CPC Definition - Subclass H01L

This place covers:

in general

- discrete and integrated semiconductor devices and

- other electric solid state devices (as far as not provided for in another subclass) and

- details thereof.

This includes the following kind of devices:

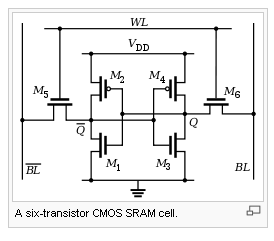

- integrated circuit devices, e.g. CMOS integrated devices, DRAM, EPROM or CCD;

- semiconductor devices (e.g. field-effect, bipolar) adapted for rectifying, amplifying, oscillating or switching, e.g. diodes, transistors or thyristors;

- semiconductor devices sensitive to radiation, e.g. photo diodes, photo transistors or solar cells;

- incoherent light emitting diodes, e.g. LED;

- solid state devices using organic materials as the active part or using a combination of organic materials with other materials as the active part, e.g. organic LED or polymer LED;

- electric solid state devices using thermoelectric, superconductive, piezoelectric, electrostrictive, magnetostrictive, galvano-magnetic or bulk negative resistance effects, e.g. thermo couples, Peltier elements, Josephson elements, piezo elements;

- photo-resistors, magnetic field dependent resistors or field effect resistors;

- capacitors having potential barriers or resistors having potential barriers;

- thin-film or thick-film circuits;

- processes and apparatus adapted for the manufacture or treatment of such devices, except where such processes relate to single step processes for which provision exists elsewhere.

Microstructural devices or systems are classified in subclass B81B, and the processes and apparatus specially adapted for the manufacture or treatment thereof are classified in subclass B81C. So, by way of example, microelectro-mechanical devices (MEMS), containing microelectronic and mechanical components, are classified in group B81B 7/02, and their manufacture, treatment or assembling in the relevant groups of B81C. Microstructural devices or systems working purely electrically or electronically, or related processes or apparatus for the manufacture or treatment thereof are, however, not covered by B81B or B81C and are classified in section H, for example in the groups of the current subclass H01L.

Microstructural devices or systems being of other than purely electrical or electronically type, and apparatus or processes for the manufacture or treatment thereof, which are normally classified in the subclasses B81B and B81C, may be also classified in those groups of H01L providing for their structural or functional features, whenever such features are of interest per se.

This place does not cover:

Use of semiconductor devices for measuring | |

Non-adjustable resistors from semiconductor material | |

Magnets, inductors, transformers | |

Capacitors in general | |

Electrolytic devices | |

Batteries, accumulators | |

Waveguides, resonators or lines of the waveguide type | |

Line connectors, current collectors | |

Lasers, stimulated emission devices, e.g. semiconductor laser | |

Electromechanical resonators; impedance networks | |

Loudspeakers, microphones, gramophone pick-ups or like acoustic electromechanical transducers | |

Electric light sources in general | |

Printed circuits, hybrid circuits, casings or constructional details of electric apparatus, manufacture of assemblages of electrical components |

Attention is drawn to the following places, which may be of interest for search:

Containers merely intended for transport or storage of wafers except during manufacture or finishing devices thereon | |

Conveying systems for semiconductor wafers except during manufacture or treatment of semiconductor or electric solid state devices or components thereon | |

Micromechanical Devices (MEMS) | |

Processes and apparatus specially adapted for the manufacture or treatment of microstructural devices or systems | |

Coating Material | |

Non-mechanical removal of metallic material from surface | |

Measurement of Mechanical Vibrations or Ultrasonic, Sonic or Infrasonic Waves | |

Measurement of Intensity, velocity, Spectral, Content, Polarization, Phase or Pulse Characteristic of Infrared, Visible or Ultraviolet Light | |

Measuring Electrical or Magnetic Variables | |

Details of scanning-probe apparatus, in general | |

Radio Direction-Finding; Radio Navigation; Determining Distance or Velocity by Use of Radio Waves; Locating or Presence-Detecting by Use of the Reflection or Reradiation of Radio Waves; Analogous Arrangements Using Other Waves | |

Measuring Nuclear or X-Radiation | |

Electro photography | |

Systems for Regulating Electrical or Magnetic Variables | |

Digital Computers | |

Static Stores | |

Conductive and Insulating Materials | |

Electric discharge tubes or discharge lamps | |

Amplifiers | |

Pictorial Communication, e.g. Television |

In this subclass, Indexing Codes are mainly attributed with a view to allow retrieval of documents comprising a combination of technical characteristics, some of them being unimportant per se, and, hence, identified as additional information rather than invention information.

In this subclass, both the process and apparatus for the manufacture or treatment of a device and the device itself are classified, whenever both of these are described sufficiently to be of interest.

In this place, the following terms or expressions are used with the meaning indicated:

assembly of a device | the "assembly" of a device is the building up of the device from its component constructional units and includes the provision of fillings in containers. |

complete device | a "complete device" is a device in its fully assembled state which may or may not require further treatment, e.g. electro-forming, before it is ready for use but which does not require the addition of further structural units. |

component | a "component" is one electric circuit element of a plurality of elements formed in or on a common substrate. |

container | a "container" is an enclosure forming part of the complete device and is essentially a solid construction in which the body of the device is placed, or which is formed around the body without forming an intimate layer thereon. |

device | the term "device" refers to an electric circuit element; where an electric circuit element is one of a plurality of elements formed in or on a common substrate it is referred to as a "component". |

electrodes | "electrodes" are regions in or on the body of the device (other than the solid-state body itself), which exert an influence on the solid-state body electrically, whether or not an external electrical connection is made thereto. An electrode may include several portions and the term includes metallic regions which exert influence on the solid-state body through an insulating region (e.g. capacitive coupling) and inductive coupling arrangements to the body. The dielectric region in a capacitive arrangement is regarded as part of the electrode. In arrangements including several portions only those portions which exert an influence on the solid-state body by virtue of their shape, size or disposition or the material of which they are formed are considered to be part of the electrode. The other portions are considered to be "arrangements for conducting electric current to or from the solid-state body" or "interconnections between solid state components formed in or on a common substrate", i.e. leads. |

encapsulation | an "encapsulation" is an enclosure which consists of one or more layers formed on the body and in intimate contact therewith. |

integrated circuit | an "integrated circuit" is a device where all components, e.g. diodes, resistors, are built up on a common substrate and form the device including interconnections between the components. |

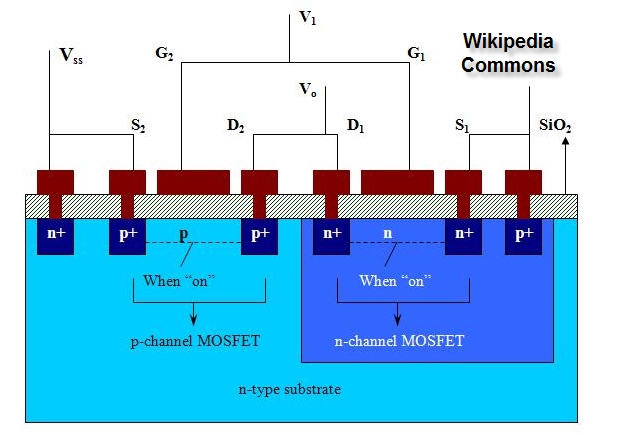

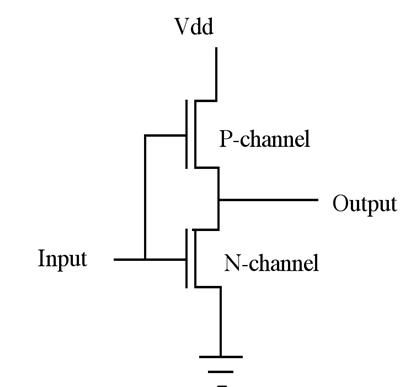

integration process | processes for the manufacture of at least two different components where the process is especially adapted to their integration, e.g. to take advantage of the integration or to reduce their manufacturing cost. Example: in a CMOS process, the same ion implant dopes the p-MOS gate and the n-MOS source and drain. Consequently, a process for the manufacture of a component per se is not considered as an integration process, even though that component will be part of an integrated circuit. |

interconnection | refers to the arrangement of conductive and insulating regions aimed at electrically connecting the respective electrodes of at least two device units, e.g. two transistors. |

parts | the term "parts" includes all structural units which are included in a complete "device". |

solid state body | the expression "solid state body" refers to the body of material within which, or at the surface of which, the physical effects characteristic of the device occur. In thermoelectric devices it includes all materials in the current path. |

wafer | a "wafer" means a slice of semiconductor or crystalline substrate material, which can be modified by impurity diffusion (doping), ion implantation or epitaxy, and whose active surface can be processed into arrays of discrete devices or integrated circuits. |

In patent documents, the following words/expressions are often used with the meaning indicated:

package | container, encapsulation. |

This place covers:

Processes and apparatus that are specially adapted for the manufacturing of semiconductor or solid state devices belonging to the type:

- Integrated circuit devices, e.g. CMOS integrated devices, DRAM, EPROM, CCD;

- Semiconductor devices (e.g. field-effect, bipolar) adapted for rectifying, amplifying, oscillating or switching, e.g. diodes, transistors, thyristors;

This main group includes;

- Manufacture or treatment of the above semiconductor devices or of parts thereof

- Manufacture or treatment of solid state devices other than semiconductor devices, or of parts thereof

- Apparatus specially adapted for handling semiconductor or electric solid state devices during manufacture or treatment thereof; Apparatus specially adapted for handling wafers during manufacture or treatment of semiconductor or electric solid state devices or components

- Manufacture or treatment of devices consisting of a plurality of solid state components formed in or on a common substrate or of parts thereof; manufacture of integrated circuit devices or of parts thereof

Attention is drawn to the following places, which may be of interest for search:

Processes or apparatus specially adapted for the manufacture or treatment of devices provided for in groups H01L 31/00, H01L 33/00, H10K 30/00, H10K 50/00, H10K 59/00, H10K 71/00, H10K 85/00, H10K 99/00, H10N 10/00, H10N 30/00, H10N 35/00, H10N 50/00, H10N 52/00, H10N 60/00H10K 99/00 or of parts thereof, see these groups | H01L 31/00, H01L 33/00, H10K 30/00, H10K 50/00, H10K 59/00, H10K 71/00, H10K 85/00, H10K 99/00, H10N 10/00, H10N 30/00, H10N 35/00, H10N 50/00, H10N 52/00, H10N 60/00H10K 99/00 |

Processes for applying liquids or other fluent materials | |

Liquid cleaning (in general) | |

Machines, Devices, or Processes for Grinding or Polishing | |

Containers, packaging elements or packages specially adapted for particular articles or materials | |

Shaped ceramic Products | |

Polishing compositions | |

Cleaning Compositions | |

Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material | |

Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating (CVD) | |

Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds,without leaving reaction products of surface material in the coating | |

Etching metallic material by chemical means | |

Processes for the Electrolytic or Electrophoretic Production of Coatings | |

Single Crystal Growth; Epitaxy | |

Testing individual semiconductor devices | |

Preparation of originals for the photomechanical production of textured or patterned surfaces | |

Photolithographic, production of textured or patterned surfaces | |

Registration or positioning of originals, masks, frames, photographic sheets or textured or patterned surfaces | |

Discharge tubes with provision for introducing objects or material to be exposed to the discharge (plasma etching; ion implantation) | |

Apparatus or processes specially adapted for manufacturing or adjusting assemblages of electric components |

Single mono-steps for which a provision exists elsewhere in ECLA need not to be classified in H01L 21/00, except if they are specific to the fabrication of semiconductor devices as defined under H01L 21/00. E.g., apparatuses which are not specific to the fabrication of these devices, e.g. apparatuses for depositing layers, are classified in C23C or C30B.

Direct pre-treatment or direct post-treatment of a specific step is classified under the specific step if no other place exists in H01L 21/00. Example: annealing after layer coating is classified together with the coating. Exception: cleaning, see H01L 21/02041

In H01L 21/00, poly-silicon is generally considered as a conductive material for classification purposes, except for its deposition (H01L 21/02365) where it is considered as semiconducting.

Polishing or chemical-mechanical polishing are not distinguished for classification.

Machines and apparatuses for which a provision exists somewhere else in CPC are not classified In H01L 21/00. For example apparatus for deposition of materials are classified in C23C or C30B.

Machines and apparatuses for which no particular provision exists in CPC are classified in H01L 21/67 and subgroups. See also the notes under H01L 21/67.

Processes mainly consisting of features of the use of the elements of the apparatus and which are necessary to operate said apparatus (like for example rotating the turntable of a polisher, evacuating the chamber of a plasma appraratus etc...) need not to be classified in H01L 21/00.

Subject matter relating to processes and apparatus which are clearly suitable for manufacture or treatment of devices whose bodies comprise elements of the fourth group of the Periodic System (silicon, germanium), and where the material used is not explicitly specified, is classified in the subgroups relating to semiconductors of the fourth group of the Periodic System (silicon, germanium).

For multistep processes, a junction between two regions of the same material but in a different crystalline state, e.g. amorphous silicon or polysilicon emitters on single crystalline silicon, is not considered as a heterojunction.

In this place, the following terms or expressions are used with the meaning indicated:

Dry Process | refers to processes wherein only gases or vapours are provided on the surface of a substrate, e.g. a wafer, irrespective of the physical state of the reaction products, gaseous, liquid or solid. |

Wet Process | refers to processes wherein only liquids are provided at the surface of a wafer, including the condensation on the surface of a wafer of gaseous components. |

Pre-, post-treatment | direct, for example in situ, treatment, preceding or following a main technological step, aimed at improving said main technological step or its result. Not considered as a technological step per se. Examples: - annealing or crystallisation after deposition of insulating layers, - cleaning before or after a technological step, - modifying an insulating layer just after its formation, e.g. implantation after deposition |

After treatment | Subsequent main technological step. Examples: - patterning or polishing of a layer after deposition- modifying an insulating layer after a step which is not the formation of the insulating layer |

In patent documents, the following abbreviations are often used:

CVD | Chemical vapour deposition |

PECVD | Plasma enhanced CVD |

LPCVD | Low pressure CVD |

PVD | Physical Vapour Deposition |

ALD | Atomic layer deposition |

ALE | Atomic layer epitaxy |

CMP | Chemical mechanical polishing |

ECMP | Electrochemical CMP |

SOI | Silicon on Insulator |

BESOI | Bonded and Etched-Back Silicon-On-Insulator |

SOS | Silicon on Sapphire |

HSG | Hemispherical grain |

RIE | Reactive ion etching |

BSG | boron silicate glass |

PSG | phosphorous silicate glass |

BPSG | boron phosphorous silicate glass |

USG | Undoped silicate glass |

FSG | Fluorine silicate glass |

PZT | Lead zirconate titanate |

BST | Barium strontium titanate |

HSQ | Hydrogen silsesquioxane |

MBE | Molecular beam epitaxy |

ELO | Epitaxial lateral overgrowth |

MIS | Metal-insulator-semiconductor |

MOS | Metal-oxide-semiconductor |

CMOS | Complementary MOS |

DMOS | Double diffused MOS |

VDMOS | Vertical DMOS |

LDMOS | Lateral DMOS |

IMPATT | Impact Ionization Avalanche Transit Time |

TRAPATT | Trapped Plasma Avalanche Triggered Transistor |

SITh | Static induction thyristor |

FCTh | Field controlled thyristor |

IGBT | Insulated Gate Bipolar Transistor |

HET | Hot electron transistor |

SET | Single electron transistor |

SIT | Static Induction Transistor |

MBT | Metal base transistor |

RHET | Resonant tunnelling hot electron transistor |

RTT | Resonant tunnelling transistor |

BBT | Bulk barrier transistor |

PBT | Permeable Base Transistor |

HFET | Heterostructure FET |

HIGFET | Heterostructure Insulated Gate FET |

SISFET | Semiconductor-insulator-semiconductor FET |

HJFET | Hetero Junction FET |

MISFET | Metal-insulator-semiconductor FET |

JFET | Junction FET |

FinFET | FET with Fin-type channel |

MuGFET | Multi Gate FET |

HEMT | High Electron Mobility Transistor |

PDBT | Planar doped barrier transistor |

CHINT | Charge injection transistor |

LDD | lightly doped drain |

DDD | Double diffused drain |

EPIC | Epitaxial Passivated Integrated Circuit |

LOCOS | Local Oxidation of Silicon |

SWAMI | Side Wall Masked Isolation |

SILO | Sealed Isolation LOCOS |

SIMOX | Separation by Implantation of Oxygen |

FIPOS | Full Isolation by porous oxidized silicon |

ELTRAN | Epitaxial Layer Transfer |

SEG | Selective Epitaxial Growth |

DRAM | Dynamic RAM |

CCD | Charge Coupled Device |

This place covers:

Multi-step processes for the manufacture of semiconductor wafers for the fabrication of semiconductor devices as defined under H01L 21/00, prior to the fabrication of any device or part of device, i.e. between the sawing of ingots (covered by B28D) and the cleaning of the wafers (H01L 21/02041), e.g. grinding followed by lapping and polishing.

Covers the preparation of bulk semiconductor wafers (e.g. bulk silicon wafers).

See also H01L 21/8258, which has been used for classifying the fabrication of substrates containing parts of Group-IV and Group AIII-BV semiconductors.

See also C30B 33/00.

This place does not cover:

Thermal smoothening | |

The fabrication of inhomogeneous wafers, like SOI | |

Marking of wafers | |

The fabrication of wafers comprising portions of different materials | |

Forming flats |

Wafers per se are classified in H01L 29/06

This place covers:

Bulk, homogeneous wafers:

- Group IV, Si, Ge,

- Group III-V, GaAs, InP,

This place covers:

Multistep process for preparing wafers where the accent is put on a specific step.

This place covers:

Multistep process for preparing wafers where the accent is put on the grinding or lapping, e.g. multiple grinding steps.

This place covers:

Multistep process for preparing wafers where the accent is put on the backside treatment.

Includes backside treatment for recognition purposes

This place covers:

Multistep process for preparing wafers where the accent is put on the chemical etching step or steps.

Attention is drawn to the following places, which may be of interest for search:

Chemical or electrical treatment, e.g. electrolytic etching |

This place covers:

Multistep process for preparing wafers where the accent is put on the edge treatment, e.g. chamfering.

This place does not cover:

Does not cover the processing of edges of Smart Cut donor substrates, classified in reclaiming/reprocessing |

This place covers:

Multistep process for preparing wafers where the accent is put on the mirror polishing.

In case a mechanical mirror polishing is completed by a chemical flattening step, e.g. a gaseous flattening step, the latter is classified independently.

This place covers:

Multistep processes for preparing wafers having a specific orientation planes as useful plane, or a specific orientation plane in a plane parallel to the surface.

Attention is drawn to the following places, which may be of interest for search:

Single-crystal growth by pulling from a melt characterised by the seed, e.g. its crystallographic orientation |

This place covers:

Making a surface of the wafer porous. Includes formation of internal porous regions.

This place does not cover:

Localized formation (using e.g. masks) of porous regions |

This place covers:

Multistep processes for reclaiming or re-processing, a wafer containing more than a cleaning process. Also contains the re-processing of Smart-Cut donor substrates.

Attention is drawn to the following places, which may be of interest for search:

Specific cleaning for reclaiming or reprocessing |

This place covers:

Processes adapted to change the shape of a wafer, either in the surface plane (e.g. square, rectangular wafers), or in cross section (bone cross section).

This place does not cover:

The provision of flats, classified with the fabrication of the ingot |

This place covers:

Cleaning of wafers before or during manufacturing;

Cleaning is the removal of entities which were always unwanted, like particles, impurities, stringers, fences etc. Also includes the removal of edge beads or unwanted coatings on edges or backside of the wafers etc., except photoresist edge beads and photoresist on backside.

Removal of entities which have had a use or a function (sidewalls, resists etc.) is not considered to be a cleaning.

Includes the removal of natural oxide, see also the section "Special rules for classification within this group" below.

Starts with the deep cleaning carried out before first fabrication step (Piranha-RCA) up to cleaning after singulation.

Rinsing and drying are seen as a post-treatment of a wet cleaning, classified together with wet cleaning in H01L 21/02052.

This place does not cover:

Does not cover the transformation of an impurity or contaminant in something else remaining on the device, e.g. passivation, classified with passivation in general | |

Processes for the removal of only photoresists, classified in | |

Removal of excess metal after silicidation, classified in | |

Does not cover processes for the removal of photoresists edge beads after coating |

Attention is drawn to the following places, which may be of interest for search:

Cleaning apparatus | |

Cleaning by methods involving the use of tools, brushes, or analogous members, the use or presence of liquid or steam, the use of air flow or gas flow; Cleaning by electrostatic means | |

Detergent compositions, e.g. cleaning solutions or liquids |

Removal of only natural oxide is also classified in H01L 21/311 if the process is of special relevance for thick oxides.

Removal of impurities, e.g. side walls after RIE, together with the photoresist is classified in H01L 21/02041, and additionally in H01L 21/311, if the resist removal method is peculiar.

In patent documents, the following abbreviations are often used:

RCA | standard clean composed of SC-1 and SC-2 at least, with piranha and HF or DHF |

SC-1 | standard clean 1: NH4OH-H2O2 |

SC-2 | standard clean 2: HCl, H2O2 |

DHF | diluted HF |

Piranha | H2SO4-peroxide |

This place covers:

Cleaning of the wafer before any manufacturing step for the device is carried out.

Attention is drawn to the following places, which may be of interest for search:

Does not cover the transformation of an impurity or contaminant in something else remaining on the device, e.g. passivation | |

Processes for the removal of only photoresist | |

Removal of excess metal after silicidation | |

Does not cover processes for the removal of photoresist edge beads after coating |

This place covers:

All cleaning steps are dry, or when the invention is focussed on a dry cleaning aspect, the cleaning also containing more classical wet steps, like RCA.

This place does not cover:

Cleaning of diamond |

This place covers:

Wet cleaning.

This place does not cover:

Cleaning of diamond |

Rinsing and drying are seen as a post-treatment of a wet cleaning, classified together with wet cleaning in H01L 21/02052.

This place covers:

The sequence of combining wet and dry steps.

This place does not cover:

Cleaning of diamond |

Rinsing and drying are seen as a post-treatment of a wet cleaning, classified together wet cleaning in H01L 21/02052.

This place covers:

Cleaning when at least a fabrication step for a device (for example, first oxidation) has been carried out.

This place covers:

- Cleaning after etching gate sidewalls and etching of gate oxide.

- Cleaning after formation of a resist pattern

This place covers:

Reclaiming of semiconductor wafers as well as donor semiconductor wafers, e.g. donors in Smart-Cut®

This place does not cover:

Etching for reclaiming |

This place covers:

Special products to be cleaned, including particular materials as well as substrates comprising particular features, like vertical features, isolated sidewalls, etc.

This place covers:

Removal of edge beads.

This place covers:

Removal of impurities or unwanted materials on backside, including parasitic coatings.

This place covers:

The group covers inventions wherein the mechanical aspect is of particular importance. Does not exclude some enhancement by chemical means.

This place covers:

Covers processes wherein the laser action has a primary function, with or without chemical, mechanical or electrical assistance.

Attention is drawn to the following places, which may be of interest for search:

Cleaning using a laser per se |

This place covers:

Covers processes wherein the supercritical fluid has a primary function, with or without chemical, mechanical or electrical assistance.

This place covers:

Processes for the formation of inorganic and organic layers on a substrate, except photoresist layers (see H01L 21/027), for the fabrication of semiconductor devices as defined under H01L 21/00.

In situ pre- and post-treatments of these processes.

Processes for the formation of a multiplicity of these layers.

Processes for coating materials in general: C23C

Processes for the electrolytic coating of materials in general: C25D

Processes for the single-crystal growth of materials in general: C30B

This place does not cover:

Processes for forming photoresist layers, covered in | |

Processes for forming conductive layers, covered by |

Attention is drawn to the following places, which may be of interest for search:

- Multistep processes for fabricating laminates of insulating and conductive layers, for example insulated gates or capacitors, are classified in the corresponding application, H01L 21/28 for the insulated gates, H01L 28/40 for the capacitors etc. and do not need to be systematically classified in H01L 21/02107. However a group symbol in H01L 21/02107 may be given in case the process for forming the insulating layer is considered of general interest.

In this place, the following terms or expressions are used with the meaning indicated:

ALD | atomic layer deposition |

ALE | atomic layer epitaxy |

MBE | molecular beam epitaxy |

PECVD | plasma enhanced chemical vapour deposition |

PVD | physical vapour deposition |

CVD | chemical vapour deposition |

This place covers:

Processes for the formation of inorganic and organic insulating layers on a substrate, except photoresist layers (see H01L 21/027), for the fabrication of semiconductor devices as defined under H01L 21/00.

In situ pre- and post-treatments of these processes.

Processes for the formation of a multiplicity of these layers.

Includes fabrication of insulating

- porous layers,

- organic layers, like polyimide, cyclobutenes etc.

- Spin On Glass layers,

- silicate layers,

- inorganic layers, like SiO2, Si3N4, Al2O3, high-k layers, perovskites etc.

Processes for coating materials in general, including insulating materials: C23C

Processes for the electrolytic coating of materials in general: C25D

Organic or polymer layer composition: see C08G

This place does not cover:

Processes for forming photoresist layers |

Attention is drawn to the following places, which may be of interest for search:

Photoresist per se |

The process must be adapted or specific to the fabrication of semiconductor devices as defined under H01L 21/00. The mere mentioning of an intended use in semiconductor fabrication does not require that the document being given a group symbol in H01L 21/02107.

If the deposition is specifically adapted to a specific application, with details as to this specific application, e.g. the fabrication of a MIS or MOS electrode or interconnections, the document should additionally be classified in this specific application, for example in H01L 21/28 for the MIS or MOS aspect.

Attention is drawn to the following places, which may be of interest for search:

Layers comprising sub-layers, i.e. multi-layers, are additionally classified in | |

Porous layers are additionally classified in |

This place does not cover:

Carbon Nitride. |

Attention is drawn to the following places, which may be of interest for search:

Halogen doped silicon oxides, e.g. fluorine, containing BPSG, PSG, BSG |

Halogen containing materials, e.g. fluorine, containing BPSG, PSG, BSG, are additionally classified in H01L 21/02131

This place covers:

The formation of silicon oxide layers is classified in this group regardless of the precursor or of the process of formation.

Attention is drawn to the following places, which may be of interest for search:

In case of explicit statements on doping, on rest-groups, or on material components, see | |

Deposition of silicon oxide from organic precursors without further statements on film composition is classified here and in |

This place does not cover:

The formation of material containing Si, O and C, with or without additional elements | |

The formation of material containing Si, O and N, with or without additional elements |

This place does not cover:

The formation of material containing Si, N and C, with or without additional elements | |

The formation of material containing Si, O and N, with or without additional elements |

This place does not cover:

Materials containing silicon | |

Metal silicates |

This place does not cover:

Materials having a perovskite structure, e.g. BaTiO3 |

Perovskites are not classified in H01L 21/02175 and subgroups thereof.

Attention is drawn to the following places, which may be of interest for search:

Adhesion or buffer layers |

This place does not cover:

Mixtures of silane and oxygen |

In this place, the following terms or expressions are used with the meaning indicated:

Alkoxysilane | siloxane |

This place does not cover:

Mixtures of silane and oxygen |

Subject matter classified in the range H01L 21/0223 - H01L 21/02249 is additionally classified in H01L 21/02252, H01L 21/02255, and H01L 21/02258 depending on the type of reaction.

This place does not cover:

After treatment of an insulating film by plasma |

Attention is drawn to the following places, which may be of interest for search:

Formation of an insulating film by introduction of substances into an already existing insulating film is covered by |

This place does not cover:

Formation of insulating layers by plasma treatment, e.g. plasma oxidation of the substrate | |

After treatment of an insulating film by plasma |

This place covers:

Deposition methods in which the gas or vapour is produced by physical means, e.g. ablation from targets or heating of source materials.

This place covers:

Deposition methods in which the gas or vapour is produced by physical means, i.e. by ablation from targets.

This place covers:

- Deposition methods in which the gas or vapour is produced by heating of source materials.

- Molecular beam epitaxy

Attention is drawn to the following places, which may be of interest for search:

Formation of epitaxial insulating films by a deposition method also under |

This place does not cover:

Deposition by physical ablation of a target, like sputtering, reactive sputtering, physical vapour deposition, pulsed laser deposition |

Attention is drawn to the following places, which may be of interest for search:

Deposition by decomposition or reaction of gaseous or vapour phase compounds in the presence of a plasma (PECVD) |

Subject matter relating to cyclic plasma CVD is additionally classified in H01L 21/02274

Attention is drawn to the following places, which may be of interest for search:

Printing in general |

This place does not cover:

Formation of non-epitaxial layers by MBE | |

Atomic layer epitaxy [ALE] |

Attention is drawn to the following places, which may be of interest for search:

Epitaxial growth in general |

This place covers:

Treatments, carried out just before or just after the formation of an insulating layer, which do not participate in the formation of the layer itself, but which are directly linked to the layer formation.

This place does not cover:

Processes participating to the formation of a layer, for example oxidation or nitridation of silicon to form an oxide or nitride layer | |

After treatments like - etching - cleaning - planarising |

Pre- or post treatments of general nature (pre-, post-cleaning, pre-, post conditioning etc.) without details or routine annealing steps, i.e. thermal treatment without further features as to a special atmosphere, presence of a plasma, thermally induced chemical reactions, change of phase or crystal structure, need not to be given this group symbol.

This place covers:

- Treatments to improve adhesion or change the surface termination

This place does not cover:

Treatments by etching |

This place does not cover:

Ex situ cleaning, covered by |

This place covers:

The definition should read "post-treatment" instead of after-treatment.

Only covers processes that are part of the layer formation.

This place does not cover:

After- treatments performed after completion of the insulating layer |

Functionalization just after formation should be classified here.

In case the process would also be of interest as an after treatment (H01L 21/3105), both group symbols should be given.

This place covers:

Processes for introducing substances into the formed insulating layer e.g. introduction of phosphorus into silicon oxide, or introduction of nitrogen into silicon nitride to change stoichiometry.

Attention is drawn to the following places, which may be of interest for search:

For the method of introduction of the dopant |

Introduction of substances into the formed insulating layer is classified both here and in H01L 21/3115

This place covers:

Oxidation of silicon nitride to form silicon oxynitride.

This place covers:

Nitridation of silicon oxide to form silicon oxynitride.

Attention is drawn to the following places, which may be of interest for search:

Subject matter relating to cleaning processes for semiconductor device fabrication | |

Cleaning in general | |

Cleaning compositions in general | C30D |

This place covers:

Processes for the formation of inorganic semiconductors on a substrate.

Processes for forming doped inorganic semiconductors.

In situ pre-and post-treatments of inorganic semiconductor materials.

Processes for the formation of multiple layers of inorganic semiconductors, comprising heterostructures.

The formed semiconductor layer may be crystalline (mono-, poly-, microcrystalline) or amorphous.

This place does not cover:

Nanosized carbon materials, e.g. fullerenes, carbon nanotubes | |

Processes for forming layers only characterized by the purely chemical aspects of the used precursors |

Attention is drawn to the following places, which may be of interest for search:

Formation of inorganic semiconductors for light | |

Processes specially adapted for the manufacture or treatment of organic semiconductor or solid state devices or of parts thereof | |

Fullerenes used in semiconductor or solid state devices |

This place does not cover:

Carbon nanotubes used in semiconductor or solid state devices |

This place does not cover:

Ex situ cleaning |

This place does not cover:

After-treatments for improving the planarity of the layers, e.g. thermal smoothening of layers |

This group is not used for classification; subject matter relating to the formation of conductive material on a semiconductor substrate is classified in H01L 21/283 - H01L 21/288, H01L 21/3205 and H01L 21/768.

This place covers:

Formation of masks to be used for etching or patterning, formed out of a layer formed or deposited on the wafer. Includes inorganic masks (metallic or insulating materials) as well as organic masks.

Composition of photosensitive polymers, see G03F 7/00.

Photographic masks of the stencil tape or originals per se: G03F 1/00

Registration or positioning of photographic masks or originals: G03F 9/00

Photographic cameras G03B

Control of position G05D 3/00

This place does not cover:

masks for selective growth | |

masks for implantation | |

masks for forming insulating layers | |

Formation and use of stencil masks | |

Masks per se, e.g. free standing mask, stencil mask | |

Formation of photoresist masks per se | |

Formation of masks for non patterning purposes: |

Attention is drawn to the following places, which may be of interest for search:

In main group H01L 21/00 and subgroup thereof, a mask is defined as a layer, which is coated directly onto the surface of the wafer.

A free standing mask (stencil mask) laid on the wafer is not considered as a mask in the sense of H01L 21/00.

Masks are classified in H01L 21/00 only under the condition that its treatment or structure has been specially adapted to the fabrication of a device covered by H01L 21/00. Examples are:

- masks used for more than one technological step during device fabrication,

- masks whose structure, formation or treatment are adapted to the nature of the layers or materials used in the fabrication of semiconductor device, or to the device itself

This place covers:

Covers polymeric masks, including photo-sensitive masks (photoresist) as well as non photo-sensitive masks, e.g., wax, polyimide etc.

This place covers:

Treatment of photoresist layers peculiar to fabrication of electronic devices.

H01L 21/0273 covers the treatment of photoresist which is not peculiar to the type of resist (UV, e-beam, ion beam resist), for example:

- method of reflowing the resist,

- method of hardening the resist

Attention is drawn to the following places, which may be of interest for search:

Photoresists and processing of photoresists in general |

- If the treatment is peculiar to the resist type (light, e-beam or ion-beam resist), then it is classified in the corresponding subgroup. If not, remains in H01L 21/0273.

- Chemical amplification is considered to be peculiar to the resist type.

- fabricating masks by irradiating a resist with different types of radiation, e.g. photons and electrons, the document is classified in H01L 21/0273.

This place covers:

Anti-reflective coatings specially adapted for devices as defined under H01L 21/00.

Covers organic as well as inorganic anti-reflective coatings

Attention is drawn to the following places, which may be of interest for search:

Antireflective coatings for lithography in general |

This place covers:

Multilayer structures and special structures adapted to evacuate charges, e.g. multilayer resists with a conductive layer.

Multilayer resists for electrolithography should additionally be classified in G03F 7/00.

This place covers:

Includes multilayer structures.

Multilayer resists for Röntgenlithography should additionally be classified in G03F 7/00

This place covers:

Processes for forming masks comprising inorganic layers.

This group H01L 21/033 acts as a head group for inorganic masks for patterning layers. Multiple classification with H01L 21/31144 (masks for etching insulating layers), H01L 21/32139 (masks for etching conductive layers and polysilicon layers) and H01L 21/308 (masks for etching semiconductors) is possible.

This place covers:

Processes for forming masks to be used for lifting off another layer (for example having a multilayer structure or special profile) irrespective of their fabrication process

Example:

EP2132770

EP2132770

This place does not cover:

Lifting off for obtaining the mask |

This place does not cover:

Masks having an orientation or shape adapted to the requirements of an orientation dependent etching |

This place covers:

Mask having a shape being directly affected by and during the patterning process, e.g. erosion or re-deposition, such that the shape of the mask changes during the patterning process.

This place covers:

Processes for forming masks involving special processes, like lift-off, or sidewall formation, e.g. deposition on a step followed by anisotropic etching, or to modify the mask, e.g. oxidation of an Aluminium layer, hardening, before etching step.

This place covers:

Process specially adapted to provide a mask below the lithographic resolution limit.

Sidewall masks may also be classified in H01L 21/0337. As a sidewall spacer has inherently a sub lithographic size, it does not require an automatic group symbol here.

This place covers:

The group range from H01L 21/04 - H01L 21/326 covers processes for fabrication of semiconductor devices on substrates belonging to the semiconductors of

- group IV: Si, Ge,

- group IV: carbon, diamond,

- group III-V: GaAs, GaN, InP etc.

- group IV-IV: Silicon Carbide,

- inorganic semiconductors other than the above mentioned materials, e.g. II-VI semiconductors,

- bonding or joining semiconductor bodies

- diffusion, and alloying of impurities in these semiconductor materials

- bombardment of these semiconductor materials with radiation,

- Manufacture of electrodes on these semiconductor materials,

- special treatments of these semiconductor materials, like

thermal treatments, e.g. gettering

electroforming

mechanical treatments of these semiconductor materials

hydrogenation of these materials

treatments of insulating layers formed on these materials, including planarisation, etching,

deposition conductive or resistive layers on these semiconductor materials

treatment of these conductive layers, like planarisation, oxidation, etching, doping,

treatment of the insulating or conductive layers formed thereon,

planarisation of these semiconductor materials, or of the insulating and conductive layers formed thereon

Attention is drawn to the following places, which may be of interest for search:

Formation of insulating layers on semiconductor wafers and the direct post-treatment of this formation | |

Formation of SOI | |

Multistep manufacturing processes for semiconductor bodies of said devices | |

Multistep manufacturing processes for electrodes of said devices | |

Multistep manufacturing processes for said devices |

The presence of a potential jump barrier need not to be specified. Inventions intended to be used in the fabrication of devices having a potential barrier may be classified under H01L 21/04.

This place covers:

Passivation of semiconducting carbon, e.g. diamond

This place does not cover:

Fullerenes, e.g. C60, C70 | |

Carbon nanotubes |

Processes for fabricating devices having bodies of diamond not covered by H01L 21/041 - H01L 21/0425 are classified in H01L 21/18 - H01L 21/326 and are also mandatoril y classified in H01L 29/1602 as invention information or additional information whenever appropriate.

This place does not cover:

Preparation of SiC wafers | |

Etching, polishing of semiconducting SiC |

Processes for fabricating devices having bodies comprising crystalline silicon carbide not covered by H01L 21/045 - H01L 21/048 are classified in H01L 21/18 - H01L 21/326 and are also mandatorily classified in H01L 29/1608 as invention information or additional information whenever appropriate.

This place covers:

Processes where ion implantation of boron and subsequent annealing does produce a p-doped region in a silicon carbide.

Processes where ion implantation of boron and subsequent annealing does not produce a p-doped region are classified elsewhere, e.g. H01L 21/0445

This place does not cover:

Reduction of the copper oxide or treatment of the oxide layer |

This place covers:

Processes and apparatus which, by using the appropriate technology, are clearly suitable for manufacture or treatment of devices whose bodies comprise elements of the fourth group of the Periodic Table or AIII-BV compounds, even if the material used is not explicitly specified.

This place does not cover:

Making n- or p-doped regions for devices having semiconductor bodies of diamond; Changing their shape; Making electrodes | |

Making n- or p-doped regions for devices having semiconductor bodies comprising crystalline silicon carbide; Changing their shape; Making electrodes; Passivating silicon carbide surfaces |

This place covers:

Joining through a metal layer or eutectic layer.

This place does not cover:

Joining/bonding of semiconductor bodies through an oxide layer |

This place covers:

Direct bonding of semiconductor bodies without intermediate layer

Groups H01L 21/20 - H01L 21/2085 are no longer used for classification of documents, see H01L 21/02365 and subgroups.

This place covers:

Plasma doping.

Plasma doping is considered as doping from a gas phase, as is the case in Plasma Immersion Ion Implantation. Nevertheless, plasma doping can have ion implantation aspects like the type of ions. These aspects should be classified in ion implantation, H01L 21/265. But a group symbol e.g. H01L 21/2236 or an index code e.g. H01L 21/2236 should always be allocated to track the fact it uses a plasma.

This place does not cover:

Diffusion of killers | |

Lithium-drift |

Attention is drawn to the following places, which may be of interest for search:

Diffusion through an applied layer |

This place does not cover:

Diffusion of killers | |

Lithium-drift |

In the range H01L 21/2254 - H01L 21/2257 the main compositional part of the applied layer just before the diffusion step has to be considered for classification

This place does not cover:

Diffusion of killers | |

Lithium-drift |

This place does not cover:

Intermixing, interdiffusion or disordering of AIII-BV heterostructures |

This place does not cover:

Bombardment with radiation as post-treatment of an insulating layer |

This place does not cover:

High energy radiation creating a nuclear transmutation |

There is no exact border defining high energy. It is meant to cover alpha, beta, gamma, Röntgen... rays. The sub group H01L 21/2633 is incorrectly placed as a subgroup.

Attention is drawn to the following places, which may be of interest for search:

Thermal treatment for modifying the properties of semiconductor bodies per se | |

Ion beam tubes for localised treatment |

This place does not cover:

Crystal planes or main crystal surface and ion beam present an angle |

This place covers:

Includes processes for forming

- conductor-semiconductor,

- conductor-insulator-semiconductor, or

- conductor-insulator-conductor-insulator-semiconductor structures.

Multistep processes for manufacturing electrodes on semiconductor bodies characterized by

- a sequence of single steps, possibly including steps like deposition conductive material, alloying, silicidation,

- the structure or the shape of the electrode,

This place does not cover:

Etching for patterning the electrodes | |

Multistep manufacturing processes for data storage electrodes |

Attention is drawn to the following places, which may be of interest for search:

Mono-step processes: single diffusion of dopants, alloying of electrode materials, implantation of dopants | |

Multistep processes for forming capacitor electrodes |

Formation of electrodes only involving an etching of conductive materials, including silicide on polysilicon: H01L 21/3213 and subgroups

Information peculiar to single-step processes should also be classified in the corresponding group, e.g.

- H01L 21/311 or H01L 21/3213 for etching,

- H01L 21/3105 or H01L 21/321 for planarising

This place covers:

Processes for the fabrication of conductor-insulator-semiconductor structure, e.g. wherein the conductor is part of the interconnect (gate level interconnect).

This place does not cover:

Monosteps for forming insulators or conductors for which the application to gate electrodes is mentioned without further details. |

This place covers:

Deposition of the insulators, using epitaxiy

Deposition of the conductor and the insulator within the same process chamber.

This place does not cover:

Annealing, after the formation of the definitive gate conductor |

When the final conductor comprises a superconductor, subject matter is not classified according to H01L 21/28035 - H01L 21/28097, but instead it is classified in H01L 21/28026.

This place does not cover:

the final conductor next to the insulator having a lateral composition or doping variation, or being formed laterally by more than one deposition step |

A very thin, e.g. silicon, adhesion or seed layer is not considered as the one next to the insulator

Attention is drawn to the following places, which may be of interest for search:

Silicide formed by metal ion implantation |

To assess the coverage of groups H01L 21/28052 and H01L 21/28061, barrier layers, e.g. TaSiN, are not considered]

This place does not cover:

Conductors comprising a silicide layer formed by the silicidation reaction of silicon with a metal layer |

To assess the coverage of groups H01L 21/28052 and H01L 21/28061, barrier layers, e.g. TaSiN, are not considered]

Documents are also classified in groups H01L 21/28035 - H01L 21/28105 when the composition is also relevant

This place does not cover:

Fabrication of lithographic masks for electrodes |

Attention is drawn to the following places, which may be of interest for search:

Lift-off aspects involving multilayer masks |

Attention is drawn to the following places, which may be of interest for search:

Forming insulating materials on a substrate |

In case the formation of the insulator would be of general interest, a group symbol should be given in H01L 21/02107.

In this place, the following terms or expressions are used with the meaning indicated:

RTN | Rapid Thermal Nitridation |

RPN | Rapid Plasma Nitridation |

This place does not cover:

Evaporation, ALD, CVD, sputtering, laser deposition | |

Nitride deposition, growth, oxynitridation, NH3 nitridation, N2O oxidation, thermal nitridation, RTN, plasma nitridation, RPN |

Thin oxidation layers used as a barrier layer or as a buffer layer, e.g. before the fomation of a high-k insulator, are classified here only if important per se.

In case the transformation would be of general interest it should be classified in

This place covers:

H01L 21/283 - H01L 21/2885 cover the deposition of conductive layers directly in contact with the semiconductor for forming electrodes.

This place does not cover:

Formation of electrodes of capacitors, resistors, inductors |

Application to contacts must be mentioned with details. Moreover, details of deposition processes of conductive layers covered by H01L 21/3205 are additionally classified in this group and subgroups thereof. If a document discloses information relevant for any of the groups H01L 21/768 - H01L 21/76898, one or more of these groups should also be assigned.

This place covers:

Methods for depositing conductive layers using gases or vapours of metals or metal-containing precursors.

This place does not cover:

Deposition of polysilicon in contact with a semiconductor | |

Formation of electrodes of capacitors, resistors, inductors |

Attention is drawn to the following places, which may be of interest for search:

Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition (CVD) processes |

The deposition process (PVD, CVD, ALD etc.) must be specially adapted for forming contacts or interconnects within semiconductor devices and must be disclosed in detail, i.e. include details on deposition parameters, precursor materials, particular apparatus details etc.

If a document discloses information relevant for any of the groups H01L 21/768 - H01L 21/76898, one or more of these groups should also be assigned.

This place does not cover:

Conductive layers comprising silicides | |

Deposition of Schottky electrodes |

Deposition of polysilicon on silicon classified there only if application to contacts is mentioned. Otherwise H01L 21/02365

Deposition of polysilicon on silicon classified there only if application to contacts is mentioned. Otherwise H01L 21/02365

This place covers:

The deposition of conductive layers directly in contact with semiconductors for forming electrodes using liquid deposition techniques, e.g. electroless plating.

This place does not cover:

Formation of electrodes of capacitors, resistors, inductors |

Attention is drawn to the following places, which may be of interest for search:

Chemical coating by decomposition of either liquid compounds or solutions of the coating forming compounds, without leaving reaction products of surface material in the coating |

The deposition process must be specially adapted for forming contacts or interconnects within semiconductor devices and must be disclosed in detail, i.e. include details on deposition parameters, precursor materials, particular apparatus details etc.

If a document discloses information relevant for any of the groups H01L 21/768 - H01L 21/76898, one or more of these groups should also be assigned.

This place covers:

- mechanical treatments, like grinding, sand blasting etc.

- hydrogenation of these semiconductors

- chemical treatments, like etching,

- formation of insulating layers and after treatment of these layers, like planarisation, etching, formation of conductive layers on these insulating layers and after treatment of these conductive layers and their doping.

This place does not cover:

the treatment of II-VI compounds | |

the treatment of insulating layers | |

the treatment of metallic |

Attention is drawn to the following places, which may be of interest for search:

Manufacture of electrodes thereon |

This place covers:

Mechanical treatment of semiconductor wafers or semiconductor layers, except the mechanical treatment of insulating or conductive layers on semiconductor wafers.

This place does not cover:

Polishing of semiconductor wafers | |

Polishing of epitaxial layers on semiconductor wafers | |

Mechanical treatment of insulating | |

Conductive layers on wafers | |

Single step mechanical operations, like sawing, polishing, breaking etc. classified in the corresponding group in section B |

The mere use of a machine is classified with the machine only.

Process for the mechanical treatment, enhanced by chemical treatment, is classified in chemical treatment, but may be given a group symbol in mechanical treatment if the mechanical treatment itself is of importance for the invention.

Purely mechanical polishing is considered as chemical-mechanical polishing, and is classified accordingly.

This place covers:

Making grooves, which may result in cutting

This place does not cover:

Singulation of wafers into dies |

This place covers:

- Chemical or electrical treatment of group IV or III-V semiconductors.

- Formation of porous semiconductors,

- Functionalisation of semiconductor surfaces

This place does not cover:

Chemical or electrical treatment to form insulating layers |

This place covers:

Anisotropic liquid etching, i.e. "crystal orientation dependant" etching, using basic (pH>7) compositions. The etch composition is often composed of KOH, amines, azines, quaternary ammonium compounds

This place does not cover:

Electrolytic etching | |

Anisotropic etching for tartarising surfaces |

Attention is drawn to the following places, which may be of interest for search:

Etching for fabrication of MEMs. |

This place covers:

Reactive Ion Etching [RIE] of III-V

This place covers:

Processes for polishing semiconductors not being part of the sequence for preparing wafers from an ingot (H01L 21/02013 or H01L 21/02024).

Covers polishing or CMP of semiconductor layers deposited on a substrate, like epitaxial layers.

This place does not cover:

Polishing or CMP of bulk wafers, wherein the polishing is part of the sequence for preparing wafers from an ingot | |

Polishing or CMP of insulating layers | |

Polishing or CMP of conductive layers |

Chemical-mechanical polishing also includes purely mechanical polishing.

This place does not cover:

formation of porous materials by electrolysis |

Attention is drawn to the following places, which may be of interest for search:

Electrolytic etching in general |

This place covers:

- sputter etching,

- particle (electron, ion, photon) beam enhanced etching

- light assisted etching.

- plasma etching

- dry etching, i.e. using an etching gas without plasma

This place does not cover:

Reactive ion etching of III-V materials |

Attention is drawn to the following places, which may be of interest for search:

Laser etching without reactive atmosphere per se |

This place covers:

- Masks used for patterning semiconductors of group IV or III-V, including masks used for plasma etching/patterning, excepted masks for electrolytic etching.

- The fabrication of masks to be used for etching or patterning semiconductors (non-monocrystalline semiconductors being excluded).

This place does not cover:

Formation of masks for non patterning purposes, which are classified with the step in question: - masks for implantation - masks for forming insulating layers, - masks for selective growth, - masks for patterning semiconductors belonging to groups other than group IV and group III-V. | |

Electrolytic etching | |

Formation and use of stencil masks | |

Free standing masks, e.g. stencil masks | |

Formation of photoresist masks per se, except if the formation of the photoresist mask is specific to the device to be fabricated or semiconductor substrate |

Attention is drawn to the following places, which may be of interest for search:

General masks for patterning in the fabrication of semiconductor device | |

Masks for patterning insulating layers | |

Masks for patterning conductors, including polycrystalline or amorphous silicon |

A mask in H01L 21/00 is formed of a layer coated directly onto the surface of the wafer.

A free standing mask (stencil mask) laid on the wafer is not considered as a mask in the sense of H01L 21/00.

Masks are classified in H01L 21/308 only under the condition that its treatment or structure has been specially adapted to the fabrication of a device covered by H01L 21/00. Examples are:

- masks used for more than one technological step during device fabrication,

- masks whose structure, formation or treatment are adapted to the nature of the layers or materials used in the fabrication of semiconductor device, or to the device itself

The takes precedence rule (stemming from IPC) pointing to H01L 21/3065 is not valid for CPC: masks for etching by plasma or reactive ion etching are given a group symbol here.

Masks for electrolytic etching are classified with the electrochemical etching in H01L 21/3063.

Using stencil masks for ion implantation is classified in H01L 21/266.

This place covers:

Masks having a specific behaviour during etching process. e.g. erodible mask, shrinking mask etc.

This place does not cover:

Processes wherein the etching is interrupted to modify the mask (sequential etching), e.g. etching, followed by modifying the mask, followed by re-etching, with possible cycling of the above steps |

This place covers:

Covers pre-treatment for the formation of a mask, post treatment of the mask before etching, treatments to modify the mask before use, e.g. hardening, formation of sidewalls, multiple sidewalls etc.

This place does not cover:

Modification of the mask during etching | |

Removal of the mask after use |

Attention is drawn to the following places, which may be of interest for search:

Photoresist for lift | |

Inorganic masks for lift-off |

This place covers:

Process specially adapted to go below resolution limit of lithography.

This place covers:

Processes for forming insulating layers and their direct post-treatment.

To be used in any process, formation of interconnects, isolation oxides etc.when the invention is focussed on the insulator.

Attention is drawn to the following places, which may be of interest for search:

Insulating layers forming part of electrodes | |

Encapsulating layers |

This place covers:

Covers special treatments of insulating layers, wherein the special treatment is not a post-treatment as defined under H01L 21/00, i.e. the classical annealing of the insulating layer to improve its characteristics, but is for example

planarisation, patterning, functionalization after etching.

This place does not cover:

Classical annealing after formation of the insulator, classified together with the formation |

Functionalization just after formation should be classified with the formation.

In case the process would also be of interest as a post treatment, both classes should be given.

This place covers:

- Planarisation of insulating layers.

- Atomic scale planarisation (smoothening) of the insulating layers.

- Reflow of insulating layers.

This place does not cover:

After treatment, e.g. planarisation, of organic layers |

This place covers:

Planarisation involving a removal step not being a chemical etch step: this is the group for polishing and chemical-mechanical polishing (CMP) of insulating materials.

This place covers:

Planarisation by non selective etching, e.g. by a blanket etching reducing the protrusions.

Attention is drawn to the following places, which may be of interest for search:

Etching per se |

This place covers:

Processes where protrusions are selectively etched through a mask.

Attention is drawn to the following places, which may be of interest for search:

Etching glass |

This place covers:

Etching by wet process, or by processes wherein gaseous reactants are condensed on the surface.

Gaseous etch with HF is classified in H01L 21/31116

This place covers:

Removal of organic layers or polymers, including photoresists peculiar to semiconductor wafers or devices.

This place does not cover:

The removal of silicon-containing compounds having an organic nature. |

Attention is drawn to the following places, which may be of interest for search:

Removal of photoresist not peculiar to semiconductor wafers |

Removal of photoresist being not peculiar to semiconductors is classified in G03F 7/42.

Peculiar to semiconductor devices means that particular precautions are taken to avoid influence of the removal of the photoresist on the semiconductor wafer or device.

This place covers:

Etching by wet process, or by processes wherein gaseous reactants are condensed on the surface.

This place covers:

Etching involving a specially adapted mask

In case the mask would be of general interest, it should also be classified in H01L 21/033

Attention is drawn to the following places, which may be of interest for search:

See also after treatment of insulating layers | |

Doping with the purpose to alter resistivity or increase conductivity |

Implantation or diffusion into insulating layers is also classified under H01L 21/02318 and subgroups.

Attention is drawn to the following places, which may be of interest for search:

Photoresists per se |

H01L 21/312 - H01L 21/3128 are no longer used for classification of new documents, see H01L 21/02112.

H01L 21/314 - H01L 21/3185 are no longer used for classification of new documents. See H01L 21/02112.

This place covers:

Deposition of conductive layers exclusively on insulating layers, when the process of deposition is relevant.

This place does not cover:

Deposition of conductive layers on semiconductor |

When the technique of deposition is particular (CVD, PVD or electroplating), also classify in H01L 21/283, H01L 21/285 or H01L 21/288. When an interconnection is concerned, see also H01L 21/768 and subgroups.

This place covers:

Treatment of formed conductive layers. Includes:

- etching by chemical or physical means,

- planarisation, including chemical-mechanical polishing,

- oxidation, nitridation, or surface treatment,

- doping.

Polysilicon, amorphous silicon and silicides are considered as conductive materials for these groups.

Polysilicon, amorphous silicon and silicides are considered as conductive materials for these groups. After treatment of layers of these materials is thus classified here.

For classifying in the group range H01L 21/321 - H01L 21/3215, the explicit presence of an insulating layer below the conductive or resistive layers is not mandatory.

This place covers:

Oxidation of non-monocrystalline silicon, e.g. polycrystalline, microcrystalline or amorphous silicon.

This place does not cover:

Oxidation of monocrystalline silicon |

Polysilicon, amorphous silicon and silicides are considered as conductive materials for these groups. Oxidation of layers of these materials is thus classified here.

For classifying in the group range H01L 21/321 - H01L 21/3215, the presence of an insulating layer below the conductive or resistive layers is not mandatory.

This place covers:

Nitridation of non-monocrystalline silicon, e.g. polycrystalline, microcrystalline or amorphous silicon.

This place does not cover:

Nitridation of monocrystalline silicon |

Polysilicon, amorphous silicon and silicides are considered as conductive materials for these groups. Nitridation of layers of these materials is thus classified here.

For classifying in the group range H01L 21/321 - H01L 21/3215, the explicit presence of an insulating layer below the conductive or resistive layers is not mandatory.

This place covers:

Planarisation of conductive or resistive layers.

Polysilicon, amorphous silicon and silicides are considered as conductive materials for these groups. Planarisation of these layers is thus classified here.

For classifying in the group range H01L 21/321 - H01L 21/3215, the explicit presence of an insulating layer below the conductive or resistive layers is not mandatory.

Attention is drawn to the following places, which may be of interest for search:

CMP slurries |

This place covers:

Physical or chemical etching of conductive or resistive layers.

Etching of polysilicon layers

Etching of amorphous silicon layers

Attention is drawn to the following places, which may be of interest for search:

Machines or apparatus for liquid etching | |

Machines for plasma etching |

Polysilicon, amorphous silicon and silicides are considered as conductive materials for these groups. Etching of layers of these materials is thus classified here.

For classifying in the group range H01L 21/321 - H01L 21/3215, the explicit presence of an insulating layer below the conductive or resistive layers is not mandatory.

This place covers:

Etching processes, where no chemical reaction is involved, e.g.

sputtering, ion milling, laser ablation, pure ion beam etching.

For classifying in the group range H01L 21/321 - H01L 21/3215, the explicit presence of an insulating layer below the conductive or resistive layers is not mandatory.

This place covers:

Silicides and silicon alloys.

This place covers:

Use of Plasmas, e.g. RIE, and chemically assisted particle (ion or electron, photon) beam etching

For classifying in the group range H01L 21/321 - H01L 21/3215, the explicit presence of an insulating layer below the conductive or resistive layers is not mandatory.

This place covers:

Etching with supercritical fluids

This place covers:

Etching assisted by electrons, ions and laser beams.

This place covers:

Polysilicon, amorphous, silicides, multilayers containing silicon

This place covers:

Pre-treatments before etching, including removal of natural oxide.

Anti-corrosion post-treatments.

This place does not cover:

Post-treatment after etching, e.g. RIE |

In case the pre-treatment is a removal of natural oxide and is of general interest, a group symbol in H01L 21/02041 should be given.

In case the post treatment is a passivation by oxidation or nitridation this step should be classified independently.

For classifying in the group range H01L 21/321 - H01L 21/3215, the explicit presence of an insulating layer below the conductive or resistive layers is not mandatory.

This place covers:

Etching involving a mask specifically adapted to the etching operation.

This place does not cover:

Classical photoresist masks, except if submitted to a special treatment, for example hardening, fluorination, etc. |

In case the mask would be of general interest, it should also be classified in H01L 21/033.

For classifying in the group range H01L 21/321 - H01L 21/3215, the explicit presence of an insulating layer below the conductive or resistive layers is not mandatory.

Polysilicon, amorphous silicon and silicides are considered as conductive materials for these groups. Doping of these layers is thus classified here.

For classifying in the group range H01L 21/321 - H01L 21/3215, the explicit presence of an insulating layer below the conductive or resistive layers is not mandatory.

This place covers:

- Treatments aimed at modifying the intrinsic properties of the crystals not otherwise provided for in H01L 21/00, like crystallographic defect rate.

- Formation of defects for intrinsic or extrinsic gettering

This place does not cover:

Modification of conductivity type |

This place covers:

Extrinsic gettering

Gettering using both extrinsic and intrinsic gettering techniques is classified in both H01L 21/3221 and H01L 21/3225.

This place covers:

Intrinsic gettering

This place does not cover:

Treatment of semiconductor bodies to modify their internal properties of silicon on insulator |

Gettering using both extrinsic and intrinsic gettering techniques is classified in both H01L 21/3221 and H01L 21/3225.

This place covers:

Processes for fabricating devices having semiconductor bodies not belonging to group IV, IV-IV, III-V materials, or to Se, Te, CuO.

Processes for fabricating devices having semiconductor bodies based on II-VI materials.

This place does not cover:

Inorganic semiconducting materials used for light detecting devices, e.g. I-III-VI materials, like CuInSe | |

Processes peculiar to the fabrication of light sensitive devices | |

Processes peculiar to the fabrication of inorganic light emitting devices |

As already evident from the limiting reference in the main group title of H01L 21/00, only fabrication processes relating to devices covered by main groups H01L 21/00 - H01L 29/00 should be classified under H01L 21/34.

- A single mention of an application in manufacturing devices covered by main groups H01L 21/00 - H01L 29/00, e.g. a junction FET, is sufficient to give a group symbol.

- at the other hand processes wherein the type of fabricated device is not mentioned at all will be considered to refer to devices not belonging to those covered by H01L 21/00 - H01L 29/00, and will consequently be classified together with the most probable application, e.g. H01L 31/00 for II-VI for light-sensitive devices.

This place covers:

Doping of II-VI materials.

Attention is drawn to the following places, which may be of interest for search:

Semiconductor bodies composed of II-VI compounds for light sensitive devices |

This place covers:

Radiation covers corpuscular as well as electromagnetic radiation

This place does not cover:

Bombardment with radiation for deposition purposes | |

Bombardment with radiation for etching purposes |

Attention is drawn to the following places, which may be of interest for search:

Ion beam tubes for localized treatment |

This place covers:

Processes for implantation wherein the invention is focused on the mask aspect, e.g. mask having a specific topography.

Attention is drawn to the following places, which may be of interest for search:

Masks in general |

This place covers:

Electrodes on semiconductor materials as defined under H01L 21/34.

Covers the direct deposition of conductive materials on the semiconductor and on an insulating layer overlying the semiconductor (e.g. Tunnel contact).

The group H01L 21/44 includes specific treatments of the semiconductor before formation of the contact (e.g. degenerescence by bombardment etc.).

This place does not cover:

semiconductor materials of group IV or III-V |

This place covers:

Insulating materials, only if the contact is a tunnelling contact.

This place covers:

- Electrolytic deposition

- Electroless deposition

Classification is made in this group only if specific to the semiconductor material, or adapted to the type of device.

Classification is made in this group only if specific to the semiconductor material, or adapted to the type of device.

This place covers:

The treatment of semiconductor bodies including

- mechanical treatments, like grinding, sand blasting etc.

- chemical treatments, like etching,

- after-treatments of these semiconductors, like formation of insulating layers, planarisation or etching of these insulating layers, formation of conductive layers on these insulating layers and after treatment of these conductive layers and their doping.

Attention is drawn to the following places, which may be of interest for search:

Manufacture of electrodes thereon |

Attention is drawn to the following places, which may be of interest for search:

Chemical or electrical treatment to form insulating layers thereon |

This place does not cover:

Masks used for patterning group IV and group III-V semiconductors |

This place does not cover:

Encapsulating layers |

Attention is drawn to the following places, which may be of interest for search:

Layers forming electrodes |

This place does not cover:

Forming insulating layers using masks | |

After-treatment |

Attention is drawn to the following places, which may be of interest for search:

Formation of photoresist masks |

Attention is drawn to the following places, which may be of interest for search:

Manufacture of electrodes |

This place does not cover: