CPC Definition - Subclass B21B

This place covers:

Methods and devices for rolling of metal.

Rolling is a metal forming process in which metal is passed through a pair of rotating rolls for plastic deformation of the metall. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is termed as hot rolling. If the temperature of the metal is below its recrystallization temperature, the process is termed as cold rolling.

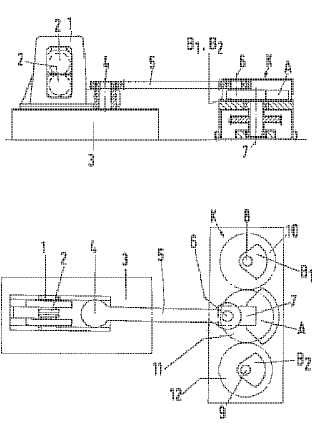

A rolling mill is a machine for plastic deformation of metal between rotating rolls. In a broader sense, a rolling mill is an automatic system or line of machines that performs both rolling and auxiliary operations: transport of the original billet from the stock to the heating furnaces and the mill rolls, transfer of the rolled material from one groove to another, turning, transport of the metal after rolling, cutting into sections, marking or stamping, trimming, packing, and conveyance to the stock of finished product.

This subclass includes the following main groups:

Rolling of metal in general:

- Methods or devices in general

- Control

- Measuring

- Operation

- Details of rolling mills

- Maintenance of rolling rolls

- Safety devices

- Cooling beds and accessories

Rolling of special formats:

- tube rolling

- accessories for tube rolling

- Extending closed shapes of metal bands

Rolling of special alloys:

Rolling of metal under special conditions (e.g. in vacuum or inert atmosphere):

Auxiliary measures for metal rolling:

This place does not cover:

Descaling of rod or wire | |

Separating tubes from mandrel | |

Technical details of coiling/ uncoiling devices | |

Technical details of devices for temporarily accumulating material | |

Manufacture of particular objects by rolling, e.g. screws, wheels, rings, barrels, balls |

Attention is drawn to the following places, which may be of interest for search:

Cleaning in general | |

Measuring, gauging, indicating, counting, or marking devices adapted for use in the production or manipulation of material in accordance with subclasses B21B - B21F | |

Working of metal otherwise than by rolling, punching | |

Casting | |

Welding | |

Relatively slidable coverings | |

Flexible coverings | |

Conveying or transporting in general | |

Altering the metallurgical properties of metal by heat treatment or by hot or cold working | |

Composition of alloys | |

Calendar rolls for paper- making machines | |

Fixed or movable closings | |

Bearings in general | |

Couplings, clutches, brakes | |

Sealings | |

Frames, casings, stands, supports in general | |

Safety devices in general | |

Heat recovering devices | |

Furnaces | |

Measuring instruments |

This place covers:

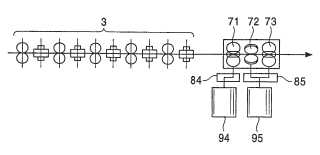

Continuous rolling processes |

|

Semi- continuous rolling process |

|

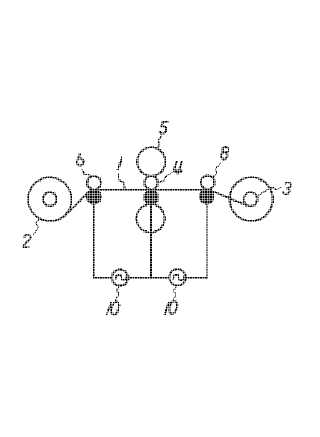

Reverse rolling |

|

Steckel mill rolling |

|

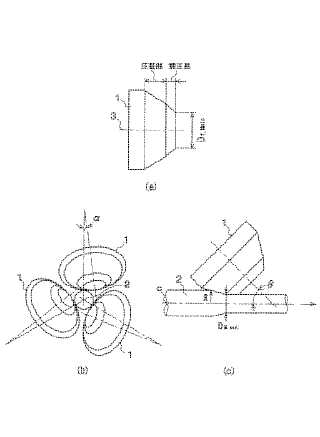

Skew rolling of wire or like small cross section" |

|

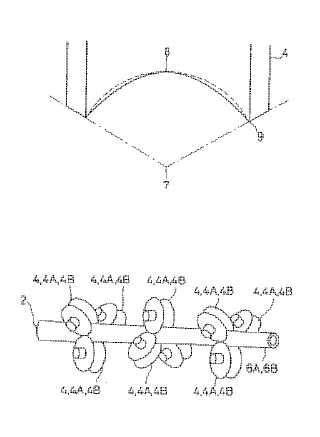

Planetary cross rolling of wire or like small cross section" |

|

Step-by-step rolling |

|

Planetary rolling |

|

"Rolling cladded products" |

|

Rolling metal immediately subsequent to continuous casting |

|

This place does not cover:

Rolling of materials of special alloys so far as the composition of the alloy requires special rolling methods or sequences | |

Extending closed shapes of metal bands by simultaneous rolling at two or more zones | |

Metal- rolling stands as units | |

Rolling methods or rolling mills for making or processing tube | |

Continuous casting into moulds having walls formed by moving rolls |

This place covers:

Rolling of stainless steel and of powder metal alloys and other metal alloys that require apparatus manipulation or special methods not required for regular hot or cold rolling.

Attention is drawn to the following places, which may be of interest for search:

In this place, the following terms or expressions are used with the meaning indicated:

Non-ferrous metal | Fe < 50% |

This place covers:

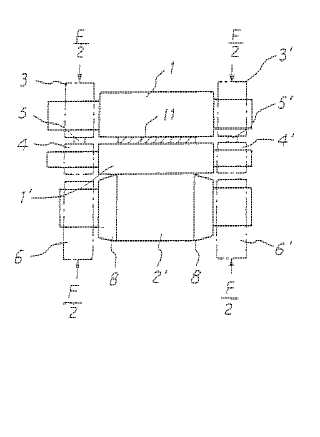

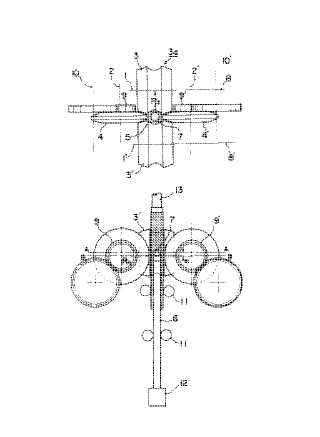

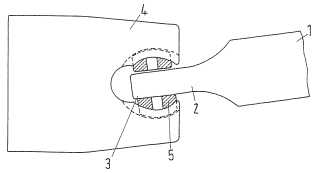

Extending closed shapes of metal bands by rolling the closed shapes between at least two rolls |

|

Attention is drawn to the following places, which may be of interest for search:

Manufacture of circular shapes, e.g. wheel rims |

This place covers:

Rolling in vacuum or in inert atmosphere |

|

Removing fumes from rolling mills |

|

Attention is drawn to the following places, which may be of interest for search:

Frames, casings, stands, supports in general |

This place covers:

Methods and devices for creating vibrations in the work or in the rolling rollers.

Attention is drawn to the following places, which may be of interest for search:

Methods or apparatus for generating mechanical vibrations of infrasonic, sonic, or ultrasonic frequency |

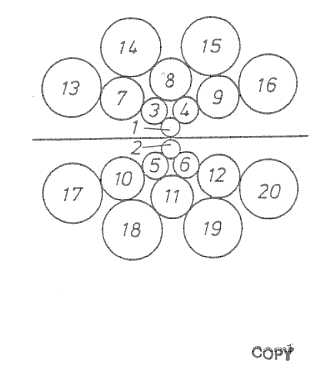

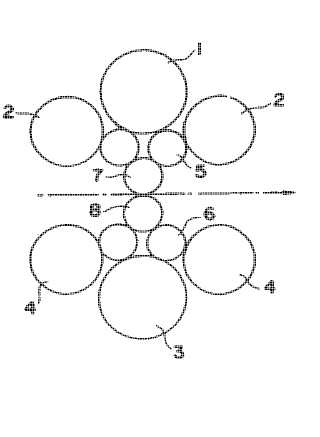

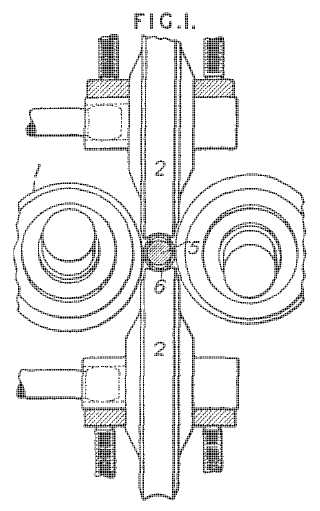

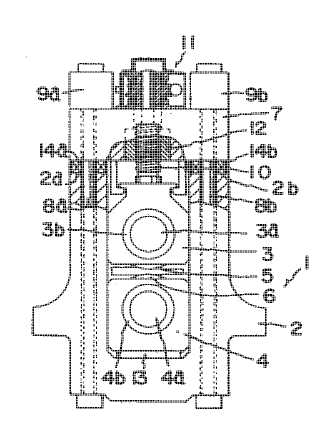

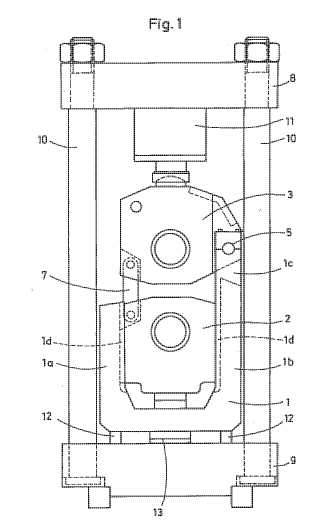

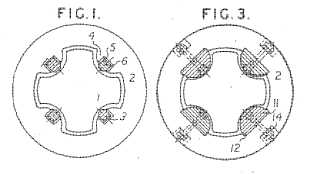

This place covers:

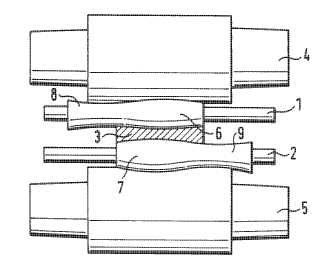

"Cantelever(ed) roll stands" |

|

"Skew rolling stands" |

|

"Cross rolling stands" |

|

" Three- high arrangement" |

|

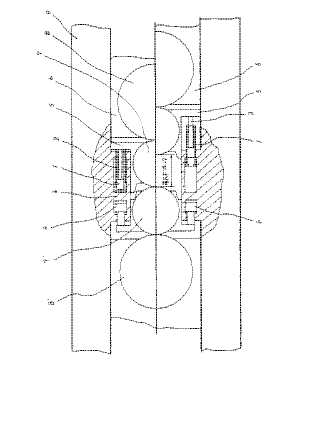

"Sendzimir mills" / "cluster mills" |

|

"Rohn mills" |

|

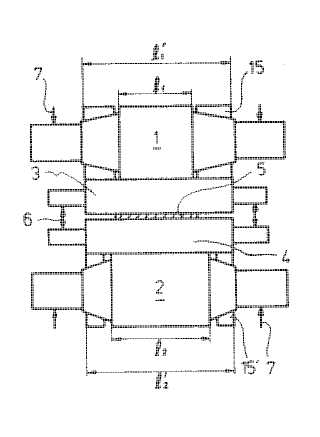

"Universal mills" |

|

Counter pressure devices to inhibit deflection of rolls under load, e.g. back- up rolls |

|

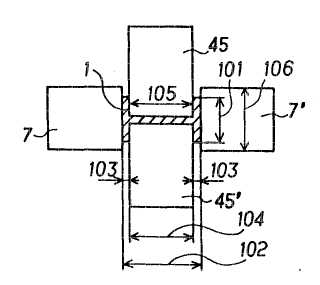

Axially shifting rolls (with tapered ends/ curved contour) |

|

Attention is drawn to the following places, which may be of interest for search:

Rolling methods | |

Counter pressure devices as such, e.g. (hydraulic) bending devices | |

Axially shifting rolls |

Rolling mill stands for tube rolling including Pilger mill stands |

In this place, the following terms or expressions are used with the meaning indicated:

CVC | Continuously Variable Crown |

In patent documents, the following abbreviations are often used:

Z- mill | Sendzimir mill |

This place covers:

Cutting or shearing the product, forging or pressing arrangements, lubricating, cooling or heating means, joining ends of the material. Arrangements when the work is subjected to permanent internal twisting, e.g. when producing reinforcement bars or concrete. Rolling methods or rolling devices specially designed for making or processing tubes.

This place does not cover:

Lubricating, cooling or heating of the rolls | |

Control of tube rolling | |

Lubricating, cooling or heating for surface treatment of the product |

Attention is drawn to the following places, which may be of interest for search:

Welding by means of a rolling mill |

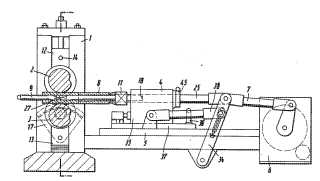

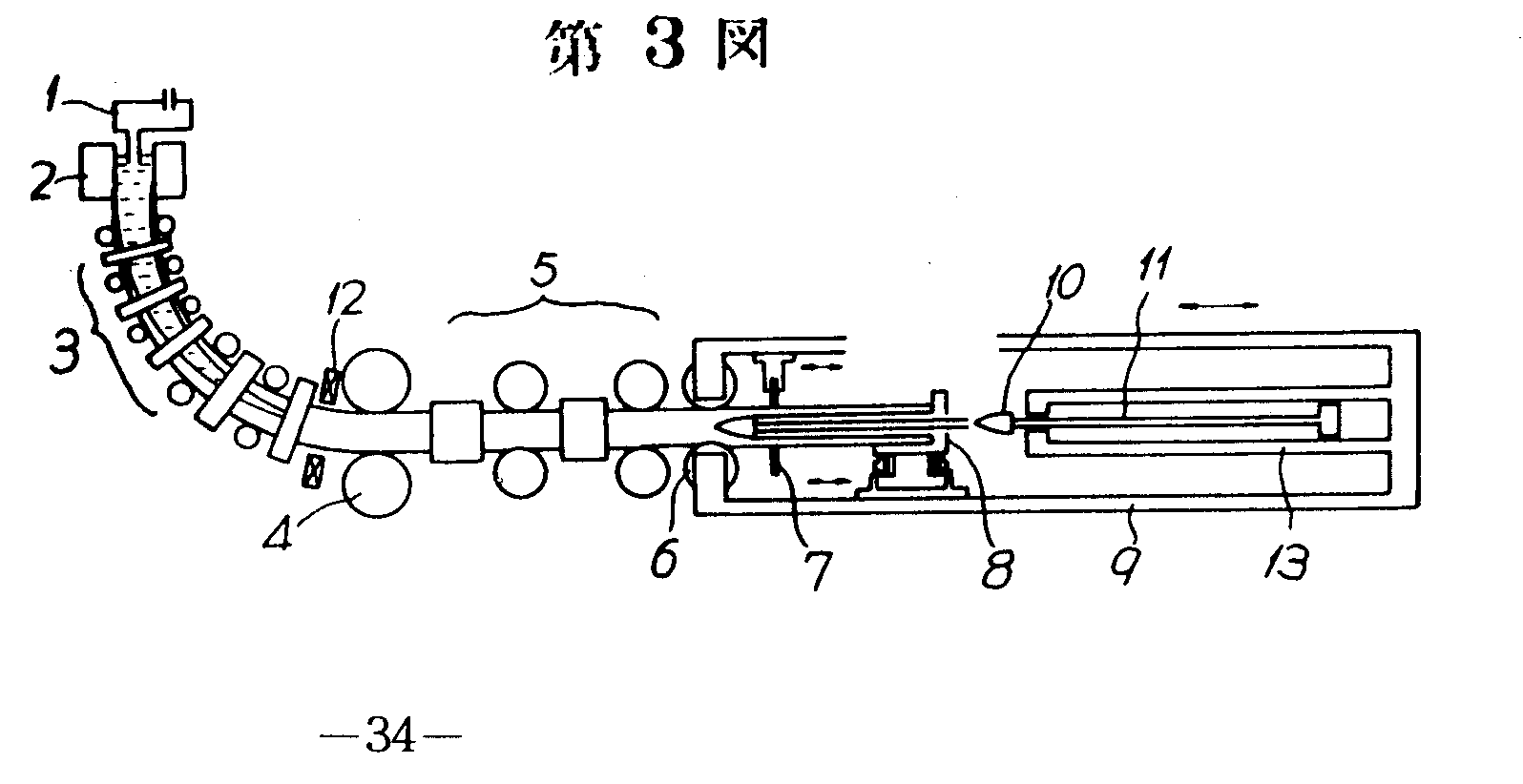

This place covers:

the manufacturing of tubular products by plug rolling, stretch rolling and elongation rolling using mandrels mills, stretch reducing mills and plug rolling mills:

Press- piercing |

|

Plug- rolling/ mandrel plugs |

|

Stretch- reducing |

|

Attention is drawn to the following places, which may be of interest for search:

Making tubes by pilgrim- step rolling | |

Combined processes for tube rolling, tube rolling not restricted to this group only | |

Mandrels for tube rolling, accessories therefore | |

Control of tube rolling | |

Making tubes with welded/ soldered seams seams |

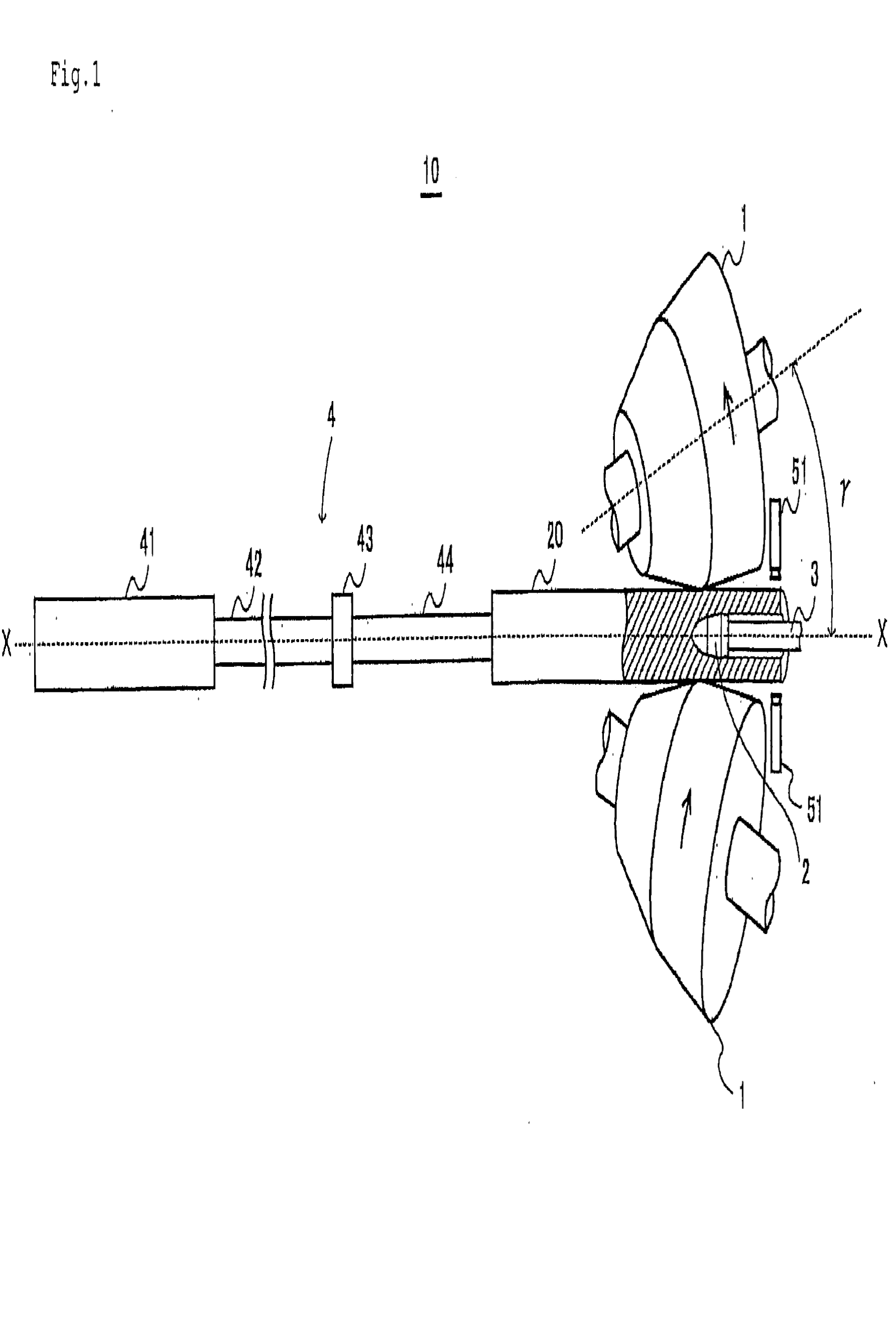

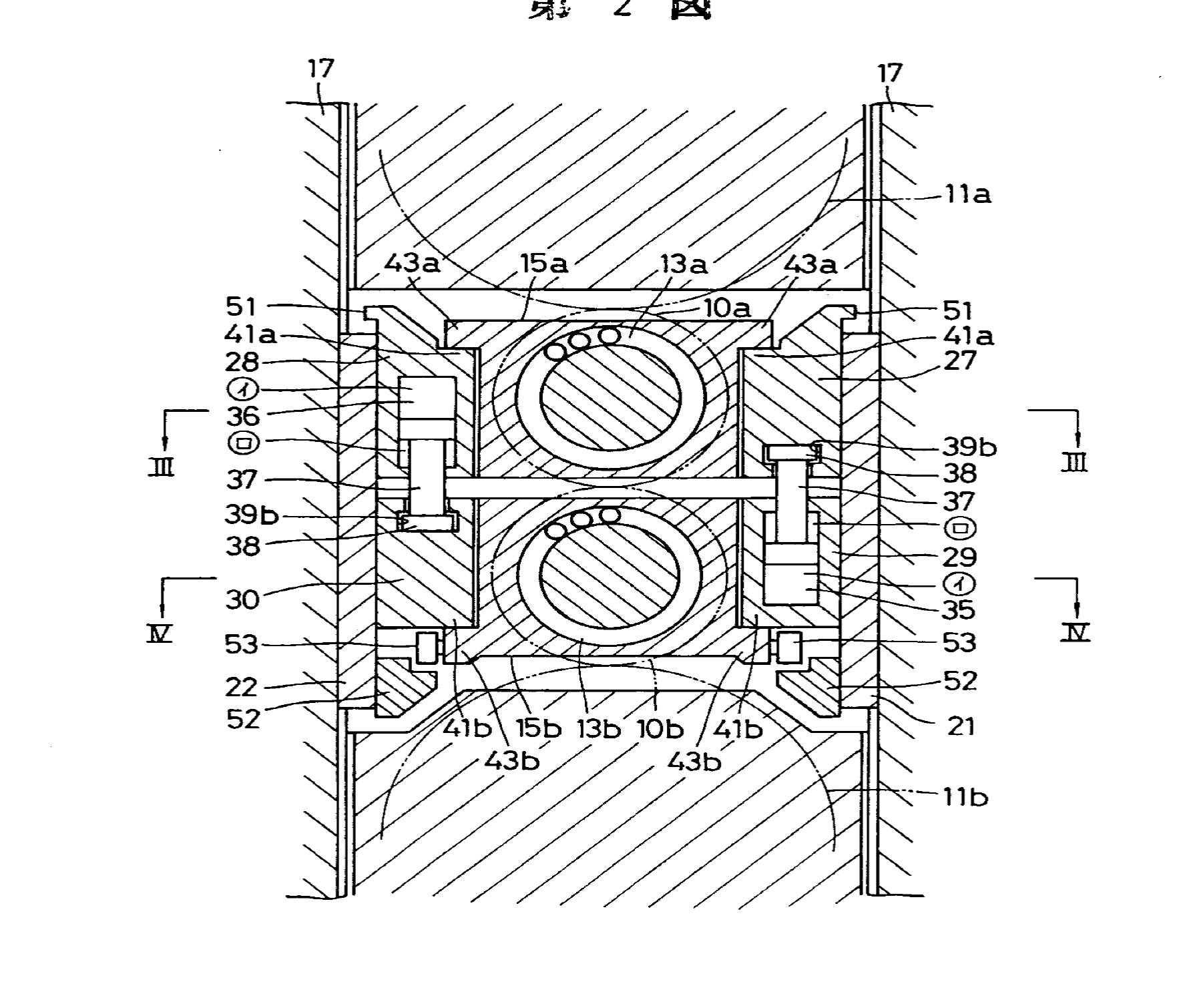

This place covers:

Cross tube rolling (Diescher mills, Stiefel disc piercers, Stiefel rotary piercers) |

|

Piercing rolling |

|

Assel mills |

|

Attention is drawn to the following places, which may be of interest for search:

Making tubes by pilgrim- step rolling | |

Combined processes for tube rolling, tube rolling not restricted to this group only | |

Mandrels for tube rolling, accessories therefore | |

Control of tube rolling | |

Making tubes with welded/ soldered seams |

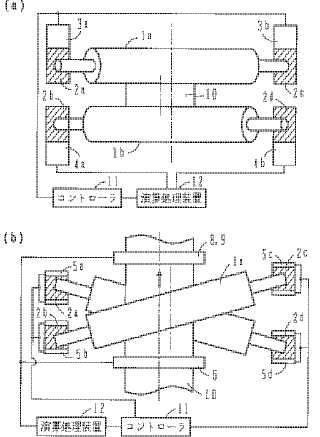

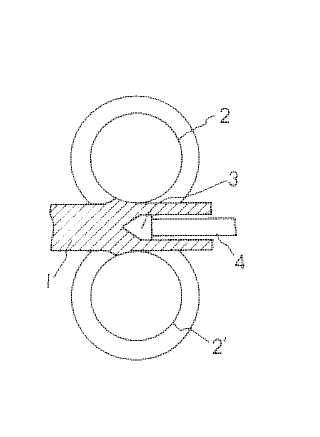

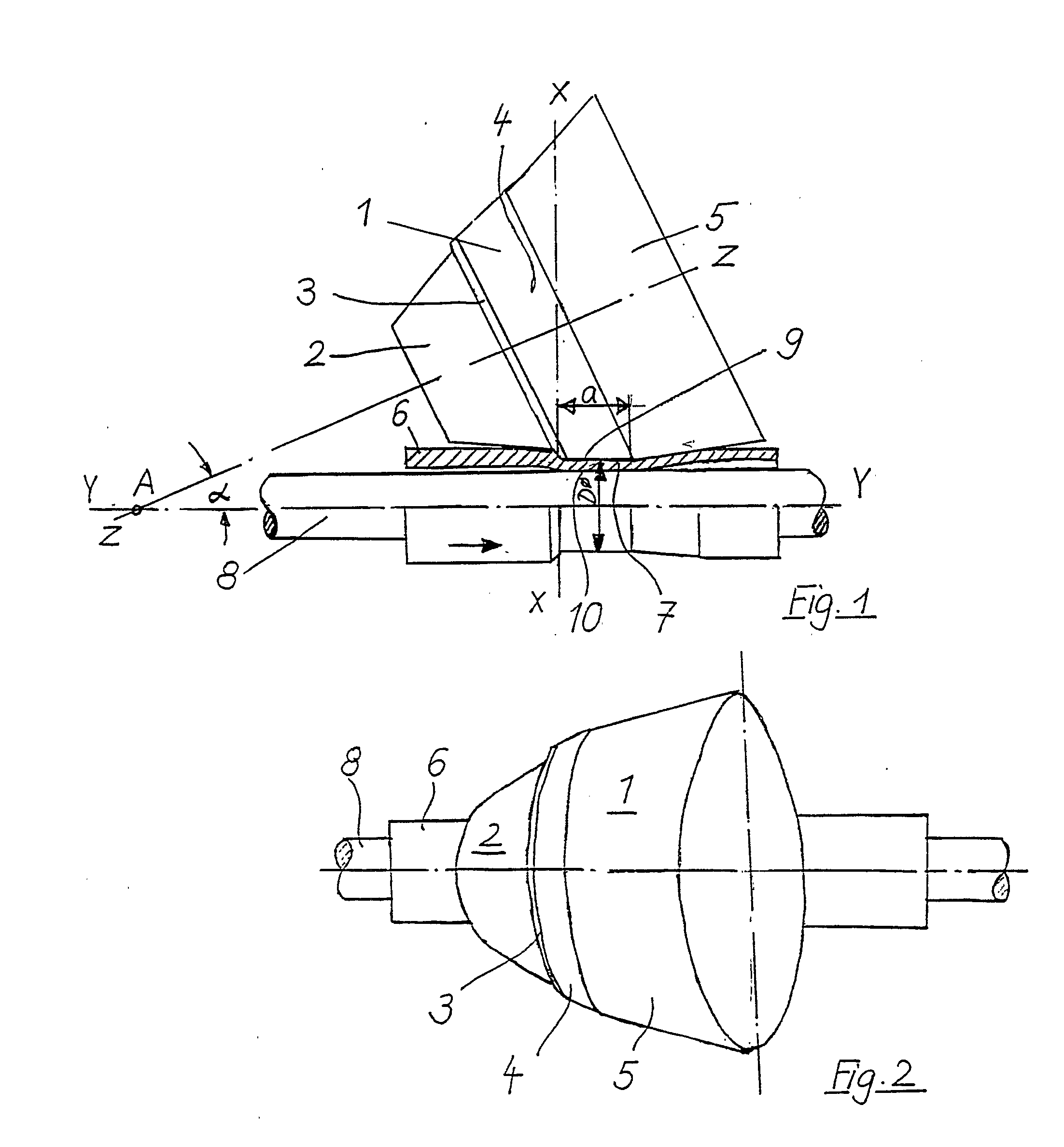

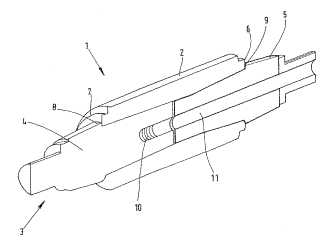

This place covers:

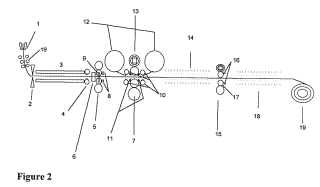

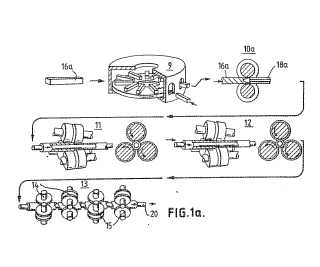

Pilgrim and pilger rolling mills with reciprocation of tubular work through a stationary roll stand or reciprocation of a rolling stand over a tube:

Pilgrim- step rolling with reciprocating the work |

|

Pilgrim- step rolling rolling with reciprocating stands |

|

Attention is drawn to the following places, which may be of interest for search:

Combined processes for tube rolling, tube rolling not restricted to this group only | |

Control of tube rolling |

In patent documents, the following abbreviations are often used:

Pilgrim- step rolling (mill) | pilger rolling (mill) |

This place covers:

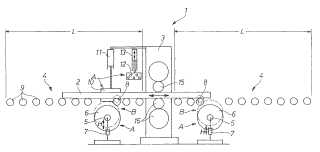

Combined tube rolling processes not restricted to methods provided for in only one of groups B21B 17/00, B21B 19/00, B21B 21/00, i.e. if the order or combination of different operations is of importance |

|

Auxiliary arrangements for tube rolling as e.g. lubricating the tube |

|

Continuous casting combined with tube rolling |

|

This place does not cover:

Tube-rolling by rollers of which the axes are arranged essentially perpendicular to the axis of the work, e.g. "axial" tube-rolling | |

Tube-rolling by rollers arranged outside the work and having their axes not perpendicular to the axis of the work | |

Pilgrim-step tube-rolling, i.e. pilger mills |

Attention is drawn to the following places, which may be of interest for search:

Mandrels for tube rolling, accessories therefore | |

Making tubes with welded/ soldered seams |

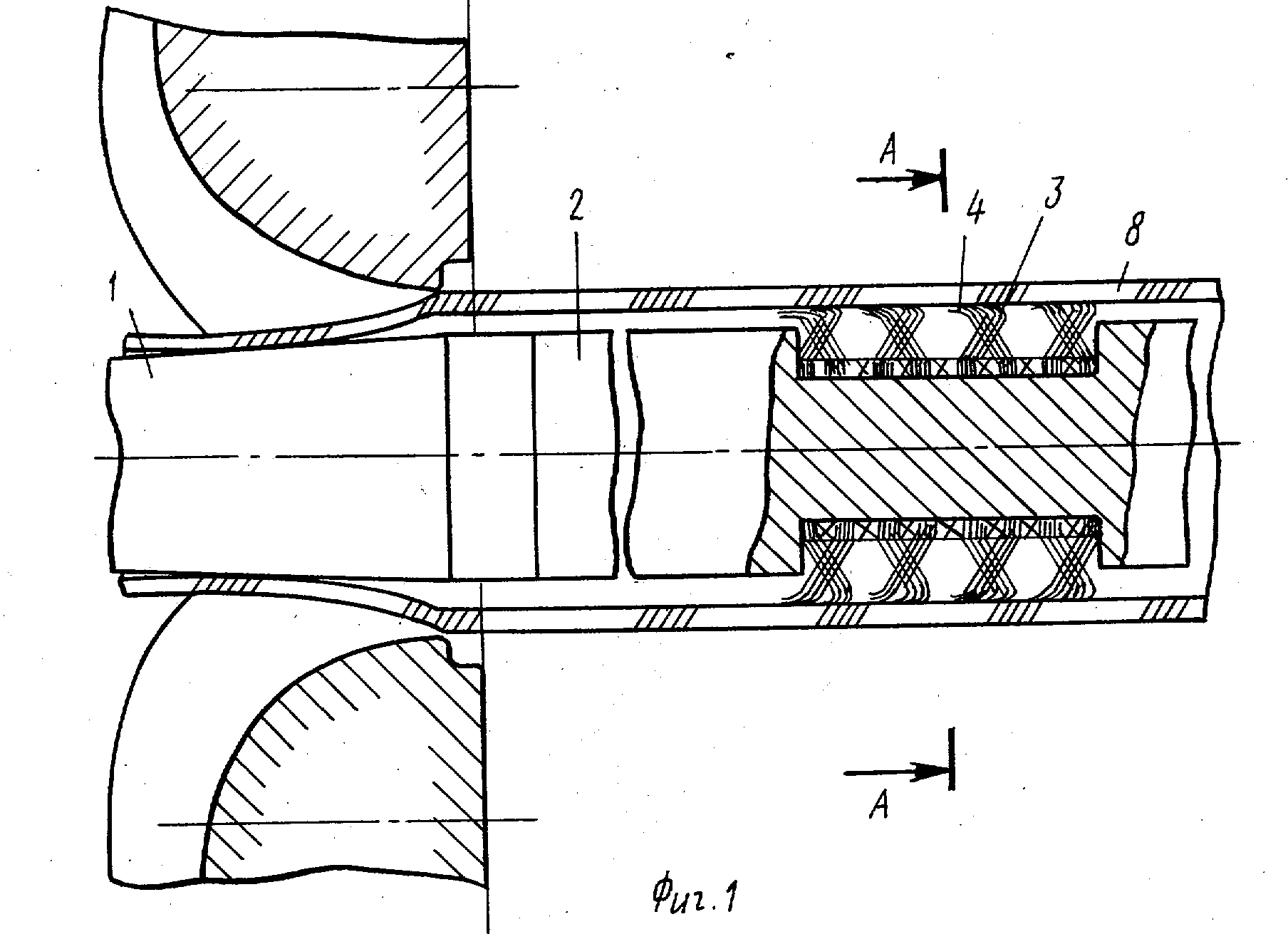

This place covers:

Construction and form of mandrels and plugs for rolling tubes and alloys for manufacturing such mandrels or plugs. Guides, supports or abutments for mandrels. Adjusting devices for mandrels. Cooling or lubricating mandrels during operation. Interchanging mandrels/ mandrel plugs. Cooling during interchanging mandrels.

Attention is drawn to the following places, which may be of interest for search:

Separating tubes from mandrel |

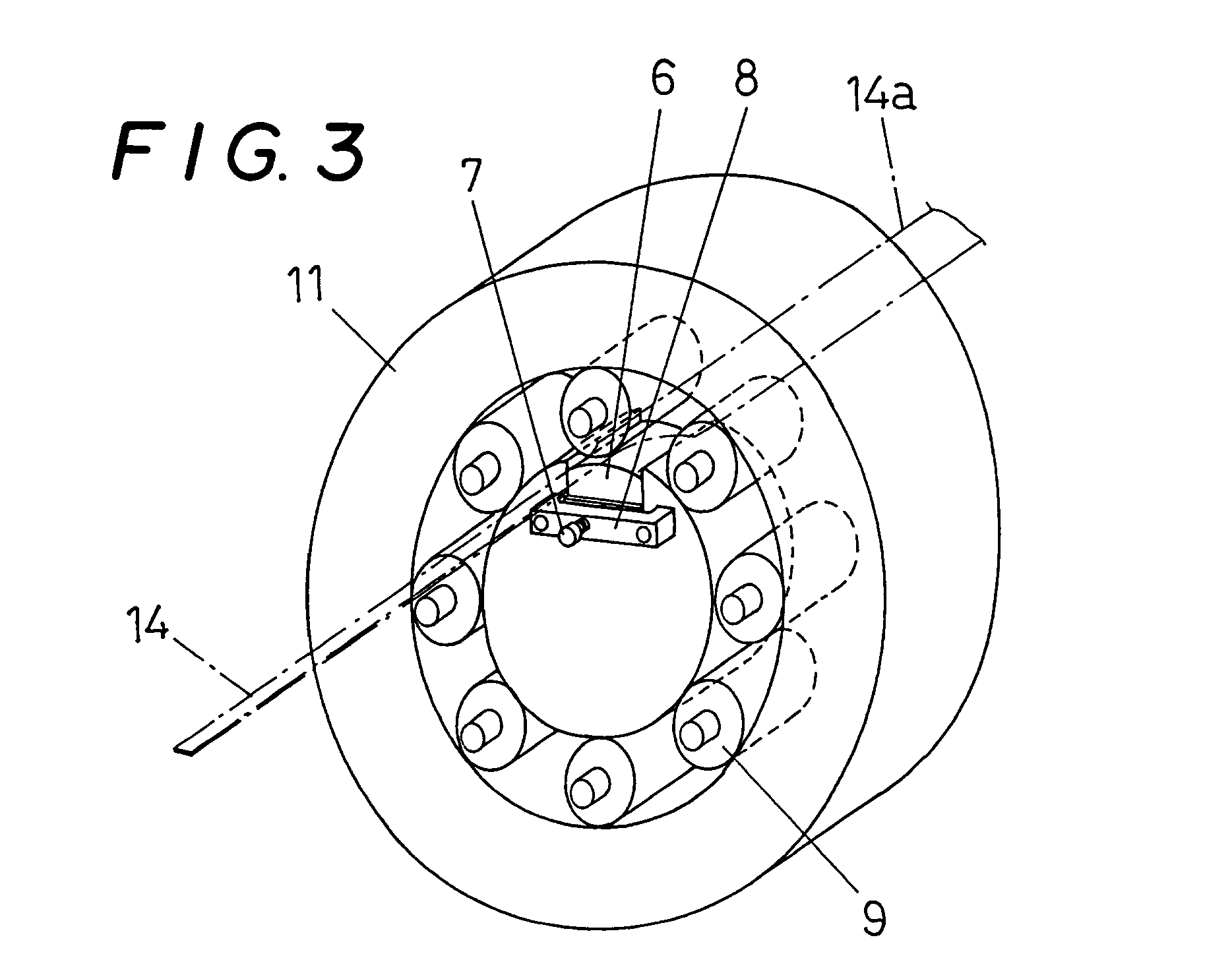

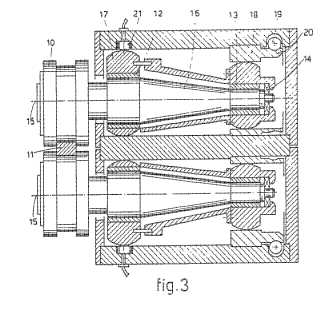

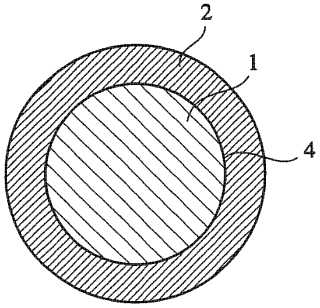

This place covers:

Shape or construction of rolls for rolling sheets, strips, bars, rods, rounds, tubes wire or the like and alloys for manufacturing such rolls. Sleeved rolls, i.e. rolls with a core and with an outer layer. Rolls with deflectable sleeves. Lubricating, cooling and heating the rolls internally or externally while in use.

This place does not cover:

Shape of working surfaces required by special processes | |

Flatness/ profile control by cooling, heating or lubricating the rolls | |

Temperature control by heating or cooling the rolls or the product |

Attention is drawn to the following places, which may be of interest for search:

Cooling, heating or lubricating the work | |

Rolling metal of indefinite length in repetitive shapes specially designed for the manufacture of particular objects | |

Rolls for paper making machines |

In this place, the following terms or expressions are used with the meaning indicated:

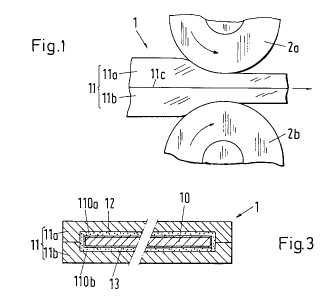

Sleeved rolls | a) Rolls which are assembled of different parts including an outer sleeve: |

This place covers:

Reconditioning of rolls by polishing/ grinding them, outside or inside their stands, while in use.

This place does not cover:

Lubricating, cooling or heating rolls while in use |

Attention is drawn to the following places, which may be of interest for search:

Machines or devices designed for grinding surfaces of revolution on work |

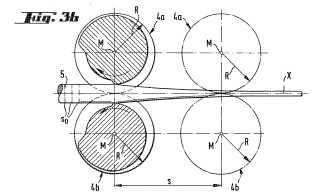

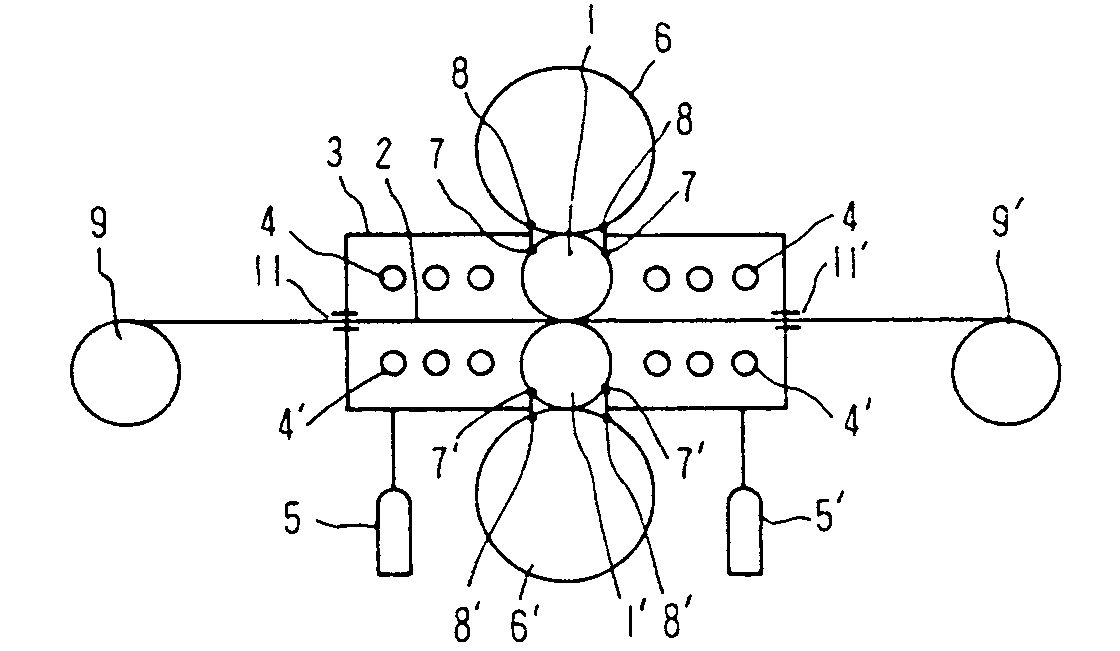

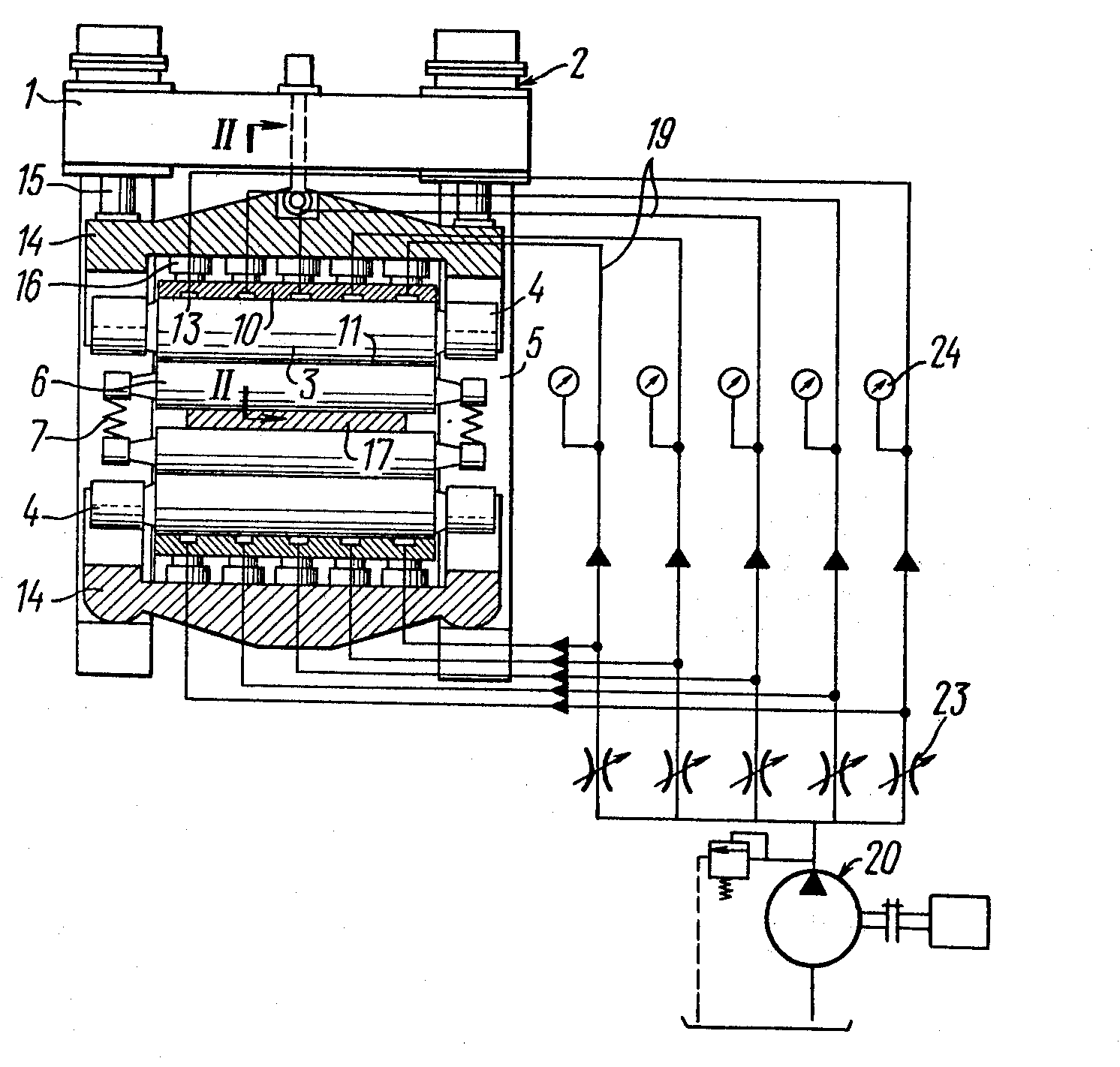

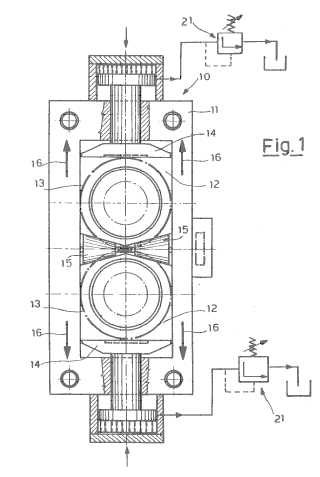

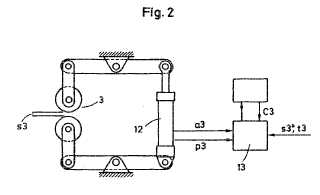

This place covers:

backup pressing devices for rollers in a roll stand including intermediate and backup rolls that inhibit deflection, perform roll bending or use hydraulic actuators to act on the rollers or roll shafts:

Backing devices for rolls |

|

Roll bending devices, e.g. hydraulic actuators acting on roll shaft ends |

|

This place does not cover:

Control of flatness/ profile by roll bending |

Attention is drawn to the following places, which may be of interest for search:

Back- up rolls per se, axially shifting the rolls, lateral support devices |

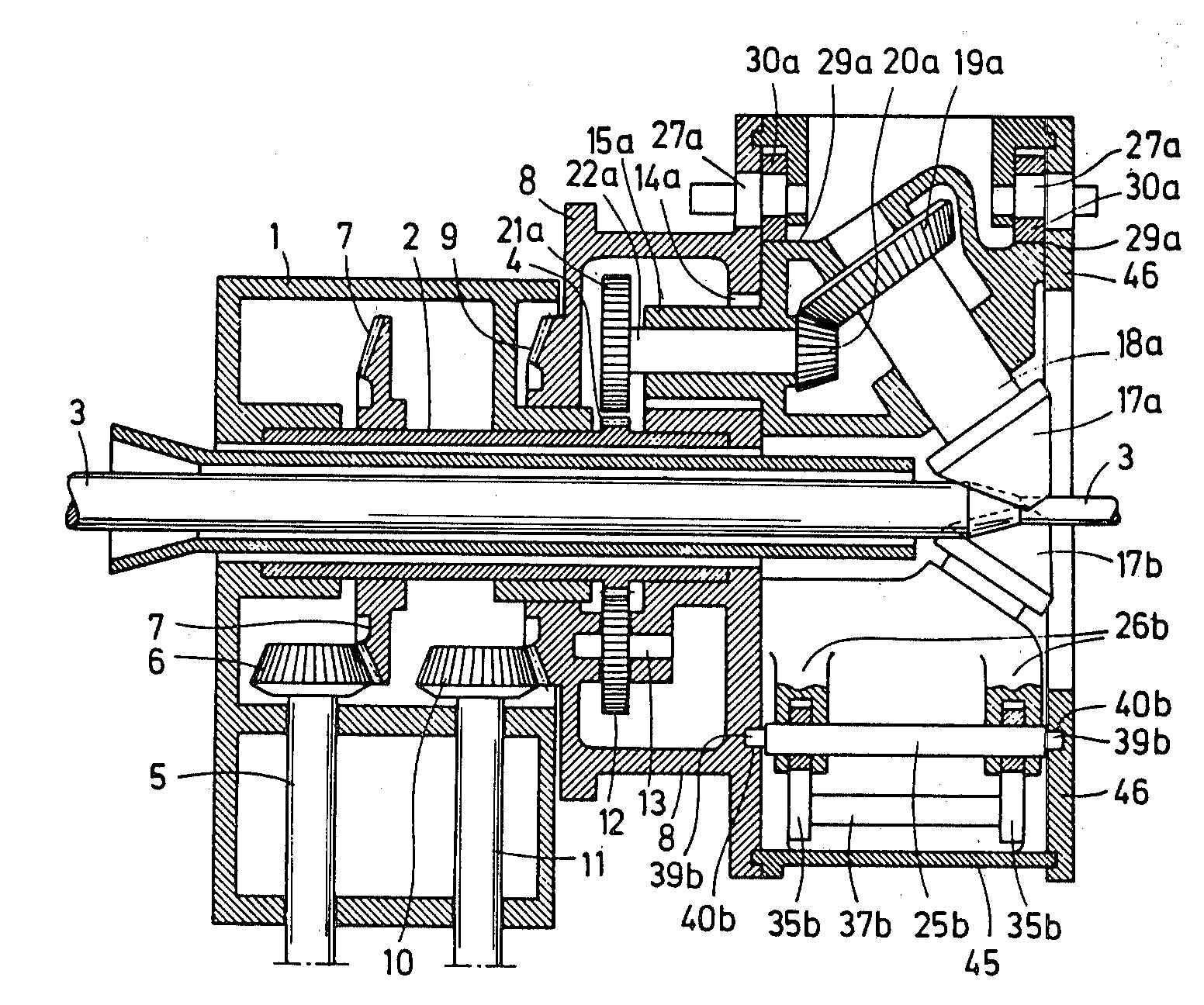

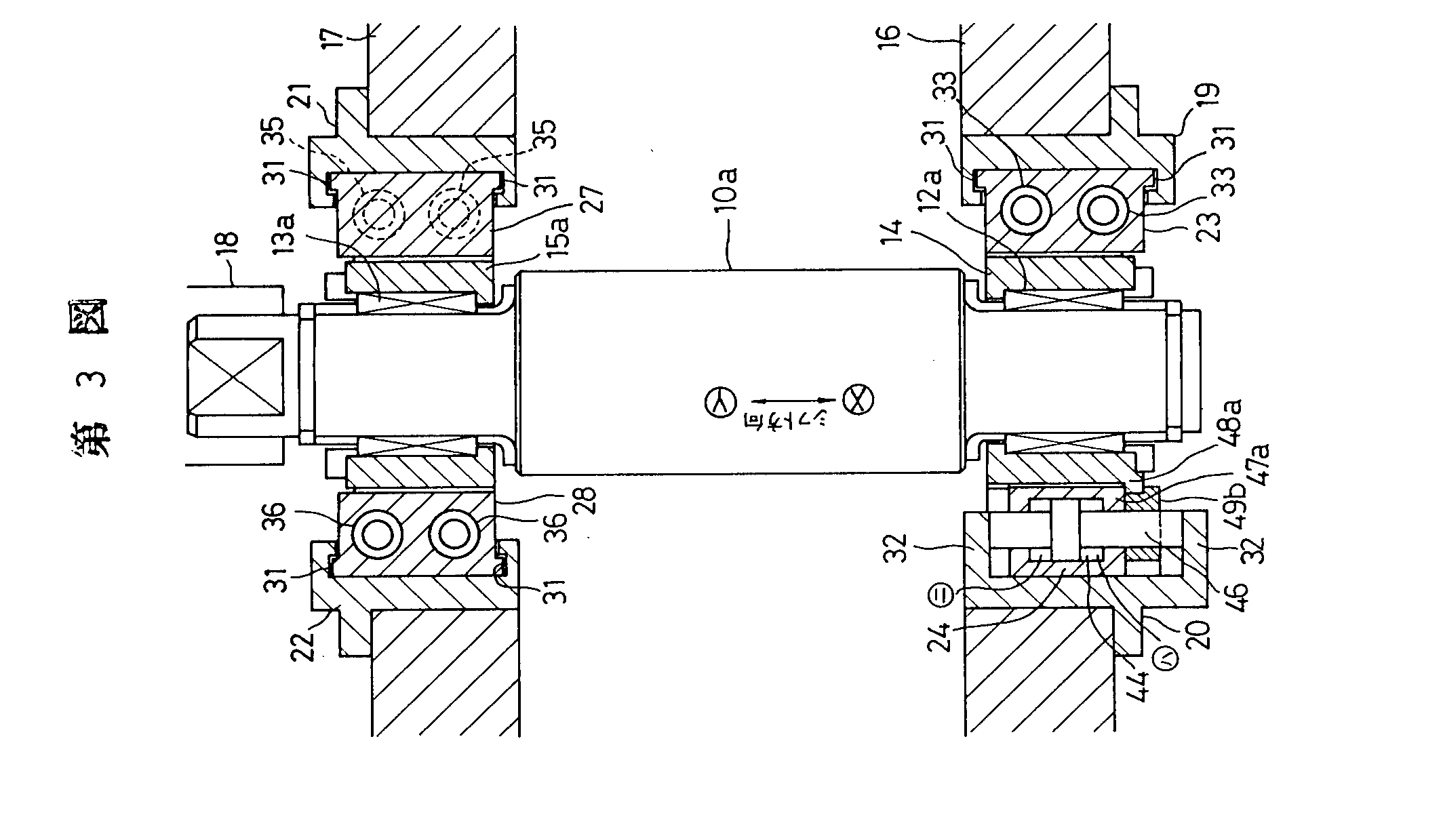

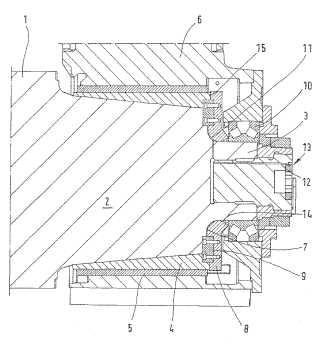

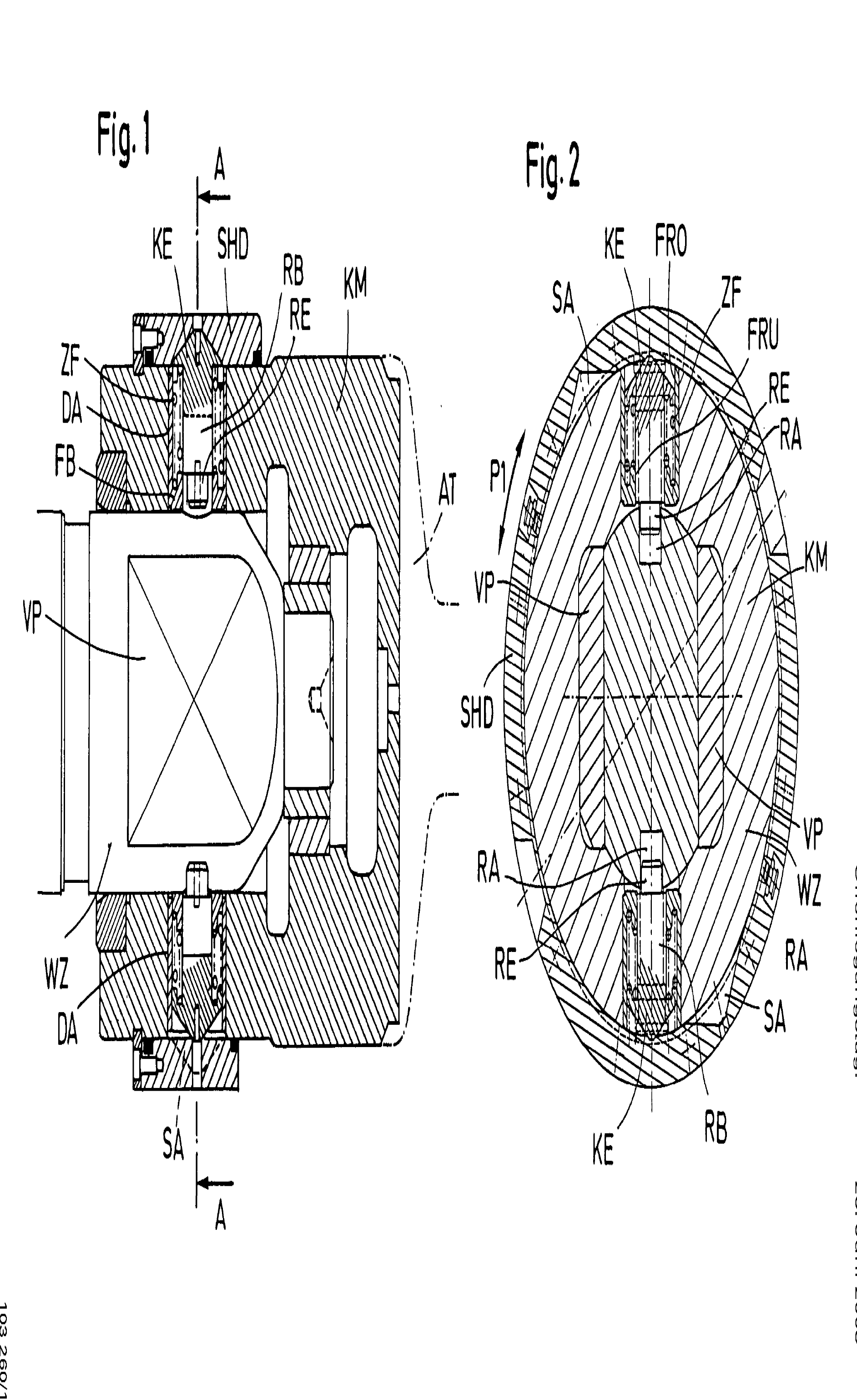

This place covers:

Prestressing of rolls or roll mountings in stands |

|

Stands with tie rods in frameless stands, e.g. presstressed tie rods |

|

Morgoil bearings |

|

Sealing devices | l |

Balancing rolls |

|

Toggle-lever mechanism |

|

This place covers:

Breaker blocks |

|

Attention is drawn to the following places, which may be of interest for search:

Relatively slidable coverings | |

Flexible coverings | |

Safety devices in general |

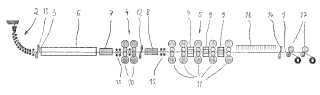

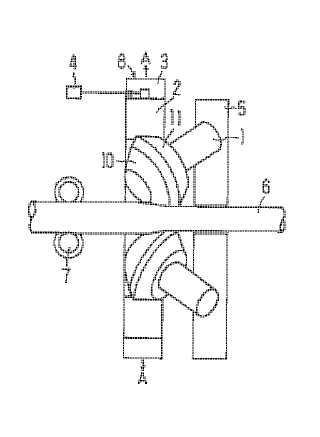

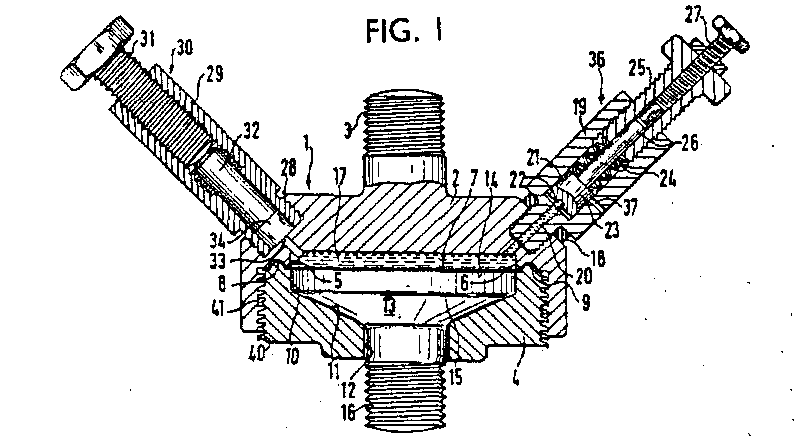

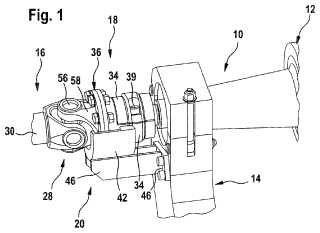

This place covers:

Drives for metal-rolling mills, e.g. hydraulic drives or electrical drives working continuously or non- continuously, couplings (rigid, yielding), driving spindles or spindle carriers.

Coupling boxes placed on roll necks |

|

Universal joints |

|

Wobbler couplings |

|

Tongue and slipper joints |

|

Attention is drawn to the following places, which may be of interest for search:

Couplings, shafts in general | |

Rigid couplings in general | |

Yielding couplings in general | |

Hooke's joint in general | |

Tongue and slipper joints in general |

In patent documents, the following abbreviations are often used:

Universal joint | universal coupling, U- joint, Cardan joint, Hardy-Spicer joint or Hooke's joint |

This place covers:

Control devices or methods specially adapted for metal-rolling mills or the work produced thereby, e.g. control of flatness, profile, tension, roll speed, drive motor, roll gap, roll force, elongation, length, rear end/ front end temperature, cooling, camber or steering control, control of tube rolling.

Attention is drawn to the following places, which may be of interest for search:

Methods or devices for measuring specially adapted for metal-rolling mills |

In patent documents, the following abbreviations are often used:

AGC | Automatic Gauge Control |

This place covers:

Methods or devices for measuring, detecting or monitoring specially adapted for metal-rolling mills, e.g. position detection, inspection of the product, e.g. position detection, inspection of the product, temperature, vibration, chatter (marks), flatness, profile of strips, thickness, width, diameter or other transverse product dimensions, tension/ compression, roll- force, roll- gap (including calibrating or presetting), roll camber.

This place does not cover:

Measuring/ control of thickness of liquid films for cooling or lubricating |

Attention is drawn to the following places, which may be of interest for search:

Control devices or methods specially adapted for metal-rolling mills or the work produced thereby |

This place covers:

Piling, unpiling, unscrambling. Transverse moving. Pinch roll sets. Rollers for roller conveyors.Feeding or supporting work. Braking or tensioning arrangements. Guiding, positioning or aligning work. Revolving, turning-over, or like manipulation of work.

This place does not cover:

Guides in which work is subjected to permanent internal twisting |

Attention is drawn to the following places, which may be of interest for search:

Guiding, conveying, or accumulating easily-flexible work in loops or curves | |

Guides specially associated with cooling-beds | |

Conveying or transporting in general |

This place covers:

Returning work to repeat the pass or passes. In which the direction of movement of the work is turned through approximately 180 degrees, e.g. repeaters, i.e. from one stand to another. Without overall change in the general direction of movement of the work, e.g. loop deflectors. Arrangements of interest only with respect to provision for indicating or controlling operations.

This place does not cover:

Arrangements for moving, supporting, or positioning work, or controlling its movement, combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills |

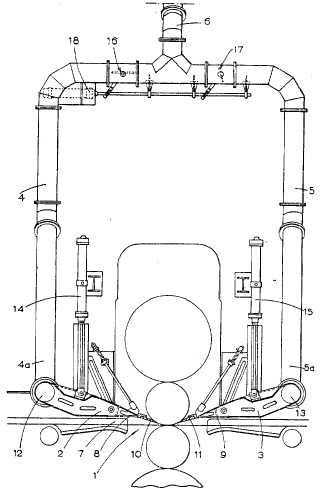

This place covers:

Transfer from/ to cooling beds and means as e.g. suitable braking means. Cooling beds comprising racks, walking beams, bars, rolls, worms, carriages, revolving drums, recycling chains or discs or other work- shifting elements to transport the work through the cooling bed. Devices for positioning workpieces "flushed", i.e. with all their axial ends arranged in line on cooling beds or on co-operating conveyors.

Attention is drawn to the following places, which may be of interest for search:

Conveying means in general |

This place covers:

Devices for surface or other treatment of work, specially combined with or arranged in, or specially adapted for use in connection with, e.g. cooling the work, coolants, lubricating, cleaning, measuring/ control of thickness of liquid films, removing and recovering of liquids/ lubricants, descaling (hydraulically).

Attention is drawn to the following places, which may be of interest for search:

Arrangements for performing additional metal-working operations specially combined with or arranged in, or specially adapted for use in connection with, metal-rolling mills as e.g. lubricating, cooling or heating | |

Lubricating, cooling or heating rolls | |

Cleaning travelling work by the use of liquid jets or steam/gas | |

Cleaning work by the use of liquid (cryogenic) gases or supercritical fluids | |

Technical features of scaling-off devices |

This place covers:

Auxiliary arrangements, devices or methods in connection with rolling of multi-layer sheets of metal, e.g. folding sheets before rolling. Separating layers after rolling.

Attention is drawn to the following places, which may be of interest for search:

Soaking pits |

This place covers:

Processes and equipment for metal rolling as far as not covered by the main groups B21B 1/00 - B21B 47/00.