CPC Definition - Subclass B24C

This place covers:

Abrasive or related blasting with particulate material, whereby a blast of any particles or pellets dispersed in air, gas, or liquid ( or an equivalent jet of particles or pellets projected or energised by other means ) is used for the treatment of surfaces or cutting of materials, the particles usually being of abrasive material.

Blasting with jets acting as abrasive jets, but not containing particulate material in the exceptional cases of deburring, removal of extended surface areas and jet milling of local recessions e.g. grooves.

- Abrasive machining

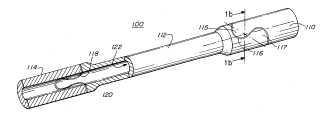

Subclass B24B of grinding and polishing complements the abrasive blasting with particulate material, which is covered by B24C.Polishing or abrading surfaces by means of tumbling apparatuses or other apparatuses in which the work or the abrasive material is loose, are covered by main group B24B 31/00.Abrading internal surfaces, e.g. of a tube or a flow channel, by operations in which a plastically deformable grinding compound is used as a loose abrasive material under the influence of pressure, known in the art as abrasive flow machining, extrude honing or hydro-erosive machining, is covered by group B24B 31/116 when the dynamic viscosity of the carrier medium is higher than that of conventional fuels such as diesel. When the dynamic viscosity of the carrier is less than or equal to that of conventional fuel (e.g. when water is used as a carrier), the machining is considered as particulate blasting of an internal surface, which is covered by B24C 3/325 and its subgroups.

- Spraying or atomising, nozzles

Spraying or atomising in general and nozzles in general are covered by subclass B05B.

Nozzles specially adapted for blasting surfaces with a jet of particulate material are covered by group B24C 5/04.

- Abrasive materials and polishing compositions

Abrasive particles, powders or compositions in general are covered by groups C09K 3/14 and C09G 1/00. Polishing compositions in general when they contain abrasives or grinding agents are covered by C09G 1/02. When used as materials for abrasive blasting, they are covered by B24C 11/00.

This place does not cover:

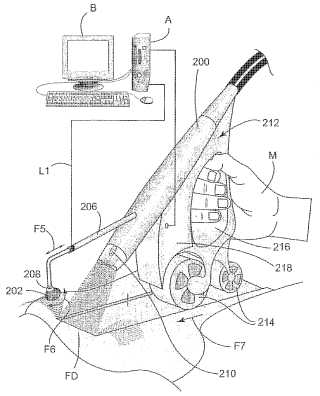

Dental tools or instruments acting like a sandblast machine | |

Energy dissipating devices for cutting jets with or without particles, known in the art as catcher tanks | |

Producing decorative effects by removing surface-material using streams of abrasive particles | |

Blasting semiconductor devices e.g. with a jet of particulate matter acting like sand blasting |

Attention is drawn to the following places, which may be of interest for search:

Application of shock-waves | |

Processes employing sonic or ultrasonic vibrations | |

Nozzles in general, Spraying or atomising in general | |

Jet flame processing in general | |

Cleaning in general; prevention of fouling in general | |

Cleaning by the force of jets or sprays without particles | |

Sonic or ultrasonic cleaning | |

Shot-peening for deforming sheet metal, tubes or profiles | |

Machines or devices for scraping | |

Cavitation peening. Treating or finishing by hammering or applying repeated pressure | |

Peening when the peening media is guided on its path during the peening action | |

Perforating by means of a fluid jet without particles | |

Severing by means of a fluid jet without particles | |

Recycling of tires | |

Implements or apparatus for removing dry paint from surfaces, e.g. by scraping | |

Shot-peening as a metallurgical treatment of iron or steel | |

Shot-peening as a metallurgical treatment of non-ferrous material | |

Earth drilling by liquid or gas jets, with or without entrained pellets | |

Production of stencils for photo mask processing | |

Stripping of photosensitive material | |

Controlling; regulating, e.g. cutting control, pierce-through measurement |

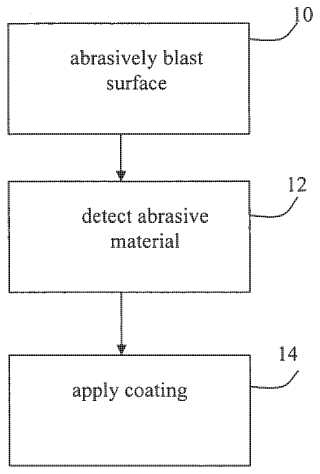

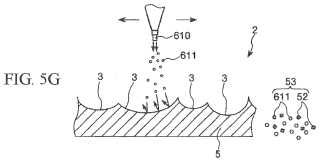

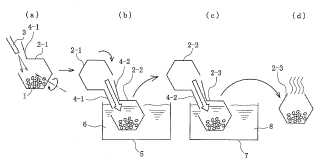

This place covers:

Abrasive blasting methods for producing particular effects and also devices configured to perform these methods.

Example(s): US20080076328, EP0015470, WO20060097133.

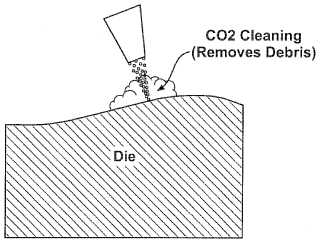

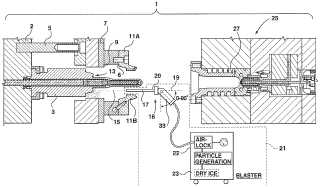

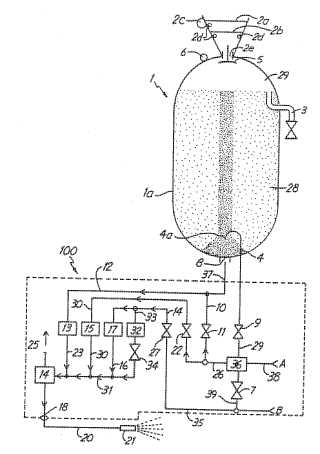

This place covers:

Example(s): US20100192655, US20060089090, DE1020040023246.

Attention is drawn to the following places, which may be of interest for search:

Solidifying carbon dioxide | |

Production, working, storing or distributing of ice |

This place covers:

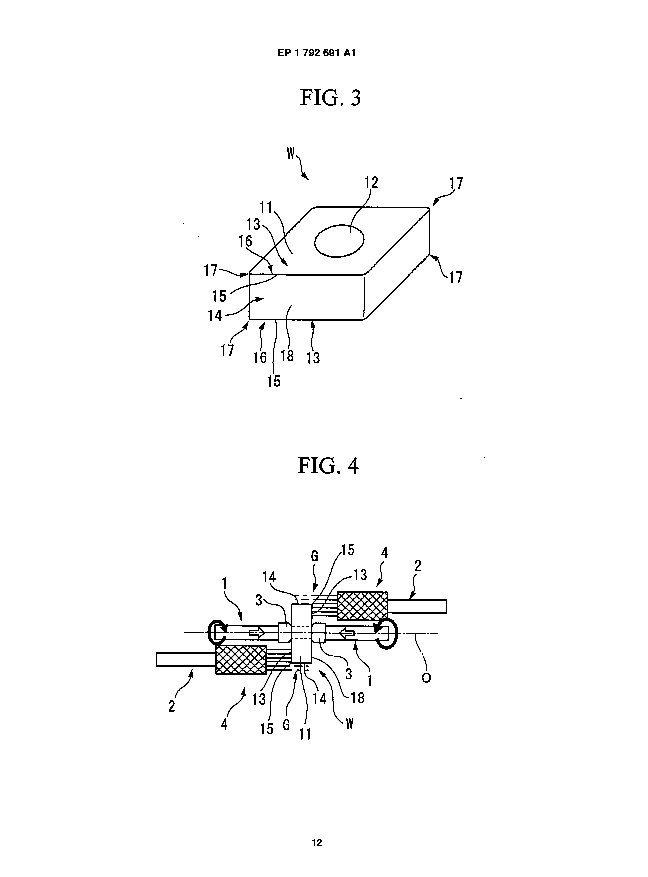

Example(s): WO9735686, EP1792691.

This place covers:

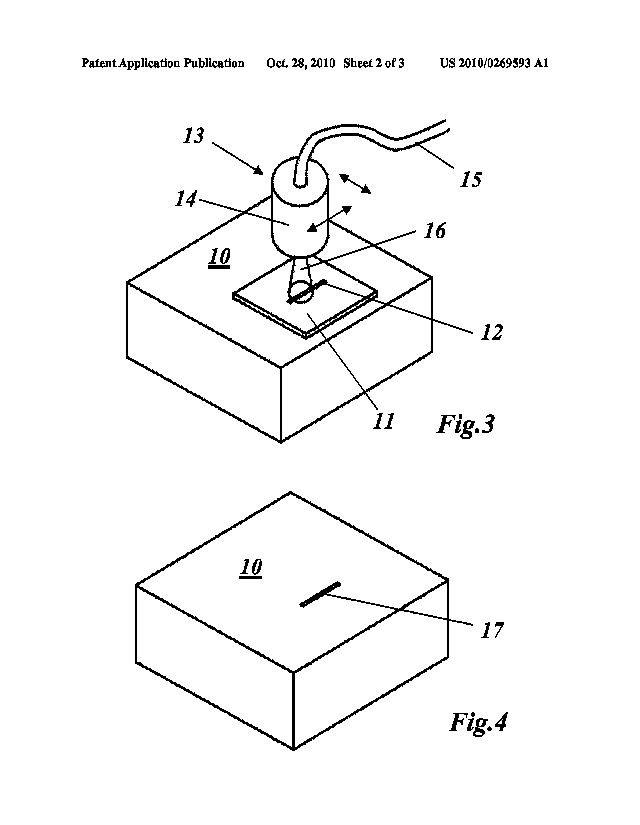

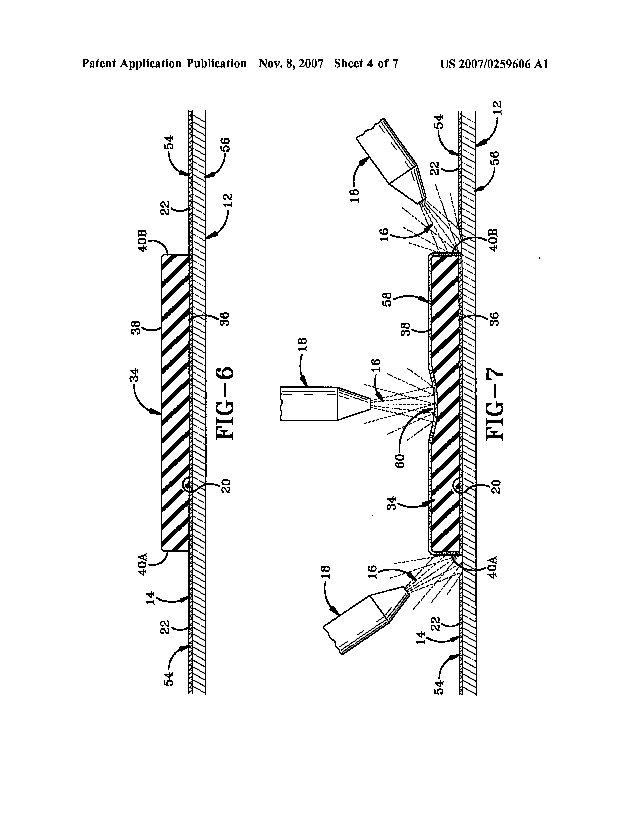

Example(s): US 20100269593, US20070259606.

This place covers:

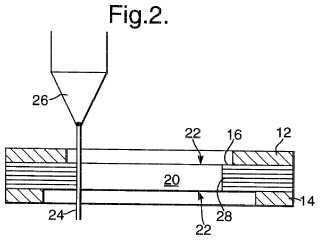

Example(s): GB2400893, US20030065424.

This place does not cover:

Energy dissipating devices for cutting jets with or without particles, known in the art as catcher tanks |

This place covers:

Example(s): EP1803532, US7131303, JP20040230549, EP0811582.

This place covers:

Example(s): EP2132001.

This place covers:

Example(s): US20040168494, EP1839801, WO20080044613.

This place covers:

Example(s): US20080108281, US20030219621, US20030116649.

Attention is drawn to the following places, which may be of interest for search:

Cleaning by the force of jets or sprays without particles |

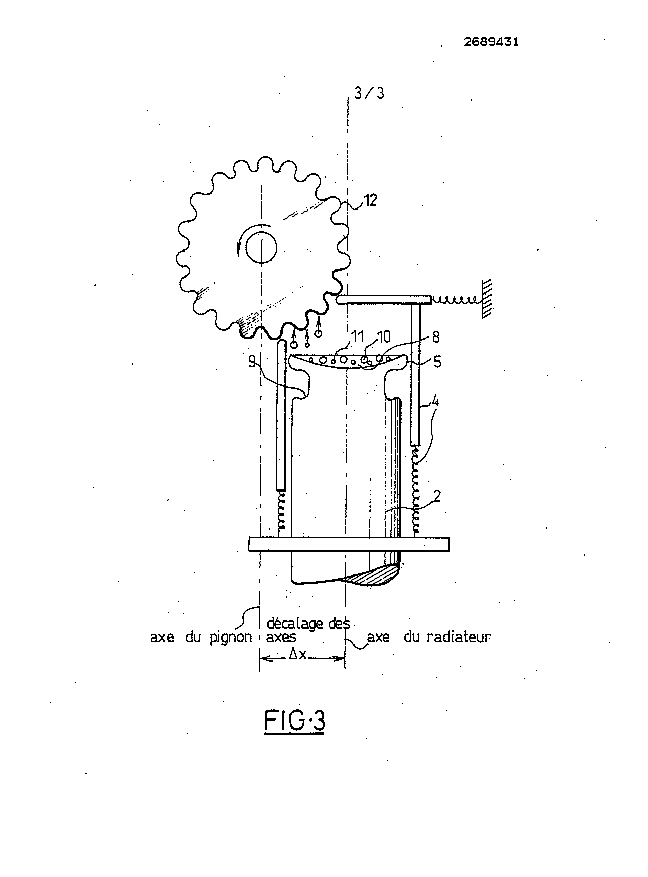

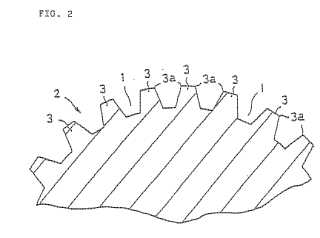

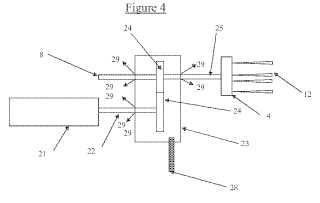

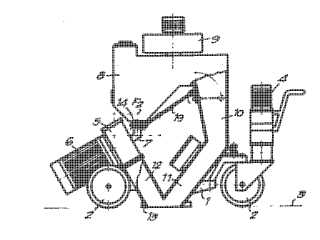

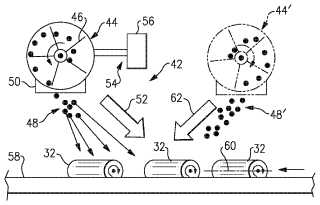

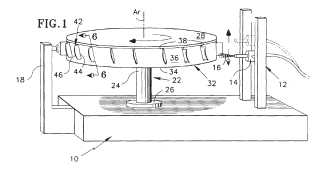

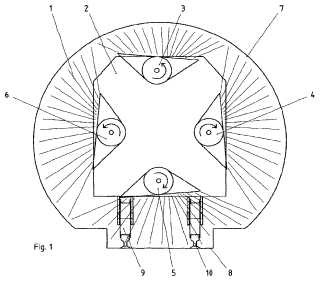

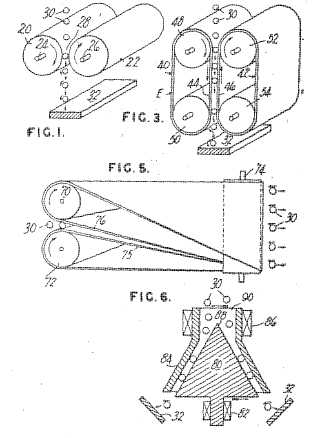

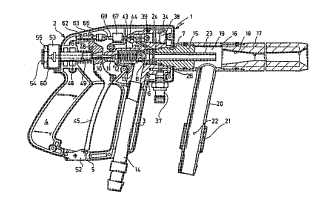

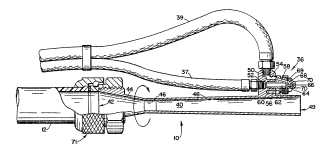

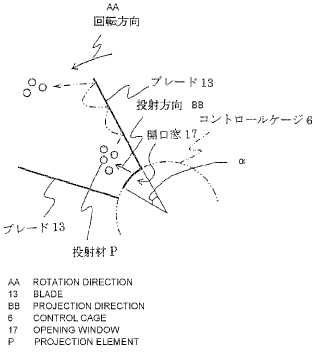

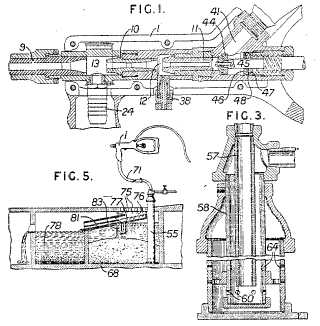

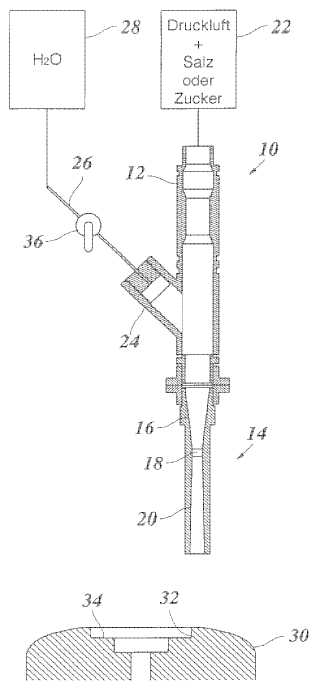

This place covers:

Example(s): FR2689431, EP0359277, US4258084, DE1020080011243.

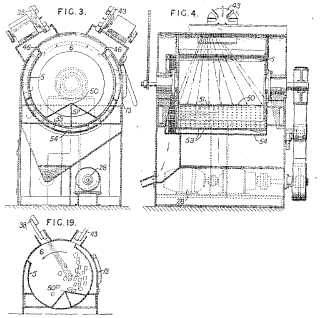

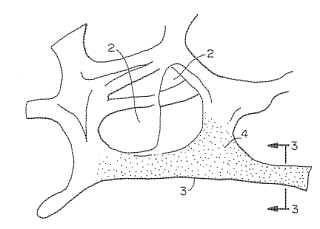

![]()

This place does not cover:

Peening when the peening media is guided on its path during the peening action |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Shot-peening for deforming sheet metal, tubes or profiles | |

Shot-peening as a metallurgical treatment of iron or steel | |

Shot-peening as a metallurgical treatment of non-ferrous material |

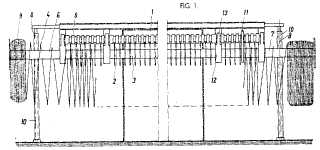

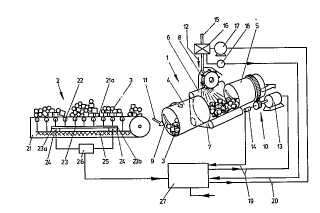

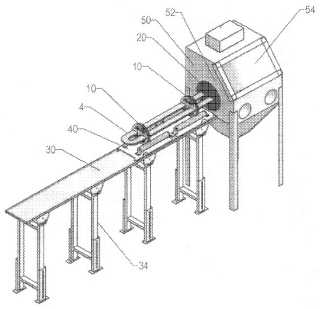

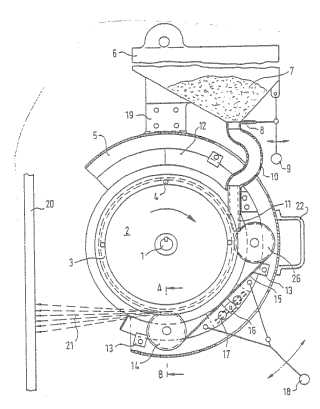

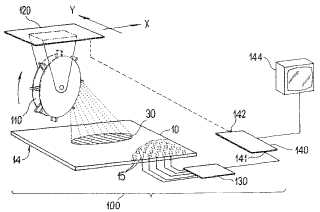

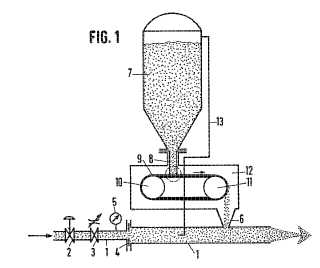

This place covers:

Abrasive blasting machines and plants.

This place does not cover:

Aspects of machines related to the processes of group B24C 1/00 and its subgroups | |

Aspects of machines related to the processes of dry ice blasting and blasting with salt dissolving during or after blasting | |

Aspects of machines related to the process of shot peening |

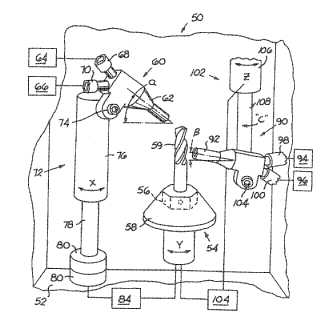

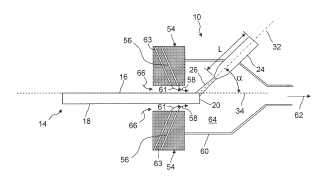

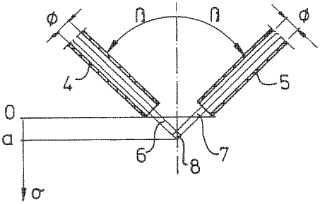

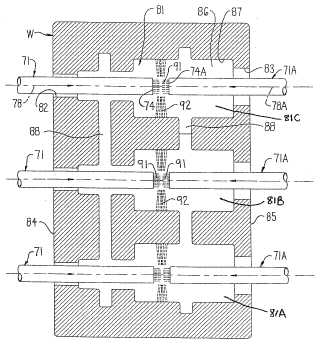

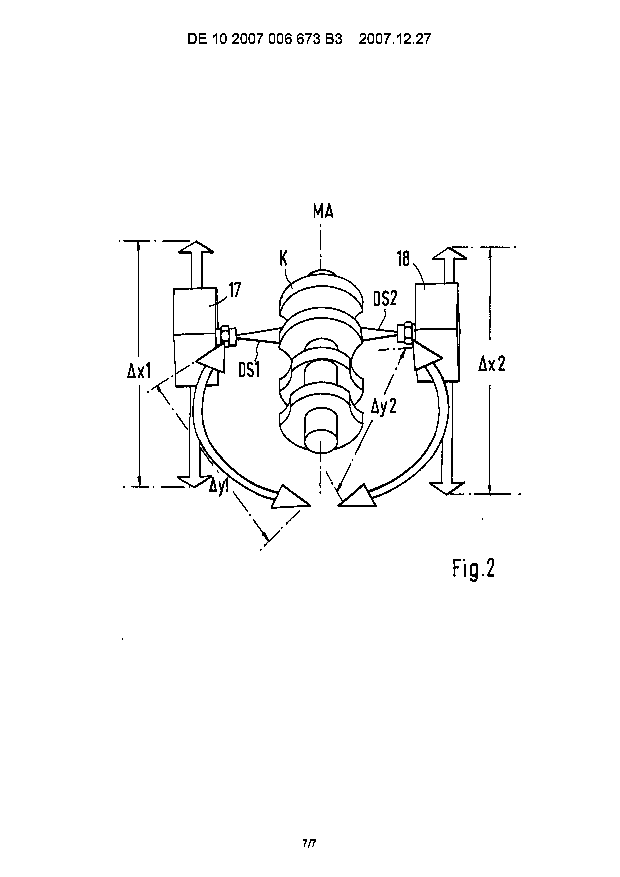

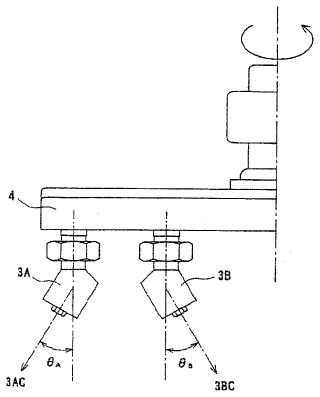

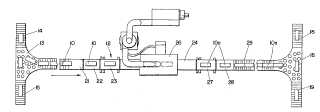

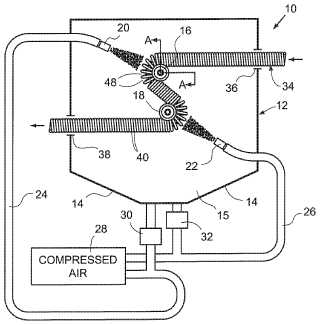

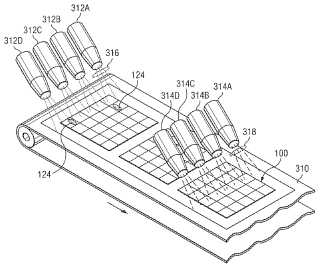

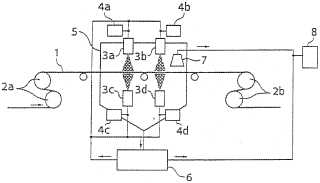

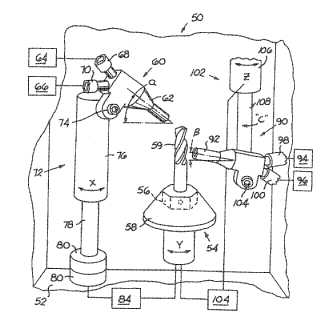

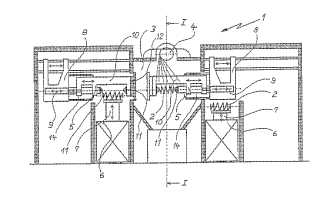

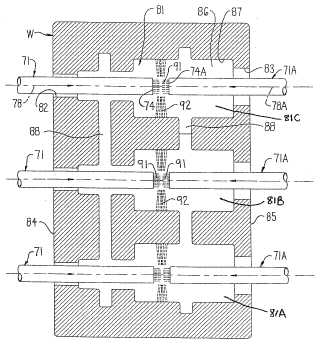

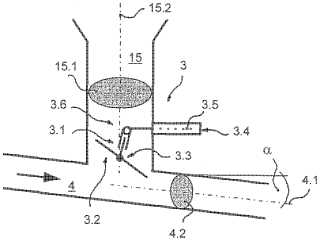

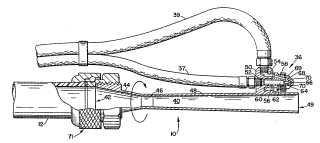

This place covers:

Also machines with intersecting and swinging or swivelling nozzles.

Example(s): US6604986 (intersecting nozzles), US20040162009, DE1020070006673 (swinging nozzles).

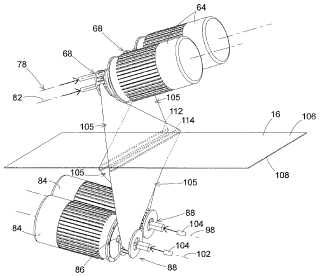

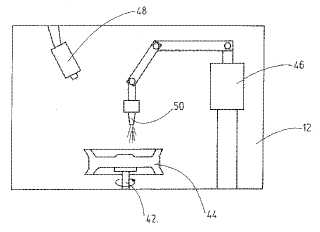

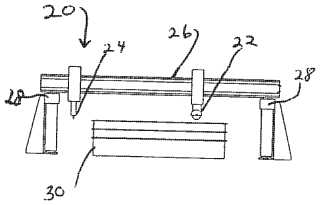

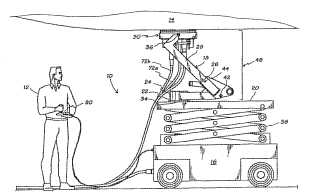

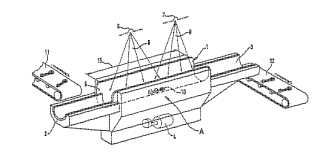

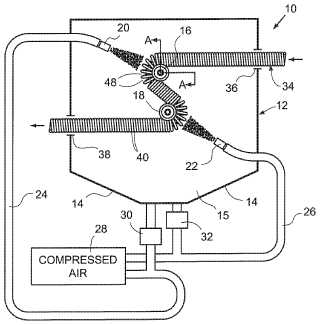

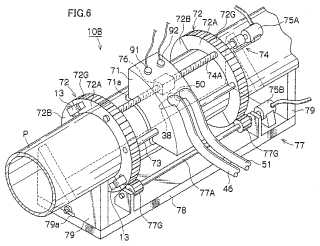

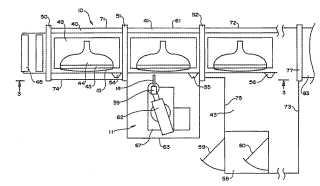

This place covers:

also devices with rotating nozzles.

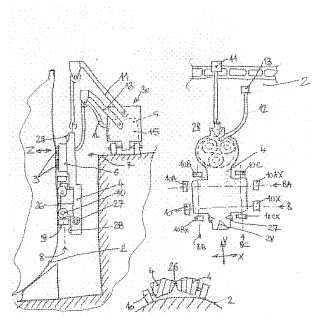

Example(s): DE1020070033788 (robot), WO20100119201 (rotating nozzles), WO9114539, US20060049285 (rotating nozzles), US20060135041 (gantry type), DE1020080027217

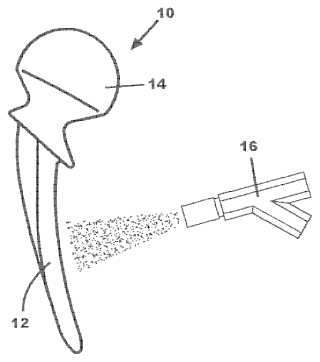

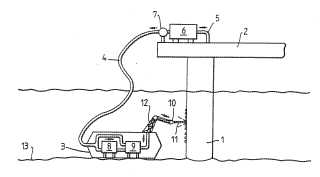

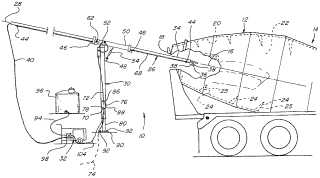

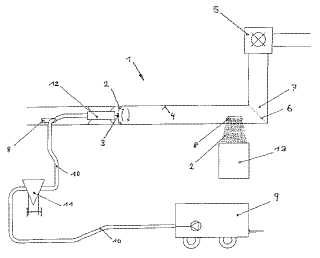

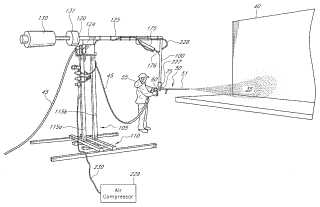

This place covers:

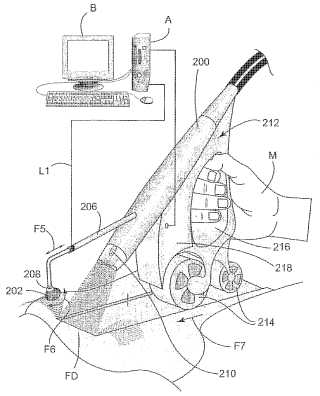

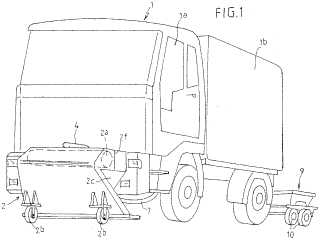

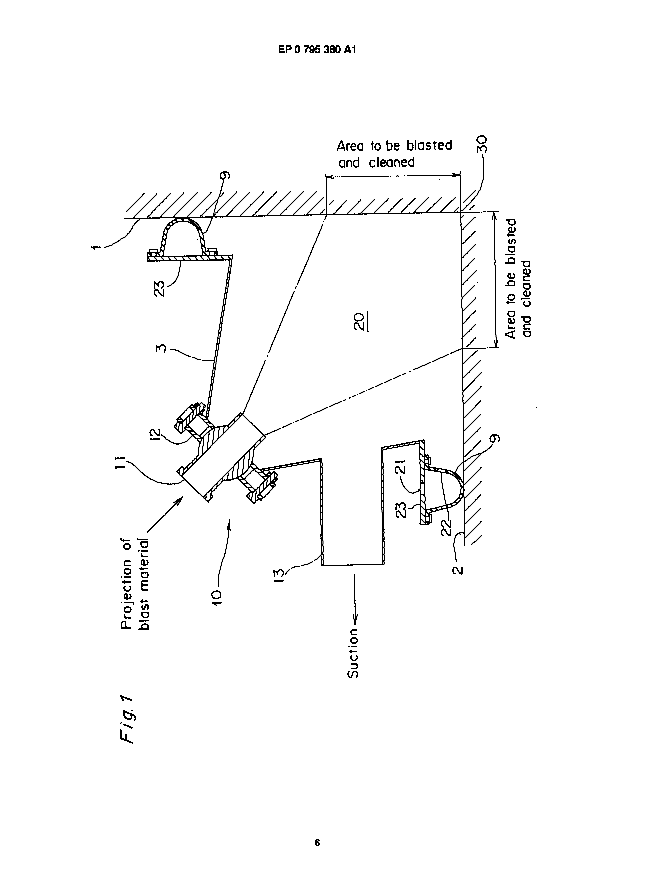

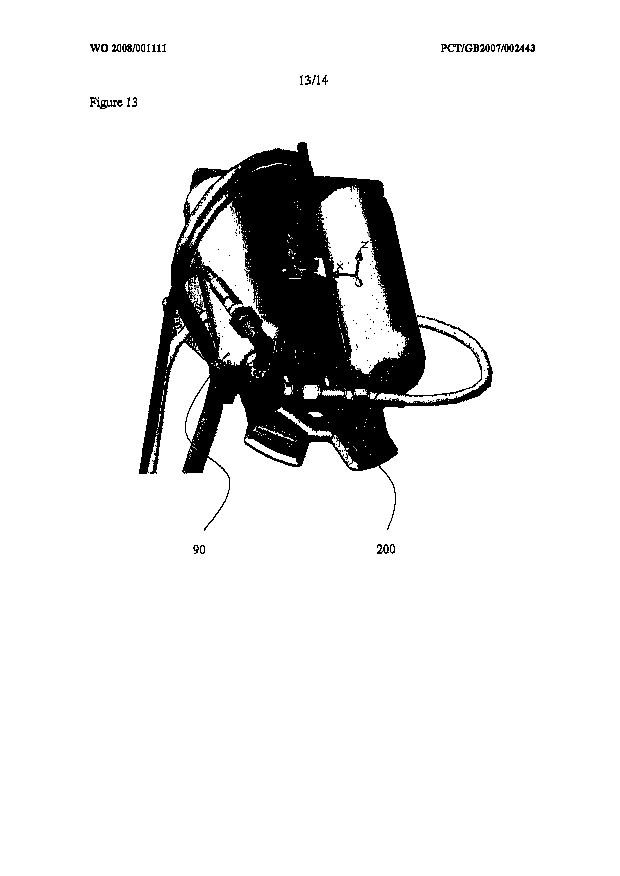

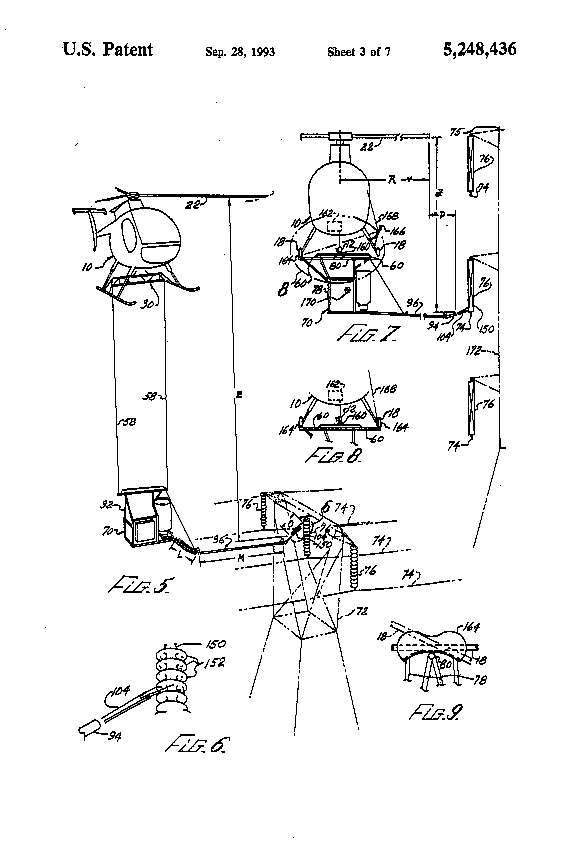

Example(s): US5191740, US5216849, WO9505922 (road barrier), US20080287039, WO20060097133 (handheld), US5181349 (handheld), EP1207235 (road vehicle), WO0048901, EP0795380 (corner), EP2038088 (portable), US5248436 (from helicopter or ship).

This place covers:

also blasting of surfaces that are not strictly vertical.

Example(s): FR2891175 (ship hull, airplane hull).

Blasting of surfaces that are not strictly vertical and containing devices with suction means are additionally classified in B24C 3/065.

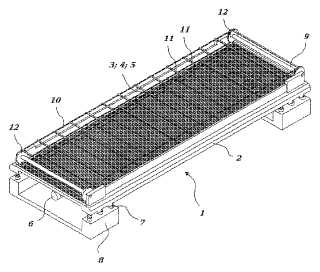

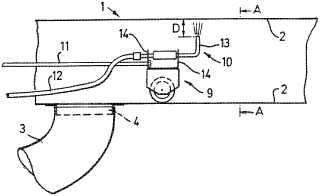

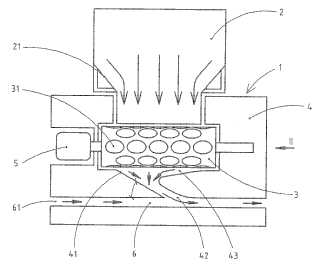

This place covers:

Devices with suction means and horizontal working plane for treating floorings.

Example(s): FR2564769.

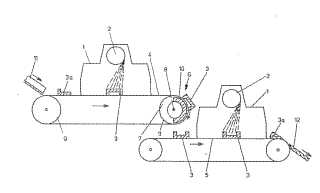

This place covers:

Example(s): US5512005, US5417608

This place does not cover:

Machines or devices where the workpieces are transported or agitated by troughed belt conveyors |

This place covers:

Example(s): GB1149317.

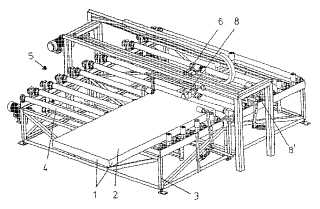

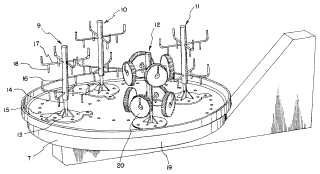

This place covers:

Example(s): EP0227275, EP0100944, GB1080030.

This place covers:

Example(s): EP2178677, US20080258367, US20080209731.

This place does not cover:

Machines or devices where the workpieces are transported or agitated by troughed belt conveyors |

This place covers:

Example(s): CH614656.

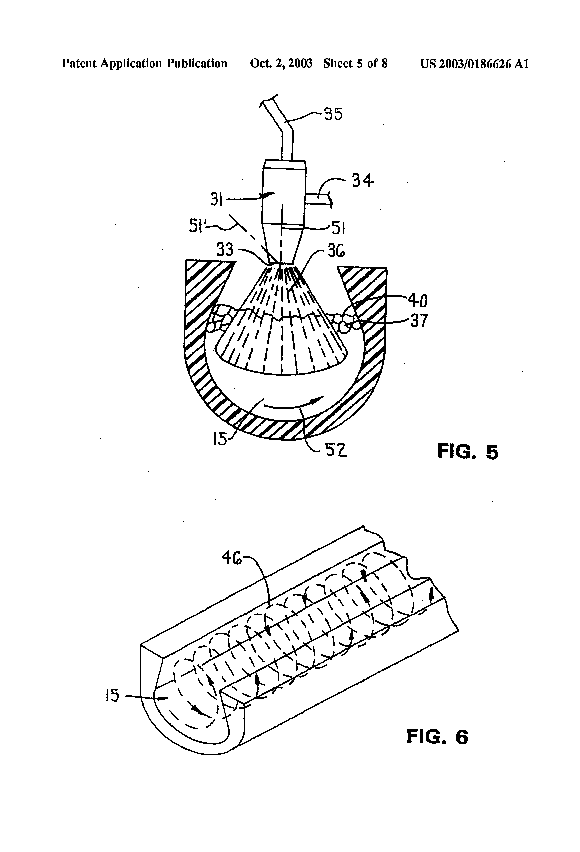

This place covers:

Example(s): DE4435333, DE1020080011663, US20030186626.

This place covers:

Example(s): US20050204528

This place does not cover:

Machines or devices where the workpieces are transported or agitated by troughed belt conveyors |

This place covers:

Example(s): US20050255795, US4251956, US20030219621.

This place covers:

Example(s): US20080209731, DE4342593.

This place covers:

Example(s): US20060189265.

This place covers:

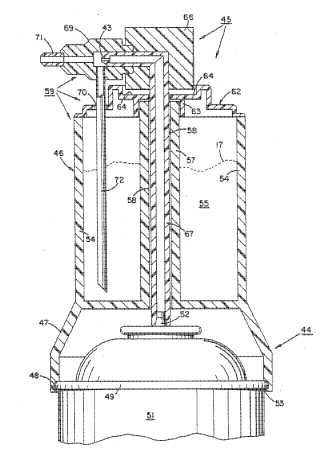

Example(s): EP0927773, WO9735686, US5272897.

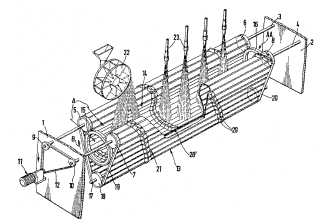

This place covers:

Example(s): US6726548, DE4408643, DE4415094.

This place covers:

Example(s): JP60034270, EP1172177, WO20040048036.

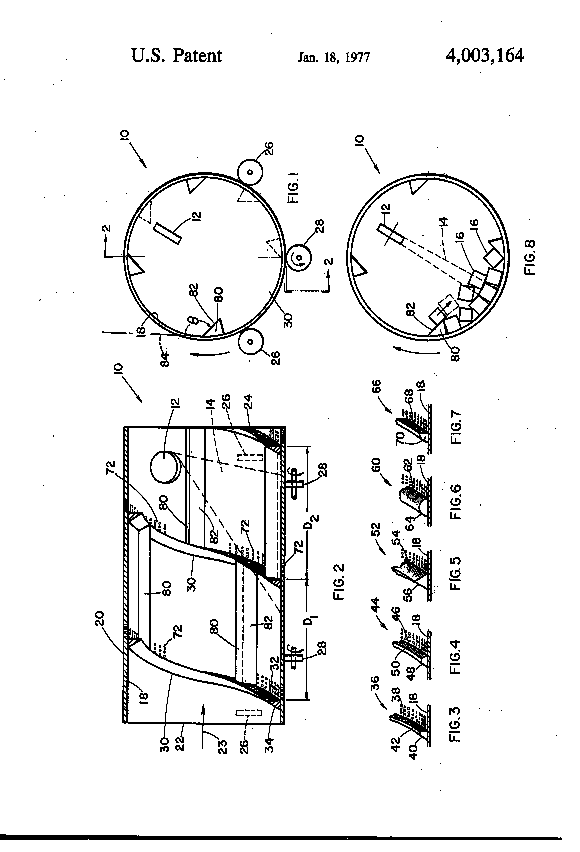

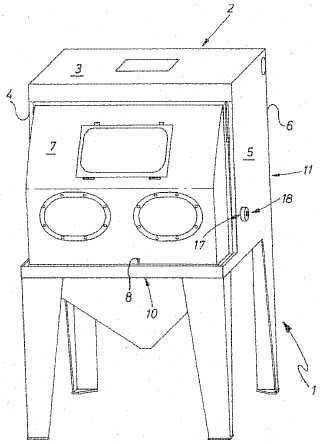

This place covers:

Example(s): CH665987, US4218854, US4003164.

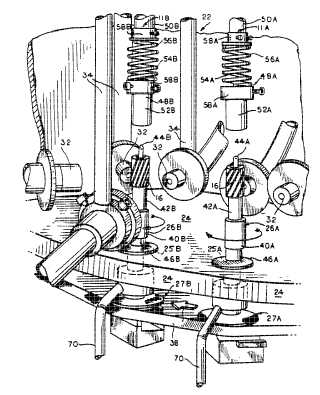

This place covers:

Example(s): EP1754573, WO9505922, GB2249045, US20030070693 (method for cleaning and injection mould), US5512007 (flexible connection), DE4408645 (springs).

Contrary to the take-precedence-rules in the title of this subgroup, documents relating to the aspects of subgroup B24C 3/08 (abrasive blasting of traveling or moving workpieces) and documents relating to the aspects of subgroup B24C 3/18 (with means for moving workpieces into different working positions) are covered in this subgroup B24C 3/32 when additionally relating to the aspects of this subgroup B24C 3/32 (designed for abrasive blasting of particular work).

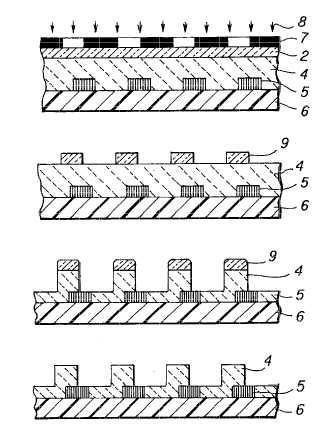

This place covers:

Example(s): WO9528256 (blasting of CRT), US5916738, US20100068976 (blasting of motor conductors).

This place does not cover:

Blasting semiconductor devices e.g. with a jet of particulate matter acting like sand blasting |

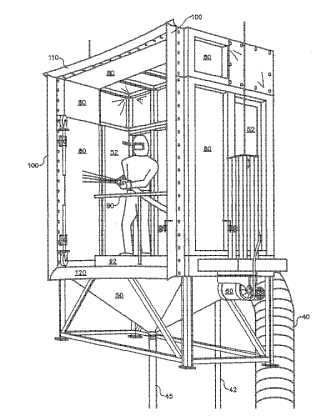

This place covers:

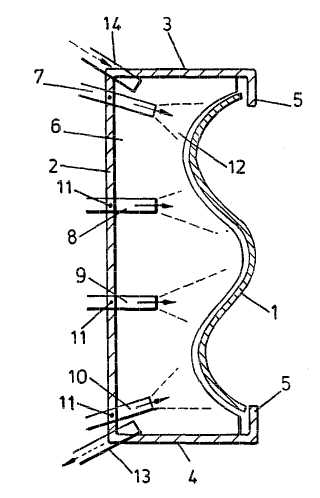

Example(s): DE1020070006661, EP1898003 (blasting of tunnel walls), EP1901894, US20040162009 (internal blasting of motor block), DE10341029, US20020179119 (internal blasting of concrete mixer), US6402854, EP1423237, GB850045, DE4015412.

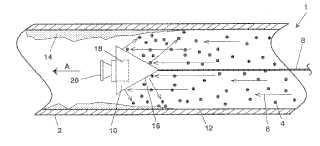

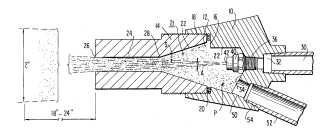

This place covers:

Blasting of internal surfaces with particulate matter and without passing a blast gun, impeller or the like along the internal surface.The flow is considered as blasting only when the dynamic viscosity of the carrier is less than or equal to that of conventional fuels like diesel, e.g. when water is used as a carrier.

Example(s): EP1312432, US5391256, DE4420579.

This place does not cover:

Machining of internal surfaces with plastically deformable grinding compound, i.e. when the dynamic viscosity of the carrier medium is higher than that of conventional fuels like diesel |

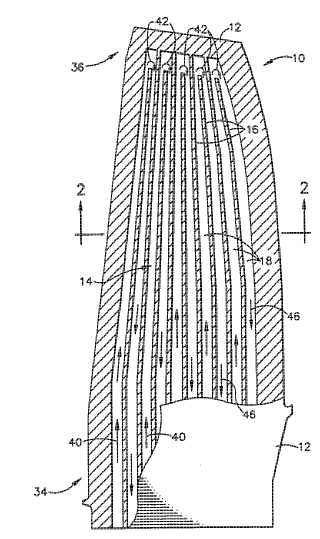

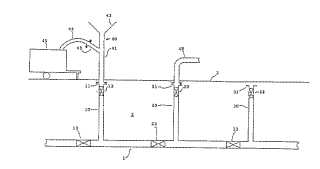

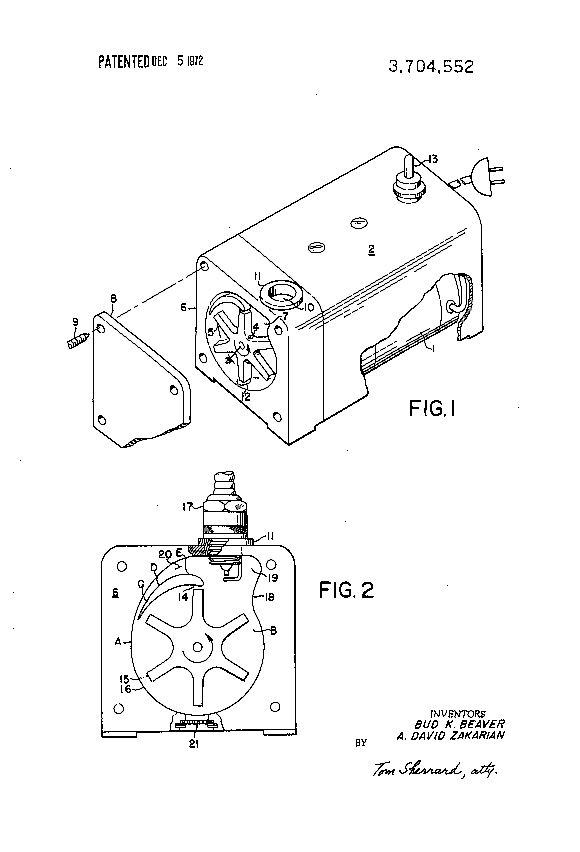

This place covers:

Example(s): US3704552, US3913273.

This place covers:

e.g. abrasive blasting with particles by jet flame processing.

Example(s): GB938025, US4616787, EP1539424 (jet flame abrasive blasting) EP1155781.

Attention is drawn to the following places, which may be of interest for search:

Jet flame processing in general |

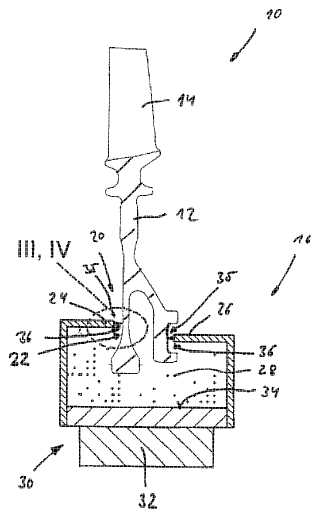

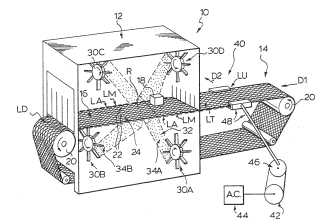

This place covers:

Example(s): EP1207013, FR2689431.

Attention is drawn to the following places, which may be of interest for search:

Sonic cleaning in general |

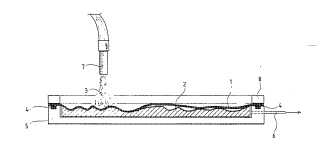

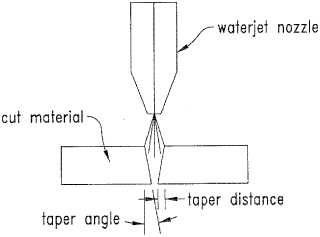

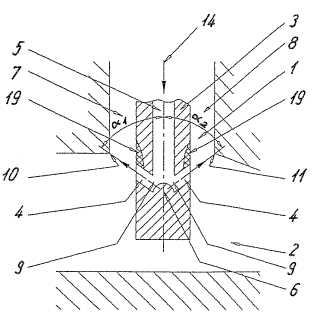

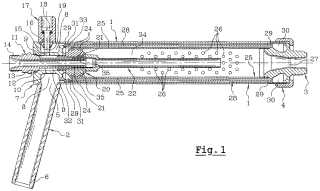

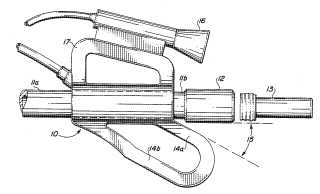

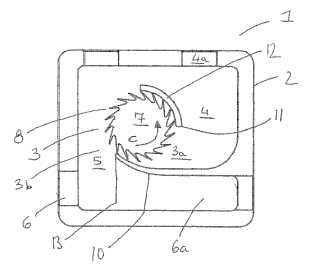

This place covers:

Example(s): US7341504, US20060276112, DE19804233, US5908349, US4932592, EP0083614.

Attention is drawn to the following places, which may be of interest for search:

Perforating by means of a fluid jet without particles | |

Severing by means of a fluid jet without particles |

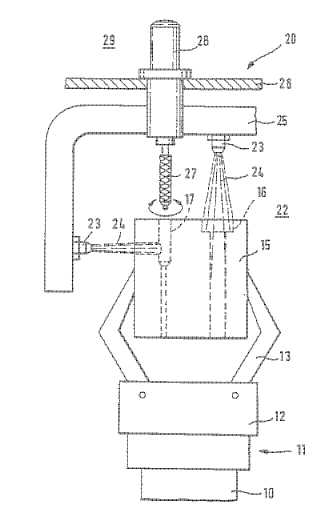

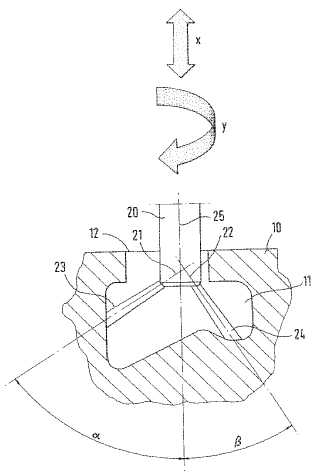

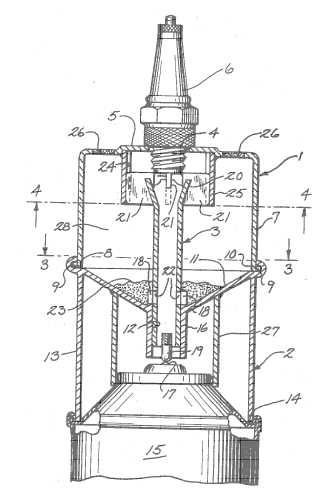

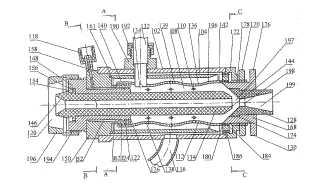

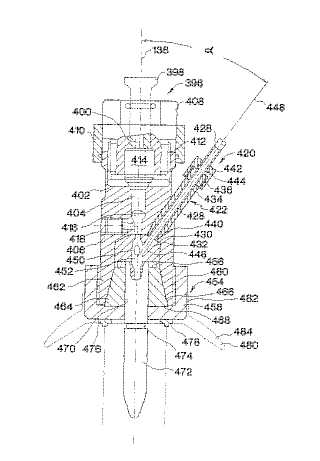

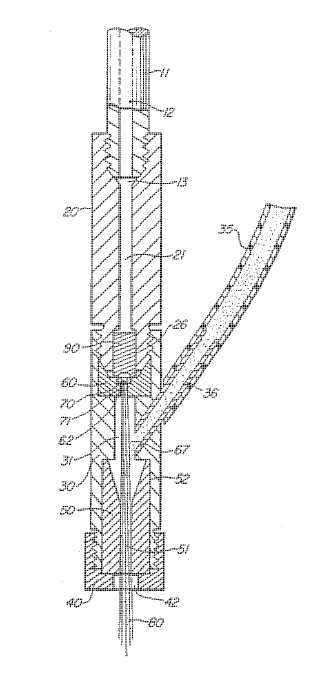

This place covers:

Example(s): EP1574290, FR2866586, DE10243855, WO03103899, EP1178873, US20030045217, US6695686, US5704825, US5484325.

Attention is drawn to the following places, which may be of interest for search:

Nozzles in general, Spraying or atomising in general |

This place covers:

Example(s): WO20070072863, WO0239078, US6126516, US5779524, DE3505468.

This place covers:

Example(s): EP1352713, US5759091, EP0688633, GB985743, GB1101107, US4069025.

This place covers:

Example(s): EP1412133, US4244150.

This place covers:

Example(s): US6692340, WO0200393, US5076028.

This place covers:

Example(s): EP1360035, EP1354667, US5688162.

This place covers:

Example(s): US20040259473 (magnetically), US5211135 (detonation cord clusters for deslagging water boilers).

Attention is drawn to the following places, which may be of interest for search:

Abrasive blasting by jet flame processing | |

Jet flame processing in general | |

Use of magnetic polishing media without forming a blasting jet |

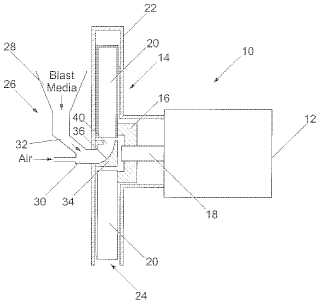

This place covers:

Equipment for feeding and controlling the characteristics of abrasive blasting material

This place covers:

Example(s): EP0322485, GB731117, EP1557223.

This place covers:

Example(s): DE19933339, US5283991.

This place covers:

Example(s): US20070207702, JP59001167.

This place covers:

Example(s): GB1424896.

This place covers:

Example(s): DE10260257, DE4335382.

This place covers:

Example(s): DE1020070039540.

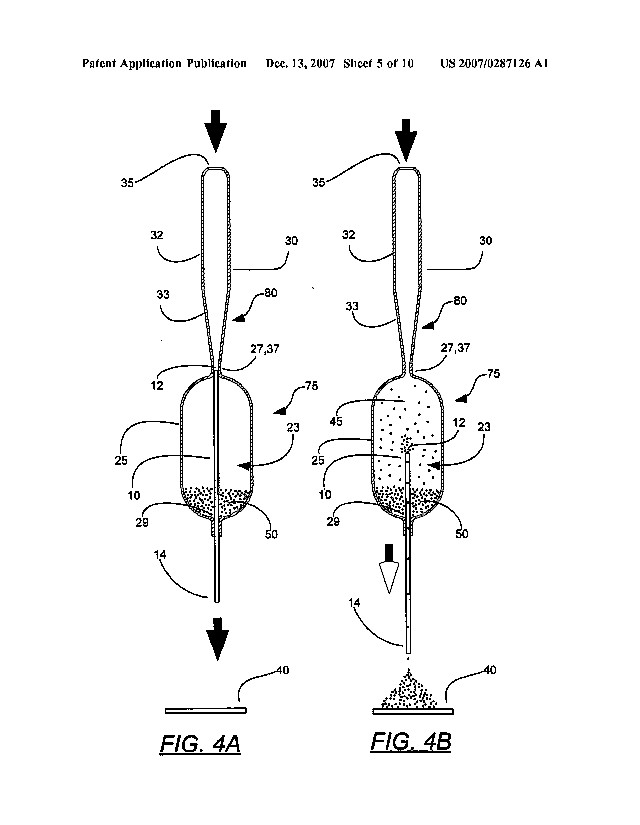

This place covers:

Example(s): DE10235097, US20070287126, EP2001637.

This place covers:

Example(s): EP0992221, US5081799.

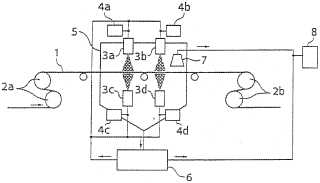

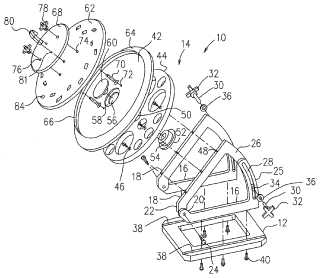

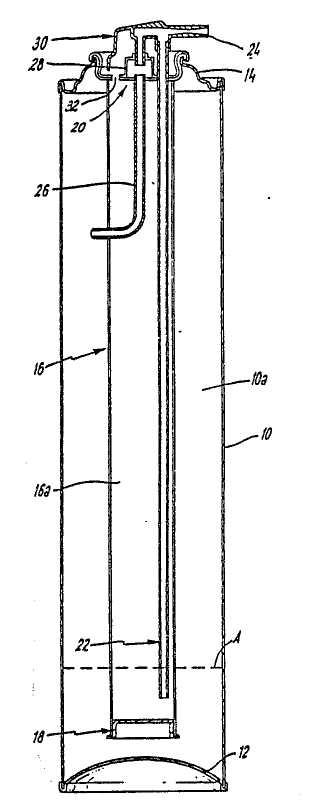

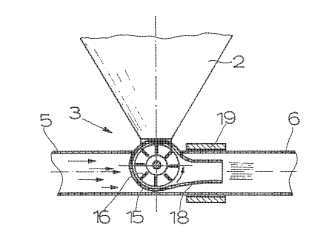

This place covers:

Example(s): EP1851003, WO20040101224, WO9635389, EP0652078, US4569161, US3858360.

This place covers:

Example(s): DE10348805, US4666083, US4218855.

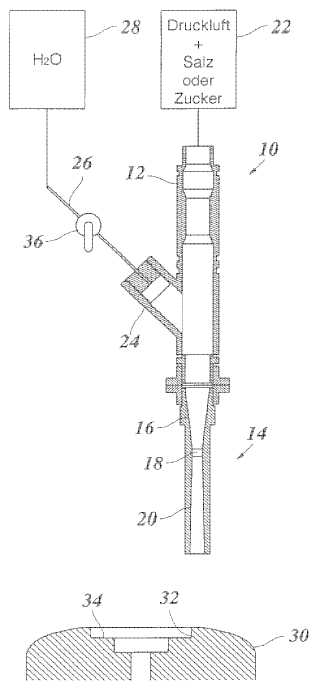

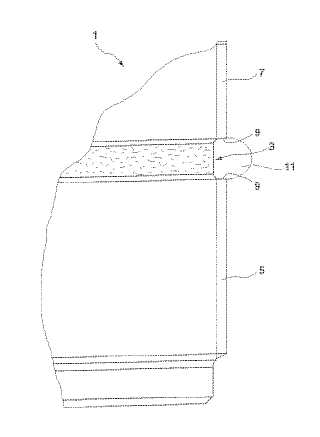

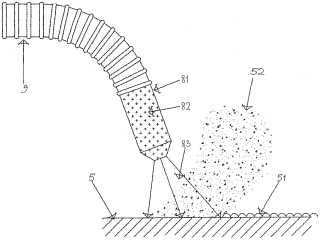

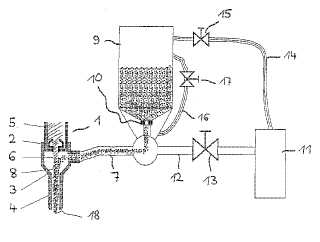

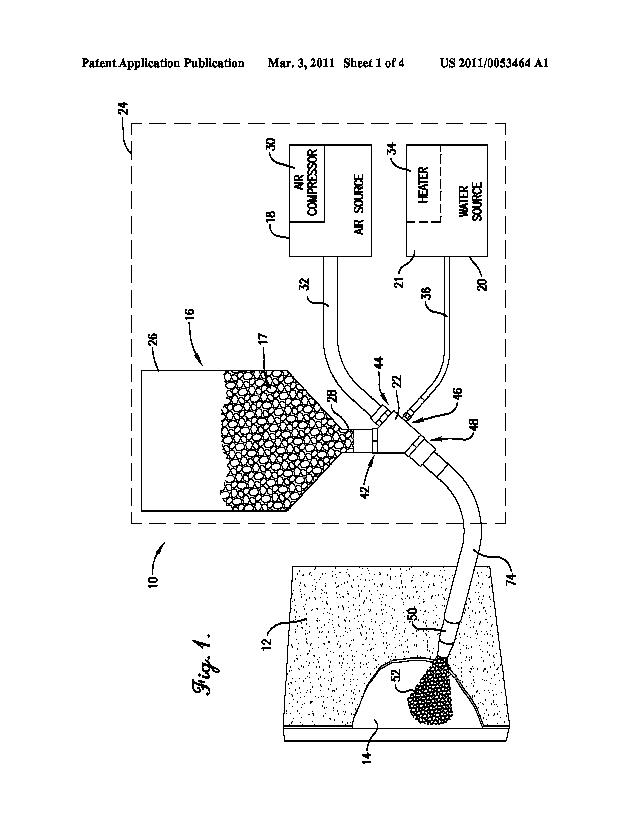

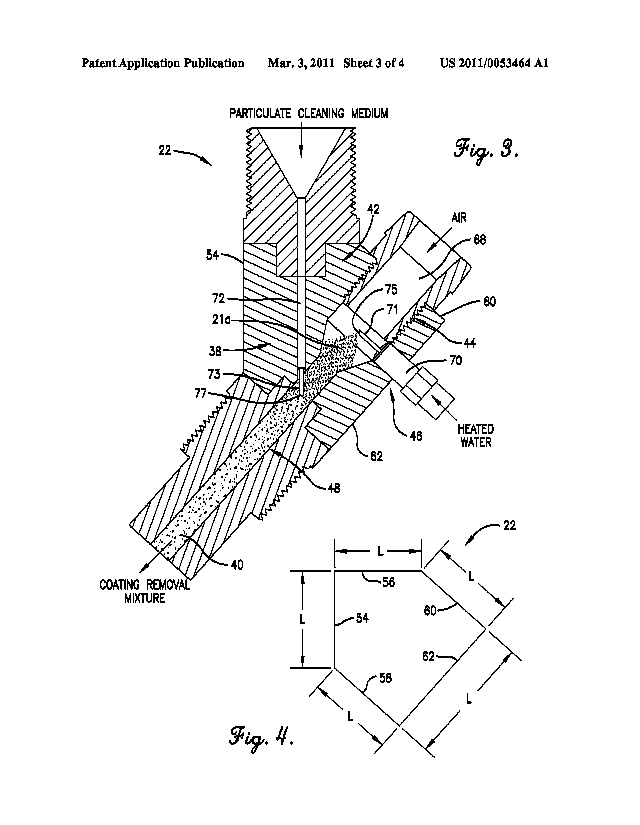

This place covers:

E.g. blasting where the abrasive is first mixed with liquid and a gas and then the mixture is fed and propelled to the working surface, or where the abrasive is added to a premixed flow of liquid and gas, or where a shrouding water curtain or water jet is added to the mixture jet of gas and abrasive.

Example(s): US20110053464, US20110053464, US5283991, WO9408753, GB498478, DE1020040023246.

This place does not cover:

Blasting with abrasive, liquid and gas, where either the gas or the liquid is used as a blasting medium to propel the mixture of the other two constituents | |

Blasting with abrasive, liquid and gas, where one of the constituents is used as an additive |

This place covers:

Example(s): DE10317663, DE3445643, GB2108399, JP58202777, WO20090096122.

This place covers:

Example(s): EP2335852, US20110053458, DE1020080011663, US20060260823, DE10216468, US5367841, US4882881, US4139970.

This place covers:

Example(s): DE19926084, DE4407956.

This place covers:

Example(s): EP1603709 GB2367777, US4275531, GB2337953.

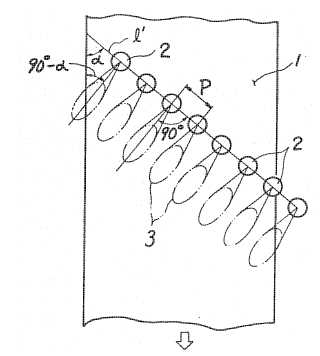

This place covers:

Example(s): WO20110052287, WO20090110231, US20060111023, JP57194878, US5344472, EP0798081.

This place does not cover:

Selection of abrasive material which changes phase after treatment |

This place covers:

Example(s): GB2403726, EP1422026.