CPC Definition - Subclass F16B

This place covers:

Fastening elements for constructional parts per se, such as: clamps, clips, dowels, nails, staples, bolts without screw thread, pins, rivets, circlips, self-cutting screws, screws and bolts with thread, nuts, lock-nuts, threaded inserts, washers, hooks, suction cups

The connection of constructional elements such as key-type connections, shrinkage connections, joining of sheets and plates, connections of rods or tubes mutually or to flat surfaces at an angle, connections of constructional elements by sticking or pressing them together, joining of furniture, connections of constructional elements by a part of one element entering a hole in the other

The fastening elements or connection of elements in this group can be employed in multiple technical application fields. However, the focus is on the fastening element or the connection of elements itself.

Fastening elements in this subclass are caracterised by their constructional or functional aspects. Fastening elements which are specially adapted or designed for a specific technical application are generally rather classified in the specific technical application field.

This place does not cover:

Couplings transmitting rotation |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Horsehoe nails | |

Nails for footwear | |

Buckles, slide fasteners | |

Ornamental heads for nails, screws, or the like | |

Means, not using staples for attaching sheets temporalily together | |

Thumb-tacks | |

Fastening devices, e.g. clips for leather-stretching used in apparatus or machines for manufacturing or treating skins, hides, leathers or furs | |

Screws or bolts for railway sleepers | |

Rail joints | |

Connections for buildings | |

For building constructions | |

Clamping means for down pipes for roof drainage | |

For hand railings | |

Fastening scaffolds against buildings | |

Scaffold couplings | |

For fencing | |

Bolts or fasteners for wings, specially for doors or windows | |

Locking bearings for parts moving only linearly | |

Hooks as integral parts of chains | |

Pipe joints | |

Supports for pipes, cables or protective tubing, e.g. hangers, holders, clamps, cleats, clips, brackets | |

Clips for connecting hoses to rigid members | |

Magnetic holding devices | |

Electrostatic holding devices |

Attention is drawn to the following places, which may be of interest for search:

As a general rule, multiple classifications can be attributed to one document. Symbols for inventive information and additional information are attributed to the corresponding fields.

If there are interesting functional features of an invention specially adapted for an application, at least a symbol for additional information in F16B should be given to this document.

Many documents describe a fastening element itself and a connection comprising the fastening element. If the focus of such a document lies e.g. on the fastening element itself, a symbol for invention information should be given for the fastening element and a further symbol for additional information should be given for the connection and vice versa according the focus.

In this main group, it is desirable to add the indexing codes of F16B 2200/00.

In this place, the following terms or expressions are used with the meaning indicated:

Connections using screw-thread elements | the connection is established by the screw-thread element |

A screw acts on another element in order to establish a clamped connection | a connection using clamps |

This place covers:

Securing devices making use of shape memory alloys, hydraulic or pneumatic action or securing devices with marking colours or the like.

Groups F16B 2/00 - F16B 47/00 take precedence over group F16B 1/00.

Group F16B 1/00 is residual.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Group F16B 1/02 is residual. Groups F16B 2/00 - F16B 47/00 take precedence.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Locking of actuators |

Group F16B 1/04 is residual. Groups F16B 2/00 - F16B 47/00 take precedence.

This place covers:

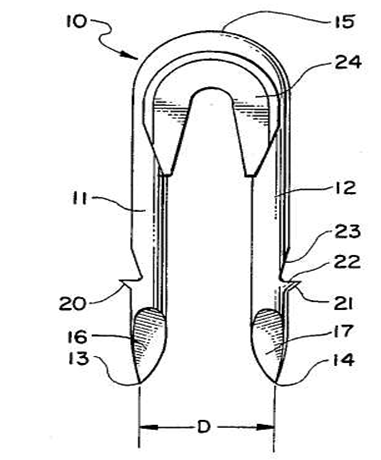

Clamps, i.e. gripping elements where the gripping action is effected by positive means other than the inheretent resistance to deformation of the material of the clamp

Clips, i.e. gripping elements where the gripping action is effected solely by inherent resistance to deformation of the material of the clip

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Friction-grip releasable connections of rods or tubes | |

Friction-grip releasable fastenings for cables or ropes |

Attention is drawn to the following places, which may be of interest for search:

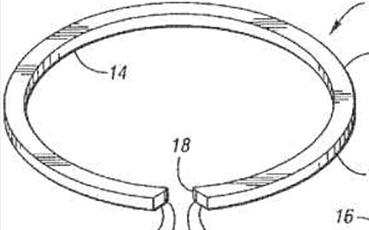

Means for preventing relative axial movement of a pin, spigot or the like, e.g. by snap in or locking by rotation features |

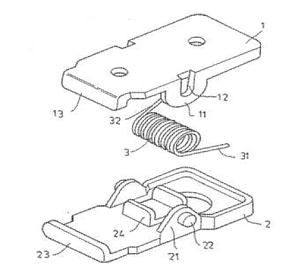

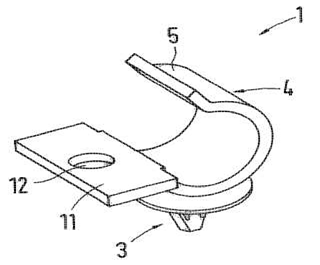

This place covers:

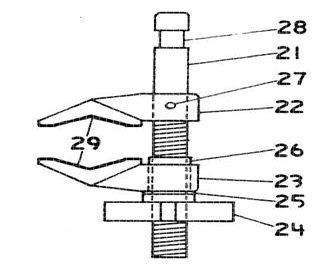

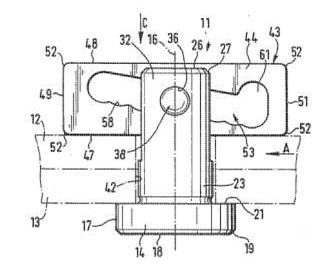

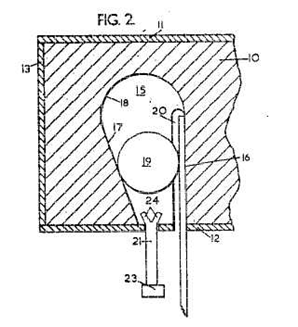

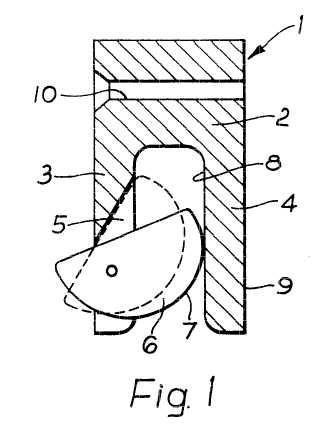

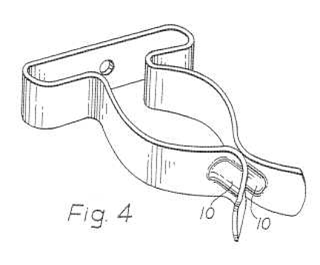

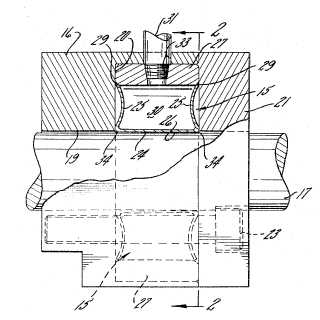

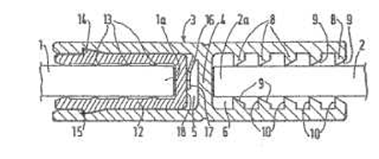

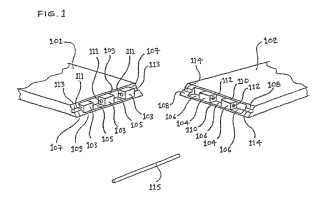

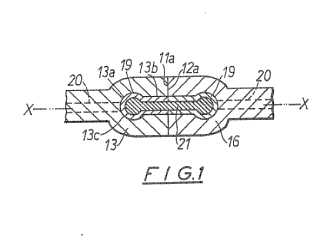

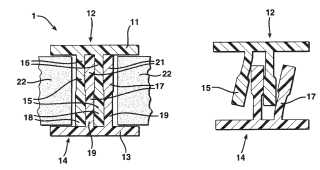

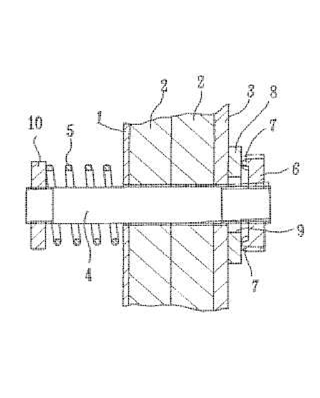

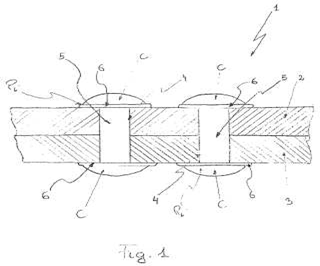

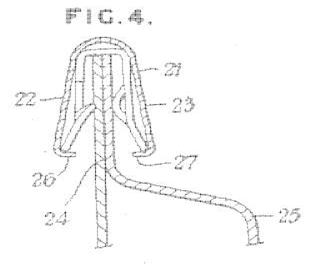

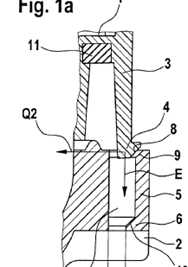

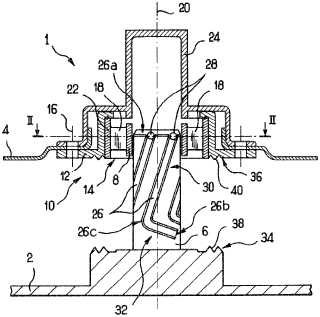

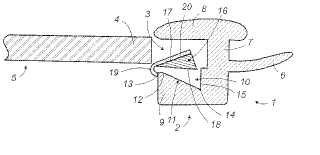

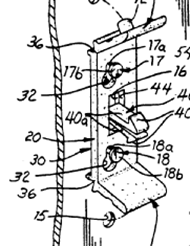

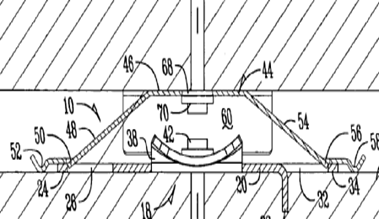

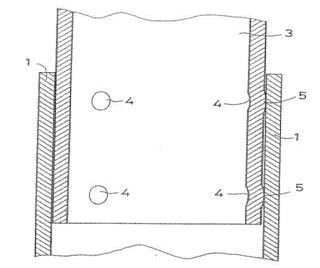

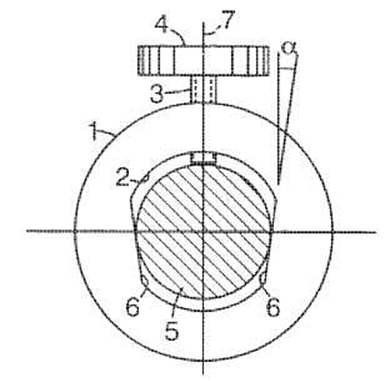

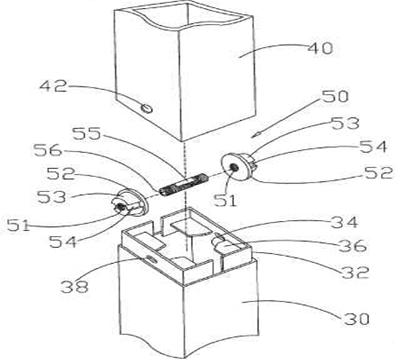

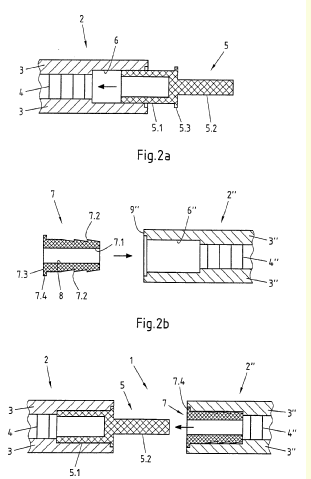

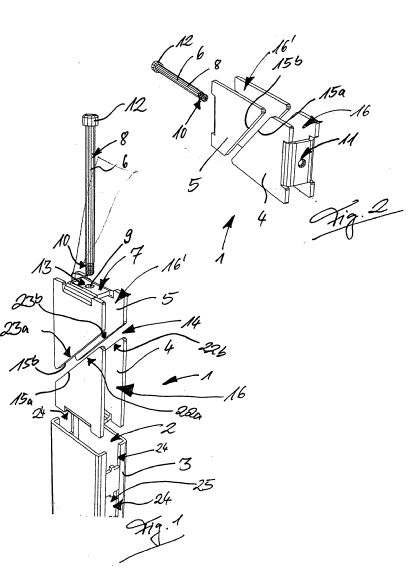

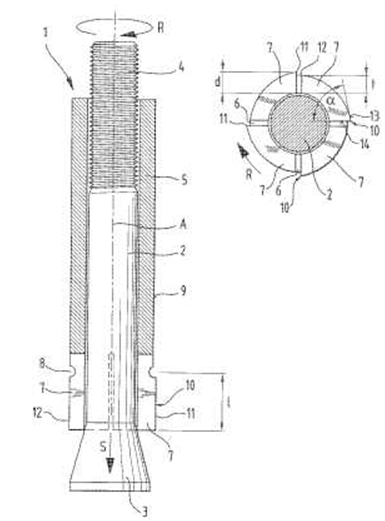

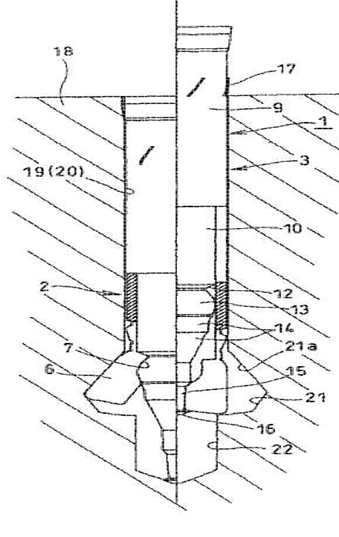

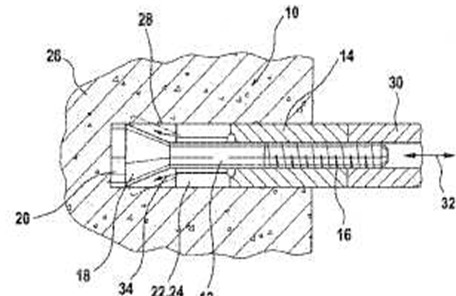

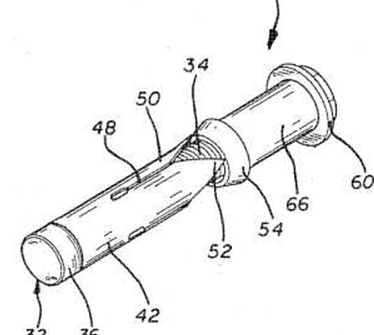

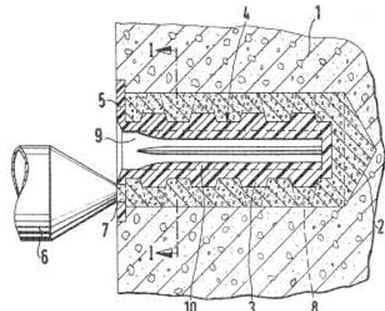

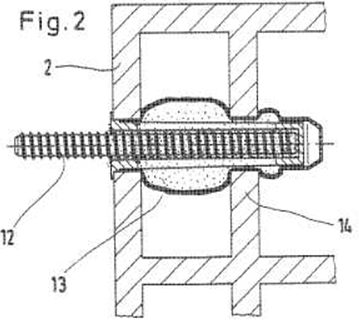

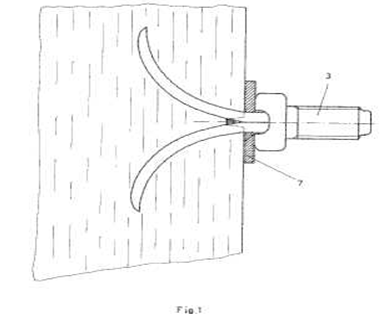

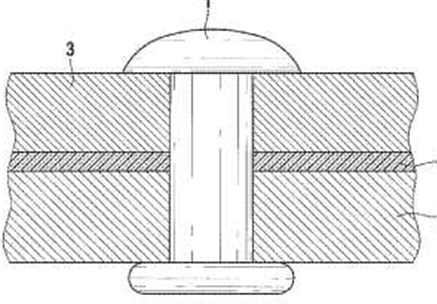

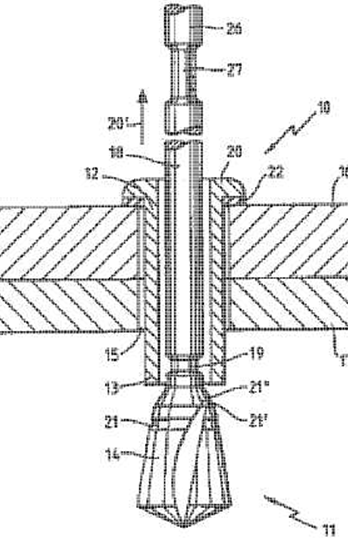

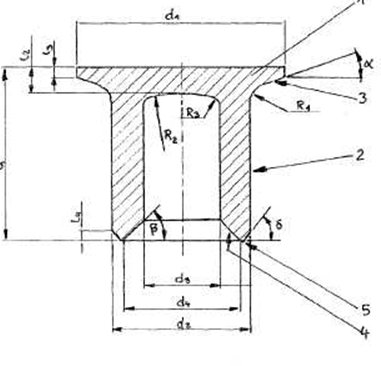

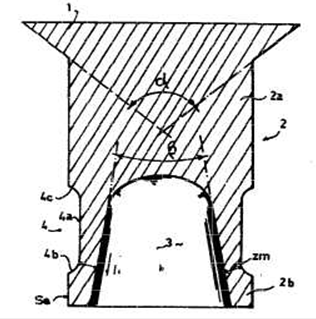

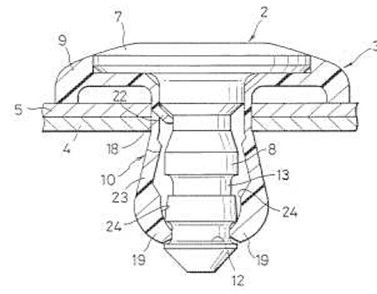

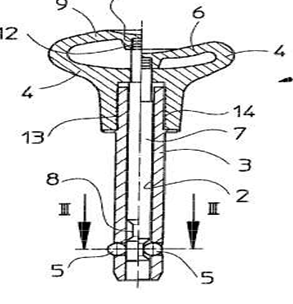

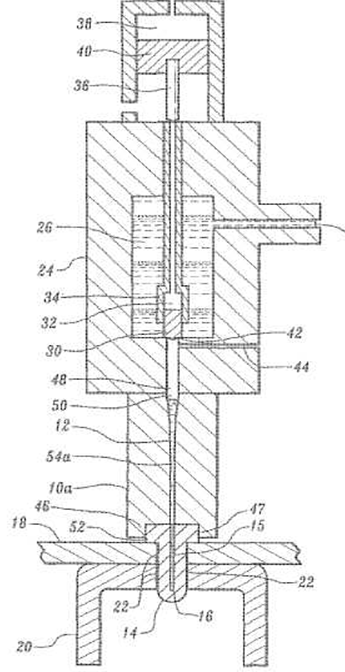

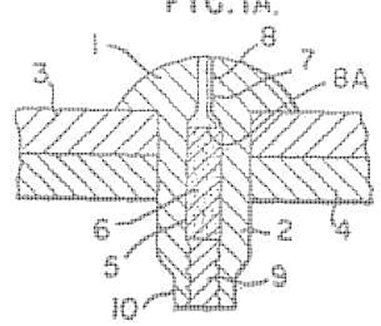

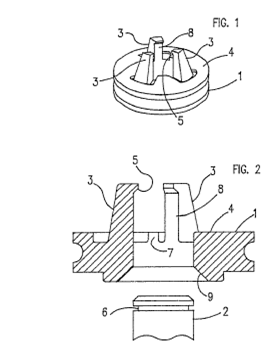

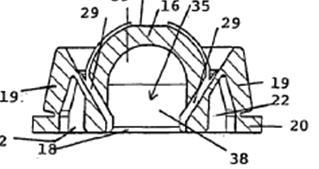

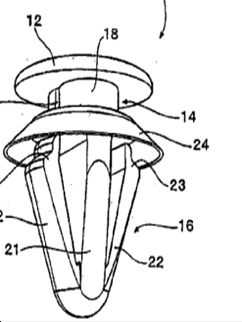

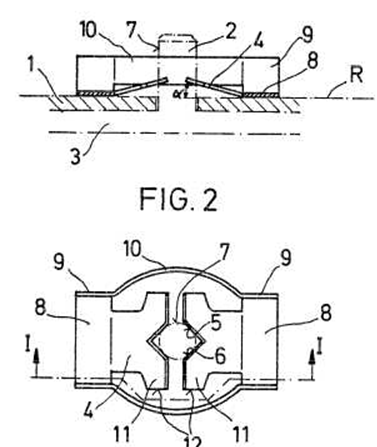

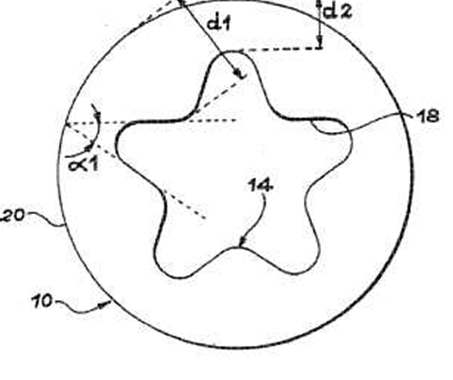

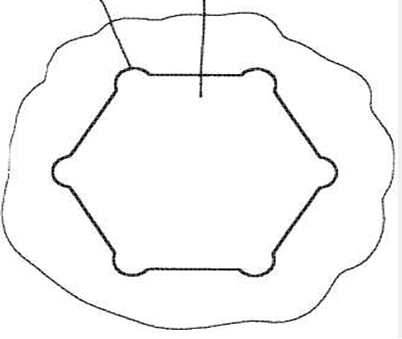

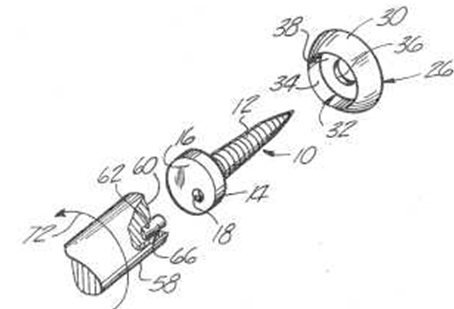

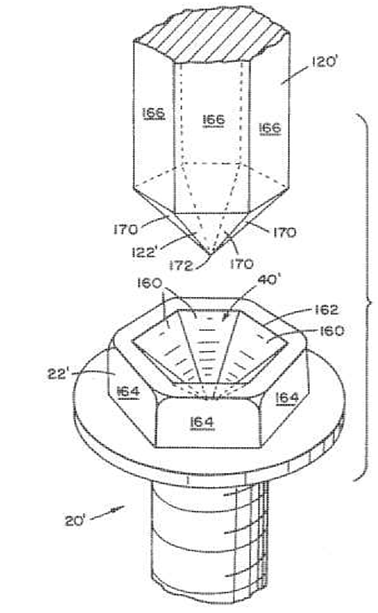

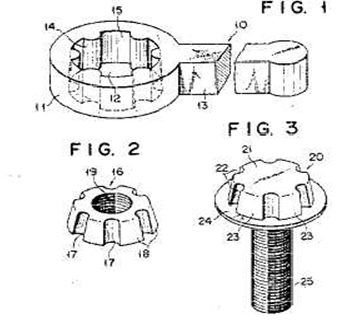

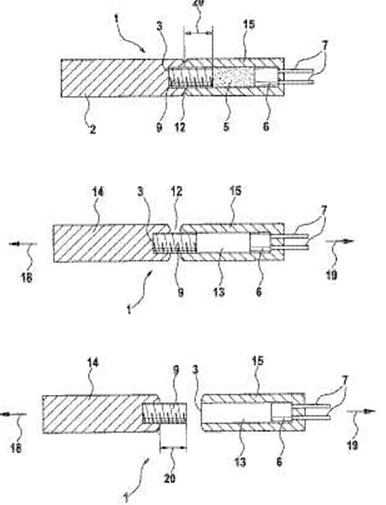

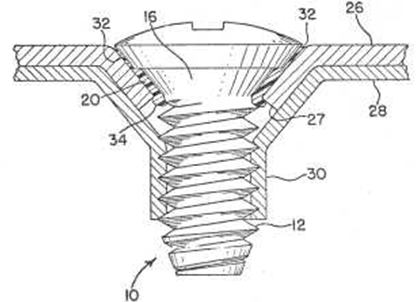

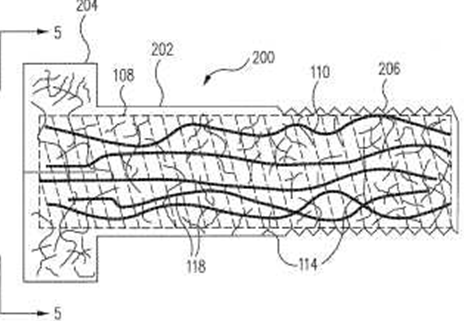

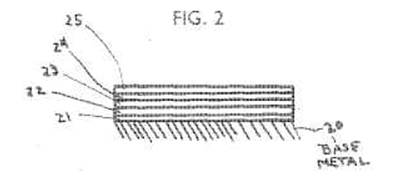

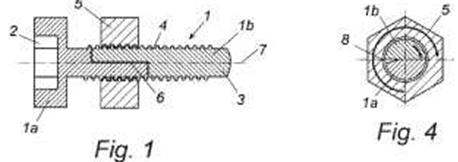

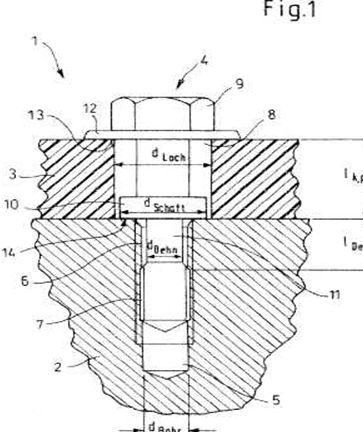

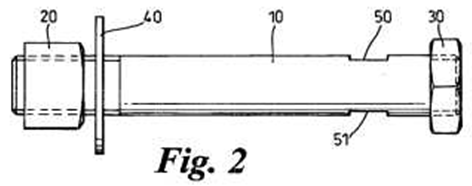

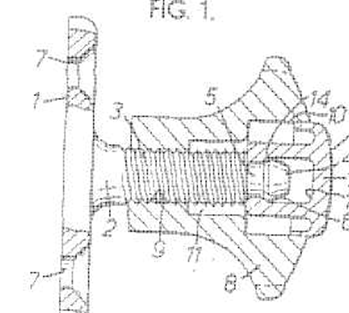

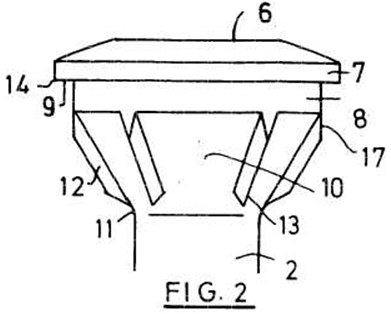

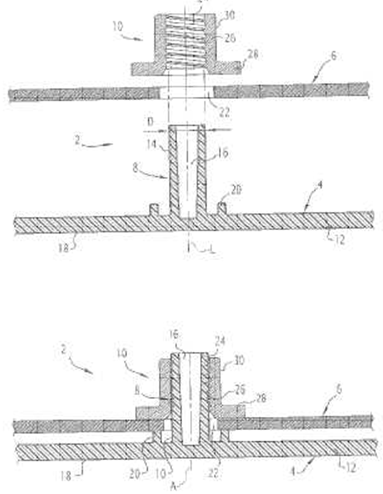

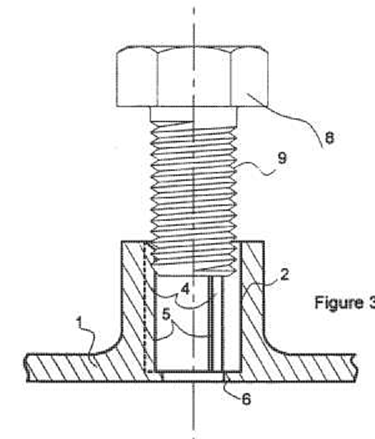

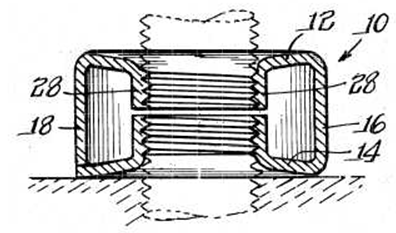

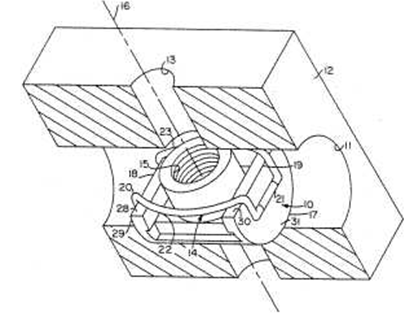

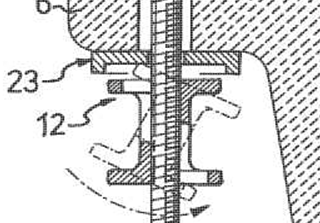

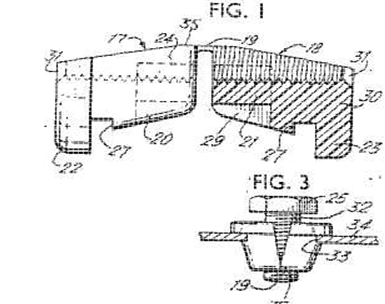

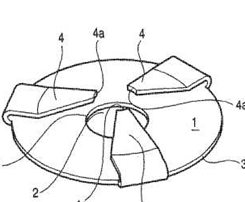

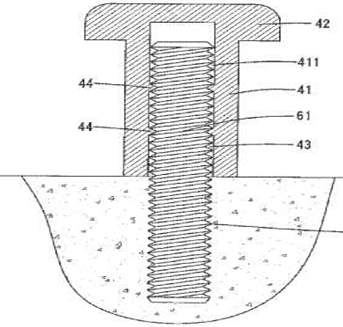

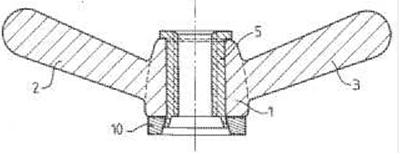

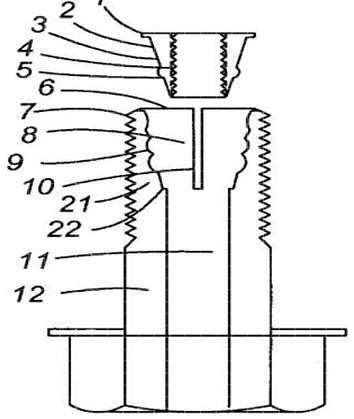

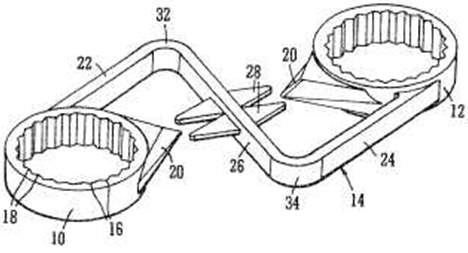

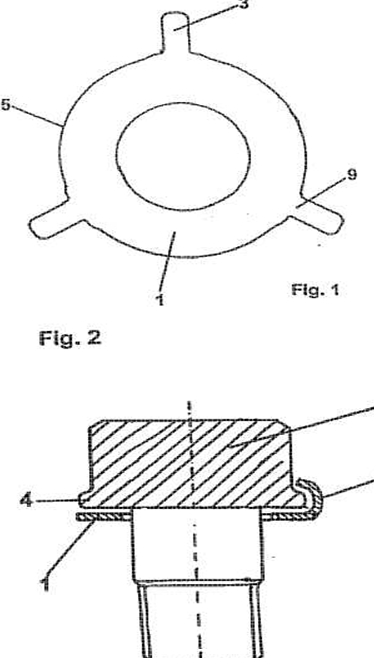

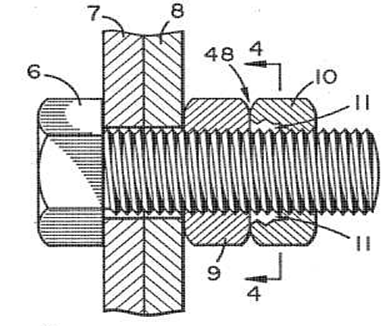

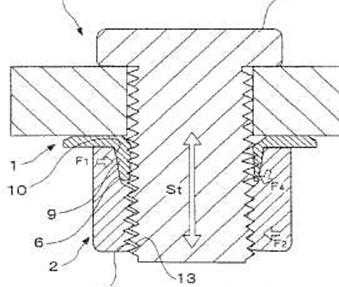

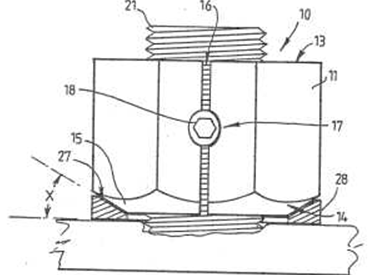

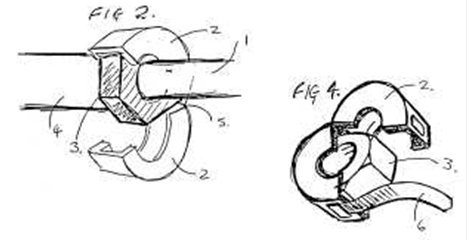

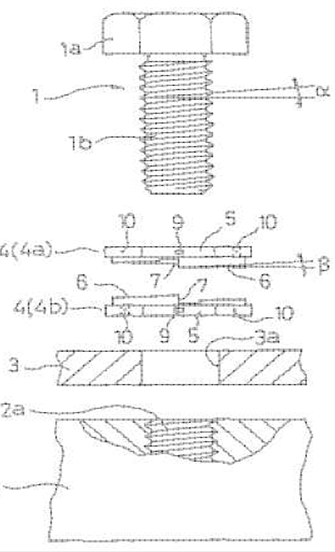

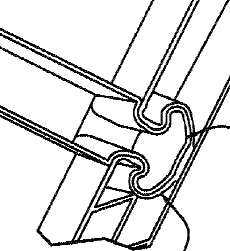

Illustrative example of subject matter classified in this group.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Paper clips |

Attention is drawn to the following places, which may be of interest for search:

Joining of furniture using clamps | |

Tools in form of clamps |

This place covers:

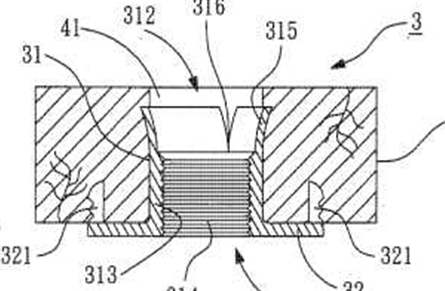

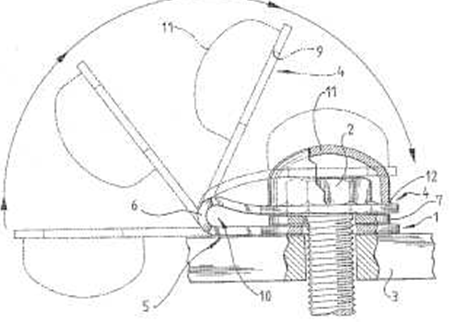

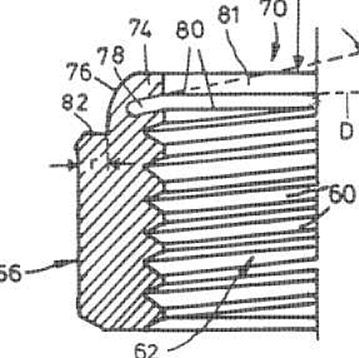

Illustrative example of subject matter classified in this group.

This place covers:

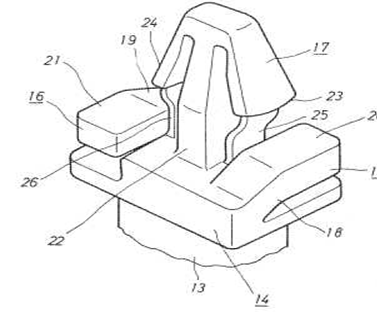

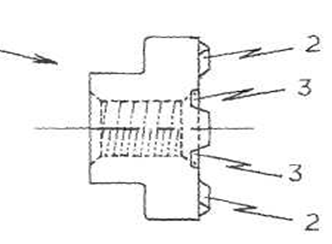

Illustrative example of subject matter classified in this group.

This place covers:

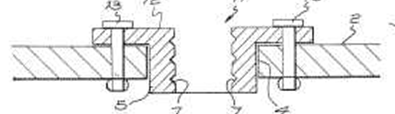

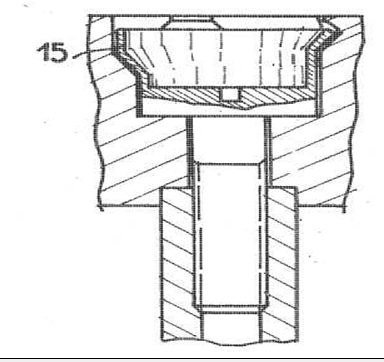

Illustrative example of subject matter classified in this group.

This place covers:

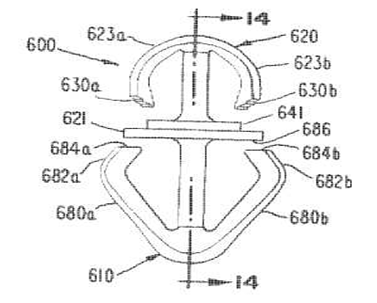

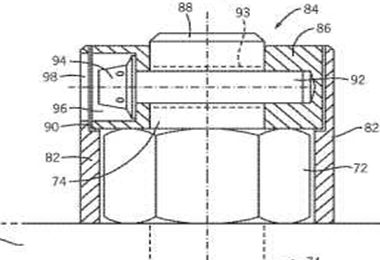

Illustrative example of subject matter classified in this group.

This place covers:

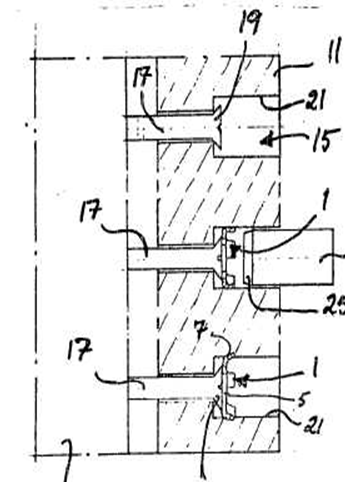

Illustrative example of subject matter classified in this group.

This place covers:

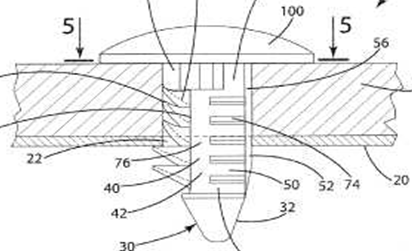

Illustrative example of subject matter classified in this group.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Clamps for rods or tubes telescopically engaged | |

Clamps used in anti-theft monitors |

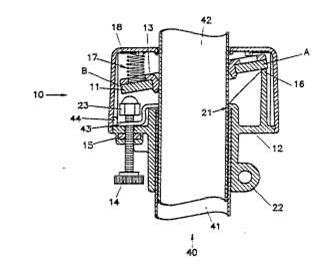

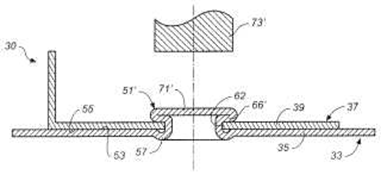

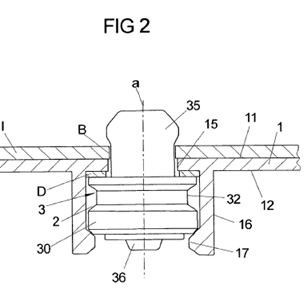

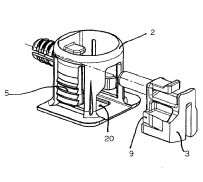

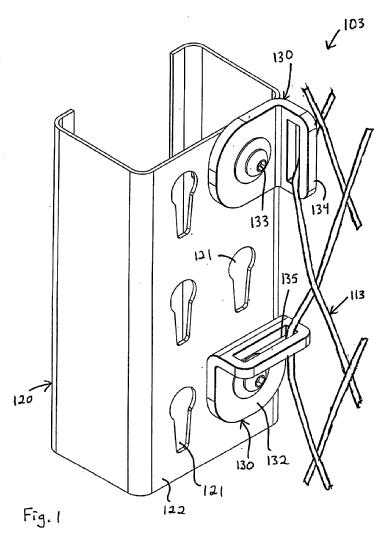

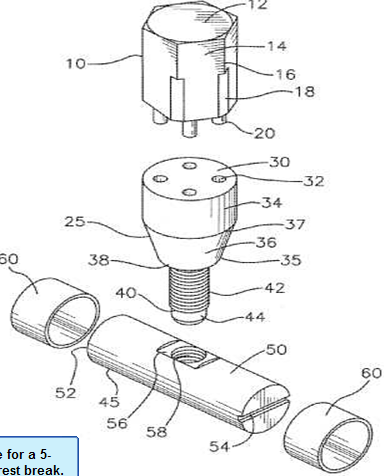

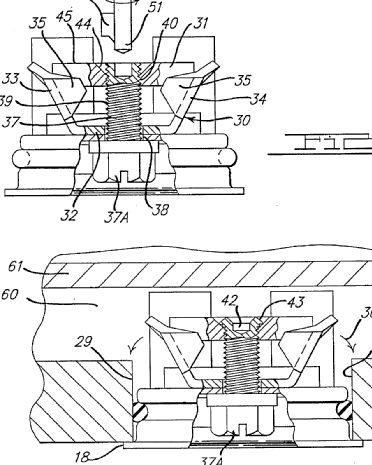

This place covers:

Illustrative example of subject matter classified in this group.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Clamps for connections of rods or tubes engaged telescopically |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

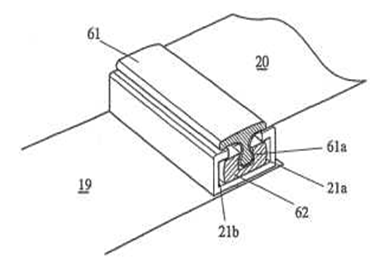

Attention is drawn to the following places, which may be of interest for search:

Clips for electric cable |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

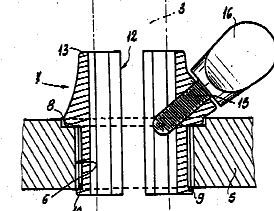

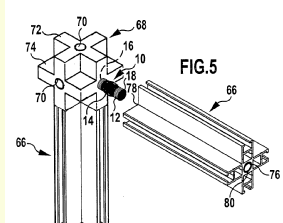

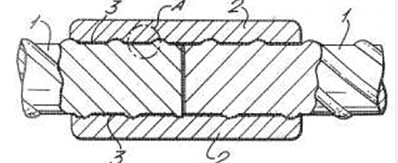

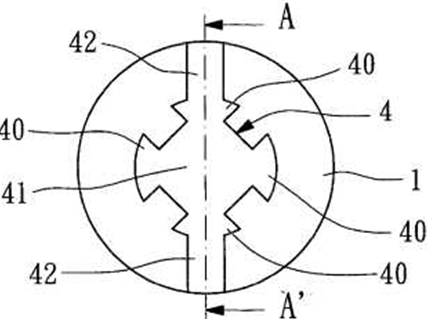

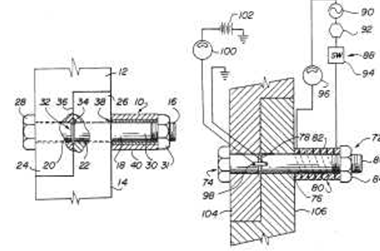

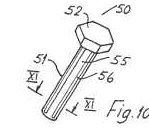

Connections by keys type elements. The key having a geometric shape that engaged to corresponding geometric shapes in the elements to be connected.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Couplings of a member on a shaft by a longitudinal key |

Attention is drawn to the following places, which may be of interest for search:

Key-type connections for rods or tubes mutually | |

Releasable fastening devices locking by rotation |

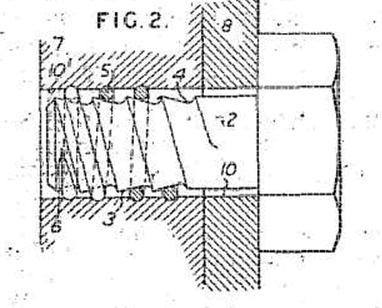

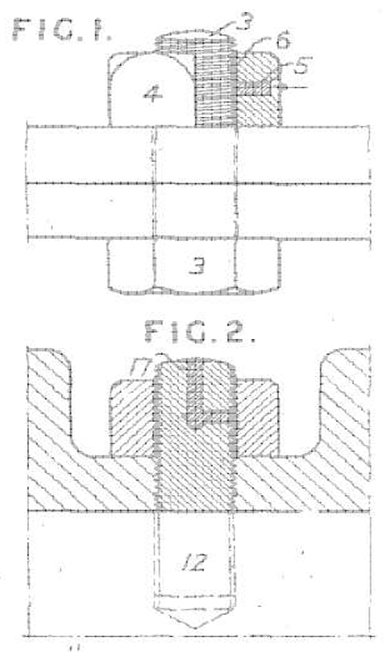

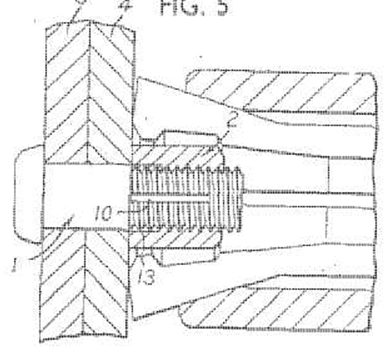

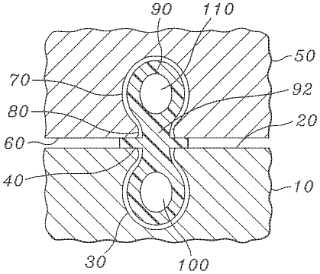

This place covers:

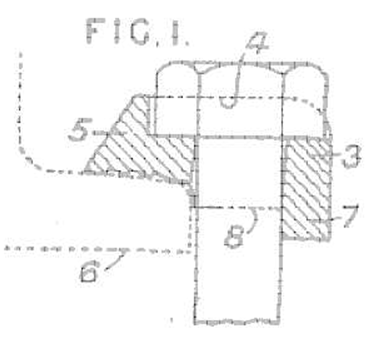

Illustrative example of subject matter classified in this group.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Non-disconnectible pipe joints obtained using a hardenable filler |

Attention is drawn to the following places, which may be of interest for search:

Joining of preformed parst by applying molten plastics |

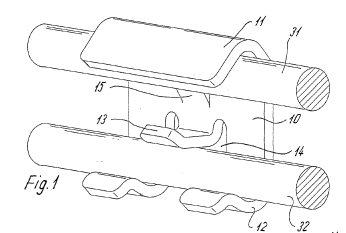

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Tapered sleeves in couplings (with transmission of torque) |

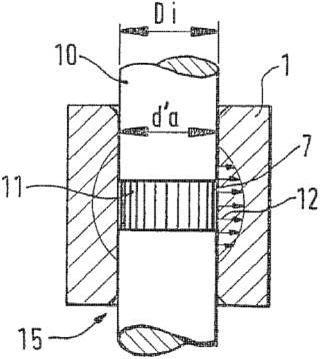

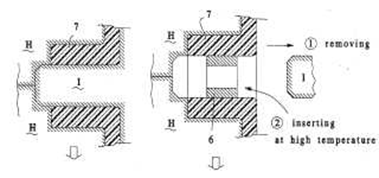

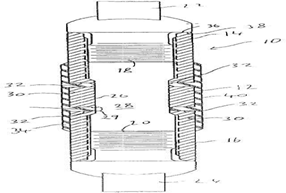

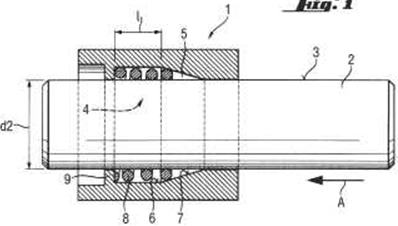

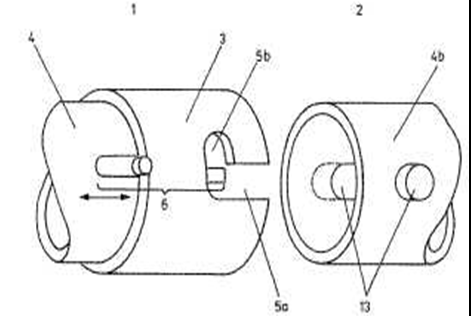

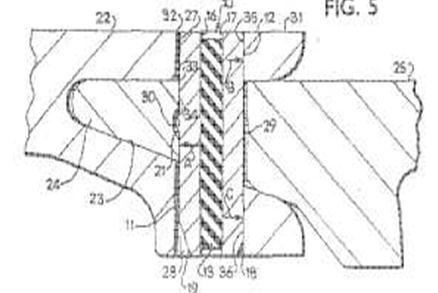

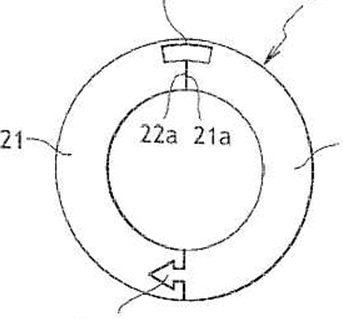

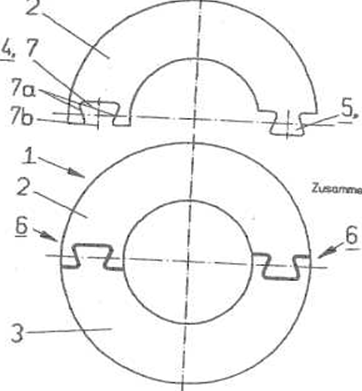

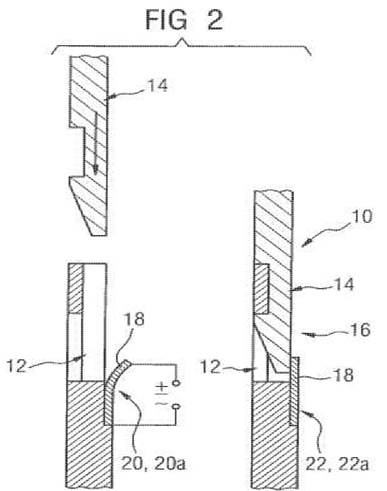

This place covers:

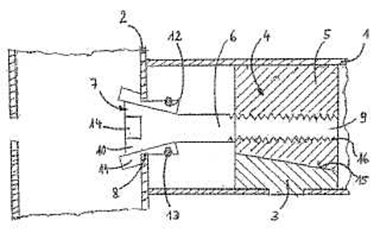

Shrinkage connections and force fits, i.e. a fastening between two parts which is achieved by friction after the parts are pushed together rather than by any other means of fastening.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Shrinkage connections using members with a shape memory material | |

Connections of a hub on a shaft by the elasticity of the hub |

Attention is drawn to the following places, which may be of interest for search:

Shrinkage connections of metal parts or objects (process) |

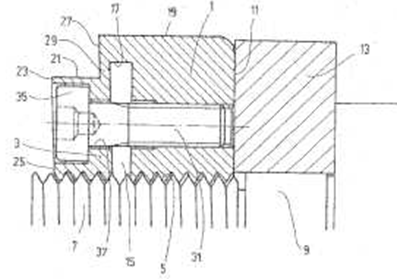

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Couplings for attaching a member on a shaft with a clamping hub with radial clamping due to deformation of a resilient body or a body of fluid |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

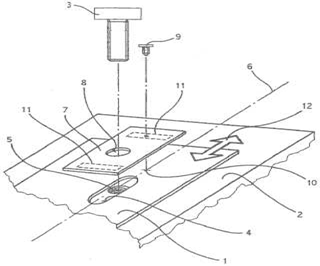

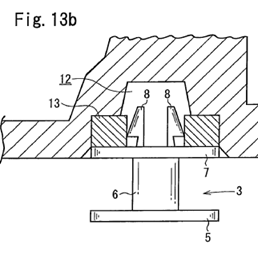

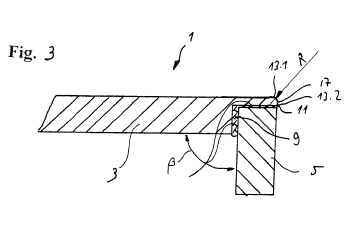

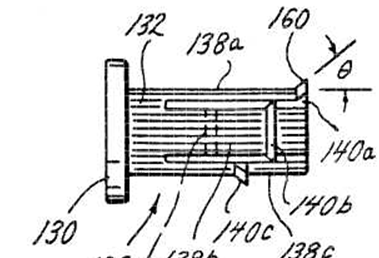

This place covers:

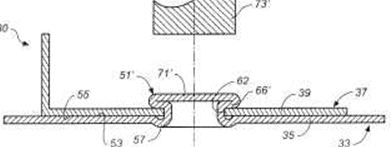

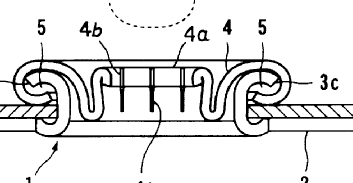

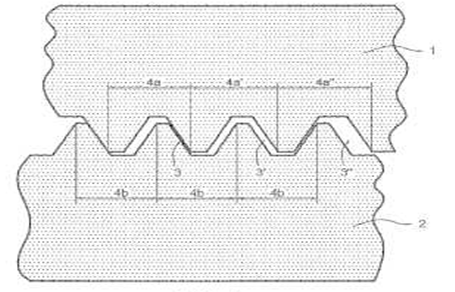

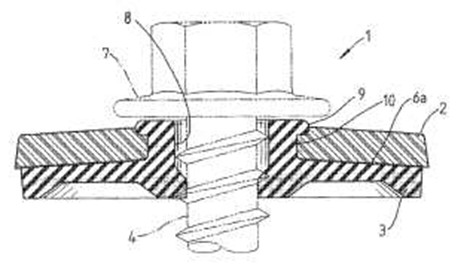

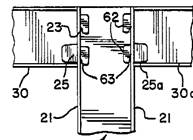

Joining of sheets and plates to one another or to strips and bars.

The focus lies on how the sheets or plates are connected and not on the fastening element itself.

This place does not cover:

Joining sheets by sticking together | |

Pin and hole connections involving plastic deformation |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Covering of walls | |

Covering of floors | |

Joining fastening signes, panels or boards to a supporting structure |

Attention is drawn to the following places, which may be of interest for search:

Joining sheets by dowel connections | |

Joining sheets by pins, including deformable elements | |

Metall working | |

Turning, boring | |

Joining of plastic sheets | |

Joining of automotive trim parts |

The groups

Fastening of honeycomb panels F16B 5/01,

Fastening of abutting sheets or plates F16B 5/0004

take precedence over the remaining subgroups in F16B 5/00

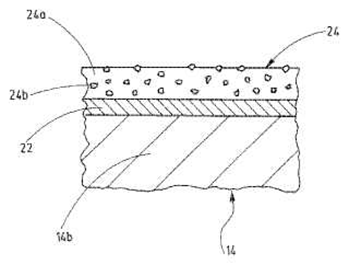

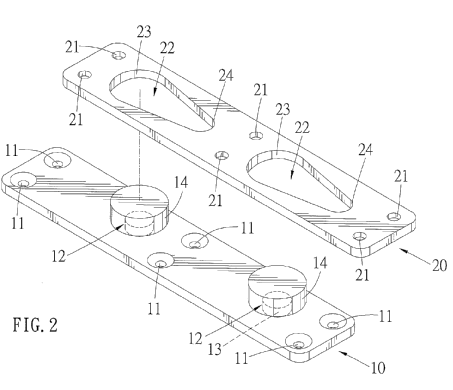

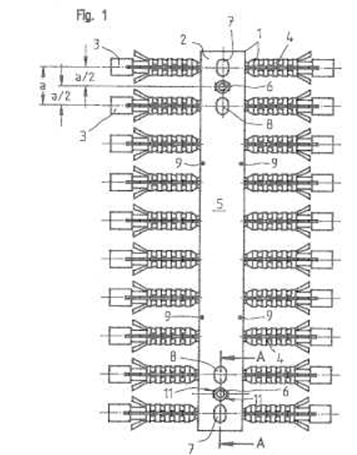

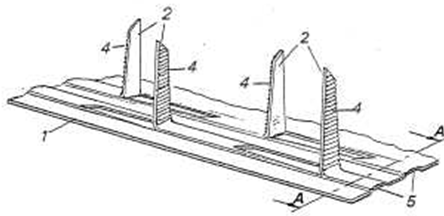

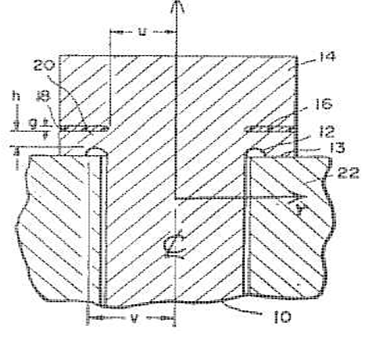

This place covers:

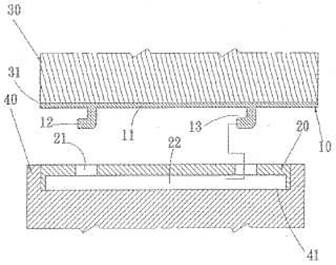

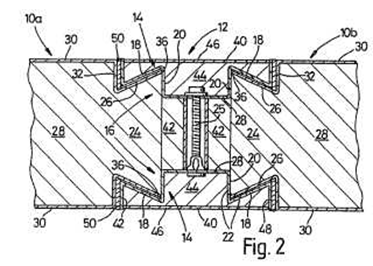

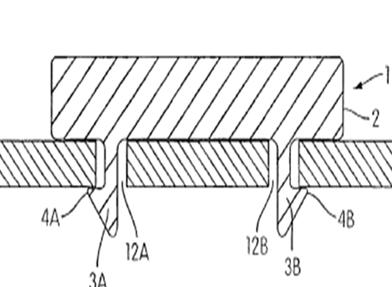

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Using I-shaped connectors with flanges moving towards each other |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Hemming of sheet metal |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Hemming connections in vehicle doors | |

Hemming connections in car bodies |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Construction of screw-threaded connections |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Bolts or sleeves for positioning machine parts |

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Grommet type mountings |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Fasteners for adjustable coverings in ceilings |

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Threaded inserts |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Rivets | |

Riveting process | |

Riveting of plastic parts with separate rivets |

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Connection of multiple plates by means of plastic deformation | |

Riveting of plastic parts without the use of separate rivets |

Attention is drawn to the following places, which may be of interest for search:

Friction-grip releasable fastenings in general | |

Clips in automotive industry |

Generally at least two groups are attributed, one for the clamping or clipping connection and one for the fastening element itself.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Releasable nuts |

This place covers:

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

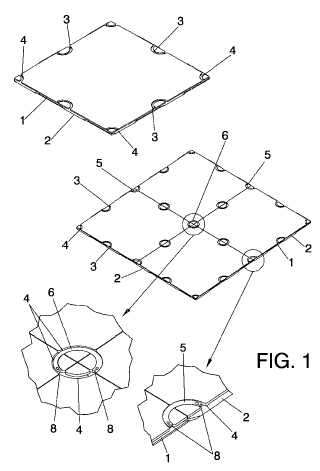

This place covers:

Illustrative example of subject matter classified in this group.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Greenhouses of flexible synthetic material | |

Fastening means for tarpaulins on vehicles | |

End or apterture-closing arrangements or devices for sacks or bags | |

Coping elements for swimming pools with fixing means for sealing foil | |

Tent fastenings |

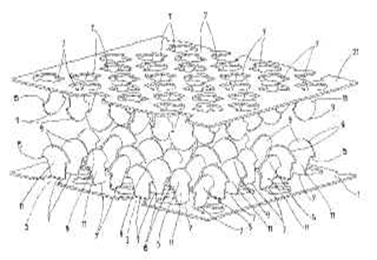

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Fasteners of the touch and close type made integrally of plastics |

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Fastening devices locking by rotation | |

Fastening devices with bayonnet catch |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Fastening rods or tubular parts to flat surfaces at an angle |

Attention is drawn to the following places, which may be of interest for search:

Friction-grip releasable fastenings |

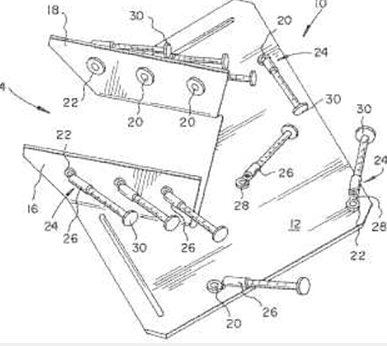

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

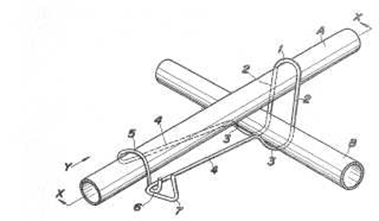

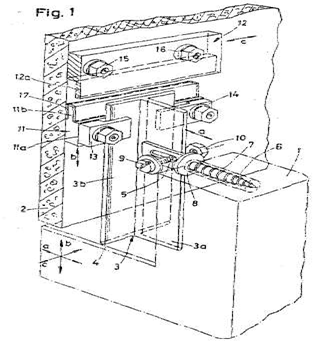

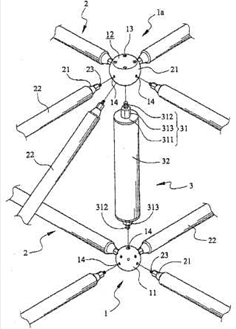

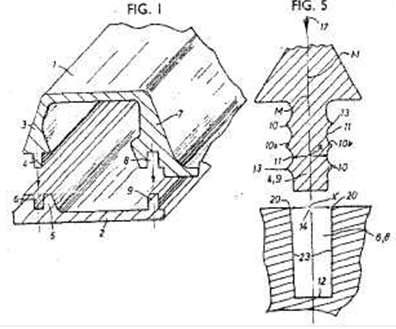

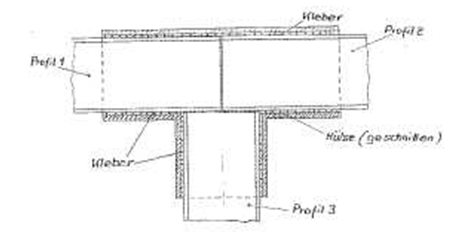

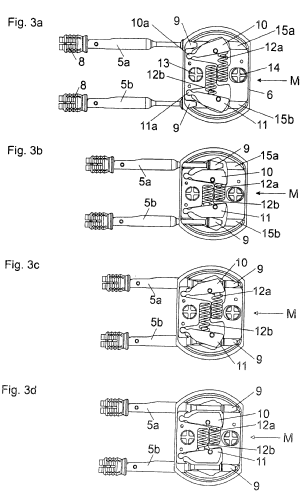

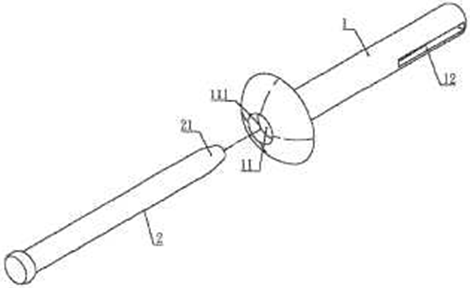

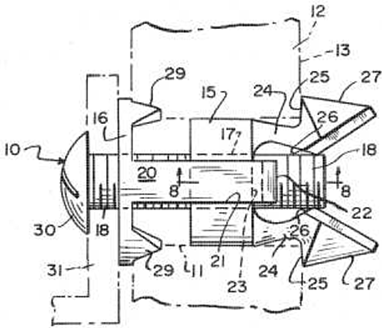

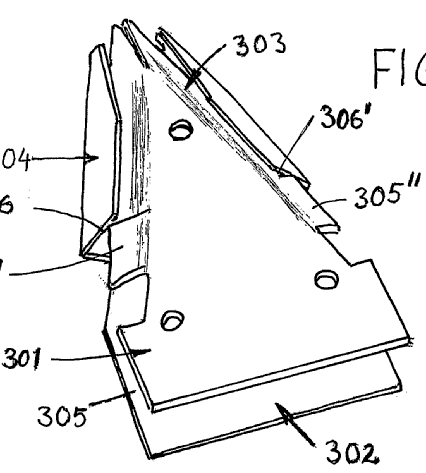

This place covers:

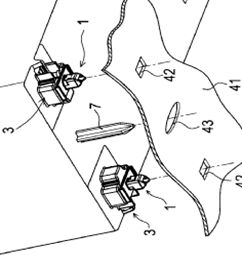

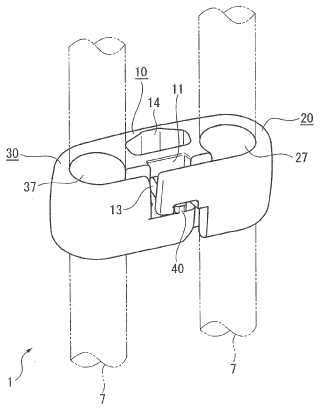

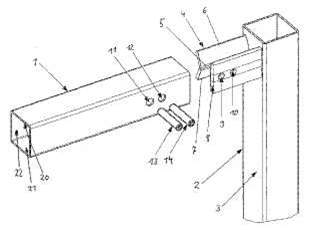

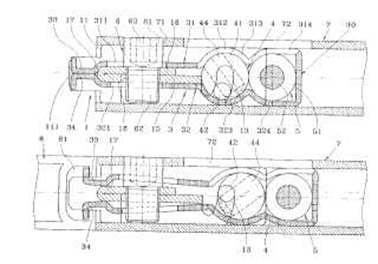

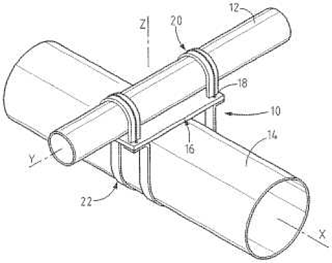

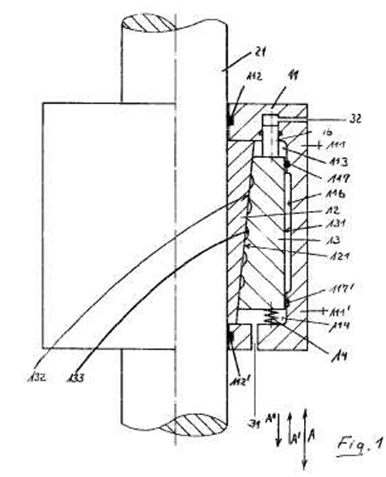

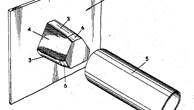

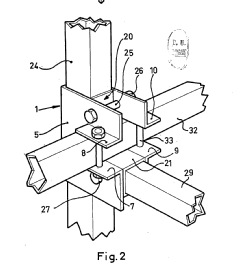

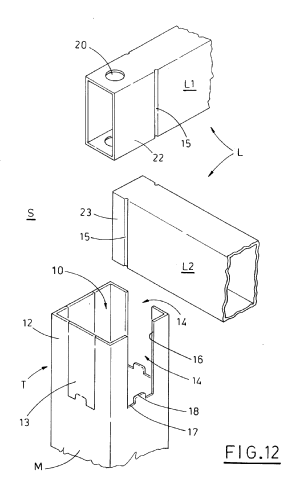

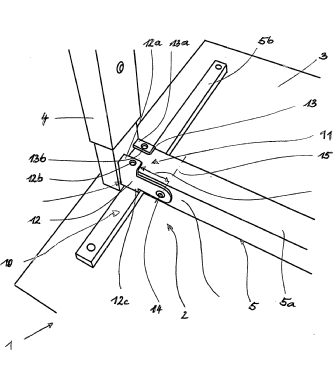

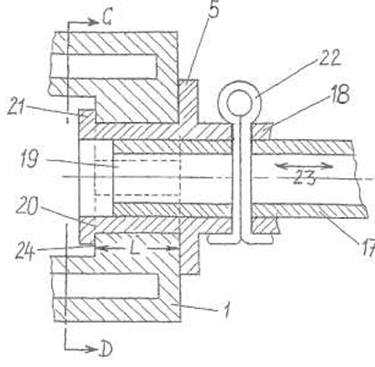

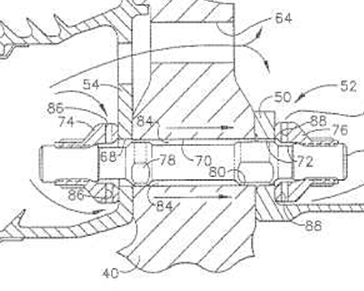

Connections of rods and tubes or profiles mutually by clamping, clipping or screwed connections.

This place does not cover:

By sticking together tubular elements or rods in coaxial engagement | |

Pin and hole connections involving plastic deformation | |

Welding or soldering of connections |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Umbrella frames | |

Railway couplings | |

Bicycle frames | |

Couplings for transmitting rotation | |

Couplings for tubes conveying fluids | |

Mounting of solar heat systems |

If connections relate to a specific application field, they should be generally classified in the application field.

Attention is drawn to the following places, which may be of interest for search:

Vehicle connections in general |

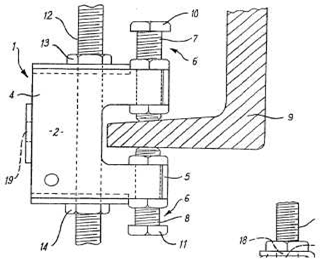

This place covers:

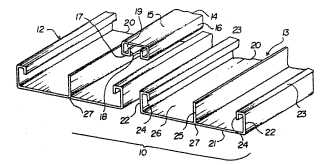

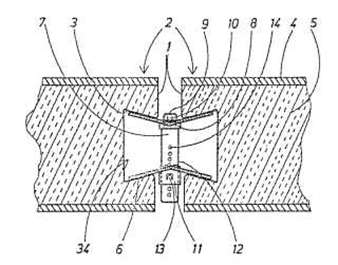

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Connections using a wedge or conical element for telescopically engaged rods or tubes |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Locking of pivots |

Attention is drawn to the following places, which may be of interest for search:

Friction-grip releasable fastenings in general |

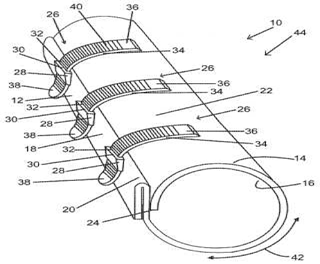

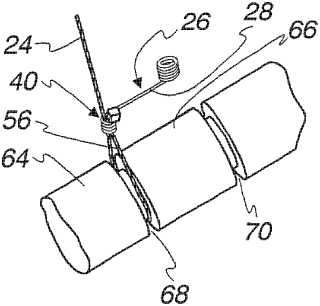

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Cables |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

with sliding nuts see |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Turnbuckles for cables, ropes or wire |

The class is directed towards connections of rods or tubes by turnbuckles.

However, if it is unclear, whether the turnbuckle is for rods or tubes or not, the document should also be classified in this group.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

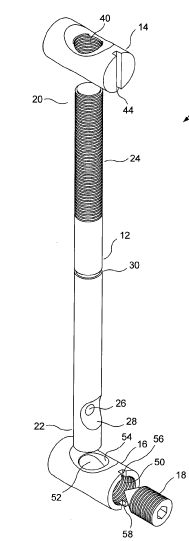

Vertically adjustable chairs | |

Vacuum cleaner | |

Telescopic steering columns | |

Telescopic scaffolding elements | |

Telescopic masts, poles or the like | |

Telescopic door or window holders | |

Telescope props for mining | |

Stands or trestles as support for apparatus or articles placed thereon |

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Locking by a titling clip |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Connections by turnbuckles |

If screws actuate a clamping connection, group F16B 7/04 takes precedence

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Channel nuts |

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Releasable fastening devices with bayonet catch |

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Angled connections of rods or tubes with hook-like parts gripping behind the flanges of a profile |

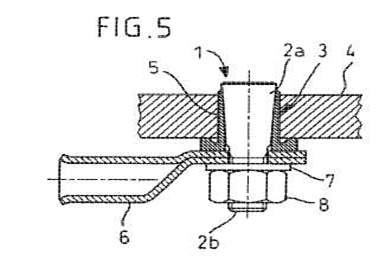

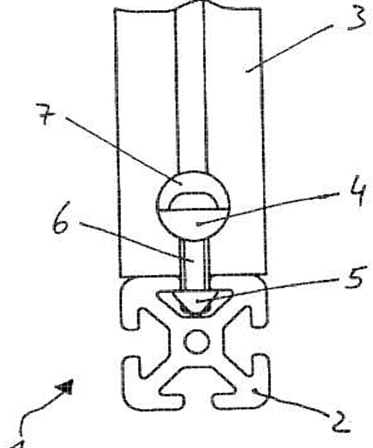

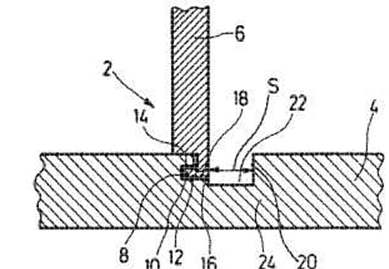

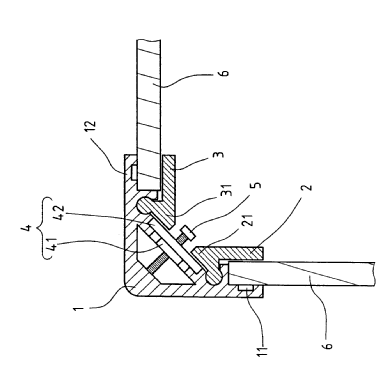

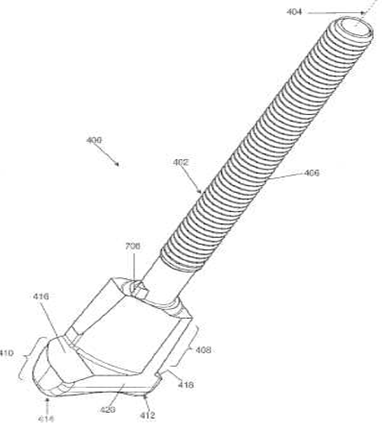

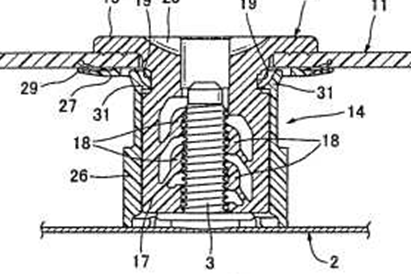

This place covers:

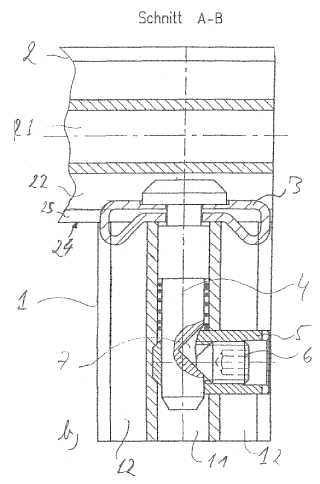

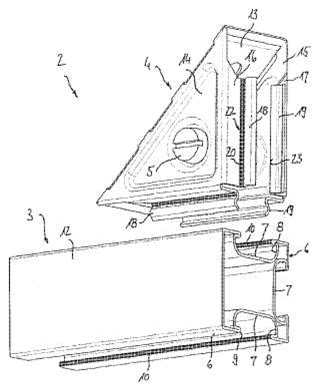

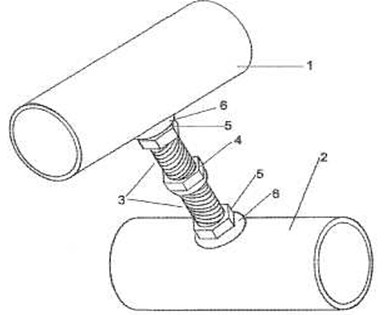

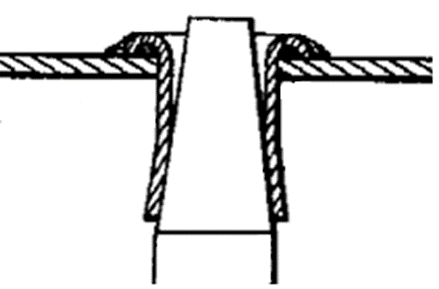

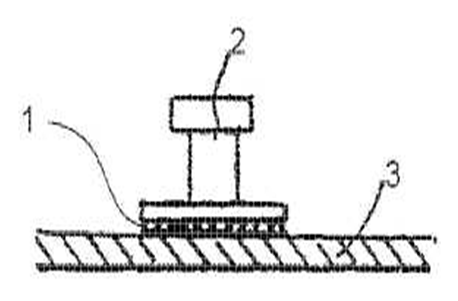

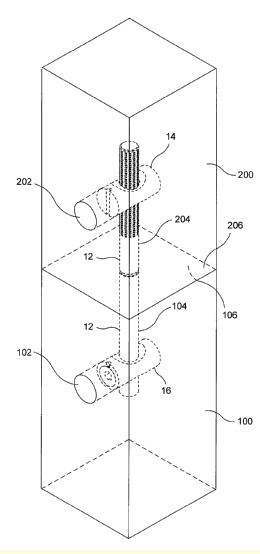

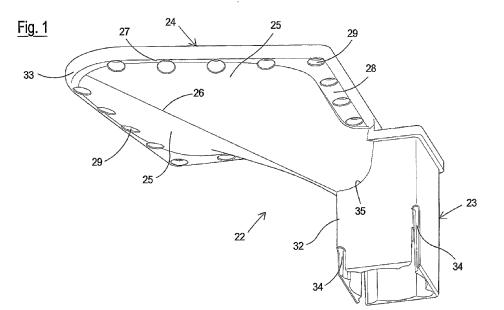

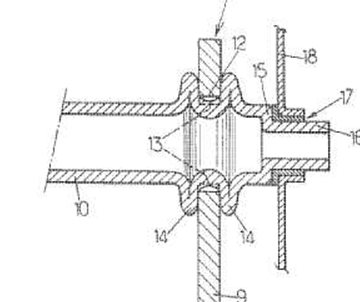

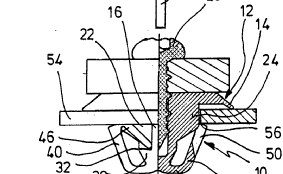

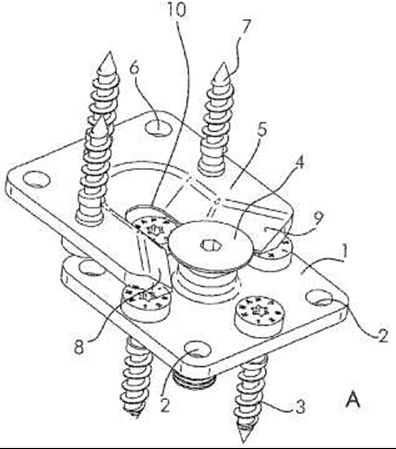

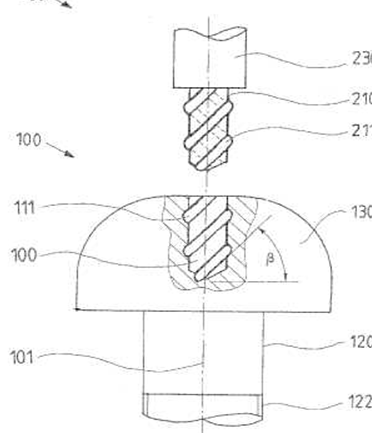

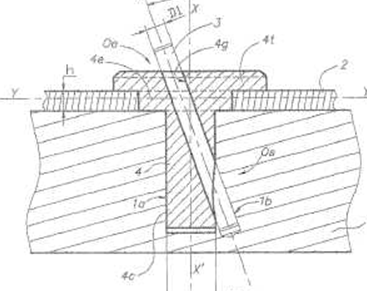

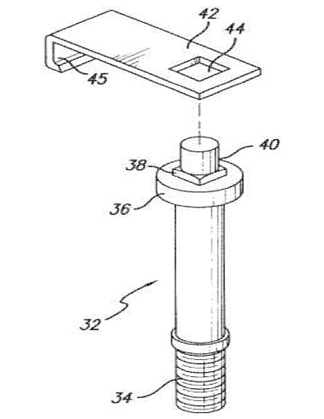

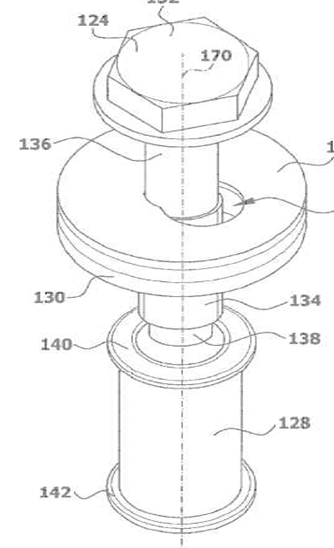

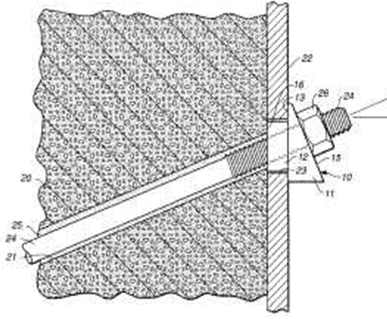

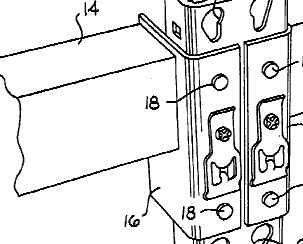

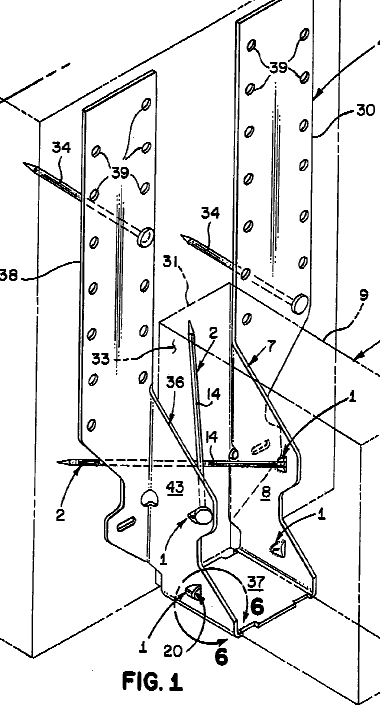

Non-torque transmitting connections of rods or tubular parts to flat surfaces at an angle, i.e. the rods or tubular parts are non-parallel with respect to the flat surfaces. The rods or tubular parts can be connected perpendicularly to the flat surfaces. The connections can involve an intermediate member.

The rods or tubular parts and the flat surfaces are constructional elements or machine parts.

The rods or tubular parts are elongated elements, of any cross-section, that do not convey fluids. Rods or tubular elements may be flexible, but not flaccid, e.g. a cord is not a rod or tubular element in the sense of F16B 9/00.

Flat surfaces are surfaces that are planar at least locally around the connection location.

Connections of rods to rods are classified in F16B 7/00 and subgroups.

Connections of rods parallel to flat surfaces are classified in F16B 5/00 and subgroups.

Connections of cables or cords to other objects are classified in F16G 11/00 and subgroups.

This place does not cover:

Connections of rods to flat surfaces whereby a part of or on one member enters a hole in the other member and involving plastic deformation |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Fluid-tight connections of pipes to reservoirs, sheets, ot the like | |

Connections of pipes to walls |

Attention is drawn to the following places, which may be of interest for search:

Friction-grip releasable fastenings in general | |

Making press-fit connections |

In this main group, it is desirable to add the indexing codes of F16B 2200/00.

References F16B 2/00, B23P 11/00, B23P 19/00, F16L, F16L 41/00 are non-limiting in the main group F16B 9/00. CPC will be updated/corrected once this inconsistency is resolved.

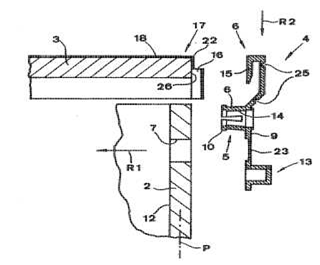

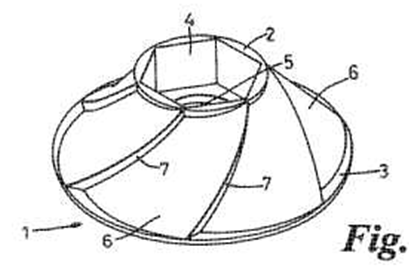

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Connections that can be detached without breaking any part.

Detachable and releasable are synonyms.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Connections with a part of or on one member entering a hole in the other and involving plastic deformation |

In this place, the following terms or expressions are used with the meaning indicated:

Elastic deformation | The parts recover their initial shape after deformation |

Plastic deformation | The parts do not recover their initial shape after deformation |

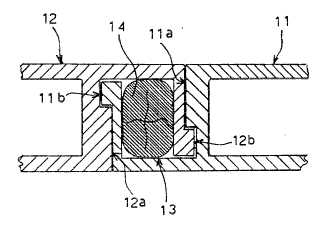

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Connections of constructional elements by glueing, cold pressure welding and by plastically deforming the elements.

This place does not cover:

Friction welding | |

Methods using adhesives independently of the form of the surfaces joined |

Attention is drawn to the following places, which may be of interest for search:

Welding in general |

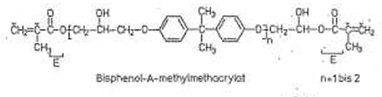

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Force fits | |

Pin and hole connections involving plastic deformation |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Gluing of plastics material | |

Glueing composition |

This place covers:

Illustrative example of subject matter classified in this group.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Connections by bonding in automotive superstructures | |

Glueing of couplings to shafts |

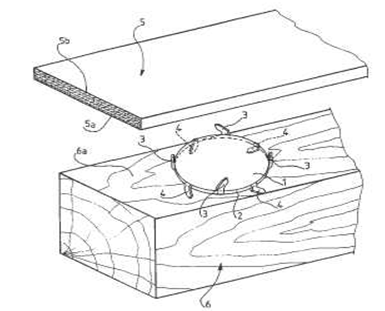

This place covers:

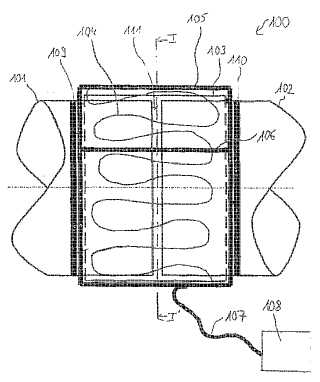

Illustrative example of subject matter classified in this group (WO2011065736)

This place does not cover:

Groups in this subclass |

Attention is drawn to the following places, which may be of interest for search:

Fastening means per se | |

Wood-working |

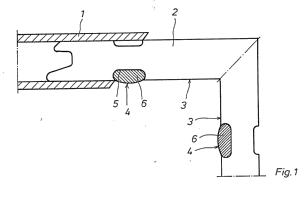

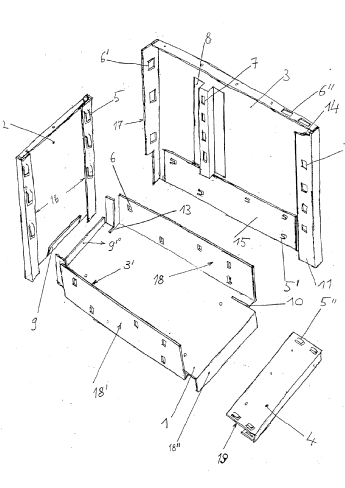

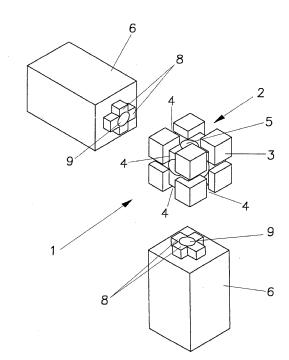

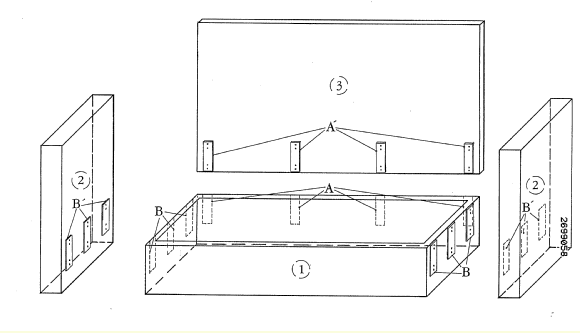

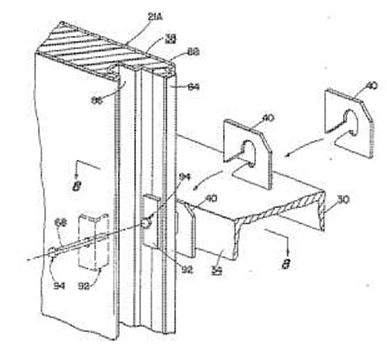

This place covers:

Illustrative example of subject matter classified in this group (DE20307683U).

Attention is drawn to the following places, which may be of interest for search:

Joining of strips or plates to one another or to strips or bars parallel to them | |

Horizontal connecting members adapted to receive and retain the edges of several panel elements |

This place covers:

Illustrative example of subject matter classified in this group (DE102004016551).

Attention is drawn to the following places, which may be of interest for search:

Connecting constructional elements by gluing |

This place covers:

Illustrative example of subject matter classified in this group (EP0639718):

This place covers:

Illustrative example of subject matter classified in this group (DE202010016369U)

Attention is drawn to the following places, which may be of interest for search:

Glued | |

Fastening means per se |

Attention is drawn to the following places, which may be of interest for search:

Bolt and nut or screw connectors |

Attention is drawn to the following places, which may be of interest for search:

Screws that cut thread in the body into which they are screwed |

This place covers:

Illustrative example of subject matter classified in this group (US2010322740).

This place covers:

Illustrative example of subject matter classified in this group (EP1530926).

Attention is drawn to the following places, which may be of interest for search:

Height adjustable shelving |

This place covers:

Illustrative example of subject matter classified in this group (FR2927677).

This place covers:

Illustrative example of subject matter classified in this group (US2010202852).

This place covers:

Illustrative example of subject matter classified in this group (US4990020).

This place covers:

Illustrative example of subject matter classified in this group (EP1856417)

This place covers:

Illustrative example of subject matter classified in this group (US2010258039).

Attention is drawn to the following places, which may be of interest for search:

Height adjustable shelving |

This place covers:

Illustrative example of subject matter classified in this group (US917433).

Attention is drawn to the following places, which may be of interest for search:

Dowels in general |

This place covers:

Illustrative example of subject matter classified in this group (DE202009014811U).

This place covers:

Illustrative example of subject matter classified in this group (DE10336968).

Attention is drawn to the following places, which may be of interest for search:

Bolt and nut or screw connectors |

This place covers:

Illustrative example of subject matter classified in this group (DE202009012657U).

Attention is drawn to the following places, which may be of interest for search:

Height adjustable shelving |

This place covers:

Illustrative example of subject matter classified in this group (US2002153340).

Attention is drawn to the following places, which may be of interest for search:

Height adjustable shelving |

This place covers:

Illustrative example of subject matter classified in this group (EP1508705).

This place covers:

Illustrative example of subject matter classified in this group (US2001044992).

This place covers:

Illustrative example of subject matter classified in this group (FR1520757).

This place covers:

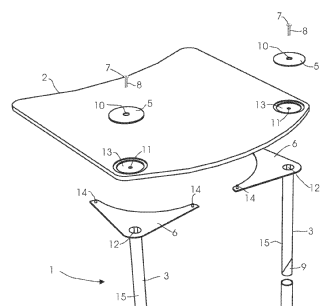

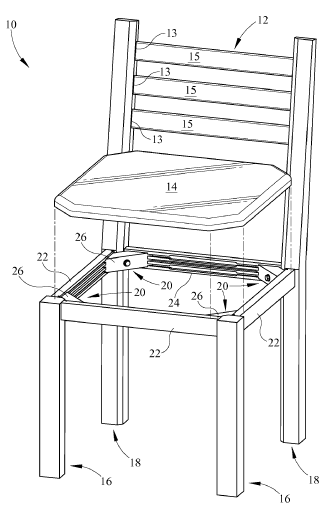

Illustrative example of subject matter classified in this group (US2011225802).

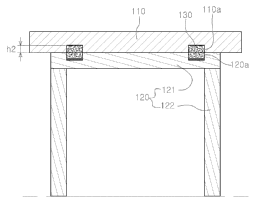

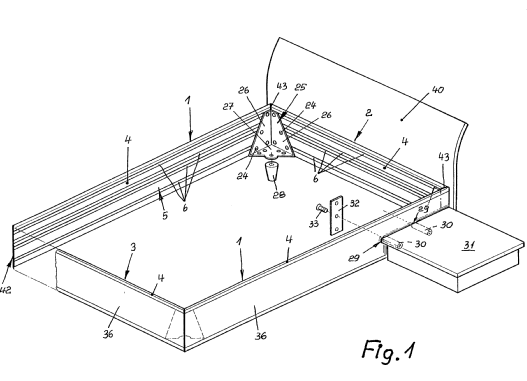

Attention is drawn to the following places, which may be of interest for search:

Connecting table tops to underframes |

This place covers:

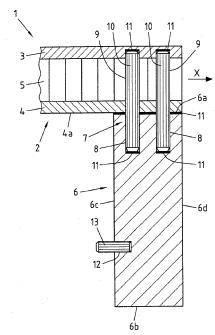

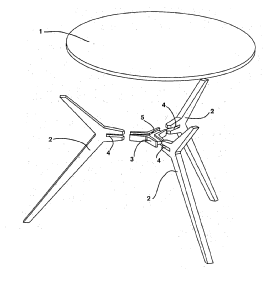

EP1464251, EP2243969.

Illustrative examples of subject matter classified in this group:

Attention is drawn to the following places, which may be of interest for search:

Connections of tubes or rods |

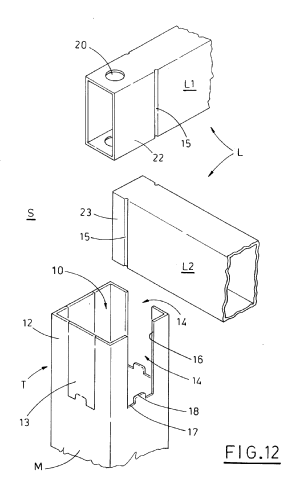

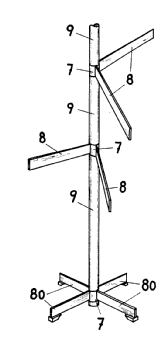

This place covers:

Illustrative examples of subject matter classified in this group (DE202006014679U, US7677830).

Attention is drawn to the following places, which may be of interest for search:

Connections of tubes or rods |

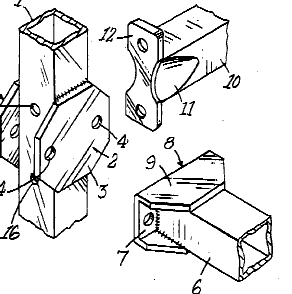

This sub-group concerns joints between two or more NON-METAL connecting elements whose connector or liaison part is non-metal or metallic.

This place covers:

Illustrative example of subject matter classified in this group (DE202009017363U, DE202010017070).

This place does not cover:

Non-metal corner connections |

Attention is drawn to the following places, which may be of interest for search:

Connections of tubes or rods |

This sub-group concerns joints between two or more NON-METAL leg connecting elements whose connector or liaison part is non-metal or metal and includes the connection between table top or similar and leg(s).

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Connections of tubes or rods |

This sub-group concerns joints between two or more METAL connecting elements whose connector or liaison part is non-metal or metal.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Metal corner connections |

Attention is drawn to the following places, which may be of interest for search:

Connections of tubes or rods |

This sub-group concerns joints between two or more METAL leg connecting elements whose connector or liaison part is non-metal or metal and includes connections between table top or similar and leg(s).

This place covers:

Illustrative example of subject matter classified in this group (DE29500500U,

GB2413759).

This place covers:

Illustrative example of subject matter classified in this group (US2006195983).

This place covers:

Illustrative example of subject matter classified in this group (FR875988, US3539211).

This place covers:

Illustrative example of subject matter classified in this group (FR2699058).

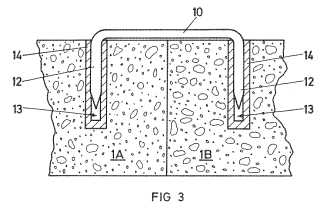

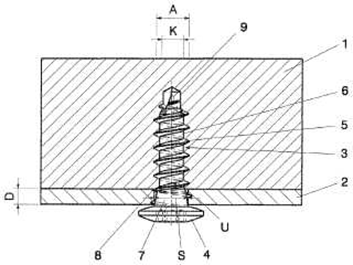

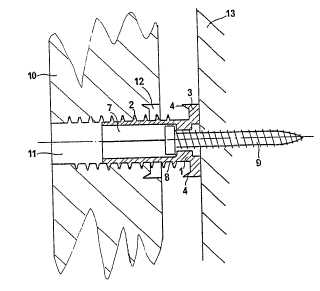

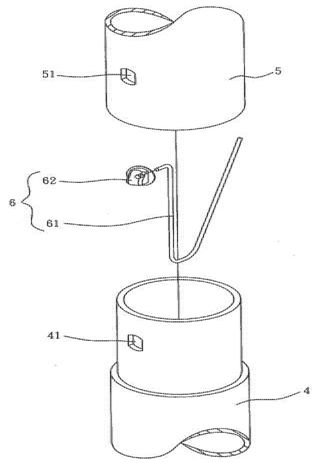

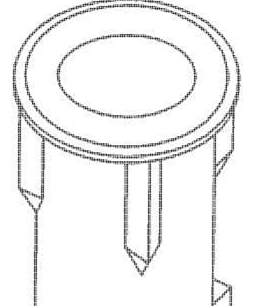

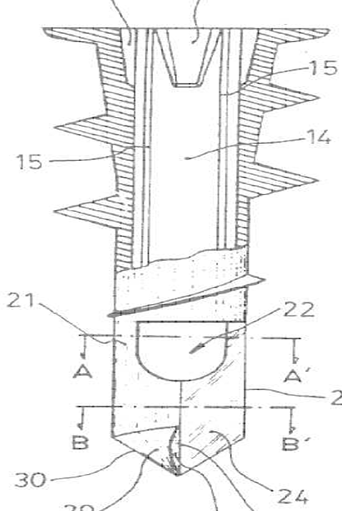

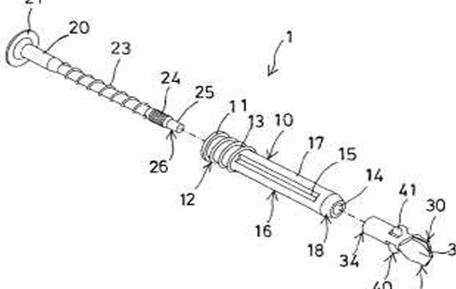

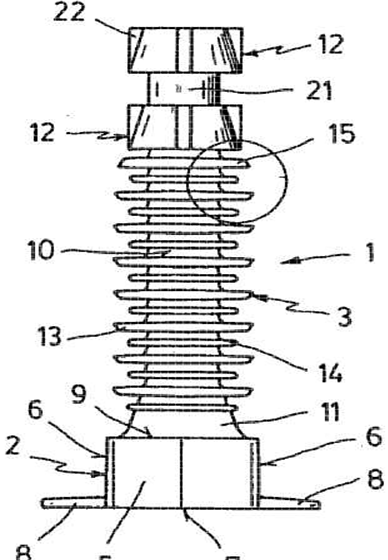

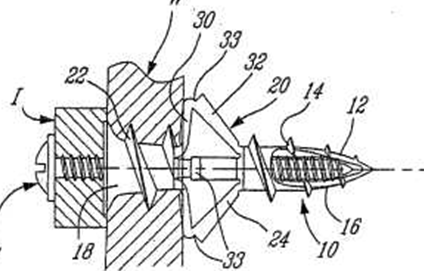

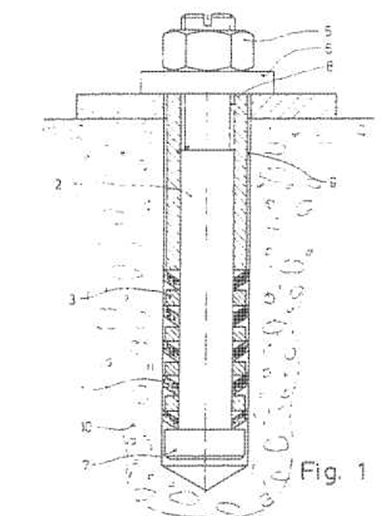

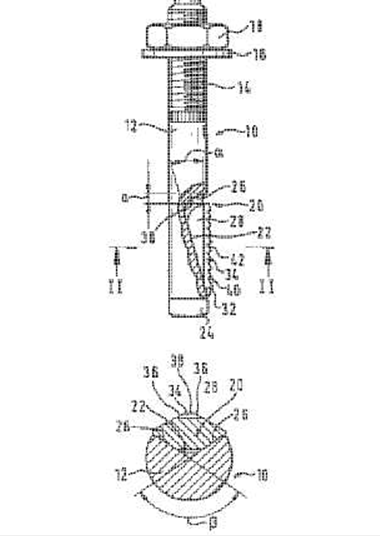

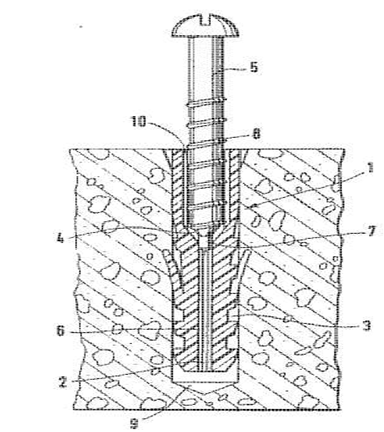

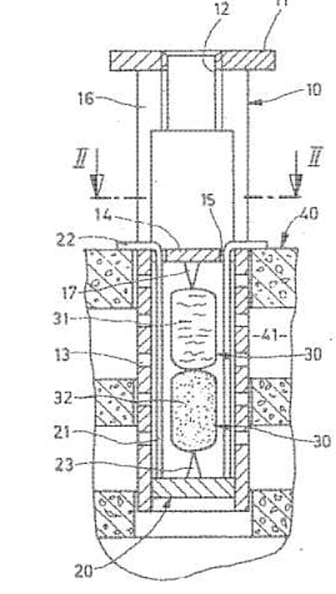

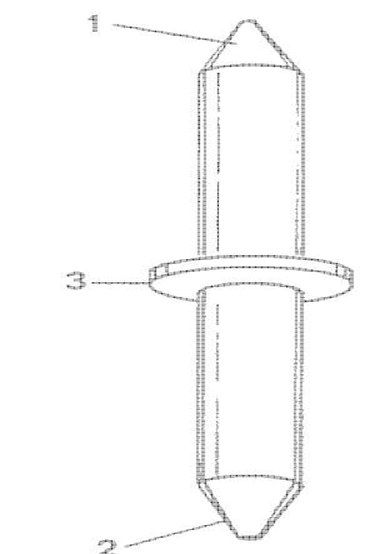

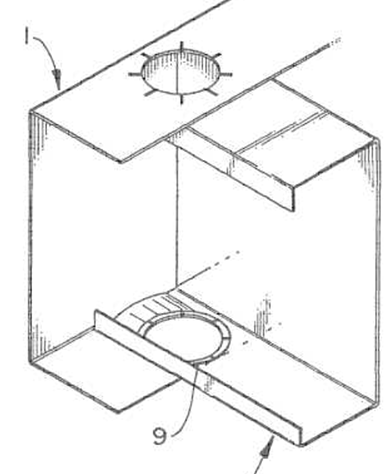

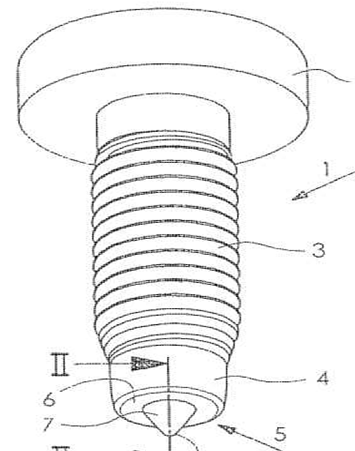

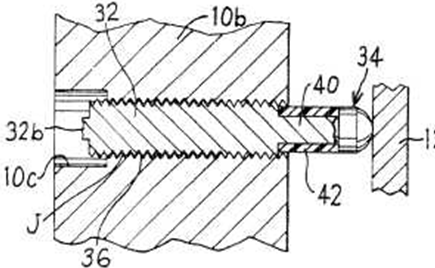

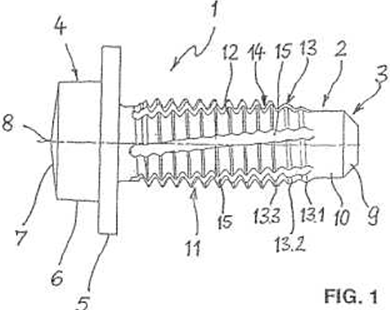

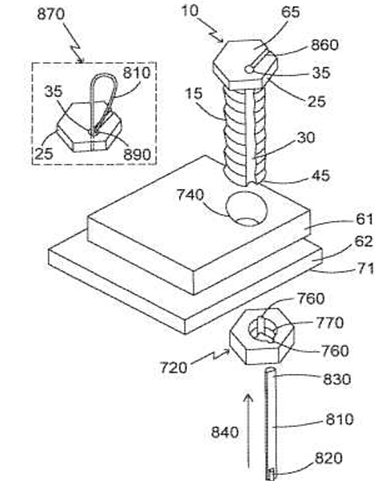

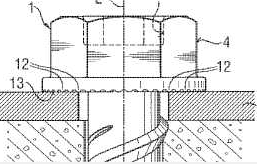

This place covers:

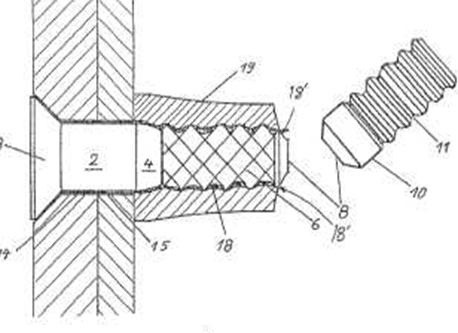

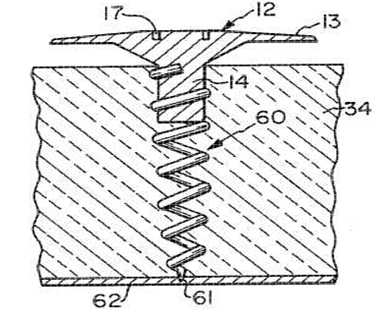

Dowels made e.g. of wood, metal or plastic.

Dowels in form of a solid rod.

Dowels having parts gripping it the hole, e.g. expanding sleeves or toggle mechanisms.

Dowels fastened by inserted an additional element.

Dowels fixed by a settable material.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Connections in furniture using dowels | |

Self-locking pins or bolts in general, stud-and-socket releasable fastenings | |

Dowels or bolts for railroad sleepers | |

Means for anchoring structural elements or bulckheads specially adapted to foundation engineering | |

Bolts or dowels used while laying bricks or casting concrete sleepers | |

Dowels fixed by grouting | |

Anchoring bolts for shafts, tunnels or galleries |

Attention is drawn to the following places, which may be of interest for search:

Nails | |

Bolts without screw-thread and rivets | |

Dowels for insulation of walls and ceilings |

In this place, the following terms or expressions are used with the meaning indicated:

Dowel | Solid cylindrical rod, usually made of wood, plastic or metal that is usually inserted into a blind hole. |

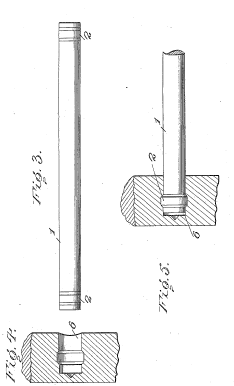

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Self-cutting screws |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Friction-grip releasable fastenings in general |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Nails with a spreading shaft |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Anchoring bolts by grouting |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

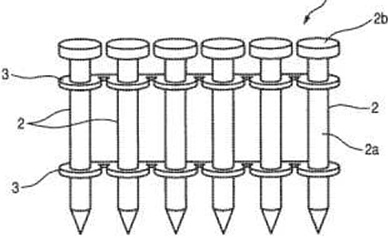

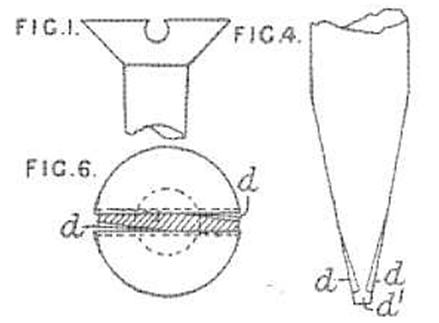

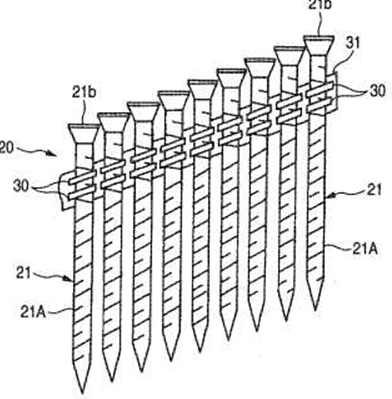

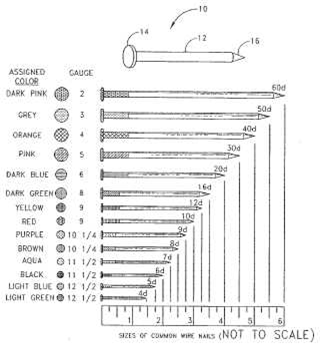

Nails, i.e. pin shaped sharp objects made mainly of hard metal alloy and being used as a fastener

Staples, i.e. two pronged fasteners made of metal.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Surgical staples | |

Thumb tacks | |

Railway spikes |

Attention is drawn to the following places, which may be of interest for search:

Manufacture of nails or staples |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Ornaments for furniture | |

Removable ornament heads for nails |

Attention is drawn to the following places, which may be of interest for search:

Fastening devices with markings, colours, indicators or the like |

References A47B 95/04 and A47G 3/00 are non-limiting in group F16B 15/02. CPC will be updated/corrected once this inconsistency is resolved in IPC.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Dowels with a drive-nail deflected by an inclined surface in the dowel body |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Bolts, screws or nuts formed in integral series | |

Arrangements for feeding screws or nuts |

This place covers:

Non-releasable connections of one element by entering a hole in a second element and subsequent plastic deformation.

Illustrative example of subject matter classified in this group.

This place does not cover:

Rivets; Spigots or the like fastened by riveting |

Attention is drawn to the following places, which may be of interest for search:

Construction of pins, bolts or rivets | |

Means for preventing withdrawal of a pin, spigot or the like from its operative position, stud-and-socket releasable fastenings |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Joining sheets by riveting without the use of separate rivets |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Joining of superposed plates by local deformation |

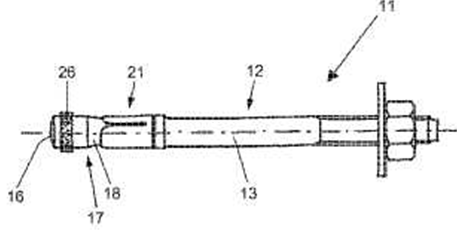

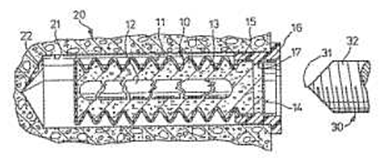

This place covers:

Bolts without screw-thread, pins and rivets, such as solid rivets or blind rivets.

This place does not cover:

Means for preventing relative axial movement of a pin, spigot, shaft and the like | |

Screwed connection with deformation of nut or auxiliary member |

Attention is drawn to the following places, which may be of interest for search:

Riveting (process) |

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Dowels with elastic discs or spring washers |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Sealing of bolts and nuts | |

Sealing washers |

This place covers:

Illustrative example of subject matter classified in this group.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Lead seals |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Nuts fastened by riveting |

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Dowels fastened by inserting a screw, nail or the like | |

Releasable fastening devices with snap action with an additional locking element |

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Means for preventing axial movement of a pin by separate parts with radially resilient locking members |

Attention is drawn to the following places, which may be of interest for search:

Special clamping devices for workpieces to be riveted together, e.g. operating through the rivet holes | |

Hand tools for temporarily connecting sheets before or during assembly operations |

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Bolts shot by means of detonation-operated nailing tools into concrete constructions, metal walls or the like |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

- Means for preventing axial movement of a pin or the like by rotation, snap in features, engagement in a keyhole slot, separate parts, such as circlips and other locking members.

- Releasable stud-and-socket connections where the stud or the socket or both parts being resilient.

This place does not cover:

Rivets or deformable spigots |

This place covers:

Illustrative example of subject matter classified in this group.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Electrical connectors locked by rotation |

Attention is drawn to the following places, which may be of interest for search:

Releasable devices with snap-action | |

Studs or coupling pins with resilient protrusions |

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Quickly-detachable or mountable nuts to threaded bolts |

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Rivets fastened by a drive pin |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Dowels | |

Snap in sockets |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

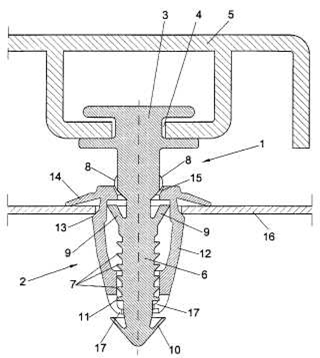

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Resiliently deformable pins made in one piece |

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Snap in sockets |

This place covers:

Illustrative example of subject matter classified in this group.

In exeptional cases, namely if details of the snap in portion of the fastener are of interest, pipe or cable fasteners may be classified here

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Locking screws or nuts against rotation by separate parts |

Attention is drawn to the following places, which may be of interest for search:

Key-type connections |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Temporary rivets |

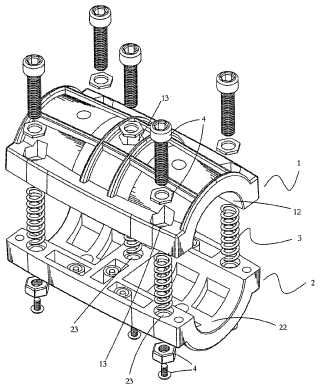

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Connections of non-slidable parts in machine tools |

Attention is drawn to the following places, which may be of interest for search:

Component parts of injection moulding machines |

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Telescopic connections of tubes locked with balls or rollers |

Attention is drawn to the following places, which may be of interest for search:

Clamps with rollers and balls |

This place does not cover:

Spring-washers for locking nuts | |

Adjusting rings |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Releasable fastenings by rings resilient in their plane |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Detachable ornamental heads for screws |

Attention is drawn to the following places, which may be of interest for search:

Screwdrivers, wrenches |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

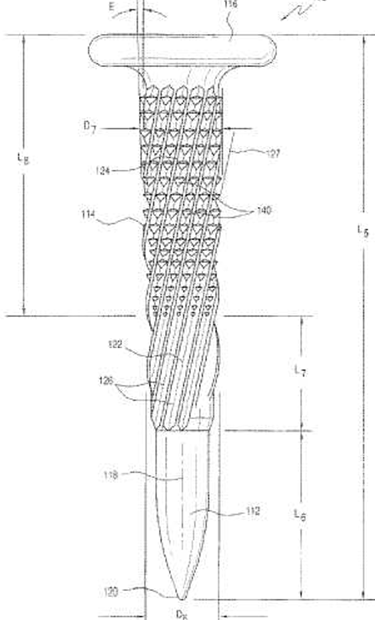

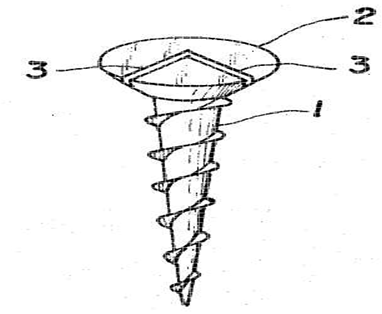

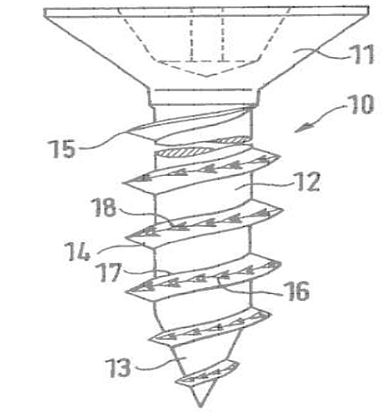

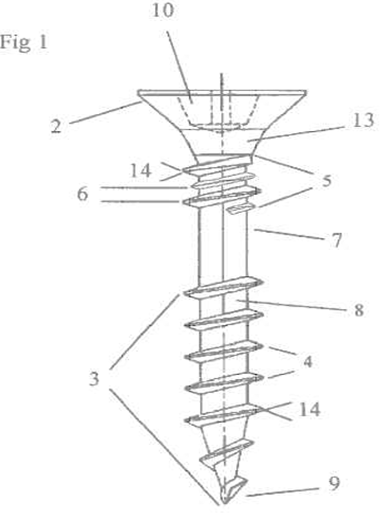

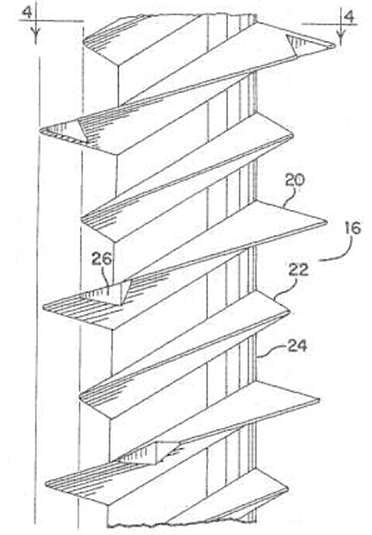

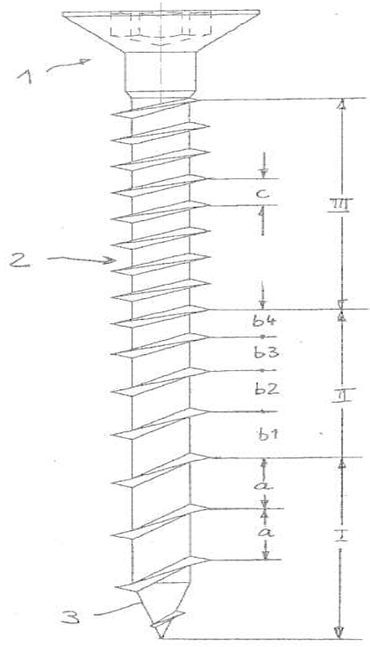

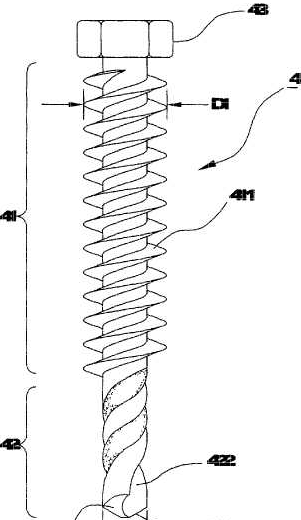

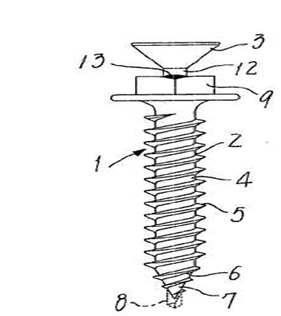

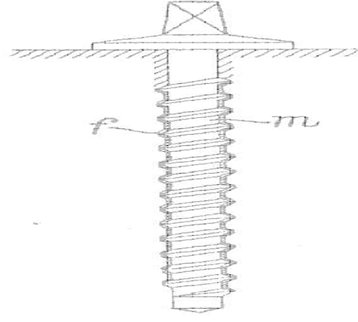

This place covers:

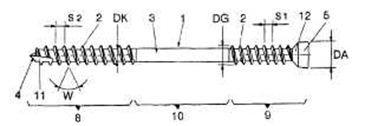

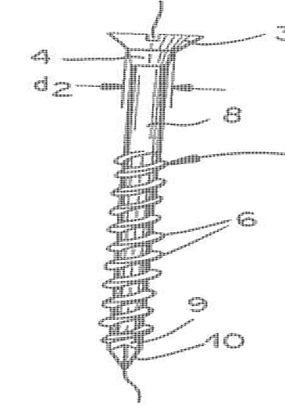

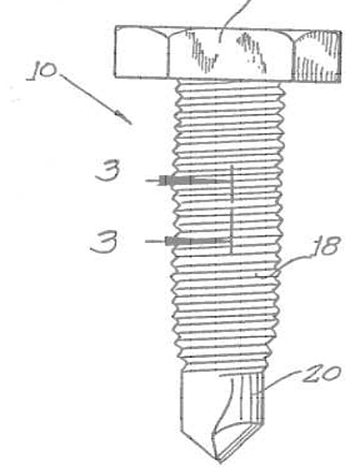

Self tapping or self-cutting screws used for securing constructional elements or machine parts together.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Self cutting screws used for medical purposes |

Attention is drawn to the following places, which may be of interest for search:

Joining sheets or plates using screws with two separate threads | |

Using screws with adjustment sleeves | |

Self-cutting dowels | |

Geometry of the head |

For self cutting screws at least one classification in F16B 25/00 should be attributed. Several classes in F16B 25/00 in the inventive information field are generally to be attributed.

No additional classification should be attributed in F16B 35/00, except for F16B 35/06 and F16B 35/065.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Threaded wire inserts |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Tools for drilling machines |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Nail formed in integral series but easily separable | |

Arrangements for feeding screws or nuts |

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Nuts fastened to surfaces by riveting | |

Members deformed for locking screws, bolts or nuts |

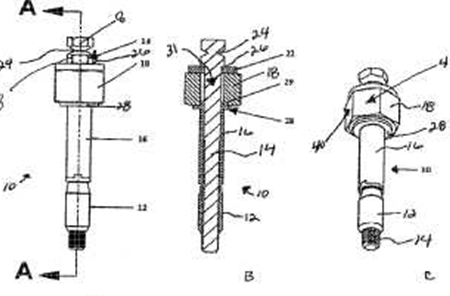

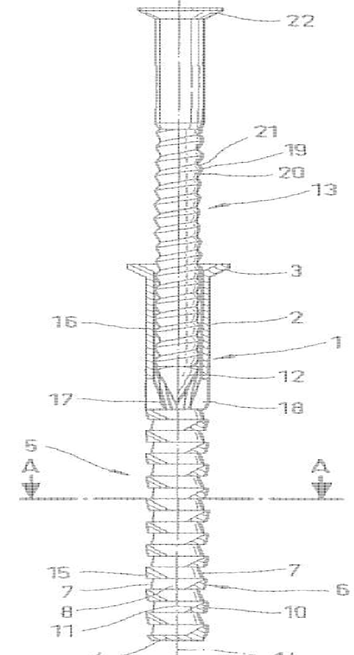

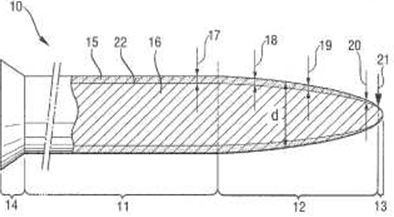

This place covers:

Breakbolts

Screwed connections with indication of the load

Screwed connections maintaining a specific load

Screwed connections modified in view of a possible fatigue rupture

This place does not cover:

Shape of thread |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Couplings with safety member for disconnecting |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Apparatus for, or method of, determining value of torque or twisting moment for tightening a nut or other member similarly stressed |

This place covers:

Illustrative example of subject matter classified in this group.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Break members in torque limiters or torque indicators in wrenches of screwdrivers |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Hydraulic bolt tensioners |

This place covers:

Illustrative example of subject matter classified in this group.

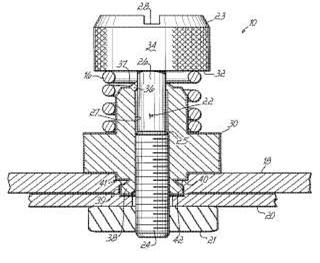

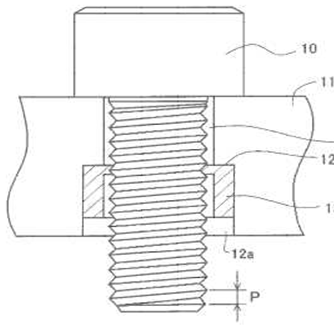

This place covers:

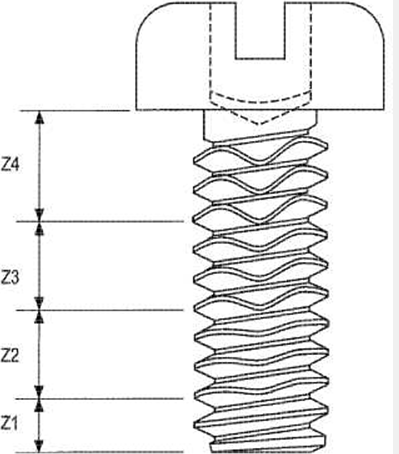

Features of fastening members with thread that are common to bolt and nut.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Sealing of rivets | |

Sealing by means of washers |

In this place, the following terms or expressions are used with the meaning indicated:

Insulation | includes electric insulation |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Used to remove paint or durt layers | |

Used as screw-locking device |

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Corrosion preventing means | |

Settable coatings for locking threaded members | |

Deformable coatings for locking threaded members |

Attention is drawn to the following places, which may be of interest for search:

Heat treatment for screws, bolts |

This place covers:

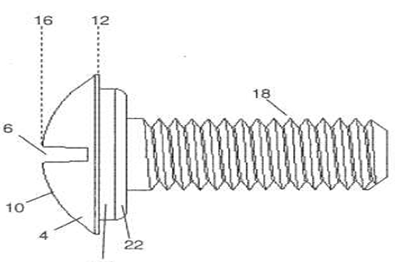

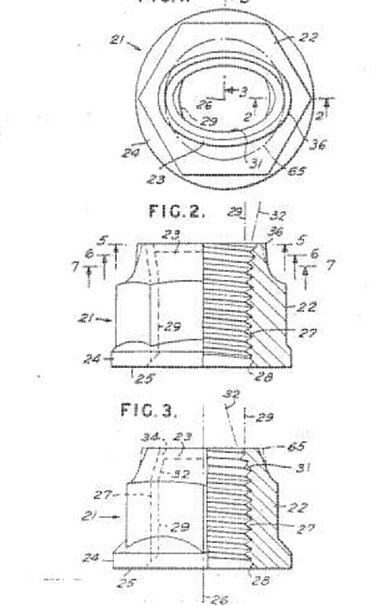

Screws or bolts, i.e. fastening elements having an external thread, i.e. a helical ridge wrapped around its shaft

Attention is drawn to the following places, which may be of interest for search:

Joining sheets or plates using screws with two separate threads | |

using screws with adjustment sleeves | |

Thread cutting screws |

Thread cutting screws are classified in F16B 25/00. An additional entry can be attributed in F16B 35/06.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Locking the bolt against turning in the object by the use of accessory parts |

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Shape of thread |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Separate hook adaptors for bolts |

Self threaded screws with specially shaped heads are also classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

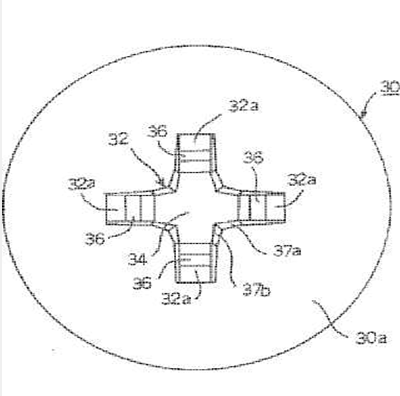

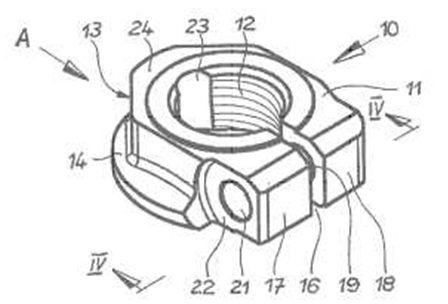

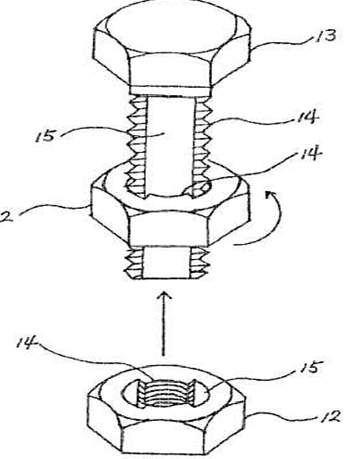

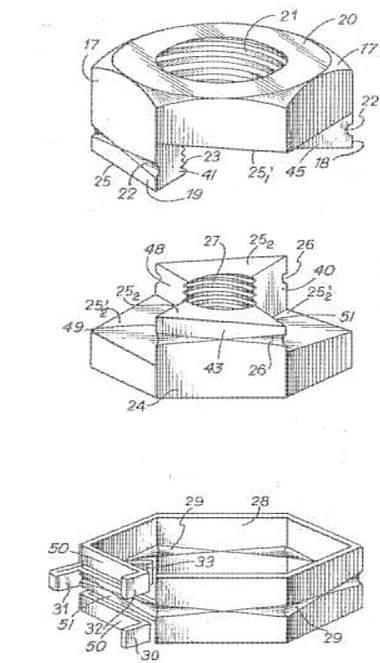

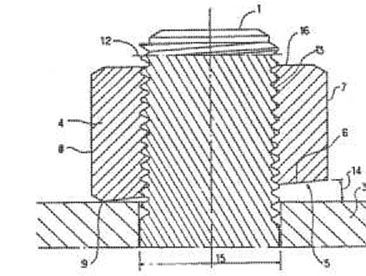

This place covers:

Nuts, i.e. fasteners with a threaded hole.

Attention is drawn to the following places, which may be of interest for search:

Specially adapted for rotation by a tool | |

Making of nuts |

Groups F16B 37/04 comprise also threaded studs that are fastened to a surface.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Nuts made of thin sheet material used as lock-nuts |

Attention is drawn to the following places, which may be of interest for search:

Fastening nuts to surfaces |

This place does not cover:

Nuts fastened behind a wall by a toggle mechanism | |

Threaded inserts | |

Measures against loss of bolts, nuts or pins |

Attention is drawn to the following places, which may be of interest for search:

Joining sheets by clamps or clips fastened over the edges of the sheets or plates |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Stud welding |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Machines for feeding nuts |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Mounting devices |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

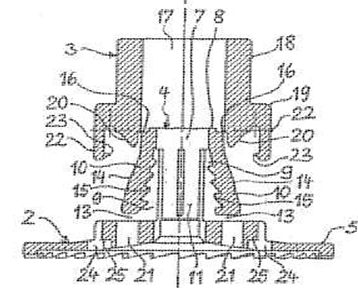

This place covers:

Locking of screws by means of a settable material, plastic deformation, geometric engagement or friction.

This place does not cover:

Measures against loss of bolts and nuts (preassembling) | |

Measures against unauthorised operation of bolts, nuts or pins |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Locking of bottle closures | |

Locking of rail-fastening bolts for permanent ways | |

Locking of fastening means for railway fishplates | |

Locking devices for valves or cocks |

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Split-pins, circlips, or the like for preventing relative axial movement only | |

Fastening nuts by welding or riveting |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

Attention is drawn to the following places, which may be of interest for search:

Locknuts per se made of thin sheet metal |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Locking to the screw-thread | |

Locking by deformable inserts or the like parts | |

Locking with conical parts |

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Locknuts |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Shape of thread |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Measures against loss of bolts, nuts or pins in preassembling and against unauthorised operation

This place does not cover:

Locking of bolts, nuts or pins |

Attention is drawn to the following places, which may be of interest for search:

Seals |

This place covers:

Illustrative example of subject matter classified in this group.

This place does not cover:

Devices for fastening nuts to surfaces |

This place covers:

Illustrative example of subject matter classified in this group.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Locks, keys | |

For valves, taps or cocks | |

For pipe-joints with swivel-nuts |

Attention is drawn to the following places, which may be of interest for search:

Anti-theft devices for car wheels |

This place covers:

Illustrative example of subject matter classified in this group.

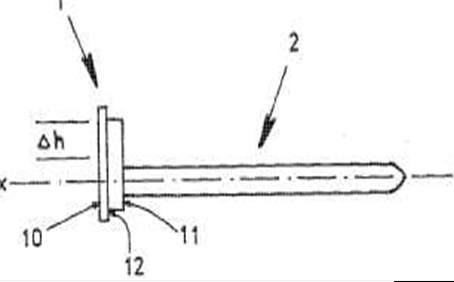

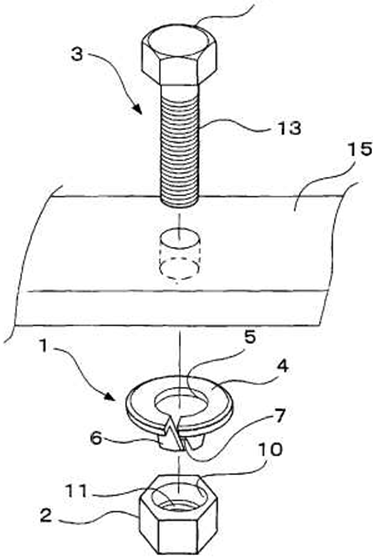

This place covers:

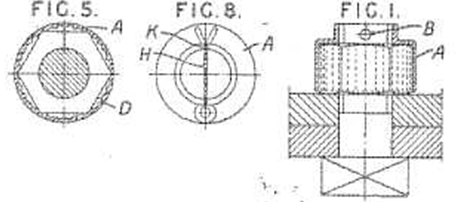

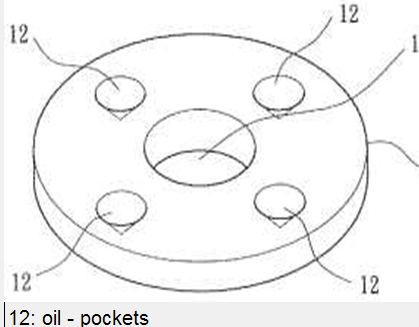

Washers or equivalent devices, i.e. is a thin, typically disk shaped, plates with a hole that is used to distribute the load of a threaded fastener, such as a screw or a nut.

Example:

This place does not cover:

Circlips | |

Washers for indicating tensile load | |

Locking bolts or nuts by means of a fixed plate or ring, or washer-like resilient plates |

Attention is drawn to the following places, which may be of interest for search:

Washers forming a whole with the bolt or nut | |

Method of making washers | |

Belleville type springs |

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Illustrative example of subject matter classified in this group.

This place covers:

Curved fastening member used for fastening or securing constructional elements or machine parts together. This group also covers snap-hooks for mountaineering.

This place does not cover:

Dowels or other devices fastened in walls or the like by inserting them in holes made therein for that purpose | |

Nails; Staples | |

Bolts without screw-thread; Pins, including deformable elements; Rivets | |

Screws that cut thread in the body into which they are screwed, e.g. wood screws | |

Screw-bolts; Stay-bolts; Screw-threaded studs; Screws; Set screws | |

Suction cups for attaching purposes; Equivalent means using adhesives |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Hooks for hanging pictures or the like | |

Clothes hangers | |

Towing hooks for ships | |

Hooks for hoisting or hauling purposes | |

Hooks or eyes with integral parts designed to facilitate quick attachment to cables or ropes at any point |

Attention is drawn to the following places, which may be of interest for search:

Mountaineering |

References A47G 1/16, B63B 21/58, B66C, F16G 11/14 are non-limiting in the main group F16B 45/00. CPC will be updated/corrected once this inconsistency is resolved in IPC.

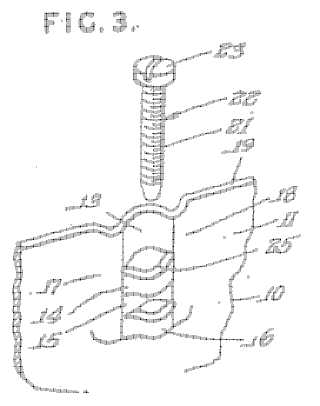

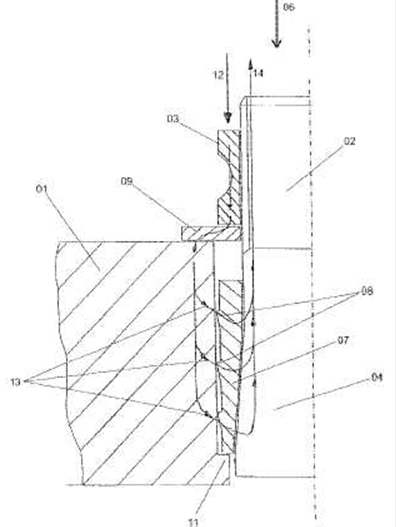

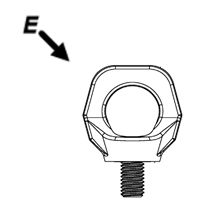

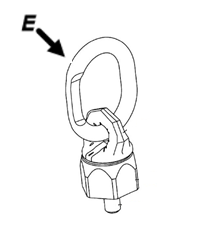

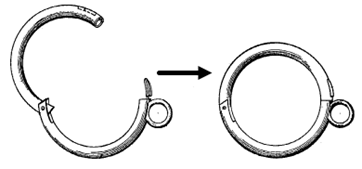

This place covers:

The figures below are illustrative examples which fall within the scope of this subgroup. In the figures are shown examples of eyes E.

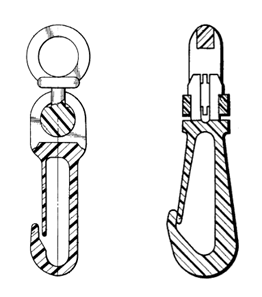

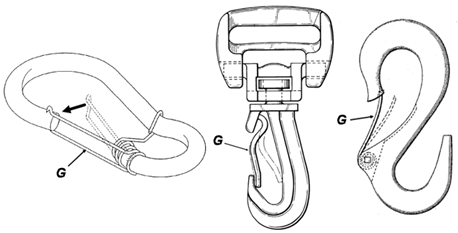

This place covers:

The figures below are illustrative examples which fall within the scope of this subgroup. In the figures are shown examples of a plastic hook.

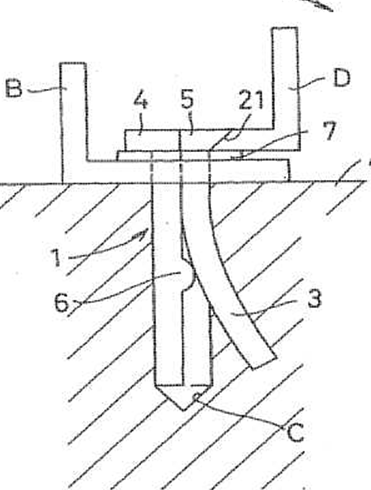

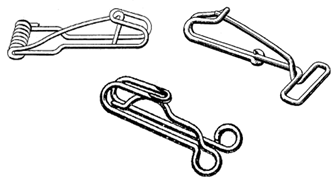

This place covers:

The figures below are illustrative examples which fall within the scope of this subgroup. In the figures are shown examples of a hook formed from a wire material.

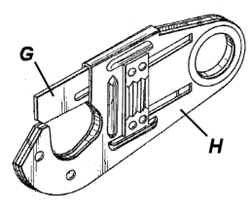

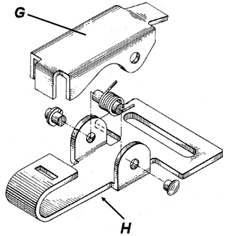

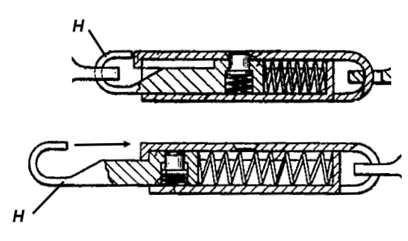

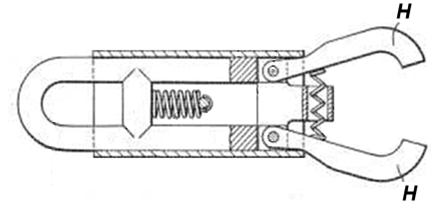

This place covers:

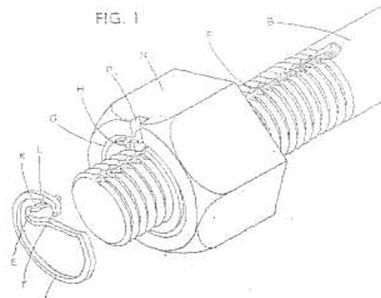

The figures below are illustrative examples which falls within the scope of this subgroup. In the figures, each of the closing members G and hook bodies H are formed from sheet metal.

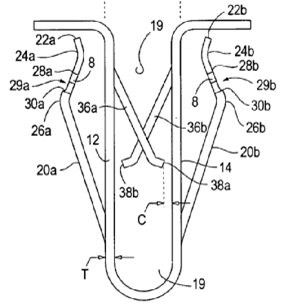

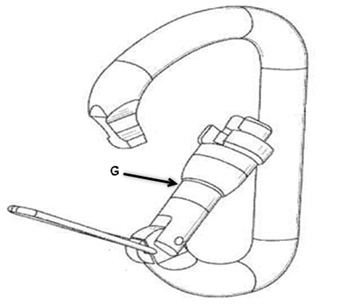

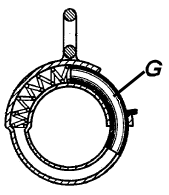

This place covers:

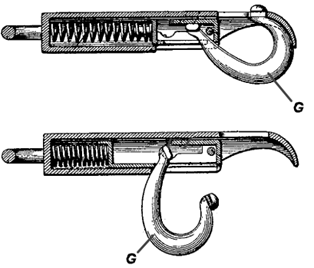

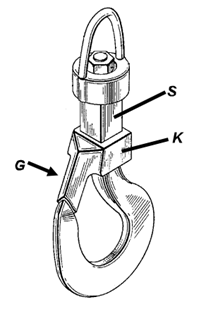

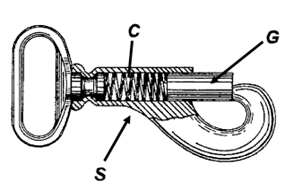

Illustrative example of a hook with pivoting closing member (G).

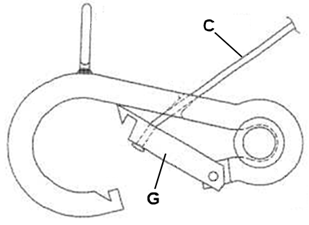

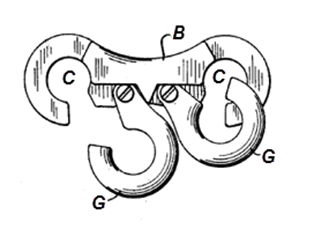

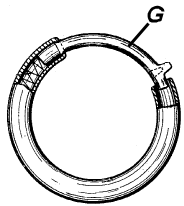

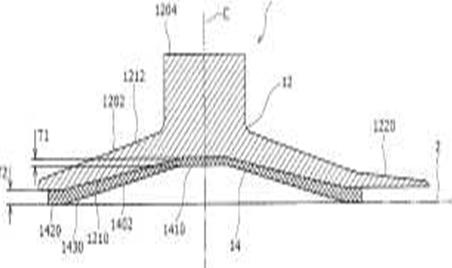

This place covers:

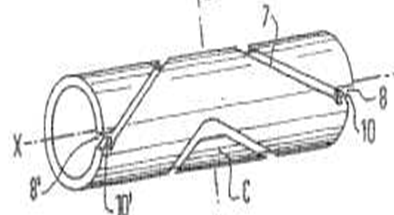

Illustrative example of the closing member G being maneuverable remotely with cable C.

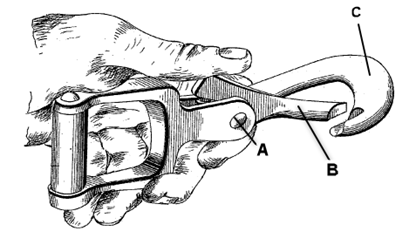

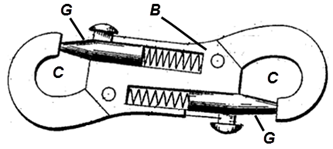

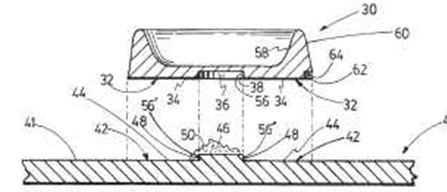

This place covers:

Illustrative example shows closing member B pivoting about axis A which lies in the plane of hook C.

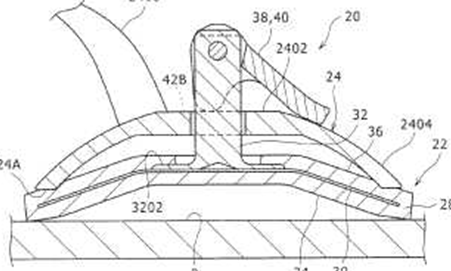

This place covers:

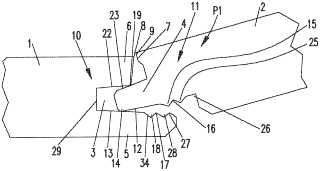

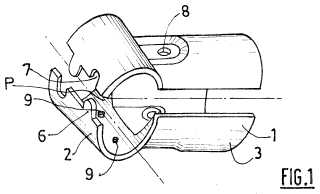

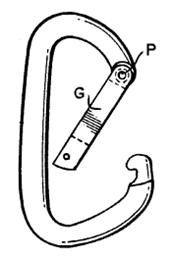

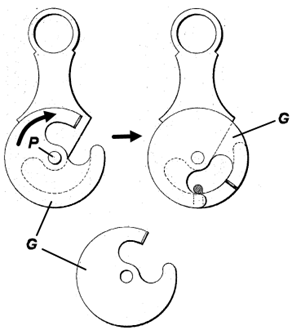

The following figure shows an example of a hook with closing member G which pivots about perpendicular axis P.

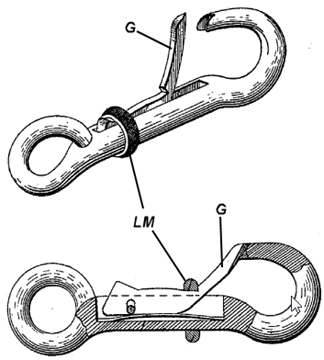

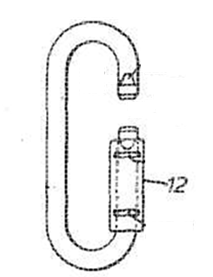

This place covers:

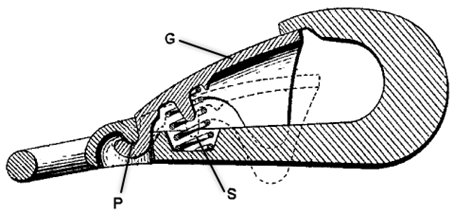

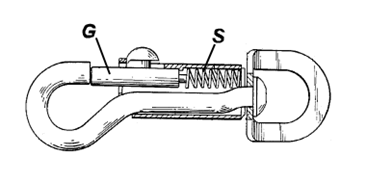

Illustrative example of a hook with spring S which biases closing member G about pivot P.

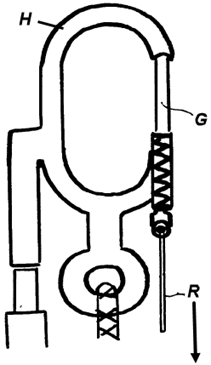

This place covers:

Illustrative example of a hook with coil spring S which biases closing member G about pivot P.

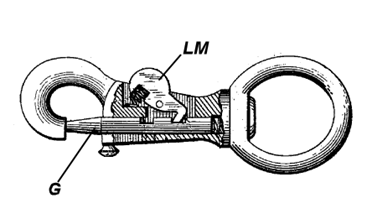

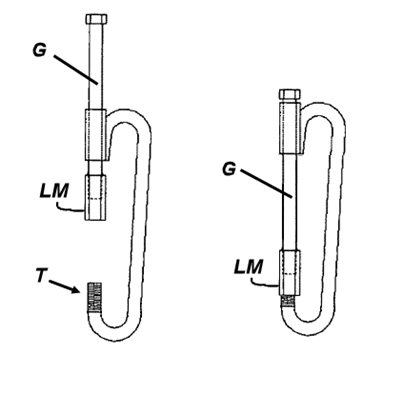

This place covers:

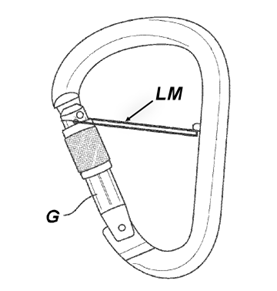

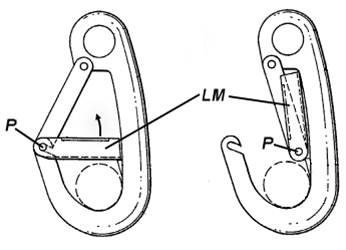

The exemplary figure below shows a hook where the position of closing member G is prevented from moving by locking means LM.

This place covers:

The exemplary figure below shows locking means LM being pivotally connect at pin P.

This place covers:

Illustrative example of a hook where locking means LM is slidably mounted to lock pivoting member G.

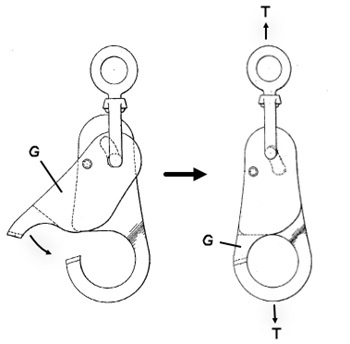

This place covers:

Illustrative example of a hook where closing member G closes when tension T is applied to the hook as shown.

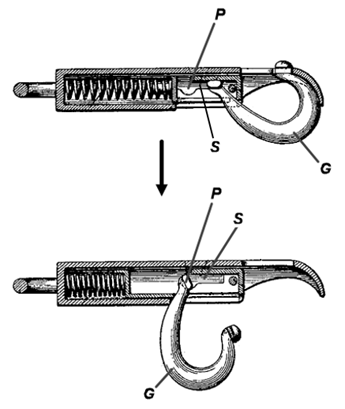

This place covers:

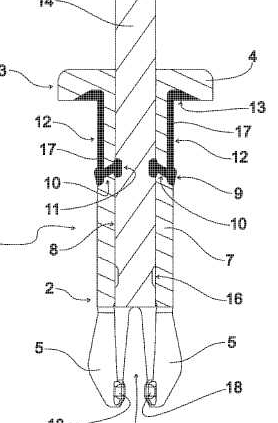

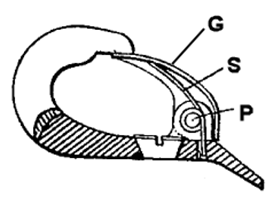

The figure below is an illustrative example which falls within the scope of this subgroup. In the figure, the closing member G is slidable along slot S which is relative to pivot point P.

This place covers: