CPC Definition - Subclass B23G

This place covers:

Thread cutting by chip removal.

Production of threads with no removal of chips by means of tools similar in form and manner of use to thread cutting tools.

Working of screws, bolt heads and nuts in conjunction with thread cutting.

For further details of the interpretation of these terms, please refer to the notes under the relevant main group heading.

This place does not cover:

Thread forming by corrugating tubes | |

Making threaded elements by forging/hammering | |

Making nuts by forging or hammering | |

Making screwthreads by rolling | |

Turning helical grooves | |

Turning tools for threading | |

Milling helical grooves | |

Making gears (inc wormwheels) | |

Making milling cutters for threading | |

Making threading tools | |

Multi stage processes involving threading and also other operations classed in B23B, B23C, B23D, B23F, making particular items | |

Details of machine tools and accessories not related to the operation being performed including: | |

- evacuation of swarf, | |

- guarding & protective coverings | |

- conveying workpiece into and from machine | |

- tool changing | |

- measuring or sensing | |

Adaptive control and/or computer controls for turning, boring or drilling processes | |

Grinding helicoidal grooves | |

Fasteners per se |

Classification in this subclass is generally according to a literal interpretation of the group and subgroup headings by a reader with a background in, and familiar with, metal cutting processes.

Indexing Codes from the 200 series (i.e ICO codes from the following groups: B23G 2200/00 - B23G 2200/50, B23G 2210/00 - B23G 2210/48, B23G 2225/00 - B23G 2225/60 and B23G 2240/00 - B23G 2240/60) should be added to documents at every possible opportunity for deep indexing.

A mirror image code scheme (i.e. B23G 1/00 - B23G 11/00) has recently been created for additional information. However, this scheme should NOT be used for classification of new documents.

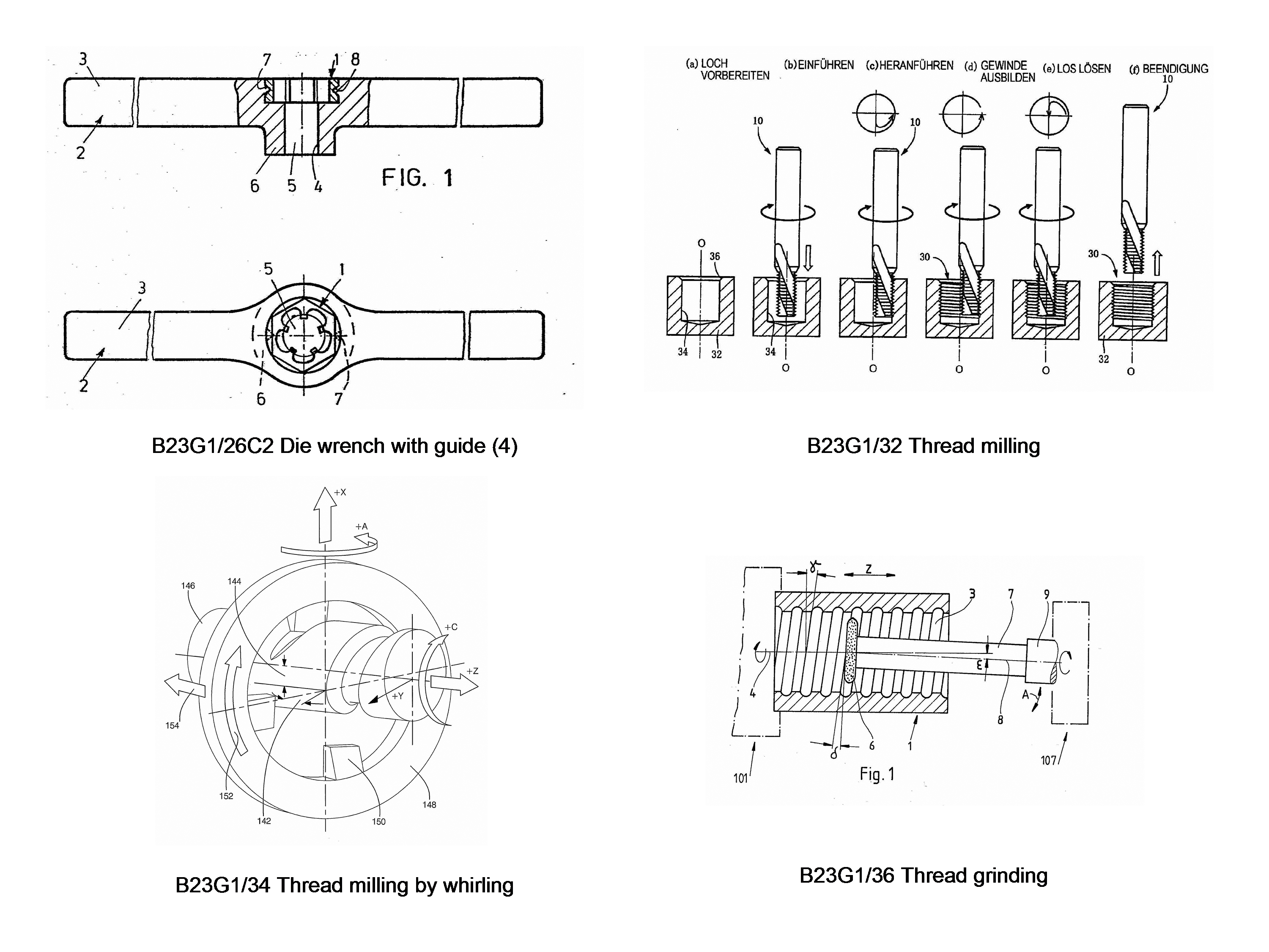

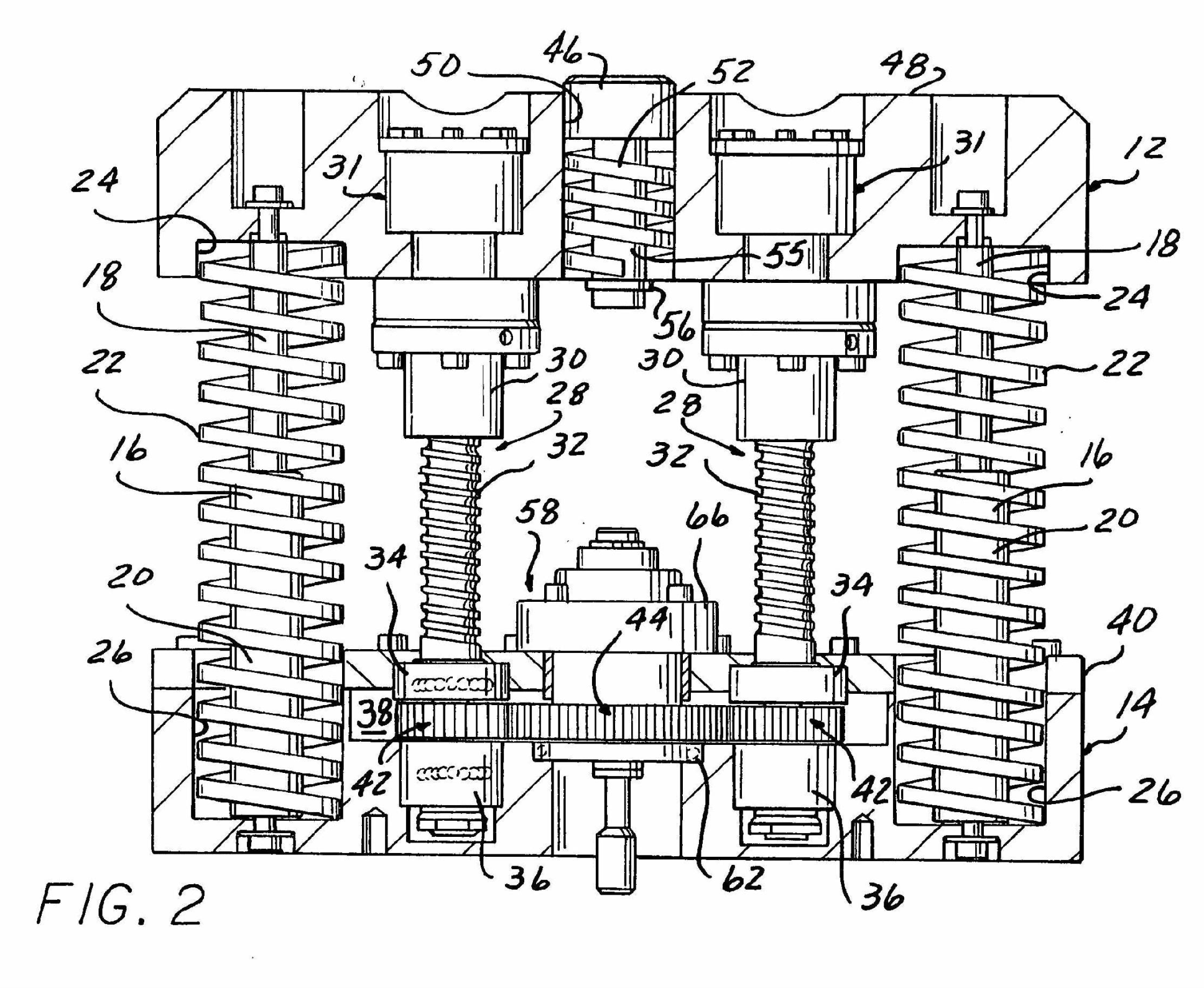

At the end of each section of this document drawings have been provided, which give examples of the items classified in the most widely used subgroups. The example drawings have each been taken from a document classified within the subgroup, for which the example is provided.

This place covers:

The cutting of threads and automatic machines specially designed therefor. A thread is to be understood as "a helical groove in a cylindrical hole" or a "helical ridge on a cylindrical bar, rod or shank". The term "cutting" should be understood as being by means of the removal of material, especially in the form of chips.

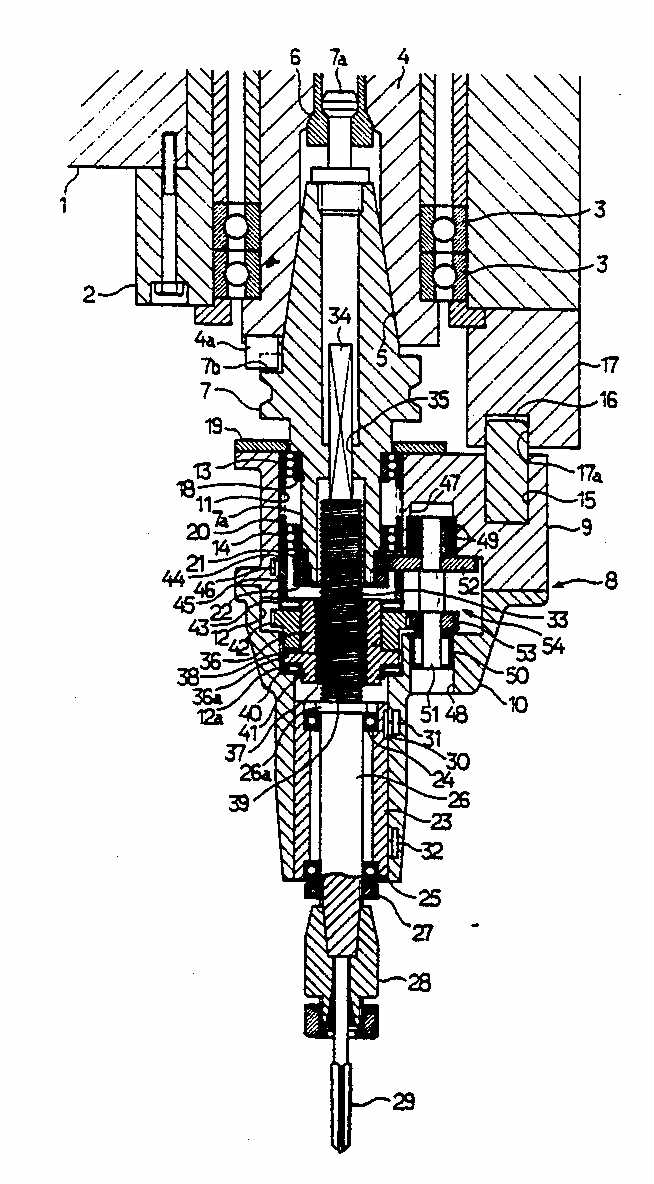

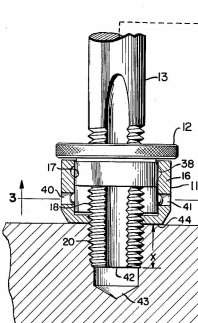

Illustrative example of subject matter classified in this group.

Notes:

None of the drawings is original and no copyright is claimed.

The majority of the drawings are each taken from a document classified in the group or subgroup, to which the example refers.

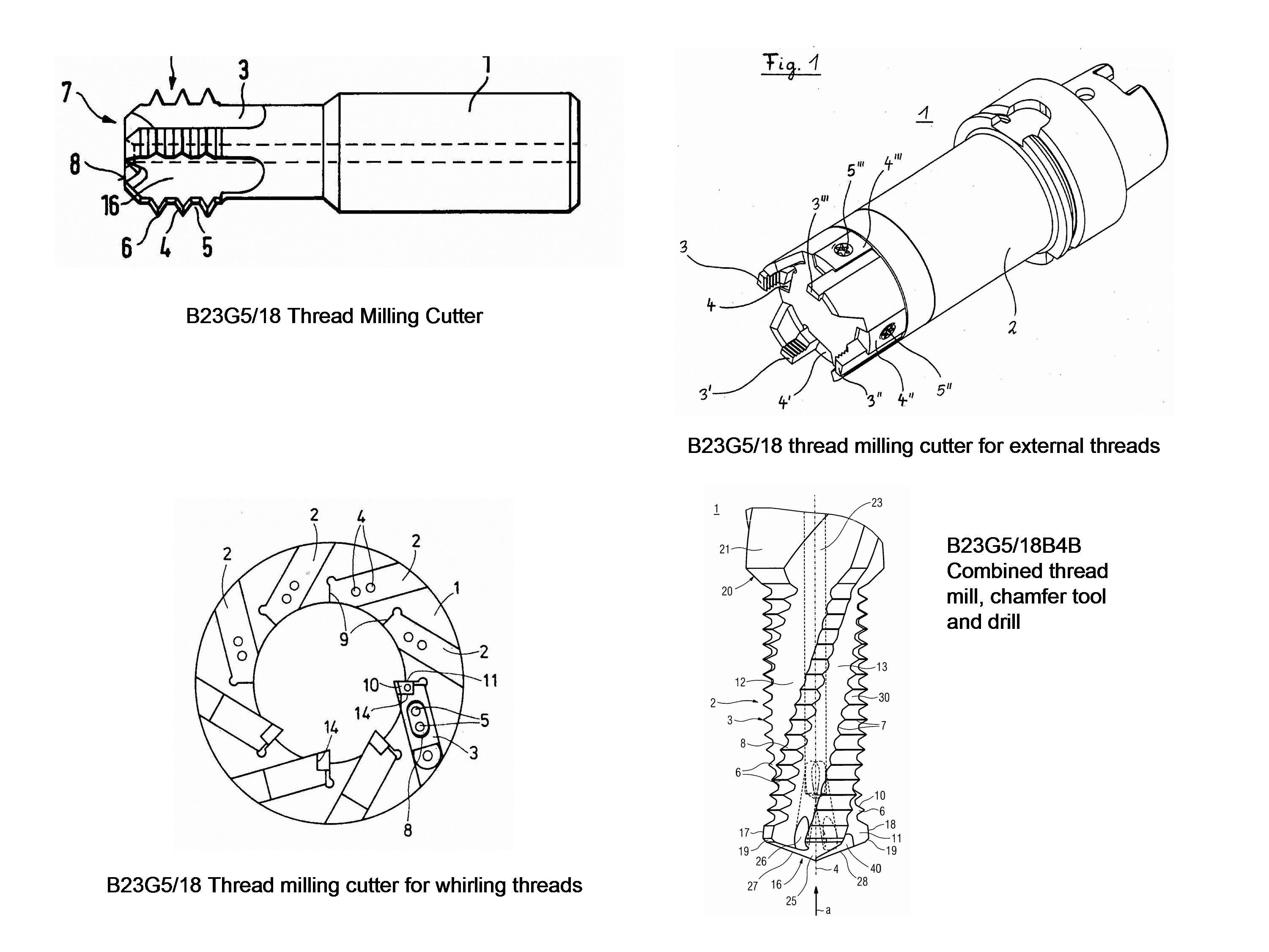

B23G 1/16 Thread cutting by tapping

B23G 1/185 Machine for tapping nuts with one working spindle (see also B23G 9/00)

(for accessories see B23G 1/52)

B23G 1/262 Tap wrench

Classification within this group is according to literal interpretation of the titles of the sub-groups.

This place covers:

Arrangements or accessories for enabling machine tools not specially designed only for thread cutting to be used for this purpose, e.g. arrangements for reversing the working spindle.

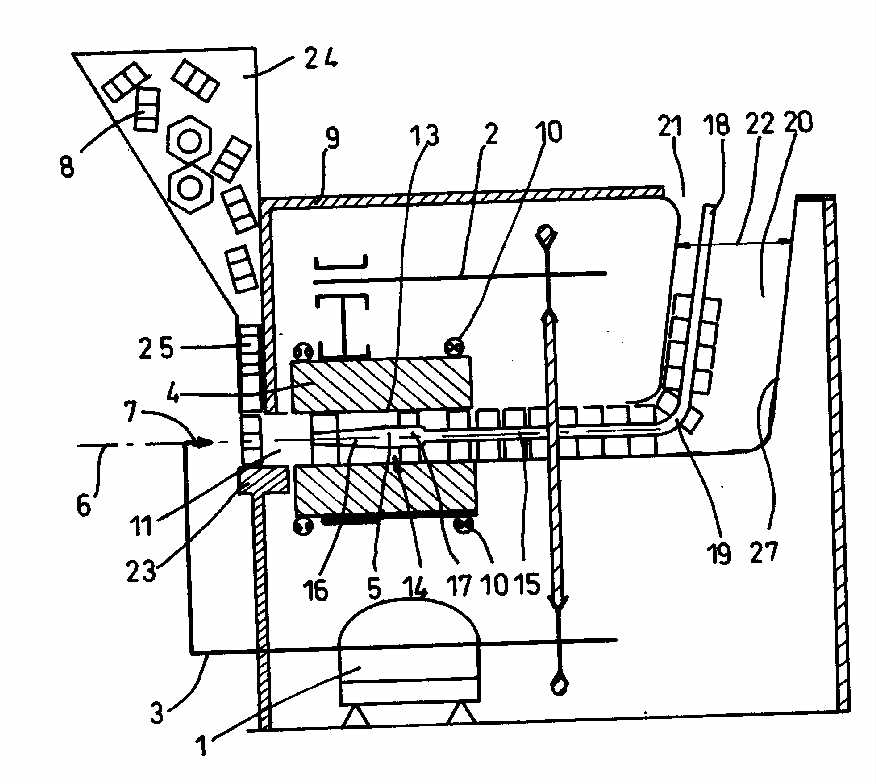

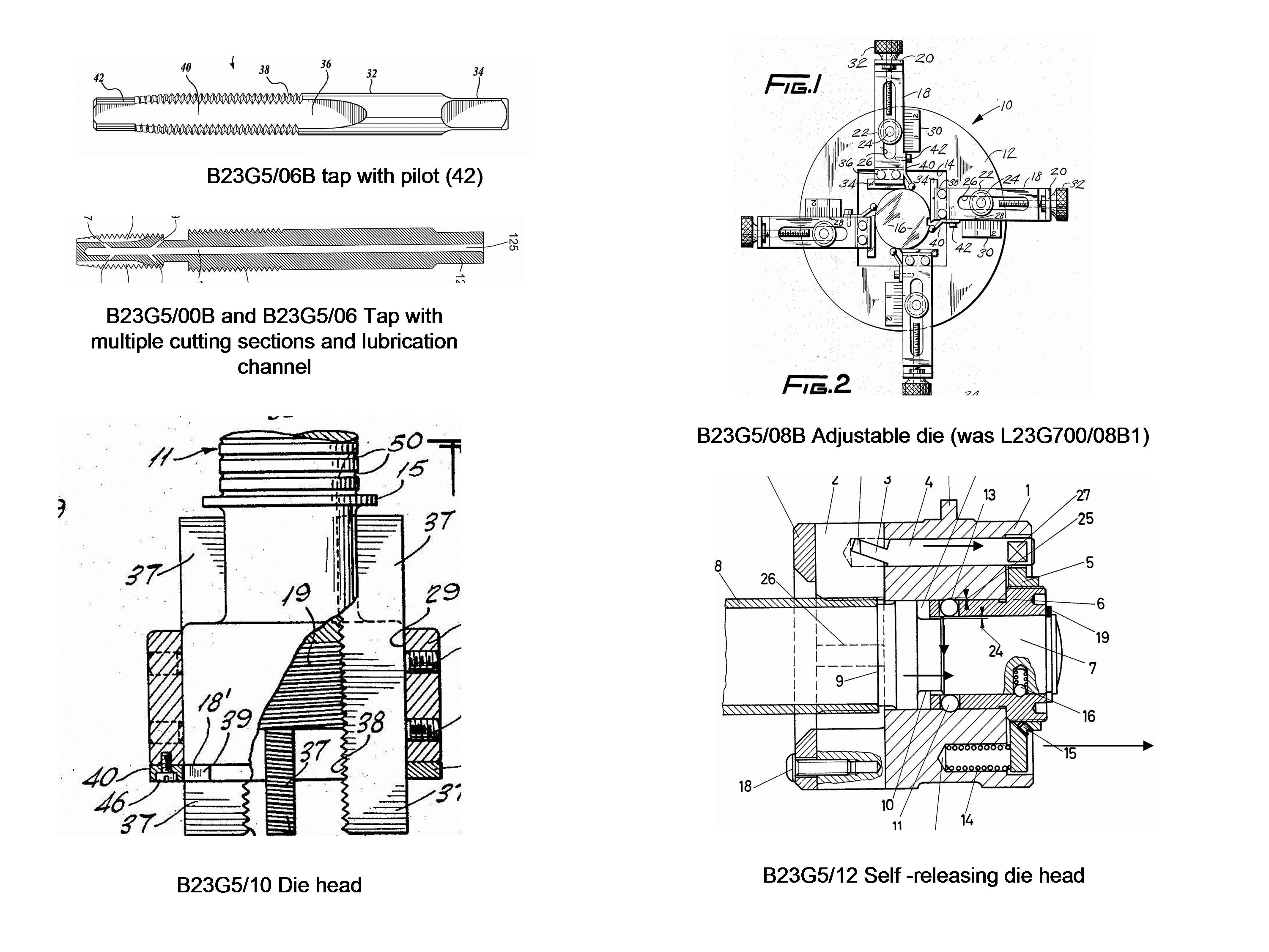

Illustrative example of subject matter classified in this group.

Notes:

The drawing is not original and no copyright is claimed. The drawing is taken from a document classified in the subgroup B23G 3/005, to which the example refers, and which is the only subgroup within B23G 3/00, within which documents are regularly classifie since the advent of CNC control.

B23G 3/005 device to allow threading on a press

This place does not cover:

Tool holders suitable for tapping tools that allow for expansion or contraction, as commonly used in the threading process, either with or without an overload clutch. |

This place covers:

Thread-cutting tools and die-heads. The thread cutting tools of this group are the parts of the thread cutting arrangement containing the cutting edges. This can be in the form of a tool removable from a machine, manually operable, or both. Example: a tap characterised by the features of the tap itself would be classed in B23G 5/06. A machine using such a tap with special features of the machine or the process of tapping is classed in B23G 1/16. A tap wrench for manually using the tap is classed in B23G 1/261.

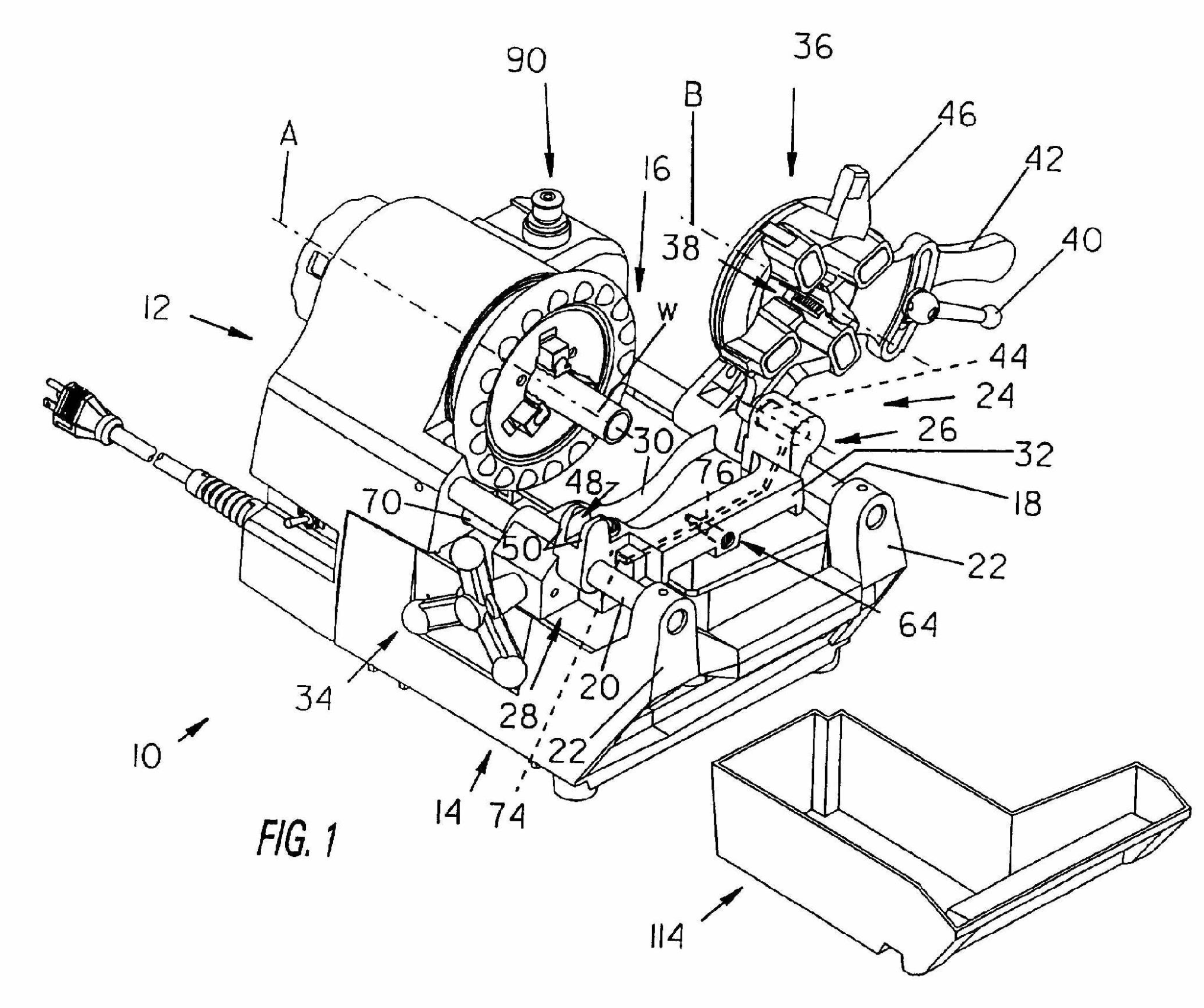

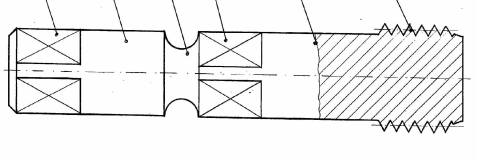

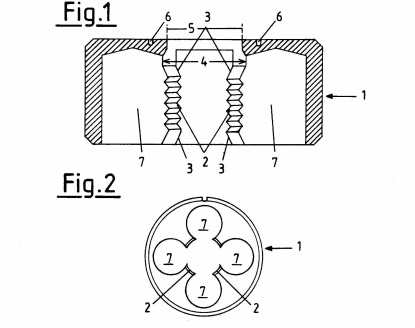

Illustrative example of subject matter classified in this group.

Notes:

None of the drawings is original and no copyright is claimed.

The majority of the drawings are each taken from a document classified in the group or subgroup, to which the example refers.

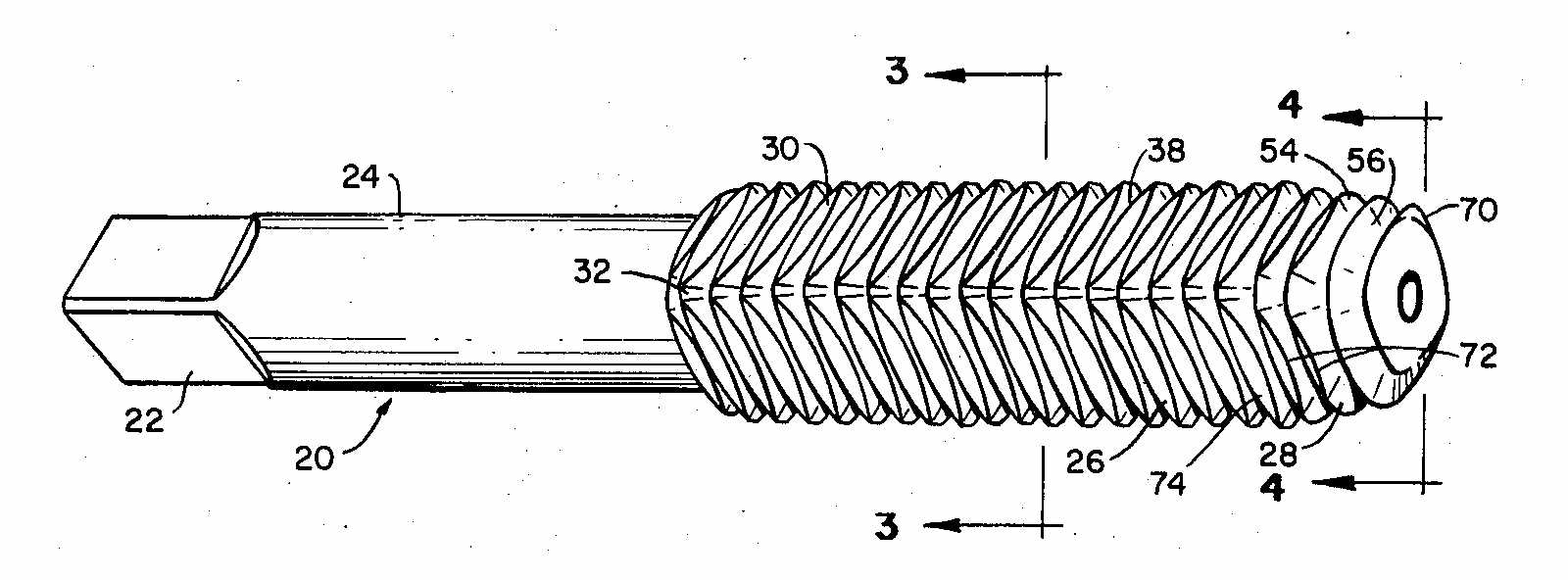

B23G 5/064 & B23G 5/068 Tap with weakened shank and means to remove broken tap

B23G 5/043 threading die with guide (5)

B23G 5/066 Tap with stop

The preceding image includes references to B23G5/06B, B23G5/00B, B23G 5/06, B23G5/08B, B23G 5/10, and B23G 5/12.

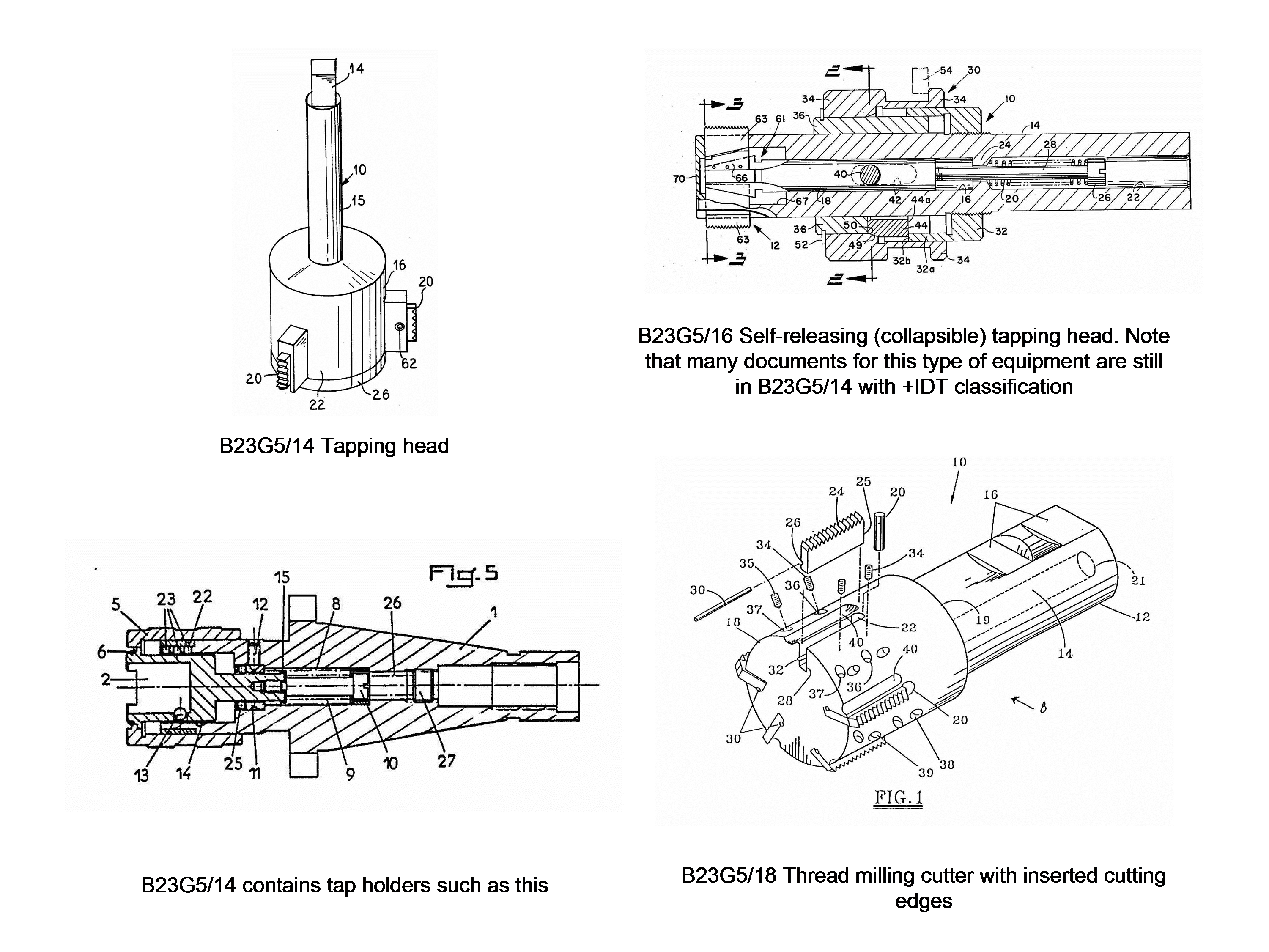

The preceding image includes references to B23G 5/18.

Classification within this group is per literal interpretation of the subgroup headings by a reader skilled in the art of metal cutting.

This place covers:

Forming threads by means of tools similar both in form and in manner of use to thread-cutting tools, but without removing any material.

The term "similar in form and in manner of use to thread cutting tools" of B23G 7/00 should be strictly interpreted. The forming tool being used should bear a very close resemblance to known cutting tools. Examples of such tools are forming taps (roll taps i.e. a tool similar to a cutting tap, rotated on its own axis and fed linearly with feed per revolution equal to thread pitch), and forming tools resembling milling cutters rotated on their own axes and used with a helical feed in which the pitch of the helix corresponds to that of the thread being produced. Although these are the most common examples, the use of thread-forming dies, similar to in form to thread cutting dies or indeed any tool falling under the term, "similar both in form and in manner of use" that isn't classed elsewhere in ECLA can be classed here.

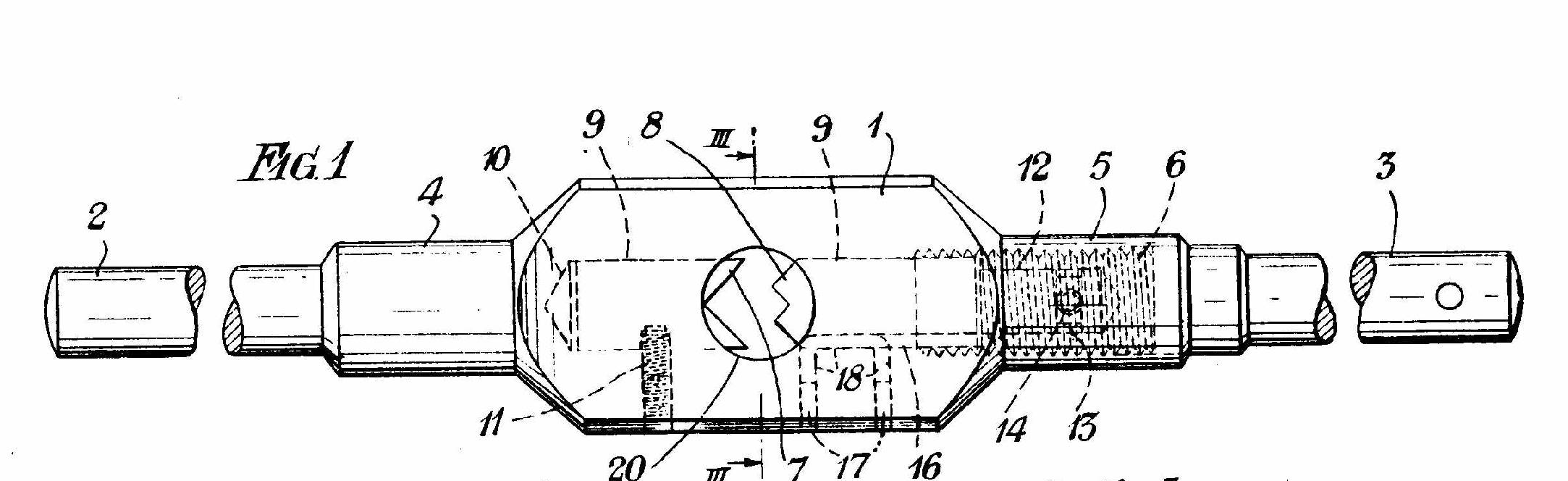

Illustrative example of subject matter classified in this group.

Notes:

None of the drawings is original and no copyright is claimed.

The majority of the drawings are each taken from a document classified in the group or subgroup, to which the example refers.

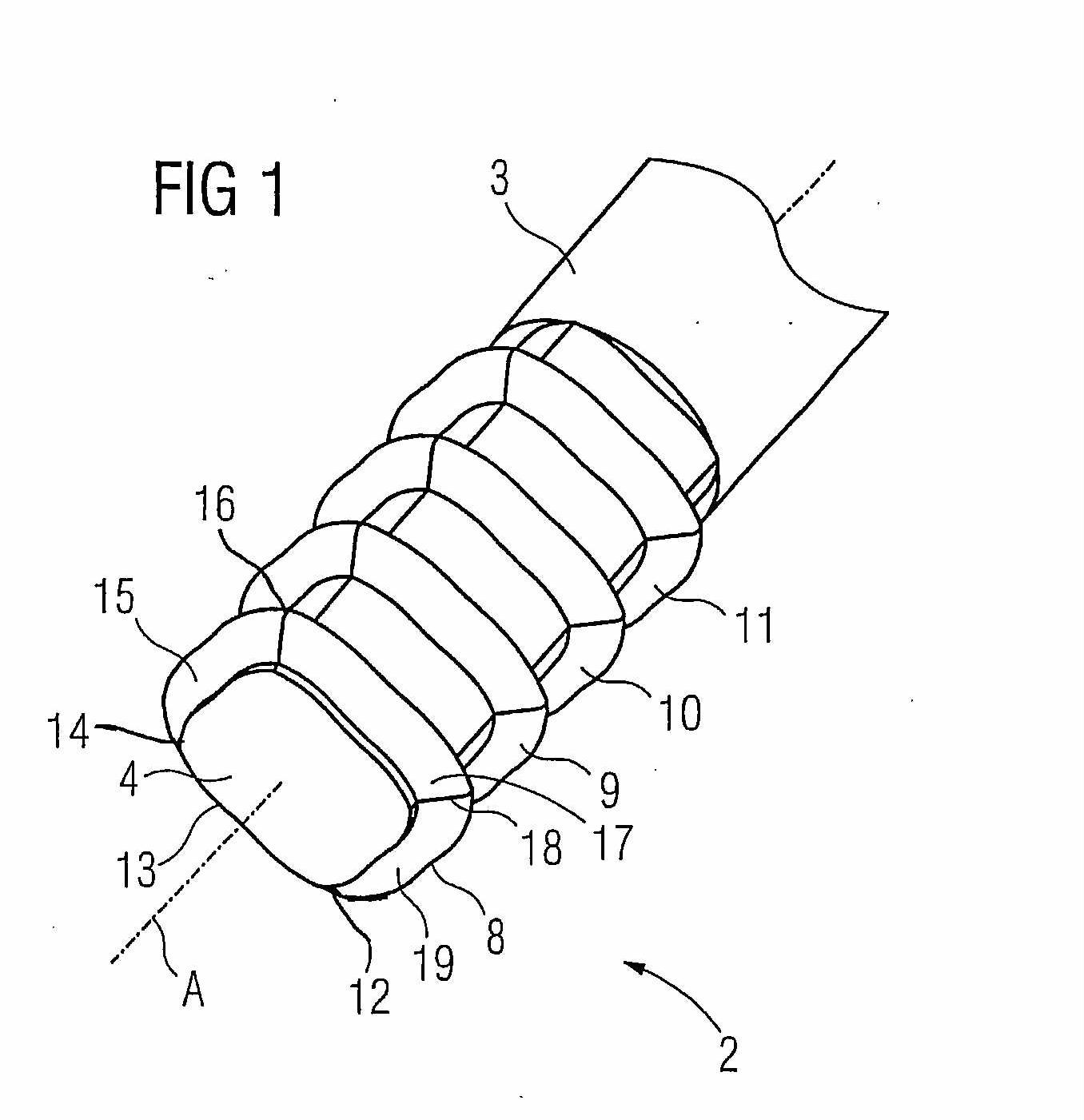

B23G 7/02 Roll tap

B23G 7/02 Tool for forming a thread by a procedure similar to milling

This place does not cover:

Thread forming by corrugating tubes | |

Making screwthreads by rolling | |

Making threaded elements by forging/hammering | |

Making nuts by forging or hammering |

As the tools used in these processes are not similar in form and manner of use to a thread-cutting tool.

Classification is per a literal interpretation of the group/subgroup heading by a person skilled in the art of metal cutting.

This place covers:

Working screws, bolt heads, or nuts in conjunction with thread cutting, e.g. slotting screw heads or shanks, removing burrs from screw heads or shanks; Finishing, e.g. polishing, any screw-thread.

The term "in conjunction with thread cutting" in the title of group B23G 9/00 should be interpreted in a very strict and limited manner. Documents should only be classified in B23G 9/00 if the content refers to the mechanical working of the screw, bolt or nut. The working of screws, bolt heads or nuts MUST be in conjunction with the cutting of the thread. For example the coating of screw threads should be classified either according to the fastener per se or according to the process being used.

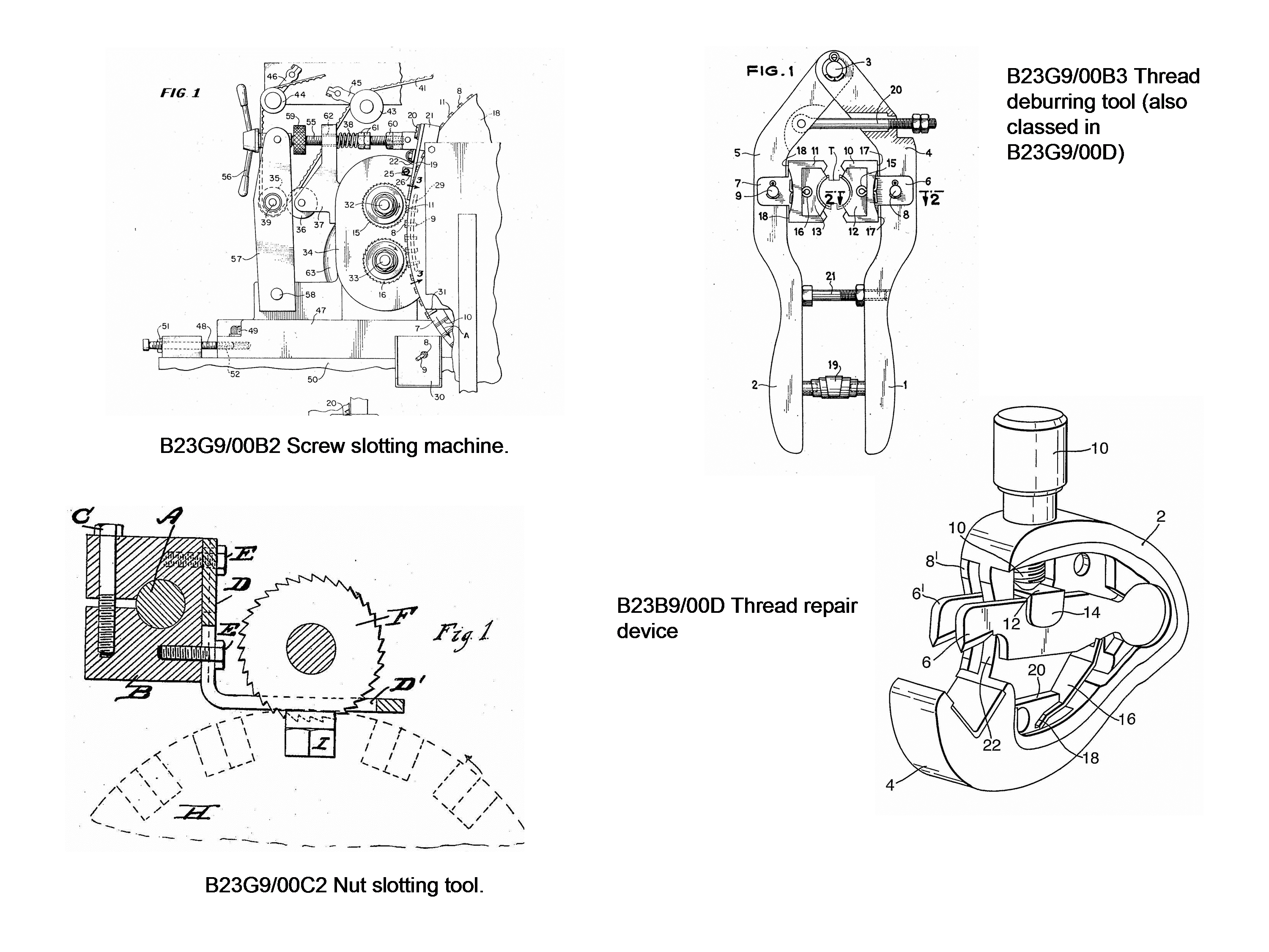

Illustrative example of subject matter classified in this group.

Notes:

None of the drawings is original and no copyright is claimed.

The majority of the drawings are each taken from a document classified in the group or subgroup, to which the example refers.

The preceding image includes references to B23G9/00B2, B23G9/00B3, B23G9/00C2, and B23G9/00D,

Classification is per a literal interpretation of the group/subgroups headings by a person skilled in the art of metal cutting.

This place covers:

Feeding or discharging mechanisms combined with, or arranged in, or specially adapted for use in connection with, thread-cutting machines (for machines tools in general B23Q)

B23G 11/00 refers to feeding or discharging mechanisms in so far as they are specifically destined for thread cutting machines. B23Q 7/00 is used for feeding or discharging mechanisms in general.