CPC Definition - Subclass H02N

This place covers:

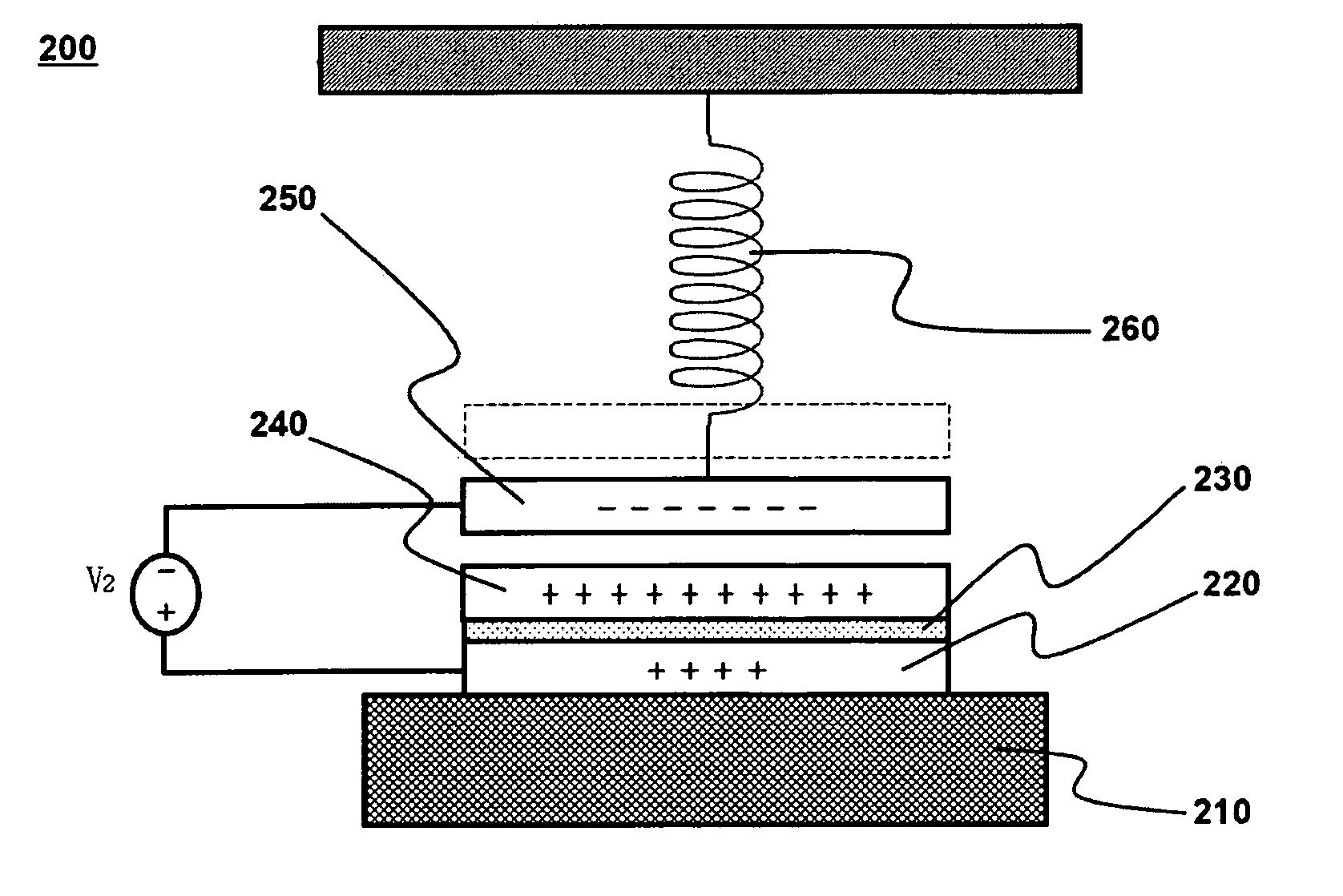

Electrostatic generators, motors, clutches, or holding devices;

Other non-dynamo-electric generators or motors;

Holding or levitation devices using magnetic attraction or repulsion;

Arrangements for starting, regulating, braking, or otherwise controlling such machines unless in conjoint operation with a second machine.

This place does not cover:

Switches making use of micromechanics | |

Electrostatic relays; Electro-adhesion relays | |

Making use of micromechanics |

Attention is drawn to the following places, which may be of interest for search:

Reflecting element being a micromechanical device and being moved or deformed by electrostatic means |

Electroactive polymers: see rules of classification in H02N 1/006

This place covers:

electrostatic actuators:

This place does not cover:

Electrostatic motors, in which a body is moved along a path due to interaction with an electric field travelling along the path |

Attention is drawn to the following places, which may be of interest for search:

Electro-chemical actuators |

The electroactive polymers (EAPs) are of three types:

1) The EAPs based on some electrochemical effect inside the polymer (e.g. or i.e. ionic EAPs). Electric machines with the same are classified in F03G 7/00.

2/3) The EAPs based on electrostrictive, or electrostatic (or a combination of electrostrictive and electrostatic) effects. Electric machines based on electrostrictive / electrostatic EAPs are classified in H02N 2/00.

This place covers:

Comb shaped motors the direction of movement is parallel to the extension direction of the comb teeth, among others

This place does not cover:

Details of microelectro-mechanical resonators | |

Constructional features of microelectro-mechanical resonators of material which is not piezoelectric, electrostrictive, or magnetostrictive |

Attention is drawn to the following places, which may be of interest for search:

Details of microelectro-mechanical resonators |

Comb shaped motors with oscillating movement are classified in H02N 1/006

This place covers:

Including conveyor belt carrying conductive charge carriers charged by induction, i.e. like capacitors.

This place does not cover:

Machines of the corona charging type in which an (usually) insulating belt is charged by charges generated by corona effect |

Influence type generators built as a conveyor belt can be of two types (according to the way the belt is charged): induction charging type and corona charging type.

The corona charging type usually comprises an insulating belt charged by charges generated by corona effect. This type of machine is classified in H02N 1/12 (even if the belt comprises some conductive element)

The induction charging type are a conveyor belt version (i.e. a linear version) of capacitor machines in which conductive charge carriers are charged by induction ( i.e. like capacitors). This type of machine is classified in H02N 1/08.

This place covers:

Machines of the corona charging type in which an (usually) insulating belt is charged by charges generated by corona effect. (if the belt contains some conductive element see Special Rules of Classification).

This place does not cover:

Machines of the induction charging type i.e. in which the belt carries conductive charge carriers charged by induction |

Influence type generators built as a conveyor belt can be of two types (according to the way the belt is charged): induction charging type and corona charging type.

The corona charging type usually comprises an insulating belt charged by charges generated by corona effect. This type of machine is classified in H02N 1/12 (even if the belt comprise some conductive element)

The induction charging type are a conveyor belt version (i.e. a linear version) of capacitor machines in which conductive charge carriers are charged by induction ( i.e. like capacitors). This type of machine is classified in H02N 1/08.

This place covers:

Electric motors or generators using piezoelectric (PE) or magnetostriction (MS) devices described under H10N 30/00 as primary motion producing or electricity generating parts. In particular:

Linear or rotary motors, including positioners or actuators, based on at least one PE or MS device in cooperation with at least one driven element as mechanical output, e.g. a rotor or translating shaft. The motors can operate based on standing or travelling waves or quasi-static deformation generated by said PE or MS devices;

Generators based on at least one PE or MS device in cooperation with at least one driving element as mechanical input;

Aspects such as the operating principle, mechanical construction built around said PE or MS devices, driving or control circuits or methods, and methods relating to manufacturing of the engines.

Further information:

In this group the PE or MS devices are seen as black boxes which could in principle be replaced by any device of equal electromechanical conversion functionality.

If no relevant details of the PE or MS devices themselves are given classification is done only in this group. If particular details of the PE or MS devices are concerned, e.g. these devices appear to be relevant to other technical fields as well, classification in H10N 30/00 is required. If no details other than the PE or MS devices themselves are described, e.g. PE stacks or benders are just called actuators or generators, classification is done only in H10N 30/00.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Mechanical vibration generators | |

Adjustable work or tool supports in machining tools, e.g. motorised platforms | |

Hair clippers; Shavers | |

Typewriters | |

PE generators - in tyre sensors- in spark lighters - in firing or trigger mechanisms of weapons - for measurement devices- in photographic flash ignition | B60C 23/0411, F23Q 2/287, F23Q 3/002, F41A 19/62, G01, G03B 15/0463 |

Fuel injection in combustion engines - Control circuits or methods for injectors - Injectors- Injection valves | |

Pumps - Diaphragm type micropumps - Tube type- Oscillatory type, e.g. fans | |

Brakes | |

Adjustable optical elements, e.g. motorised lenses or objectives |

Attention is drawn to the following places, which may be of interest for search:

Electrostatic motors or generators | |

Motors using thermal drive effects | |

Motors or generators not provided for elsewhere; Alleged electric or magnetic perpetua mobilia | |

Liquid wave driven, e.g. ocean powered, generators | |

Oscillatory wind driven generators | |

Oscillatory dynamo-electric generators | |

PE or MS devices in general, e.g. PE stacks or benders; Structural details and fabrication thereof |

In this group, in the absence of an indication to the contrary, an invention is classified in the last appropriate place.

In this place, the following terms or expressions are used with the meaning indicated:

Motor | Apparatus producing mechanical motion from electrical energy, the motion may be continuous or in separate strokes ;The term includes thus actuators or positioners, wherein the driven element is movable along a certain linear or angular stroke (limited stroke motors) |

Ultrasonic motor | PE or MS motor operating in ultrasonic frequency range |

perpetua mobilia | latin expression for devices having perpetual motion |

BAW | Bulk acoustic wave |

EAP | Electroactive polymer |

MEMS | Microelectromechanical system |

MS | Magnetostrictive |

PE | Piezoelectric or electrostrictive |

PEG | Piezoelectric generator |

SAW | Surface acoustic wave |

USM | Ultrasonic motor |

Travelling wave motorVibration wave motor | PE or MS motor |

This place covers:

Motors wherein the type of motion is irrelevant, e.g. driving devices which may be used to advance a driven body in arbitrary directions, and details thereof.

This place does not cover:

Attention is drawn to the following places, which may be of interest for search:

Friction linings | |

Springs in general | |

Casings for dynamo-electric machines |

This place covers:

Linear motors comprising at least two clamping devices and one intermediate driving device which are excited in sequence to grip and move a driven body.

This place covers:

Linear motors comprising a driving device which is excited asymmetrically during multiple phases such that in one phase the static friction between a driven body and its support is overcome, thereby effecting a sliding motion between them.

This place covers:

Linear motors wherein a driven body, e.g. a translating rail, is moved by vibrations of one or more vibrators pressed against the driven body.

This place does not cover:

Details of the vibrator |

This place covers:

Linear motors wherein a driven body is moved by Rayleigh type surface acoustic waves only.

This place covers:

Rotary motors wherein a rotor is moved by vibrations of one or more vibrators pressed against the rotor.

This place does not cover:

Details of the vibrator |

This place covers:

Rotary motors wherein a cycloid type motion of a rotor is caused by radial or tangential driving devices excited in different phases.

This place covers:

Rotary motors wherein a substantially rod-shaped vibrator excited to axial vibrations, e.g. a longitudinal mode, combined with lateral vibrations, e.g. a bending or torsion mode, creates a hula-hoop like progressive wave on its surface, thereby driving a rotor.

This place covers:

Rotary motors wherein a rotor is moved by Rayleigh type surface acoustic waves only.

This place covers:

Generators based on the collection of free electrical charges in the flow. e.g. inonized gas in a thermal engine exhaust.

This place does not cover:

Discharge tubes functioning as thermionic generators | |

Use of naturally-occurring electricity, e.g. lightning or static electricity |

This place covers:

Devices working around the Curie point.

This place does not cover:

Radiation pyrometers | |

Thermometers using thermo-electric or thermomagnetic elements | |

Selection of materials for magnetography, e.g. for Curie-point writing | |

Thermomagnetic generators, e.g. ;using Nernst-Ettinghausen effect (plurality of solid state components formed in or on a common substrate) | |

Using thermal change of magnetic permeability, e.g. working above and below the Curie point |

Attention is drawn to the following places, which may be of interest for search:

Mechanical-power-producing mechanisms using a shape memory alloy |

Attention is drawn to the following places, which may be of interest for search:

Alleged perpetua mobilia obtained by hydrostatic pressure | |

Alleged perpetua mobilia obtained by mechanical means | |

Alleged perpetua mobilia obtained by dynamo-electric means, including arrangements of permanent magnets interacting with other permanent magnets |

In this place, the following terms or expressions are used with the meaning indicated:

perpetua mobilia | latin expression for devices having perpetual motion |

This place does not cover:

Radiation pyrometers | |

Thermometers using thermo-electric or thermomagnetic elements | |

Selection of materials for magnetography, e.g. for Curie-point writing | |

Electrochemical current or voltage generators | |

Thermoelectric generators comprising a junction of dissimilar materials, i.e. exhibiting Seebeeck or Peltier effect with or without other thermo-electric effects or thermomagnetic effects | |

Thermomagnetic generators, e.g. using Nernst-Ettinghausen effect (plurality of solid state components formed in or on a common substrate) | |

Using thermal change of magnetic permeability, e.g. working above and below the Curie point |

This place does not cover:

Actuators with elements stretchable when contacted with liquid rich in ions, with UV light, with a salt solution | |

Actuators having a material for absorbing or desorbing gas, e.g. a metal hydride | |

Electro-chemical actuators | |

Actuators using the difference in osmotic pressure between fluids |

Electroactive polymers: see rules of classification in H02N 1/006

This place does not cover:

Perpetua mobilia obtained by the reciprocal attraction / repulsion of a system of magnets arranged as the coils and or the magnets of the normal electrodynamic machines, including systems comprising only permanent magnets |

Attention is drawn to the following places, which may be of interest for search:

Supporting structures for apparatus specially adapted for handling semiconductors using electrostatic chucks |

Attention is drawn to the following places, which may be of interest for search:

Electric or magnetic devices for holding work on machine tools | |

Monorail vehicle propulsion or suspension | |

Sliding or levitation devices for railway systems | |

Material handling devices associated with conveyors incorporating devices with electrostatic or magnetic grippers | |

Separating thin or filamentary articles from piles using magnetic force | |

Delivering thin or filamentary articles from magnetic holders by air blast or suction | |

Bearings using magnetic or electric supporting means | |

Relieving bearing loads using magnetic means | |

Magnets | |

Apparatus specially adapted for handling semiconductor using electrostatic chucks | |

Details of electrostatic chucks | |

Dynamo-electric clutches or brakes | |

Electric furnaces with simultaneous levitation and heating |

Attention is drawn to the following places, which may be of interest for search:

Superconductors or hyperconductors in general |