CPC Definition - Subclass G01F

This place covers:

- Apparatus or methods for measuring the volume flow or mass flow of fluids or fluent solid materials.

- Apparatus or methods for metering by volume.

- Apparatus or methods for measuring the capacity of containers or cavities, or the volume of solid bodies, fluids or fluent solid materials.

- Level indicators.

- Details, accessories, testing or calibrating of the apparatus as described.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Milk flow sensing devices in milking machines or devices | |

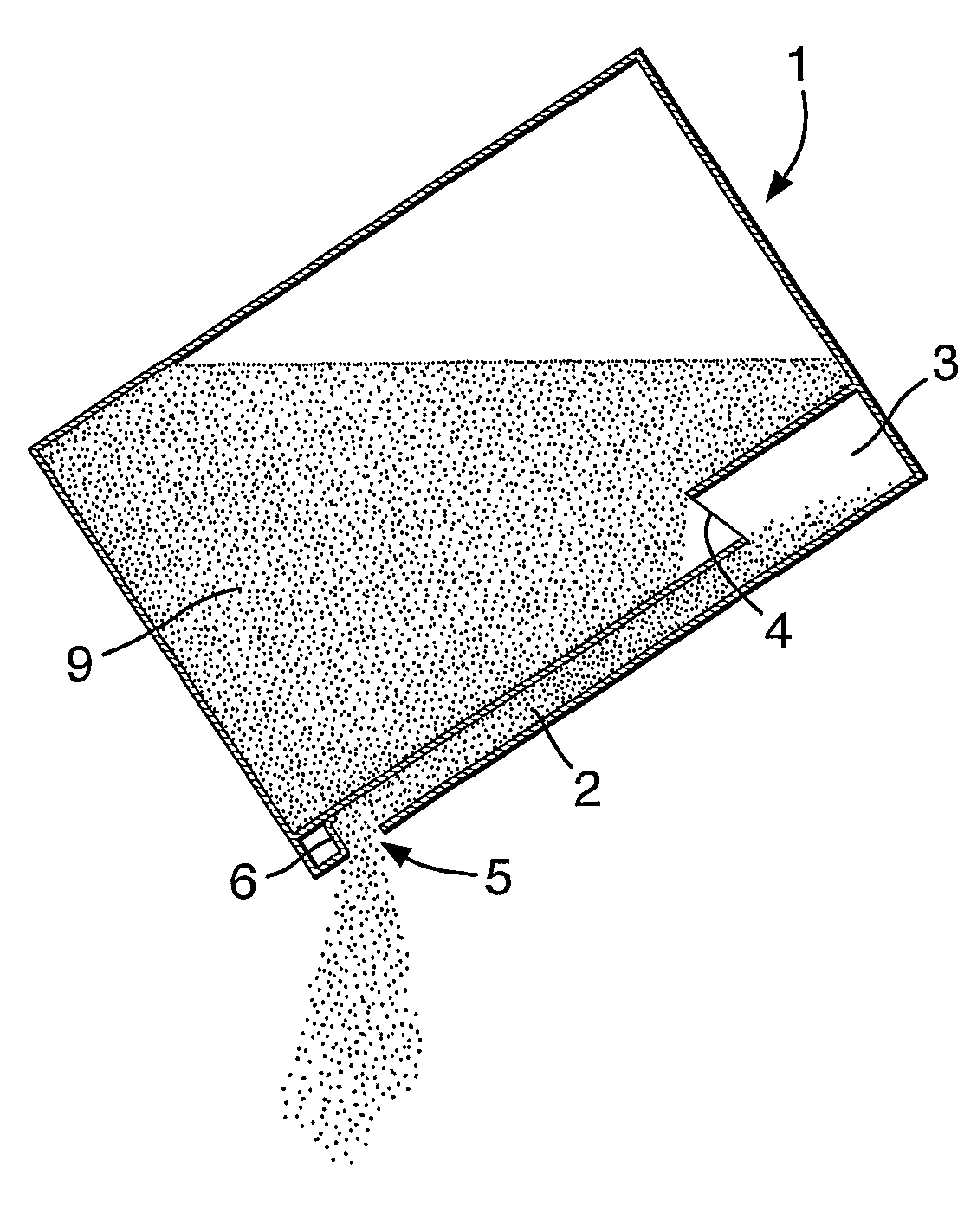

Food containers with dispensing devices for dispensing a certain quantity of powdered or granulated foodstuffs | |

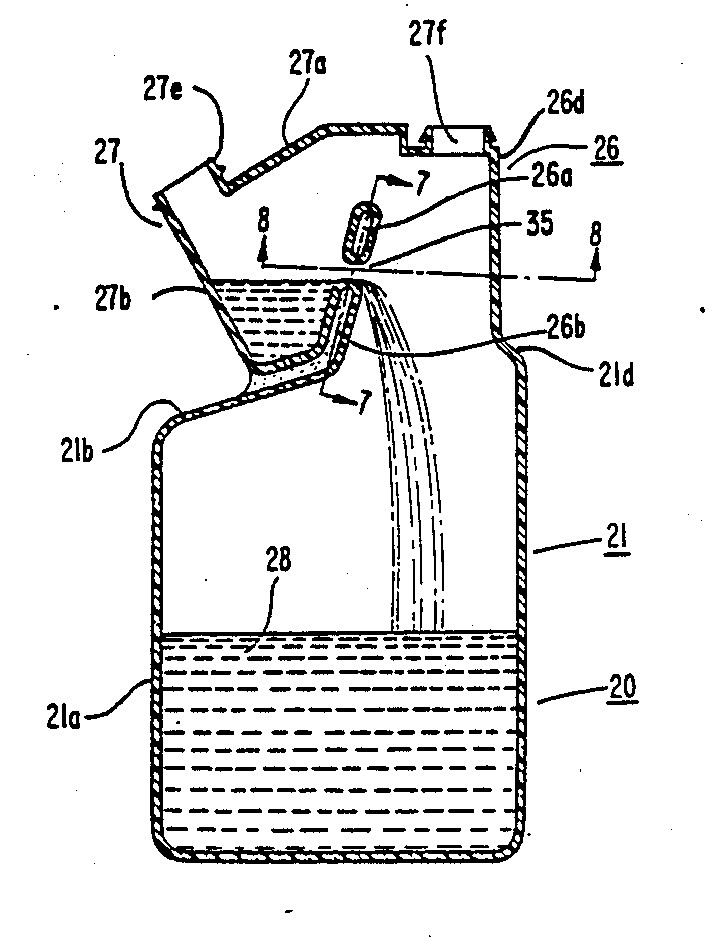

Apparatus for making beverages having water-level controls | |

Measuring blood flow | |

Metering media introduced into the human body, e.g. drip meters | |

Controlling the quantity of fluent-solid material fed into a container during packaging by volumetric measurement | |

Controlling the quantity of plastic material, semi-liquids, liquids, or mixed solids and liquids, fed into a container during packaging by volumetric measurement | |

Separating measured quantities from supply by volume measurement | |

Bottling liquids or semi-liquids with provision for metering the liquids to be introduced, e.g. when adding syrups | |

Flowmeters used in apparatus or devices for dispensing beverages on draught | |

Arrangements of liquid volume meters or volume-flow meters in liquid-delivering apparatus, e.g. for retail sale purposes | |

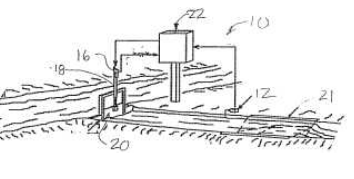

Measuring liquid level in wells | |

Indicating devices for lubricant level | |

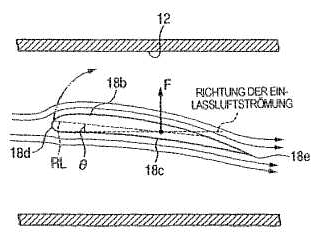

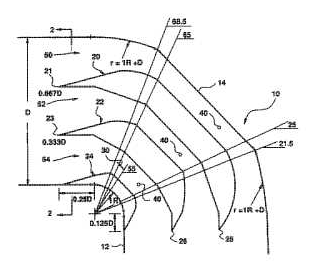

Measuring intake air flow to generate a control signal for control of supply of combustible mixture in combustion engines | |

Proportioning devices in lubricating systems | |

Arrangements for measuring the quantity of conveyed product in pipe-lines | |

Adaptation of level indicators to, or mounting on, steam boilers | |

Controlling water feed or water level for steam generation | |

Rainfall or precipitation gauges | |

Apparatus actuated by coins, cards or the like with meter-controlled dispensing of liquid or gas | |

Reactor-coolant flow measuring or monitoring in nuclear reactors;Moderator- or coolant-level detecting devices in nuclear reactors | |

Accumulators combined with arrangements for measuring, testing, or indicating condition, e.g. level or density of the electrolyte |

Attention is drawn to the following places, which may be of interest for search:

Filters | |

Burettes or pipettes | |

Measuring linear dimensions to determine volume | |

Weighing a continuous stream of material during flow | |

Measuring pressure | |

Sampling; Preparing specimens for investigation | |

Measuring speed of fluids, e.g. of air stream | |

Determining a distance or velocity using sonar, radar or lidar techniques | |

Control of flow; Control of level | |

Ratio control | |

Alarm devices | |

Electric switches operated by change of liquid level, e.g. float switches, or by a change of fluid flow |

This place covers:

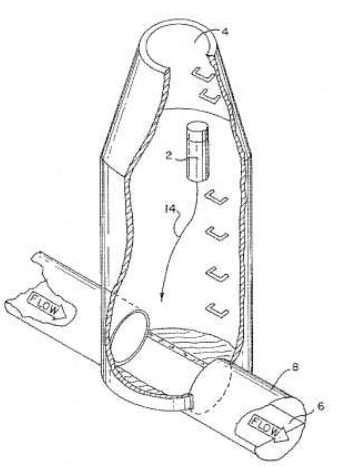

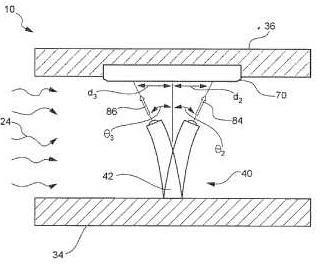

Devices specially adapted to be used in open channels

Devices operating

- by measuring the level variations of storage tanks relative to the time

- by using mechanical effects

- by using electric or magnetic effects

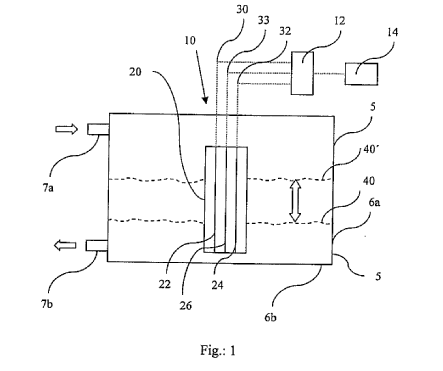

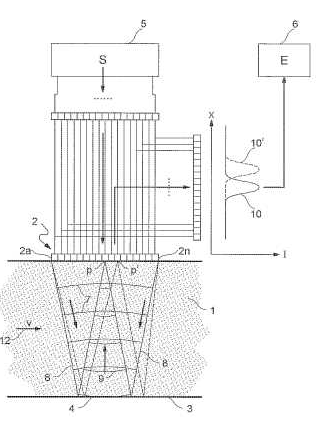

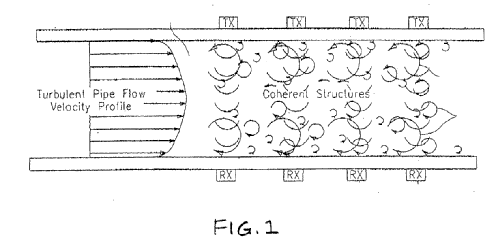

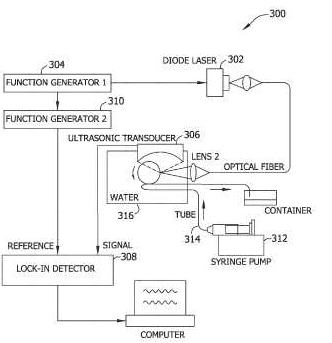

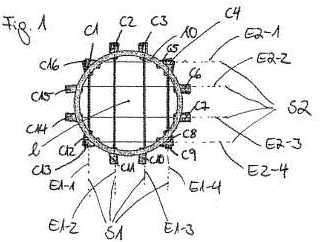

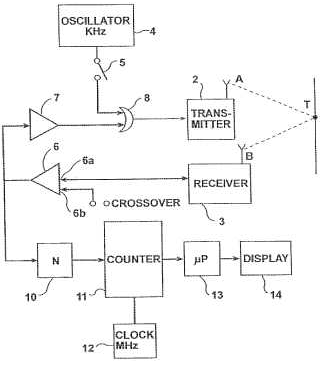

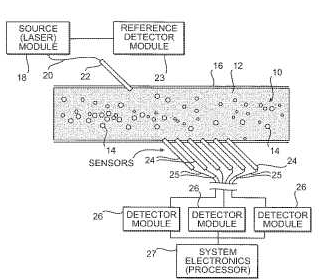

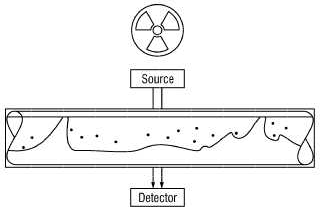

- by measuring frequency, phaseshift, or propagation time of electro-magnetic or other waves, e.g. ultrasonic flowmeters

- by using thermal effects

Devices using marked regions or existing inhomogeneities within the fluid stream, e.g. statistically occurring variations in a fluid parameter Devices for measuring pulsing fluid flows

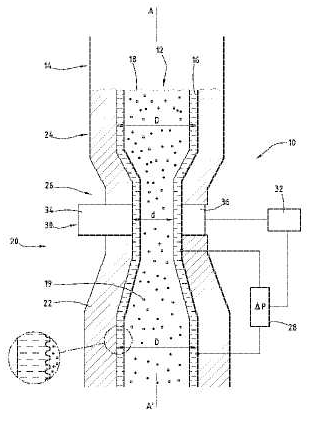

Devices for measuring flow of a fluid or flow of a fluent solid material in suspension in another fluid

Devices for measuring mass flow of a fluid or a fluent solid material

Although measuring speed of fluids is classified in G01P 5/00, determination of speed of fluids flowing through tubes is considered as belonging to flow measurement and is generally not classified in G01P 5/00, but in G01F, e.g. G01F 1/66, even if volume flow is not explicitly mentioned in the documents.

This place does not cover:

Measuring a proportion of volume flow |

Attention is drawn to the following places, which may be of interest for search:

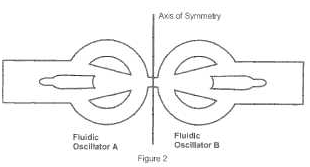

Fluidic oscillators | |

Weighing a continuous stream of material during flow | |

Detection means in general | |

Measuring speed by using correlation means in general | |

Arrangements or constructions of Pitot tubes for measuring speed of fluids | |

Indicating presence or absence of flow | |

Magnet, inductances; transformers; selection of materials for their magnetic properties |

Devices using Peltier or Seebeck effects are also classified under G01F 1/6888.

Devices for measuring pulsing fluid flow and devices for measuring bidirectional flow are classified in G01F 1/72.

In this place, the following terms or expressions are used with the meaning indicated:

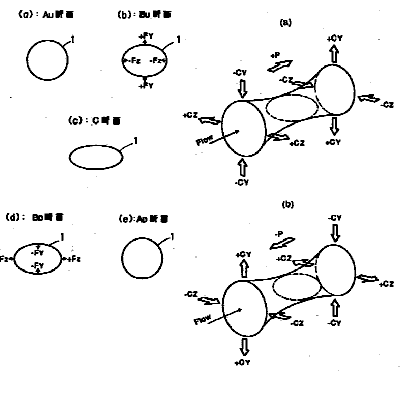

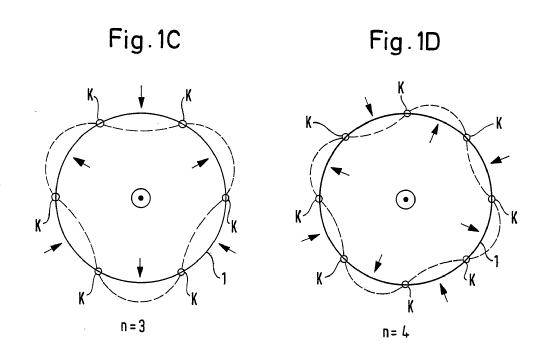

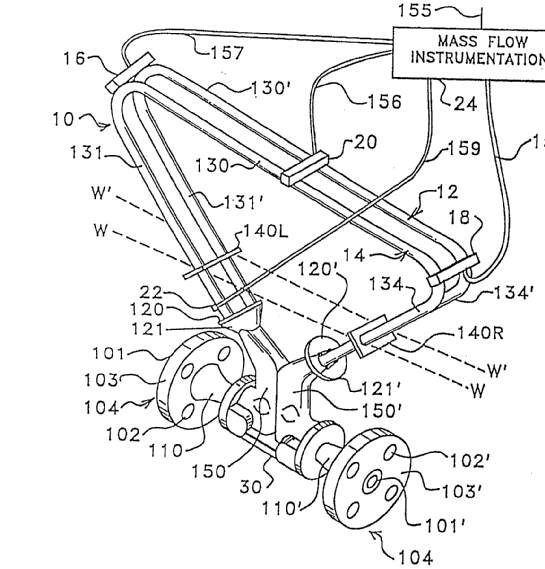

Multiple exciters or detector pairs | Vibrating tube Coriolis mass flowmeters with more than one driver or more than one pair of pick-offs (this group is a subgroup of the previous one but, at present, incomplete) |

Special driving or detecting modes | Vibrating tube Coriolis mass flowmeters with special/unusual arrangements of exciters and/or detectors, such as: more than one driver or more than one detector pair; or unusual driving modes |

This place covers:

Illustrative example of subject matter classified in this group

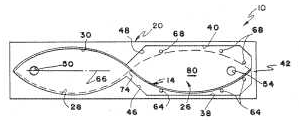

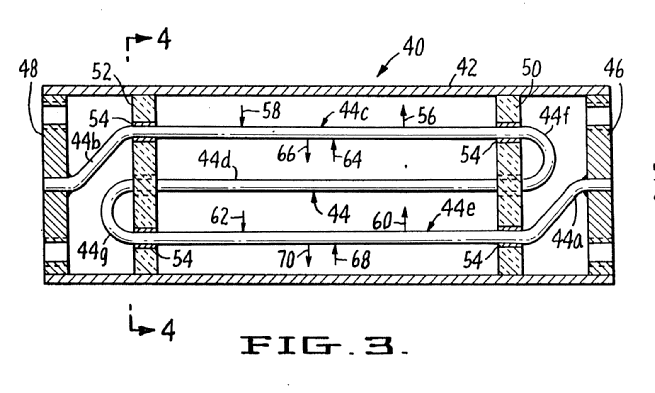

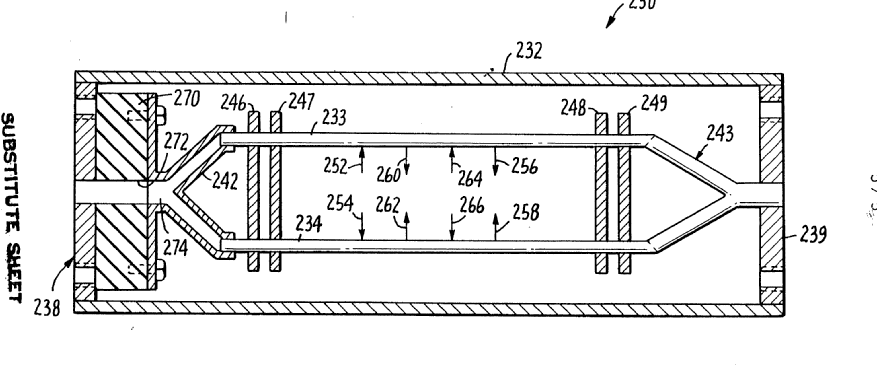

US5684250

US2002066484

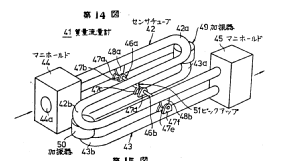

This place covers:

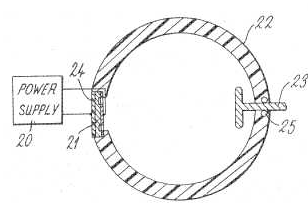

Illustrative example of subject matter classified in this group

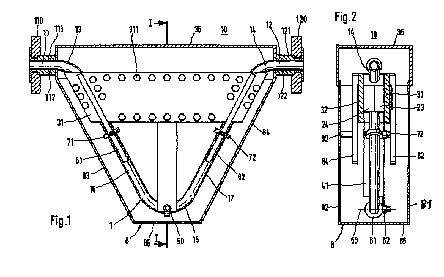

EP2265905

US4669308

This place covers:

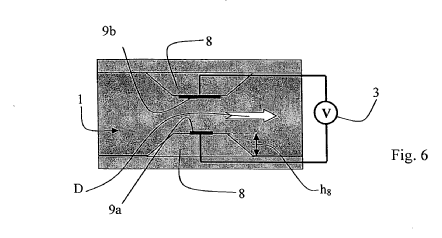

Illustrative example of subject matter classified in this group

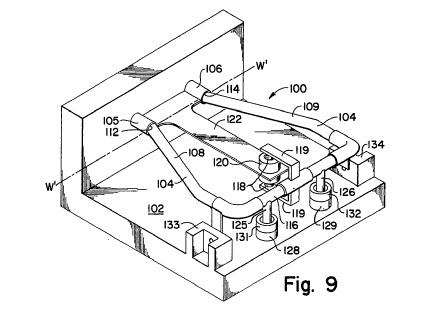

WO2008044917

This place covers:

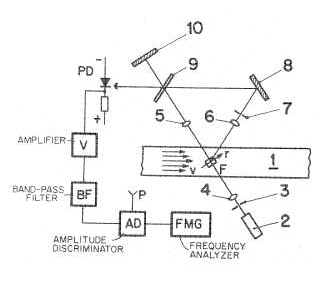

Illustrative example of subject matter classified in this group

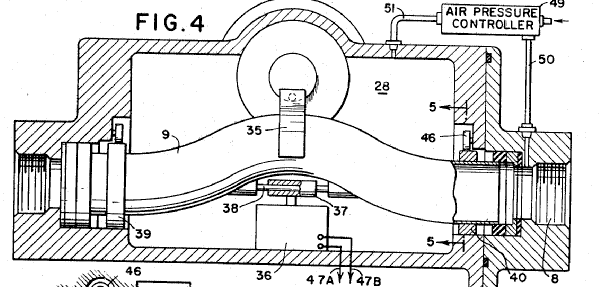

US6079281

This place covers:

Illustrative example of subject matter classified in this group

WO2004020894

EP1992916

This place covers:

Illustrative example of subject matter classified in this group

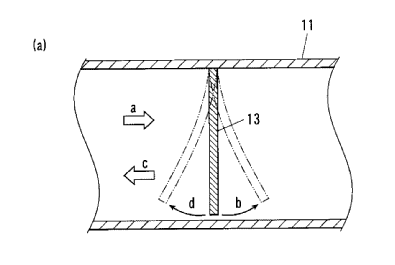

WO2006062007

DE102007057060

This place covers:

Illustrative example of subject matter classified in this group

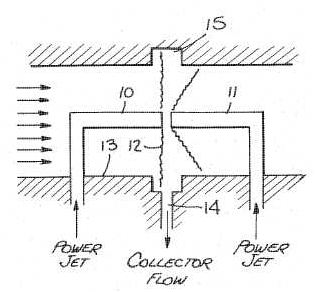

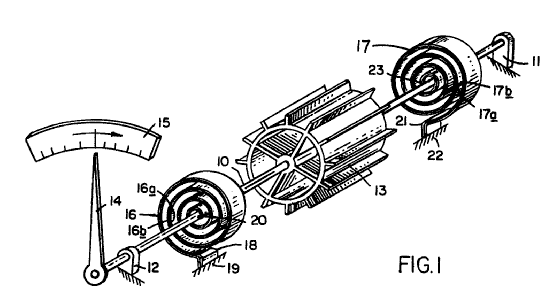

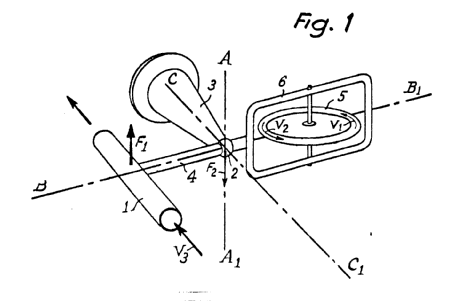

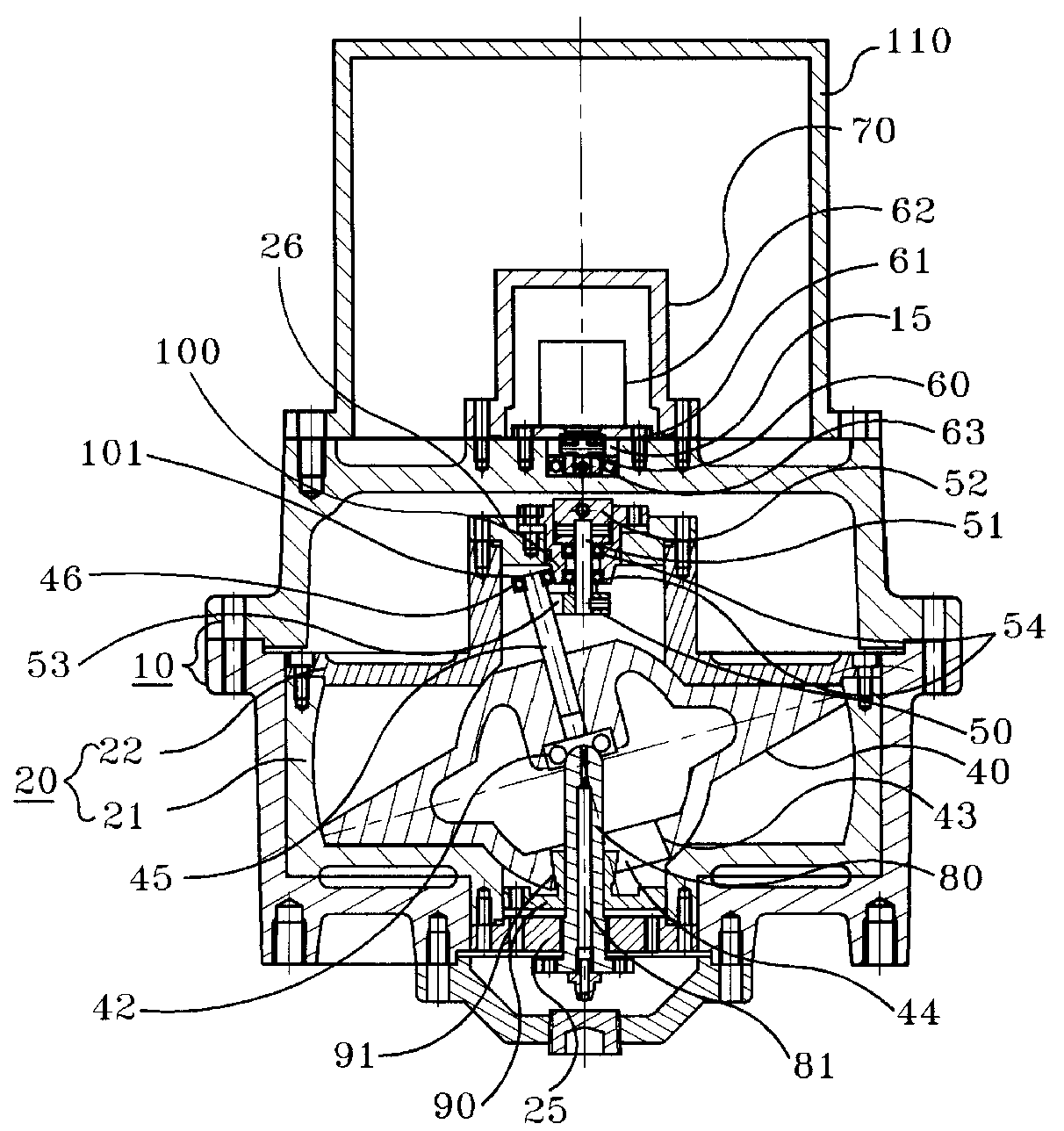

US3709213

US3705534

This place covers:

Illustrative example of subject matter classified in this group

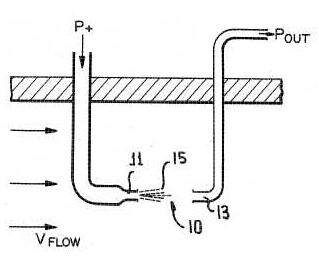

DE102007000445

US5687768

US5687768

US5571974

WO9702470

WO9702470

This place covers:

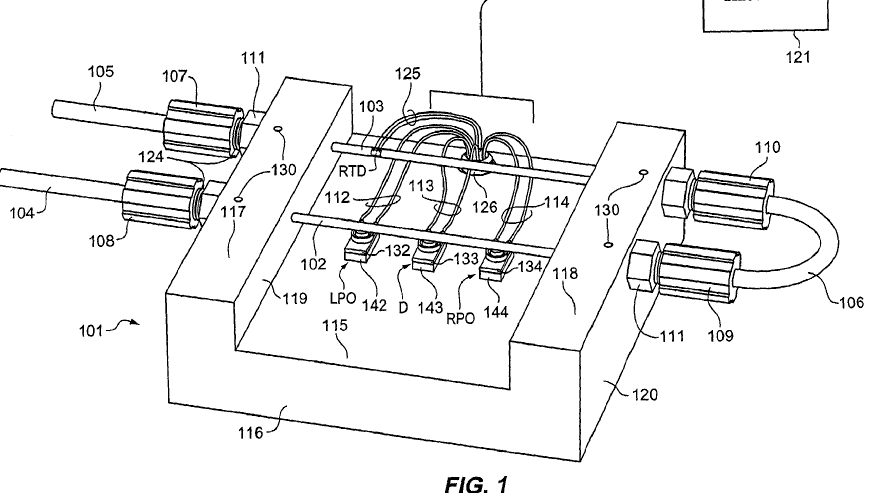

Illustrative example of subject matter classified in this group

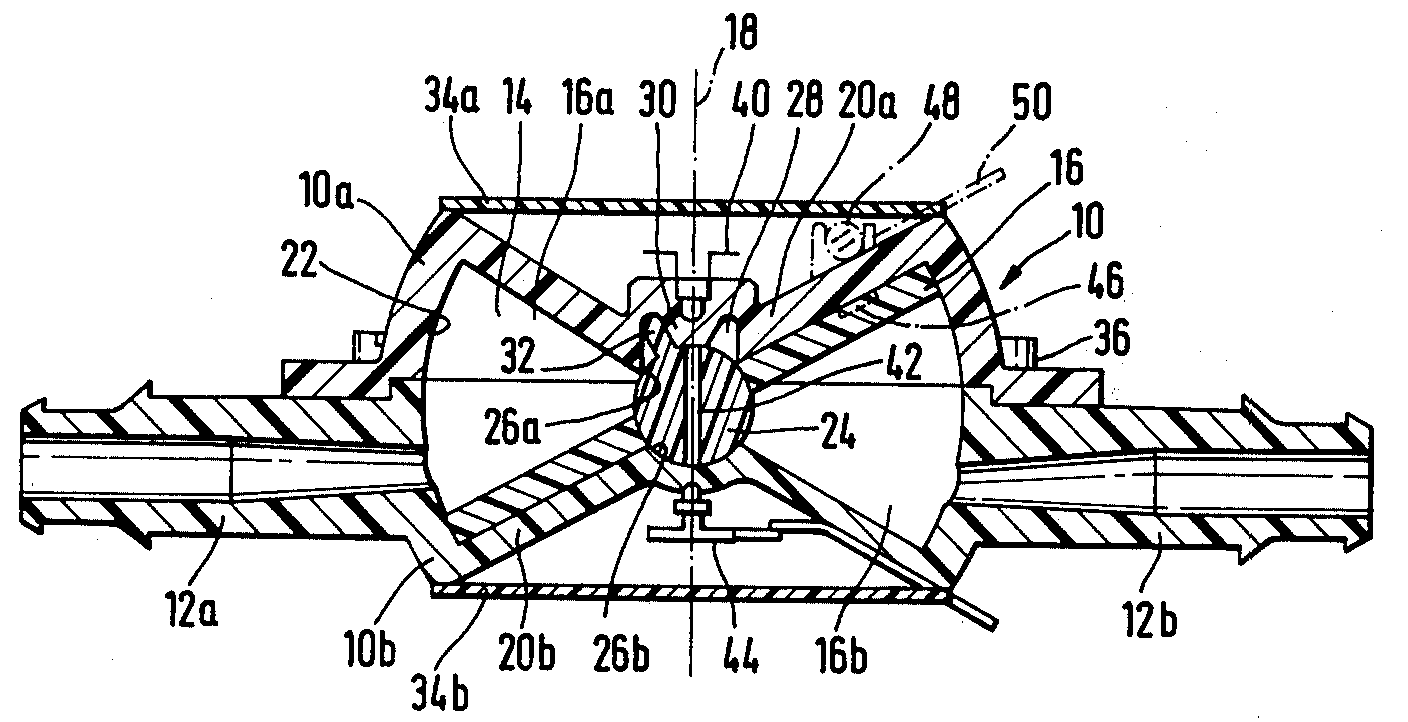

EP1094303 EP0295845 US4182172

This place covers:

Illustrative example of subject matter classified in this group

EP0783056

GB402685

GB402685

This place covers:

Illustrative example of subject matter classified in this group

WO9300571

US4594890

This place covers:

Illustrative example of subject matter classified in this group

US3742263

WO2010000977

WO2010000977

Attention is drawn to the following places, which may be of interest for search:

This place covers:

Illustrative example of subject matter classified in this group

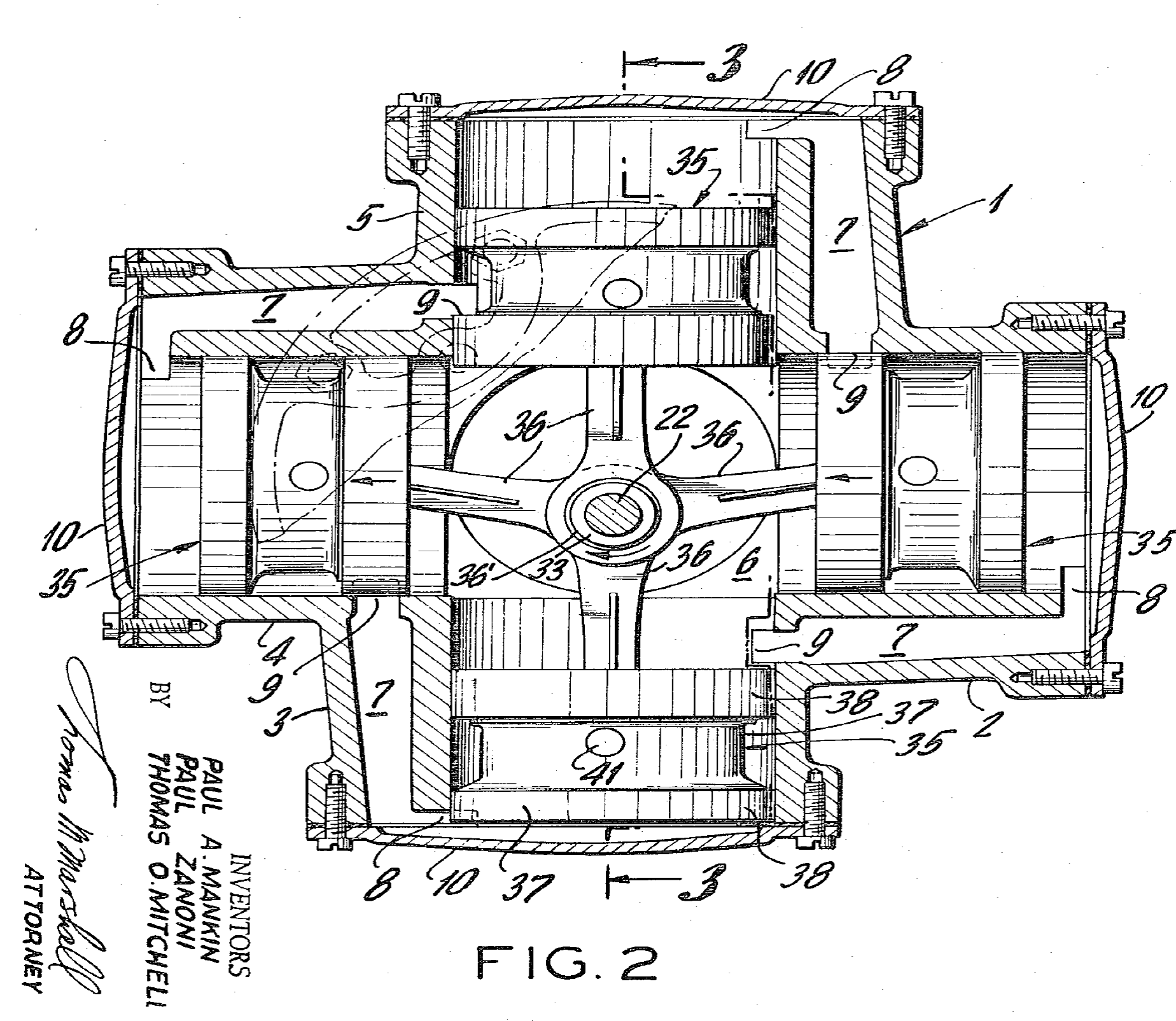

US3709599

This place covers:

Illustrative example of subject matter classified in this group

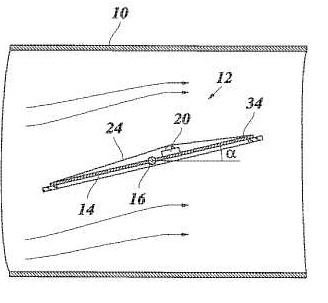

US2007227261

EP2236993

This place covers:

Illustrative example of subject matter classified in this group

EP1728054

US2008088819

US2008088819

This place covers:

Illustrative example of subject matter classified in this group

US2009158858

This place covers:

Illustrative example of subject matter classified in this group

US2009138215

EP2072972

US2002105340

This place covers:

Illustrative example of subject matter classified in this group

US2005235757

This place covers:

Illustrative example of subject matter classified in this group

EP1907801

EP1754957

This place covers:

Illustrative example of subject matter classified in this group

DE102007038474

GB2447425

This place covers:

Illustrative example of subject matter classified in this group

FR2936312

US7738084

US2010280757

This place covers:

Illustrative example of subject matter classified in this group

Attention is drawn to the following places, which may be of interest for search:

Weighing a continuous stream of material during flow |

This place covers:

Illustrative example of subject matter classified in this group

EP0737302

This place covers:

Illustrative example of subject matter classified in this group

WO9702470

US2007193371

This place covers:

Illustrative example of subject matter classified in this group

GB1087350

This place covers:

Illustrative example of subject matter classified in this group

Details of flow meter manufacturing methods:

Methods for designing flow meters, e.g. numerical simulations of flow meter behaviour or modelling to refine the flow meter design (e.g.. eigenvector design): (XP002096659, WO99/28708, US2003097883, EP0271605,WO0165213)

WO0165213:

This place covers:

Illustrative example of subject matter classified in this group

Constructional details

This place covers:

Illustrative example of subject matter classified in this group

Means for influencing the flow meter's motional or vibrational behaviour, e.g., conduit support or fixing means, or conduit attachments:

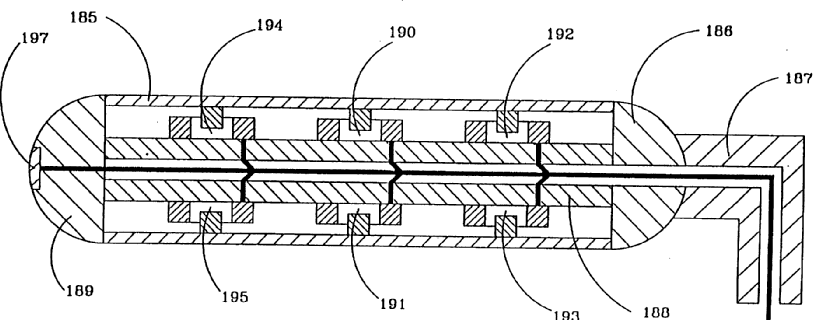

Details of tubes, casings or special casings for gyroscopic mass flow meters, e.g. central support manifold fixing the tube(s) ends US5343764:

improved node plates/brace bars: WO2009123632, US5370002;

stiffening means EP0547455, figs 1,3:

Casings influencing the vibrational behaviour should go both to G01F 1/8409 and G01F 1/8413

This place covers:

Illustrative example of subject matter classified in this group

Motion or vibration balancing means:

US4957005, US2009145244, EP1001254, US2923154

Rebalancing means (e.g.. masses or actuators) EP0759542; Rebalanced flow meter design;

US2001035055:

US2002020228:

This place covers:

Illustrative example of subject matter classified in this group

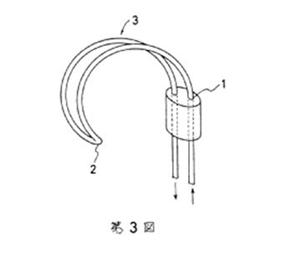

Exciters: constructional details for exciters, FR2316582, EP1719983, WO8505677

This place covers:

Illustrative example of subject matter classified in this group

Detectors: constructional details for detectors, e.g. details of the optical detectors US4311054, US2006243066, EP1719983, US2009145244, US2005150311

This place covers:

Illustrative example of subject matter classified in this group

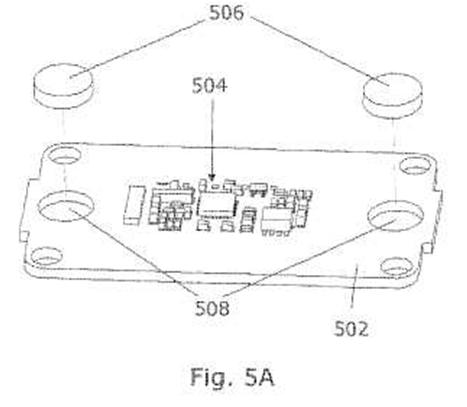

Electronic circuits: US4311054, US4680974, US5069074, WO8707714

This place covers:

Illustrative example of subject matter classified in this group

Signal processing: e.g. details of neural networks, FFT, matrix operations, analogue and digital filtering: WO0049371, US4680974, WO8505677, US5555190

This place covers:

Illustrative example of subject matter classified in this group

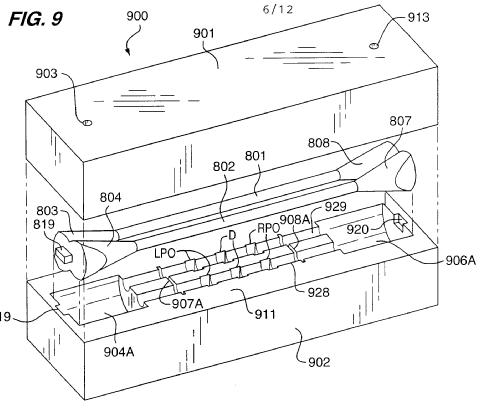

Microfluidic or miniaturised flow meters: US2005150311 (e.g. capillaries as flow metering tubes)

This place covers:

Illustrative example of subject matter classified in this group

Micromachined flow meters: US2007151335 (applying chip technology)

This place covers:

Illustrative example of subject matter classified in this group

Arrangements of measuring means, e.g., of measuring conduits

This place covers:

Illustrative example of subject matter classified in this group

Rotating or rotatingly suspended measuring conduits: Revolving (continuously rotating) measuring pipe(s)/ flow path(s): (EP0424828, DE4125424) EP0424828:

DE4125424:

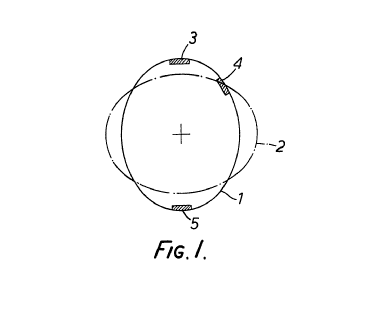

Rotating fluid guiding part DE20115010U; Oscillating tube being rotatingly suspended (tube connections allowing rotation): (BE681739, US3276257, US3485098); use of a gyroscope: BE681739:

This place covers:

Illustrative example of subject matter classified in this group

Vibrating means being located inside the measuring conduits:

Vibrating elements in flow path: EP0867694:

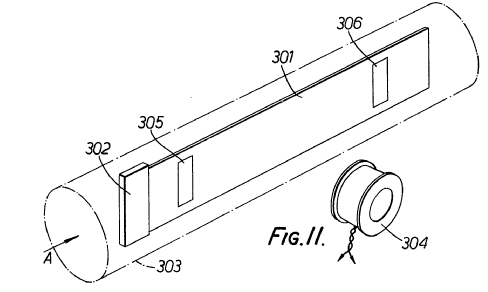

Vibrating metal strip in flow path: US4420983 (fig.11):

Vibrating cylinder in flow path: US4420983 (fig 1):

This place covers:

Illustrative example of subject matter classified in this group

The measuring conduits' cross-section being deformed during measurement, e.g. by periodically deflecting a portion of the conduits' surface:

JP6235652 (the cross-section is deformed by the action of the fluid)

EP0316908 (phase difference between deflection of successive wall sections)

This place covers:

Illustrative example of subject matter classified in this group

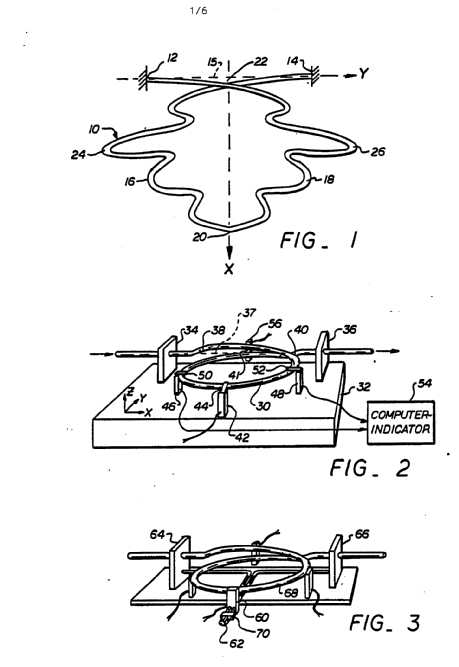

Vibrating measuring conduits:

Pipes, flow paths not covered by the sub-classes: e.g. 3-dimensional flow tube configurations not being loops, e.g. US5184518, US4879910; or an out-of-plane bent flow tube (JP4081617) need to be classified under the subclass G01F 1/8468.

US5184518:

JP4081617:

This place covers:

Illustrative example of subject matter classified in this group

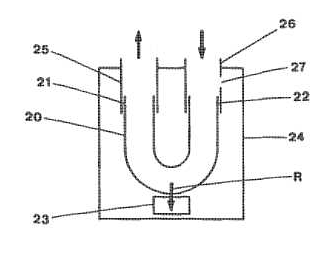

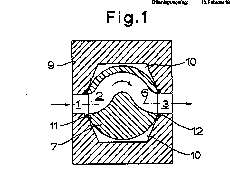

Having curved measuring conduits, i.e. whereby the measuring conduits' curved center line lies within a plane (G01F 1/8481 takes precedence):

Single S: WO8808517;

single V: US6484591;

single U: GB2001759 (fig.9):

bent oscillating tube (on bearings)US3485098:

This place does not cover:

Having loop-shaped measuring conduits, e.g. the measuring conduits form a loop with a crossing point |

This place covers:

Illustrative example of subject matter classified in this group

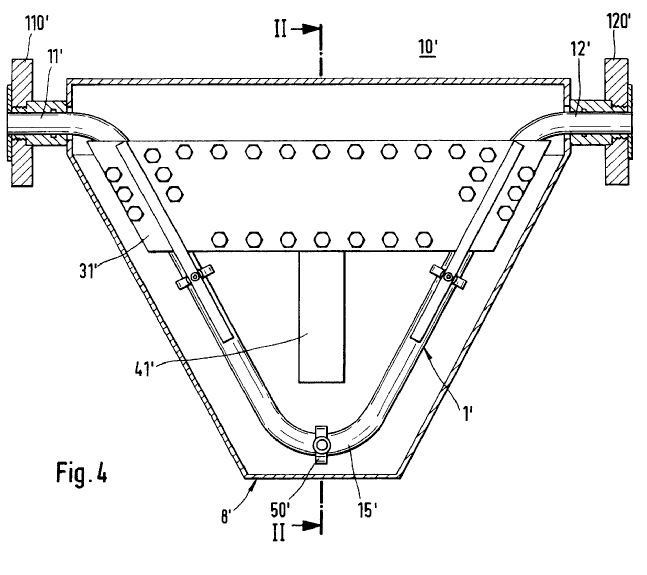

with multiple curved measuring conduits: 2x triangle in parallel:

US5497666:

2xS in parallel: JP63314415

This place covers:

Illustrative example of subject matter classified in this group

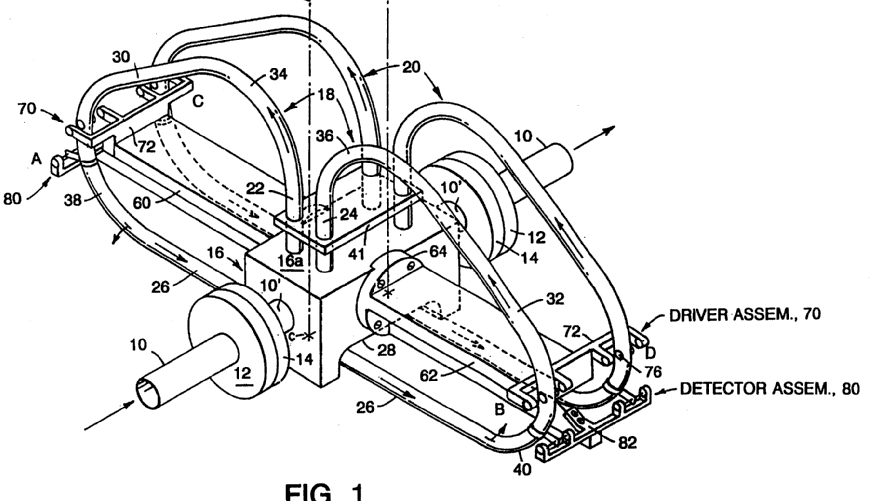

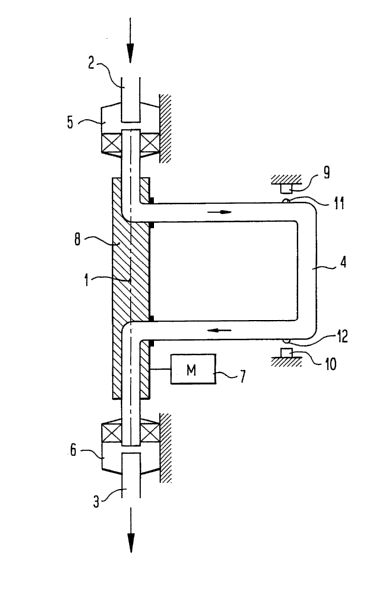

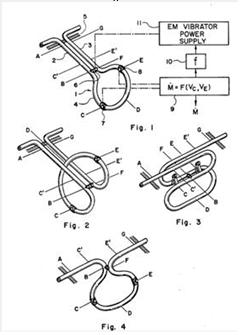

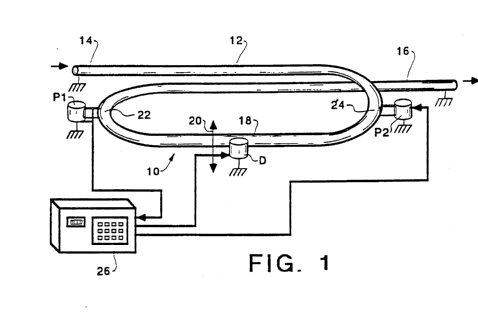

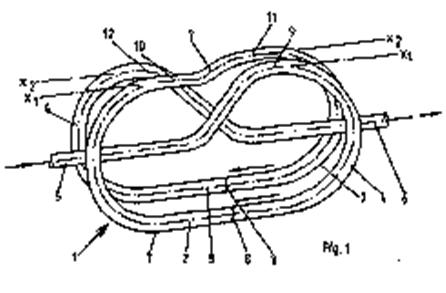

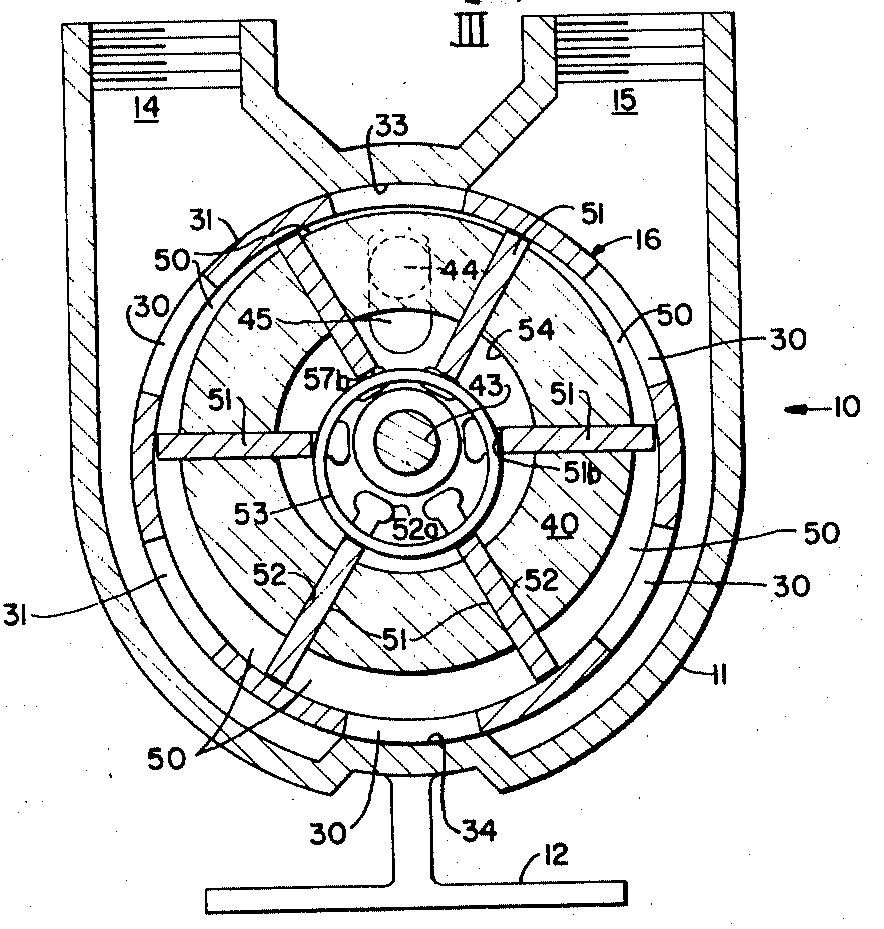

Having loop-shaped measuring conduits, e.g. the measuring conduits form a loop with a crossing point:

Single loop: US5069074

WO8505677:

An almost closed omega, even if called a "loop" should be classified in G01F 1/8472 instead.

This place covers:

Illustrative example of subject matter classified in this group

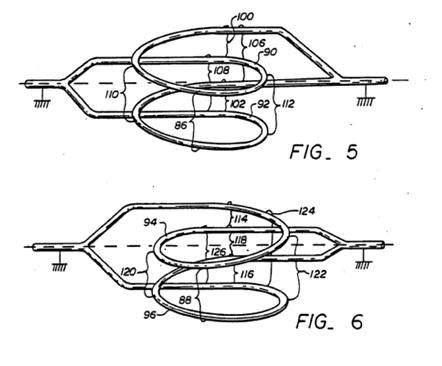

with multiple loop-shaped measuring conduits:

two loops in parallel: WO8505677

two loops in series: EP0271605:

This place covers:

Illustrative example of subject matter classified in this group

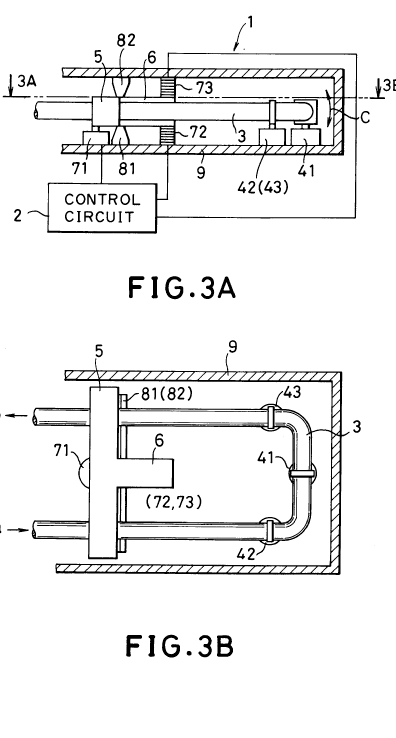

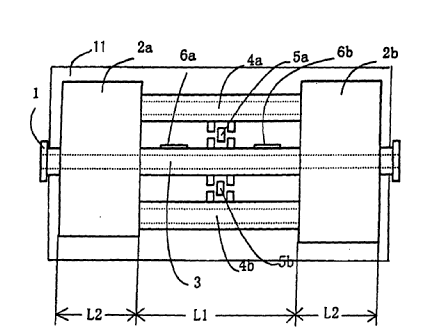

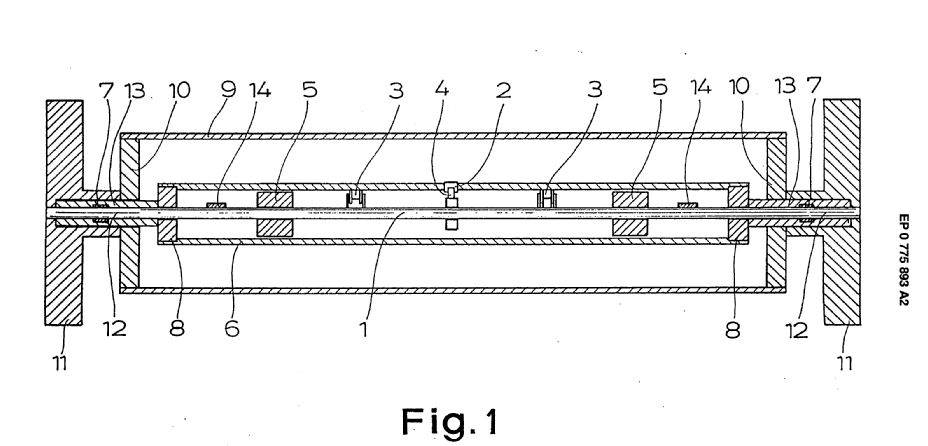

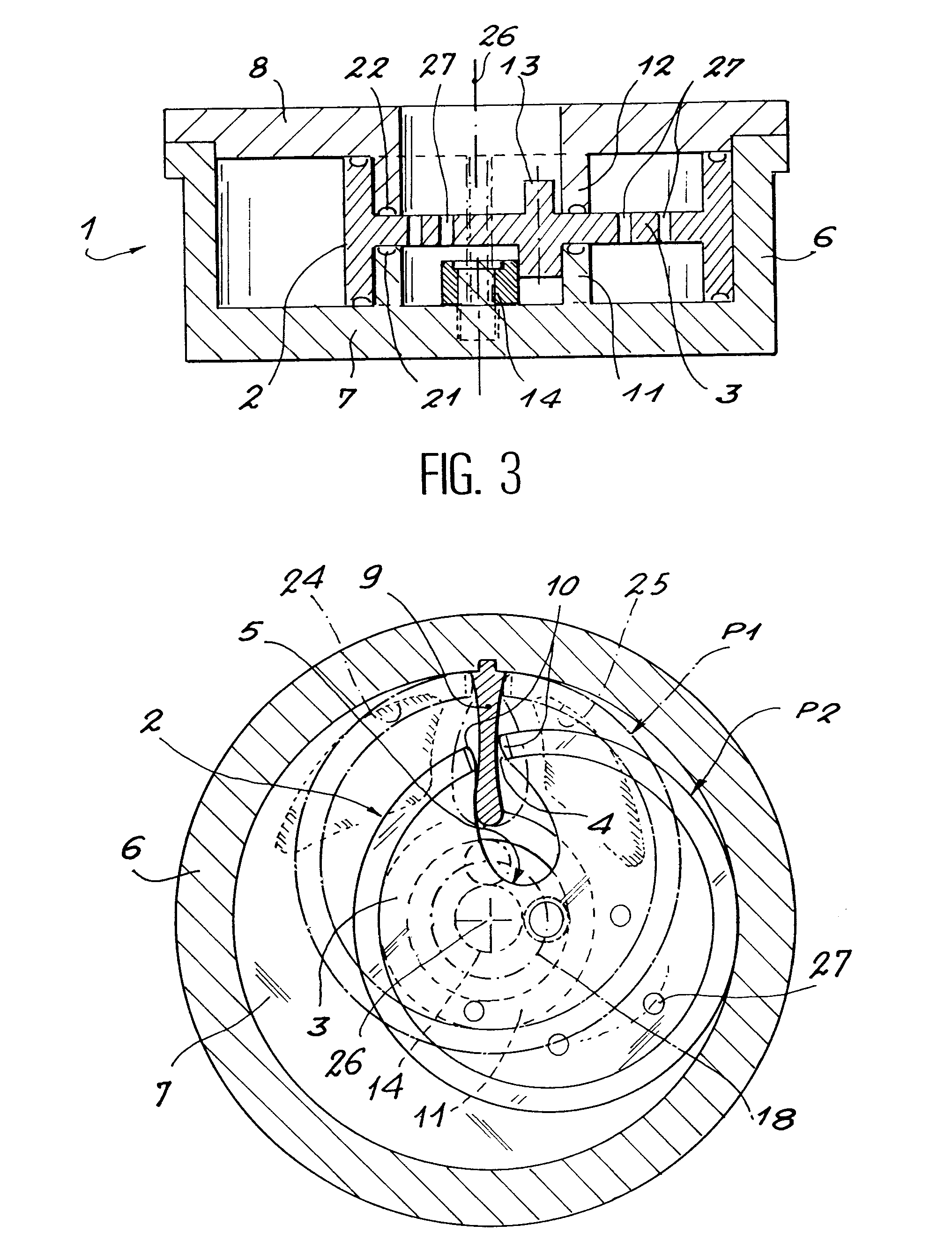

Having straight measuring conduits: single straight tube:

EP0775893:

US2002020228:

This place covers:

Illustrative example of subject matter classified in this group

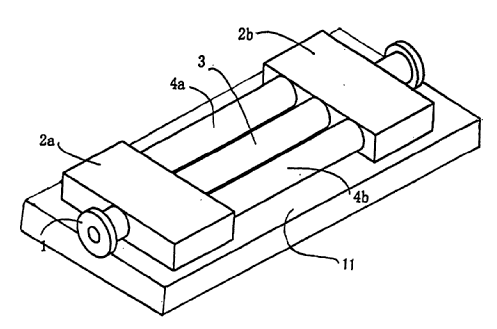

with multiple measuring conduits:

Two straight tubes in parallel: WO8808517:

Two straight tubes in series: US7005019:

This place covers:

Devices

- With measuring chambers which expand or contract during measurement;

- with measuring chambers moved during operation;

- with stationary measuring chambers having constant volume during measurement.

Wet gas-meters.

This place covers:

Illustrative example of subject matter classified in this group

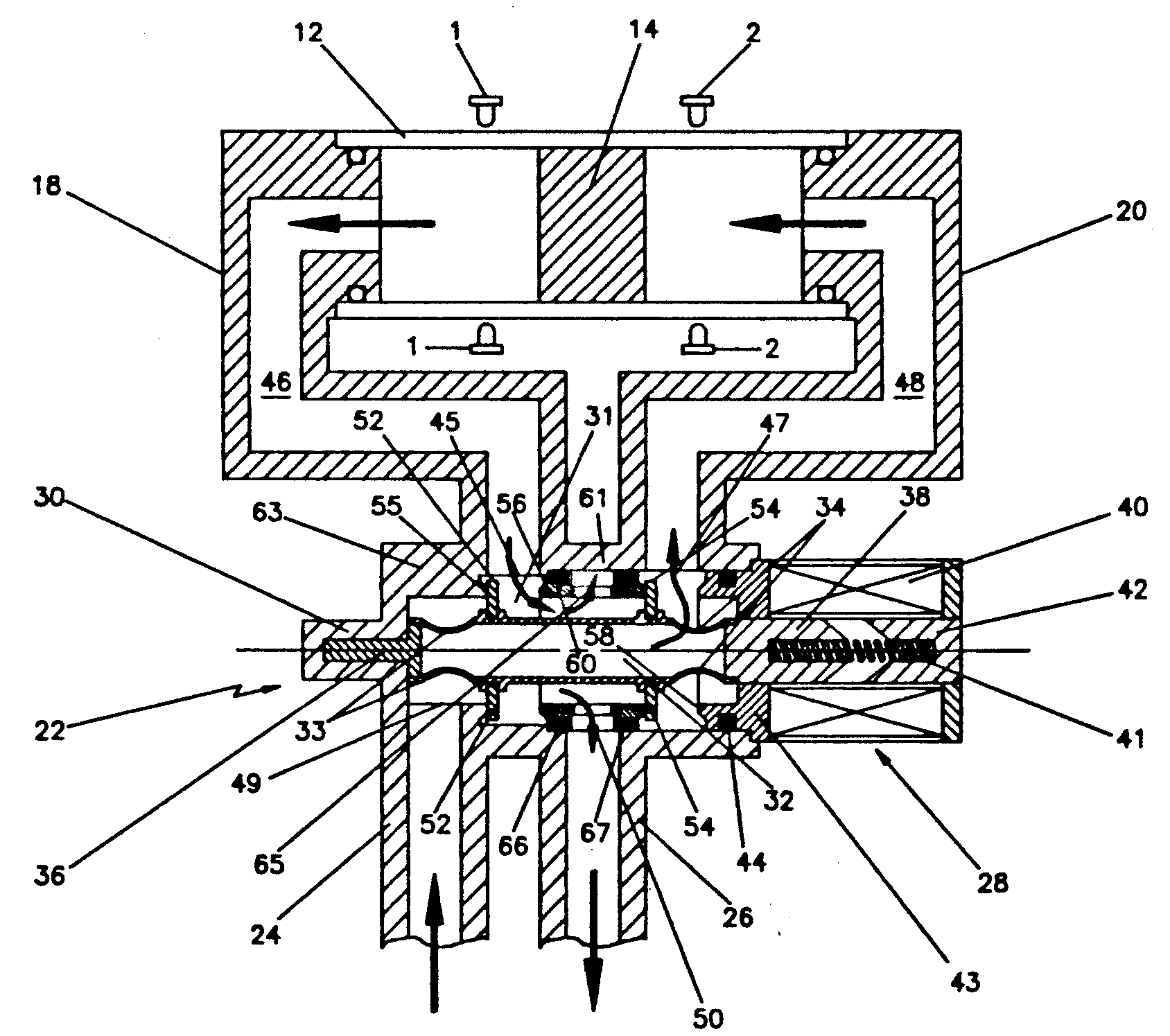

US3683694

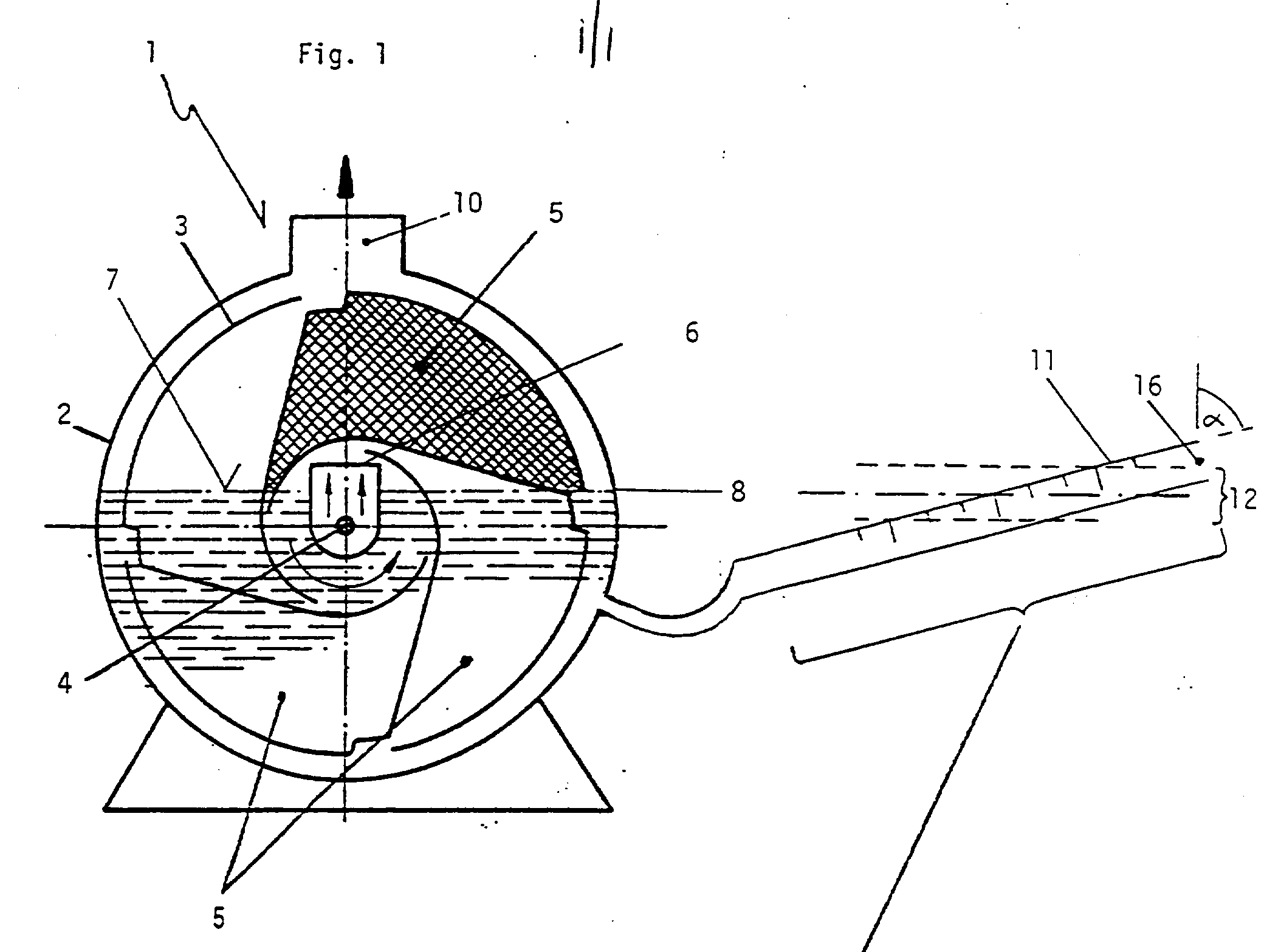

This place covers:

Illustrative example of subject matter classified in this group

US5495756

This place covers:

Illustrative example of subject matter classified in this group

US2010307234

WO0014486

WO0014486

US4856427

GB2120728

GB2120728

This place covers:

Illustrative example of subject matter classified in this group

US5824896

US4232550

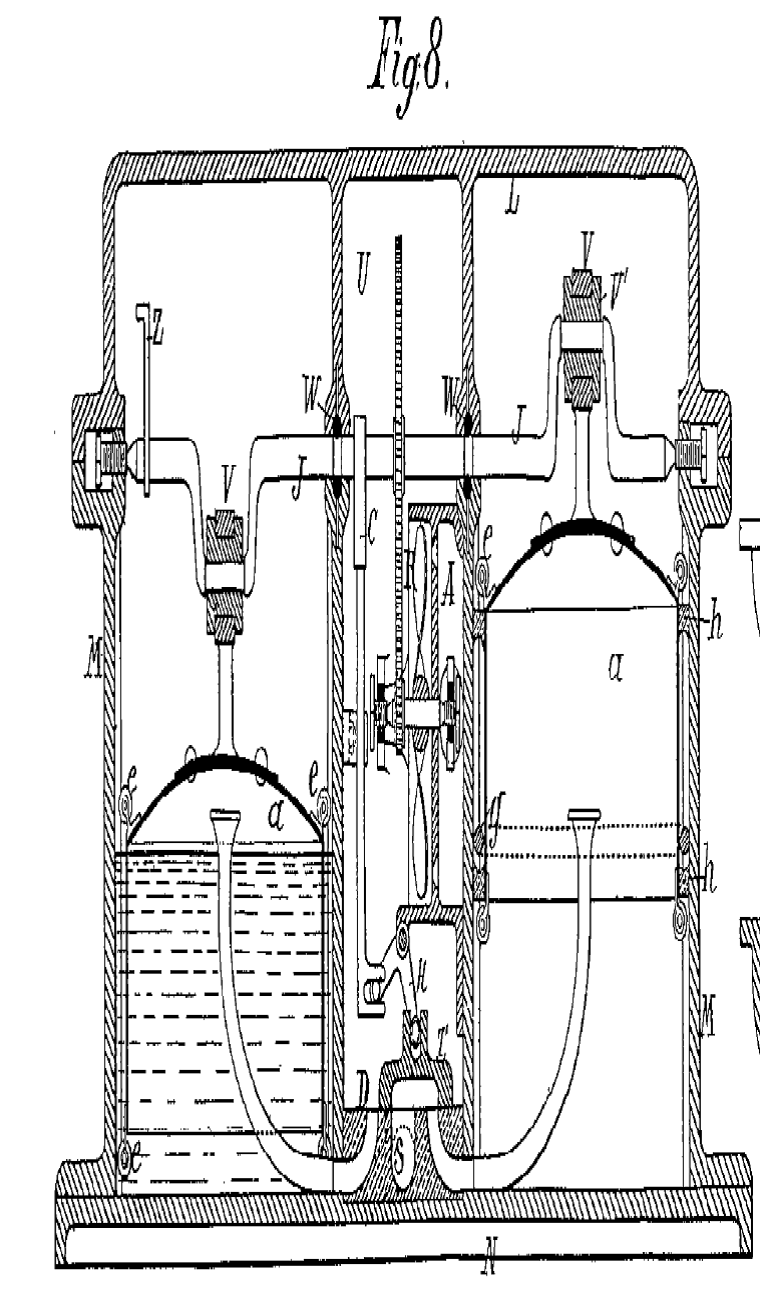

This place covers:

Illustrative example of subject matter classified in this group

US5193389

This place covers:

Illustrative example of subject matter classified in this group

GB1356762

Attention is drawn to the following places, which may be of interest for search:

Diaphragms or bellows therefor |

This place covers:

Illustrative example of subject matter classified in this group

WO2007079942

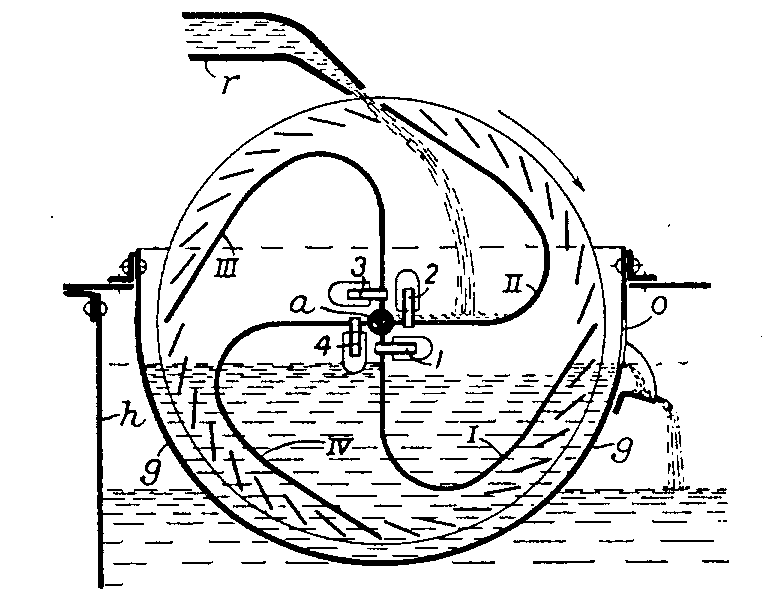

This place covers:

Illustrative example of subject matter classified in this group

GB191220935

This place covers:

Illustrative example of subject matter classified in this group

GB2316491

This place covers:

Illustrative example of subject matter classified in this group

DE31633

This place covers:

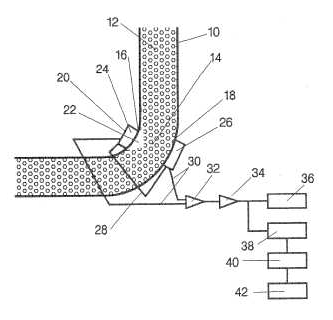

- Flowmeters of any type measuring flow in a by-pass whereby the fluid is flowing simultaneously in both at least one main conduit and a by-pass. The total flow is derived from a known relationship between the section of the by-pass and the section of the main conduit.

- Details of by-passes including such flowmeters, e.g. their arrangement within or aside of the main conduit

This place does not cover:

Compound flowmeters whereby the fluid is flowing either in a by-pass or in a main conduit depending on the flow rate, in order to provide two or more measuring ranges |

Attention is drawn to the following places, which may be of interest for search:

Controlling ratio of two or more flows of fluid |

Details of specific flowmeters classified in G01F 5/00 are also classified in the relevant sub-groups in G01F 1/00 and G01F 3/00.

Details of flowmeters of the pressure or differential pressure type classified in G01F 5/005 are also classified in the relevant groups G01F 1/34 - G01F 1/50

In patent documents, the following words/expressions are often used as synonyms:

- "auxiliary, secondary, or sub-passage" and "by-pass"

- "primary passage" and "main passage"

This place does not cover:

Flowmeters adapted for low flow rates, e.g. where flow is allowed to pass through the flowmeter only when it can be measured by a flowmeter having a specific range |

The following devices are classified in this group:

- Arrangement of at least two flowmeters each having a different range and operated only at their respective range, e.g. compound meters. Arrangement of flow conduits and valves designed to divert the flow to the meter with the proper range.

- Modification to flowmeters in order to increase their range, even when there is only a single flowmeter

- Flowmeters operated simultaneously but each covering a different range

This place covers:

Measuring volume flow relative to another variable

- with electric, electro-mechanic, electronic or mechanic means

- whereby the other variable is the flight or running time or the speed of a vehicle.

Attention is drawn to the following places, which may be of interest for search:

Economical driving | |

Testing fuel-injection apparatus | |

Testing of internal combustion engines |

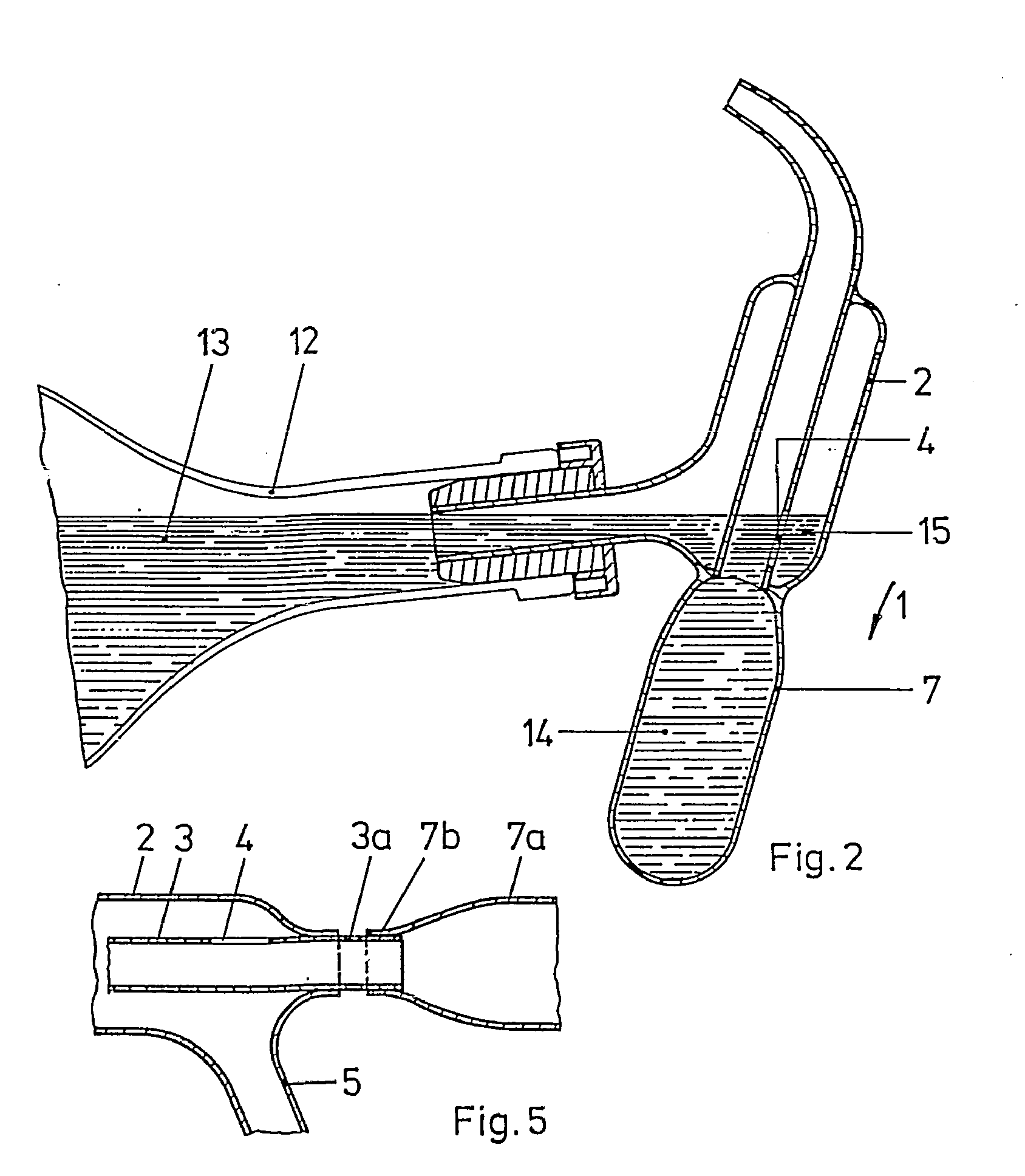

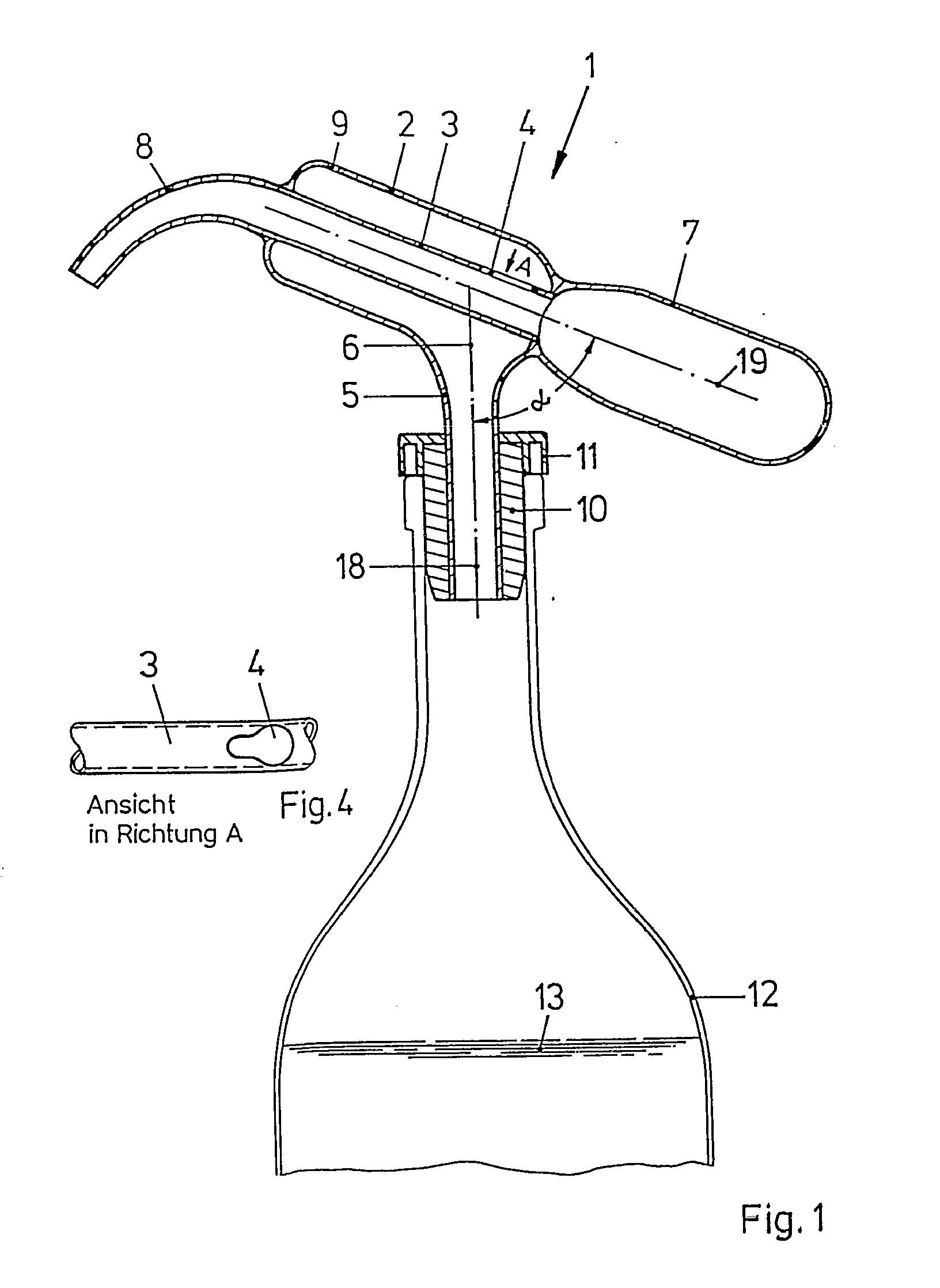

This place covers:

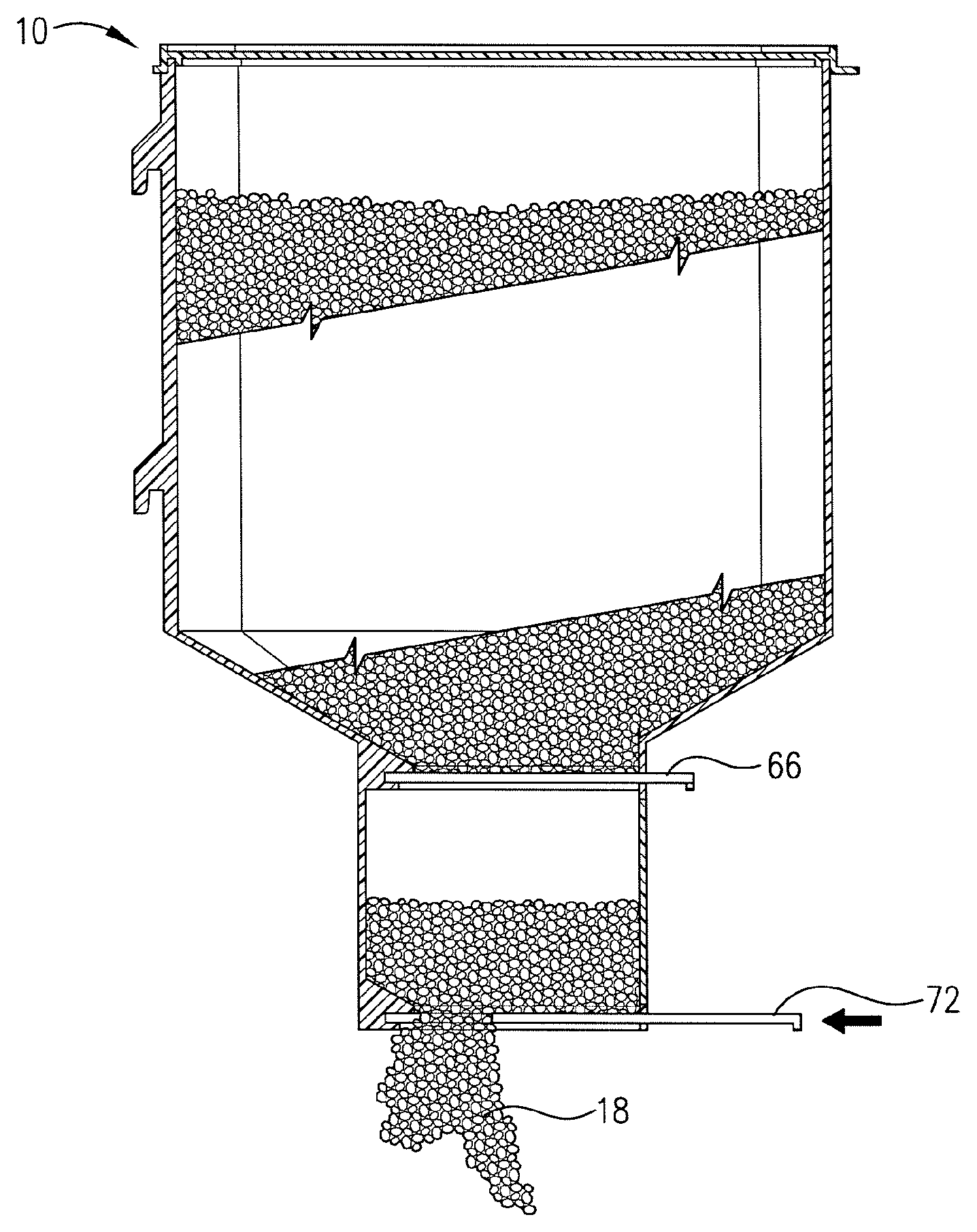

Devices especially adapted for fluent solid material

Details or accessories

Devices operating

- with measuring chambers which expand or contract during measurement

- with measuring chambers moved during operation

- with stationary measuring chambers having constant volume during measurement

This place does not cover:

Forming a predetermined ratio of substances to be mixed by feeding the components in predetermined amounts | |

Single-unit, i.e. unitary hand-held apparatuses with a pump | |

Bottling liquids with provision for metering the liquid to be introduced using dosing chambers | |

Apparatus for dispensing beverages on draught comprising means for automatically controlling the amount to be dispensed based on volumetric dosing | |

Devices for dosing additives in the treatment of water, waste water, or sewage | |

Pumps specially modified to deliver fixed or variable measured quantities |

Attention is drawn to the following places, which may be of interest for search:

Dough-dividing machines with division boxes in a revolving body with radially-working pistons | |

Food containers dispensing a certain quantity of powdered or granulated foodstuffs, e.g. sugar | |

Beverage-making apparatus with dispensing means for adding a measured quantity of ingredients | |

Dispensers for liquid or pasty soap dispensing dosed volume | |

Using squeeze bottles or the like for soap | |

Peristaltic pumps | |

Hand operated grease guns | |

Air operated grease guns |

G01F 11/04 takes precedence over G01F 11/021.

G01F 19/005 takes precedence over G01F 11/025.

G01F 11/34, G01F 11/40 and G01F 11/46 takes precedence over G01F 11/282.

G01F 11/282 and G01F 11/30 - G01F 11/46 take precedence over G01F 11/284.

This place covers:

Illustrative example of subject matter classified in this group

WO2006123228

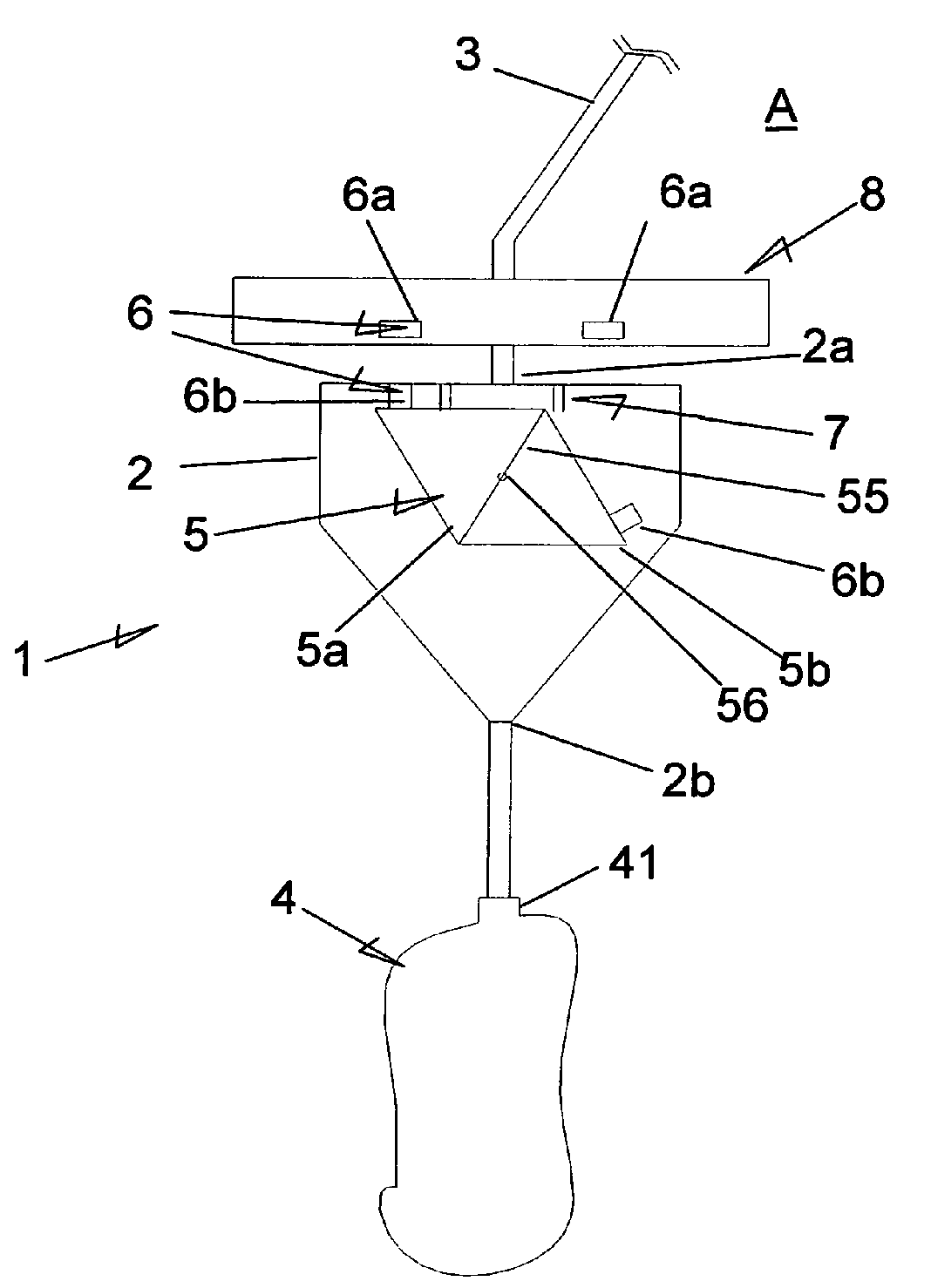

This place covers:

Illustrative example of subject matter classified in this group

US4893732

DE8624916U

FR2590555

This place covers:

Illustrative example of subject matter classified in this group

US4778087

This place covers:

Illustrative example of subject matter classified in this group

US5884816

This place covers:

Illustrative example of subject matter classified in this group

US5127553

This place covers:

Illustrative example of subject matter classified in this group

US5601212

This place covers:

Illustrative example of subject matter classified in this group

US2008099509

This place covers:

Apparatus for measuring by volume and delivering fluids or fluent solid materials, not provided for in the preceding groups

- for fluent solid material

- measuring volume in function of time

Taps comprising counting- and recording means

This place does not cover:

Apparatus for weighing a continuous stream of material | |

Control of flow |

Attention is drawn to the following places, which may be of interest for search:

Counting mechanisms |

This place covers:

Means for regulating or setting the meter for a predetermined quantity

Valves

Devices

- characterised by the use of a particular material, e.g. anti-corrosive material

- comprising means to prevent fraud

- comprising lubricating means

Means for compensating or correcting for variations in pressure, density or temperature

Indicating or recording devices, e.g. for remote indication

Air or gas separators in combination with liquid meters; Liquid separators in combination with gas meters

Means for preventing damage by freezing or excess pressure or insufficient pressure

Cleaning arrangements; Filters

Casings, e.g. of special material

Diaphragms; Bellows; Mountings therefor

Supports or connecting means for meters

Attention is drawn to the following places, which may be of interest for search:

Valves for diaphragm type gas meters | |

Diaphragm type gas meters characterized by constructional features of membranes | |

Details or accessories of dosing devices | |

Valves | |

Cleaning arrangements; Filters | |

Diaphragms; Bellows; Mountings therefor | |

Connecting means e.g. bypass conduits (not electrical connecting means) | |

Filters in general | |

Cleaning in general | |

Valves in general |

This place covers:

Methods or apparatus for determining the capacity of containers or cavities, or the volume of solid bodies, including by measurement of pressure of gas

This place does not cover:

Methods or apparatuses for measuring volume of fluids or fluent solid material, not otherwise provided for, e.g. involving measurement of pressure | |

Measuring linear dimensions to determine volume |

Attention is drawn to the following places, which may be of interest for search:

Detecting, measuring or recording for diagnostic purposes: measuring volume of limbs, e.g. plethysmography | |

Determining well or borehole volumes | |

Sensing or measuring mail pieces |

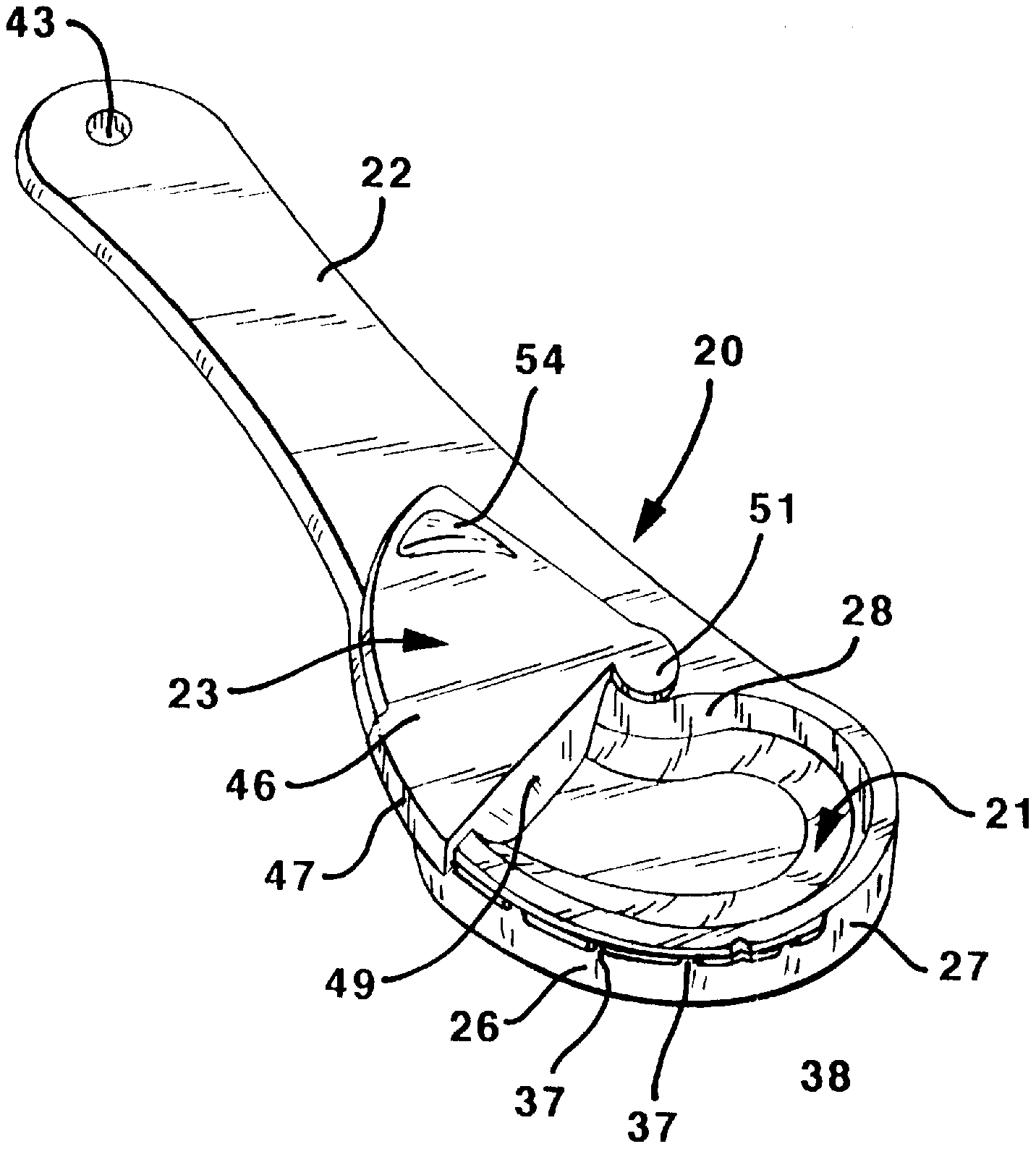

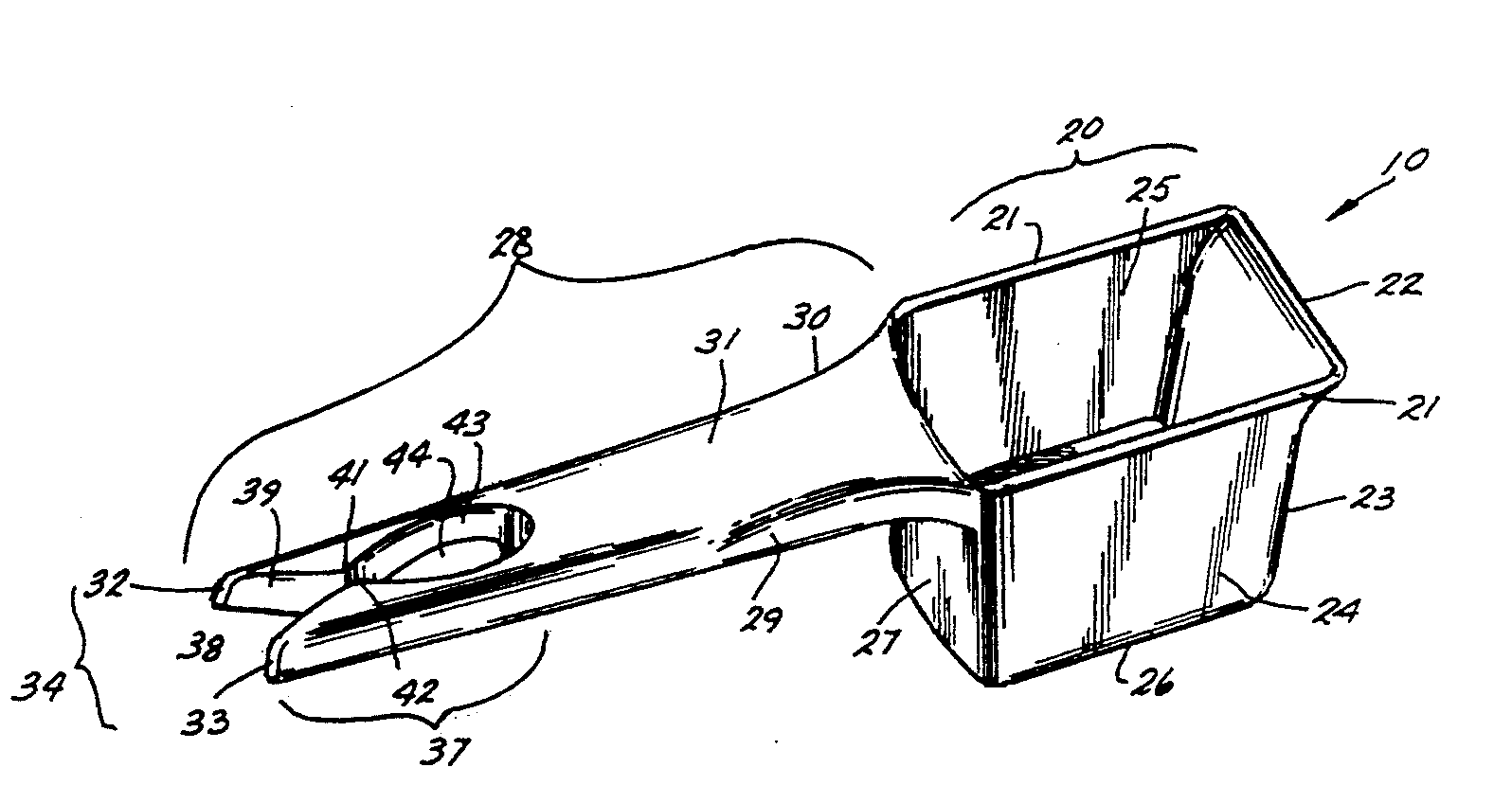

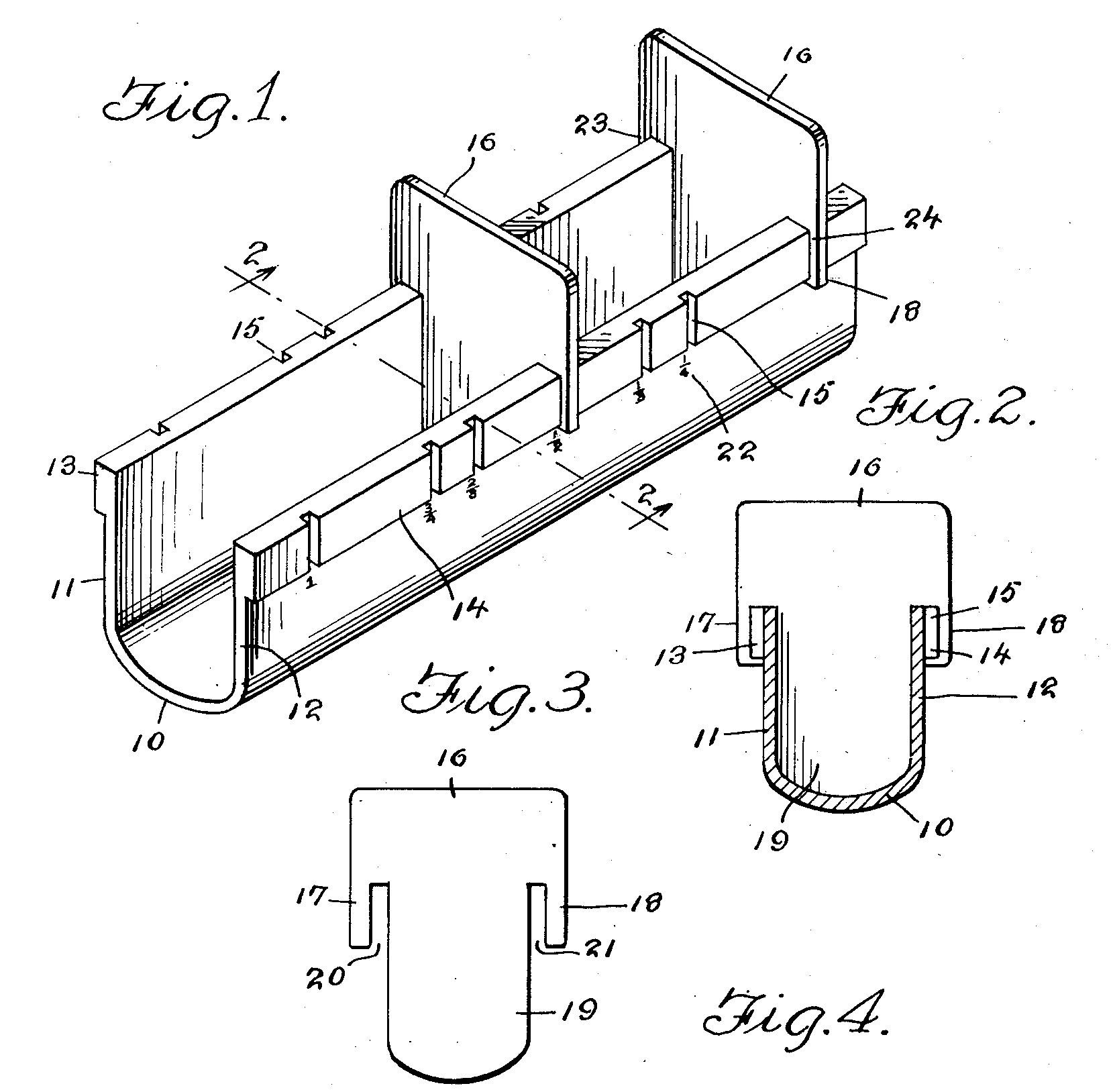

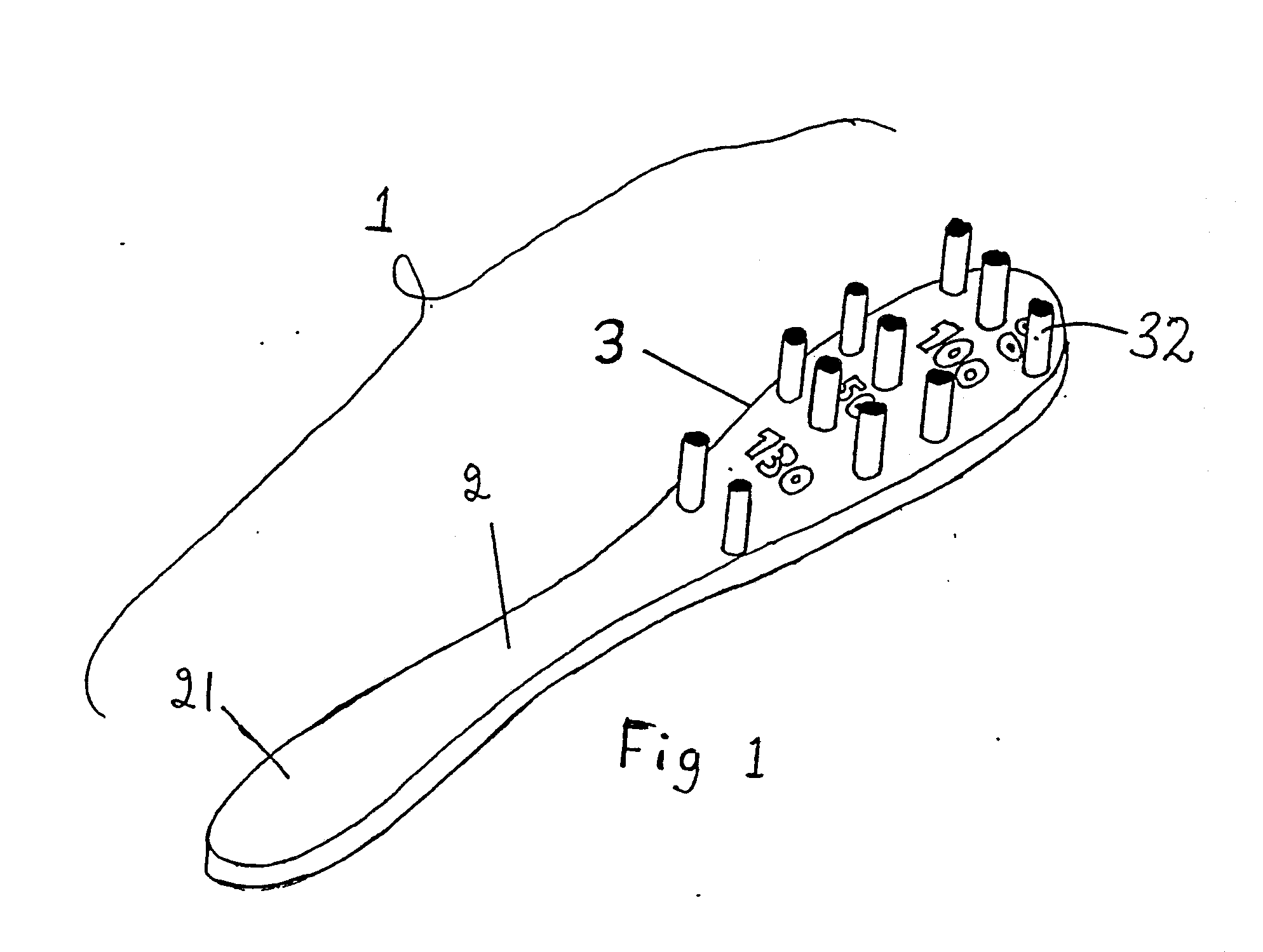

This place covers:

- Measuring spoons or scoops

- Calibrated capacity measures adapted for semi-liquid, e.g. fat or non fluent solid material, e.g. filamentary

Attention is drawn to the following places, which may be of interest for search:

Shop or like accessories: hand implements, e.g. grocers' scoops | |

Drinking vessels or saucers used for table service | |

Cooking spoons | |

Spoons for serving ice-cream | |

Devices for administering medicines orally, e.g. spoons | |

Burettes, weighing bottles | |

Weighing apparatus combined with handles of tools or household implements |

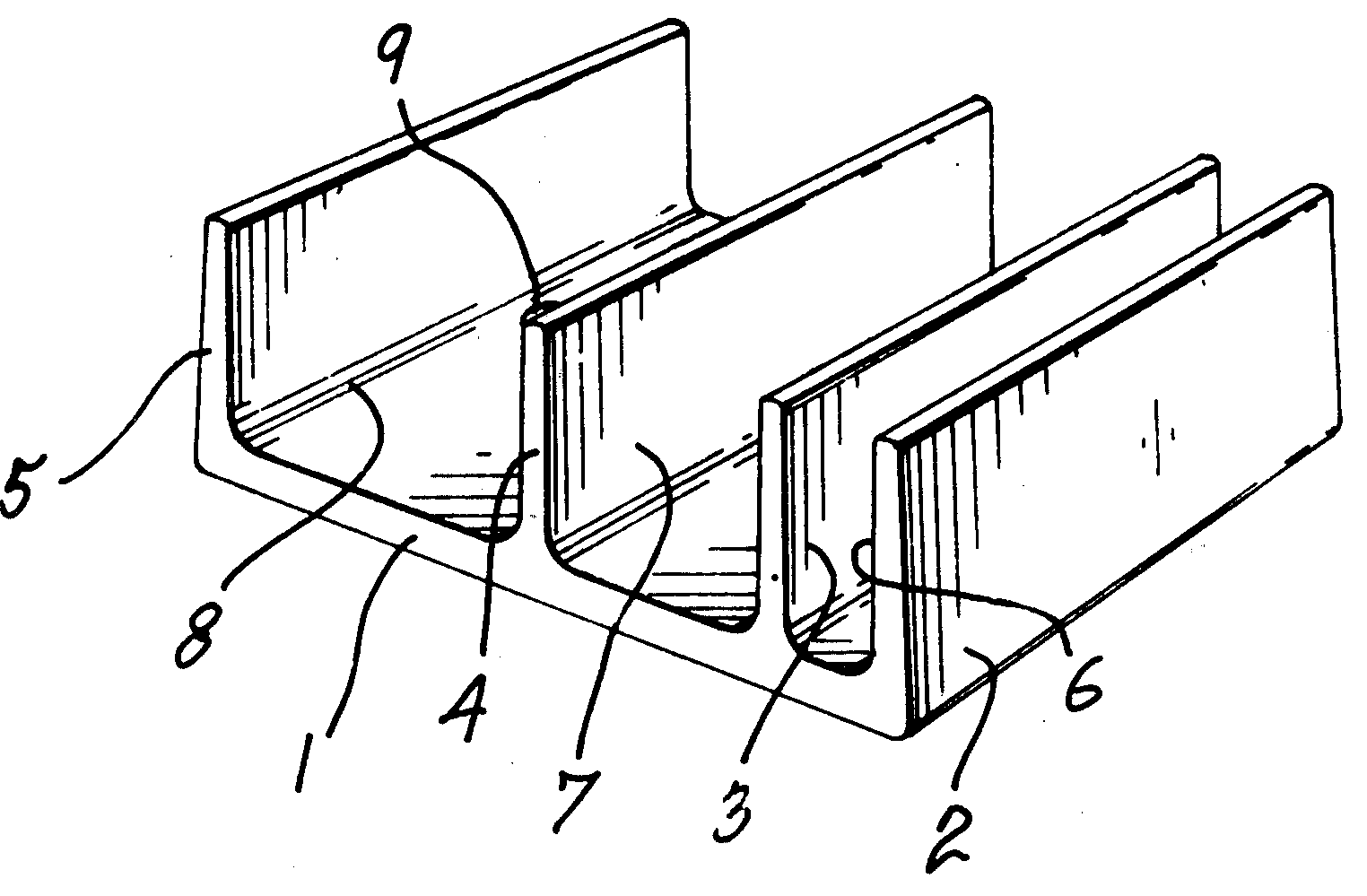

This place covers:

Illustrative example of subject matter classified in this group

US6125699

US5347865

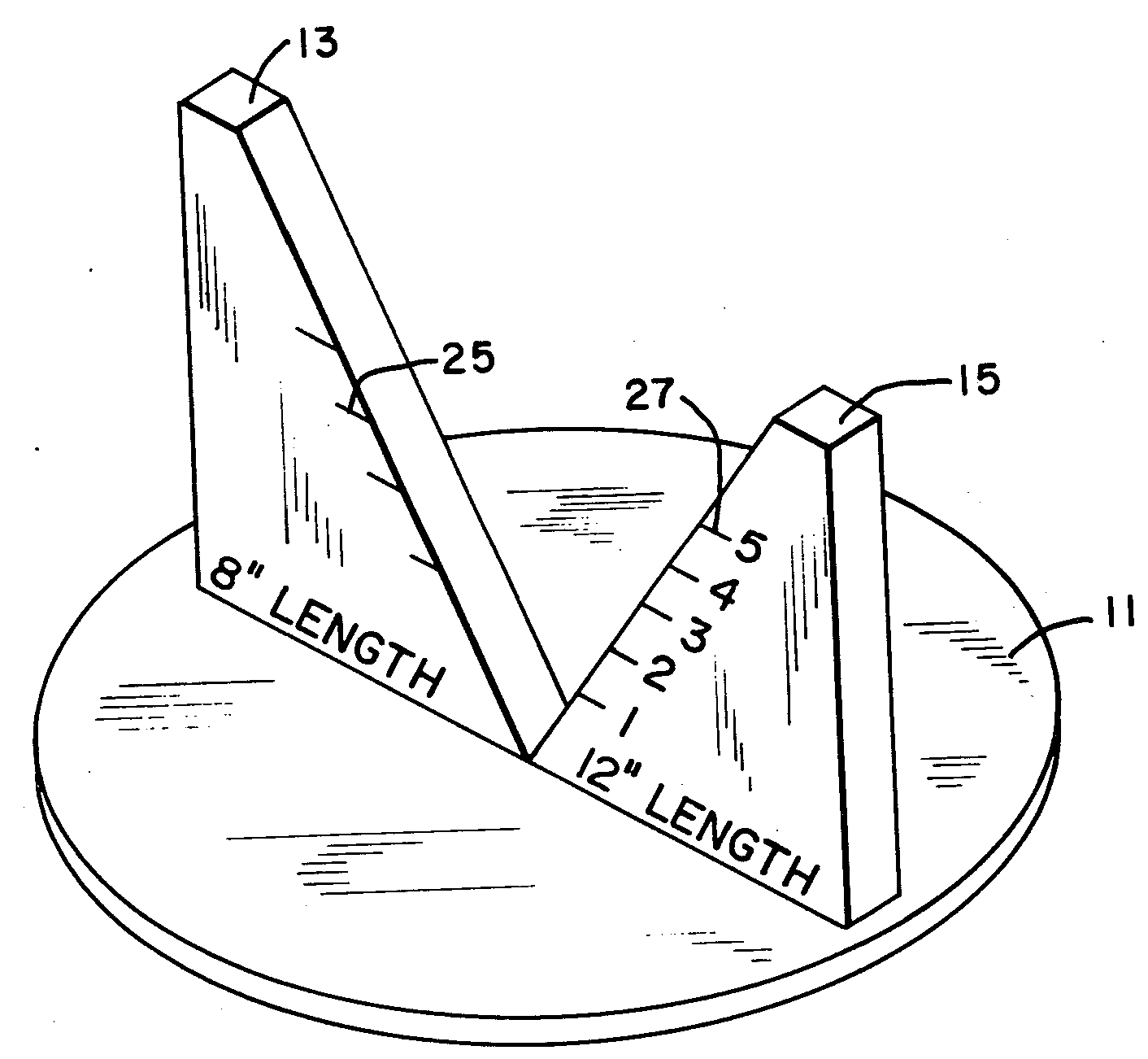

This place covers:

Illustrative example of subject matter classified in this group

US2645127

This place covers:

Illustrative example of subject matter classified in this group

US5255439

US4165565

US4120094

This place covers:

Methods or apparatus for measuring volume of fluids or fluent solid material, not otherwise provided for, e.g. involving measurement of pressure

This place does not cover:

Indicating or measuring liquid level by measurement of pressure of the liquid |

Attention is drawn to the following places, which may be of interest for search:

Methods or apparatus for determining the capacity of containers or cavities, or the volume of solid bodies |

Group G01F 22/02 contains apparatuses and methods whereby in order to determine the volume of fluids or fluid solid material in a container, the pressure of the gas above the fluid in the container is measured in order to determine the volume occupied by the gas and deduct the volume occupied by the fluid from this measurement and the known volume of the container.

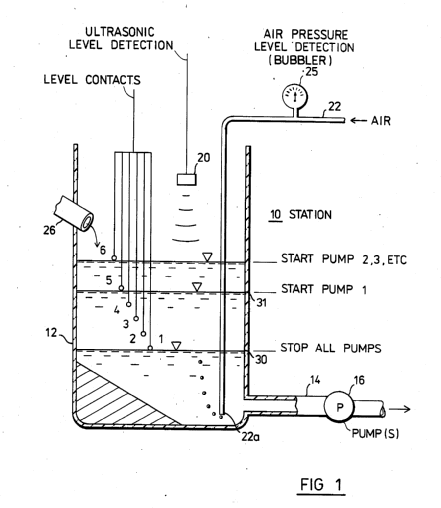

This place covers:

Devices

- for discrete indicating and measuring

- with a probe suspended by a wire or thread

- with a probe suspended by rotatable arms

- using buoyant probes

- with a stationary probe, where a liquid specimen is separated from the mean mass and measured

- with over-flow pipes

- characterised by the level signal processing means

Devices whereby the level is determined

- by gauge glasses or other apparatus involving a window or transparent tube for directly observing the level to be measured or the level of a liquid column in free communication with the main body of the liquid

- by dip members, e.g. dip-sticks

- by measurement of pressure

- by measurement of weight, e.g. to determine the level of stored liquefied gas

- by measurement of physical variables, other than linear dimensions, pressure or weight, dependent on the level to be measured, e.g. by difference of heat transfer of steam or water

- by floats

Level indicators mostly detecting and interface between liquid or fluent solid material and a gas above, but also interfaces between different phases, e.g. immiscible liquids superposed in a container.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Water level measuring or regulating devices in washing machines | |

In wells | |

Adaptation to, or mounting on, steam boilers | |

Accumulators combined with arrangements for measuring electrolyte level |

Attention is drawn to the following places, which may be of interest for search:

Monitoring infusion flow anomalies by detecting the amount of infusate remaining | |

Controlling of liquid level in devices for separation of solid particles from liquid by sedimentation | |

Arrangement of indicating or measuring devices for the level of molten metal | |

In continuous casting of metals, controlling or regulating processes or operations for pouring responsive of molten or slag level | |

In continuous casting of metals, controlling or regulating processes or operations for removing cast stock responsive of molten or slag level | |

Measuring depth of open water, e.g. sea, lake, river, canal | |

Level control | |

Alarm devices | |

Level alarms responsive to moisture | |

Switches operated by float | |

Switches actuated by a float carrying a magnet | |

Support or mounting means for aerials used in level-measurement devices |

In group G01F 23/0038 buoyant probes normally occupy a large height in a container and don't move. The force exerted by the liquid on them is detected to determine the level.

Group G01F 23/303 contains mainly mechanical arrangements around the float to prevent errors due to sloshing. Electronic circuits for compensating for sloshing should be classified in G01F 23/303 only if associated with a measurement using a float and should always be classified in G01F 23/80 or sub groups.

Attention is drawn to the following places, which may be of interest for search:

Measuring pressure in general |

Attention is drawn to the following places, which may be of interest for search:

Weighing in general |

Attention is drawn to the following places, which may be of interest for search:

Measuring inductance or capacitance |

Attention is drawn to the following places, which may be of interest for search:

Systems using reflection of acoustic waves |

Attention is drawn to the following places, which may be of interest for search:

Analysing fluids by measuring attenuation of acoustic waves |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Switches operated by floats |

This place covers:

Electrical circuits for signal processing of general applicability, e.g. filtering or averaging to compensate for sloshing or transmitting the level signals to a remote station.

Electrical circuits for power saving.

Electronic circuits handling signals other than liquid level signals or combining the processing of such signals and liquid level signals, e.g. handling both digital and analog signals to provide a compensated liquid level.

The processing of signals generated by a specific level-measuring technique to compensate for interfering variables is classified in the place covering that level-measuring technique unless the signal processing part dedicated to eliminating the effect of the interfering variables is applicable to other specific level-measuring techniques.

For example, in the measurement of a liquid level using the attenuation of visible light, circuits or signal-processing means to correct for the effect of ambient light should be classified in group G01F 23/292.

Attention is drawn to the following places, which may be of interest for search:

Testing or calibrating apparatus for measuring liquid level |

G01F 23/804 and G01F 23/806 can for example be used for inclination signals in order to compensate the level signal.

This place does not cover:

Adjusting, correcting or compensating means for flowmeters using rotating vanes with tangential admission | |

Adjusting, correcting or compensating means for flowmeters using rotating vanes with axial admission | |

Correcting or compensating means for flowmeters of the pressure or differential pressure type | |

Compensating or correcting for variations in velocity of sound in ultrasonic flowmeters | |

Thermal flowmeters comprising means to store calibration data for flow signal calculation or correction |

Attention is drawn to the following places, which may be of interest for search:

Testing or calibrating of devices for controlling, indicating, metering or registering quantity or price of liquid transferred by devices for transferring liquid from bulk storage containers into vehicles or into portable containers | |

Testing or calibrating devices for speedometers for measuring speed of fluids or speed of bodies relative to fluids |

G01F 25/11 - G01F 25/14 take precedence over G01F 25/15