CPC Definition - Subclass G01L

This place covers:

Apparatus or methods for measuring force, stress, torque or the like, and particularly:

- force or stress, in general;

- torque, work, mechanical power, or mechanical efficiency, in general;

- force, e.g. due to impact, work, mechanical power, or torque, adapted for special purposes and for testing brakes.

Apparatus or methods for measuring fluid pressure, and particularly:

- the steady or quasi-steady pressure of a fluid or a fluent solid material by mechanical or fluid pressure-sensitive elements; by electric or magnetic pressure-sensitive elements; by optical or acoustic means, or other means;

- differences of two or more pressure values, or two or more pressure values simultaneously;

- tyre pressure or the pressure in other inflated bodies;

Apparatus or methods for measuring, indicating or recording:

- rapid changes, such as oscillations, in the pressure of steam, gas or liquid;

- work or energy of steam, internal-combustion, or other fluid-pressure engines from the condition of the working fluid;

- knocks in internal-combustions engines.

- pressure in inlet or exhaust ducts of internal-combustion engines.

- Vacuum gauges.

Testing or calibrating of the apparatus as described.

Details or accessories of the apparatus as described.

For subject matter relating to sensing pressure changes for compensating measurements of other variables or for compensating readings of instruments for variations in pressure, see subclass G01D or other relevant subclasses for the variable measured.

This place does not cover:

Weighing |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Measuring blood pressure for diagnostic purposes | |

Measuring fluid pressure within the human body other than blood pressure for diagnostic purposes | |

Measuring muscular strength or the force of a muscular blow for diagnostic purposes | |

Pressure sensor specially adapted for blood pressure control | |

Measuring tension, compression or force specially adapted for metal-rolling mills | |

Devices for measuring, signalling, controlling, or distributing tyre pressure specially adapted for being mounted on vehicles | |

Applications of tensometers to sewing machine elements | |

Measuring pressure in boreholes or wells | |

Levelling between separate points or surveyors' levels by using barometric means | |

Measuring volume flow, mass flow or volume of fluid by measuring pressure or differential pressure | |

Measuring or indicating level of liquid or fluent material by measurement of pressure | |

Testing of engines by monitoring pressure in cylinders or fluid ducts | |

Meteorology | |

Method of arrangement for converting patterns of mechanical parameter (force) into electrical signal |

Attention is drawn to the following places, which may be of interest for search:

Torque indicators in wrenches or screwdrivers | |

Tyre-inflating valves | |

Seat occupant detection | |

Supplying air for tyre inflation | |

Application of tension indicators for adjusting or controlling tension in filamentary material | |

Devices for indicating tension in warp or cloth | |

Embedding pads or other sensitive devices in paving or other road surfaces | |

Indicating lubricant pressure in machines | |

Indicating coolant pressure in machines or engines | |

Special adaptations of indicating, measuring, or monitoring equipment for the filling or discharging of vessels | |

Measuring the deformation in a solid by mechanical strain gauges | |

Measuring the deformation in a solid by resistance strain gauges | |

Measuring the deformation in a solid by optical strain gauges | |

Measurement of mechanical vibrations or ultrasonic, sonic or infrasonic waves | |

Testing of bearings | |

Testing steering behaviour of vehicles | |

Investigating strength properties of solid materials by application of mechanical stress | |

Devices characterised by the determination of the variation of atmospheric pressure with height to measure the vertical components of speed | |

Scanning-probe techniques using atomic force microscopy | |

Hollow bodies deformable or displaceable under pressure, e.g. Bourdon tubes, bellows | |

Switches operated by change of fluid pressure | |

Controllable semiconductor devices by variation of applied mechanical force, e.g. of pressure | |

Dynamo-electric clutches; Dynamo-electric brakes |

In G01L, CPC is only to be used for the classification of invention information and not for classifying additional information.

In this place, the following terms or expressions are used with the meaning indicated:

Fluid | gas or liquid |

Pressure | force induced by a fluid on a surface |

In patent documents, the following abbreviations are often used:

FBG | Fibre Bragg Grating |

FSR | Force Sensing Resistor |

MEMS | Microelectromechanical Systems |

SAW/BAW | Surface/Bulk Accoustic Wave |

In patent documents, the following words/expressions are often used with the meaning indicated:

"pressure" | "force". The word "pressure" is adequate only in the case of a force generated by a fluid. |

This place covers:

Apparatus or methods for measuring force:

- by using hydraulic or pneumatic means, counterbalancing forces, piezoelectric or piezo-resistive devices, wave or particle radiation;

- by measuring elastic or permanent deformation of gauges;

- by measuring variation of frequency of stresses vibrating elements, of magnetic properties or capacitance or inductance or ohmic resistance or optical properties of the stressed material or other electrical means

Auxiliary measure taken on the apparatus or methods for measuring force

This place does not cover:

Measurement of force due to residual stress | |

Measurement of force due to impact | |

Measurement of force of explosion | |

Measurement of several components of force |

Attention is drawn to the following places, which may be of interest for search:

Measuring fluid pressure | |

Measuring deformation of bodies as a result of stress by using gauges |

Multiple classification is allowed, sometimes necessary since for example some sub-groups are devoted to what is deformed (for instance springs in G01L 1/04), other to what parameter is measured (for instance capacitance/inductance in G01L 1/14). It is the grade of detail of the disclosure of the document which is important (for instance just mentioning that the measurement is done by measuring a capacitance without other precision is not sufficient for a classification in G01L 1/14 or subgroups).

G01L 1/02; G01L 1/083 take precedence, i.e. when the hydraulic or pneumatic means are used for generating the counter-balancing forces .

This sub-group also contains sensor with elastomeric transmitting means (like rubber).

G01L 1/06; This sub-group contains force measurement system using the print of a pinpoint in material, or using indentation hardness (see also G01N 3/40 hardness testing of material).

G01L 1/08; See also similar arrangement in G01G 5/00, G01G 5/006, G01G 7/04 and G01G 7/045 in weighing systems.

G01L 1/12; The sub-group G01L 1/127 has to be chosen when it is the material under stress in which inductance is varying, otherwise classify in G01L 1/14.

G01L 1/18; See also semi-conductor devices controllable by variation of applied mechanical force H01L 29/84.

G01L 1/20; Also contains sensor with the resistance material being a part of the mechanical structure of the sensor.

The sub-group contains Force Sensing Resistor or FSR.

G01L 1/22; For search, in the case of ring shaped support adapted for measuring force along a single direction (G01L 1/2231) see also nut tightening force measurement system (G01L 5/24) using washer (G01L 5/243).

The sub-group G01L 1/2287 also contains mounting details of the strain gauges.

G01L 1/24; This group also contains pressure sensitive films or paper or coatings having changes in optical properties when stresses are applied.

The important characteristic to check for classification is to find which means are stressed by the force to be measured.

For the search, in the case of the measurement of a physical variable influencing the optical properties of an optical fibre see G01D 5/353.

For the search, Bragg grating per se see G02B 6/124

G01L 1/26; This group also contains light beam shutters.

Attention is drawn to the following places, which may be of interest for search:

Automatic balancing arrangements for measuring electric variables in which a force or torque representing the measured value is balanced by a force or torque representing the reference value |

This place does not cover:

Using resistance strain gauges |

Attention is drawn to the following places, which may be of interest for search:

Using piezo-resistive vibrators |

This place does not cover:

Magnetostrictive sensors |

Attention is drawn to the following places, which may be of interest for search:

Magnetostrictive devices in general |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Resistance strain gauges for measuring linear expansion or contraction |

This place covers:

Apparatus or methods for measuring torque:

- by using rotary-transmission dynamometer like a flexible shaft or other means;

- by using rotary-absorption dynamometers, for instance of brake type

Apparatus or methods for determining the value of power:

- by measuring torque and velocity, pressure and velocity, tractive or propulsive force and velocity;

Apparatus or methods for measuring efficiency (ratio of power input to power output).

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Attention is drawn to the following places, which may be of interest for search:

G01L 3/24;This group contains all apparatus and method for determining the value of power, not only by measuring torque, but also by measuring force or pressure multiplied by a displacement variable (angular or linear velocity).

This group do not contains measurement of power adapted to special purposes (see G01L 5/0095).

G01L 3/26; For classification and search purpose see also G01M 15/044, testing engines by monitoring power, and G01L 23/00, Indicators for determining work or energy of steam or internal combustion engines.

This place does not cover:

Magnetostrictive sensors |

Attention is drawn to the following places, which may be of interest for search:

Magnetostrictive devices in general |

Attention is drawn to the following places, which may be of interest for search:

Electrical or magnetic brakes in general |

Attention is drawn to the following places, which may be of interest for search:

Measuring velocity per se |

This place covers:

Apparatus or methods for measuring forces:

- adapted for mounting in a bore of the structure;

- associated with a bearing;

- associated with force applying means;

- due to residual stresses;

- due to impact;

- due to spring-shaped elements, like electrical connectors or paperclips;

- associated with industrial machines or actuator;

- of release of ski safety bindings;

- of explosions;

- in several directions;

- applied to control member.

Apparatus or methods for:

- measuring work or power adapted to special purposes;

- measuring tension in ropes cables, wires, threads, belts, bands or like flexible member;

- measuring axial thrust in rotary shaft;

- measuring the tractive or propulsive power of vehicles;

- measuring the energy of projectiles;

- measuring the ratio of forces;

- measuring wheel side-thrust.

Apparatus or methods for determining the value of torque:

- of a tightening nut;

- in relation to revolution per unit of time;

- associated with torque applying means.

Apparatus for testing brakes (insofar as force is measured or applied to the brake)

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Devices for sensing torque of dynamo-electric machines, or actuated thereby |

Attention is drawn to the following places, which may be of interest for search:

Measuring pressure of a fluent medium | |

Measuring rapid changes of pressure in stream, gas, or liquid | |

Measuring golf clubs, bats or rackets |

G01L 5/0009; For the search the group G01M 13/04 concerning the testing of bearing is relevant since force sensor can be used for bearing monitoring.

For the search and eventually for the classification the group F16C 19/00 concerning bearing with rolling contact is also relevant.

G01L 5/0028; This sub-group also contain apparatus and methods for measuring the force of driving nails, bolts, bolts threads or other anchoring means, for bonding wires, closing bottle caps, tying raps or other similar system.

G01L 5/0057; This sub-group contains measuring force due to electrical connectors, paperclip and similar devices.

G01L 5/0061; This sub-group covers force sensors associated with industrial machines or actuators except those force sensors associated with pumps, engines, valve actuators, cranes, drilling rods, which are classified in their own technical field (F01, F04, F16, B66, E21).

Apparatus or method for indicating the functioning of a valve are classified in F16K 37/0075.

In the sub-group G01L 5/0066 are classified the documents concerning calibration arrangements adapted to calibrate the force sensor associated with an industrial machine or actuator, otherwise calibration arrangements of force sensor are classified in G01L 25/00.

For the search, see also B25J 9/1692, calibration of robot manipulator.

In the sub-group G01L 5/0076, force sensor of presses, crimping terminals on wires, rolling machines, extruders are not classified, but are in the relevant classes from B21 - B42.

G01L 5/04; For the search and also classification, apparatus or methods adapted for the measuring of web tension are also classified in B65H 23/044;

For the search and also classification, apparatus and method for measuring tension in cables, ropes is done in G01G 19/14 (with the difference that the tension is produced by the gravitation), and overload protection is done in G01G 23/005.

For the search and classification crane hooks with load measurement device are in B66C 1/40 or B66C 13/10, and rope, cable or chain winding mechanism with overload protection are in B B66D 1/56.

For the search in the sub-group G01L 5/045 (tension across the width of a band-shaped flexible band), measuring flatness in general is G01B 5/285, G01B 7/345, G01B 11/306, G01B 13/22, G01B 15/08, G01B 21/30.

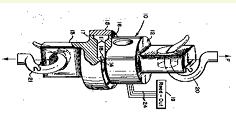

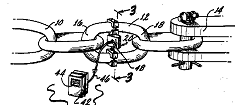

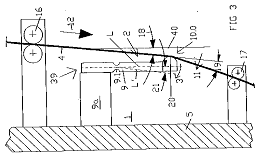

G01L 5/10; The following figures are illustration for a better understanding of the different sub-groups in G01L 5/10, measuring tension in ropes, cables with electrical means.

G01L 5/101: in which the sensor is inserted into the member

G01L 5/102: in which the sensor is located at a non-interrupted part of the member

G01L 5/103: in which the sensor is fixed at one end of the member

G01L 5/106: by measuring a reaction force applied on a cantilever beam

G01L 5/107 : by measuring a reaction force applied on an element disposed between two supports

G01L 5/108: by measuring a reaction force applied on a single support or glider

For classification: a document has to be classified with respect to the placement of the sensor on the apparatus (G01L 5/101, G01L 5/102, G01L 5/103) and by the way the reaction force is measured (G01L 5/106, G01L 5/107, G01L 5/108).

G01L 5/13; For the search and classification, the control of draught load or tractive force of lifting devices mounted on tractors see A01B 63/112.

G01L 5/16; In this group are also classified multiple torque measurements and combinations of torque and force measurements.

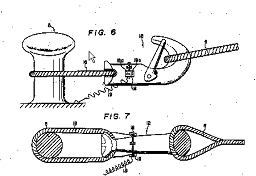

For the search and classification, hand worn input/output device see G06F 3/014; The sub-group G01L 5/221 concerning force sensors in steering wheels has an overlap with the group B62D 5/00, power assisted steering in general. The following figure is an example of document (FR2774349) classified in this group:

For search and classification in G01L 5/225 see also A61B 5/221 (Measuring muscular forces by using bicycle type apparatus) and A63B 69/16 (Cycling sport training apparatus).

G01L 5/24; This sub-group does not cover arrangements for torque limiters or torque indicators in wrenches or screwdrivers which are classified in B25B 23/14.

G01L 5/28; This group does not cover monitoring or checking brake system integrated in vehicles (B60T 17/22) and also do not cover testing or monitoring of railways brakes (B60T 17/228).

In this place, the following terms or expressions are used with the meaning indicated:

Adapted for special purposes | not easily possible to adapt the device or method to another purpose or to a more general purpose, i.e. that the device or method has been designed to solve a specific technical problem |

Attention is drawn to the following places, which may be of interest for search:

Manipulators in general |

This place does not cover:

Measuring flatness |

Attention is drawn to the following places, which may be of interest for search:

Metal rolling in general |

This place does not cover:

Using piezoresistors |

In this place, the following terms or expressions are used with the meaning indicated:

Pressure sensitive conductor | a conductor wherein the electric resistance changes with deformation caused by pressure, e.g. elastic resin having conductive materials dispersed therein |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Arrangements in wrenches or screwdrivers |

Attention is drawn to the following places, which may be of interest for search:

Using acoustic waves or acoustic emission |

This place covers:

Apparatus or methods for measuring fluid pressure:

- by using elastically deformable gauges;

- by using flexible deformable tubes, likes Bourdon gauges;

- by using bellows;

- by using flexible diaphragm;

- by using capsules;

- by using pistons;

- by using liquid as pressure sensitive medium, like liquid column gauges.

This place does not cover:

Transmitting or indicating the displacement of mechanical pressure sensitive elements by electric means | |

Pressure sensor using counterbalancing forces | |

Measurement differences of two or more pressure values | |

Measurement two or more pressures values simultaneously |

Attention is drawn to the following places, which may be of interest for search:

Measuring type pressure or the pressure of other inflated bodies | |

Vacuum gauges | |

Measuring heights (altimeter for aircraft, with barometer) or depth | |

Measuring depth of open water | |

General determination of the capacity of containers | |

Pressure sensitive fluid level or volume measuring devices | |

Hollow bodies deformable or displaceable under internal pressure per se | |

Pressure sensitive switches using Bourdon gauges |

G01L 7/02; This group does not cover blood pressure control and pressure transducer specially adapted therefor A61M 1/3639.

G01L 7/14; This sub-group also contain temperature compensating means.

This place covers:

Apparatus or methods for measuring fluid pressure:

- by using elastically deformable gauges with electric and other similar detection means;

- by using flexible deformable tubes, likes Bourdon gauges with electric and other similar detection means;

- by using bellows with electric and other similar detection means ;

- by using flexible diaphragm with electric and other similar detection means;

- by using capsules with electric and other similar detecting means;

- by using pistons with electric and other similar detection means;

- by using liquid as pressure sensitive medium, like liquid column gauges, with electric and other similar detection means;

- using semi-conductor body comprising PN-junction as detecting element;

- circuits of sensors making use of variation in ohmic resistance;

- circuits of sensors making use of piezoelectric devices;

- circuits of sensors making use of variation of inductance;

- circuits of sensors making use of variation of capacitance;

- involving the displacement of magnets;

- sensors making use of variation in the magnetic properties resulting from the application of stress;

- sensors making use of electrokinetic cells

This place does not cover:

Pressure sensor using counterbalancing forces | |

Measurement differences of two or more pressure values | |

Measurement two or more pressures values simultaneously |

Attention is drawn to the following places, which may be of interest for search:

Vacuum gauges |

G01L 9/0041; For search or classification in construction details associated to semi-conductive diaphragm sensor (G01L 9/0042), see also H01L 21/00, process or apparatus for manufacturing semiconductor devices, and B81C 1/00158, manufacturing of devices on a diaphragm.

For search and classification in G01L 2009/0066 , mounting arrangement of diaphragm sensor with resistance sensors, see also H05K 7/00, constructional details common to different types of electric apparatus.

For search and classification in G01L 2009/0067 , diaphragm pressure sensor using additional isolating diaphragms, see also G01L 13/025, devices for measuring differences of two or more pressure value using diaphragms, and G01L 2009/0063 , pressure sensor using strain gages with fluid coupling.

For search and classification in G01L 9/0079, pressure sensor with diaphragm using a Fabry-Perrot arrangement, see also G01D 5/266, Transducer not specially adapted to a specific variable using interferometer, and G01D 5/268, Transducer not specially adapted to a specific variable using fiber.

For search and classification in G01L 19/0038 and lower see also G01L 19/14, housings of pressure sensor in general.

In these groups documents are only classified therein if there are details about the circuits of the pressure sensor. For details about the physical way of measuring the pressure see the corresponding subgroups in G01L 9/00.

This place does not cover:

Using vibrations |

Attention is drawn to the following places, which may be of interest for search:

Pressure sensitive flexible, deformable tubes in general |

This place does not cover:

Using vibrations |

Attention is drawn to the following places, which may be of interest for search:

Pressure sensitive bellows in general |

Attention is drawn to the following places, which may be of interest for search:

Pressure sensitive flexible diaphragms in general |

This place does not cover:

Using vibrations |

Attention is drawn to the following places, which may be of interest for search:

Pressure sensitive capsules in general |

This place does not cover:

Using vibrations |

Attention is drawn to the following places, which may be of interest for search:

Pressure sensitive pistons in general |

This place does not cover:

Using vibrations |

Attention is drawn to the following places, which may be of interest for search:

Pressure sensitive liquid mediums in general |

The documents concerning pressure sensor are classified in this group if the pressure measurement method do not fit in G01L 7/00 or G01L 9/00. Especially classification in G01L 11/02 (using optical means) cannot be given if the document fit with for instance G01L 9/0076 (diaphragm pressure sensor using optical means). See G01L 7/00 or G01L 9/00 before classifying here.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Specially adapted for mounting on vehicles or tyres |

Attention is drawn to the following places, which may be of interest for search:

Connection of valves to inflatable elastic bodies |

This place covers:

- Connecting means of pressure sensor;

- Pressure sensor associated with other sensor;

- Arrangement for compensating or preventing effects of inclination or acceleration;

- Temperature compensation means;

- Overload and other protection means;

- Recording means;

- Housings of pressure sensor;

- Dials and mounting of dials.

G01L 19/0007; For search or classification in connecting means for flowthrough system having a flexible pressure transmitting element (G01L 19/0023), see also measuring deformation of fluid transporting tubes in G01L 7/02 and G01L 9/0001.

G01L 2019/0053 ; For search and classification: this sub-group only concerns the measurements of pressure plus another variable and for not only compensation purposes. Measurements of a plurality of variable see G01D 21/02. For compensation purposes see relevant group in G01L 19/00, G01L 19/02, G01L 19/04, G01L 9/025, G01L 9/045, G01L 9/065, G01L 9/085, G01L 9/105, G01L 9/125.

G01L 19/02; This sub-group also contains humidity, static pressure, range adjusting or extension means, and zero setting means with exception of aneroid barometers (see G01L 7/14).

G01L 19/04; For search an classification: this sub-group only concerns non electrical compensating means. With electrical compensation means see relevant group in G01L 19/00, G01L 19/02, G01L 19/04, G01L 9/025, G01L 9/045, G01L 9/065, G01L 9/085, G01L 9/105, G01L 9/125. For temperature compensation of aneroid barometers (see G01L 7/14).

G01L 19/06; For search or classification in the sub-group G01L 19/0672, leakage or rupture detection in pressure sensor, see also leak detection per see in G01M 3/00, and leak detection in membrane, B01D 65/102.

G01L 19/12; This subgroup does not cover pressure switches (H01H 35/24 - H01H 35/40).

Attention is drawn to the following places, which may be of interest for search:

Use of coupling membranes with a coupling fluid in general |

Attention is drawn to the following places, which may be of interest for search:

Detection of leakage per se |

Attention is drawn to the following places, which may be of interest for search:

Pressure measurements in the body | |

Catheter tips per se |

Attention is drawn to the following places, which may be of interest for search:

Langmuir probes for plasma diagnostics |

Attention is drawn to the following places, which may be of interest for search:

Tubes therefor |

Attention is drawn to the following places, which may be of interest for search:

Apparatus for recording steady or quasi-steady pressure |

Attention is drawn to the following places, which may be of interest for search:

Calibration of sensors per se |

Attention is drawn to the following places, which may be of interest for search:

Malfunction detection of sensor not measuring a specific variable per se |