CPC Definition - Subclass B67C

This place covers:

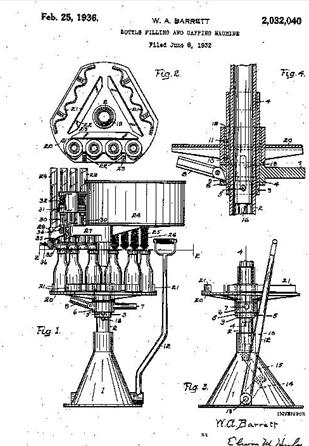

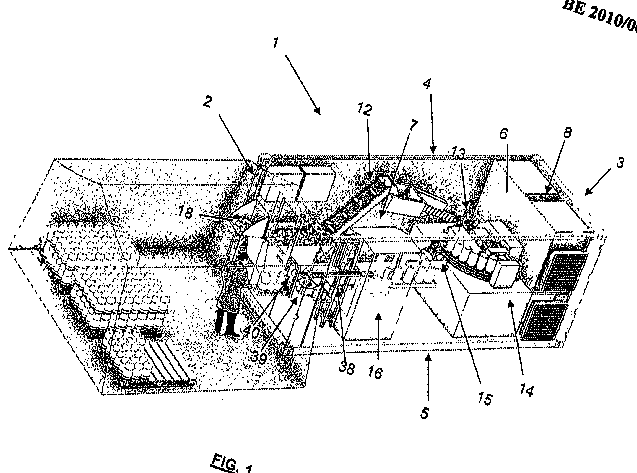

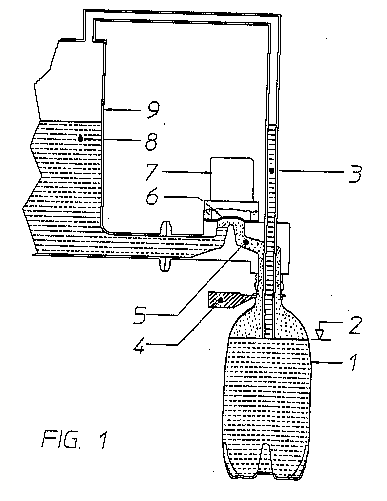

Bottling liquids or semiliquids; Filling jars or cans with liquids or semiliquids using bottling or like apparatus; Filling casks or barrels with liquids or semiliquids (filling containers with liquids or semiliquids using apparatus other than bottling or like apparatus B65B 3/00).

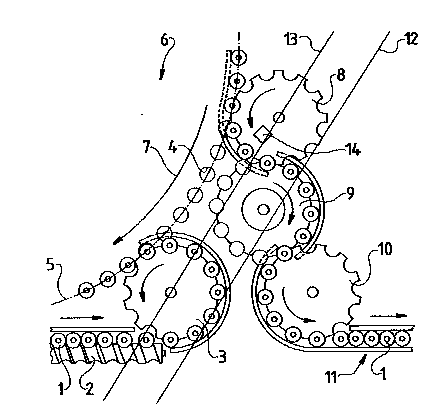

Concurrent cleaning (or sterilizing), filling, and closing of bottles; Processes or devices for at least two of these operations.

Devices for emptying bottles, not otherwise provided for during preparation of alcoholic beverages except beer C12G 1/00.

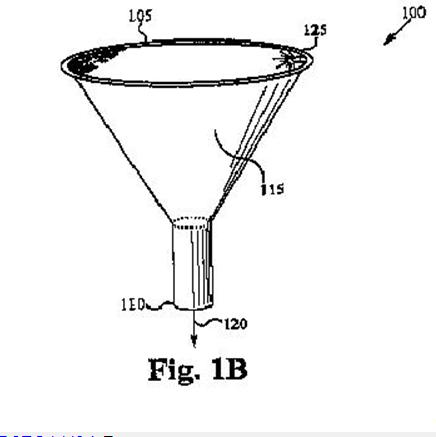

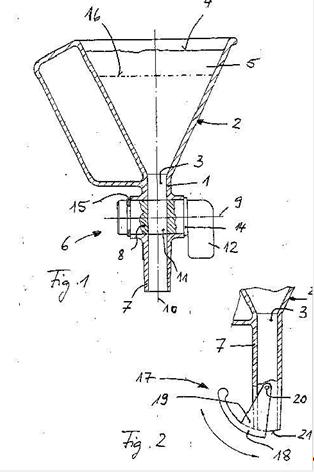

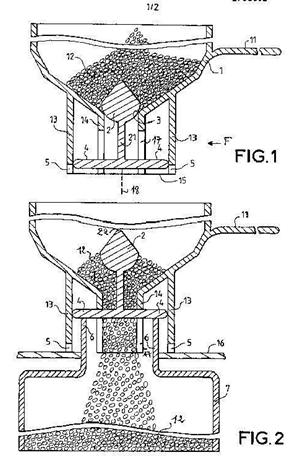

Funnels, e.g. for liquids (filter funnels B01D 29/085; volume flow-meters G01F).

This place does not cover:

Heat treatment of liquids, i.e. pasteurising or sterilising | |

Disinfecting or sterilising as such of objects | |

Mixing of liquids | |

Filling bags, sacks, cartons, pouches, cups, etc. | |

Filling medical containers such as ampoules, vials, syringes or the like | |

Forming and filling of bottles in a mould | |

Devices for transferring samples or any liquids to, in, or from, the analysis apparatus, e.g. suction devices, injection devices |

Attention is drawn to the following places, which may be of interest for search:

Pasteurising or sterilising of liquids | |

Sterilising or disinfecting of objects: | |

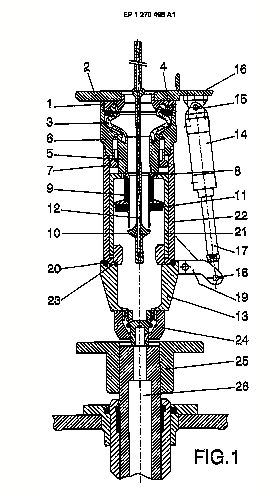

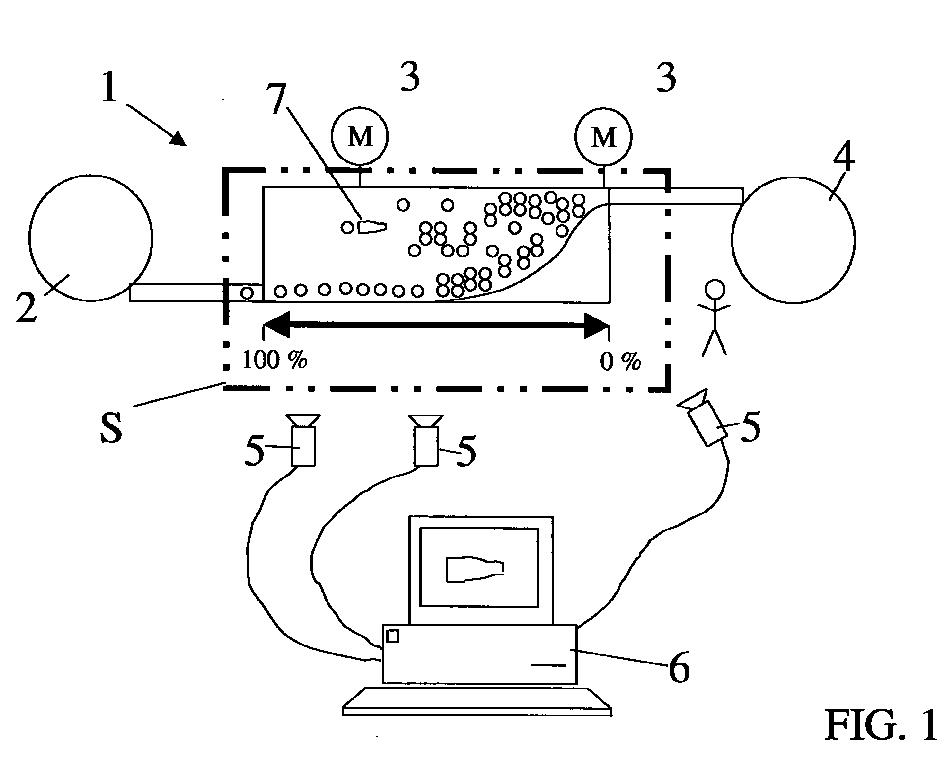

Sorting containers according to e.g. fill level | |

Forming and filling of bottles in a mould | |

Pressurizing filled containers | |

Nozzles with flow cut-off means | |

Preservation of foods in combination with packaging | |

Grippers | |

Safety devices for opening doors or panels | |

Filling of gas bottles | |

Liquid level control in general | |

Measuring volume, or volume flow, in general | |

Weighing of fluids | |

Detection/Investigating the presence of flaws or contamination in a container or its contents | |

Total factory automation | |

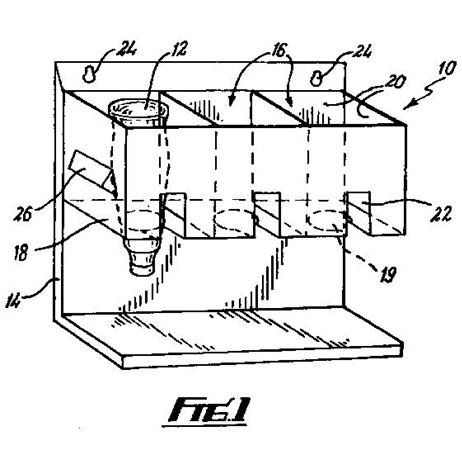

Vending machines including the filling of containers (e.g. WO2008037974) |

This place covers:

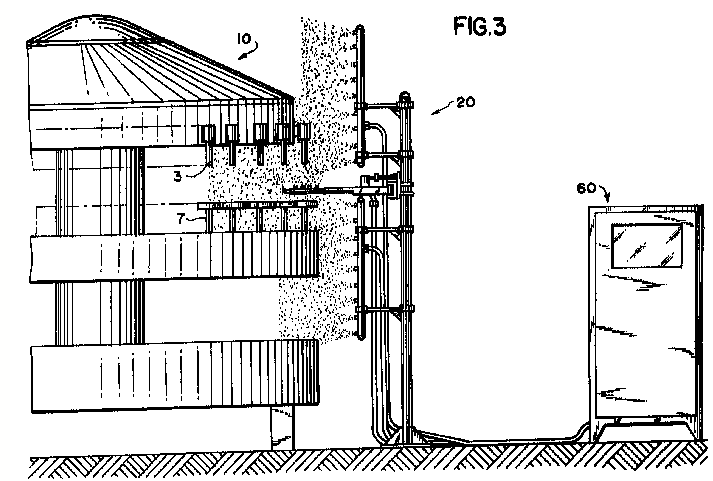

Bottling liquids or semiliquids; Filling jars or cans with liquids or semiliquids using bottling or like apparatus; Filling casks or barrels with liquids or semiliquids.

Concurrent cleaning (or sterilizing), filling, and closing of bottles; Processes or devices for at least two of these operations.

Devices for emptying bottles, not otherwise provided for during preparation of alcoholic beverages except beer C12G 1/00.

Funnels, e.g. for liquids (filter funnels B01D 29/085; volume flow-meters G01F).

This place does not cover:

Filling containers with liquids or semi-liquids using apparatus other than bottling or like apparatus | |

Detection/Investigating the presence of flaws or contamination in a container or its contents |

Attention is drawn to the following places, which may be of interest for search:

Pasteurising or sterilising of liquids | |

Sterilising or disinfecting of objects | |

Mixing of liquids | |

Sorting containers according to e.g. fill level | |

Grippers | |

Filling bags, sacks, cartons, pouches, cups, etc. | |

Filling medical containers such as ampoules, vials, syringes or the like | |

Forming and filling of bottles in a mould | |

Pressurizing filled containers | |

Nozzles with flow cut-off means | |

Preservation of foods in combination with packaging | |

Safety devices for opening doors or panels | |

Devices for transferring samples or any liquids to, in, or from, the analysis apparatus, e.g. suction devices, injection devices |

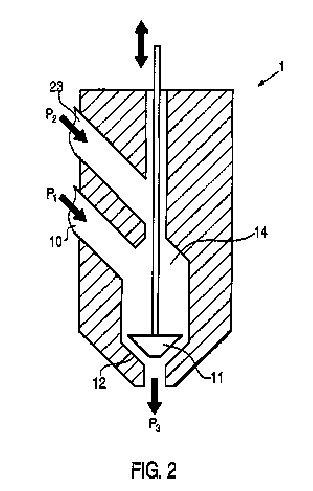

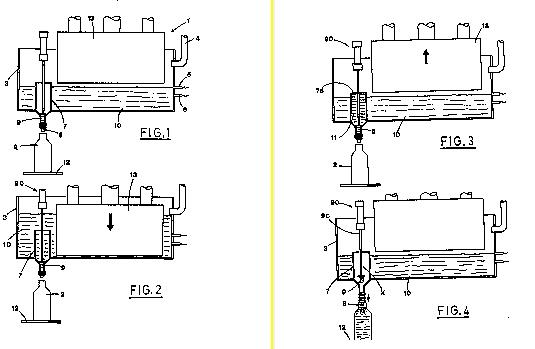

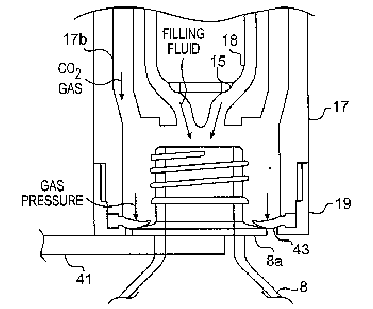

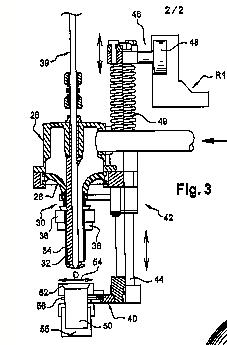

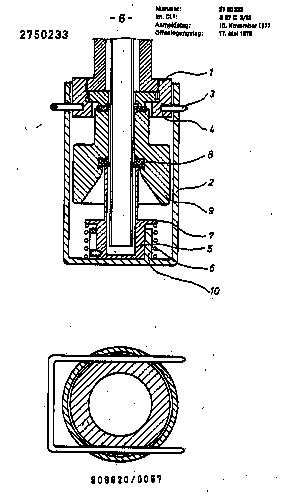

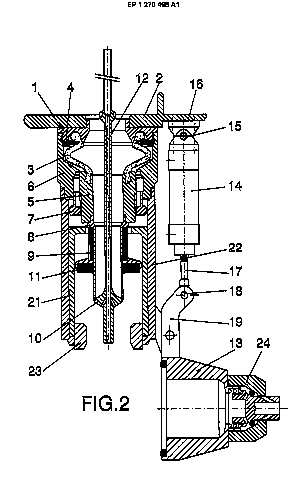

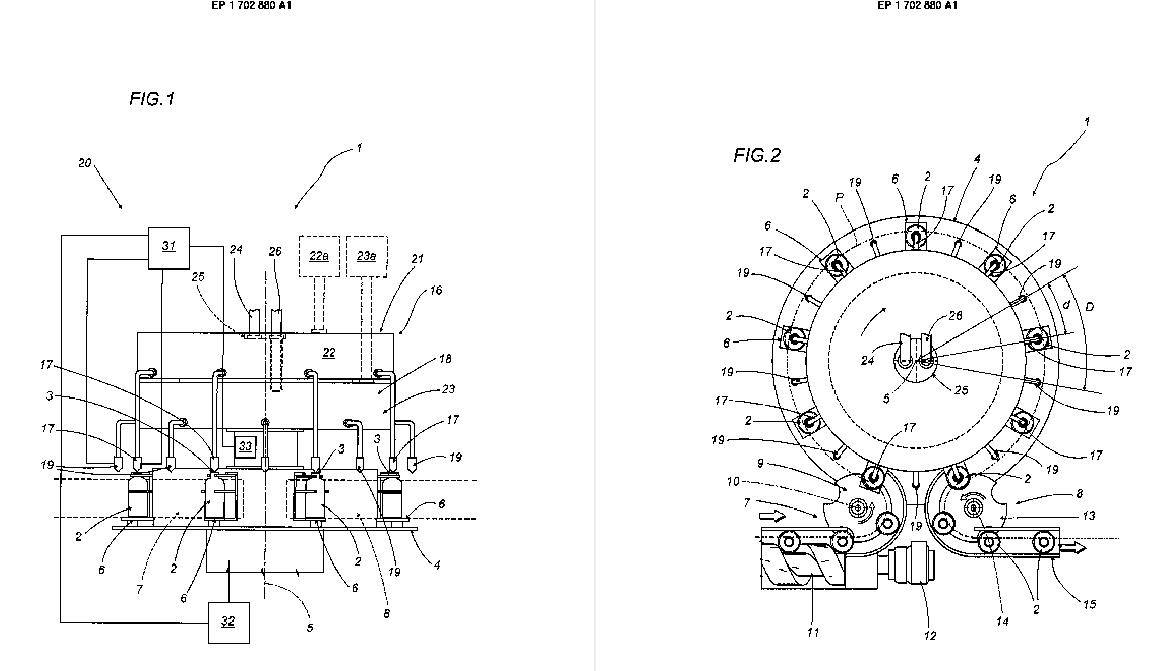

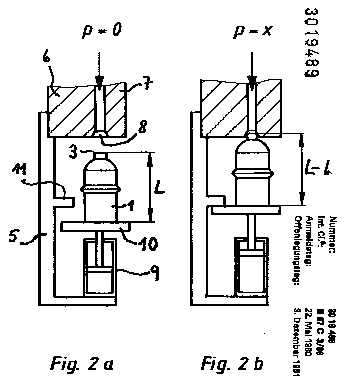

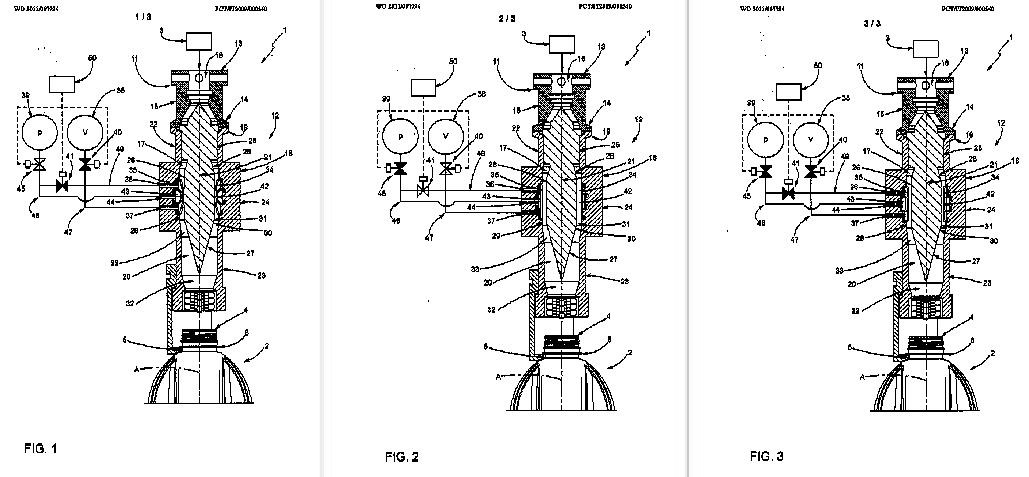

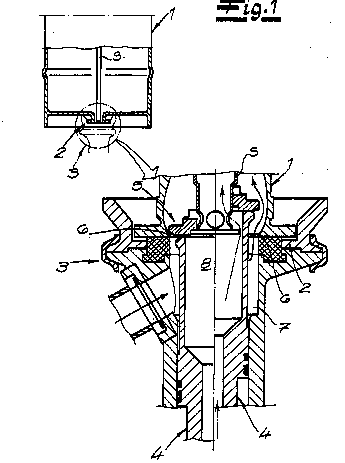

Pressure-control in counter-pressure filling classified in B67C 3/12.

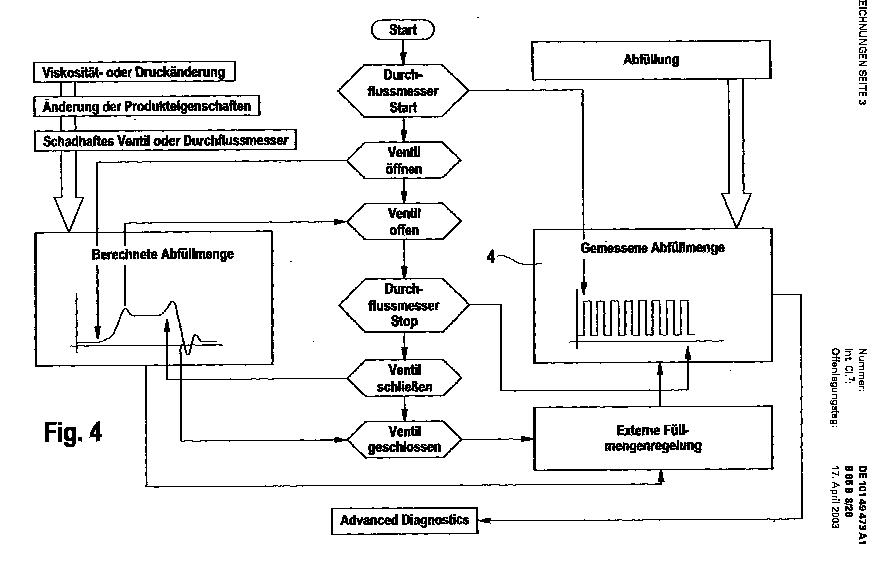

Flow control devices classified in B67C 3/28.

Filling heads specially adapted for filling cans are also classified in B67C 2003/2657.

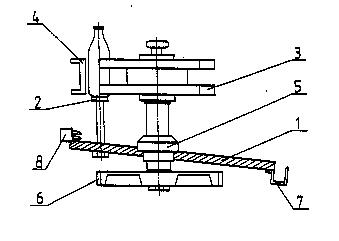

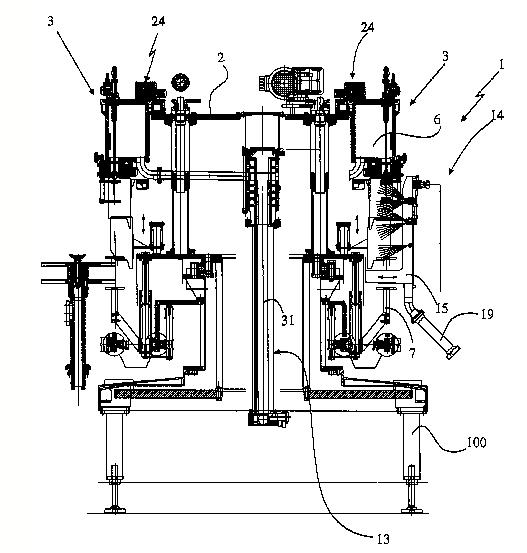

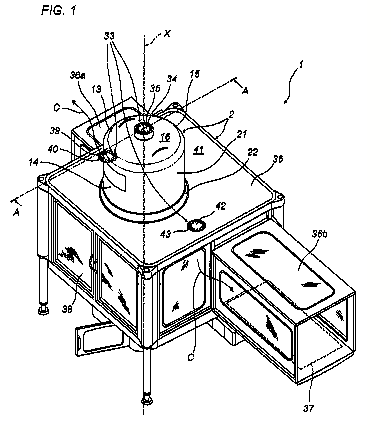

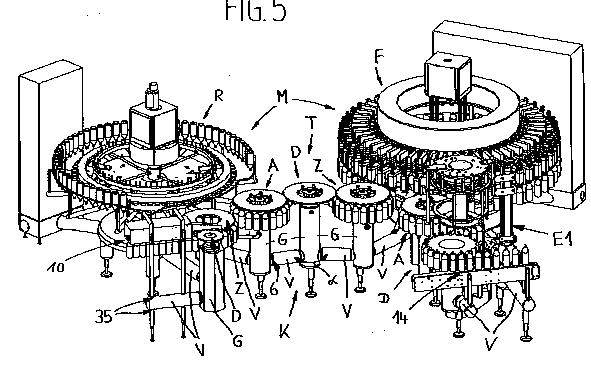

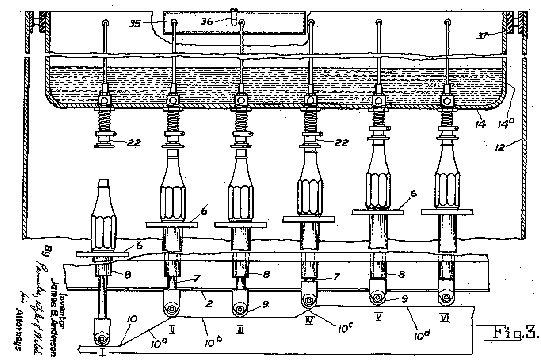

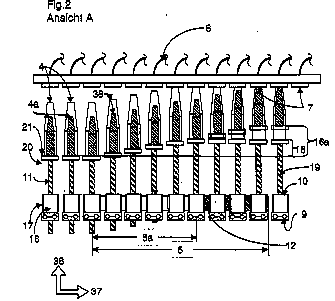

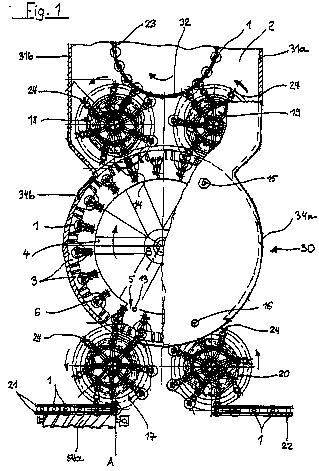

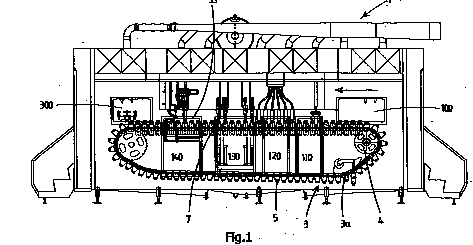

Constructional details of bottling equipment or filling machines are classified in B67C 3/22, e.g. frame or support details, or B67C 3/22, e.g. automatic exchange of components.

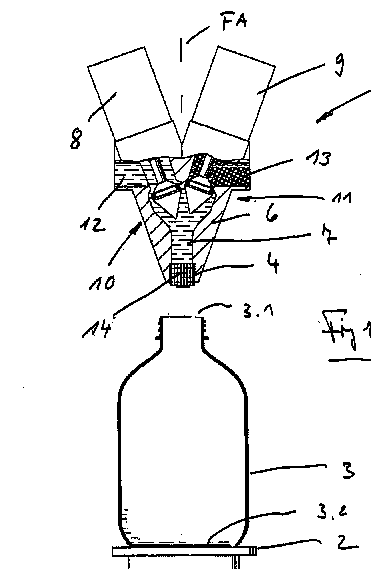

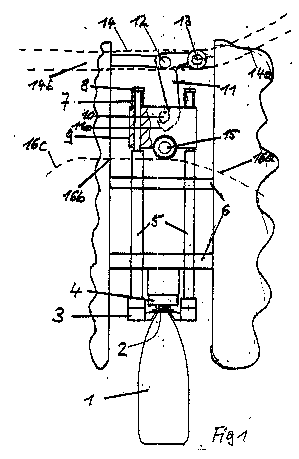

Constructional details of filling heads are also classified in B67C 3/26.

Classes B67C 3/2617 and B67C 3/2625 and subgroups also comprise documents not explicitly directed to counter-pressure filling.

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

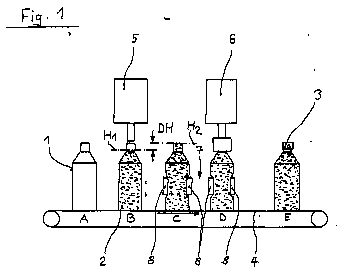

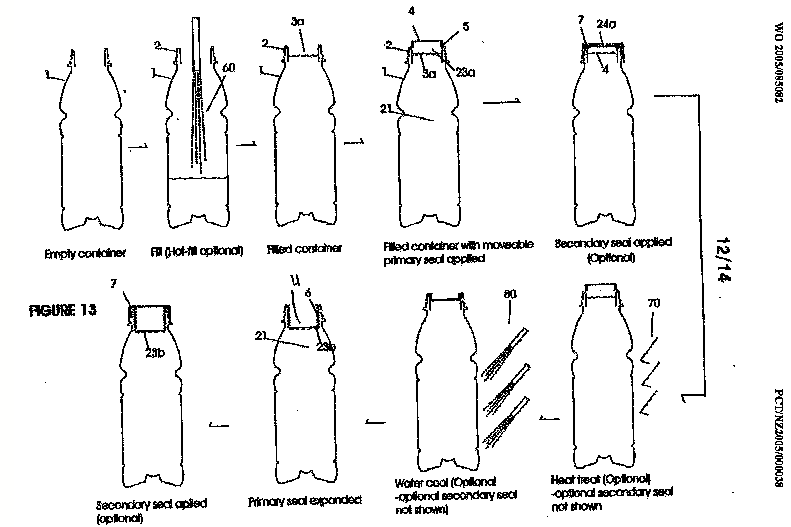

Attention is drawn to the following places, which may be of interest for search:

Topping-up containers or receptacles to ensure complete filling | |

Adding fluids for preventing deformation of filled and closed containers |

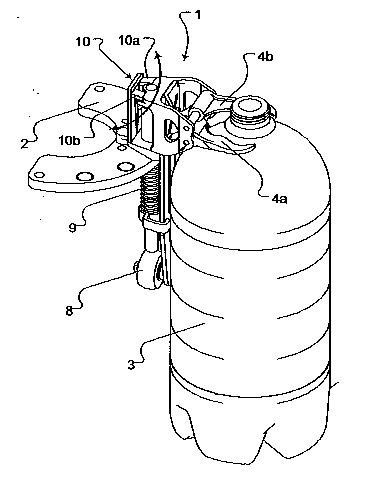

This place covers:

This place covers:

Attention is drawn to the following places, which may be of interest for search:

Pucks used as container carrier in handling devices such as conveyors |

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

Details of conveying or synchronising.

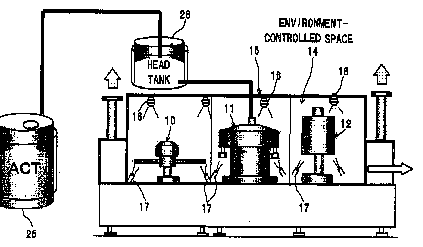

Sterilising, aseptic filling and closing.

Lever action devices operated by hand or foot.

This place does not cover:

Heat treatment of liquids, i.e. pasteurising or sterilising | |

Details about sterilising processes or apparatuses as such, only in combination with some form of subsequent process in/of a bottling line | |

Disinfecting or sterilising as such of objects | |

Mixing of liquids | |

Forming and filling of bottles in a mould |

Attention is drawn to the following places, which may be of interest for search:

Pasteurising or sterilising of liquids | |

Sterilising or disinfecting of objects | |

Cleaning in general | |

Cleaning of containers | |

Details related to subsequent processes of blow moulding and filling | |

Preservation of foods in combination with packaging | |

Packaging in aseptic tunnels | |

Packaging in aseptic chambers | |

Conveying of containers in general | |

Grippers |

This place covers:

This place covers:

This place covers:

This place covers:

This place covers:

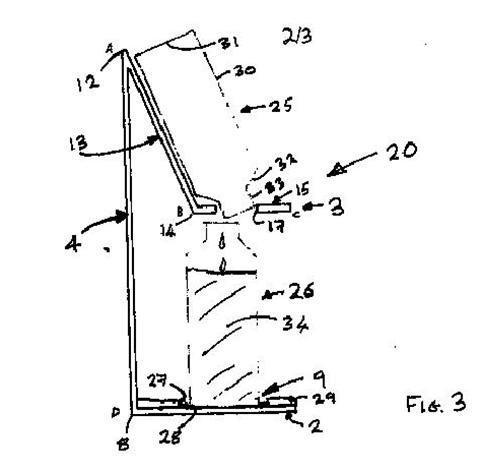

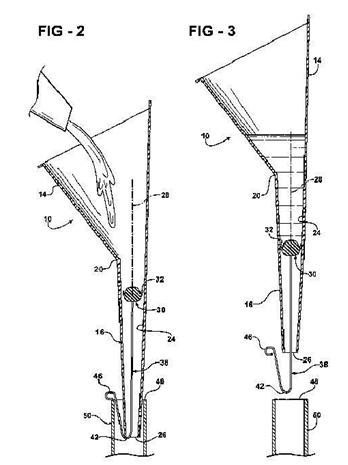

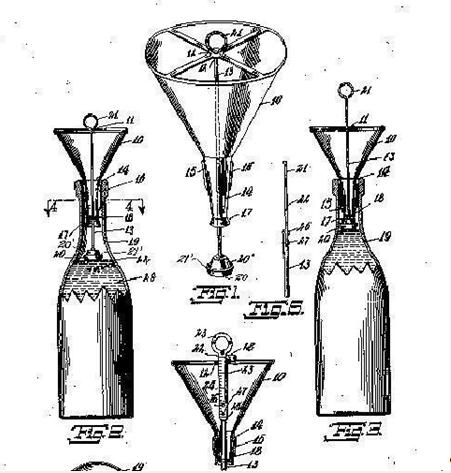

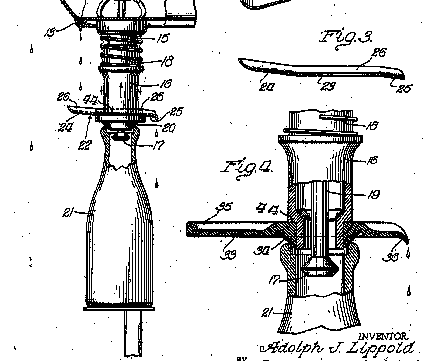

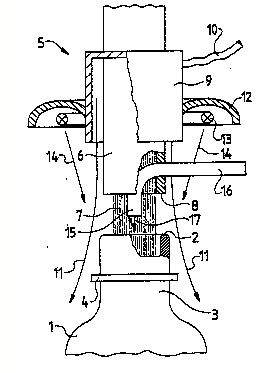

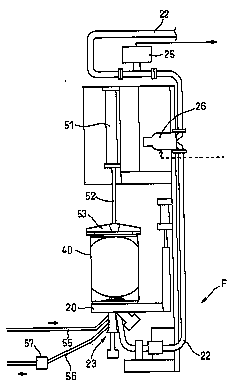

Funnels without discharge valves.

Funnels with non-automatic discharge valves.

Funnels with automatic discharge valves.

Attention is drawn to the following places, which may be of interest for search:

Devices for aerating of wine | |

Funnels for introducing articles or materials in containers or wrappers | |

Filling or draining lubricant of or from machines or engines | |

Measuring spoons or scoops |