CPC Definition - Subclass F02D

This place does not cover:

Vehicle fittings, acting on a single sub-unit only, for automatically controlling vehicle speed | |

Conjoint control of vehicle sub-units of different type or different function, road vehicle drive control systems for purposes other than the control of a single sub-unit |

Attention is drawn to the following places, which may be of interest for search:

Cyclically operating valves for combustion engines | |

Controlling combustion engine lubrication | |

Cooling internal combustion engines | |

Controlling gas-turbine plants, jet-propulsion plants or combustion-product engine plants, see the relevant subclasses for these plants, e.g. | |

Supplying combustion engines with combustible mixtures or constituents thereof, e.g. carburettors, injection pumps | |

Starting of combustion engines | |

Controlling of ignition | |

Automatic controllers for prime movers, in general |

In this place, the following terms or expressions are used with the meaning indicated:

Engine | "engine" means a device for continuously converting fluid energy into mechanical power. Thus, this term includes, for example, internal-combustion piston engines, but it excludes single-stroke devices |

This place covers:

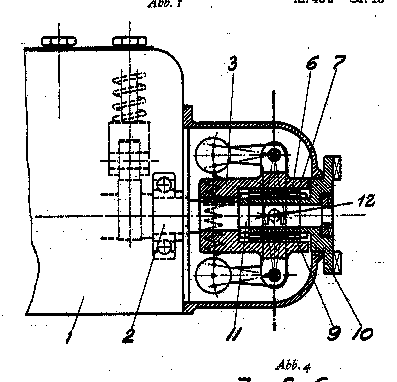

Controlling fuel-injection pumps, e.g. of the high pressure injection type and pertains in particular to mechanical controlling and linkage of mechanically controlled fuel injection pumps.

This place does not cover:

Controlling low-pressure fuel injection, i.e. where the air-fuel mixture containing fuel thus injected will be substantially compressed by the compression stroke of the engine, by means other than controlling only an injection pump |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Peculiar to engines characterised by their use of non-liquid fuels, pluralities of fuels, or non-fuel substances added to the combustible mixtures | |

Peculiar to supercharged engines |

Attention is drawn to the following places, which may be of interest for search:

Controlling fuel-injection electrically | |

Cyclically operating valves for combustion engines | |

Controlling combustion engine lubrication | |

Cooling internal combustion engines | |

Controlling gas-turbine plants, jet-propulsion plants, or combustion-product engine plants see the relevant subclasses for these plants | |

Supplying combustion engines with combustible mixtures or constituents thereof, e.g. carburettors, injection pumps | |

Control of modern common rail fuel pumps | |

Starting of combustion engines | |

Controlling of ignition | |

Automatic controllers for prime movers, in general |

This place does not cover:

Not restricted to adjustment of injection timing, e.g. varying amount of fuel delivered |

Attention is drawn to the following places, which may be of interest for search:

Rotary distributor pumps | |

Adjustment of injection timing by adjustment of pumping elements |

This place covers:

E.g. using a centrifugal governor to adjust the angular timing of pump shaft.

This place covers:

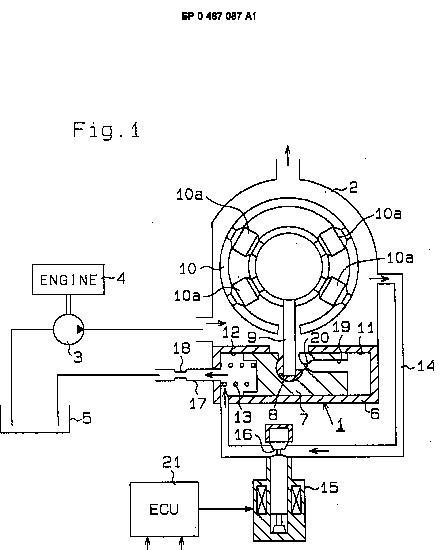

Hydraulic adjustment of injection timing. E.g. using a hydraulic phase shifter device between pump and pump drive or angularly adjusting a cam profile to adjust the timing.

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Peculiar to engines characterised by their use of non-liquid fuels, pluralities of fuels, or non-fuel substances added to the combustible mixtures | |

Peculiar to supercharged engines |

Attention is drawn to the following places, which may be of interest for search:

Cyclically operating valves for combustion engines | |

Controlling combustion engine lubrication | |

Cooling internal combustion engines | |

Supplying combustion engines with combustible mixtures or constituents thereof, e.g. carburettors, injection pumps | |

Low pressure fuel-injection apparatus | |

Starting of combustion engines | |

Controlling of ignition |

Documents disclosing controlling the feeding of liquid fuel from storage containers to carburetors or fuel-injection apparatus are normally classified in F02D 33/003.

This place does not cover:

Control of fuel injection peculiar to engines characterised by their use of non-liquid fuels, pluralities of fuels, or non-fuel substances added to the combustible mixtures | |

Control of supercharged engines | |

Electric fuel-injection control |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Peculiar to engines characterised by their use of non-liquid fuels, pluralities of fuels, or non-fuel substances added to the combustible mixtures | |

Peculiar to supercharged engines |

Attention is drawn to the following places, which may be of interest for search:

Cyclically operating valves for combustion engines | |

Controlling combustion engine lubrication | |

Cooling internal combustion engines | |

Supplying combustion engines with combustible mixtures or constituents thereof, e.g. carburettors, injection pumps | |

Starting of combustion engines | |

Controlling of ignition | |

Automatic controllers for prime movers, in general |

Attention is drawn to the following places, which may be of interest for search:

Apparatus for injecting fuel by means of high pressure gas | |

Apparatus for low pressure fuel injection by compressed air |

This place covers:

Valves for controlling the air or air and fuel admission into or the exhaust out of the engine and the arrangement of such valves in intake or exhaust conduits.

General aspects of valves can be found in F16K

This place does not cover:

Lift valves | |

EGR valves | |

Lift valves in general |

Attention is drawn to the following places, which may be of interest for search:

Valves in general |

In this place, the following terms or expressions are used with the meaning indicated:

Pivotally-mounted flaps | Flaps rotating around an axis |

In patent documents, the following words/expressions are often used as synonyms:

- "butterfly valve" and "pivotally-mounted flap valve"

This place covers:

Hand- and/or foot pedal operated engine control initiation means and control linkages between the hand and/or foot pedal and the controlled device, e.g. throttle valve, carburettor or fuel injector. The control linkage can be mechanical, e.g. combined with power drive assistance, or non-mechanical, e.g. hydraulic linkage e.g. combined with power drive assistance.

This place does not cover:

Engine control initiation means for reversing |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Arrangement or mounting of prime-mover control devices in vehicles |

Attention is drawn to the following places, which may be of interest for search:

Controlling members, e.g. knobs or handles; assemblies or arrangements thereof; |

Documents disclosing electronic engine control initiation means are normally classified in F02D 11/10.

In this place, the following terms or expressions are used with the meaning indicated:

Power drive assistance | Drive assistance for hand or foot |

In patent documents, the following words/expressions are often used as synonyms:

- "prime mover" and "engine"

This place covers:

Mechanical aspects/construction of electric throttles; Links between throttle and pedal as long as it concerns the electrical aspects, or the mechanical linking of the motor to the rest, e.g. clutch etc.

This place covers:

Throttles characterised by the function of linking demand to actuation using:

- Different response curves between pedal and throttle, combination of pedal (or cable) displacement and motor movement, free gaps

- Torque control, i.e. conversion accelerator position -> torque demands -> actuator commands

This place covers:

Detection of throttle position or accelerator position

This place covers:

Controlling the engine output power by varying inlet or exhaust valve operating characteristics, e.g. timing. The inlet and exhaust valves within an internal combustion engine are used to control the flow of the intake and exhaust gases into and out of the combustion chamber. The timing, duration and lift of these valve has a significant impact on engine performance. In a standard engine, the valve events are fixed, so performance at different loads and speeds is always a compromise between driveability, e.g. power and torque, fuel economy and emissions. An engine equipped with a variable valve actuation system is freed from this constraint, allowing performance to be improved over the engine operating range.

Attention is drawn to the following places, which may be of interest for search:

Electrical control of supply of combustible mixtures | |

Modifications of valve gear |

In this place, the following terms or expressions are used with the meaning indicated:

Miller-Atkinson cycle | Combustion cycle characterised by extending the stroke and raising the expansion and compression ratio. Premature detonation is overcome by using valve timing variations to make the effective compression and expansion strokes asymmetrical. |

In patent documents, the following abbreviations are often used:

VVT | Variable valve timing |

SOHC | Single overhead camshaft |

DOHC | Double overhead camshaft |

EGR | Exhaust gas recirculation |

This place covers:

Varying compression ratio to adjust internal combustion engine cylinder compression ratios. For automotive use this needs to be done dynamically in response to the load and driving demands. Higher loads require lower ratios to be more efficient and vice versa. Variable compression engines allow for the volume above the piston at TDC to be changed.

Other engines, F02B 75/00; varying inlet or exhaust valve operating characteristics, F02D 13/00; electrical control of supply of combustible mixtures, F02D 41/00.

Attention is drawn to the following places, which may be of interest for search:

Modifying valve-gear | |

Engines with variable distances between pistons at top dead-centre positions and cylinder heads. |

In this place, the following terms or expressions are used with the meaning indicated:

TDC | Top Dead Centre |

This place covers:

Controlling engines by cutting out individual cylinders; Rendering engines inoperative or idling. Cylinder deactivation is used to reduce the fuel consumption and emissions of an internal combustion engine during light-load operation. In typical light-load driving the driver uses only around 30 percent of an engine's maximum power. In these conditions the throttle valve is nearly closed and the engine needs to work to draw air. This causes an inefficiency known as pumping loss. Some large capacity engines need to be throttled so much at light load that the cylinder pressure at top dead centre is approximately half that of a small 4-cylinder engine. Low cylinder pressure means low fuel efficiency. The use of cylinder deactivation at light load means there are fewer cylinders drawing air from the intake manifold, which works to increase its air pressure. Operation without variable displacement is wasteful because fuel is continuously pumped into each cylinder and combusted even though maximum performance is not required.

Control systems for hybrid vehicles: B60W 20/00;

Controlling engines driving vehicles: F02D 29/00;

Starting engines: F02N 11/00.

This place does not cover:

Varying inlet or exhaust valve operating characteristics | |

Cutting out cylinders by varying inlet or outlet valve operating characteristics | |

Rendering engine inoperative or idling by varying inlet or outlet valve operating characteristics |

Attention is drawn to the following places, which may be of interest for search:

Engines with air storage chambers | |

Piston pumps for charging |

This place covers:

Mechanical and control aspects of engines using gaseous fuels, solid fuels or a combination of gaseous and non gaseous fuels. The latter simultaneously or non simultaneously used. Important aspects of the group are: configuration and control of the fuel supply system, special operating modes depending on the type of fuel and measuring and estimating of the fuel and engine parameters.

Control of engines using non-liquid fuels, F02D 41/0025

This place does not cover:

Controlling engines being supplied with gaseous non-fuel substances | |

Electronic control of engines using non-liquid fuels |

Attention is drawn to the following places, which may be of interest for search:

Engines characterised by operating on gaseous fuels | |

Apparatus for supplying engines with gaseous fuels |

In this place, the following terms or expressions are used with the meaning indicated:

Non-fuel gas | Oxygen, exhaust gas etc. |

Attention is drawn to the following places, which may be of interest for search:

Control of dual fuel engines with at least on fuel being gaseous | |

Electrical control of the supply of the combustible mixture for controlling engines with gaseous fuels | |

Apparatus, or control parts thereof, for mixing gas and air |

This place covers:

The group covers the control of engines, which are supplied with non-fuel substances or anti-knock agents. This includes controlling engines wherein engines are supplied with water.

Attention is drawn to the following places, which may be of interest for search:

Apparatus, or control parts thereof, for delivering such substances or agents | |

Engine-pertinent apparatus for adding non-fuel substances or small quantities of secondary fuel to combustion-air, main fuel or fuel-air mixture | |

Apparatus for adding water to combustion-air, main fuel or fuel-air mixture |

This place covers:

Control systems in which oxygen or secondary air and/or exhaust or other non-fuel gases are being fed to the engine in order to increase the engine output power and/or to clean the exhaust gases.

Engine-pertinent apparatus for adding non-fuel substances or small quantities of secondary fuel to combustion-air, main fuel, or fuel-air mixture, F02M 25/00;

Electrical control of supply of combustible mixture or its constituents, F02D 41/00; Methods of operating engines involving adding non-fuel substances or anti-knock agents to combustion air, fuel or fuel-air mixtures of engines, F02B 47/00.

This place does not cover:

Methods and electrical aspects of controlling exhaust gas recirculation |

Attention is drawn to the following places, which may be of interest for search:

Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, fuel gases, aerosols. |

In this place, the following terms or expressions are used with the meaning indicated:

Non-airborne oxygen | Oxygen not from the air |

Secondary air | Air not entering main intake |

Attention is drawn to the following places, which may be of interest for search:

Circulation of exhaust gas in oxygen-fed engines |

Attention is drawn to the following places, which may be of interest for search:

Apparatus, or control parts thereof, for delivering secondary air |

This place covers:

Control systems for controlling the power output or rotational speed of the engine by other means than the throttle valve. In case of a supercharged engine it is possible for the power output or rotational speed to be additionally influenced for example by way of a controllable valve which is arranged parallel to the compressor in the induction track of the engine.

Engines characterised by provision of pumps for charging or scavenging, F02B 33/00; engines characterised by provision of pumps driven at least for part of the time by exhaust, F02B 37/00.

This place does not cover:

Electrical control of supply of combustible mixture or its constituents |

Attention is drawn to the following places, which may be of interest for search:

Component parts, details, or accessories relating to, driven charging or scavenging pumps, not provided for in groups F02B 33/00 - F02B 37/00 |

In this place, the following terms or expressions are used with the meaning indicated:

Supercharged | Turbocharged |

In patent documents, the following words/expressions are often used as synonyms:

- "supercharged" and "turbocharged "

This place covers:

Methods and devices for controlling engine arrangements comprising at least a first and a second internal combustion engine, wherein each engine comprises a crankshaft and at least one cylinder with a piston connected to said crankshaft, a controllable clutch arranged between the crankshafts, an engine control unit (ECU) for controlling the first and second engine and sensors for monitoring at least one operating parameter for the said engines connected to the engine control unit.

Propulsion units for ships, B63H 21/00; propulsion units for trains, B61C 11/00; power plants, F01K 7/00; transmitting power from propulsion power plant to

propulsive elements, B63H 23/00.

This place does not cover:

Cutting out individual cylinders | |

Controlling engines, such controlling being peculiar to the devices driven thereby | |

Conjoint control of vehicle sub-units of different type or different function |

Attention is drawn to the following places, which may be of interest for search:

Combinations of two or more engines, not otherwise provided for |

In this place, the following terms or expressions are used with the meaning indicated:

Conjoint control | Control of 2 or more cooperating engines |

Master and slave engine | Primary and secondary engine |

This place covers:

Engines that can be operated in two directions, i.e. of which the crankshaft can turn in two directions during running of the engine. These engines require amongst others displaceable camshafts. The reversing requires a control program during which several parameters of the engine, e.g. speed, throttle- position, fuel supply should be controlled.

Ship propulsion units, B63H 21/00.

This place does not cover:

Toothed gearings for reversing rotary motion |

Attention is drawn to the following places, which may be of interest for search:

Use of propulsion power plants or units on vessels | |

Modifications of valve-gear to facilitate reversing | |

Other engines |

This place covers:

Programme-control of engines. Although operator control is suitable for automobile engines, there are many systems, such as standby emergency electric power systems, where this type of control is impractical and expensive. For these applications, automatic program control systems have been devised which perform necessary engine control functions without operator attendance. Programme-control is also used in remote starting systems for automobile engines for example heating up the passenger cabin.

Attention is drawn to the following places, which may be of interest for search:

Automatic vehicle control systems | |

Starting of engines by means of electric motors | |

Programme-control in general | |

Traffic control systems for road vehicles |

F02D 13/00 – Controlling the engine output power by varying inlet or exhaust valve operating characteristics, e.g. timing

F02D 35/00 – Controlling engines, dependent on conditions exterior or interior to engines

F02D 41/00 – Electrical control of supply of combustible mixture or its constituents

F02D 43/00 – Conjoint electrical control of two or more functions

This place covers:

Control systems characterised by the device driven by the engine. This device can be for example a vehicle, a pump or an electric generator.

Electrical control of internal combustion engines, F02D 39/00- F02D 45/00; positive displacement machines for liquids, F04B/00; controlling electric generators, H02P.

This place does not cover:

Arrangement or mounting of plural diverse prime-movers for mutual or common propulsion, e.g. hybrid propulsion systems comprising electric motors and internal combustion engines | |

Conjoint control of vehicle sub-units of different type or different function | |

Control systems specially adapted for hybrid vehicles |

Attention is drawn to the following places, which may be of interest for search:

Propellers | |

Control e.g. of pump delivery, or of pump pressure, or safety measures for, machines, pumps, or pumping installations, not otherwise provided for. | |

Arrangements for controlling electric generators for the purpose of obtaining a desired output |

This place covers:

Mechanical governors, e.g. Watt type

This place covers:

Electrical control of engine rotation speed, e.g. by including a speed feedback loop

This place covers:

Controlling the air supply, mainly by changing the throttle position, in order to control the engine speed

This place does not cover:

Vehicle cruise control |

This place covers:

Throttle opening control after engine speed in idle mode; also setting of idle speed

This place covers:

Control whereby an electric actuator urges the throttle, or the throttle lever from its closed position

This place covers:

Control whereby in a bypass the air flow must be controlled after engine speed and throttle position

This place covers:

Control whereby throttle is used to limit engine speed.

This place covers:

Rotation speed control by fuel amount, e.g. Diesel governors

This place covers:

Feedback control of idling speed using fuel supply

This place covers:

Controlling the feeding of liquid fuel from storage containers to carburettors or fuel-injection apparatus or the controlling the delivery of combustion air.

Electrical control of supply of combustible mixtures, F02D 41/00; apparatus or systems for feeding liquid fuel from storage containers to carburettors or fuel-injection apparatus, F02M 37/00.

This place does not cover:

Controlling air supply using exhaust gas sensors | |

Controlling fuel supply using exhaust gas sensors |

Attention is drawn to the following places, which may be of interest for search:

Control of electrical fuel pumps | |

Control of fuel flow to a common rail |

In this place, the following terms or expressions are used with the meaning indicated:

Storage containers | Fuel tanks |

In patent documents, the following words/expressions are often used as synonyms:

- "common rail" and "fuel rail"

This place covers:

Controlling engines using information, e.g. sensor signals, about conditions exterior or interior to engines

This place covers:

Position feedback on an electrical actuator.

This group contains engine controls using an exhaust gas sensor. Engine control using a gas sensor for sensing composition of combustion gases is classified in F02D 41/1438.

This place covers:

Control of air supply as a function of an air/fuel sensor signal

This place covers:

Fuel supply control after an air/fuel sensor.

This place covers:

Carburettor control after an air/fuel sensor

This place covers:

Controlling the emulsifying air only wherby most of the carburettors have a sub carburettor and it is the air/fuel mixture made in this sub carburettor (easier to control) which is drawn into the main venturi of the carburettor.

This place covers:

Fuel flow control via a valve in series in the fuel alimentation of the said sub carburettor or via a valve controlling the supply of air above the constant level fuel reservoir. If this valve is closed, less fuel can be sucked into the engine.

This place covers:

Fuel flow using variable venturi carburettors, i.e. a special type of horizontal carburettor still used in the 80s.

This place covers:

Control according to parameters interior to the combustion chamber that may be used to influence this combustion

This place does not cover:

Knock control using ignition timing | |

Ignition timing control based on combustion pressure |

This place does not cover:

Ionic sensor for testing of ignition |

If the sensor is located in the combustion gases then classify in F02D 35/021 and F02D 41/1444 .

This place does not cover:

Optical sensors in the exhaust system |

This place covers:

Conjoint control using ignition timing and at least another parameter, e.g. air amount or fuel injection.

Attention is drawn to the following places, which may be of interest for search:

Ignition control per se | |

Automatically advancing or retarding ignition combined with electronic control of other engine functions, e.g. fuel injection |

This place covers:

Non-electrical control of four- or two-stroke engines; of engines adding the fuel substantially at the end or before the compression stroke; of free piston engines.

Controlling engines, dependent on conditions exterior or interior to engines, not otherwise provided for F02D 35/00

This place does not cover:

Controlling engines, such controlling being peculiar to the devices driven thereby | |

Two stroke engines | |

Rotary engines | |

Free piston engines |

Attention is drawn to the following places, which may be of interest for search:

Other types of engines, e.g. double acting engines |

In this place, the following terms or expressions are used with the meaning indicated:

Free piston engines | Engines without rotary main shaft |

In patent documents, the following words/expressions are often used as synonyms:

- "non-electrical control" and "mechanical control"

This place covers:

Electrical or electronical control of combustion engines

Non-electrical aspects of electrically controlled devices are covered by

groups F02D 1/00 - F02D 39/00 or by subclass F02M;

- both electrical and non-electrical aspects of electrically controlled devices

are covered by groups F02D 1/00 - F02D 39/00 or by subclass F02M

This place does not cover:

Conjoint electrical control in which the control of air amount follows the control of fuel amount | |

Control of engine starters | |

Electrical control of engine ignition timing |

Attention is drawn to the following places, which may be of interest for search:

Conjoint control of vehicle sub-units including control of combustion engine | |

Detection of engine knocking | |

Detection of engine misfires | |

Gas sensors, e.g. oxygen sensors |

No classification at main group level F02D 41/00. Use residual sub-group F02D 41/3005 instead.

In this place, the following terms or expressions are used with the meaning indicated:

EGR | Exhaust gas recirculation |

In patent documents, the following abbreviations are often used:

VVT | Variable valve timing |

This place covers:

Control of intake air amount, e.g. by using:

Throttle

Swirl throttle (Dralldrossel) on the side of intake pipe or in a second special intake pipe. It makes air flow to be twisted at low speeds to promote homogenization between air and fuel mist.

Variable valve timing and/or lift

Attention is drawn to the following places, which may be of interest for search:

VVT |

Attention is drawn to the following places, which may be of interest for search:

Mechanical control of turbocharged injected engine | |

Control of turbochargers and superchargers per se |

This place covers:

Controlling engines running with:

- non-liquid fuels- multiple fuels, e.g. different octane rates, alcohol + gasoline- additives added to the fuel/air (for catalyst, for enhancing burning (pure O2, N2O), etc)- alcohol, methanol and problems linked to the fuel quality/property

This place does not cover:

Gas engines | |

Control using fuel type or fuel quality sensor | |

Control using fuel type or fuel quality estimation |

Attention is drawn to the following places, which may be of interest for search:

More mechanical aspects of control | |

Corresponding arrangements |

This place covers:

Control of the supply of fuel vapours which are normally drawn from a canister which adsorbs fuel vapours generated in the fuel tank

Attention is drawn to the following places, which may be of interest for search:

System arrangements for fuel vapour purging | |

Fuel vapour system diagnosis |

This place covers:

Engine conditions are taken into account and purging is controlled

This place covers:

Purging is used for a particular effect on the engine, e.g. to warm-up catalyst

This place covers:

Control of purging to achieve conditions which are suitable for engine Diagnosis. - If the expected effect due to purging does not occur, failure is determined- Switch off of purging to prevent influence on diagnosis

This place does not cover:

Diagnosis of purge control systems |

This place covers:

Details specific to the control of the purge valve itself

This place covers:

Control of the engine mixture is adapted to purging taking place

This place covers:

Details specific to the estimation, calculation or any kind of determination of the purge quantity

This place covers:

Electrical control of exhaust gas recirculation (EGR)

Attention is drawn to the following places, which may be of interest for search:

Mechanical control of EGR | |

Constructional aspects of EGR circuits | |

Temperature control using EGR cooler | |

Diagnosis of EGR |

This place covers:

Feedback control using EGR for all parameter not directly related to EGR. This might include:

intake amount amount

intake manifold pressure

air/fuel ratio

combustion timing

engine roughness

This place does not cover:

Internal EGR rate or amount feedback | |

External EGR rate or amount feedback |

The feedback parameter should be classified in the corresponding groups as well

This place covers:

Special control of EGR for non-ordinary operating conditions, e.g.:

- engine diagnosis- during fuel cut- Exhaust catalyst regeneration

This place covers:

EGR control according to or during engine operation with specific combustion modes, e.g. special engines with two EGR modes on both sides of the peak of smoke which appears when the EGR rate is increased in a diesel engine or HCCI without anything specific to EGR control

Feedback control of EGR to control combustion timing e.g. in HCCI mode; F02D 41/0052

Attention is drawn to the following places, which may be of interest for search:

Combustion modes |

This place covers:

Exhaust gases are redirected into the combustion chamber or kept as residual gases during positive or negative valve overlap

Attention is drawn to the following places, which may be of interest for search:

Valve overlap control | |

Arrangements for internal EGR |

This place covers:

Determination of the EGR rate or residual gas amount remaining in the cylinder when internal EGR is used

Only as additional information if parameter is only mentioned without details on how to determine it

This place covers:

something specific to external EGR, e.g. considering transport delays or when using low pressure and high pressure EGR circuits

This place covers:

Determination of the EGR rate in external EGR circuits

Only as additional information if parameter is only mentioned without details on how to determine it

Attention is drawn to the following places, which may be of interest for search:

EGR valve position sensors |

This place covers:

Operation of individual engine cylinders with different operating parameters, e.g. different fuel amounts or air amounts

Attention is drawn to the following places, which may be of interest for search:

Cylinder individual control of ignition timing |

Multiple classification for the corresponding actuator(s) applies

This place covers:

Operation of cylinder groups with different operating parameters, e.g. first cylinder group operating lean and second cylinder group operating rich to achieve heating or regeneration of catalysts

This group is not used for deactivation of cylinder banks which should be classified in F02D 41/0087 only

This place covers:

Control to equalise engine operating parameter for all cylinders

There might be some overlap with F02D 41/1498, however F02D 41/1498 covers at least measuring/detecting roughness per se, control according to roughness when all cylinders are controlled in the same way (e.g. idling/lean rough limit). If there is roughness detection and individual control then both groups should be used. Some overlap with engine roughness

This place covers:

Selective activation or deactivation of cylinders: every cylinder is fed with an optimal fuel quantity for an optimal combustion or with no fuel at all. The engine power also being controlled by the number of fed cylinders and not by the throttle and the air/fuel per cylinder.

This place does not cover:

Complete fuel-cut in all cylinders during deceleration |

This place covers:

Detection of engine crank angle position and generation of synchronisation signals, i.e. information about which cylinder is in which cycle (intake, compression, expansion or exhaust cycle).

Attention is drawn to the following places, which may be of interest for search:

Position for ignition |

This place covers:

Detection and measurement of engine speed.

Attention is drawn to the following places, which may be of interest for search:

Rotation speed measurement in general |

This group should not be used.

This place covers:

Generator, pump or PTO (e.g. agricultural Power Take Off) engines with an externally needed regulated speed control.

This place does not cover:

Vehicle cruise speed control |

This place covers:

Control according to particular conditions exterior to the engine, e.g.

- positional information from navigation systems

- road conditions

- engine control in relation with other vehicle sub-systems

The conditions exterior to the engine should also be classified in F02D 2200/70.

This place covers:

Control of the engine in relation with gearbox and/or clutch

Attention is drawn to the following places, which may be of interest for search:

More general aspects of driveline control, conjoint control of driveline elements |

This place covers:

Special control during the gear shift. Usually torque or speed control to target values

Attention is drawn to the following places, which may be of interest for search:

Conjoint control to improve gear change |

This place covers:

Control of engine in order to achieve specific effect on exhaust gas treatment device, e.g. regeneration or warming-up

Borderline between F02D 41/0235 and F01N is defined based on where the intervention to achieve heating or regeneration takes place:

- F02D 41/0235 if the engine control is affected

- F01N if the control takes place in the exhaust, e.g. by injection into the exhaust pipe or electrical heating for catalysts

This place covers:

Engine control to increase the temperature of an exhaust gas catalyst or filteralso given for regeneration, when method for temperature increase is important

This place covers:

Methods for raising catalyst temperature wherein additional heat is generated by combustion inside cylinder, e.g. by early post injection and delaying (main) injection timing.

This place covers:

Methods for raising catalyst temperature wherein additional heat is generated in exhaust pipe or on catalyst, e.g. by late post injection with surplus of oxygen from same/other cylinder, or by driving cylinders with different air/fuel ratios so that exhaust gases from these cylinders mix in exhaust pipe.

This place covers:

Engine control without special control according to the type of catalyst

Parameters characterising the state of the exhaust gas treating apparatus should be classified in F02D 2200/08 as well. F02D 2200/0806-F02D 2200/0811 are of particular importance for NOx traps.

Parameters characterising the state of the exhaust gas treating apparatus should be classified in F02D 2200/08 as well. F02D 2200/0818 is of particular importance for the desulfurisation of NOx traps.

Attention is drawn to the following places, which may be of interest for search:

Regenerating particle filter with means in exhaust; |

Parameters characterising the state of the exhaust gas treating apparatus should be classified in F02D 2200/08 as well. F02D 2200/0812 is of particular importance for the regeneration of particle filters.

This place covers:

Control of engine air/fuel ratio so that amount of oxygen that is stored on (three-way)-catalyst with oxygen storage capacity meets target value.

Parameters characterising the state of the exhaust gas treating apparatus should be classified in F02D 2200/08 as well. F02D 2200/0814 and F02D 2200/0816 are of particular importance for this group.

This place covers:

Control for stopping the engine or during the engine stopping period

Attention is drawn to the following places, which may be of interest for search:

Stopping of diesel engines |

This place covers:

Control combining partial pressures of vapour fuel, fresh air, recycled exhaust gas, less deposited fuel to calculate real air/fuel ratio taken in each cylinder

Control using models to determine fuel film on intake and cylinder walls

This place covers:

Corrections during engine start or warm-up.

This place covers:

Corrections during engine start linked to a delay or timer.

This place covers:

Corrections during engine start.

This place covers:

Engine control during engine start when engine is cold, e.g. increase of fuel injection amount to compensate increased fuel demand.

This place covers:

Engine start when engine is warm or immediate restart, e.g. after stall or during engine start/stop control

This place covers:

Purely electrical chokes as well as mechanical automatic chokes where the bimetallic spiral or wax actuator is electrically heated when the engine has started.

This place covers:

Warming-up measures, e.g. fast idle to accelerate warming-up

This place covers:

Engine control during idling

Attention is drawn to the following places, which may be of interest for search:

Feedback control of idling speed |

This place covers:

Engine control during idling considering external loads, e.g.

- air condition

- generators

- power steering

This place covers:

Engine control during acceleration, e.g. increase of fuel injection amount to meet increased demand.

This place covers:

Increase of the number of injectors in intake low pressure injection to increase fuel flow

This place covers:

Control with extra fuel pulse at start of acceleration in addition to ordinary fuel pulses which are sequentially injected at regular intervals

This place covers:

The fuel being cut off in all cylinders during deceleration as long as there is no serious reason to restart.

Attention is drawn to the following places, which may be of interest for search:

Selective activation/deactivation of some, but not all cylinders |

This place covers:

When the engine is decelerating it is necessary to restart the engine before idle speed is reached to avoid stalling if injection is restarted too late. Transitional measures may also be taken before. Special control to bring back catalyst to normal working range

This place covers:

Documents giving details on the feedback loop should be put in this group and groups when it is not a PID or some basic controller, then prefer to classify in F02D 41/1473 and F02D 41/1477

Attention is drawn to the following places, which may be of interest for search:

Classifiy as well according to what is controlled or what is measured., e.g. F02D 41/1438, F02D 41/16

This place covers:

The parameters/coefficients of the controller are set/tuned on-line according to the output of the system (there must be a feedback). Also called Self-Tuning regulator.

Not to be confused with "learning" where some values are stored to be re-used. This should be classified in F02D 41/2429. A controller having different coefficients stored in a table and where the coefficients are chosen according to operating conditions should be classified in F02D 2041/1422.

Attention is drawn to the following places, which may be of interest for search:

Dithering for learning in air/fuel ratio control |

This place covers:

Control according to a characteristic of the combustion gases.

This place covers:

Use of a gas concentration sensor in the intake manifold, e.g. to measure the O2/fuel ratio before the mixture enters the combustion chambers on order to avoid the two-revolutions delay.

This place covers:

Multiple sensor arrangements in the exhaust system, e.g. one sensor before the catalyst converter and one after to check its functioning

Downstream sensor might be used for tuning the air/fuel ratio loop based on the upstream sensor

This place covers:

A sensor is provided for each cylinder group or bank, e.g.in the case of V- or flat engines for example

Attention is drawn to the following places, which may be of interest for search:

Gas sensors in general |

This place covers:

Use of an optical sensor in the exhaust system, e.g. for smoke measurements by evaluating the color/transparency of the exhaust gases.

This place does not cover:

Optical sensors in combustion chamber |

This place covers:

Engine control to achieve an air-fuel ratio deviating from the stoichiometric air/fuel ratio, e.g. by:

- shifting the comparator level- having different rising and descending slopes for the integral or the proportional part of the control- using a linear sensor

This place covers:

Two-states sensors wherein a flow of O2 ions across the porous sensor is simulated by simply sending electrons

This place covers:

Air/fuel ratio control circuits and its components

This place covers:

Air/fuel ratio control with two-state air/fuel ratio sensor wherein the air/fuel ratio sensor signal is compared with a variable reference to have a lambda regulation value different from 1

Adaptation of the comparator value to variation of sensor characteristics, e.g. with temperature or age

This place covers:

Air/fuel ratio control using a plurality of comparators, e.g. by selecting among them according to circumstances, to have a lambda regulation value different from 1.

This place covers:

Control related to the problem caused by the delay between the fuel injection and the sensing of exhaust gas properties due to travel in intake, compression, expansion, exhaust and travel in exhaust. To reduce the generated oscillation in steady some delays are introduced in the regulation loop.

This place covers:

Air/fuel ratio control during particular operating conditions, e.g. during transient conditions.

This place covers:

Deactivation of air/fuel control based on exhaust sensor measurements, e.g. during transitions

This place covers:

Constructional details of the air/fuel control circuit or its componentsAir/fuel ratio sensor input circuits

This place covers:

Control of heating of an exhaust gas sensor to its operating temperature

This place covers:

Detection of abnormalities in the air/fuel ratio feedback system, especially air/fuel ratio sensor failure detection, e.g. by checking its temperature, its resistivity, its speed of reaction or its output voltage range.

Attention is drawn to the following places, which may be of interest for search:

Sensor diagnosis per se |

This place covers:

Control using demanded and measured torque, power etc...

This place covers:

Detection of roughness caused by misfires due to insufficient fuel in the cylinder or due to a too late ignition not able to reach the fuel cloud. Misfire is a lack of combustion. Detection of roughness caused by different contributions of individual cylinders

This place covers:

Direct air mass measurement

Three types of sensors:

- air flaps normally classified here, with a plate pushed away by air dynamic pressure, which moves a potentiometer giving a resistance or a voltage proportionnal to air flow,

- vortex (Karmann) flowmeters which give a frequency directly proportionnal to the mass of air flowing in the pipe see F02D 41/185

- hot wires using a wire which resistance varies with temperature, and which is heated by electric current and cooled by the air passing on it: they also give a voltage, see F02D 41/187.

Computed air flow after manifold depression or throttle opening may also be here with the keyword "parameter measurement - air model"

There are two schools of injection control: the density based injection where an intake vacuum was combined with rpm after eventual temperature correction and the air-mass based injection where a direct air mass flow measure is used.

Attention is drawn to the following places, which may be of interest for search:

Measuring flow, in general |

This place covers:

Circuits for driving injection valves but also gas exchange valves in engines

Attention is drawn to the following places, which may be of interest for search:

Current control in inductive loads in general |

Attention is drawn to the following places, which may be of interest for search:

Drive and control circuit for piezoelectric devices in general |

This place covers:

Devices and methods for diagnosing the engine or specific components, e.g. actuators or sensors

For the diagnosis, the type of the diagnosed actuator or the diagnosed sensor should be classified as well in the corresponding group, e.g.

F02D 41/30 for fuel injectors and F02D 41/1444 for exhaust sensors others than air/fuel ratio sensors

This place does not cover:

This group does not cover diagnosis of:

Electric control linkage, e.g. throttles | |

Air/fuel ratio feedback systems including air/fuel ratio sensor diagnosis | |

Fuel vapour purge systems | |

EGR systems | |

Exhaust gas treatment systems, e.g. catalytic converters |

Attention is drawn to the following places, which may be of interest for search:

Testing of engine ignition | |

Detection of engine knocking | |

Testing of engines on test benches | |

Detection of engine misfires | |

Testing electrical properties on transport means | |

Registering data indicating performance e.g. black boxes |

This place covers:

Choice of addressing parameters for parameter retrieval using maps, e.g. rpm, throttle opening and intake pressure, for example

This place covers:

Maps with only one input parameter

This place covers:

Use of interpolation for operating points which are grid points of the maps

This place covers:

Choice of a logarithmic or an inverted value for a parameter to save memory space

This place covers:

Choice of different tables according to certain criteria, e.g. fuel type, to combustion modes

This place covers:

Learning of engine, sensor or actuator characteristics, e.g. by learning an additive or multiplicative correction value to displace a complete table or a plurality of points of a complete table depending on the results of the learning.

Learning to consider dispersions between actuators or sensors.

Learning of control values to considers changes of engine, sensor or actuator characteristics due to aging

This place covers:

Rewriting part of the controller memory with new data, e.g. during engine inspections, and associated methods

This place covers:

Use of (semi-)permanent memories or using permanent batteries to feed normal memories

This place covers:

Analog or digital circuits in addition to the main control unit, e.g.

- a second control unit, e.g. cylinder control units controlling the actuators associated to one cylinder. - watchdog circuits for monitoring the main CPU

This place covers:

Interface circuit between the control unit and associated elements, e.g. multiplexers or signal processing units between sensors and control unit.

This place covers:

Gasoline engines with a stratified charge, which is usually caused by injection late in the compression stroke and subsequent ignition.

Semi-stratified mode with injections in intake and compression stroke should additionally receive F02D 41/402

This place covers:

Engines with stratified and homogeneous modes

This place covers:

Engine control for engines wherein the mixture is partly or homogeneously premixed and then ignited by compression.

Also called HCCI for homogeneous charge compression ignition.

This place covers:

Means used to trigger the compression-ignition in premixed charge compression ignition engines, e.g.:

- injection of fluids or gases, e.g. water to delay ignition or pressurized air to create pressure wave- activation of a spark-plug to change the mixture composition- change of compression ratio shortly before TDC- laser ignition aid

This place covers:

A second, small injection shortly before the compression stroke TDC to get local air-fuel ratio above self-ignition limit. Said fuel might also be ignited by spark to cause pressure increase and subsequent self-ignition of the homogeneous mixture

Multiple Injections per se, e.g. with a first injection during the negative valve overlap normally called activation injection, should be classified in F02D 41/402

This place covers:

Engines controlled to change from 2-cycle to 4-cycle or 6-cycle mode, e.g. by changing valve actuation and injection frequency

Attention is drawn to the following places, which may be of interest for search:

Engine conversions to change number of cycles |

This place covers:

Special measures to avoid problems during combustion mode transitions, e.g. considering the delay between different actuators

This place covers:

Conditions other than load/speed map for selecting one of a plurality of combustion modesAdaptation of load/speed maps for selecting combustion modes

Control of electrical low pressure pumps in common rail systems only ass additional information

This place covers:

Control of fuel injection into intake manifold which is not air-mass based fuel injection control, i.e. essentially air density control after intake pressure and rpm is classified here

Attention is drawn to the following places, which may be of interest for search:

Control of injection duration after air flow | |

Control of duration after manifold pressure | |

Injection timing | |

Ignition timing |

Attention is drawn to the following places, which may be of interest for search:

Arrangement of ignition distributors |

This place covers:

High pressure fuel injection control, e.g. control of fuel amount of electronically controlled direct injectors.

Attention is drawn to the following places, which may be of interest for search:

Electronic control of mechanical fuel pumps |

This place covers:

Controlling the fuel pressure in the common rail, also setting of target values

This place covers:

This includes both diverting the fuel directly from the high pressure pump and the control of fuel amount directed to the pump inlet via the so-called suction control valves

This place covers:

The amount of fuel supplied to the high pressure pump is (indirectly) controlled using the low pressure fuel pump, fuel pressure regulators in the low pressure part of the common rail system or other elements in the low pressure circuit

This place does not cover:

Suction control valve in the pump inlet |

This place covers:

Common rail pressure control via pressure relief valves.

This place covers:

Short actuations of the injector which cause some fuel to leak out of the injector and return to the fuel tank. These actuations are usually too short to cause fuel injector opening and therefore supply of fuel to engine.

This place covers:

Fuel amount control in in-line injection pumps

This place covers:

Fuel amount control in distributor injector pumps

Attention is drawn to the following places, which may be of interest for search:

Electrical control of exhaust gas treating apparatus per se |

This group covers only conjoint electrical control in which the control of air amount follows the control of fuel amount. Any other conjoint electrical control is not to be classified in F02D 43/00 and its subgroups but in the respective subgroups of F02D 41/00. For example, conjoint control of intake air and fuel injection, where the air control does not follow the fuel control, is covered by groups F02D 41/0002 and F02D 41/30 or their respective sub-groups.

Attention is drawn to the following places, which may be of interest for search:

Electrical control of exhaust gas treating apparatus |