CPC Definition - Subclass F16P

This place covers:

Safety systems allowing protection of the operator from a machine, a machine tool, a press. Safety systems designed specifically for certain machine/tool/application should be classified in the group related to this specific machine/tool/application if a group related to this safety system exists.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Safety devices in or for harvesters or mowers | |

Protection in threshing machines or balling presses | |

Garments affording protection | |

Headwear affording protection | |

Masks for protection of eyes of workers | |

Safety belts or harnesses in general | |

Safety devices for machines for crushing | |

Safety devices for machines rolling metal | |

Safety devices for machines cutting or perforating of sheet metal | |

Safety guard for turning machines | |

Safety devices for machine tools | |

Protective coverings for machine tools | |

Safety devices for grinding or polishing machines | |

Safety devices for portable percussive tools | |

Safety devices for manipulators | |

Safety devices for cutting machines | |

Safety guards or devices for saws | |

Details of presses | |

Control systems for packing | |

Control during transport of goods (by conveying, loading, storing) | |

Safety devices in spinning or twisting apparatus | |

Safety devices in paper making apparatus |

F16P is only related to general use and general configuration of safety systems. More detailed systems, or specific features of these systems should be classified in the corresponding subclasses. For example a general description of a light grid used to avoid a person to enter a dangerous area has to be classified in F16P, however if the invention is related to a specific feature of the light grid (e.g. detailing the elctronical circuits or the light grid) and not linked directly to the safety, F16P should not be given but rather G01V.

This place covers:

Safety systems which are independent from the machine, and which are meant to protect the operator by creating a physical barrier between the operator and a dangerous area. No interaction exist between the safety system and the machine.

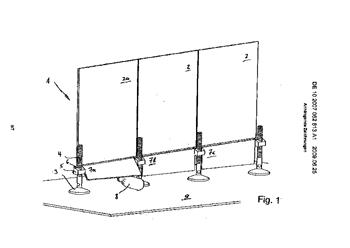

This place covers:

Illustrative example of subject matter classified in this group: The document DE102007062813 discloses a screen (4) which provides a barrier in order to avoid an operator to enter a dangerous area. In use the barrier does not move, except that the panels (2) can be adjusted in height. Once these panels are adjusted, the screen generally does not move with respect to the machine.

Attention is drawn to the following places, which may be of interest for search:

Safety enclosures for children | |

Safety guards for machine tools |

This place covers:

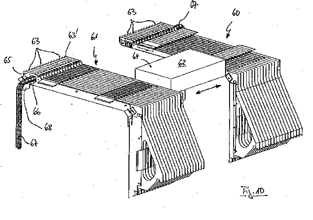

Illustrative example of subject matter classified in this group: EP1908546

Attention is drawn to the following places, which may be of interest for search:

Welding | |

Protective screens for laser working |

This place covers:

Safety systems which depend on the machine by way of any possible interactions and which are meant to protect the operator from being injured by the machine.

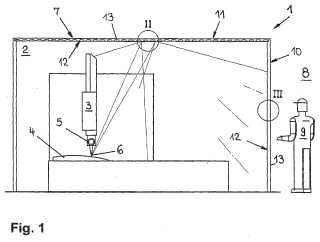

This place covers:

Illustrative example of subject matter classified in this group: The document EP1990130 discloses a screen which depends on the functioning of the machine, in the sense that there is an interaction between the screen and the machine. Here the safety device performs an opening and closing travel in order to restrict access to the machine.

This place covers:

Illustrative example of subject matter classified in this group: EP2039960

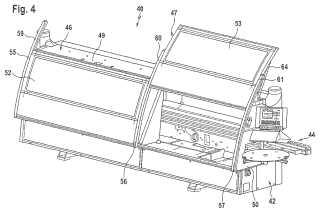

This place covers:

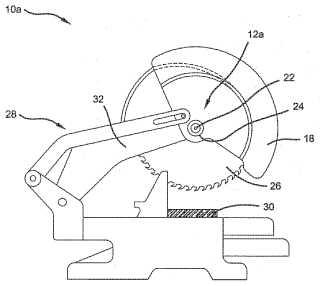

Illustrative example of subject matter classified in this group: US2004226424

This place covers:

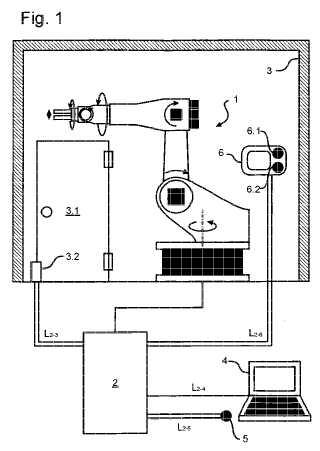

The activation or desactivation of the machine is linked to the state of the lock which is provided on the doors, covers guards or like members which give access to moving machine parts or by extension to the machine in general.

Illustrative example of subject matter classified in this group: EP2289672 if the door 3.1 is closed the machine 1 can be active. If the door 3.1 is opened the machine can not be active.

This place does not cover:

Safety locks for washing machines | |

Locks in general |

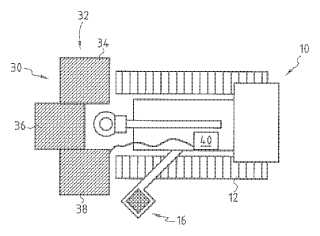

This place covers:

Illustrative example of subject matter classified in this group: FR2885401

(carpet 34, 36, 38 analysing the pressure exerted by an operator)

Attention is drawn to the following places, which may be of interest for search:

Safety devices for manipulators | |

Program controled system monitoring safety |

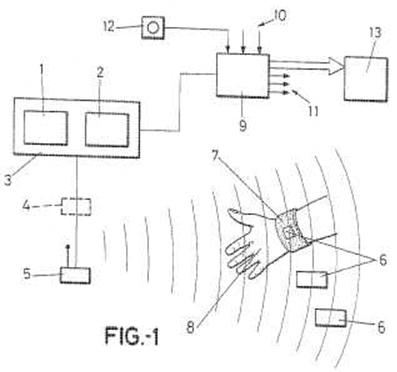

This place covers:

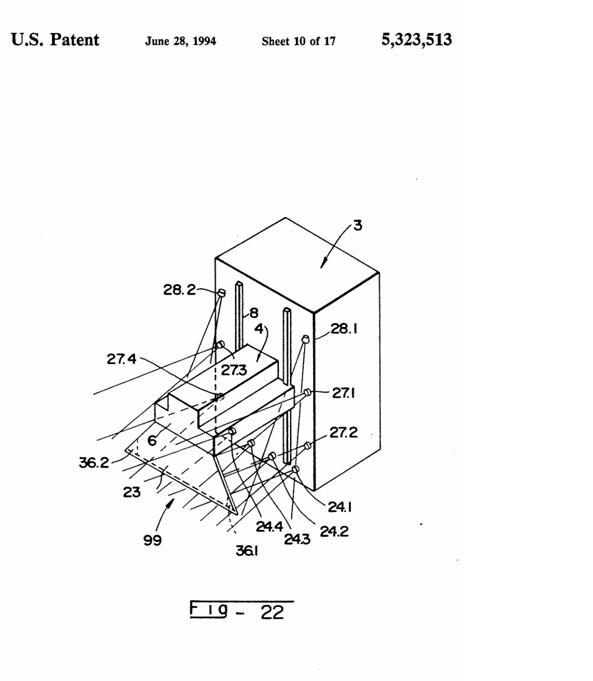

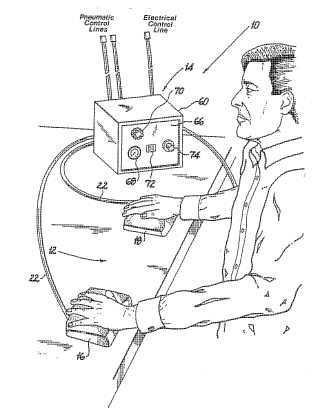

Safety device using e.g. ultrasound. Illustrative example of subject matter classified in this group: US5323513

This place covers:

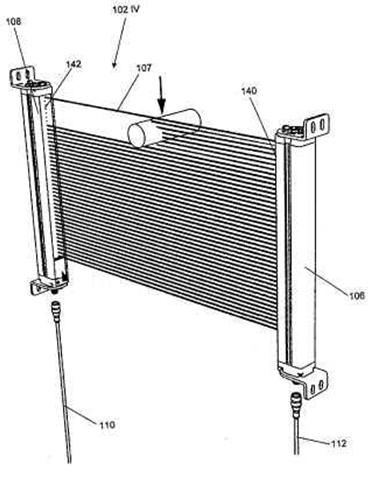

Illustrative example of subject matter classified in this group

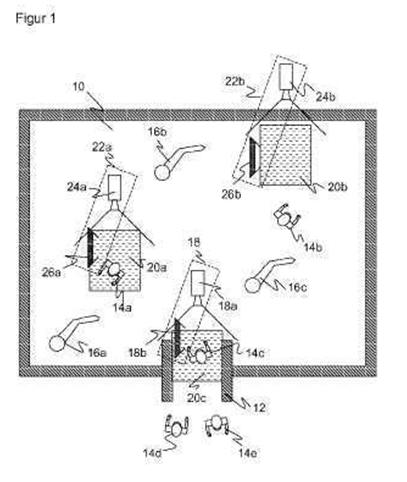

Using a light grid: US2007069114

Attention is drawn to the following places, which may be of interest for search:

Light barriers |

This place covers:

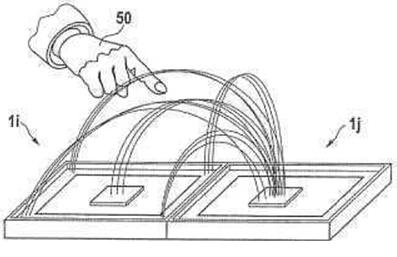

Illustrative example of subject matter classified in this group

e.g. US2011050256

This place covers:

Illustrative example of subject matter classified in this group

e.g. WO2009050316

This place covers:

Illustrative example of subject matter classified in this group

Using magnetic or capacitive sensors: e.g.US2011050256

This place covers:

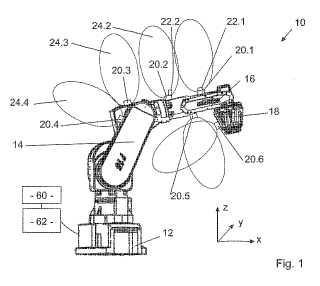

Illustrative example of subject matter classified in this group: WO2010072193, the document shows feelers (20) which are provided on the moving arm parts (14, 16, 18).

This place covers:

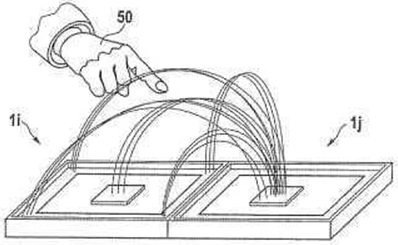

Illustrative example of subject matter classified in this group: US5396222

This place covers:

Safety systems which render ineffective a coupling conveying reciprocating movement if the motion of the driven part is prematurely resisted. The safety system is preventing the machine from being damaged.

This place does not cover:

Safety means disconnecting couplings |