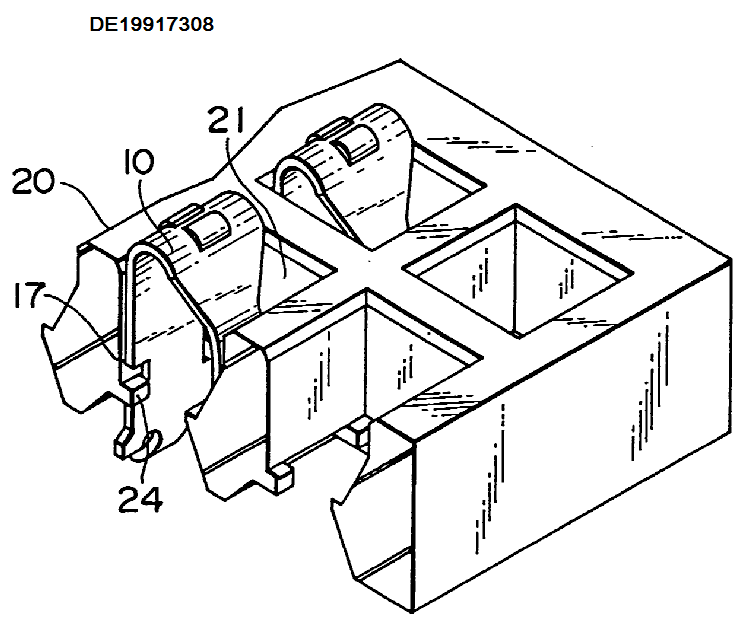

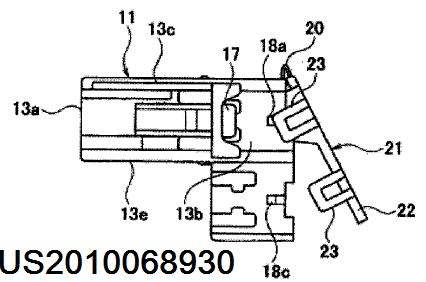

The following figures show an actuating mean 17 that is sliding left/right to bias or release the beam (16) of the leaf spring.

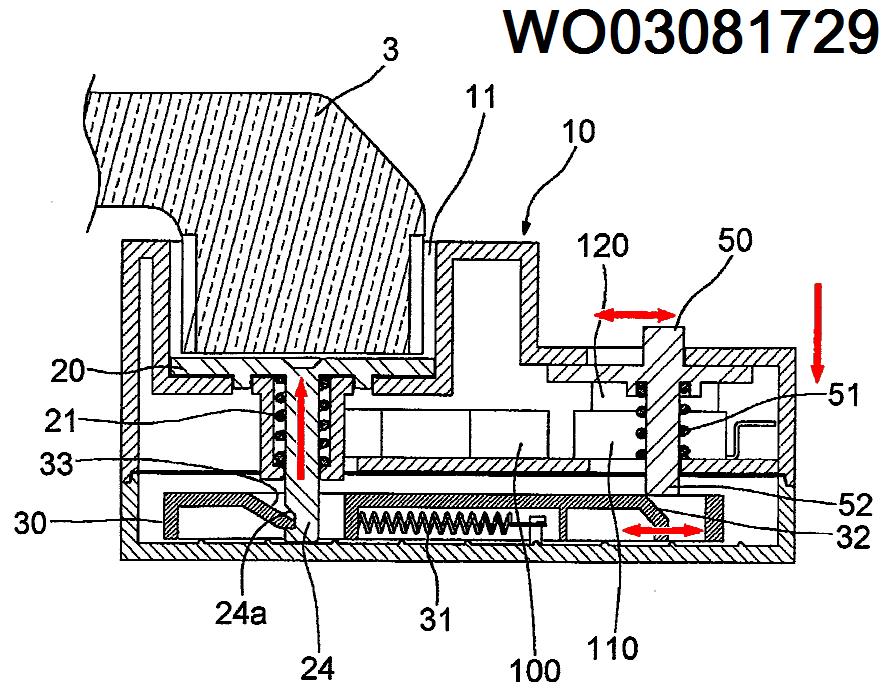

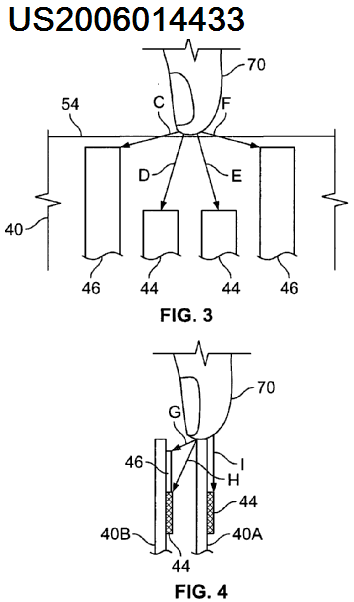

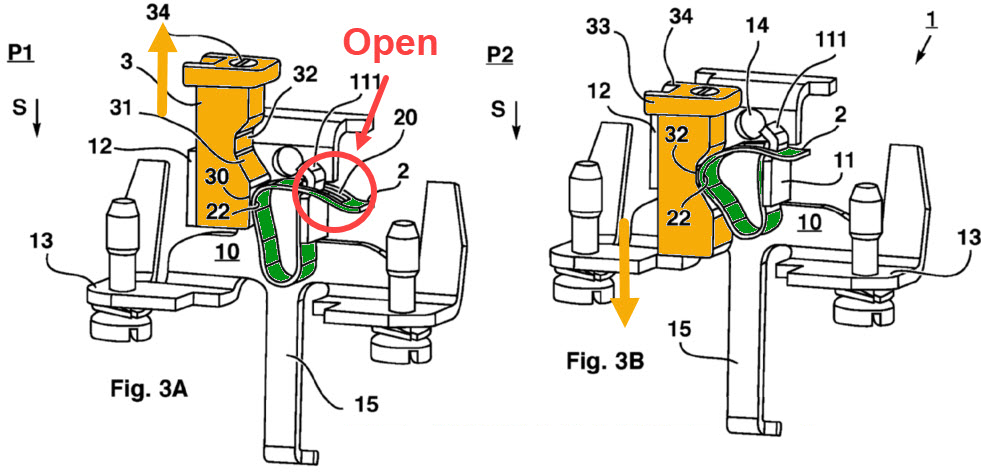

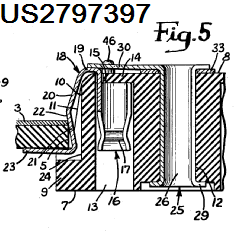

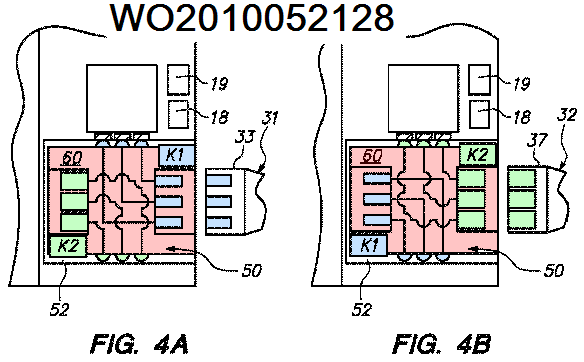

The following figures show on figure 3A the activating arrangement (3) is slid up to open or bias the leaf spring (2) and allows insertion of the wire between the busbar (111) and the leaf spring (2). On figure 3B the activating arrangement (3) is slid down to close or release the leaf spring (2) thereby closing the connection site if no wire is present (case of figure 3B) or clamping the wire on the busbar if a wire would be present.

This place covers:

Activating arrangements which are mechanically stable in biased and un-biased position of the spring. Usually in the position where the activating arrangement is biasing the spring, the force of the spring tend to push the activating arrangement back, except in the case, for example, where the arrangement will be latched or locked somehow by the housing.

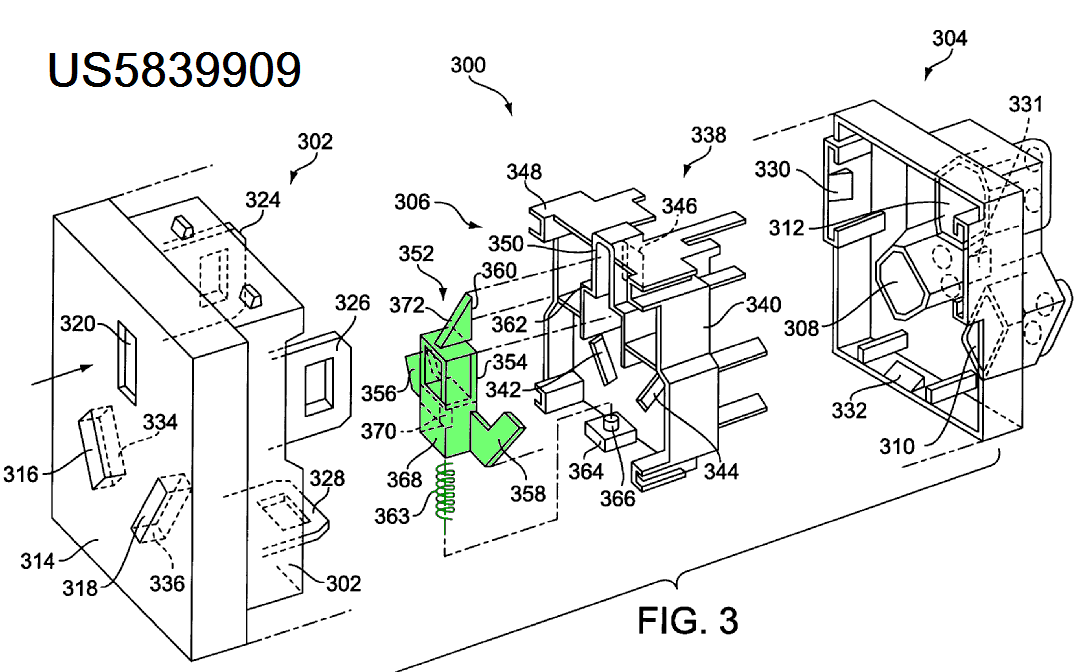

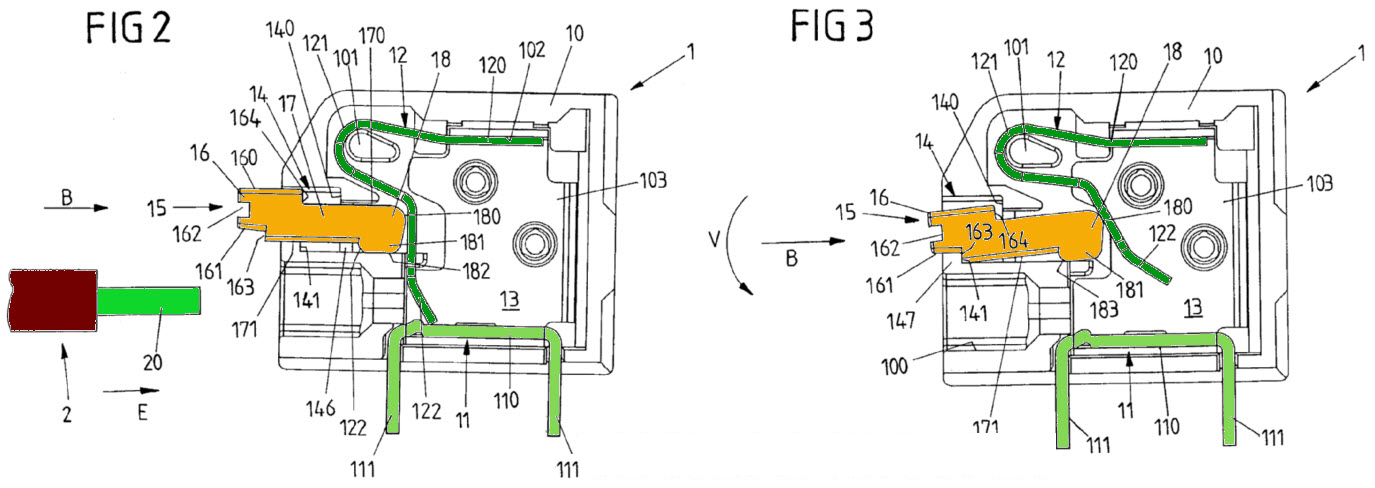

The following figures show an activating arrangement (15) which on figure 3 is mechanically locked behind a shoulder (141) of the housing. Because of this locking, the counter force created by the biasing of the leaf spring (12) does not slide the activating arrangement (15) back and the spring is blocked in the open position.

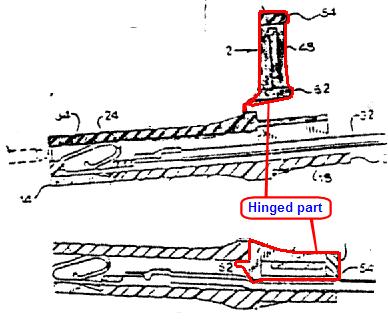

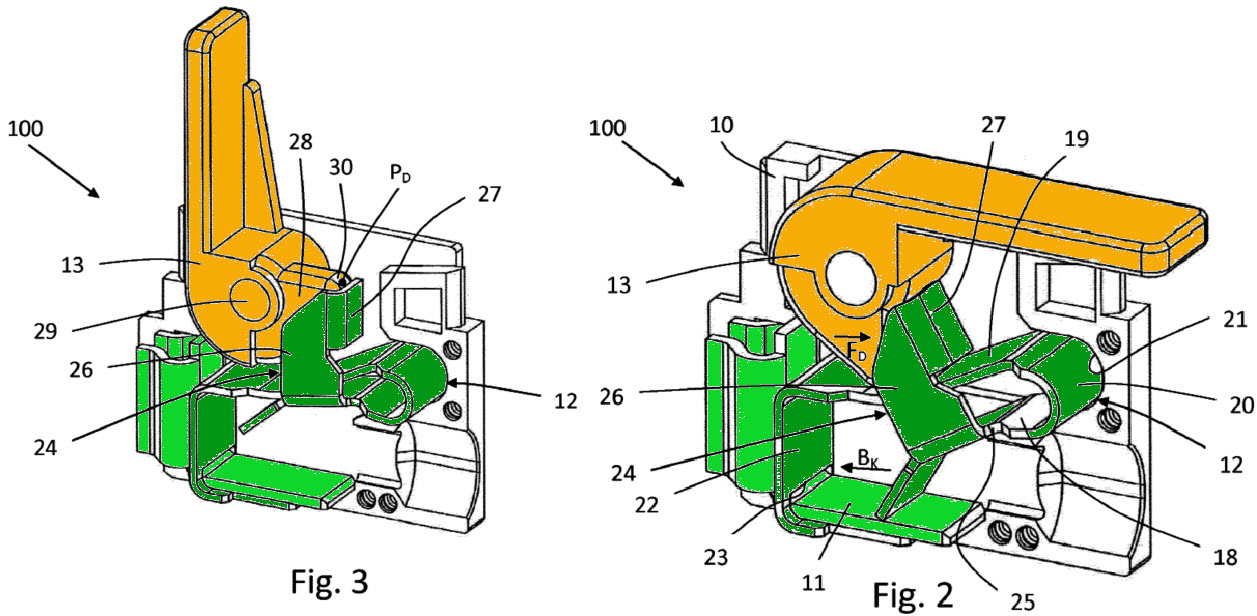

The following figures show an activating arrangement (13) suitable for activating the leaf spring (12). As it is visible on figure 3, because of the flat shape (27) and the shape of (30) and the position of the hinge (29), the biased position is also a mechanically stable position for the lever (13). The user does not need to hold the lever in the open position while inserting the wire.

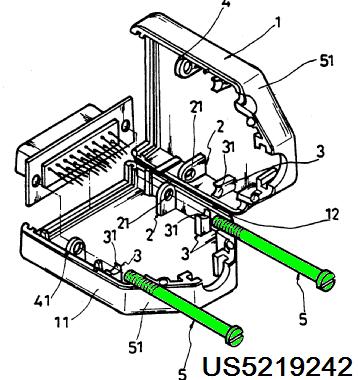

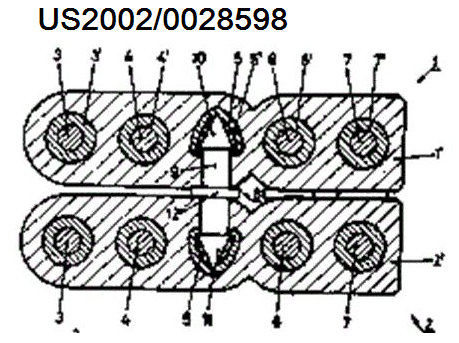

This place covers:

Clamping devices comprising several leaf springs which are actuated by a common device.

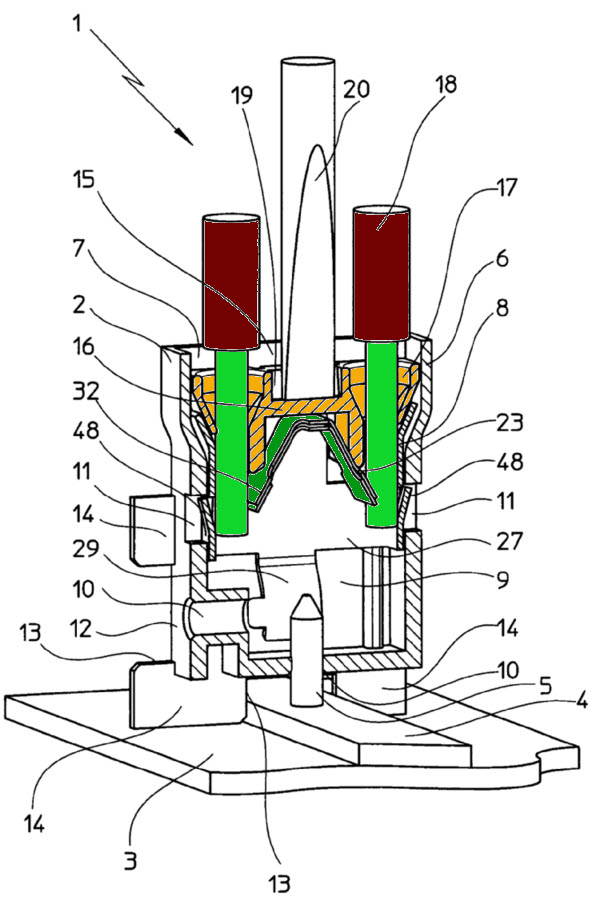

The following figure shows a clamping device with two connection sites for two different wires (18). It further comprises a single actuating arrangement (16, greyed-out below) actuating both connection sites at the same time. Therefore, even if the spring (23) is common to both connection sites, this is not considered for the classification and only the fact that the arrangement actuates springs in at least two sites is considered.

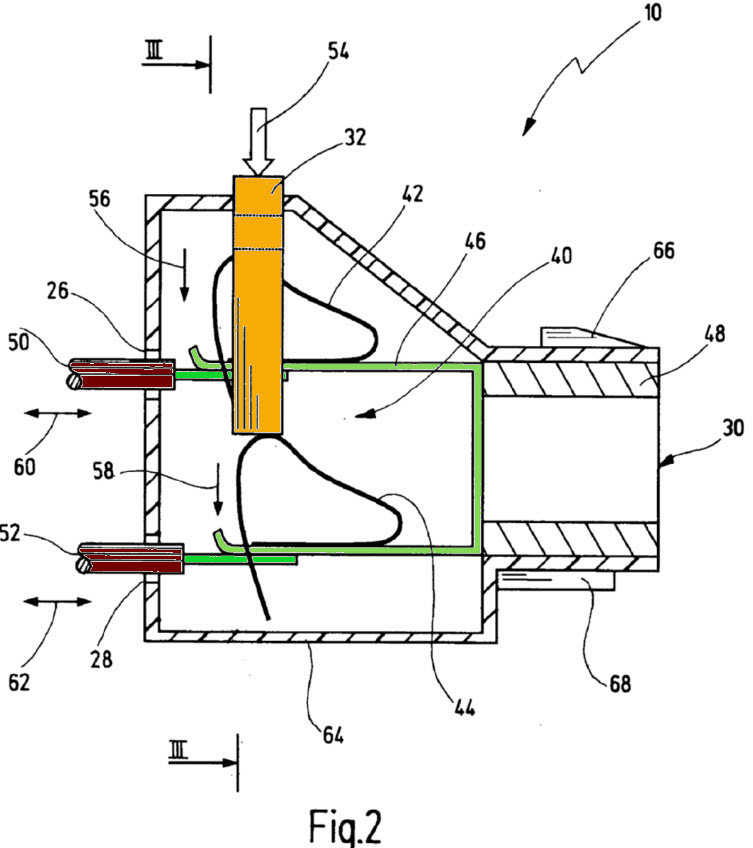

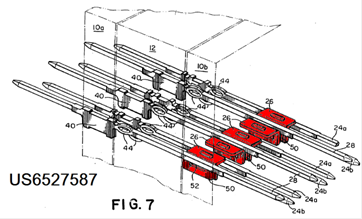

The following figure shows a clamping device with a single actuating arrangement (32) suitable for biasing both leaf springs (42) and (44) at the same time.

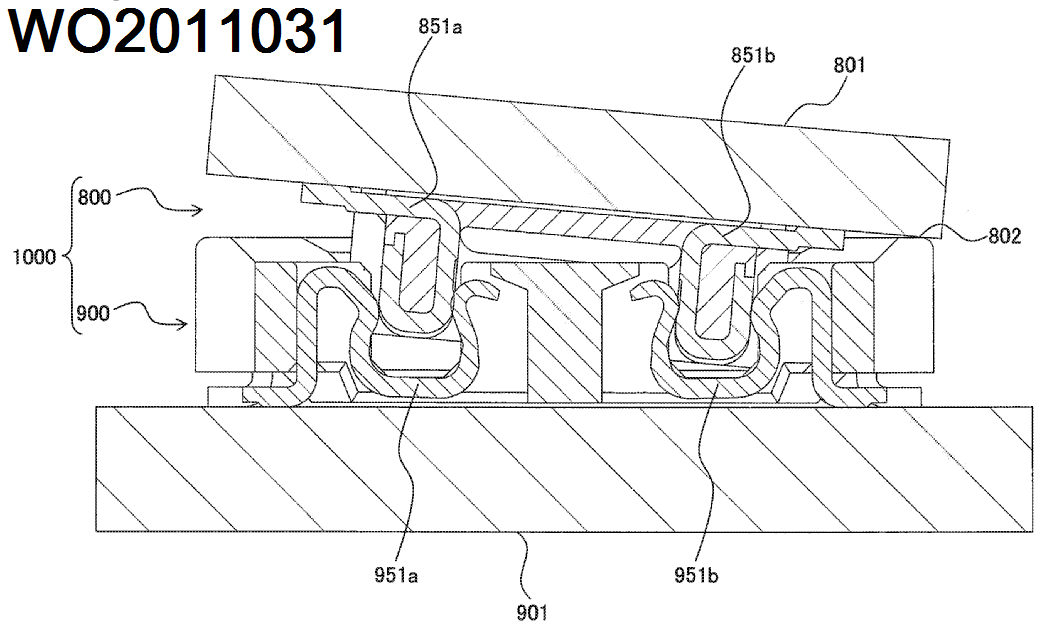

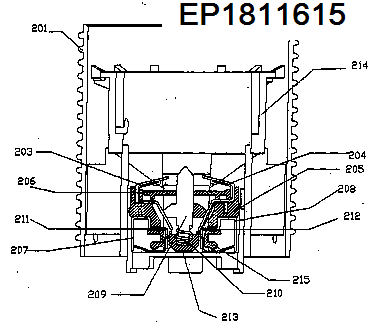

This place covers:

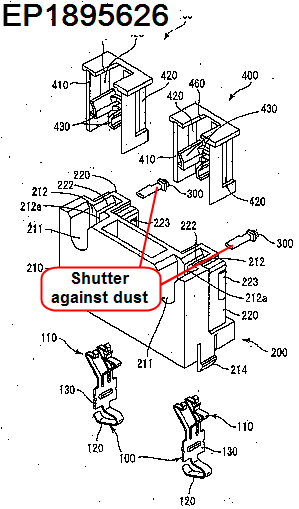

Details about the housing covering the leaf spring (e.g. waterproofing features, assembling elements being part of the invention).

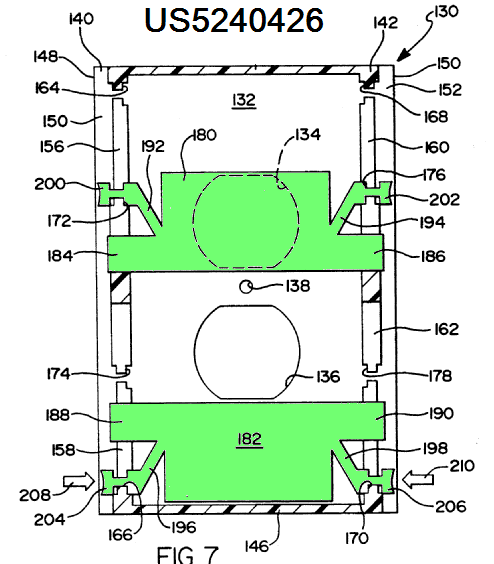

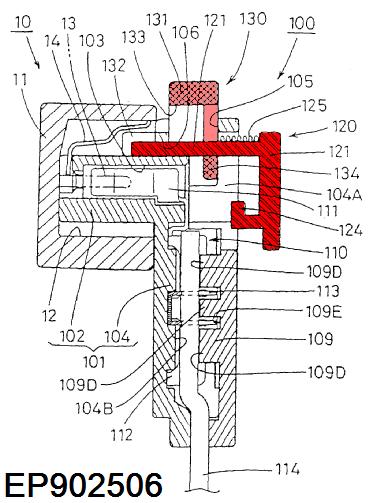

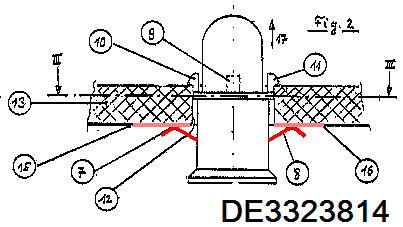

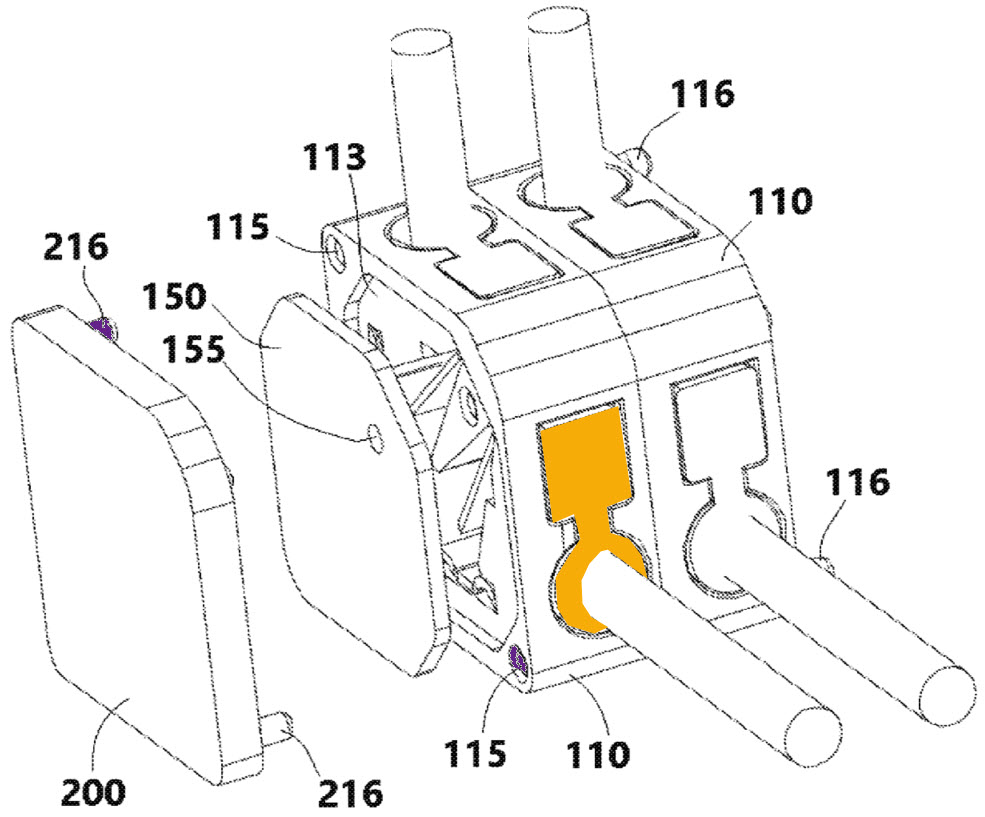

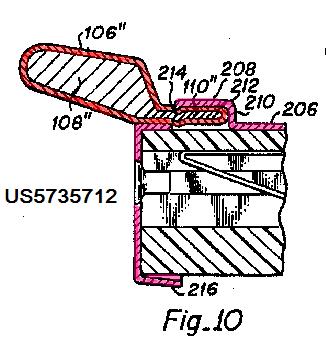

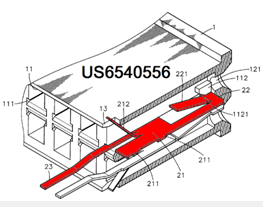

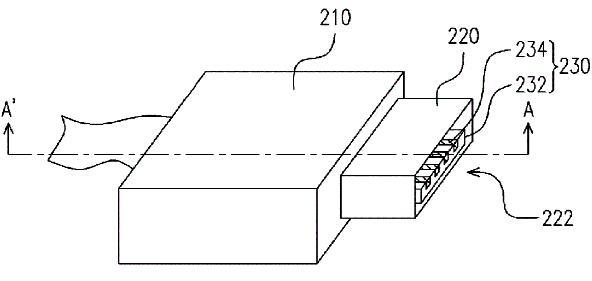

The following figure shows a housing of the leaf spring comprising sealing members (120, greyed-out in the figure below) and special assembling elements (216) to mount several slices next to each other. Those details are both to be classified in class H01R 4/484.

This place covers:

Leaf springs with an opening in the housing to allow the insertion of a tool for biasing the leaf spring.

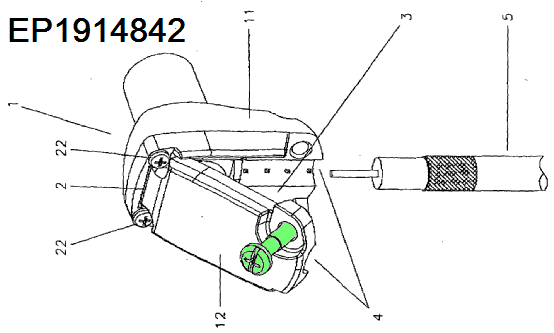

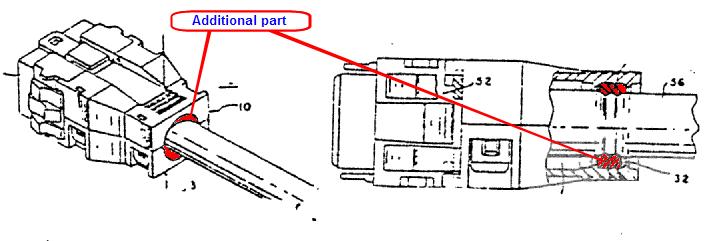

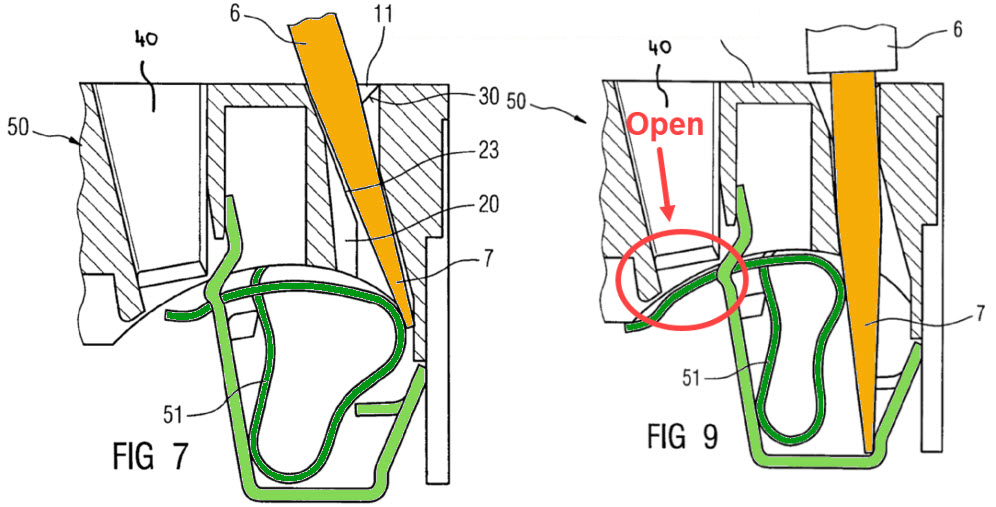

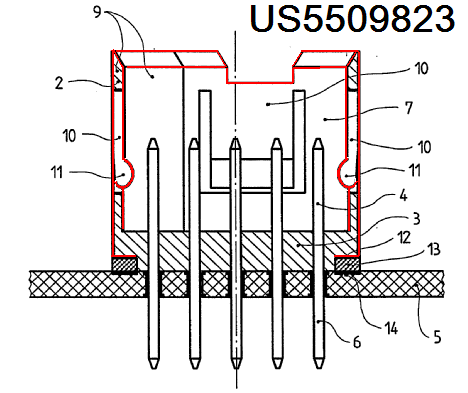

The following figures show a housing (50) comprising a hole (11) suitable for insertion of a tool (6) e.g. screwdriver or jig, suitable for biasing the leaf spring (51) as visible on figure 9. The activating arrangement is not part of the device, it is an additional part.

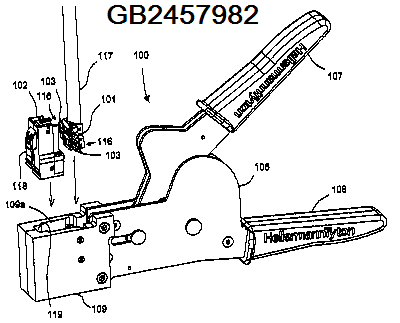

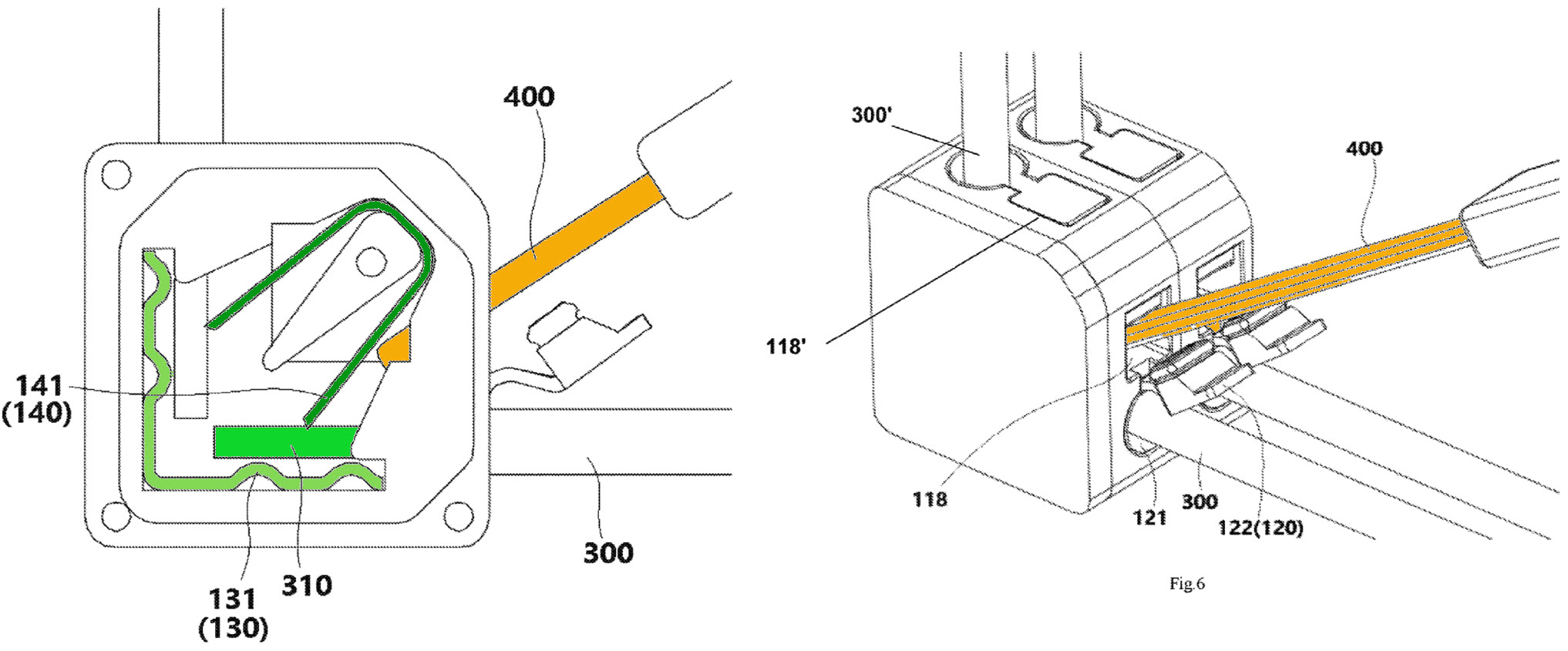

The following figures show a tool (400) that is inserted inside the hole (118) of the housing to bias the spring (140) in the open position thereby allowing the removal of wire (310) from the busbar (130).

Activating arrangements located between the tool and the leaf spring are covered by H01R 4/4828.

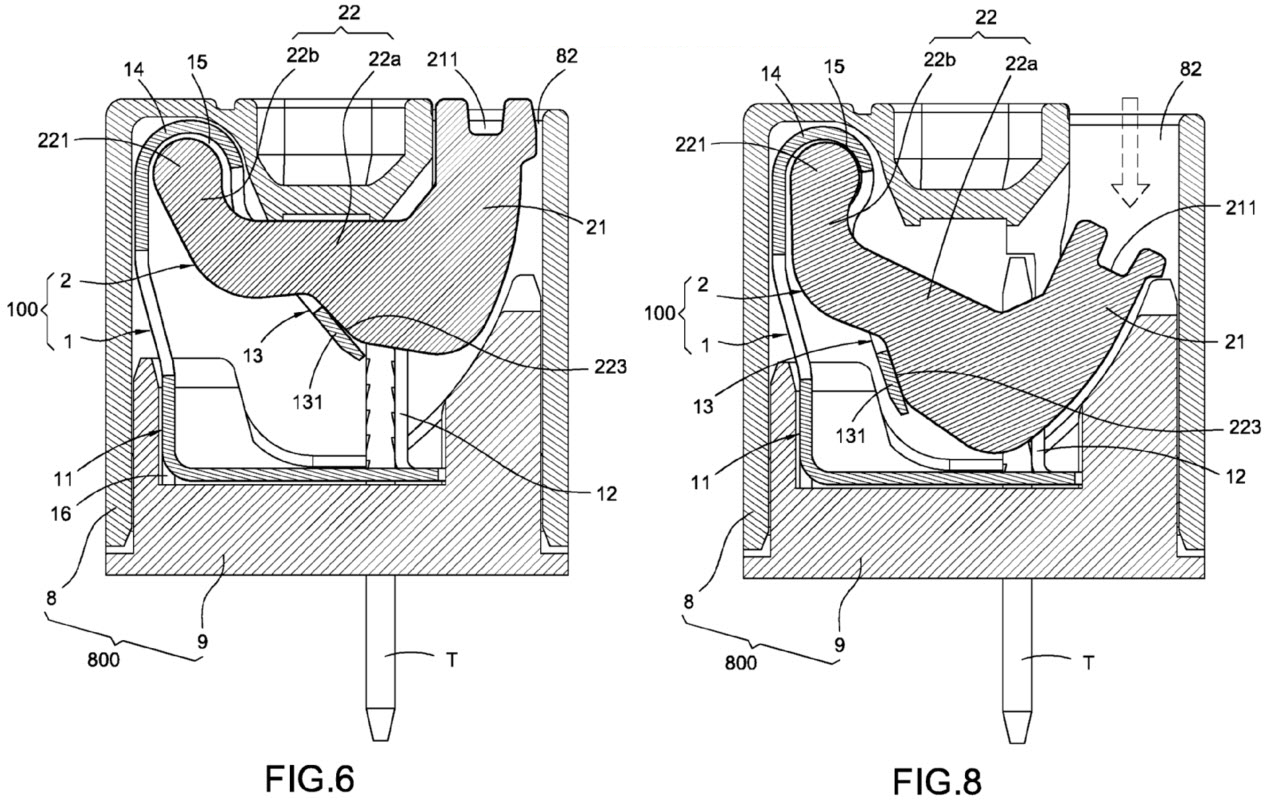

This place covers:

Leaf springs comprising a housing having at least two holes to allow the insertion of a tool for biasing the leaf spring from different angles.

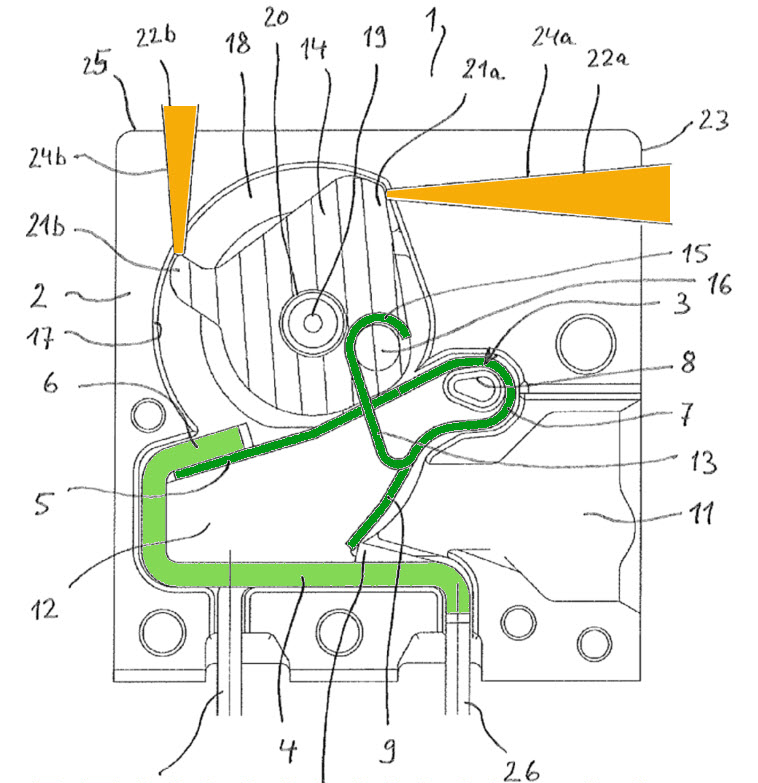

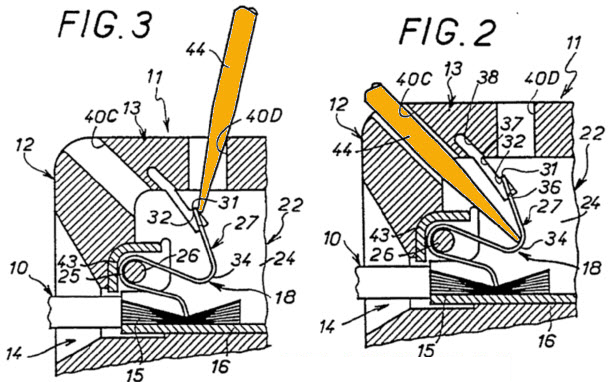

The following figure shows two holes for inserting two different tools (22a) or (22b) in the housing from different angles.

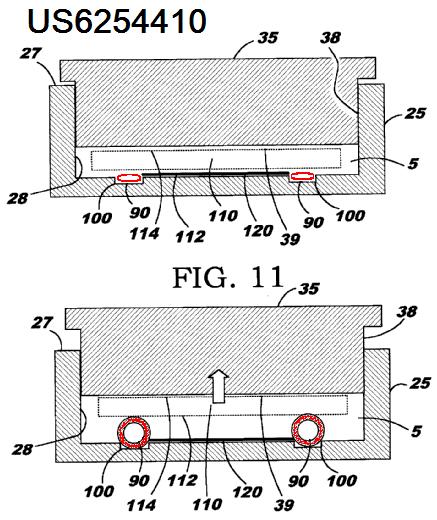

The following figures show a housing (12) comprising two holes (40C) and (40D) both suitable for receiving an activating arrangement (tool 44) used to act on the leaf spring (27).

This place covers:

Clamping devices in which the leaf spring and the busbar are two parts of the same element. The leaf spring and busbar are both unitary.

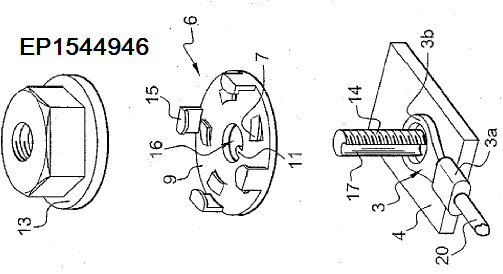

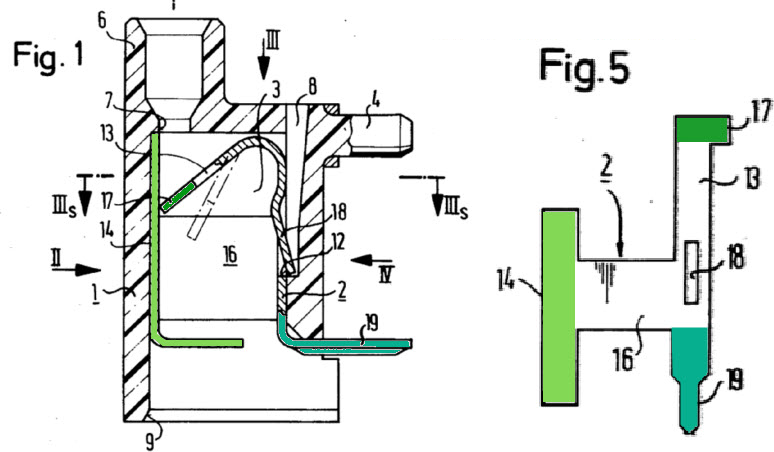

The following figures show a leaf spring (17) and a busbar (14) made of the same metal piece. The metal piece is visible on the right before folding.

The following figure shows a leaf spring (29 greyed-out below) and a busbar (part 31 contacting the wire, horizontal greyed-out part below) being made of the same element.

This place covers:

Leaf spring clamping devices comprising a common busbar to several connection sites. E.g. a clamping device suitable for shunting different wires to the same potential.

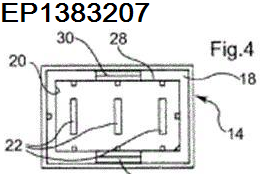

The following figure shows a single busbar (10) common to three different springs (7, 8, 9 greyed-out).

The following figures show a single busbar (14) connecting three different connection sites for three different wires.

This place covers:

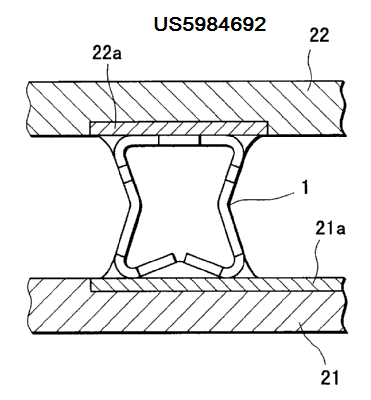

Leaf spring clamping devices with the busbar presenting an uneven surface at the position connecting with the wire, usually the exact position where the leaf spring biases the wire on the busbar.

The following figure shows an uneven surface on the busbar at the position (inside the circle below) connecting to the wire (4). Those dents have the function to decrease the contact resistance between the busbar and the wire.

The following figures show an uneven surface on the busbar at the position (inside the circle below) connecting to the wire. The dents (4,24) can have different patterns on the busbar (see left and right).

This place does not cover:

Using shape memory materials |

Attention is drawn to the following places, which may be of interest for search:

Heat recovarable plastics |

This place covers:

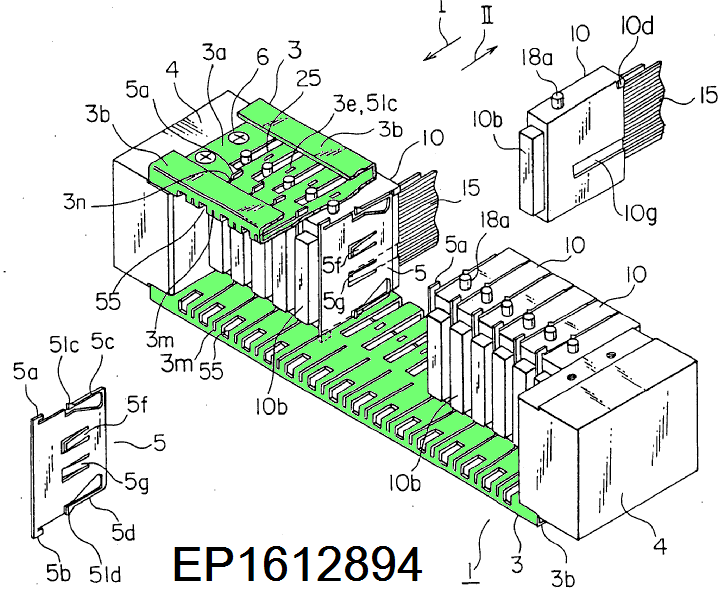

Structural associations of mutually-insulated electrical connecting elements

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Specially adapted for printed circuits, flat or ribbon cables, or like generally planar structures |

Attention is drawn to the following places, which may be of interest for search:

Individual connecting parts | |

Coupling devices | |

Flexible or turnable line connectors |

This place does not cover:

Insulation penetrating contact members in general |

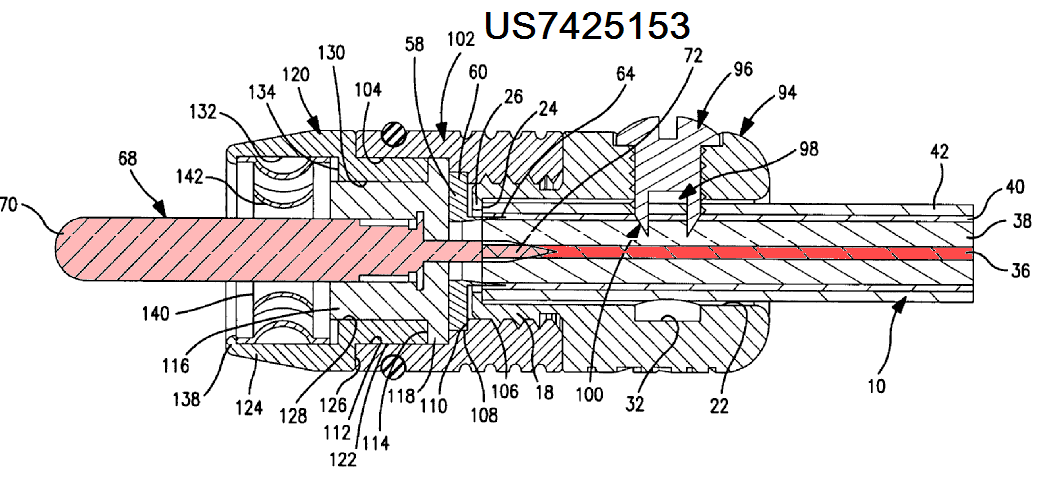

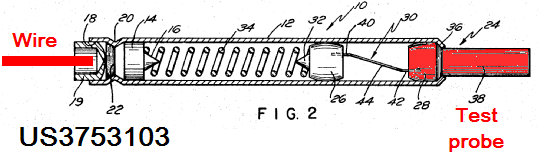

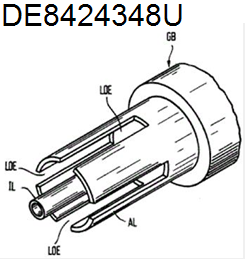

This place covers:

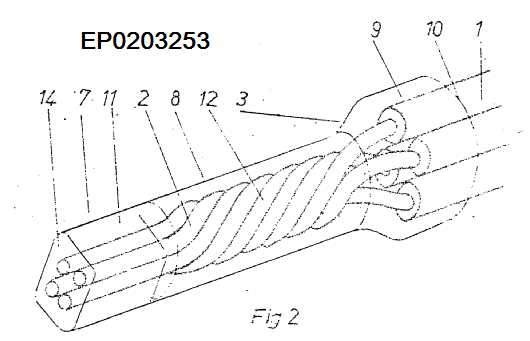

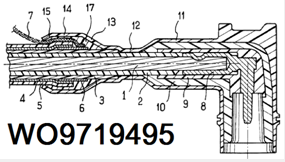

Structural associations of coaxial cables

This place does not cover:

Connection to outer conductor in general | |

Connection to a rigid planar substrate |

Attention is drawn to the following places, which may be of interest for search:

Lead-through insulators |

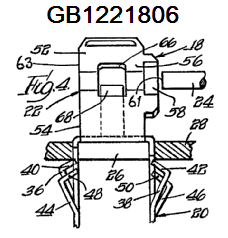

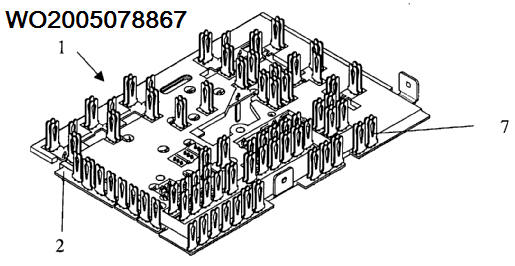

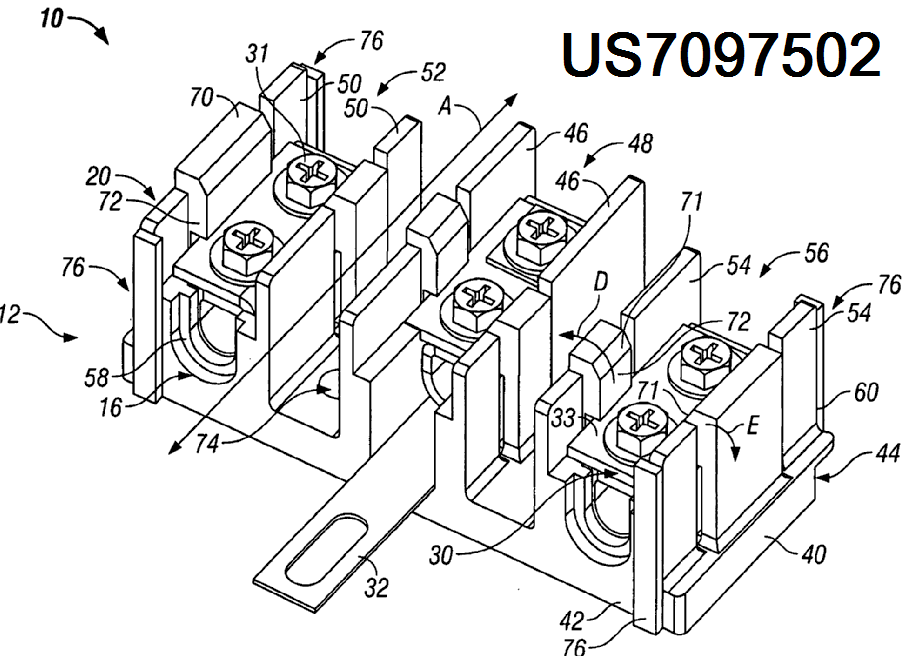

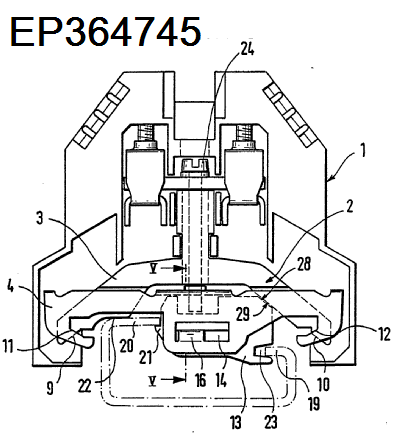

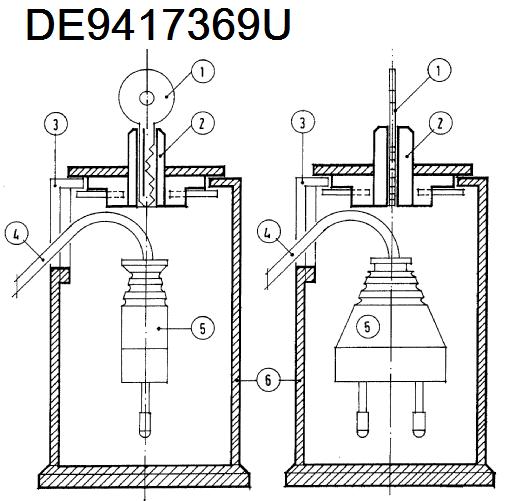

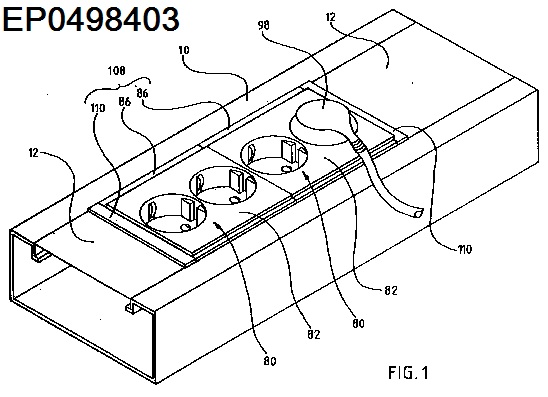

This place covers:

Terminal strips, blocks, bases

This place does not cover:

Bases for printed circuits |

This place does not cover:

Insulating enclosures for switches |

This place does not cover:

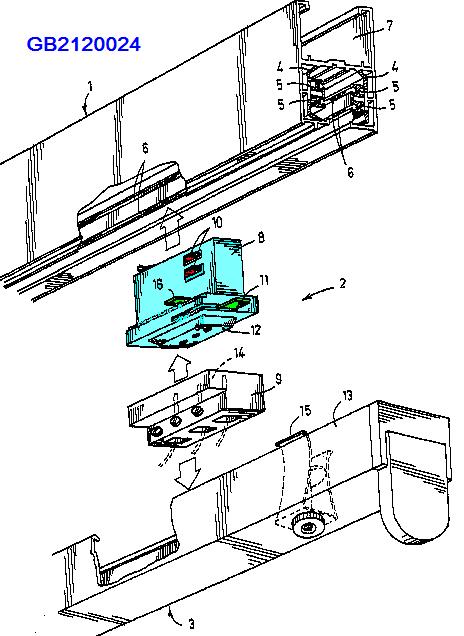

Clip-on terminal blocks for side-by-side rail- or strip-mounting |

This place does not cover:

Structural association with built-in components for coupling parts |

This place does not cover:

Clip-on terminal blocks for side-by-side rail- or strip-mounting with ground wire connection to the rail | |

Fastening means for switch or other electrical device |

Attention is drawn to the following places, which may be of interest for search:

Connections between members in direct contact | |

Structural associations of a plurality of mutually-insulated electrical connecting elements | |

Coupling devices | |

Flexible or turnable line connectors |

This place does not cover:

End pieces or tapping pieces for wires, supported by the wire and for facilitating electrical connection to some other wire, terminal or conductive member |

This place does not cover:

For multiconductor cables |

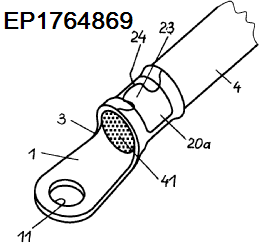

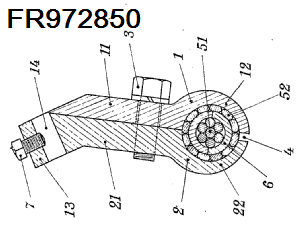

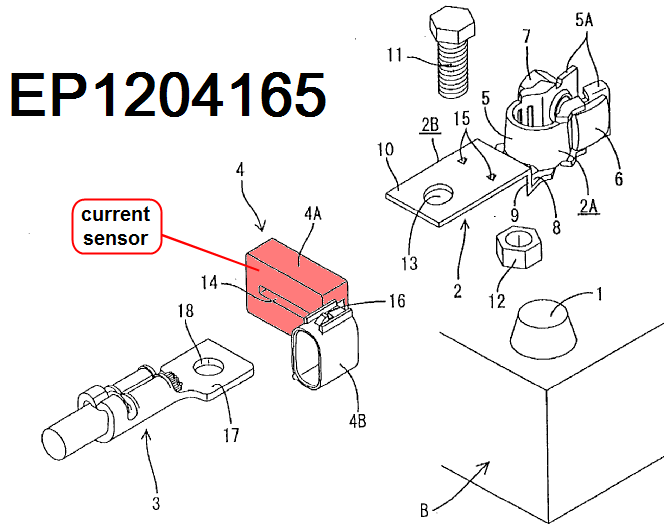

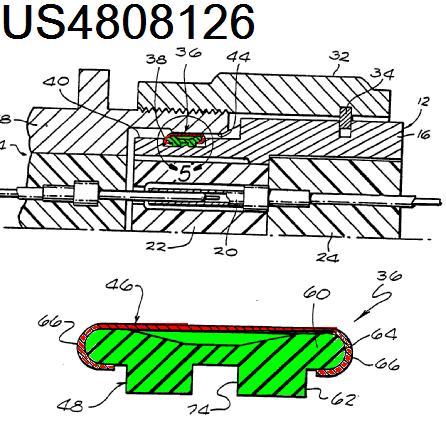

This place covers:

Connectors for car batteries

This place does not cover:

Printed connections to, or between, printed circuits |

This place covers:

Fixed connections for PCB's, flat or ribbon cables or like structures

This place covers:

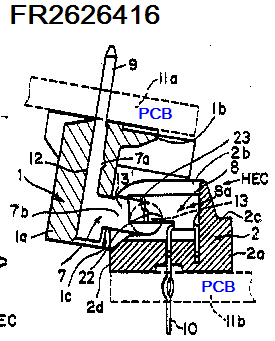

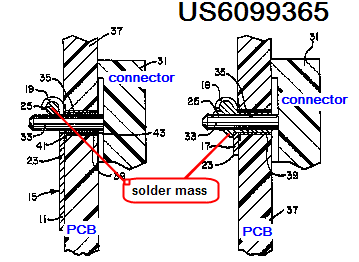

Fixed connection of which one party is a rigid printed circuit board.

Fixed connection for members (e.g. connectors) to rigid printed circuit board by other structures than terminals (e.g. housing) that are not covered by H01R 12/52- H01R 12/58.

Those characterized by the terminals are classified in H01R 12/55- H01R 12/58.

This place covers:

Fixed connection of which both of the connecting parties are rigid printed circuit board.

This place does not cover:

Printed circuits being on the same board with plated through holes |

This place covers:

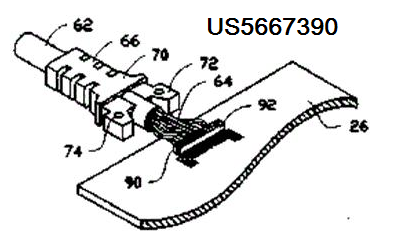

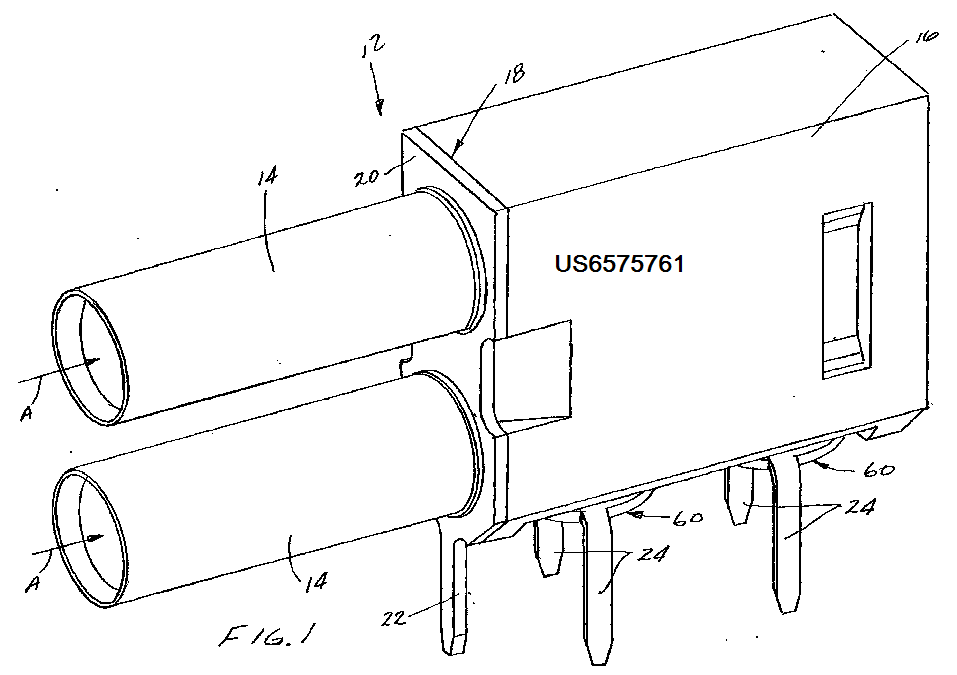

Fixed connection for cables mounted on rigid printed circuit board, the cable having a circular or similar cross section.

Attention is drawn to the following places, which may be of interest for search:

Connections with flat or a ribbon cables |

This place covers:

Fixed connection for terminals to the rigid printed circuit board characterized by the shape or the mounting means of terminals, e.g. edge contact, including mounting of connectors to the printed circuit board.

This place covers:

Fixed connection for terminals (including terminals of the connector) mounted directly on the rigid printed circuit board by using soldering, etc.

This place covers:

Fixed connection for terminals (including terminals of the connector) inserted into holes that are provided on rigid printed circuit board.

This place covers:

Fixed connection of which one party is flexible printed circuit board.

Fixed connection for members (e.g. connectors) to flexible printed circuit board by other structures than terminals (e.g. housing) that are not covered by H01R 12/61- H01R 12/69.

Those characterized by the connection of terminals are classified in H01R 12/65- H01R 12/69.

This place covers:

Fixed connection directly connecting between flexible printed circuit boards.

This place covers:

Fixed connection directly connecting between flexible printed circuit board and rigid printed circuit board.

This place covers:

Fixed connection for cables directly mounted on flexible printed circuit board.

This place covers:

Fixed connection characterized by the terminals directly mounted on flexible printed circuit board, e.g. edge contact.

This place covers:

Fixed connection by terminals penetrating the flexible printed circuit board e.g. insulation displacement terminal.

This place covers:

Fixed connection by partially deformed terminals connected to conductors of flexible printed circuit board e.g. Crimping terminals Excluding those penetrating the flexible printed circuit board H01R 12/67,H01R 12/68.

This place covers:

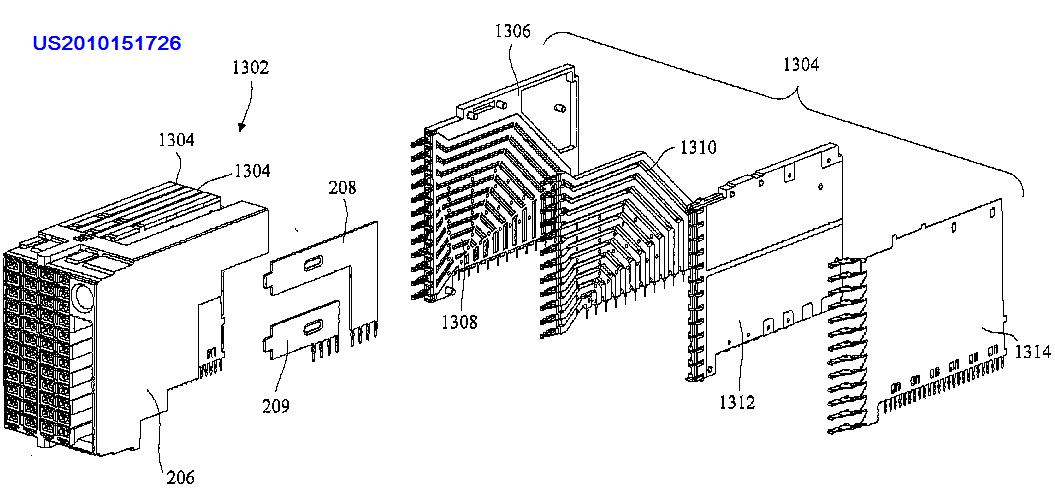

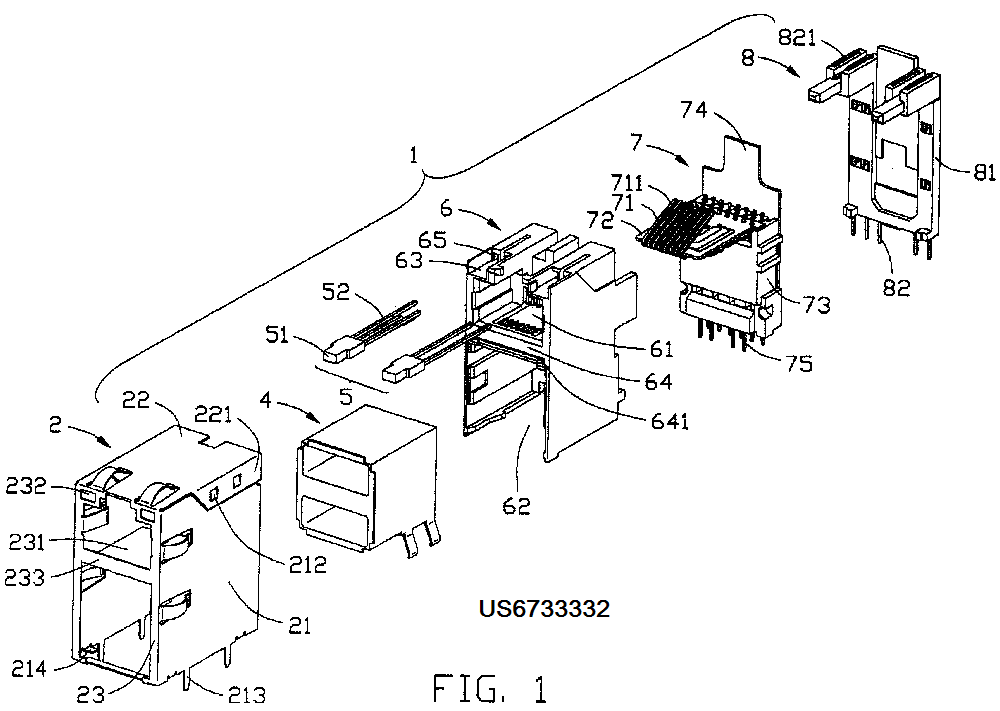

Connection of printed circuit boards by connectors in a demountable manner.

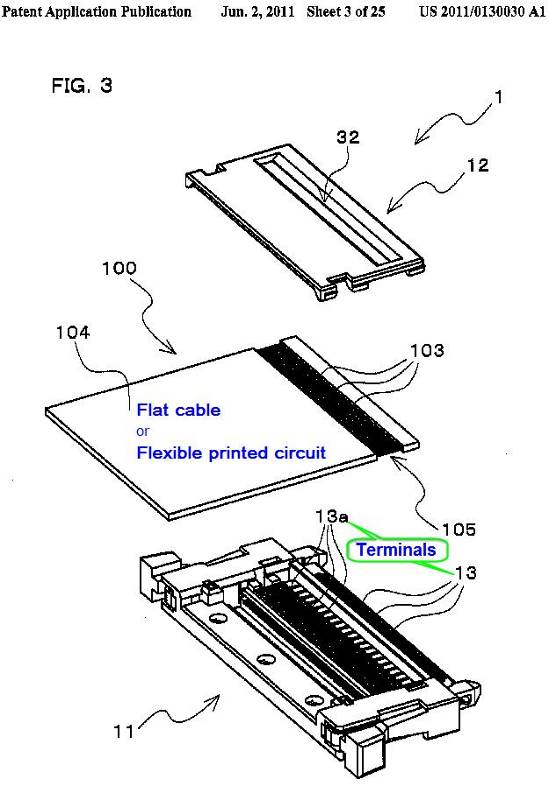

Coupling devices for PCB's, flat or ribbon cables or like structures

When the identification of the subject of connection for the connector is not clear in the patent specification or drawings, classification is given in this subgroup too.

In the following classification, it should be noted that the subdivision is effected depending on the counterpart of the connection and on the subject of mounting of that connector which is one party having a character for classification.

This place does not cover:

Guiding, mounting, polarizing or locking means; Extractors for printed circuit boards |

This place does not cover:

Press fitting |

This place covers:

Coupling device of which the subject of connection for the connector is rigid printed circuit board and that are not covered by H01R 12/72- H01R 12/75.

This place does not cover:

Coupling with the edge of the rigid printed circuits or like structures |

This place does not cover:

Contacts for abutting |

This place covers:

Coupling device of which the subject of connection for the connector is provided at the edge of, or nearby place to the edge of, rigid printed circuit board, and the subject of mounting is either not rigid printed circuit board or unidentifiable.

This place covers:

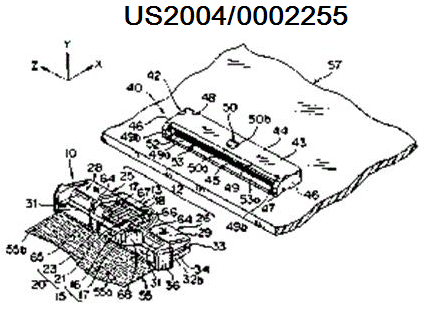

Coupling device of which the subject of connection for the connector is rigid printed circuit board, and the subject of mounting of the connector is also rigid printed circuit board.

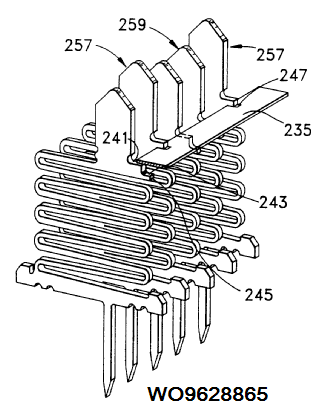

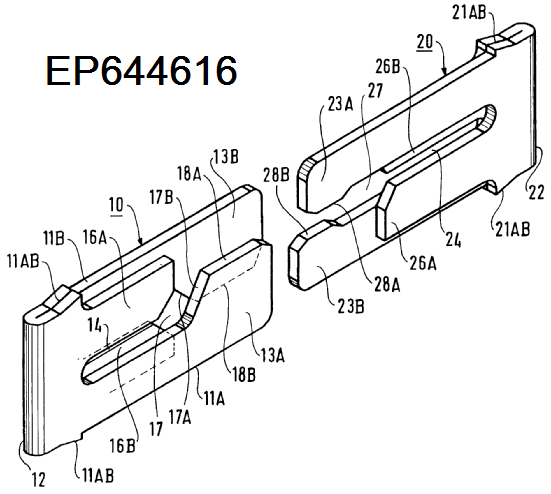

WO96/11513A

This place does not cover:

For printed connections |

This place covers:

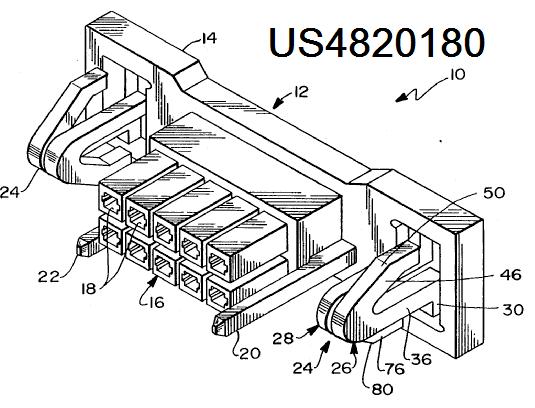

Coupling device of which the subject of connection for the connector is cables, and the subject of mounting is rigid printed circuit board.

This place covers:

Coupling device of which the subject of connection for the connector is flexible printed circuit board, and that are not covered by H01R 12/78- H01R 12/81.

This place does not cover:

Connecting to other flexible printed circuits, flat or ribbon cables or like structures | |

Connecting to rigid printed circuits or like structures |

This place does not cover:

Connecting to other flexible printed circuits, flat or ribbon cables or like structures | |

Connecting to rigid printed circuits or like structures |

This place covers:

Coupling device of which the subject of connection for the connector is flexible printed circuit board, and the subject of mounting is also flexible printed circuit board.

This place covers:

Coupling device of which the subject of connection for the connector is flexible printed circuit board, and the subject of mounting is rigid printed circuit board.

This place covers:

Coupling device of which the subject of connection for the connector is cables, and the subject of mounting is flexible printed circuit board.

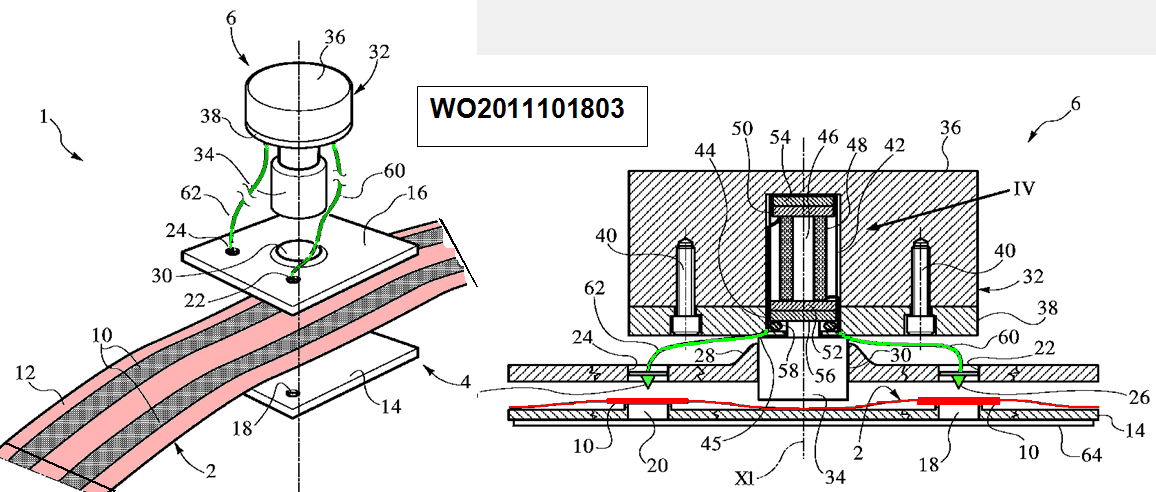

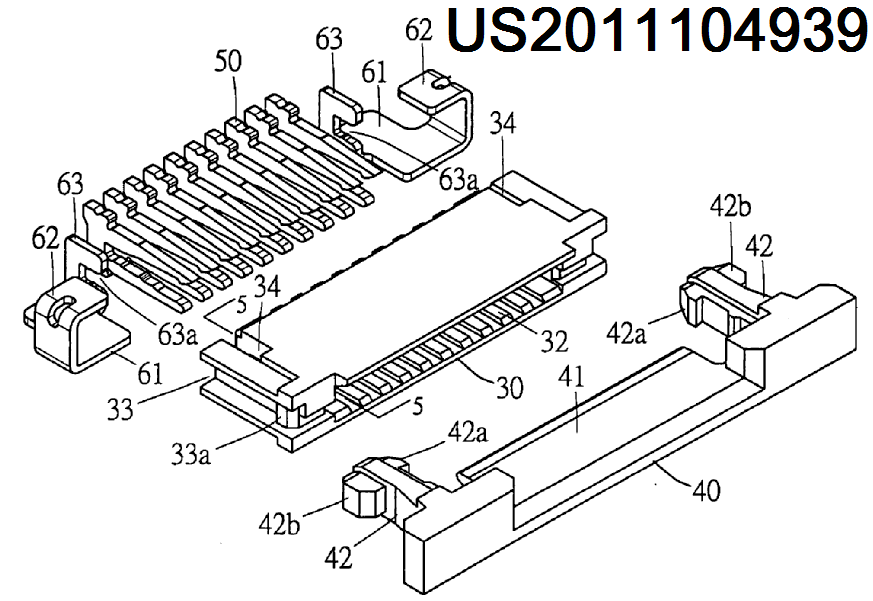

This place covers:

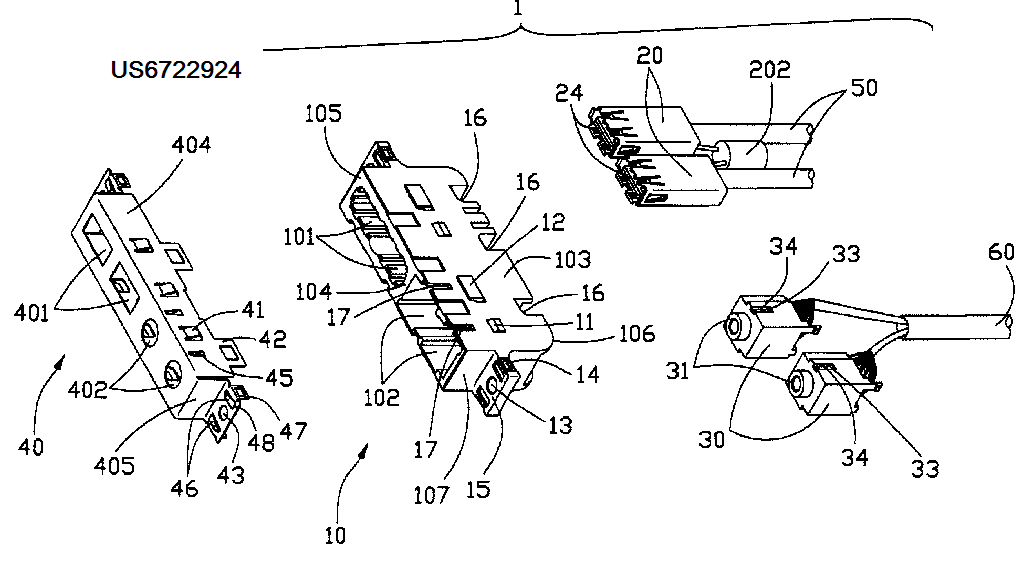

A connector performing the connection by zero insertion force or low insertion force

Coupling device which has the order of insertion for instance or cannot be classified in H01R 12/83- H01R 12/89.

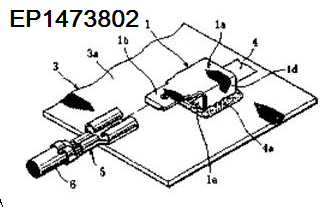

This place covers:

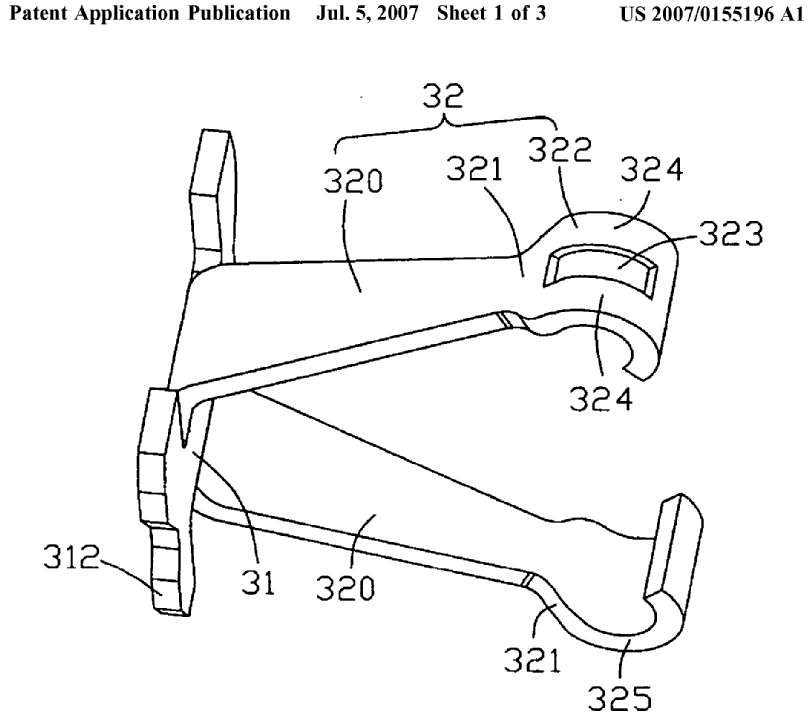

Coupling device that is activated by pivoting motion after insertion of the subject of connection.

This place covers:

Coupling device that is activated by applying certain force on the contact by certain means, its using actuator or screw, etc. that is not classified in H01R 12/87- H01R 12/89.

This place covers:

Coupling device that can perform the connection of zero insertion force or low insertion force with only insertion of the subject of connection and without any other operation.

This place covers:

Coupling device that can perform the connection of zero insertion force or low insertion force connection by activating pivoting member installed within the housing. If it is automatically functioning by the insertion of the subject of connection, it is classified in H01R 12/87.

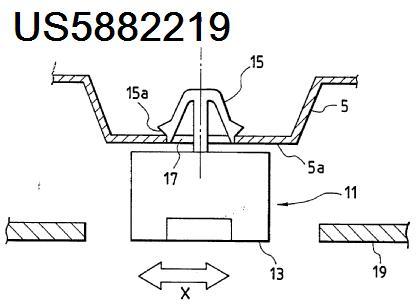

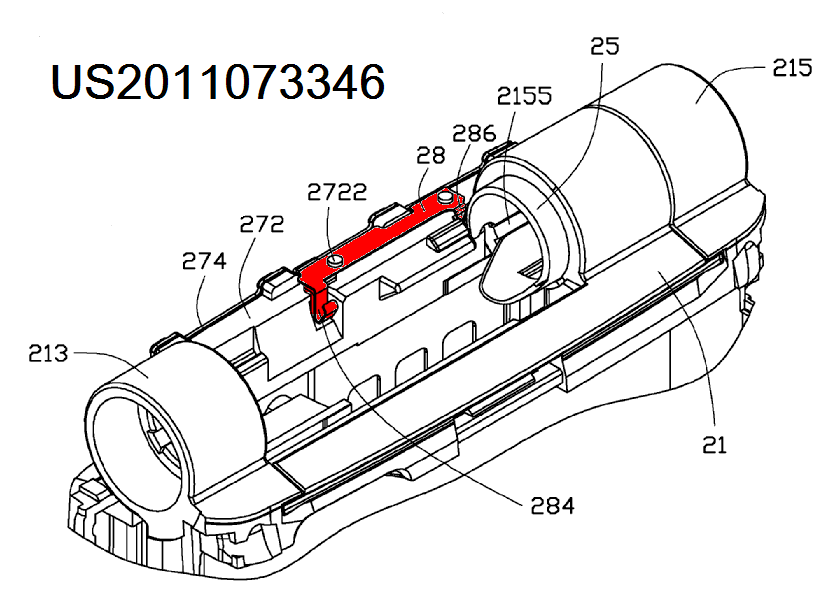

This place covers:

Coupling device that can perform the connection of zero insertion force or low insertion force connection by activating linear motion member installed within the housing. If it is automatically functioning by the insertion of the subject of connection, it is classified in H01R 12/87.

This place covers:

Coupling device of which connection is performed through automatic adjustment of the position between connectors to be connected.

US5306169A

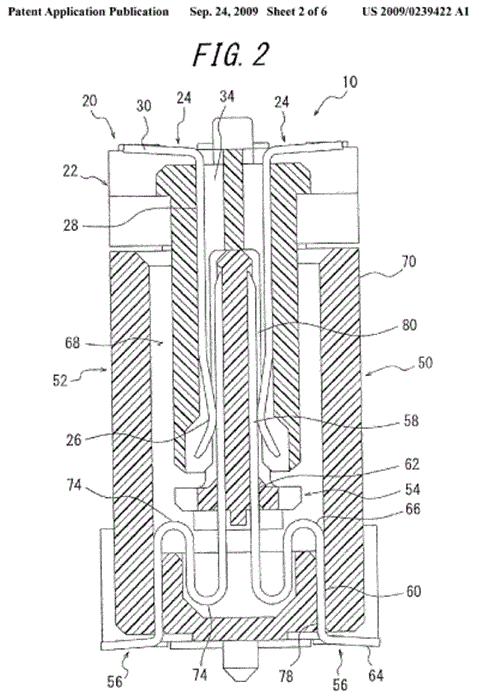

US2009/0239422A1

This place does not cover:

For coupling devices not specially adapted for printed circuits, flat or ribbon cables, or like generally planar structures, |

This place covers:

Details of contacts for coupling devices

Attention is drawn to the following places, which may be of interest for search:

Electro-optical connectors |

This place covers:

Contact members, pins, blades, sockets

This place does not cover:

Carrying separate resilient parts |

This place does not cover:

Carrying separate resilient parts |

This place does not cover:

Means for increasing contact pressure at the end of engagement of coupling part combined with printed circuit boards |

This place does not cover:

Pin or blade contacts for sliding co-operation for modular jack type connectors |

This place does not cover:

Hermaphroditic coupling devices |

Attention is drawn to the following places, which may be of interest for search:

Coupling parts adapted for co-operation with two or more dissimilar counterparts |

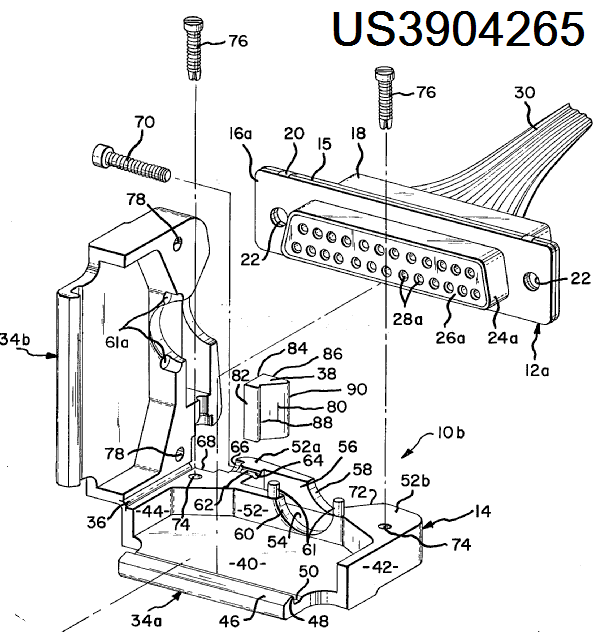

This place covers:

Bases;Cases; Security means

This place does not cover:

Making use of a switch actuated by engagement of counterpart |

This place does not cover:

Means facilitating correct wiring, e.g. marking plates, identification tags | |

Marking plates or tabs |

This place does not cover:

Bases or cases composed as a modular blocks or assembly |

This place does not cover:

Bases or cases composed as a modular blocks or assembly |

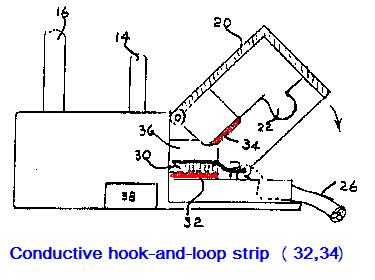

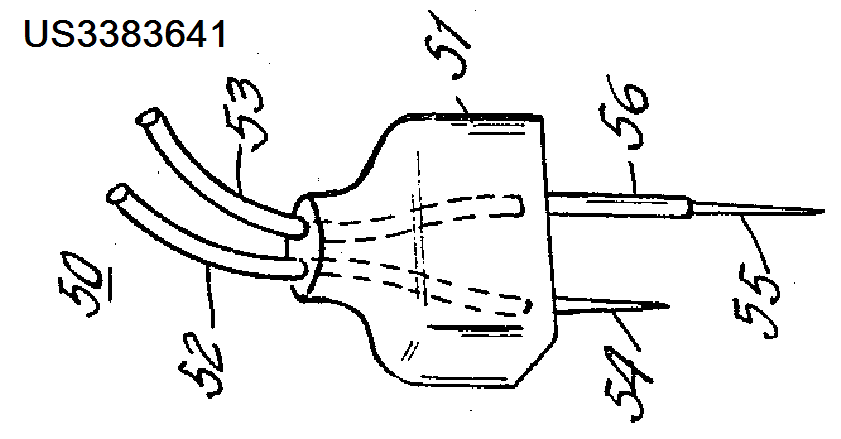

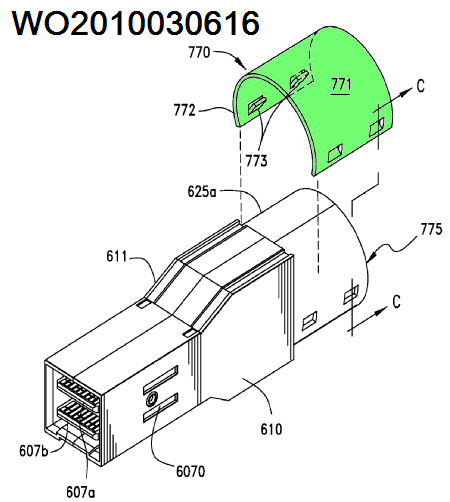

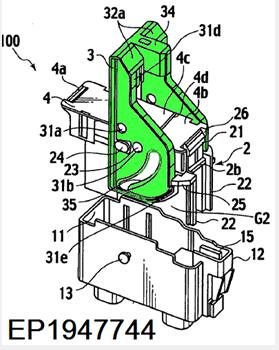

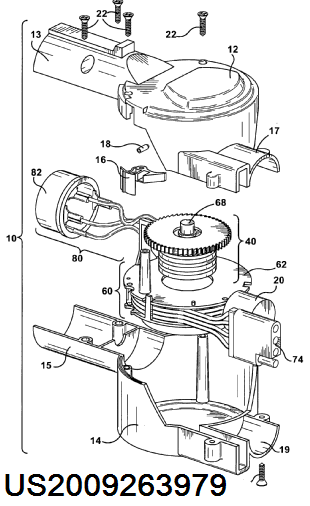

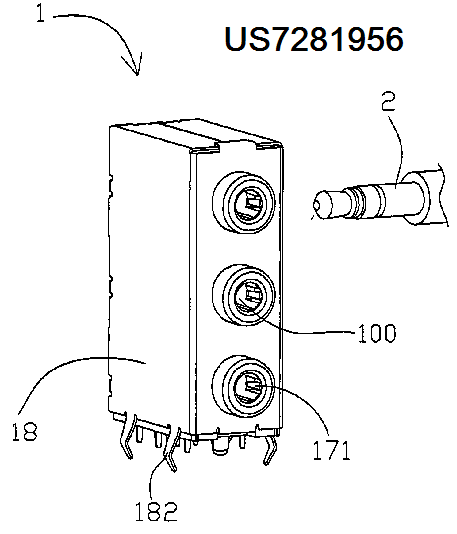

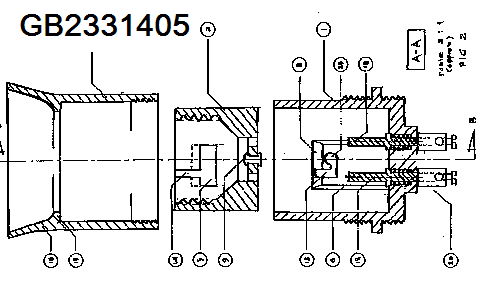

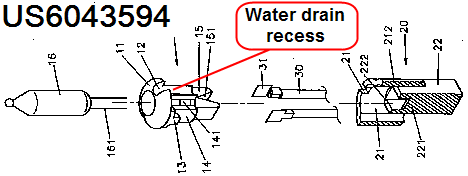

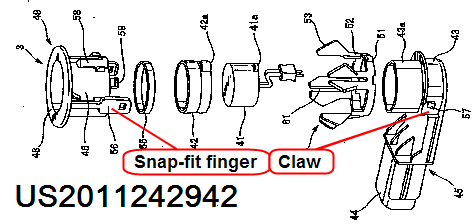

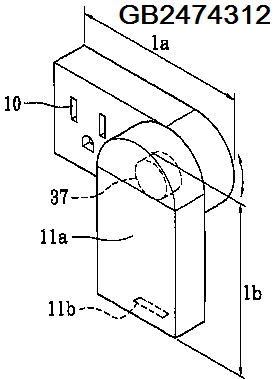

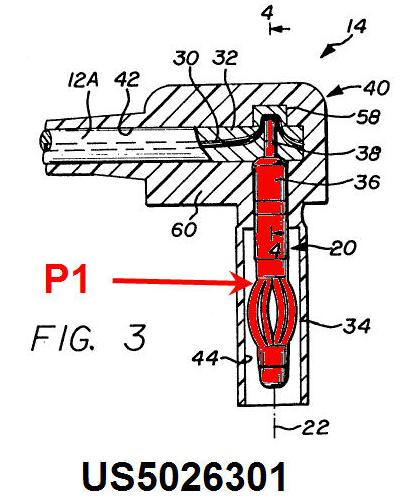

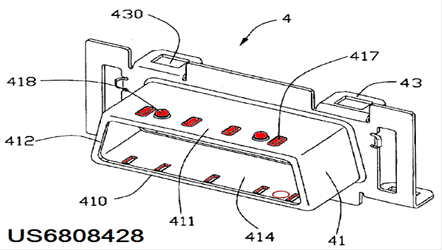

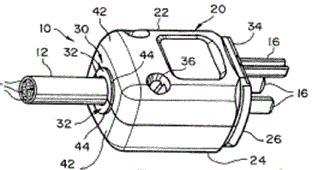

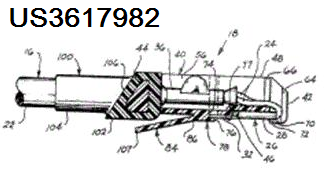

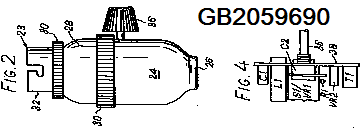

This place covers:

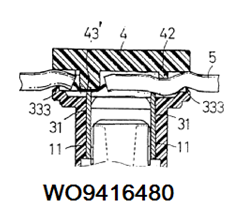

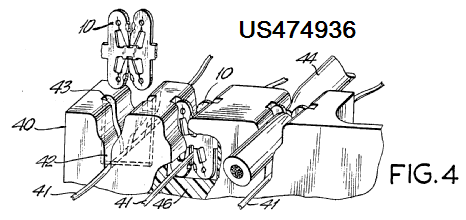

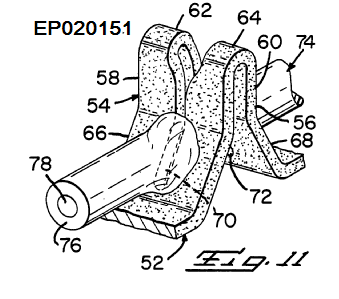

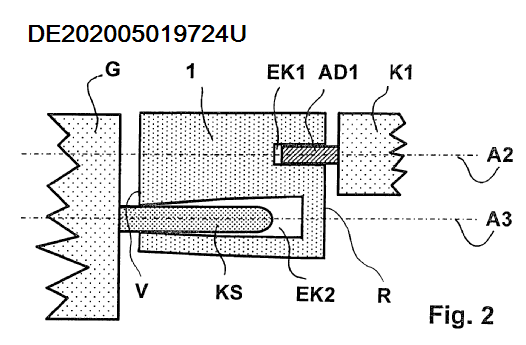

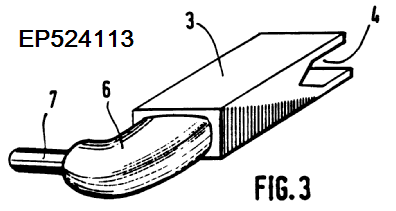

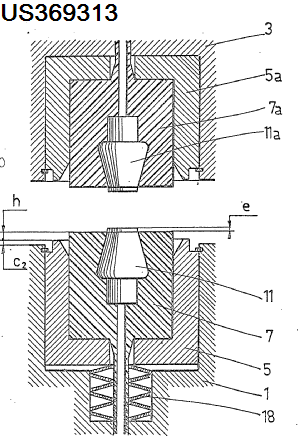

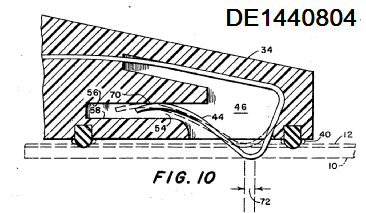

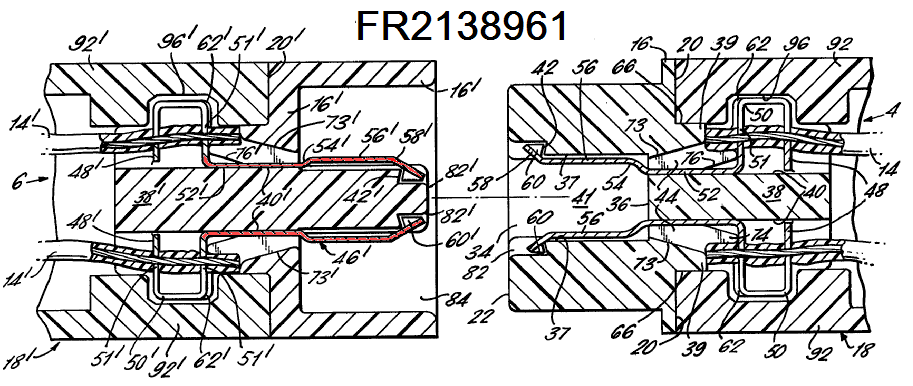

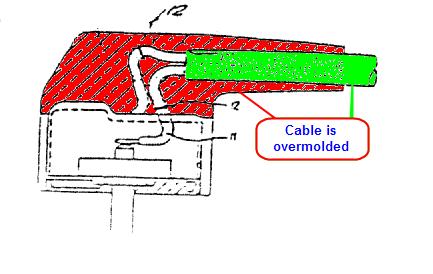

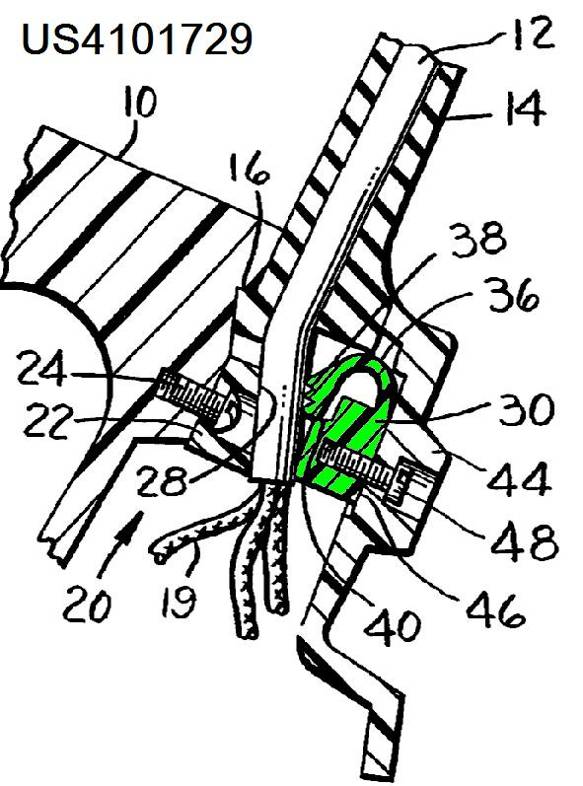

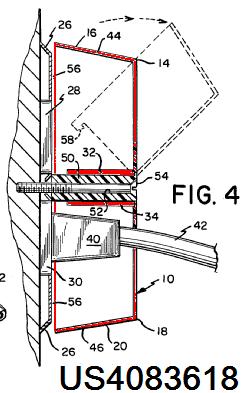

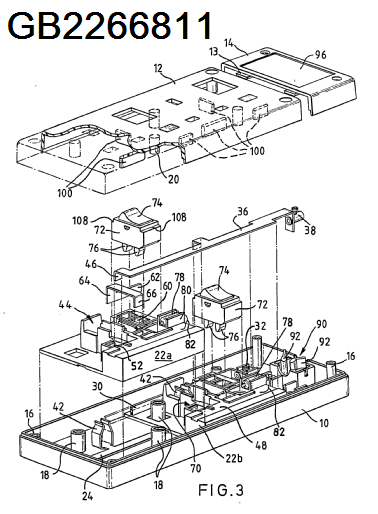

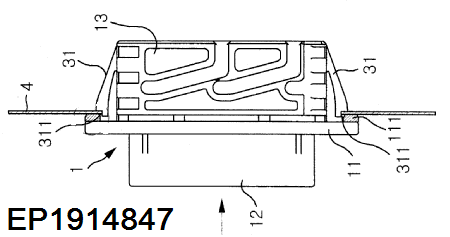

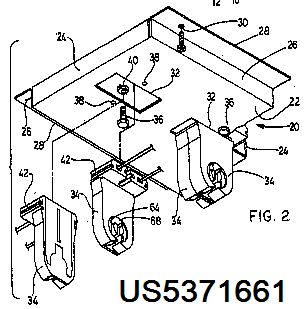

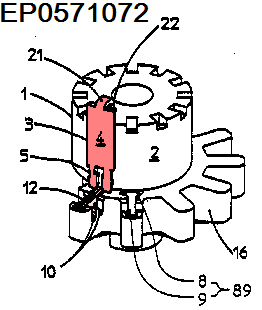

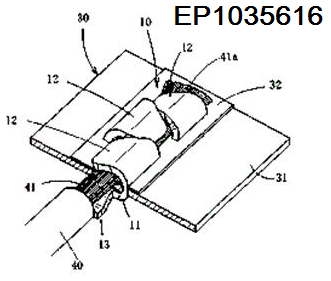

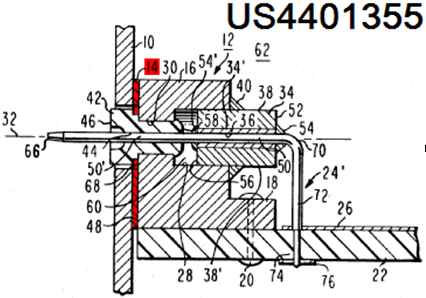

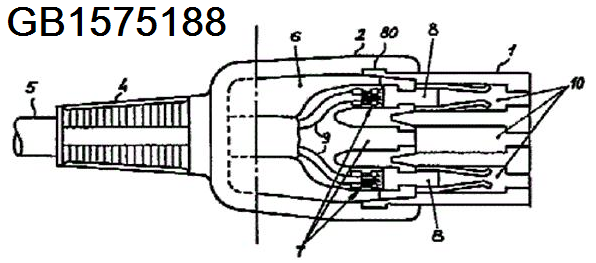

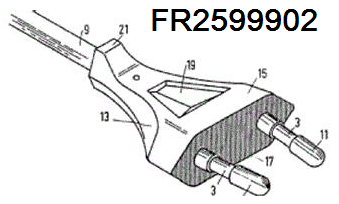

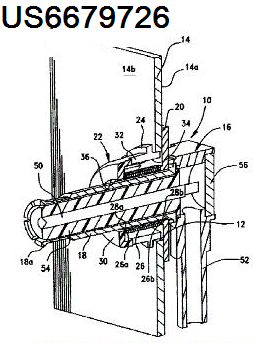

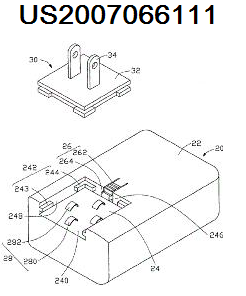

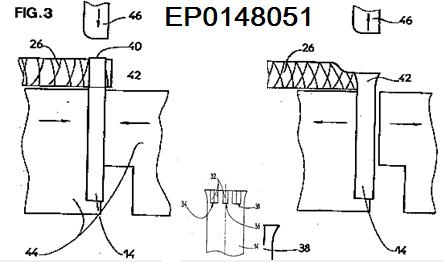

Illustrative example of subject matter classified in this place:

This place does not cover:

Sealing means between coupling parts having cable sealing means |

This place does not cover:

Structural association with built-in electrical component with built-in switch |

This place does not cover:

Dustproof, splashproof, drip-proof, waterproof, or flameproof cases |

This place does not cover:

Means for avoiding loosening of connections between wires and terminals within a coupling device terminating a cable for flat or ribbon cables |

This place does not cover:

Means for relieving strain on wire connection, allowing different orientations of the cable with respect to the coupling direction |

This place does not cover:

Crimping for cylindrical elongated bodies comprising a U-shaped wire-receiving portion |

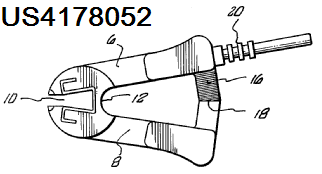

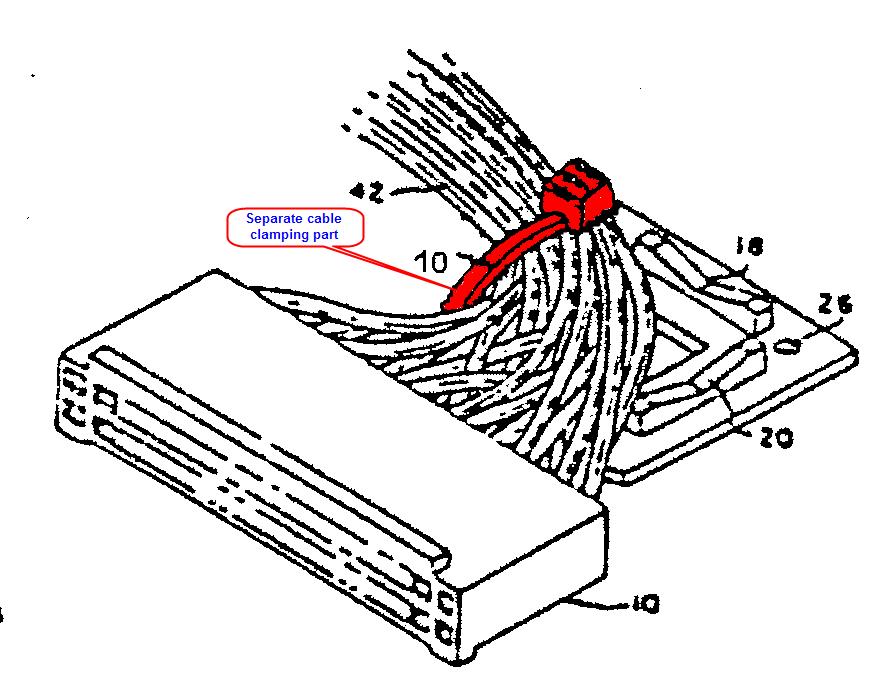

This place covers:

This place does not cover:

Means for relieving strain on wire connection, the cable being clamped between assembled parts of the housing |

This place does not cover:

Means for relieving strain on wire connection, the cable being clamped between assembled parts of the housing, the means comprising additional parts captured between housing parts and cable |

This place covers:

This place covers:

Means provided on coupling devices and specially designed for facilitating engagement or disengagement of coupling parts or for holding them in engagement.

This place does not cover:

Casing or ring with helicoidal groove |

This place does not cover:

Casing or ring with helicoidal groove | |

Snap or like fastening comprising one or more balls engaging in a hole or a groove | |

Snap or like fastening comprising a pin snapping into a recess |

This place does not cover:

Casing or ring with helicoidal groove | |

Snap or like fastening comprising one or more balls engaging in a hole or a groove | |

Snap or like fastening comprising a pin snapping into a recess |

This place does not cover:

Separate tools or apparatus |

This place does not cover:

Comprising exclusively pivoting lever | |

Means for preventing incorrect coupling by indicating incorrect coupling; by indicating correct or full engagement |

This place does not cover:

For coupling devices specially adapted for printed circuits, flat or ribbon cables, or like generally planar structures |

This place does not cover:

In combination with safety switch |

This place covers:

Specially adapted for: Bases; Cases; Security means

This place covers:

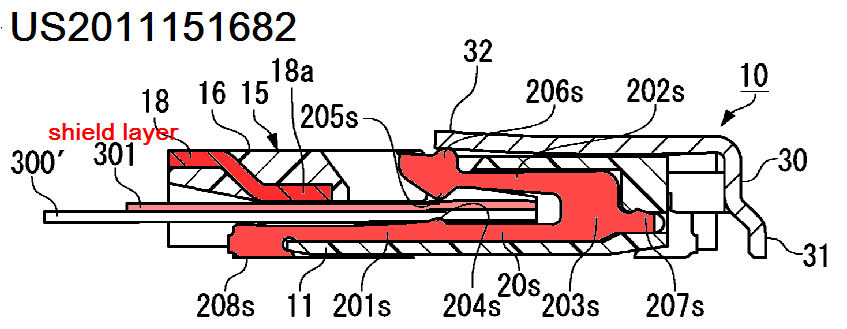

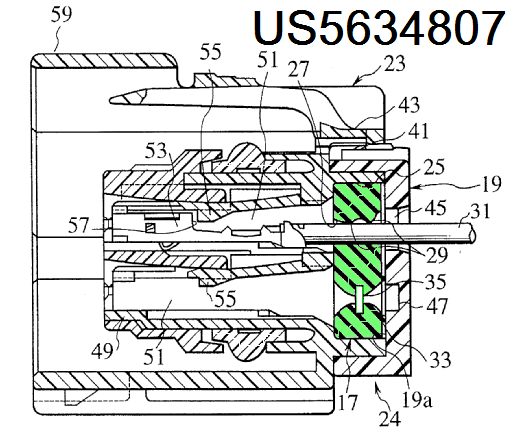

Coupling devices specially adapted for high-frequency;

Protection, grouding, shielding arrangements.

This place does not cover:

Protective earth or shield arrangements | |

Specially adapted for high frequency |

This place does not cover:

Coaxially arranged shields |

This place does not cover:

Electrostatic discharge protection in general | |

For electric apparatus |

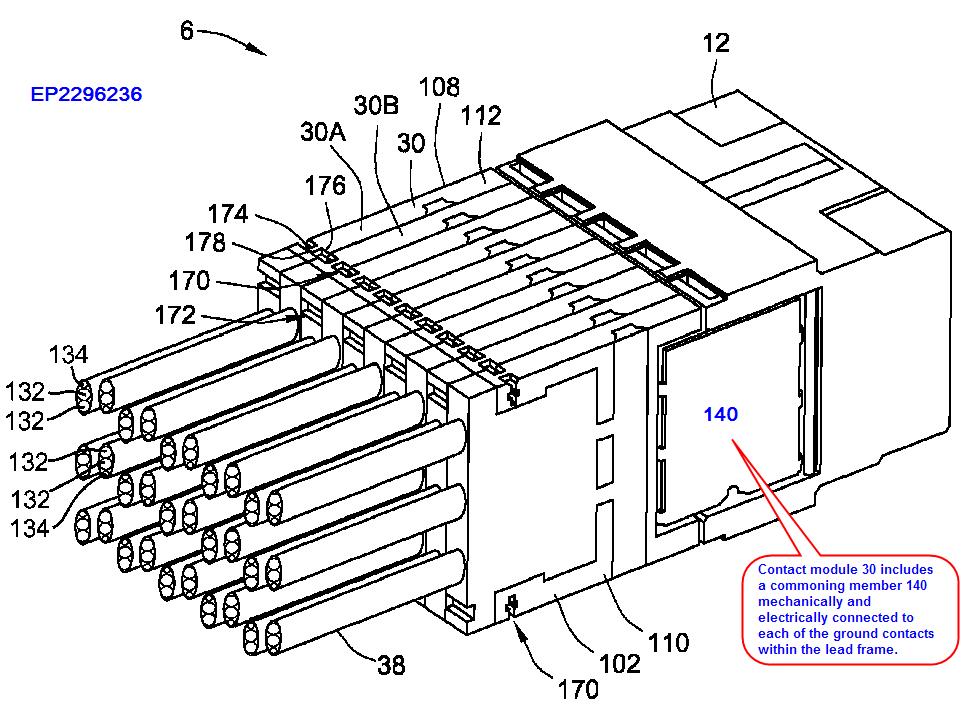

This place covers:

Subject matter under group H01R 13/648 comprising a conductive means for preventing or reducing (a) detrimental effects induced within a connector or contact due to capacitive or inductive coupling with electric or magnetic fields generated from a source outside of the connector or contact, (b) induced electrical interference or signal loss due to capacitive or inductive coupling between mutually insulated contacts within a plural-contact connector, (i.e. reducing cross-talk), or (c) undesirable loss of electrical information or signal due to electrical radiation of signal from connector or contact.

This place does not cover:

For coaxial cable | |

For flat or ribbon cable connectors | |

Coaxial coupling devices specially adapted for high frequency |

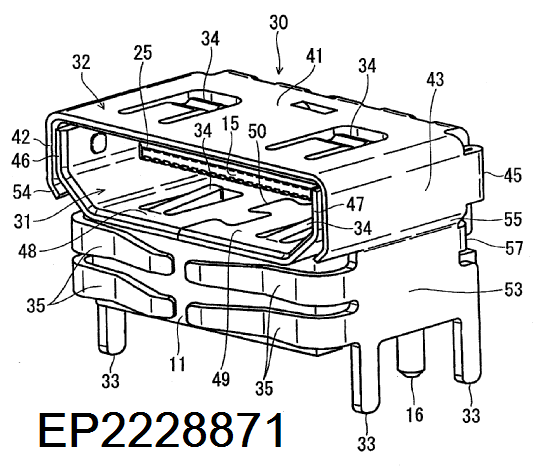

This place covers:

Subject matter under group H01R 13/658 comprising details of the shape or construction of a shield.

This place covers:

Subject matter under group H01R 13/6581

comprising shielding arrangements including

a resilient means on one connector for engaging a mating connector.

This place covers:

Subject matter under group H01R 13/6582 including

additional resilient means for electrically connecting

the shields of two mating connectors.

Examples:

This place covers:

Subject matter under group H01R 13/6583 wherein

the separate resilient means comprises a

conductive material having elastic properties.

Examples:

This place covers:

Subject matter under group H01R 13/6581 comprising conductive material either (a) formed around but spaced apart from at least a portion of at least one contact, so that the contact is inductively shielded from one or more other contacts, or (b) interposed between two or more contacts, so that the contacts are inductively shielded from one another. Examples:

This place covers:

Subject matter under group H01R 13/6585 wherein the shielding material separates two or more assemblies of plural contacts.

This place covers:

Subject matter under group H01R 13/6586 wherein the shield has means to facilitate mounting on a printed circuit board.

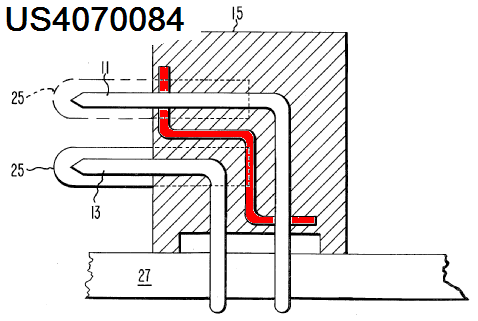

This place covers:

Subject matter under group H01R 13/6585 wherein the shield has apertures corresponding to individual contacts.

(Example: US 4070084)

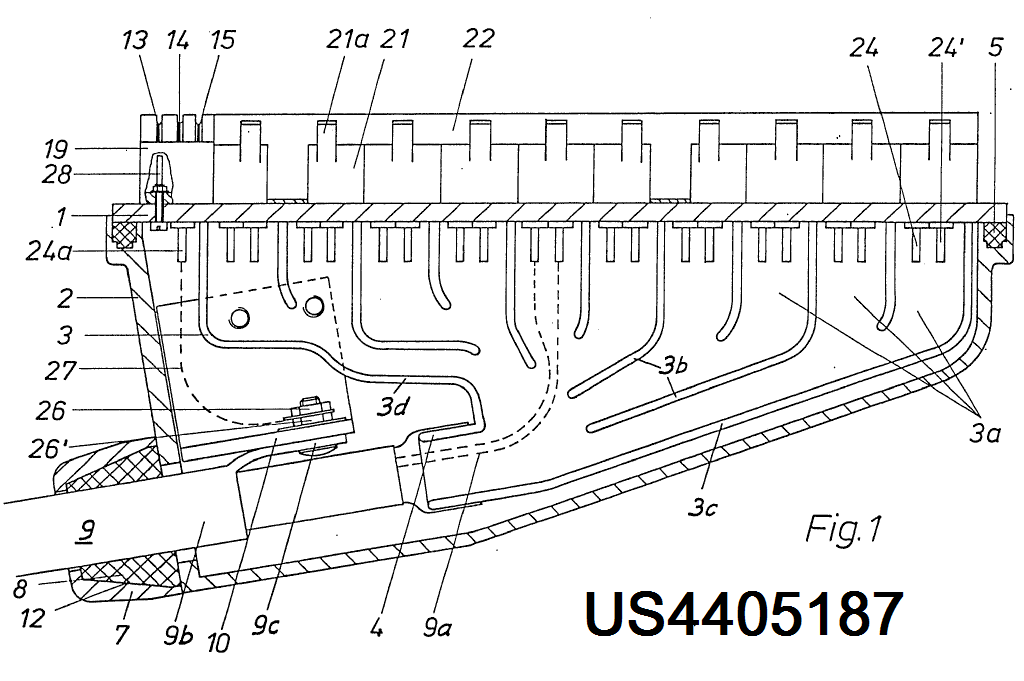

This place covers:

Subject matter under group H01R 13/6585 wherein the shield includes a conductive wall portion that separates enclosed wires. Examples:

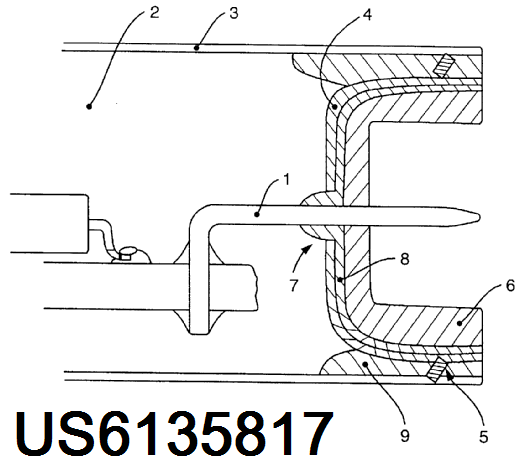

This place covers:

Subject matter under group H01R 13/6581 wherein the shield encloses two or more connectors. Examples:

This place covers:

Subject matter under group H01R 13/658 including specific features of a connection between the conductive shield and a conductive member of the connector or another component.

This place covers:

Subject matter under group H01R 13/6591 wherein the connection is to an external conductive sheath of an electric cable.

This place covers:

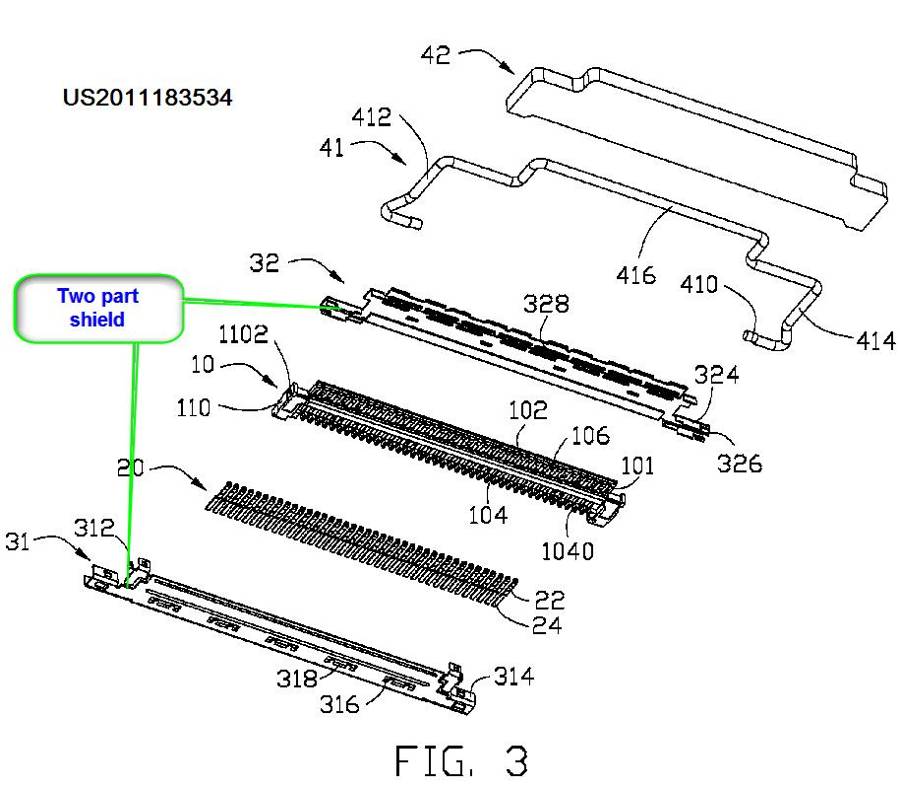

Subject matter under group H01R 13/6592 wherein the shield is comprised of assembled parts.

This place covers:

Subject matter under group H01R 13/6591 wherein the shield is mounted on a printed circuit board and is electrically connected to a conductor on the circuit board.

This place covers:

Subject matter under group H01R 13/6594 wherein the shield is attached to the printed circuit board by a separate element or member. Examples:

This place covers:

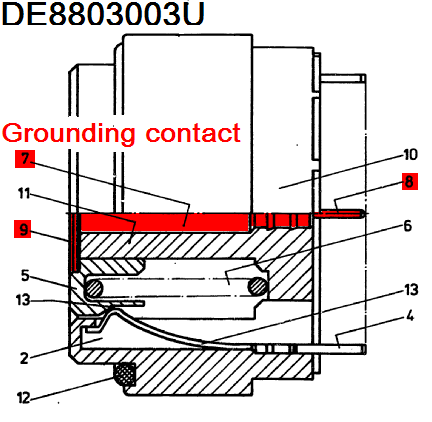

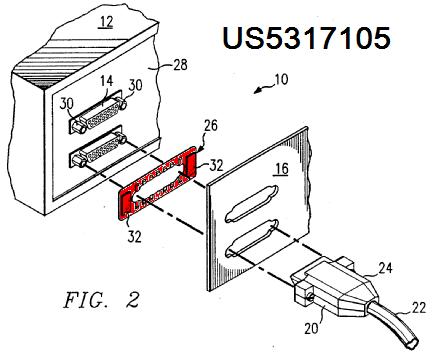

Subject matter under group H01R 13/6591 including specific features of a connection between the conductive shield and an electrically grounded metal panel. Examples:

This place covers:

Subject matter under group H01R 13/6591 including specific features of a connection between the conductive shield and a contact of the connector. Examples:

This place covers:

Subject matter under group H01R 13/658 comprising the composition or properties of the shielding material.

This place covers:

Subject matter under group H01R 13/6598 comprising a dielectric material having conductive additives or coatings. Example:

This place covers:

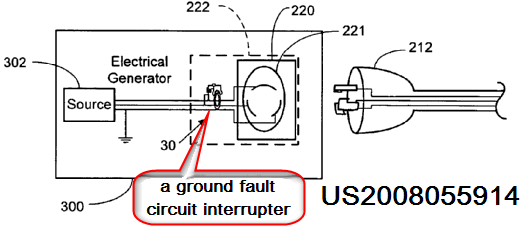

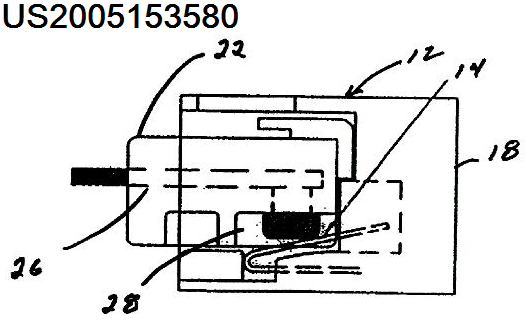

Subject matter under group H01R 13/00 comprising details of the structural relationship of a coupling device other than a non-coaxial connector and an electrical component housed within the device.

This place does not cover:

Coupling devices having concentrically or coaxially-arranged contacts |

Attention is drawn to the following places, which may be of interest for search:

Specially adapted to a specific shape of cables |

This place does not cover:

Structural association with built-in fuse | |

Structural association with built-in switch |

This place does not cover:

Structural association with built-in switch | |

Structural association with built-in component specially adapted for high frequency |

This place does not cover:

Structural association with built-in overvoltage protection | |

Structural association with built-in signalling means |

This place does not cover:

Built-in light source |

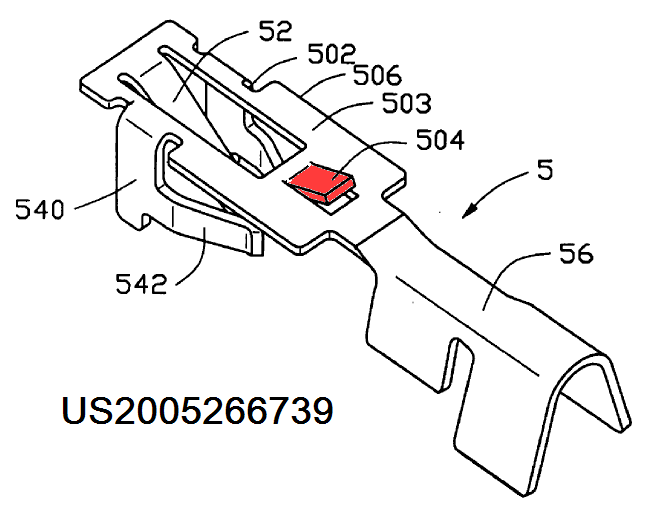

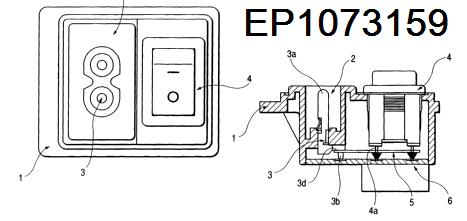

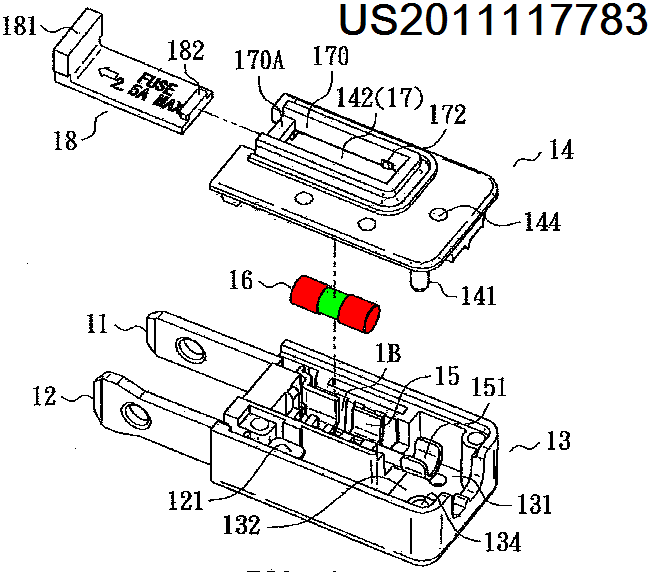

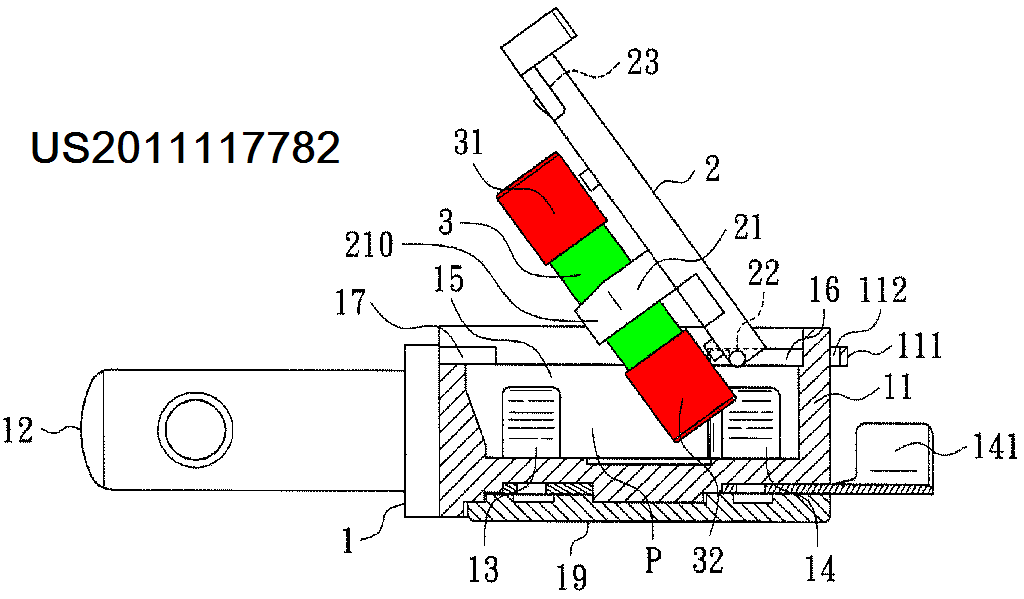

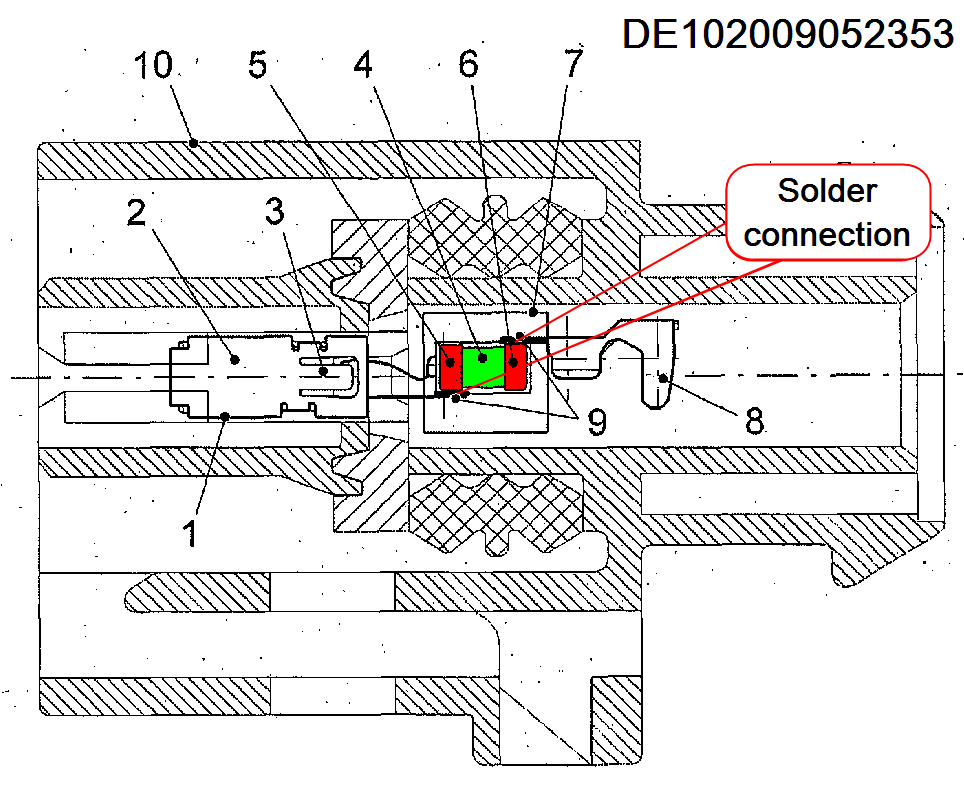

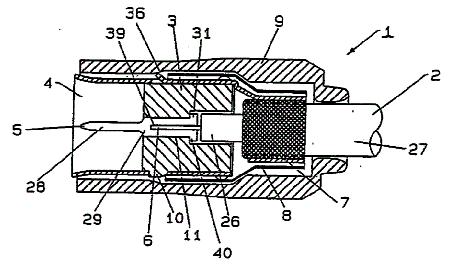

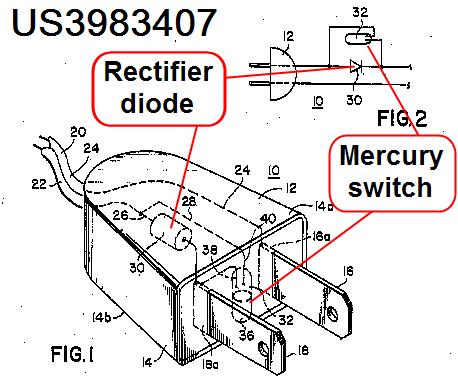

This place covers:

Subject matter under group H01R 13/66 wherein the built-in electrical component is a fusible circuit breaker.

This place covers:

Subject matter under group H01R 13/68 wherein the built-in fuse is removable from the coupling device.

This place covers:

Subject matter under group H01R 13/684 wherein the coupling device includes an opening or a removable or repositionable portion which permits access to the built-in removable fuse.

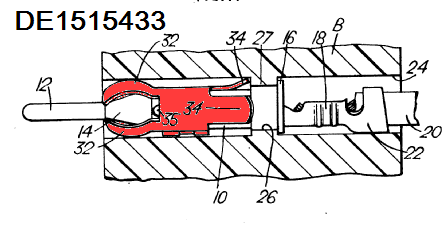

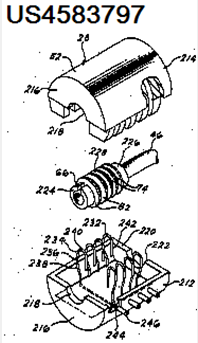

This place covers:

Subject matter under group H01R 13/688 wherein the housing part is rotatable, e.g. threadably connected or hinged, to permit access to the built-in removable fuse.

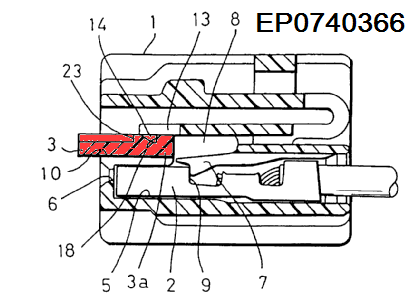

This place covers:

Subject matter under group H01R 13/68 wherein the built-in fuse is irremovably attached to a contact of the coupling device.

This place does not cover:

Contact members of coupling parts operating as switch |

This place does not cover:

Terminals being in direct electric contact separated by double sided connecting element for printed circuit board |

This place does not cover:

Safety switches having ejecting mechanisms |

This place does not cover:

Safety switches having ejecting mechanisms |

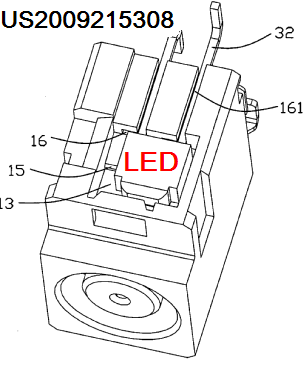

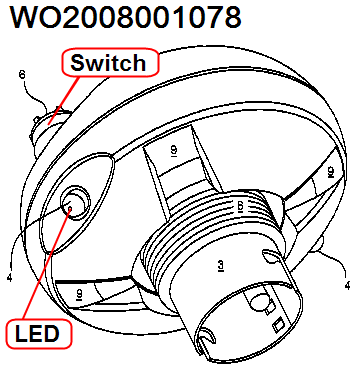

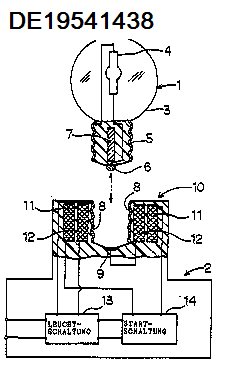

This place covers:

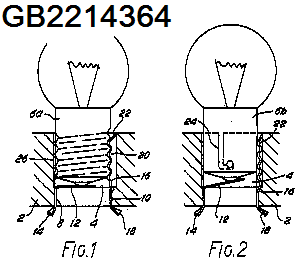

Subject matter under group H01R 13/66 wherein in the built-in electrical component is an electric light source.

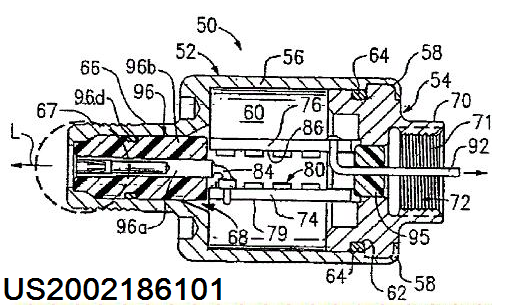

This place covers:

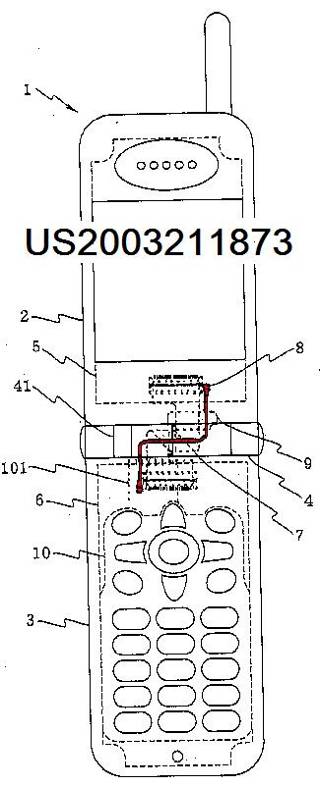

Subject matter under group H01R 13/66 comprising coupling devices having built-in electrical components or other features which adapt for use with high frequency alternating currents or voltages.

In patent documents, the following words/expressions are often used with the meaning indicated:

"filter" | "noise-reducing member". |

This place covers:

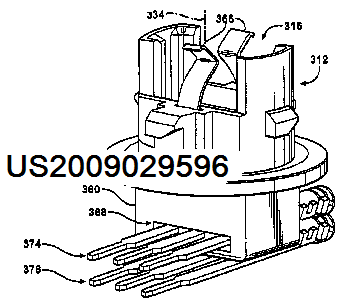

Subject matter under group H01R 13/719 wherein the built-in electrical component is a ferrite filter.

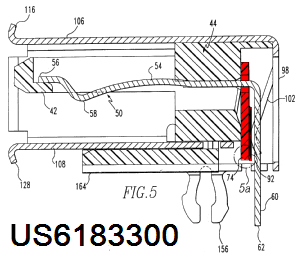

This place covers:

Subject matter under group H01R 13/719 wherein the built-in electrical component consists of a flat, i.e. essentially two-dimensional, filter circuit device, e.g. a PCB with a filter fixed thereon, with apertures to permit engagement of mating contacts.

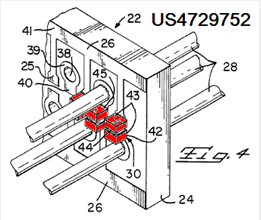

(Examples: US 4729752; US 6183300)

This place covers:

Subject matter under group H01R 13/719 wherein the built-in electrical component consists of a filter integral with, or fitted onto, at least one connector contact.

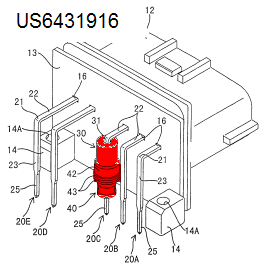

(Example: US 6431916)

This place does not cover:

Means for mounting coupling parts in openings of a panel using a screw ring |

This place covers:

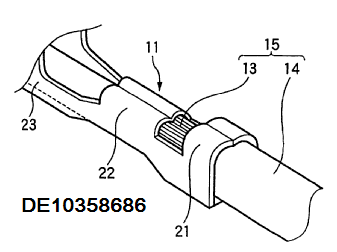

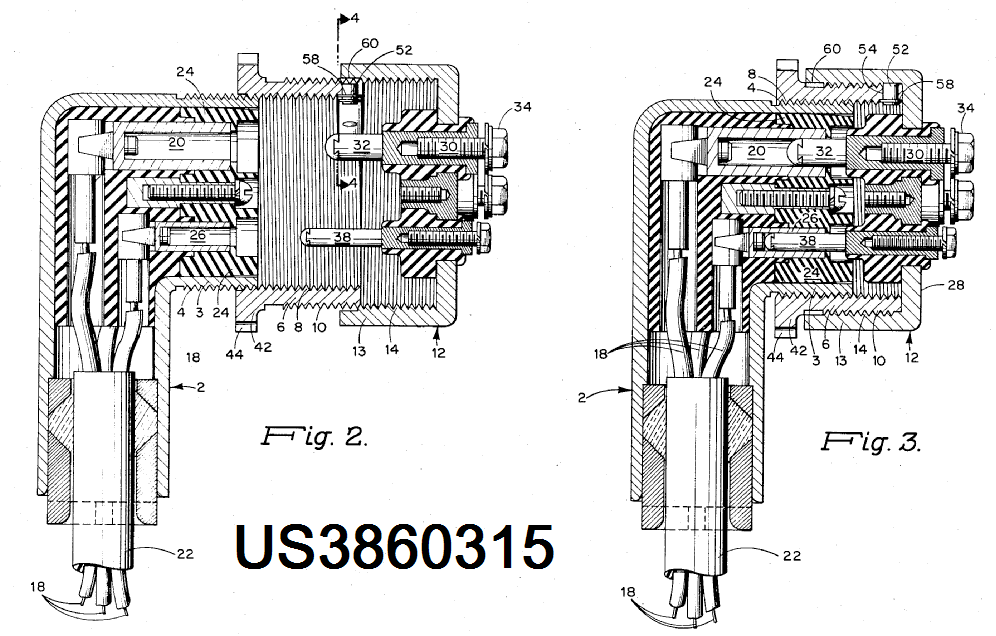

Coupling devices attached to cables or attached to structures

This place does not cover:

Contact members | |

Securing contact members in or to a base or case | |

Bases; Cases | |

Means for supporting coupling part when not engaged | |

Means for facilitating engagement or disengagement of coupling parts | |

Means for preventing, inhibiting or avoiding incorrect coupling |

Attention is drawn to the following places, which may be of interest for search:

Special adaptation for high-frequency, e.g. structures providing animpedance match or phase match | |

Protective earth or shield arrangements on coupling devices | |

Structural association with built-in electrical component | |

Coupling devices in which a holder is adapted for supporting apparatus to which its counterpart is attached: Separate parts thereof | |

One pole | |

Two poles | |

Three poles | |

Four or more poles |

An Indexing Code of the groups H01R 2101/00- H01R 2107/00 is preferably given to each document classified in this group and the sub-groups.

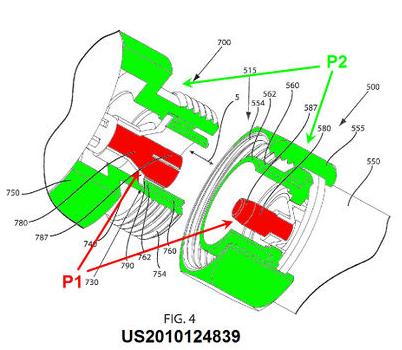

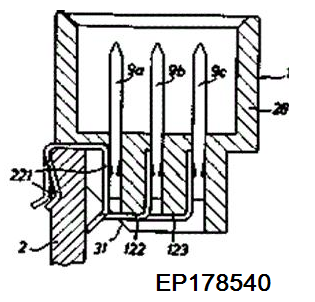

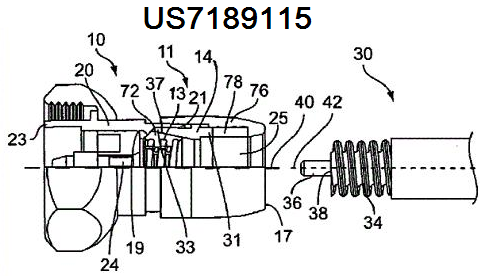

This place covers:

The subject matter under H01R 24/20 comprises cooperating parts having cavities with conducting properties extending into a support structure. At least one of the cavities is connected to an elongated electrical conductor attached to the support structure.

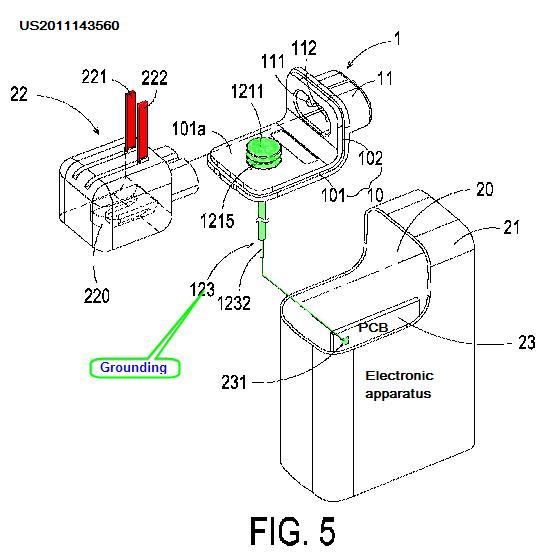

This place covers:

The subject matter under H01R 24/22 comprises cooperating parts having cavities with conducting properties extending into a support structure. At least one of the cavities is connected to an elongated electrical conductor attached to the support structure, whereby the support structure comprises a grounding structure.

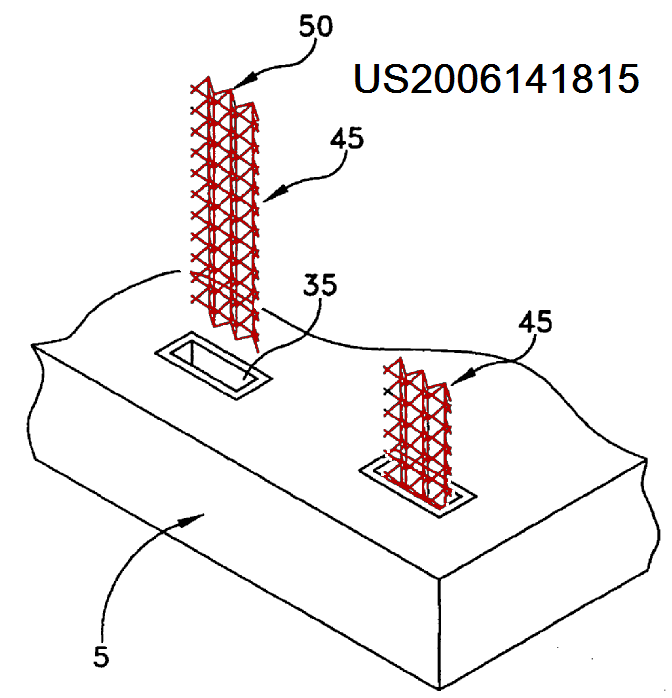

This place covers:

The subject matter under H01R 24/28 comprises cooperating parts having protruding members with conducting properties extending from a support.

At least one of the protruding members is connected to an elongated electrical conductor.

This place covers:

The subject matter under H01R 24/30 comprises cooperating parts having protruding members with conducting properties extending from a support structure and connected to an elongated electrical conductor, whereby one conductor is grounded.

This place covers:

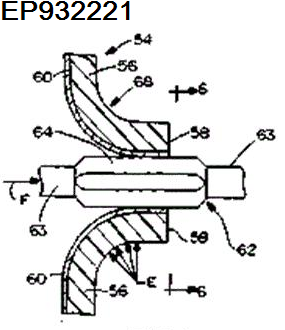

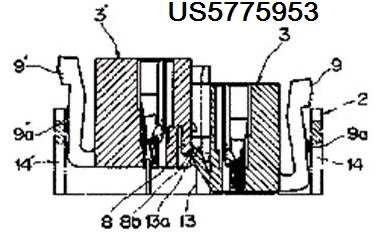

The subject matter under H01R 24/38 comprises cooperating parts having a center contact and cylindrical contacts concentrically disposed thereabout.

This place covers:

The subject matter under H01R 24/40 comprises cooperating parts having a center contact and cylindrical contacts concentrically disposed thereabout and adapted for signals used for radio transmission.

DE19528552

This place covers:

The subject matter under H01R 24/42 comprises cooperating parts for radio transmission having a center contact and cylindrical contacts concentrically disposed thereabout and at least one component, except components covered by H01R 24/46 or H01R 24/48.

Attention is drawn to the following places, which may be of interest for search:

Impedance matching, filters per se |

This place covers:

The subject matter under H01R 24/44 comprises cooperating parts for radio transmission having a center contact and cylindrical contacts concentrically disposed thereabout and means for setting the output impedance of a signal source equal to the input impedance of the load to which it is ultimately connected, usually in order to maximize the power transfer and minimize reflections from the load.

This place does not cover:

Impedance matching switches | H01R17/12H4 |

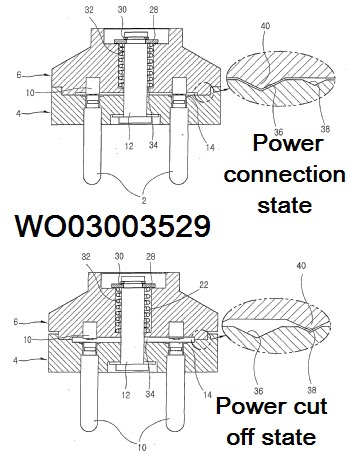

This place covers:

The subject matter under H01R 24/46 comprises cooperating parts for radio transmission having a center contact and a cylindrical contact concentrically disposed thereabout and means for interrupting, shorting or bypassing signals carried by the center contact.

This place covers:

The subject matter under H01R 24/48 comprises cooperating parts for radio transmission having a center contact and a cylindrical contact concentrically disposed thereabout and means for reducing voltages above its upper design limit (e.g. transient voltages or voltage spikes).

This place covers:

The subject matter under H01R 24/50 comprises cooperating parts for radio transmission having a center contact and a cylindrical contact concentrically disposed thereabout, and adapted for mounting on a substrate providing electrically conductive paths.

US6140977

This place covers:

The subject matter under H01R 24/52 comprises cooperating parts for radio transmission having a center contact and a cylindrical contact concentrically disposed thereabout and adapted for mounting on a support except a printed circuit board as in H01R 24/50.

This place covers:

The subject matter under H01R 24/54 comprises cooperating parts for radio transmission having a center contact and a cylindrical contact concentrically disposed thereabout and specially adapted as coupling part between two or more counterparts, characterized by the relationship of the counterparts, e.g. different kinds of counterparts, right angle relationship between counterparts, one counterpart connected to a plurality of counterparts.

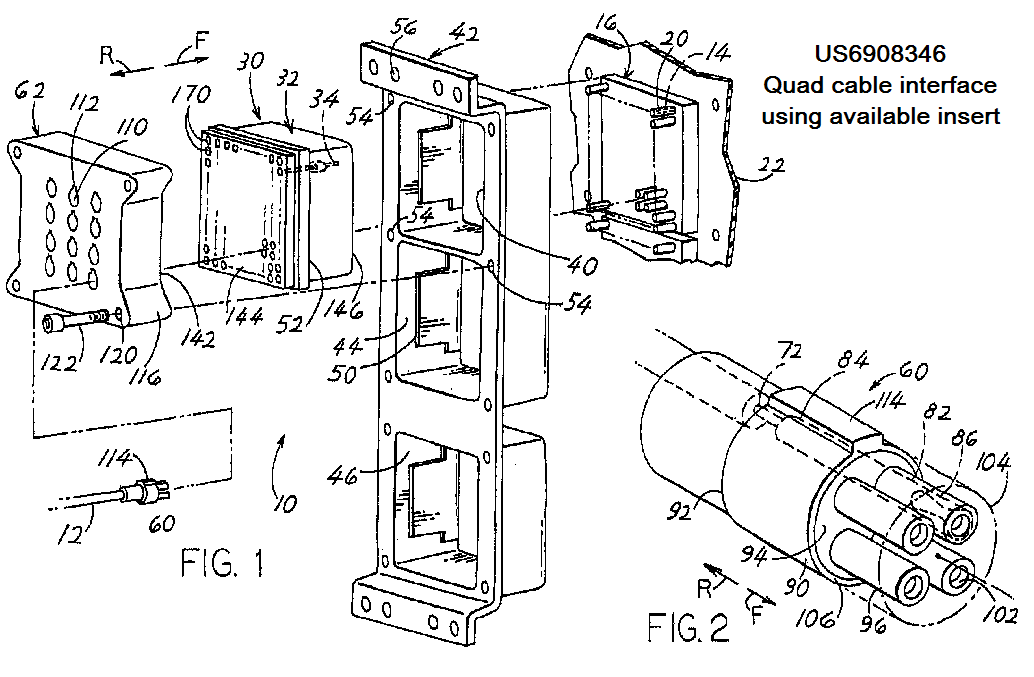

This place covers:

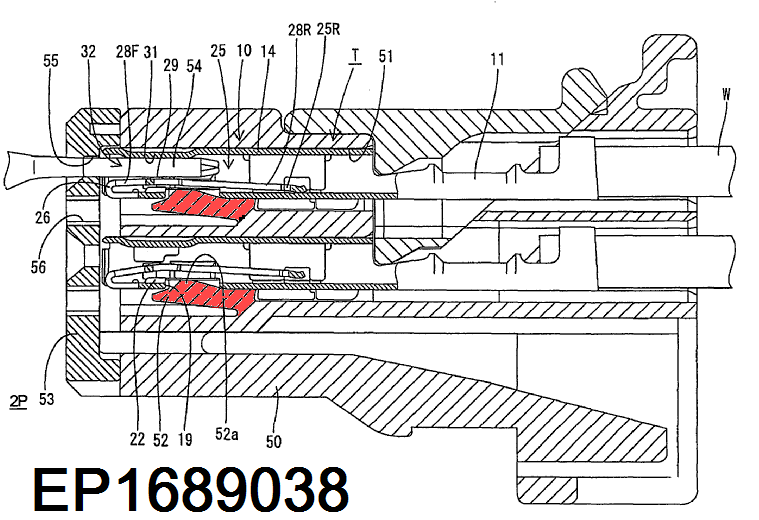

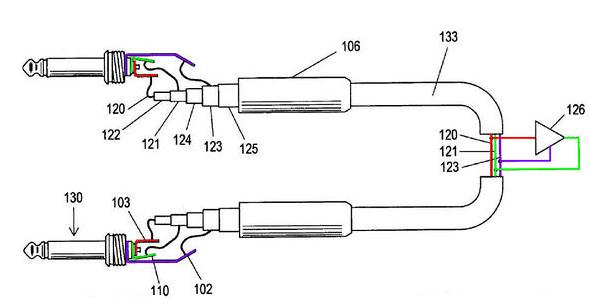

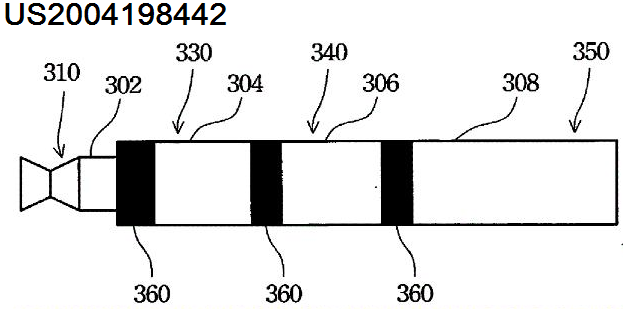

The subject matter under H01R 24/56 comprises a plurality of cooperating parts for radio transmission having a center contact and a cylindrical contact concentrically disposed thereabout, being adapted to connect elongated conductors having a center conductor and a shielding layer with special features.

This place covers:

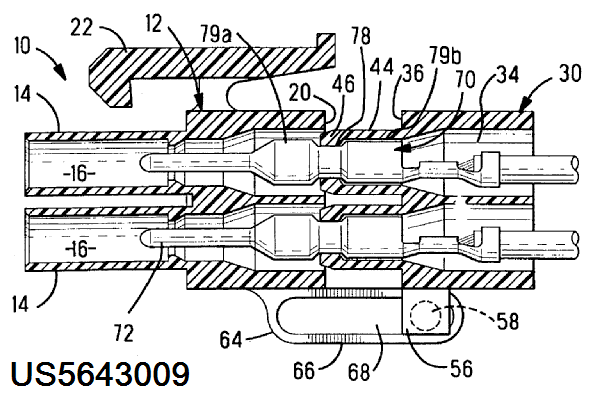

The subject matter under H01R 24/58 comprises coupling parts with contacts disposed serially along a line parallel to the longitudinal axis along which the coupling part engages its mating coupling part.

This place covers:

The subject matter under H01R 24/60 comprises coupling parts with contacts disposed serially along a line orthogonal to the longitudinal axis along which the coupling part engages its mating coupling part.

US2007178734

This place covers:

The subject matter under H01R 24/62 comprises coupling parts with contacts disposed serially along a surface orthogonal to the longitudinal axis along which the coupling part engages, its mating coupling part being accessible only on one side.

This place covers:

The subject matter under H01R 24/64 comprises coupling parts with contacts disposed serially along a surface orthogonal to the longitudinal axis along which the coupling part engages its mating coupling part, the coupling part has special features for high speed transmissions.

This place covers:

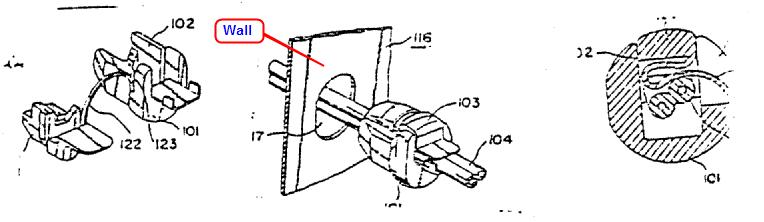

The subject matter under H01R 24/66 comprises cooperating parts having protruding members with conducting properties extending from a support attached to a wall of an apparatus or structure.

This place covers:

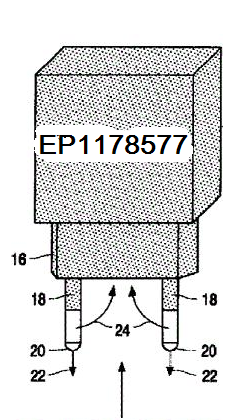

The subject matter under H01R 24/68 comprises cooperating parts having protruding members with conducting properties extending from a portable device.

This place covers:

The subject matter under H01R 24/70 comprises cooperating parts having protruding members with conducting properties extending from a support, one of the protrusions on the portable device having grounding means.

This place covers:

The subject matter under H01R 24/76 comprises cooperating parts having recesses with conducting properties extending into a support attached to a wall of an apparatus or structure.

This place covers:

The subject matter under H01R 24/78 comprises cooperating parts having recesses with conducting properties extending into a support attached to a wall of an apparatus or structure, one of the recesses having grounding means.

This place covers:

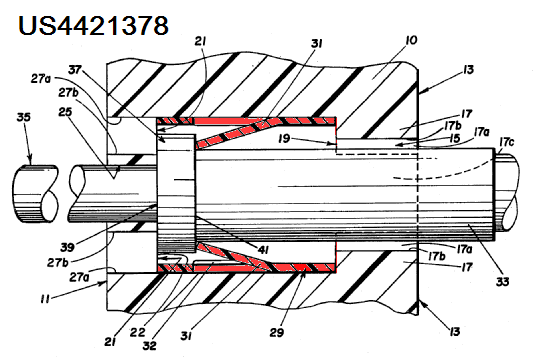

The subject matter under H01R 24/84 comprises cooperating parts which are identical in configuration in the interfitting portions thereof.

This place covers:

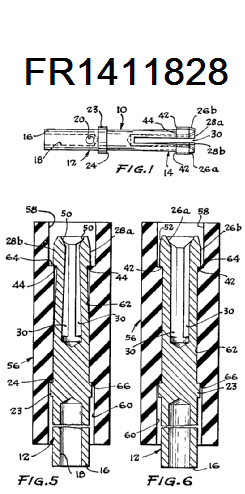

The subject matter under H01R 24/86 comprises cooperating parts with electrically mating conductors extending in the same direction about the longitudinal axis along which the cooperating part engages its mating coupling part.

This place covers:

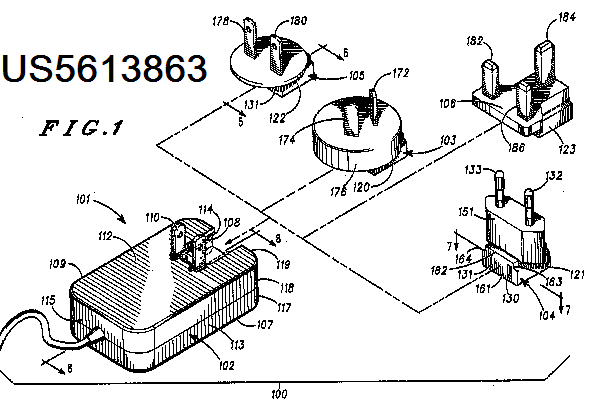

Coupling parts for multiple or alternative co-operation withidentical counterparts

This place does not cover:

Supported only by co-operation with a counterpart | |

With a holder adapted for supporting apparatus to which its counterpart is attached |

This place does not cover:

Direct electrical contact between the supporting element and electric conductors running along the guiding element |

Attention is drawn to the following places, which may be of interest for search:

Installation of bus bars |

This place does not cover:

Low voltage devices |

This place does not cover:

Rails having primarily a non electrical function |

This place covers:

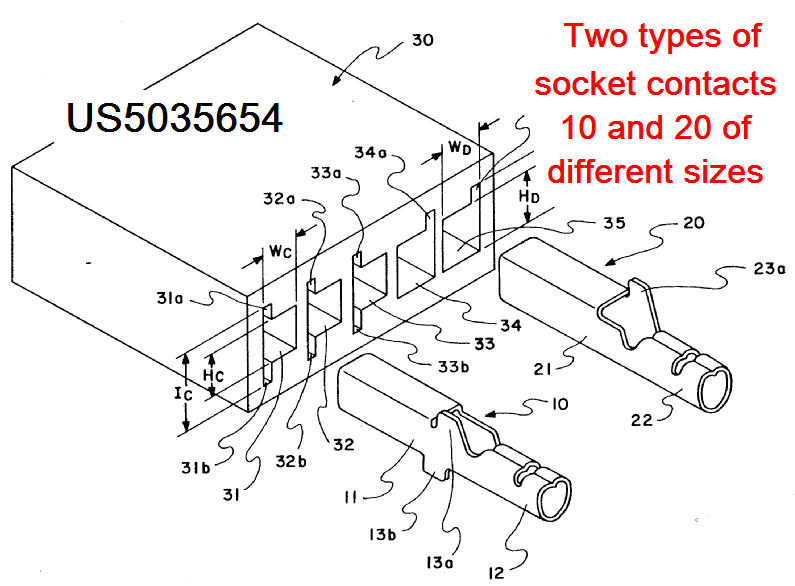

Coupling parts for multiple or alternative co-operation with non-identical counterparts

This place does not cover:

For dissimilar contact members | |

Supported only by co-operation with a counterpart | |

With a holder adapted for supporting apparatus to which its counterpart is attached |

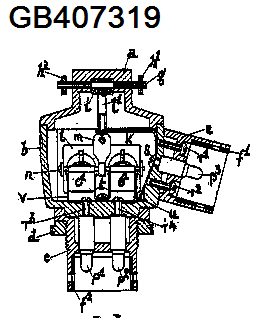

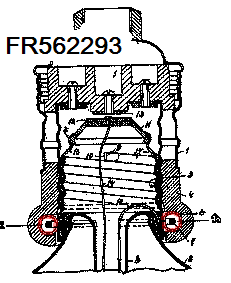

This place covers:

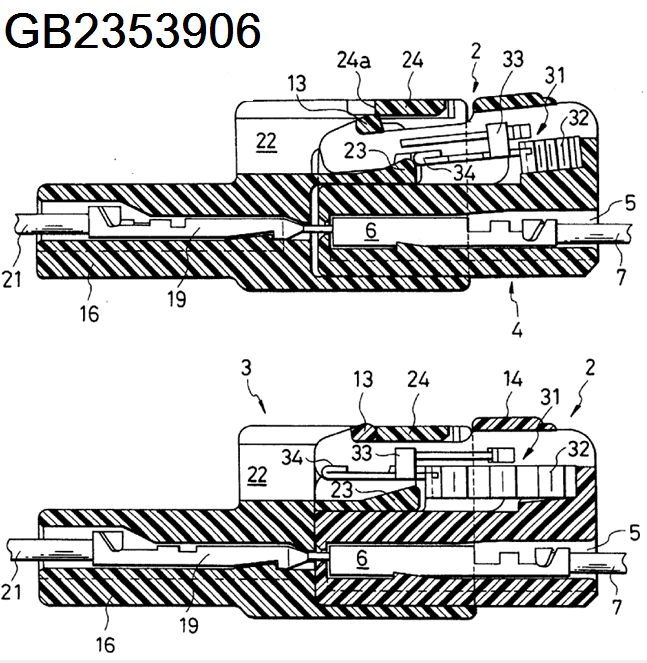

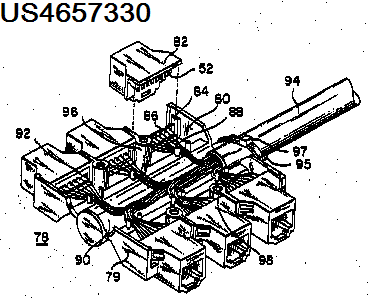

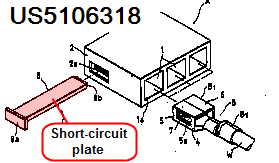

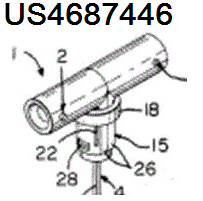

Illustrative example of subject matter classified in H01R 29/00

e.g.: Programmable plugs/sockets;

Plug/socket comprising a fixed wiring pattern insertable in a counterpart.

This place covers:

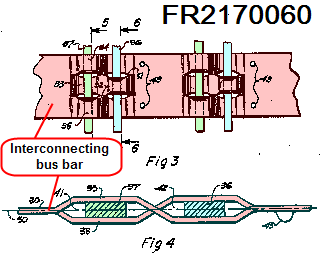

Linking part forming an intermediate coupling mean between the two parts of coupling devices.

This place does not cover:

For linking coupling parts that cannot co-operate | |

With a holder adapted for supporting apparatus to which its counterpart is attached |

This place does not cover:

With a holder adapted for supporting apparatus to which its counterpart is attached |

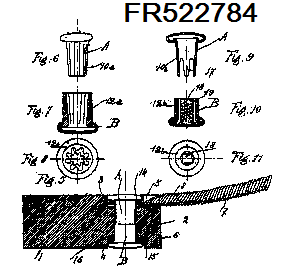

This place covers:

Coupling devices specially adapted for supporting, holding and electrically connecting with an apparatus.

This place does not cover:

For starters only |

This place does not cover:

For two-pole devices |

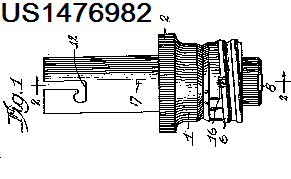

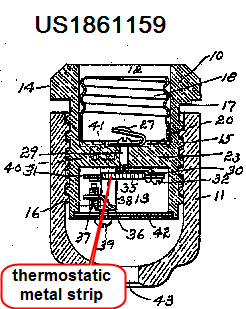

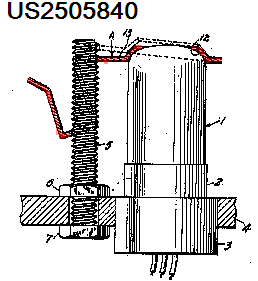

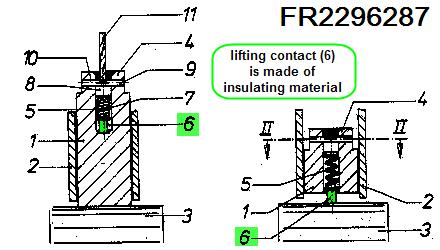

This place covers:

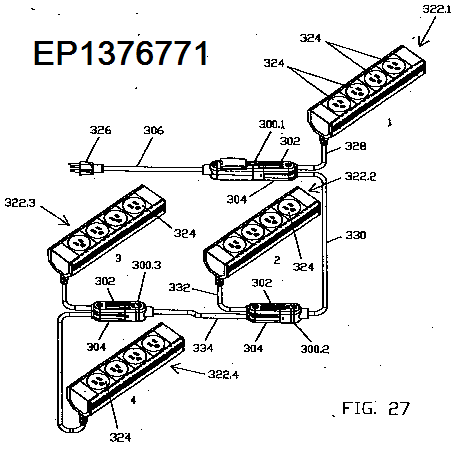

Illustrative example of subject matter classified in H01R 33/9456

with fuse; with thermal switch

This place covers:

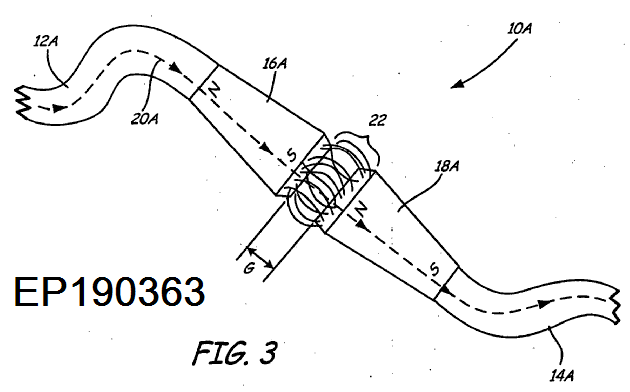

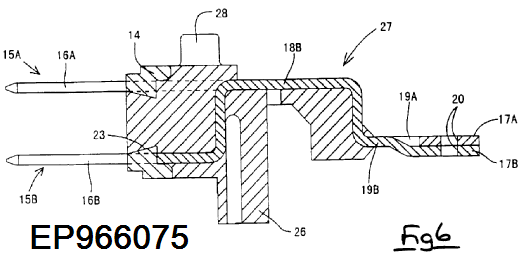

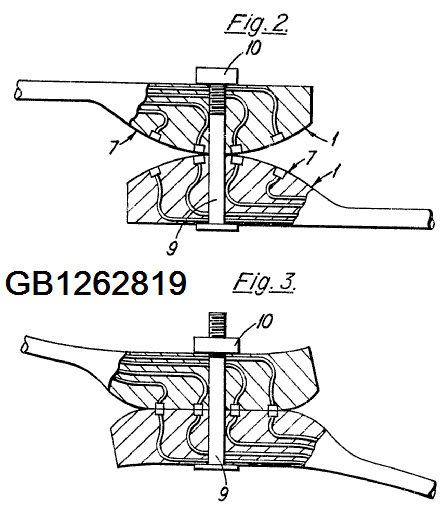

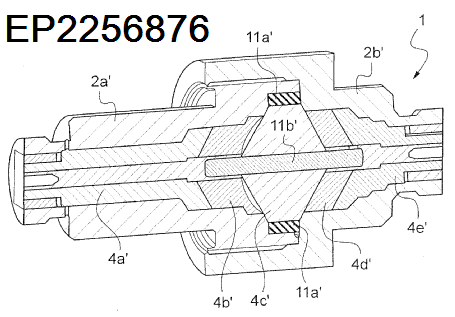

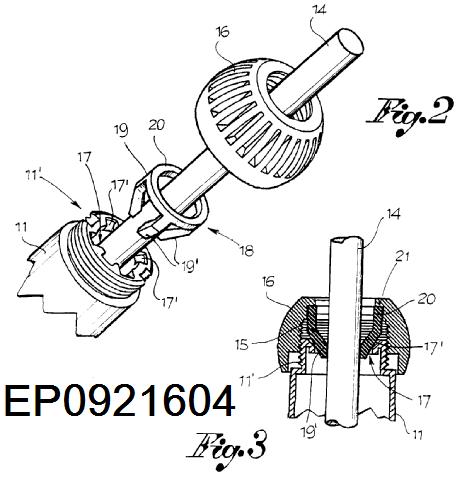

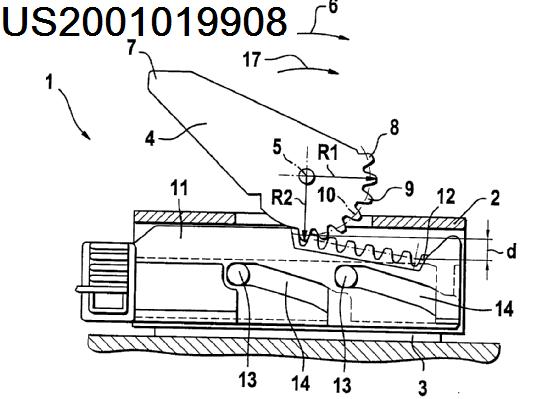

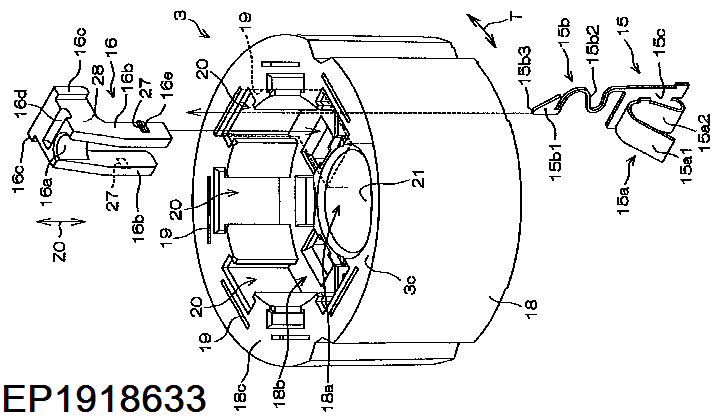

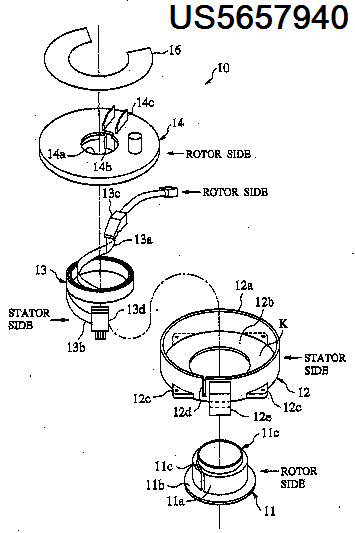

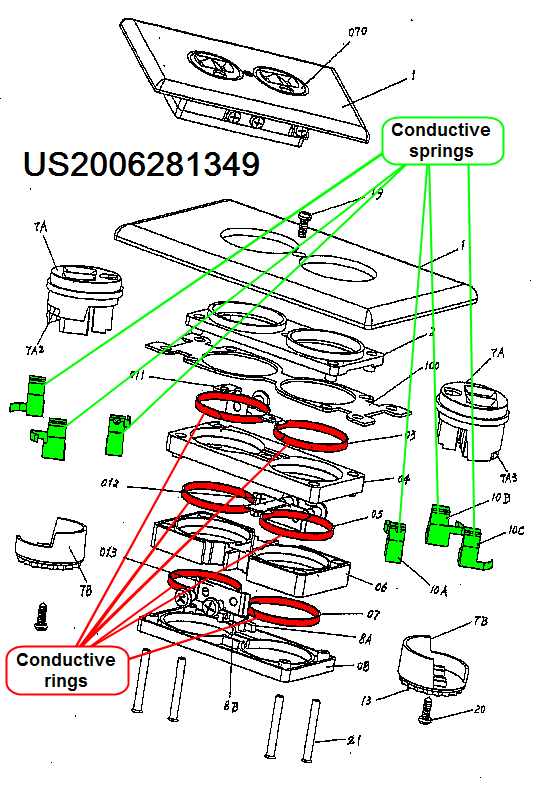

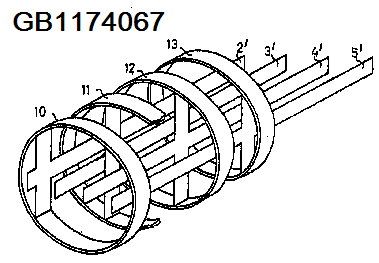

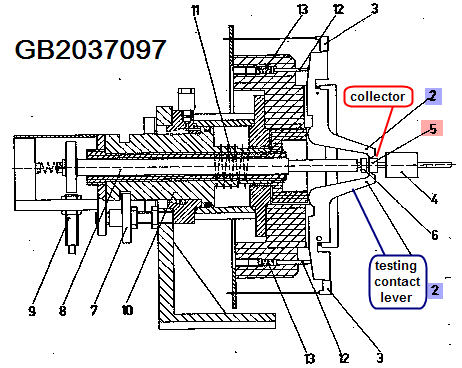

Rotary coupling devices allowing limited motion between the moving and the stationary parts.

This place does not cover:

Rotary current collectors, distributors |

Attention is drawn to the following places, which may be of interest for search:

Arrangement of these connectors in vehicle steering wheels | |

Arrangements of electric cables or lines between relatively movable parts |

This place covers:

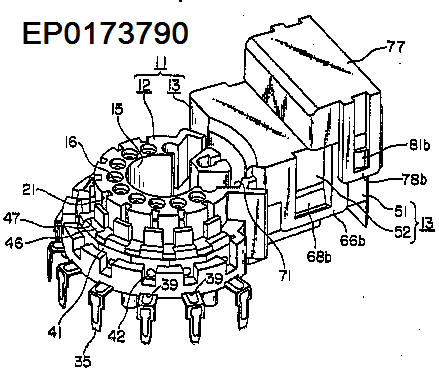

Turnable connectors with unlimited rotation angle.

Attention is drawn to the following places, which may be of interest for search:

Cam-operated switches | |

Structural association with dynamo-electric machine |

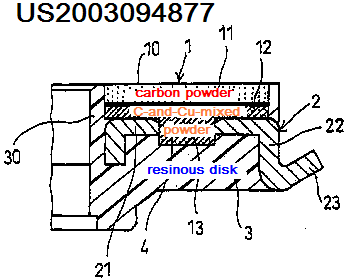

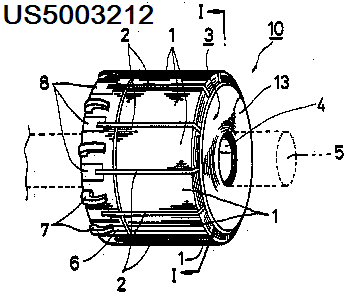

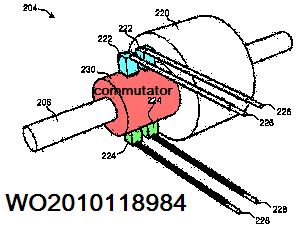

This place does not cover:

For current collectors not particulary for dynamo electric machines |

Attention is drawn to the following places, which may be of interest for search:

Commutators wherein the segments are formed by extensions of dynamo-electric machine winding |

This place does not cover:

Means structurally associated with the current collector for indicating condition thereof |

Attention is drawn to the following places, which may be of interest for search:

Self-interrupters | H01H, e.g. H01H 51/34 |

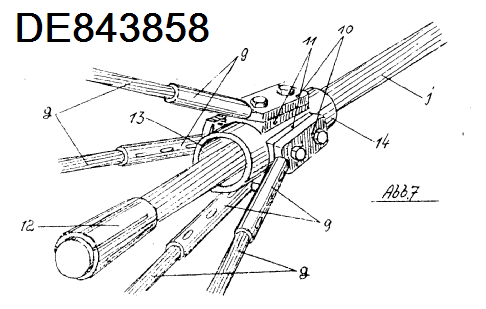

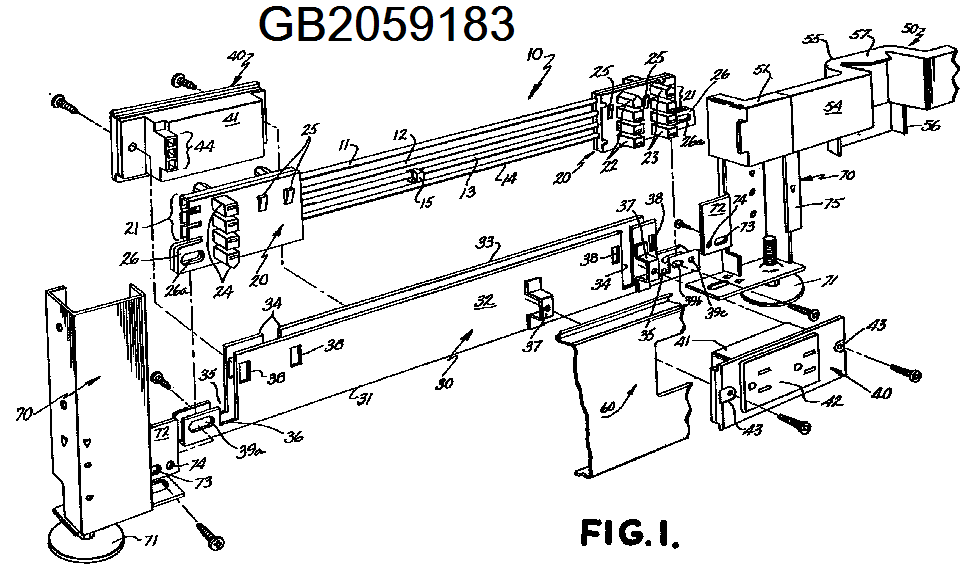

This place covers:

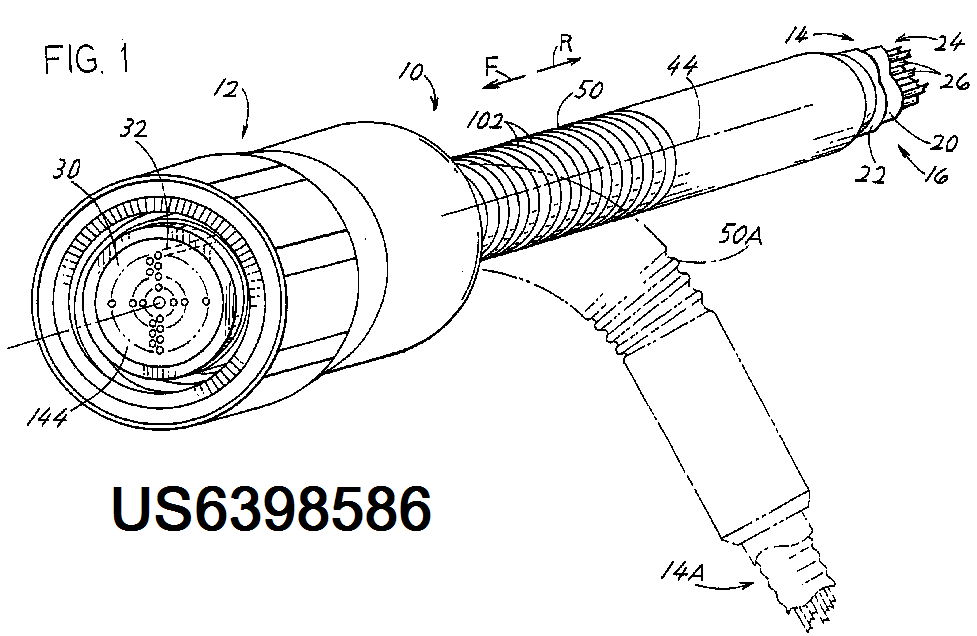

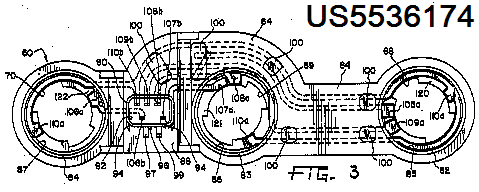

Non-rotary current collectors allowing limited or unlimited movement between moving and stationary parts.

This place does not cover:

End pieces terminating in a hook or the like |

Attention is drawn to the following places, which may be of interest for search:

Current collectors for power supply lines of electrically-propelled vehicles |

Attention is drawn to the following places, which may be of interest for search:

Electrically-operated selector switches |

This place does not cover:

Joining electric conductors of trolley lines |

Attention is drawn to the following places, which may be of interest for search:

Joining cables |

This place does not cover:

Apparatus or processes specially adapted for soldered or welded connections without preliminary removing of insulation before soldering or welding |

This place does not cover:

Apparatus or processes specially adapted for soldered or welded connections without preliminary removing of insulation before soldering or welding |

This place does not cover:

Apparatus or processes specially adapted for soldered or welded connections without preliminary removing of insulation before soldering or welding |

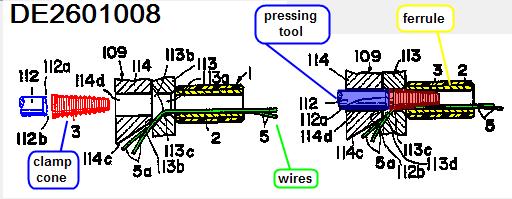

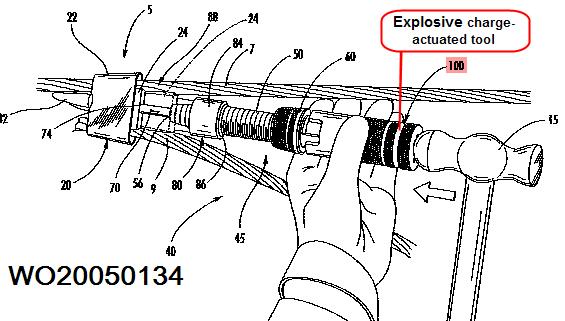

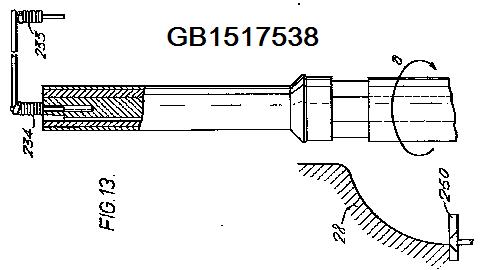

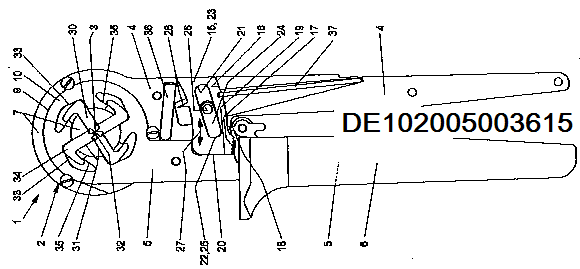

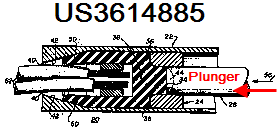

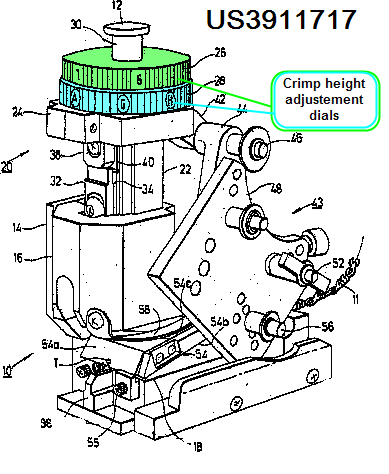

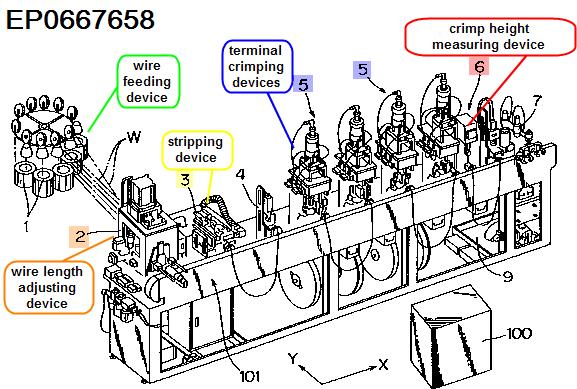

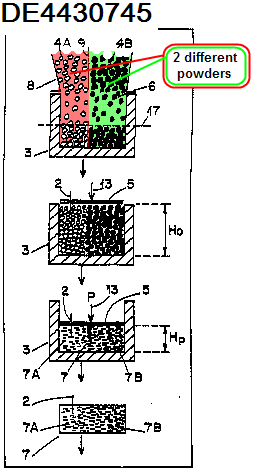

This place covers:

This group covers all kind of apparatus, processes, methods specially adapted for forming electrical connections by deformation.

This place covers:

All kind of apparatus, processes, methods specially adapted for forming electrical connections by crimping.

This place does not cover:

Hand tools for crimping |

This place does not cover:

Structural association with two-part coupling device |

This place does not cover:

Apparatus or processes specially adapted for soldered or welded connections | |

Apparatus or processes specially adapted for connecting conductors by clips | |

Apparatus or processes specially adapted for wrapping or unwrapping wire connections | |

Apparatus or processes specially adapted for forming connections by deformation | |

Manufacture of commutators | |

Manufacture of slip-rings | |

Manufacture of brushes | |

Maintenance of current collectors | |

Apparatus or processes specially adapted for manufacturing contact members | |

Apparatus or processes specially adapted for manufacturing bases or cases for contact members | |

Apparatus or processes specially adapted for assembling or disassembling contact members with insulating base, case or sleeve | |

Apparatus or processes specially adapted for engaging or disengaging the two parts of a coupling device |