CPC Definition - Subclass D03D

This place covers:

Woven fabrics or weaving processes resulting in particular woven fabrics. These aspects are covered by D03D 1/00 - D03D 27/00.

Specific types of weaving machines or processes to operate such weaving machines. These aspects are covered by D03D 29/00 - D03D 47/00.

Details or features common to different types of weaving machines. These aspects are covered by D03D 49/00 and D03D 51/00.

This place does not cover:

Attention is drawn to the following places, which may be of interest for search:

Class D06 takes precedence over this subclass in respect of processes involving both weaving and finishing steps and in respect of the finished fabrics.

In this subclass, further classification in indexing scheme D10B for aspects relating to textiles is required.

A method of weaving is classified in the group designating the fabric woven unless the method is characterised by the operation of a particular loom rather than by the production of a particular fabric. In this case, the method is classified in the group for the loom.

In this subclass, if there is any doubt as to which of the essential features is the most important (this is usually the most restrictive feature), the groups designating woven fabrics should be considered in the order in which they appear at each level of indentation, except that groups designating woven pile fabrics are to be considered as taking precedence over groups designating other woven fabrics.

This place covers:

Woven fabrics or weaving methods where the structure or method makes the fabric specifically suitable for a certain application (e.g. a warp and weft yarn density can make a fabric specifically suitable for use as an airbag).

Attention is drawn to the following places, which may be of interest for search:

Special materials for outerwear | |

Floor fabrics | |

Fire-resistant or fire-fighters' clothes | |

Fibrous reinforcements in composites | |

Papermaking fabrics | D21F 1/0036, D21F 1/0054, D21F 1/105, D21F 1/12, D21F 1/16, D21F 7/10 |

Surfaces simulating grass | |

Window screens | |

Lighting devices or systems using a string or strip of light sources, e.g. lighting webs |

Documents should only be classified here if the invention is specifically directed to the weaving of the product and has general relevance for weaving. Otherwise the documents should only be classified in the relevant application fields (see informative references).

The following Indexing Codes should be used in D03D 1/00:

- physical properties D10B 2401/00;

- wearing apparel D10B 2501/00;

- domestic or personal use D10B 2503/00;

- industrial use D10B 2505/00;

- sport or military use D10B 2507/00;

- medical or hygiene use D10B 2509/00.

Attention is drawn to the following places, which may be of interest for search:

Safety belts in general |

Attention is drawn to the following places, which may be of interest for search:

Cleaning cloths |

This place covers:

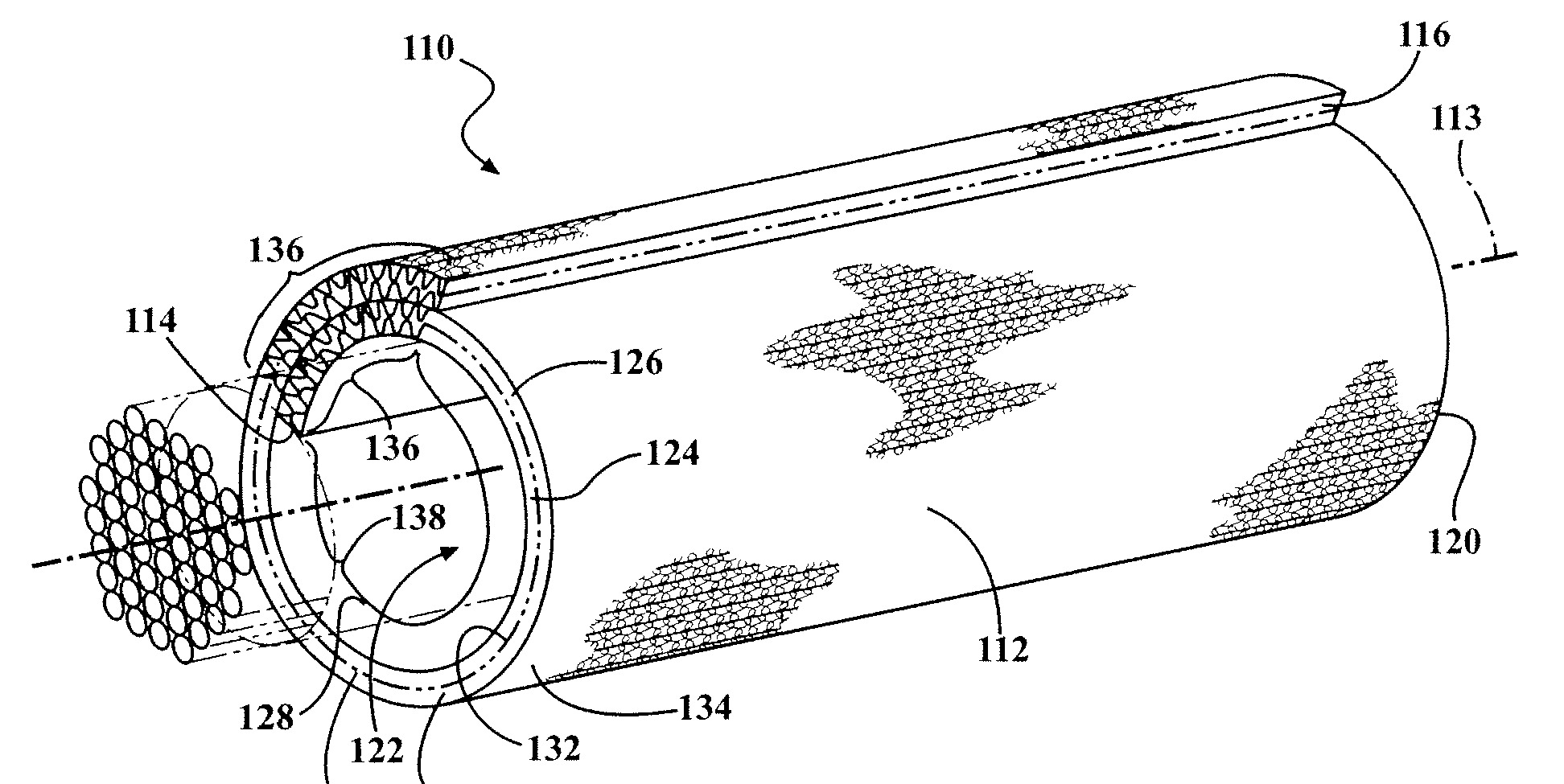

Protective sleeves for elongated members, e.g. for insulating conductive wires or for covering reinforcement wires in clothing. The sleeve can be woven as a tubular fabric or as a flat fabric which is subsequently rolled-up into a tubular shape.

Illustrative example of subject matter classified in this group:

Attention is drawn to the following places, which may be of interest for search:

Woven tubular fabrics characterised by their shape | |

Protecting means for wire harnesses | |

Protective tubings or conduits |

Protective sleeves that are integrally woven as tubular fabrics should additionally be classified in D03D 3/02.

This place covers:

Camouflage fabrics e.g. for visual or thermal camouflage, e.g. with heat reflective properties.

This place covers:

Antiballistic woven fabrics or woven layers.

Attention is drawn to the following places, which may be of interest for search:

Armoured or projectile- or missile garments, composite protection fabrics | |

Armour or armour plates comprising fibre or fabric reinforced layers |

This place covers:

Fabrics normally used to provide protection from sun or UV-radiation, i.e. sunscreens.

This place covers:

Woven fibre structures for solar cells.

Attention is drawn to the following places, which may be of interest for search:

Flexible or folded printed circuits |

Attention is drawn to the following places, which may be of interest for search:

Garments adapted to accommodate electronic equipment |

This place covers:

All kinds of woven belts not covered by other groups.

This place does not cover:

Tapes or ribbons |

Attention is drawn to the following places, which may be of interest for search:

Conveyor belts with reinforcing layers | |

Reinforcement belts for tyres | |

Driving belts in general |

Attention is drawn to the following places, which may be of interest for search:

Airbags in general | |

Airbags characterised by their material |

Attention is drawn to the following places, which may be of interest for search:

Means for forming pleats in curtains on curtain rods or rails |

This place covers:

Two tapes that are connected by threads or connecting layers that are designed to hold slats of fabric, wood, plastic or metal that adjust by rotating from an open position to a closed position by allowing slats to overlap. The scope of this group also covers full-width fabrics having tapes or fabrics connected by connecting layers whereby the connecting layers themselves constitute the slats that adjust by rotating from an open position to a closed position by allowing the slats to overlap.

This place does not cover:

Details of ladder tapes or ladder chains for venetian blinds |

This place covers:

Fabrics which are woven to assume a special shape. This shape is not achieved by cutting or by any other post-processing step.

This place covers:

Tapes or ribbons not covered by other groups.

This place does not cover:

Safety belts | |

Tapes for labels | |

Belts | |

Curtain heading tapes | |

Ladder tapes | |

Slide fastener tapes |

Attention is drawn to the following places, which may be of interest for search:

Smallware looms |

This place covers:

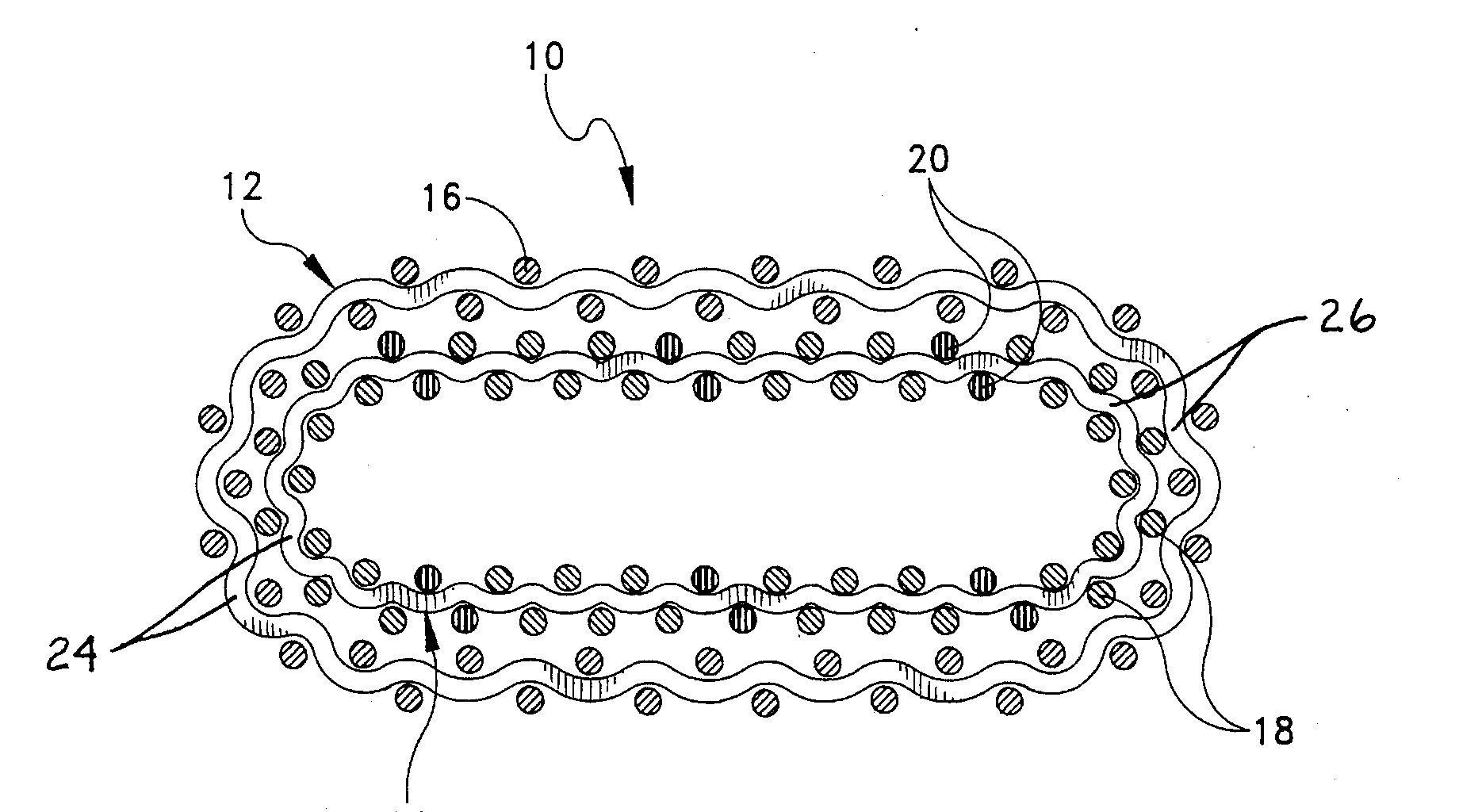

Sleeve-like structures integrally woven in a tubular shape.

Illustrative example of subject matter classified in this group:

Attention is drawn to the following places, which may be of interest for search:

Vascular stents | |

Hoses made of fibres or threads | |

Insulation of connections using a heat shrinking insulating sleeve |

Tubular woven fabrics that are intended for use as protective sleeves should additionally be classified in D03D 1/0043.

In this place, the following terms or expressions are used with the meaning indicated:

Tubular fabric | A tubular woven fabric is either a (1) flat-woven multi-layer fabric integrally woven as a tube, i.e. with a continuous weft connecting the layers at both edges of the fabric, and only at the edges, or (2) an integrally circular woven fabric. Woven fabrics where the tubular shape is achieved after weaving, e.g. a flat woven fabric rolled up into a tubular shape, are not considered as tubular fabrics. |

This place covers:

Endless fabrics, for example belts without a seam.

This place does not cover:

Papermaking fabrics | D21F 1/0036, D21F 1/0054, D21F 1/105, D21F 1/12, D21F 1/16, D21F 7/10 |

This place covers:

Selvedges, i.e. the side edges of woven fabrics.

This place does not cover:

Means to form selvedges | |

Selvedge jacquards | |

Leno shedding mechanisms | |

Selvedge shedding mechanisms not forming part of main shedding |

This place covers:

Multi-layered fabrics with elastic yarns connecting the individual layers in particular spacer fabrics.

This place covers:

Net like fabrics, with spaced apart warp and weft yarns, where the spacing results from the weaving process.

Attention is drawn to the following places, which may be of interest for search:

Ladder-tape fabrics | |

Gauze or leno-woven fabrics | |

Filtering materials | |

Wire nets | |

Mesh fabrics as backings |

This place covers:

Fabrics with multiple woven layers connected by warp or weft yarns, the layers being all of the same size, i.e. the dimension of the layers does not vary in the z-direction (i.e. the direction perpendicular to the warp and weft yarns).

This place does not cover:

Multi-ply fabrics in which the length or width direction is limited to a predetermined dimension in order to create a rectangular or other three dimensional shape | |

Layered products whereby the layers are not connected by warp or weft yarns, i.e. layers connected by lamination |

Attention is drawn to the following places, which may be of interest for search:

Fibrous reinforcements for composites |

This place does not cover:

Fabrics consisting of a single tube |

Attention is drawn to the following places, which may be of interest for search:

Fabrics for curtain heading tapes |

Attention is drawn to the following places, which may be of interest for search:

Fabrics with non-woven perpendicular yarns, which can be connected by woven weft and/or warp yarns |

This place covers:

Fabrics characterised by their weave pattern.

Fabrics having a non-standard weave pattern (standard weave patterns are e.g. plain weave, twill, basket, sateen etc).

Fabrics having a standard weave pattern but new effects are created due to the pattern.

This place covers:

Fabric patterns with a leno binding yarn additional to the weft and warp yarns, e.g. for fixing yarns in reinforcement fabrics.

This place does not cover:

Leno yarns in selvedges | |

Gauze or leno woven fabrics (i.e. fabrics consisting mainly of leno yarns in the warp) |

This place covers:

Fabrics characterised by the yarn fineness, the weave density or surface weight.

This place covers:

Woven fabrics obtained by interlacing of warp and weft elements.

Documents classified here are directed to the weaving and have general relevance for weaving. If the application relates to properties of the yarns per se and a woven fabric is mentioned only by way of example, the corresponding place should be identified.

Attention is drawn to the following places, which may be of interest for search:

Documents should only be classified here if the invention is directed to the weaving and has general relevance for weaving. Documents should not be classified here if a woven fabric is mentioned only by way of example.

Classification within D03D 15/00 also requires an appropriate Indexing symbol in D10B.

In patent documents, the following words/expressions are often used as synonyms:

- "polymeric fibre" and "synthetic fibre"

In patent documents the following terms, "polymeric fibre" and "synthetic fibre" are often used as keywords that would be useful to a searcher.

In patent documents, the following terms "fiber", "fibre" and "filament" are often used as keywords that would be useful to a searcher.

In patent documents, the following terms "yarn" and "thread" are often used as keywords that would be useful to a searcher.

Cellulose-based fibres or filaments, e.g. vegetable fibres are also classified with an appropriate Indexing symbol in D10B 2201/00.

In this place, the following terms or expressions are used with the meaning indicated:

Plant | Vegetable that usually grows in earth and may have a stem, leaves, roots or flowers, or may produce seeds. |

This place covers:

Fabrics with warp and/or weft yarns or threads comprising protein-based fibres or filaments, e.g wool fibres.

Protein-based fibres or filaments, e.g. animal fibres are also classified with an appropriate Indexing symbol in D10B 2211/00.

This place covers:

Fabrics with warp and/or weft yarns or threads comprising cashmere or silk fibres.

This place covers:

Fabrics with warp or weft yarns or threads comprising a mineral like rock or basalt.

Attention is drawn to the following places, which may be of interest for search:

Yarns or threads made from mineral substances |

This place covers:

Fabrics with warp or weft yarns or threads comprising "noble metal", e.g. gold, silver, platinum or iridium.

Attention is drawn to the following places, which may be of interest for search:

Yarns or threads made from glass or the like |

This place does not cover:

Cellulose-based artificial fibres |

- Fibres or filaments made from polymers obtained by reactions only involving carbon-to-carbon unsaturated bonds are also classified with an appropriate Indexing symbol in D10B 2321/00.

- Fibres or filaments made from polymers obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds, e.g. polycondensation products, are also classified with an appropriate Indexing symbol in D10B 2331/00.

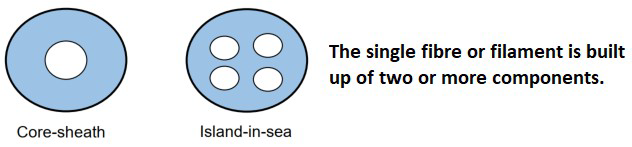

This place covers:

Fabrics with warp or weft yarns or threads comprising conjugate fibres or filaments, i.e. bi- or multicomponent fibres or filaments, e.g. core-sheath and island-in-sea.

Attention is drawn to the following places, which may be of interest for search:

Multicomponent yarns or threads, e.g. blended yarns or threads | |

Formation of man-made conjugate filaments | |

Conjugated, i.e. bi- or multicomponent, man-made filaments or the like; Manufacture thereof |

In this place, the following terms or expressions are used with the meaning indicated:

Conjugate | Indicates fibres or filaments having two or more different components within the individual fibre or filament, e.g. a polyethylene sheath component and a polyester core component. |

This place covers:

Fabrics with warp or weft yarns or threads with extremely fine staple fibres or filaments, typically less than 1 dtex.

Attention is drawn to the following places, which may be of interest for search:

Yarns with characteristics dependent on the amount or direction of twist |

This place covers:

Fabrics comprising separate yarns or threads of different diameters or linear densities or with different diameters within individual yarns or threads.

This place covers:

Fabrics with warp or weft yarns or threads defined by a particular cross-sectional shape, e.g. flat, oval or asymmetrical.

This place covers:

Fabrics with warp and/or weft yarns or threads which are flat or tape-like or films.

Attention is drawn to the following places, which may be of interest for search:

Looms for weaving flat yarns |

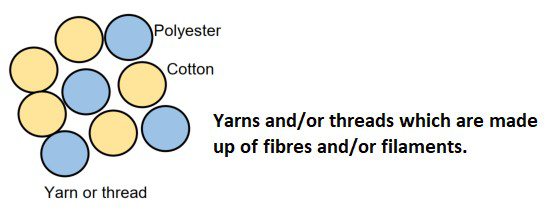

This place covers:

Fabrics with warp or weft yarns or threads comprising yarns or threads of different materials, e.g. cotton and polyester.

This place does not cover:

Multicomponent fibres or filaments |

In this place, the following terms or expressions are used with the meaning indicated:

Multicomponent | Yarns or threads having two or more different types of fibres or filaments that are combined together into a yarn or thread structure, indicates yarns or threads built up of two or more components which are joined, e.g. core spun yarn or plied yarn. |

This place covers:

Fabrics with warp or weft yarns or threads comprising textured or fancy yarns.

This place does not cover:

Chenille |

Attention is drawn to the following places, which may be of interest for search:

Yarns or threads having slubs, knops, spirals, loops, tufts or other irregular or decorative effects |

This place covers:

Fabrics with warp and/or weft yarns or threads of knitted strips.

Attention is drawn to the following places, which may be of interest for search:

Warp knitted yarns |

This place covers:

Fabrics with warp or weft yarns or threads having magnetic properties.

Attention is drawn to the following places, which may be of interest for search:

Special materials for outerwear against fire and heat | |

Protective clothing affording protection against heat or harmful chemical agents | |

Heat-resistant, fireproof or flame-retardant yarns or threads |

Attention is drawn to the following places, which may be of interest for search:

Special materials for thermally protective outerwear |

Attention is drawn to the following places, which may be of interest for search:

Yarns or threads with antistatic properties | |

Floors or floor coverings specially adapted for discharging static charges |

This place covers:

Fabrics with effects due to the use of warp or weft yarns or threads of specific colour(s).

Attention is drawn to the following places, which may be of interest for search:

Yarns with coloured effects |

This place covers:

Fabrics with warp or weft yarns or threads comprising elastic or stretchable yarns or threads.

Attention is drawn to the following places, which may be of interest for search:

Woven fabrics which elastic or stretch properties are due to the manner of weaving | |

Elastic yarns or threads |

Attention is drawn to the following places, which may be of interest for search:

Yarns in which fibres are united by adhesives |

This place covers:

Woven fabric characterised by elements not covered by subgroups D03D 15/20 - D03D 15/593, or by using the element as an extra component, either in the machine direction or in the cross direction, e.g. as a reinforcement or an effect.

This place covers:

Fabrics with warp or weft components formed from strips of materials, e.g. leather straps.

This place covers:

Fabrics with warp or weft yarns or threads of paper, often paper strips.

Attention is drawn to the following places, which may be of interest for search:

Paper yarns or threads |

This place covers:

Fabrics containing temporary warp or weft yarns or threads.

This place covers:

Fabrics with warp and/or weft threads containing beads, pearls and the like.

This place covers:

Woven fabrics having elastic or stretch properties due to the manner of weaving.

This place does not cover:

Fabrics using stretchable or elastic threads |

This place covers:

Fabrics comprising mainly leno yarns outside the selvedges. The leno yarns are normally provided to ensure that the warp yarns do not slide along the weft yarns in loosely woven fabrics.

This place does not cover:

Selvedges with or without leno yarns | |

Fabric with a leno binding yarn additional to the weft and warp yarns, e.g. for fixing yarns in reinforcement fabrics | |

Leno shedding mechanisms |

Attention is drawn to the following places, which may be of interest for search:

Filtering materials | |

Wire nets | |

Mesh fabrics as backings |

This place covers:

Fabrics with yarns passing only over part of the width or length of the fabric.

In this place, the following terms or expressions are used with the meaning indicated:

Lappet | weaving is figured by the introduction of additional warp yarns which pass only over part of the length of the fabric |

Swivel | weaving is figured by the introduction of additional weft yarns which pass only over part of the width of the fabric |

This place covers:

Weaving methods of fabrics which are not specific for a certain loom.

This place covers:

Woven fabrics not otherwise provided for.

This place covers:

Integrally woven 3D-constructions. It also covers multi-ply fabrics in which the length or width direction is limited to a predetermined dimension in order to create a rectangular shape.

This place does not cover:

Multi-ply fabrics which extend, apart from having a certain thickness, in two directions |

Attention is drawn to the following places, which may be of interest for search:

Fibrous reinforcements in composites |

This place covers:

Woven pile fabrics.

Attention is drawn to the following places, which may be of interest for search:

Carpets in general |

This place covers:

Terry fabrics, e.g. towels, beach robes.

This place covers:

Fabrics consisting of two layers which are connected by pile yarns, the two layers being simultaneously woven on the loom.

Attention is drawn to the following places, which may be of interest for search:

Face to face fabrics which are not cut |

This place covers:

In particular fabrics woven on Axminster looms.

Attention is drawn to the following places, which may be of interest for search:

Chenille threads |

In this place, the following terms or expressions are used with the meaning indicated:

Chenille yarn | is manufactured by placing short lengths of yarn, called the "pile", between two "core yarns" and then twisting the yarn together. The edges of these piles then stand at right angles from the yarn's core, giving chenille both its softness and its characteristic look. Chenille will look different in one direction compared to another, as the fibres catch the light differently. |

This place covers:

Looms where the weft thread is inserted by hand.

In this place, the following terms or expressions are used with the meaning indicated:

Lappet | weaving is figured by the introduction of additional warp yarns which pass only over part of the length of the fabric |

Swivel | weaving is figured by the introduction of additional weft yarns which pass only over part of the width of the fabric |

This place covers:

Multiple looms, i.e. two or more looms assembled together, whether or not they have mechanisms in common.

This place covers:

Smallware looms, i.e. looms for weaving ribbons or other narrow fabrics.

Attention is drawn to the following places, which may be of interest for search:

Ribbons or narrow fabrics |

This place covers:

Looms where the weft inserting means follows a circular path.

Attention is drawn to the following places, which may be of interest for search:

Woven pile fabrics wherein pile tufts are inserted during weaving |

This place covers:

Axminster looms where the yarn comes from a tube, actuated mechanically, without gripper.

Attention is drawn to the following places, which may be of interest for search:

Methods or apparatus with yarn packages as yarn supply | |

Creels |

This place covers:

The tuft yarn selection in Axminster looms.

This place covers:

Sley movement adjusting type terry looms.

This place covers:

Looms not otherwise provided for, e.g. for weaving chenille yarns.

This place covers:

Looms with a rotor having multiple weft insertion channels in each of which a weft is inserted into the shed simultaneously.

Documents relating to the Sulzer rotor loom.

This place covers:

Looms with a vertical arrangement of the warp yarns at the weft insertion position.

This place covers:

Looms especially adapted to weave fabrics with flat yarns in the warp or weft.

Attention is drawn to the following places, which may be of interest for search:

Fabrics using flat yarns |

This place covers:

Shuttle looms which have shuttle boxes for storing multiple shuttles, in particular with different weft yarns, from which the shuttles are selected in accordance with a specific pattern.

This place covers:

Change boxes with compartments in a non-rotary arrangement, in which the shuttles are dropped.

This place covers:

Change boxes with compartments in a rotary arrangement, in which the shuttles are dropped.

This place covers:

Automatic replenishment of weft yarn stored in a shuttle.

This place does not cover:

Automatic replenishment in smallware looms | |

Automatic replenishment in circular looms |

Attention is drawn to the following places, which may be of interest for search:

Bobbins rewound on loom |

This place covers:

Looms in which the weft yarn is stored outside the shed (often at the side) and taken up by weft insertion means for introduction into the shed, e.g. rapier looms, needle looms and fluid jet looms.

This place covers:

Looms wherein loops of continuous weft thread are inserted, e.g. smallware looms where loops of weft yarn are normally inserted with a needle.

This place covers:

Looms wherein single picks of weft thread are inserted, e.g. with a rapier.

This place covers:

Means for holding the weft at the side of the shed.

Attention is drawn to the following places, which may be of interest for search:

Stretching or holding the weft in jet looms | |

Forming selvedges by inserting cut end of weft in next shed |

This place covers:

Details of rapier grippers.

This place covers:

Carrying, giver or bringing grippers for transporting the weft to the middle of the shed.

Documents describing additionally the drawing gripper in detail are additionally classified in D03D 47/236.

This place covers:

Drawing, taker, pulling or receiving grippers for transporting the weft from the middle of the shed to the end of the shed.

Documents describing additionally the carrying gripper in detail are additionally classified in D03D 47/233.

This place covers:

Projectile looms, where the shuttle does not carry a bobbin.

This place does not cover:

Travelling-wave-shed looms | |

Inserting mechanisms for shuttles |

Attention is drawn to the following places, which may be of interest for search:

Gripper or dummy shuttles |

This place covers:

Looms having multiple phase shifted sheds and a rotary reed.

This place covers:

Drive or guide means for weft thread insertion.

This place does not cover:

Guide mechanisms for pneumatic looms (normally means for creating an air channel for weft insertion) | |

Carrying the weft thread with a fluid through the shed |

Attention is drawn to the following places, which may be of interest for search:

Drive means for shuttle looms |

In this place, the following terms or expressions are used with the meaning indicated:

In this group, the following terms are relevant for correct classification:

Rapier | means for carrying the weft thread through the shed with a rod (sometimes also called lance or needle) or a flexible band |

Drive mechanism | the part outside the shed driving the means for carrying the weft thread through the shed |

Guide mechanism | parts inside and outside the shed to guide the means for carrying the weft threads through the shed |

This place covers:

Rapiers, i.e. means to insert the weft thread with a flexible band or rod.

This place covers:

Details of the rapier rod.

This place does not cover:

Needles for smallware looms |

In the documents, the following words "rod", "lance" and "needle" are often used as synonyms.

However, weft insertion needles as used in smallware looms are not considered to be rapier rods.

This place covers:

The part outside the shed driving the means for carrying the weft thread through the shed.

This place covers:

Guides for all insertion means except shuttle. For example: grippers, bands, lances or dummy shuttles.

This place covers:

Means for creating an air channel for weft insertion.

This place covers:

The weft yarn selection on air jet looms.

Attention is drawn to the following places, which may be of interest for search:

Lift valves with valve members of conical shape (i.e. throttle valves) | |

Operating means, releasing means using a motor in general |

This place covers:

All aspects concerning the handling of the weft yarns from the weft yarn supply means (i.e. normally bobbins) up to (but not including) the weft insertion.

Attention is drawn to the following places, which may be of interest for search:

Methods and apparatuses for unwinding or paying-out filamentary material from packages in general | |

Forwarding filamentary material | |

Guides for filamentary material | |

Guides for filamentary material adapted to prevent excessive ballooning |

This place covers:

Systems for detecting wefts with faults such as knots.

If the knot detection is part of a weft stop motion additionally the class D03D 51/34 is given.

This place covers:

Bulk storage bobbins which are rotatable supported and/or driven for lateral unwinding without inducing twist to the yarn.

This place covers:

Braking devices for weft yarns to be inserted.

Attention is drawn to the following places, which may be of interest for search:

Warp yarn tension regulation | |

Adjusting or controlling tension in filamentary material in general |

This place covers:

Devices and methods of measuring and cutting the weft.

Devices for measuring and temporary storing the weft.

Cutting weft threads is classified in D03D 49/70.

Attention is drawn to the following places, which may be of interest for search:

Cutting weft threads | |

Devices for temporarily storing filamentary material during forwarding in general | |

Applications or devices for metering predetermined lengths of running material (i.e. yarns) in general |

Attention is drawn to the following places, which may be of interest for search:

Clamping devices (i.e. yarn stoppers) in general |

This place covers:

Braking bodies being constituted by a brush.

This place covers:

Feeding devices in which the weft is temporarily stored in an air chamber, e.g. as loops or coils.

This place covers:

Communication systems between pre-winders and the loom.

Attention is drawn to the following places, which may be of interest for search:

Programme-control systems in general |

This place does not cover:

Pneumatic weft pattern mechanisms |

This place covers:

Means, other than a separate shedding mechanism, necessary for the formation of selvedges, i.e. the side edges of woven fabrics.

This place does not cover:

Elvedges | |

Selvedge jacquards | |

Selvedge shedding mechanisms not forming part of main shedding mechanism |

Attention is drawn to the following places, which may be of interest for search:

Temples | |

Sliding-contact bearings | |

Clutches in which the members have interengaging parts |

Attention is drawn to the following places, which may be of interest for search:

Climatic conditioning or removing lint or dust |

Attention is drawn to the following places, which may be of interest for search:

Construction of warp beam |

This place covers:

Controlling warp tension by means other than let-off mechanisms, e.g. by cloth take-up.

Attention is drawn to the following places, which may be of interest for search:

Back rest; lease rods; brest beams |

Attention is drawn to the following places, which may be of interest for search:

Methods or apparatus in which yarn packages do not rotate | |

Methods or apparatus in which yarn packages rotate | |

Creels |

Attention is drawn to the following places, which may be of interest for search:

Measuring tension of threads in general |

Attention is drawn to the following places, which may be of interest for search:

Storage racks for beams |

This place covers:

Bars which extend across the width of the warps or of the woven fabric.

Attention is drawn to the following places, which may be of interest for search:

Shuttles per se |

This place covers:

The cutting of weft threads including the cutting of weft threads for removing selvedges.

This place does not cover:

Cutting weft in looms with automatic weft replenishment |

Attention is drawn to the following places, which may be of interest for search:

Forming selvedges | |

Apparatus for slitting fabric | |

Removing of selvedges not on the loom |

Attention is drawn to the following places, which may be of interest for search:

Controlling a group of looms | |

Clutches in which the members have interengaging parts | |

Programme-control systems in general | |

Dynamo-electric machines (i.e. electric motors in general) | |

Cryptographic protocols | |

Network security protocols | |

Protocols for real-time services in data packet switching networks | |

Network protocols for data switching network services |

This place covers:

Operation and synchronisation of independent motors in looms.

This place covers:

Controlling one or more looms, e.g. by speed variation, to find an optimal operating condition.

This place covers:

Methods and their implementations to detect broken warp or weft yarns and to stop the weaving machine upon this detection.

Attention is drawn to the following places, which may be of interest for search:

Warning or safety devices for yarns in general |

This place covers:

Methods and their implementations to detect broken warp yarns and to stop the weaving machine upon this detection.

This place covers:

Methods and their implementations to detect broken weft yarns and to stop the weaving machine upon this detection.

Attention is drawn to the following places, which may be of interest for search:

Knot detection |

This place covers:

Methods and their implementations to detect broken weft yarns which are inserted by a shuttle and to stop the weaving machine upon this detection.

This place covers:

Methods and their implementations to stop the weaving machine upon detection of failure in the operation of one or more of the loom mechanisms.