CPC Definition - Subclass B21H

This place covers:

Methods and devices for forming metal objects by rolling operations which are not combined with further different metal-working operations.

This place covers:

Methods and devices for manufacturing rotationally symmetric bodies.

This place does not cover:

Attention is drawn to the following places, which may be of interest for search:

Rolling tubes | |

Flanging of tubes by rolling |

This place covers:

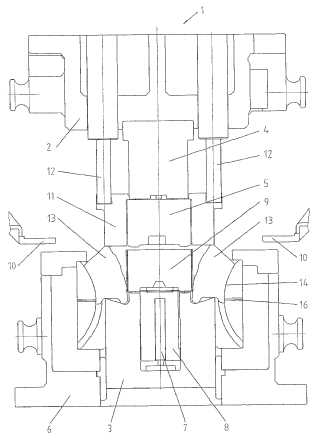

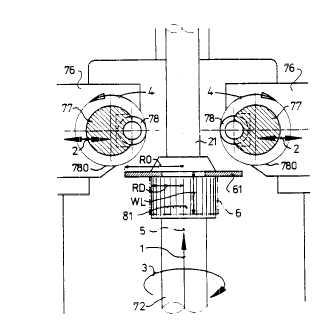

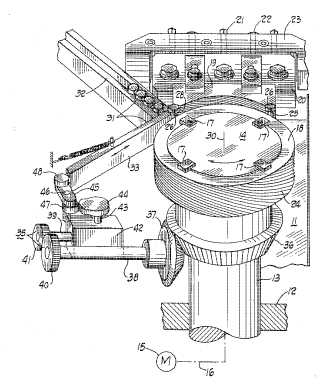

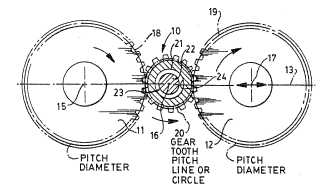

Cross-rolling of cylindrical workpieces with rollers having an axis of rotation parallel to the axis of the workpiece. In most cases recesses are formed on the workpiece by a profile on the rollers which varies in width.

(from US 4459880 (A))

This place does not cover:

Manufacturing of gear toothing by rollers having an axis of rotation parallel to the axis of the workpiece |

Attention is drawn to the following places, which may be of interest for search:

Spinning |

This place covers:

Forming of profiles or reduction in cross-section by rollers or roller-segments having an axis of rotation not parallel to the axis of the workpiece.

Forming of profiles with roller-segments |

|

Reduction in cross-section |

|

Attention is drawn to the following places, which may be of interest for search:

Continuous reduction in cross-section of workpieces |

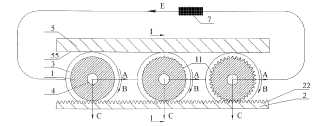

This place covers:

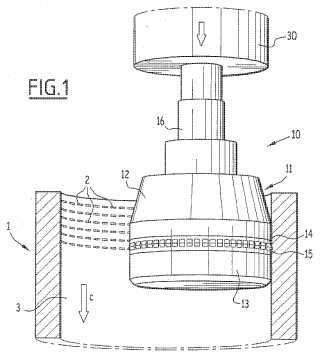

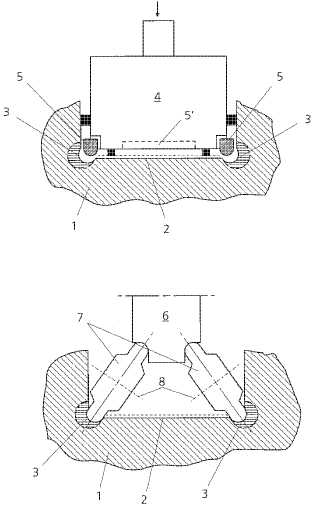

Forming of profiles or reduction in cross-section with the help of rollers or roller-segments comprising a die

(from DE 102004016193 (A1))

Attention is drawn to the following places, which may be of interest for search:

Cross-rolling of cylindrical workpieces |

This place covers:

Methods and devices for forming a helical structure like a thread or helical flutes on a body by a chipless rolling process. The group covers plastic deformation of the metal body to produce a thread structure without cutting or milling and includes cold thread rolling (swaging).

Attention is drawn to the following places, which may be of interest for search:

Making helical gears, i.e. worms | |

Bending of a body into helical form | |

Corrugating tubes helically | |

Coiling wire helically | |

Forming of helical structures on a body by forging or pressing | |

Screws | |

Self-tapping screws | |

Screws having a special thread-form | |

Locking screws |

This place covers:

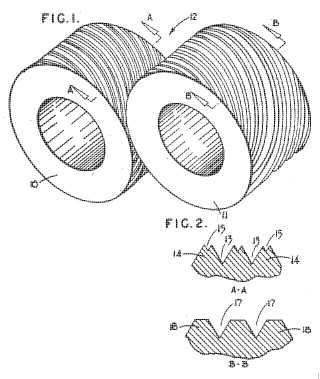

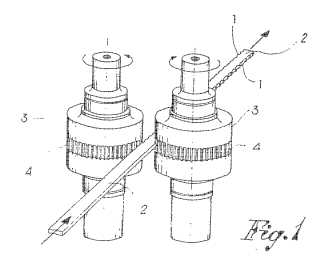

Methods and devices in which the external screw-thread is manufactured by means of profiled rolls, but which do no comprise or further specify the use of a thread rolling head.

(from GB 999785 (A))

This place does not cover:

Profiled rolls for making gear wheels |

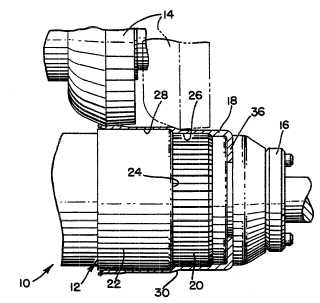

This place covers:

Handtools for rolling a thread on a workpiece. General aspects of thread rolling heads and methods of using a thread rolling head not related to a special type of thread-rolling head.

This place covers:

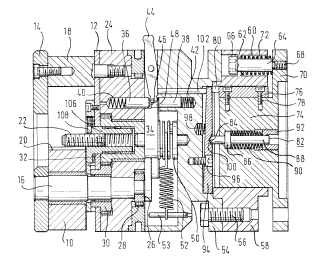

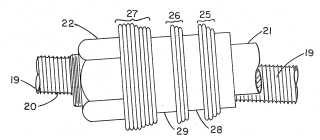

Axial thread rolling methods and devices for forming external screw-threads using a thread-rolling head working axially, i.e. the rollers have a continuous and constant profile about their circumference and run axially along the workpiece. During rolling the workpiece passes through an axial bore within the rolling head.

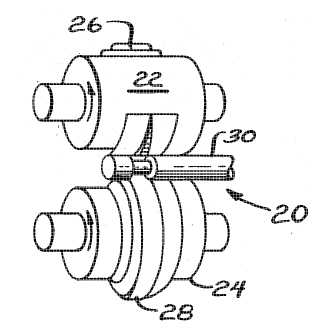

(from EP 0417416 (A2))

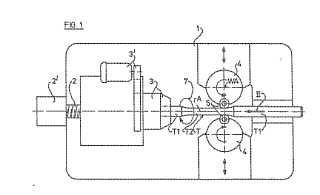

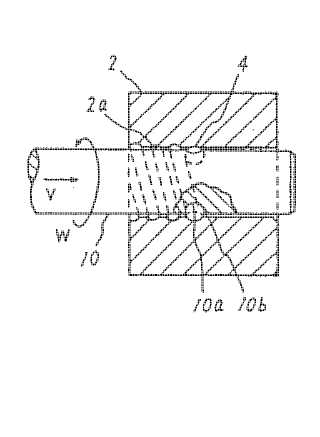

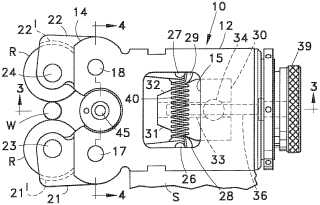

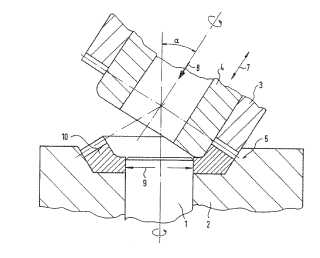

This place covers:

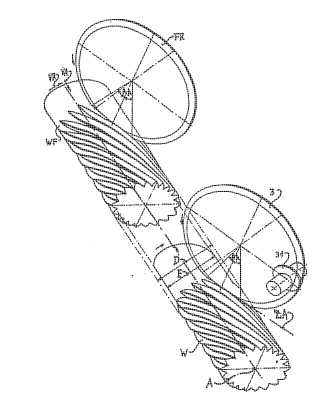

Radial thread-rolling methods and devices, the thread-rolling head forming a thread in one single rotation of either the workpiece within the rollers or the rolling head about the workpiece. The rollers are provided with a circumferentially varying profile and/or are eccentrically mounted within the rolling head. The workpiece is inserted axially into the rolling head. After insertion of the workpiece the rollers approach the workpiece radially.

(from US 5924317 (A))

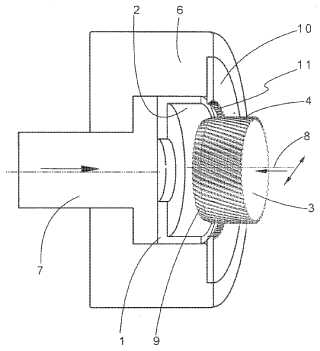

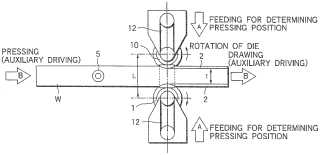

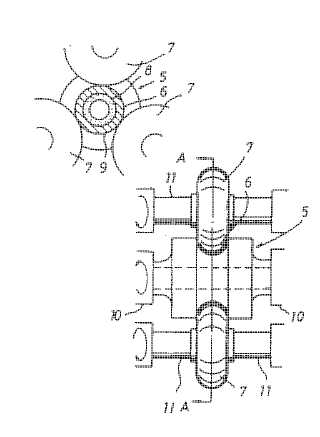

This place covers:

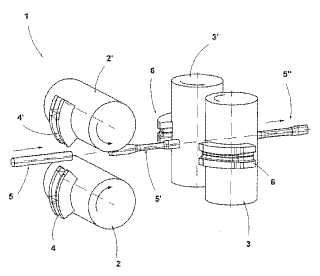

Tangential thread-rolling methods and devices, the thread-rolling head being fed tangentially against the rotating workpiece.

In order to allow a tangential insertion of the workpiece into the rolling head, the radial distance between the rollers can be varied. Some rolling heads comprise rollers having a varying circumferential profile in order to allow the insertion of the workpiece.

(from US 6202461 (B1))

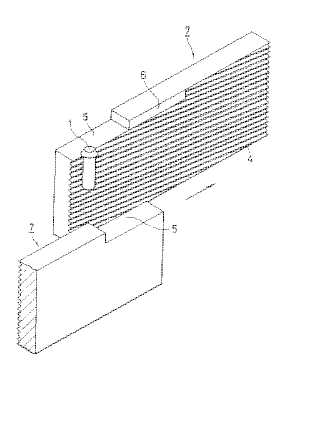

This place covers:

Rolling of threads by means of reciprocating flat dies, wherein the dies are reciprocated in relation to one another or a stationary die is provided and the other die is reciprocated.

(from JP 62158541 (A))

Attention is drawn to the following places, which may be of interest for search:

Rolling of cylindrical gears by means of reciprocating flat dies |

This place covers:

Planetary thread rolling methods and devices, i.e. rolling of threads between a stationary and a rotatable die.

(from JP 57094439 (A)) (from US 3733867 (A))

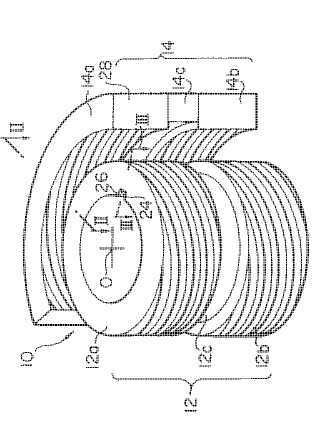

This place covers:

Methods and devices for forming a helical structure like helical fins on a workpiece by rolling, including a workpiece that is rotated and longitudinally moved relative to rolling dies or the dies are rotated and the workpiece is longitudinally moved relative to rolling dies without rotation.

(from US 3745801 (A))

Attention is drawn to the following places, which may be of interest for search:

Manufacturing of helical gear worms |

This place covers:

Methods and devices for manufacturing or finishing geared workpieces by a chipless rolling process. This group does not only cover the manufacturing or finishing of gear wheels, but also of racks, spline shafts and worms.

Attention is drawn to the following places, which may be of interest for search:

Manufacturing of gear wheels by forging or pressing | |

Manufacturing of toothed racks by forging or pressing | |

Making gears or toothed racks by other methods | |

Making gear wheels by other methods |

This place covers:

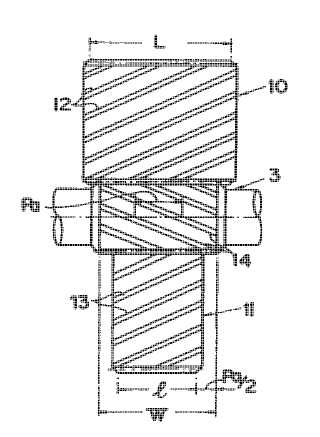

Making work wheels or gears with a helical toothing

(from CH 668726 (A5))

Attention is drawn to the following places, which may be of interest for search:

Toothed members, worms |

This place covers:

Methods and devices for manufacturing external gear toothing on cylindrical workpieces by means of die rolls.

(from JP 59209451 (A))

Attention is drawn to the following places, which may be of interest for search:

Finishing of preformed gear wheels | |

Making of internal gear wheels by rolling | |

Manufacturing of gear wheels by means of flat dies | |

Rolling of bevel gears | |

Spinning in order to manufacture other products than gear wheels |

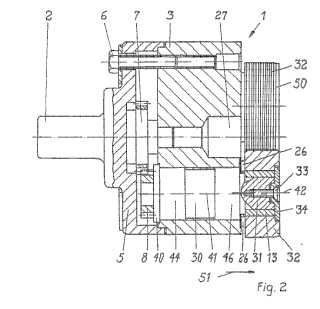

This place covers:

Methods and devices for finish-rolling of preformed gear wheels, in particular of sintered gear wheels, by rolling or burnishing, including compacting of sintered powder gearing teeth by rolling.

(from US 5230234 (A))

Attention is drawn to the following places, which may be of interest for search:

Rolling of toothing into cylindrical blanks without preformed gear teeth | |

Finishing gear teeth by other tools |

This place covers:

Methods and devices for manufacturing internal gear toothing on cylindrical workpieces. This subgroup also covers the manufacturing of such gears by spinning or by the so-called "Grob"-process, in which eccentrically mounted rollers hit the workpiece

Manufacturing of internal gear toothing by rolling |

|

Manufacturing of internal gear toothing by spinning |

|

Manufacturing of internal gear toothing by the "Grob"-process |

|

Attention is drawn to the following places, which may be of interest for search:

Rolling of external toothing into cylindrical blanks without preformed gear teeth |

This place covers:

Manufacturing of gear teeth on a workpiece by relatively reciprocating flat dies or racks.

(from WO 2004022259 (A1))

Attention is drawn to the following places, which may be of interest for search:

Manufacturing of external threads on a workpiece by means of reciprocating flat dies |

This place covers:

Methods and devices for rolling bevel gears.

(from US 6076387 (A))

This place covers:

Methods and devices for manufacturing particular articles by rolling.

Attention is drawn to the following places, which may be of interest for search:

Making particular articles by working sheet metal | |

Making particular articles from wire | |

Making of needles, pins and nails | |

Making particular articles by forging or pressing | |

Making specific metal objects by operations not covered by a single other subgroup |

This place covers:

Methods and devices for forming annular grooves in a workpiece by rolling.

(from JP 57036033 (A))

This place covers:

Methods and devices for finishing, i.e. burnishing, of annular grooves by rolling, in particular for deep rolling of crankshaft fillets.

(from WO 2006119944 (A1))

Attention is drawn to the following places, which may be of interest for search:

Burnishing machines or devices |

This place covers:

Methods and devices for forming helical or rectilinear grooves in a workpiece by rolling.

Rolling of helical grooves |

|

Rolling of rectilinear grooves |

|

Attention is drawn to the following places, which may be of interest for search:

Making articles with helicoidal surface by rolling | |

Making worms by rolling |

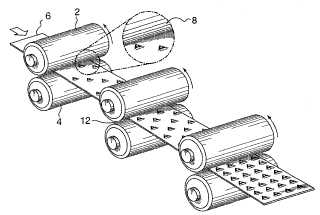

This place covers:

Methods and devices for forming repetitive structures on a workpiece by rolling.

(from GB 2135613 (A))

This place covers:

Methods and devices for roll embossing or roll stamping of workpieces, i.e. for impressing a discrete pattern into a sheet, strip or roll of metal, often for creating a decorative pattern.

(from EP 1819460 (A1))

Attention is drawn to the following places, which may be of interest for search:

Surface roughening or texturing within a rolling mill | |

Rolls with a roughened or textured surface; methods for making the same | |

Machines and rolls for embossing decorations | |

Pressing or stamping ornamental designs |

This place covers:

Methods and devices for feeding blanks to be rolled into or extracting rolled workpieces from a rolling device.