CPC Definition - Subclass B21C

This place covers:

The methods and devices for working metal as follows:

Metal drawing (covered by B21C 1/00 - B21C 19/00)

Metal extrusion (covered by B21C 23/00 - B21C 35/00)

Methods for manufacturing metal sheets, bars, wires tubes or the like. (covered by B21C 37/00)

Devices for cleaning metal products adapted for use with machines of this subclass (covered by B21C 43/00)

Separating mandrels from work (covered by B21C 45/00)

Winding-up, coiling, winding-off metal wire or metal band (covered by B21C 47/00)

Devices for temporarily accumulating material (covered by B21C 49/00)

Measuring, gauging, indicating, counting, marking devices adapted for use with subclasses B21B - B21F (covered by B21C 51/00)

Other subject-matter concerning the manufacture of metal sheets, wire, rods, tubes or profiles otherwise than by rolling as well as other subject-matter concerning auxiliary operations used in connection with metal-working without essentially removing material (covered by B21C 99/00).

This place does not cover:

Working or processing of sheet metal or metal tubes, rods or profiles |

Attention is drawn to the following places, which may be of interest for search:

Methods for manufacturing metal sheets, bars, wires tubes or the like by rolling | |

Devices for cleaning metal sheet from scale, i.e. descaling, in combination with rolling | |

Making forged or pressed products | |

Soldering, welding | |

Other working of metal, combined operations | |

Transport or storage devices, e.g. conveyors for loading | |

Handling thin or filamentary material, e.g. sheets, webs, cables | |

Devices for cleaning in general |

This place covers:

Methods, devices and drives for metal drawing.

Metal drawing consists in reducing the cross-section of a work piece (e.g. reducing the diameter of a metal rod or wire) by forcing it through a die. Metal drawing differs from extrusion by the lower rate of reduction.

This place covers:

All aspects relating to drawing special alloys with the purpose, for example, of modifying the physical properties of such alloys, and all special drawing methods.

Attention is drawn to the following places, which may be of interest for search:

Modifying the physical properties by deformation during manufacturing of ferrous alloys rods or wires | |

Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working | |

Ropes or cables built-up from metal wires, e.g. of section wires around a hemp core, the wires being characterised by an anticorrosive or adhesion promoting coating |

This place covers:

All aspects relating to drawing metal sheets, metal wire, metal rods, metal tubes applying vibratory energy, for example, to the mandrel and/or the dies.

This place covers:

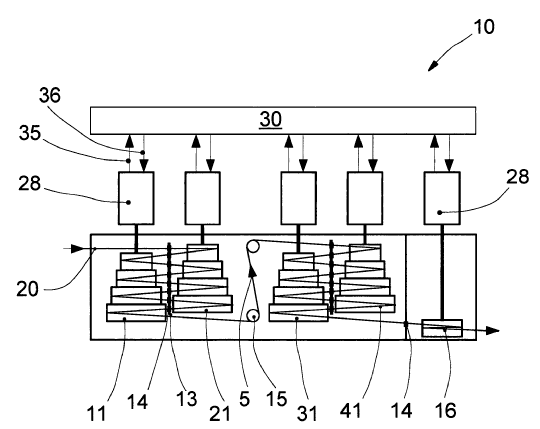

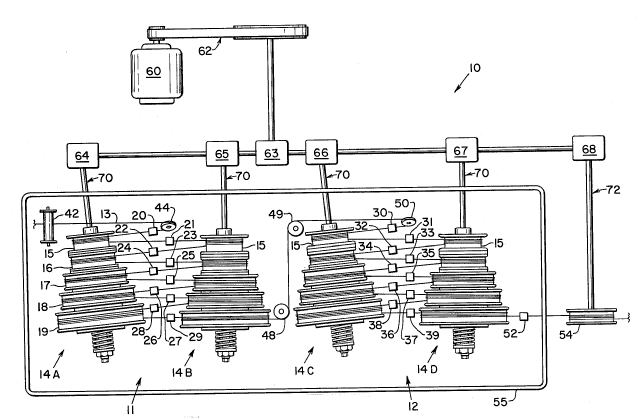

All aspects relating to the drawing action effected by drums.

This place covers:

All aspects relating to drawing dies operating in series.

This place covers:

All aspects relating to wire drawing devices and methods whereby positive slip insures that all portions of the wire are taut and that there is adequate frictional force exerted on the wire by the drums to pull the wire through the dies.

This place covers:

All aspects relating to wire drawing devices and methods whereby wire slips on the drawing drums are eliminated.

This place covers:

All aspects relating to wire drawing devices and methods whereby a certain amount of wire is accumulated in order, for example, to allow steady operation of the machine, even though the speeds of the various drums are not in exact proportion to the elongation of the wire.

Attention is drawn to the following places, which may be of interest for search:

Devices for temporarily storing filamentary material during forwarding, e.g. for buffer storage |

This place covers:

All aspects relating to wire drawing devices and methods, whereby drums are controlled to apply the correct tension on the wire.

Details of drives for drums.

Stop or relief mechanisms.

Attention is drawn to the following places, which may be of interest for search:

Couplings for drums |

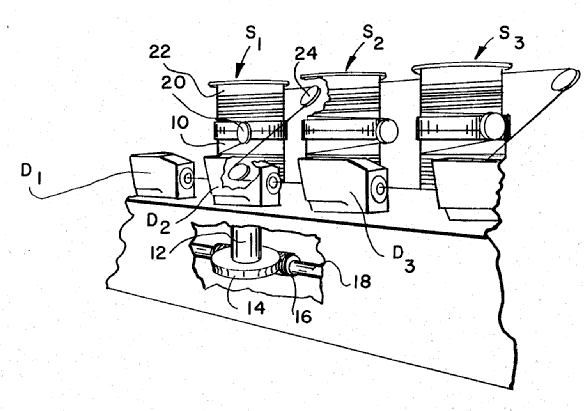

This place covers:

All aspects relating to wire drawing capstans and gripping means cooperating with said capstans.

Attention is drawn to the following places, which may be of interest for search:

Capstans or winches in general |

This place covers:

All aspects relating to metal drawing devices and methods not provided in the sub-groups.

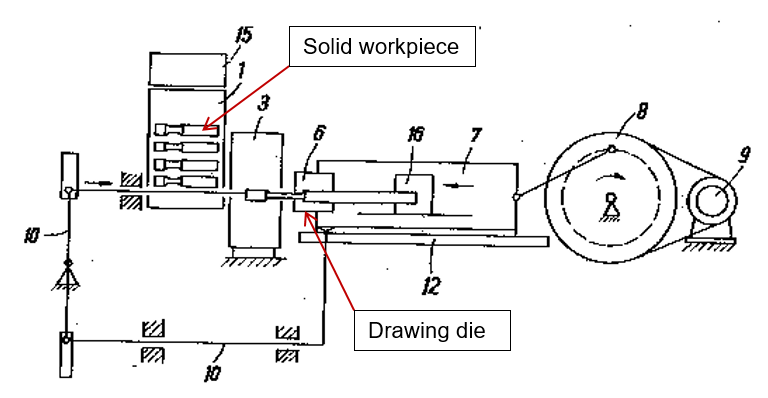

This place covers:

All aspects relating to drawing devices and methods from solid stocks of limited length.

This place does not cover:

Metal drawing by machines specially adapted for making tubular articles |

This place covers:

All aspects relating to drawing devices and methods from stock of unlimited length.

This place does not cover:

Metal drawing by machines specially adapted for making tubular articles |

This place covers:

All aspects relating to drawing devices and methods specially adapted for making tubular articles, also starting from stock of limited length.

Attention is drawn to the following places, which may be of interest for search:

Tube-rolling not restricted to methods provided for in only one of groups B21B 17/00, B21B 19/00, B21B 21/00, e.g. combined processes | |

Bending sheet metal along straight lines, e.g. to form simple curves for making tubes | |

Rigid pipes wound from sheets or strips, with or without reinforcement, made of metal |

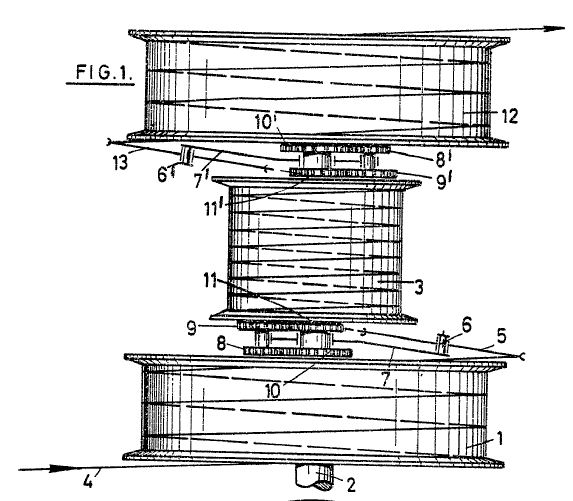

This place covers:

All aspects relating to drawing devices and methods specially adapted for making tubular articles by means of mandrels.

Attention is drawn to the following places, which may be of interest for search:

Mandrels | |

Making helical or similar guides in or on tubes without removing material, e.g. by drawing same over mandrels, by pushing same through dies; {Making tubes with angled walls, ribbed tubes and tubes with decorated walls} |

This place covers:

All aspects relating to drawing devices and methods specially adapted for making tubular articles by means of mandrels by push-bench drawing.

Attention is drawn to the following places, which may be of interest for search:

Mandrels; Mounting or adjusting same | |

Tube-rolling not restricted to methods provided for in only one of groups B21B 17/00, B21B 19/00, B21B 21/00, e.g. combined processes | |

Shaping without cutting, by deep-drawing |

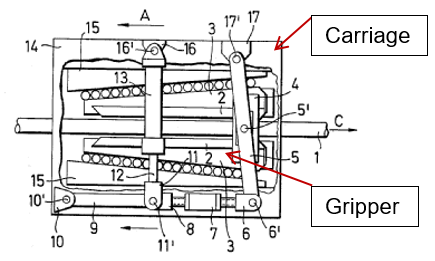

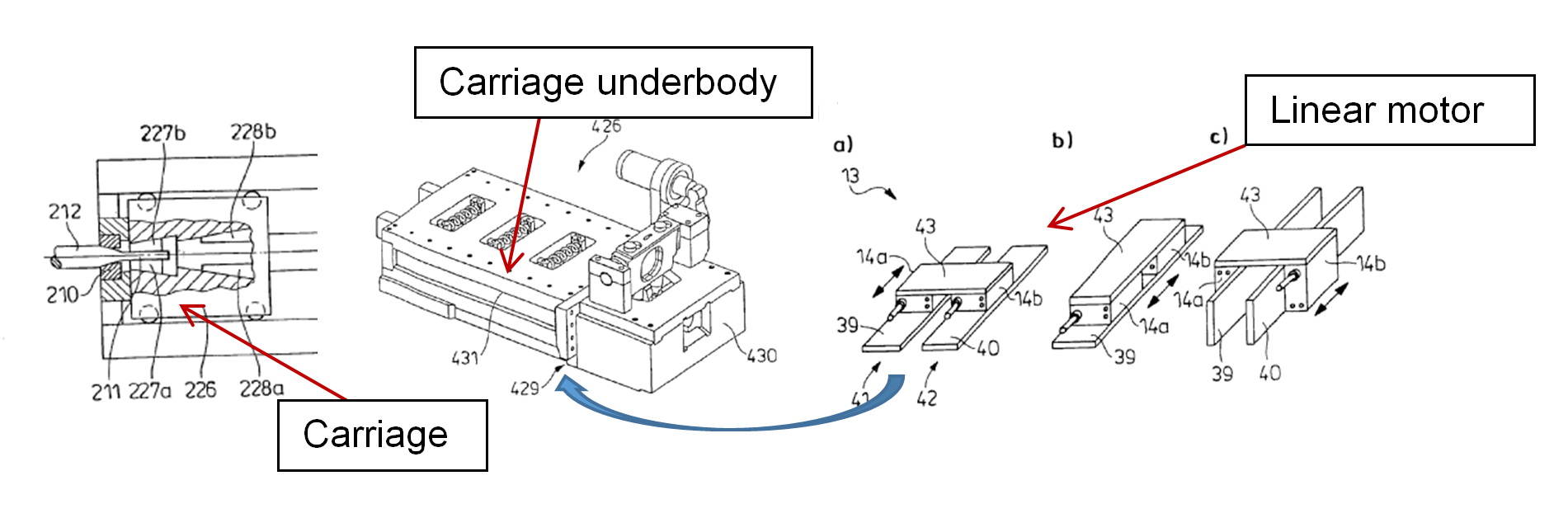

This place covers:

All aspects relating to drawing carriages and drives.

This place covers:

All aspects relating to drawing carriages, connections of grippers thereto and grippers.

Attention is drawn to the following places, which may be of interest for search:

Grippers for drawing machines of the drum type |

This place covers:

All aspects relating to drives for drawing.

This place does not cover:

Endlessly revolving chain systems |

Attention is drawn to the following places, which may be of interest for search:

Removing or drawing-off work | |

Forwarding filamentary material; Aprons, endless belts, lattices, or like driven elements |

This place covers:

All aspects relating to electric linear motors for drawing.

Attention is drawn to the following places, which may be of interest for search:

Propulsion systems in which a rigid body is moved along a path due to dynamo-electric interaction between the body and a magnetic field travelling along the path; Linear motors; Sectional motors |

This place covers:

All aspects relating to feeding or discharging the material or mandrels.

This place covers:

All aspects relating to guiding or supporting the material or mandrels.

This place covers:

All aspects relating to metal drawing tools (dies, die holders, mandrels).

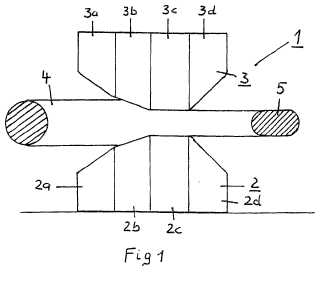

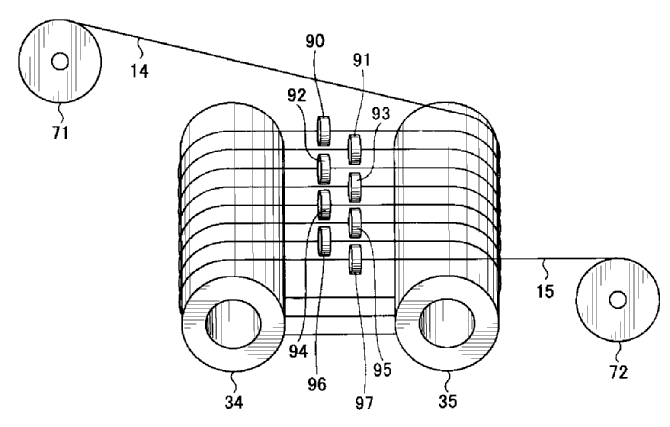

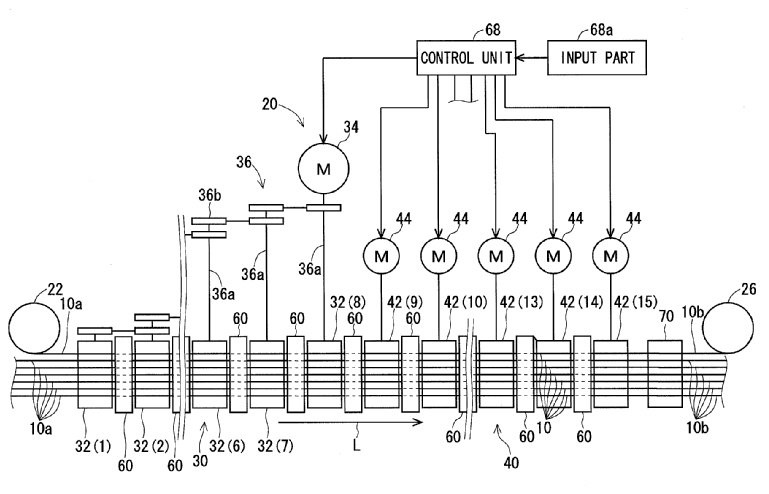

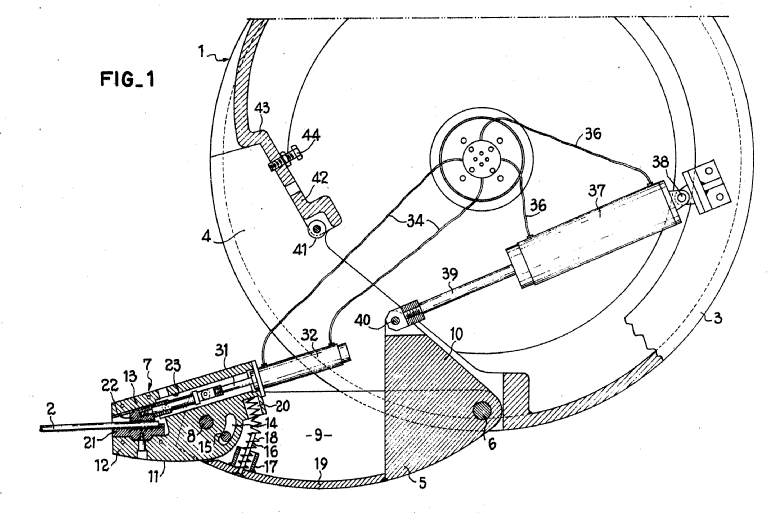

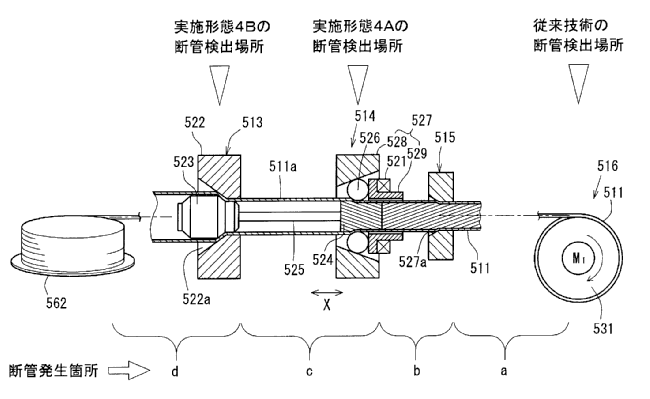

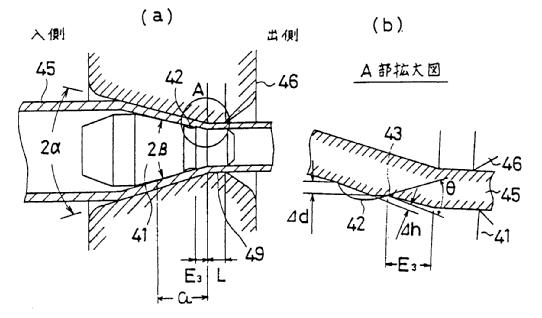

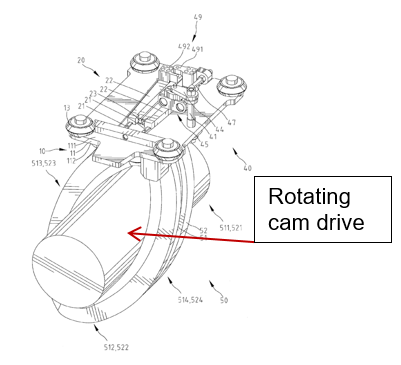

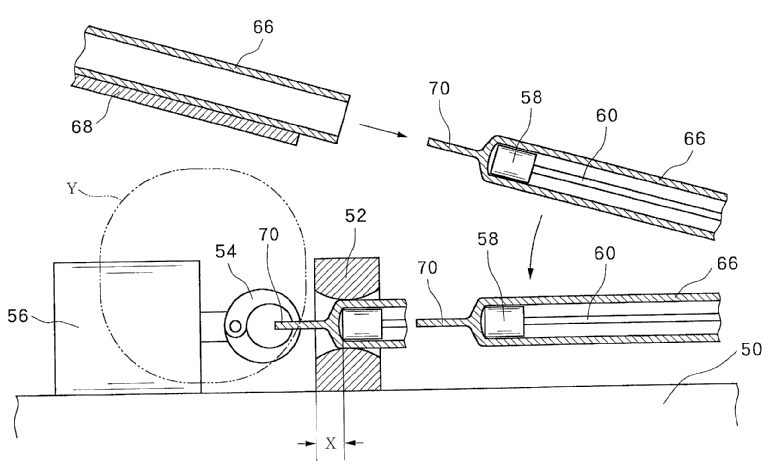

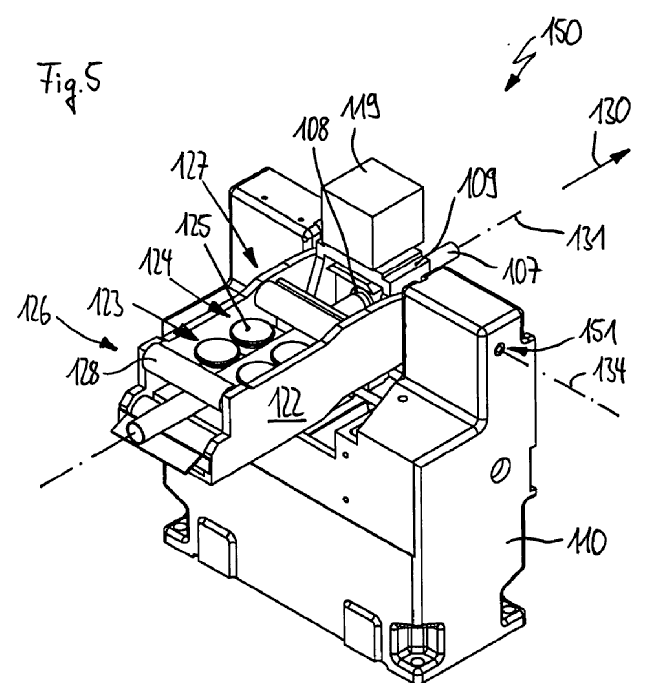

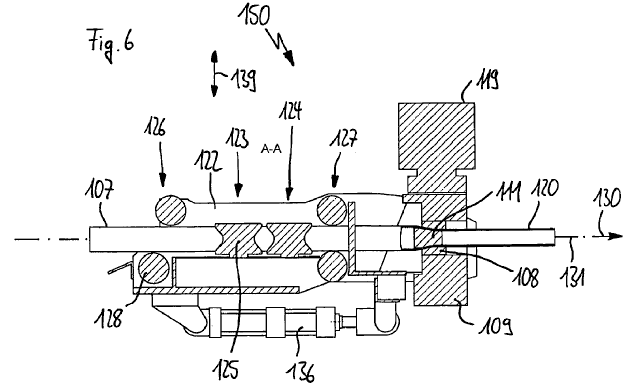

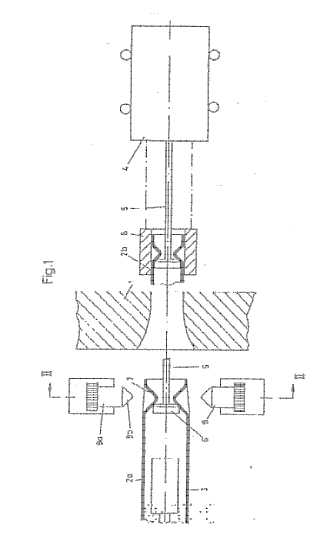

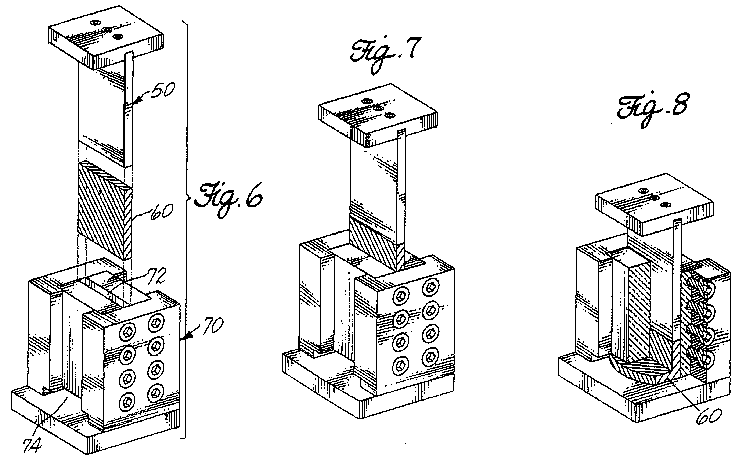

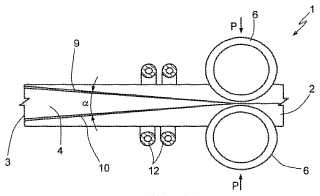

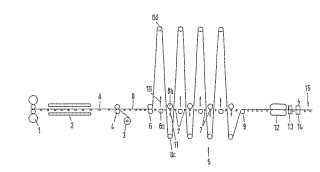

Source: WO2008010614

Source: WO2008010614

Attention is drawn to the following places, which may be of interest for search:

Separating mandrels from work |

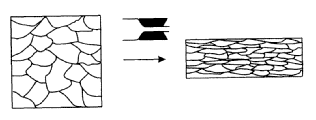

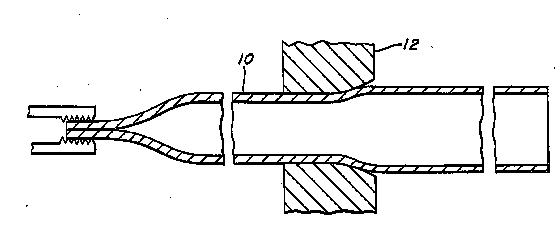

This place covers:

Reducing the cross-section of the material's leading end for easing its insertion into the drawing die prior to drawing.

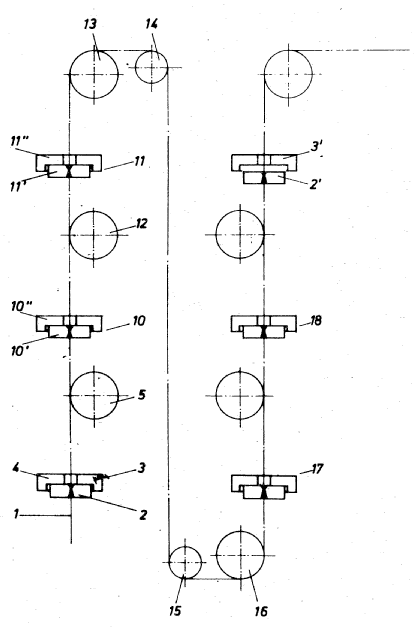

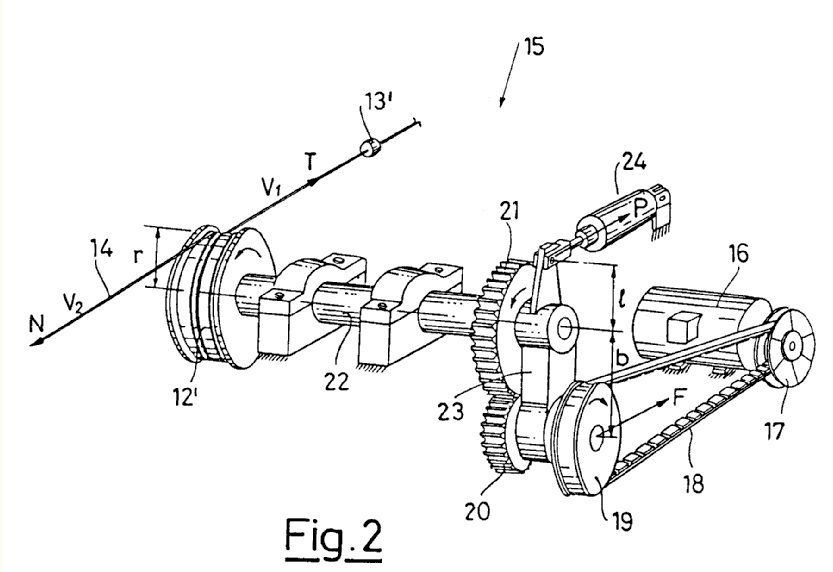

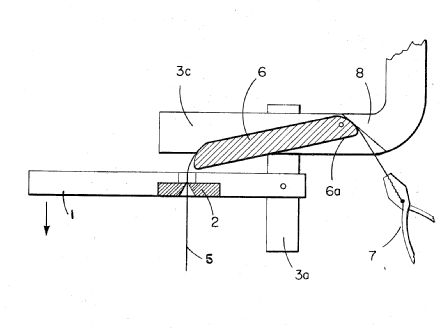

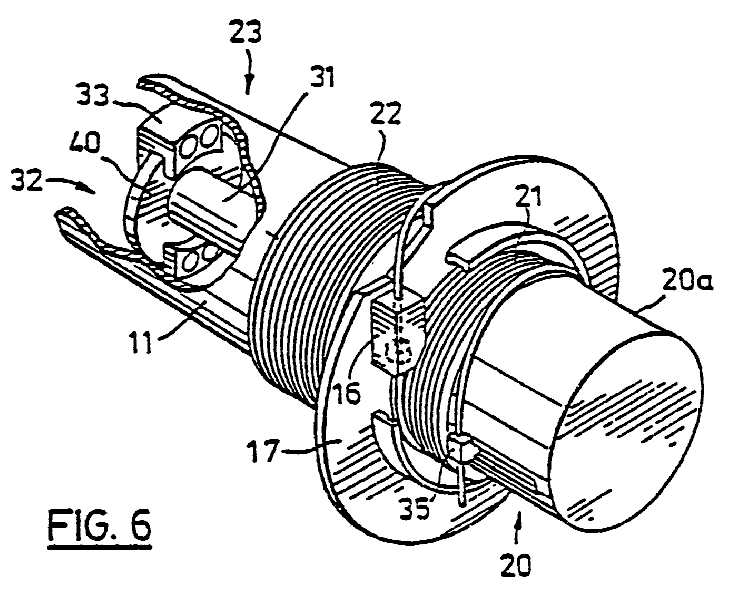

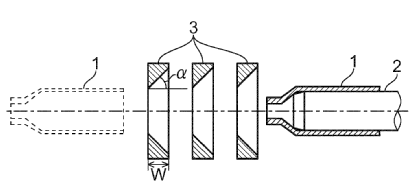

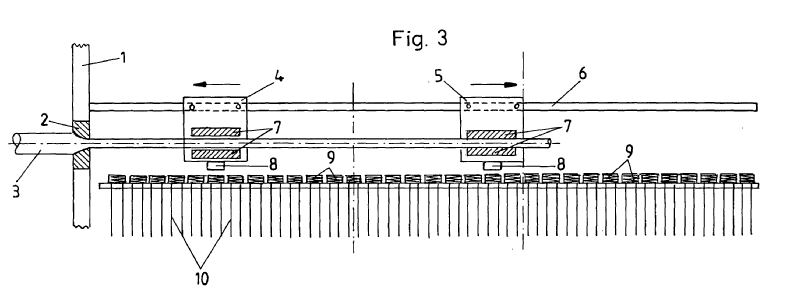

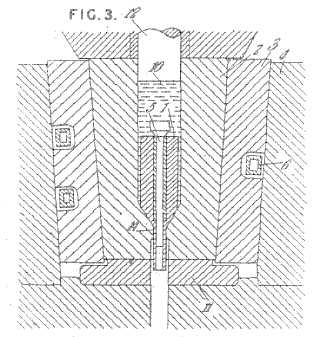

Source: DE3634229

Source: DE3634229

This place covers:

All aspects of cooling, heating or lubricating the drawing material and/or the drawing devices or dies.

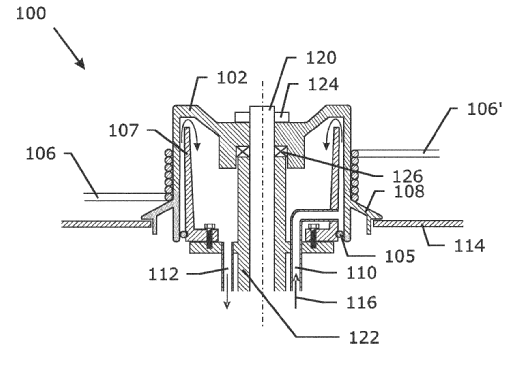

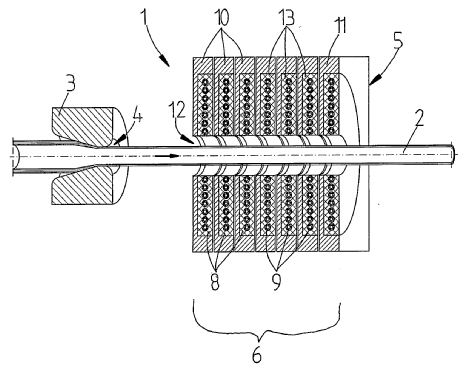

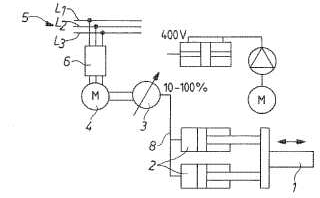

Source: DE19817088

Source: DE19817088

This place covers:

Devices either:

- for straightening wire, wherein the straightening action is realized by using drawing dies, or

- for straightening wire, which devices are used in combination with wire drawing or winding machines (e.g. straightening prior to drawing).

Attention is drawn to the following places, which may be of interest for search:

Winding, coiling | |

Straightening or restoring form of metal rods, metal tubes, metal profiles, or specific articles made there from. | |

Working of wire by straightening |

This place covers:

Methods and devices for metal extrusion; products obtained by metal extrusion as well as lubrication aspects.

The title refers to impact extrusion. This is however only one specific metal extrusion technique covered by this group.

Metal extrusion consists in forcing solid metal through a suitably shaped orifice using compressive forces. Metal extrusion differs from metal drawing by the higher rate of reduction.

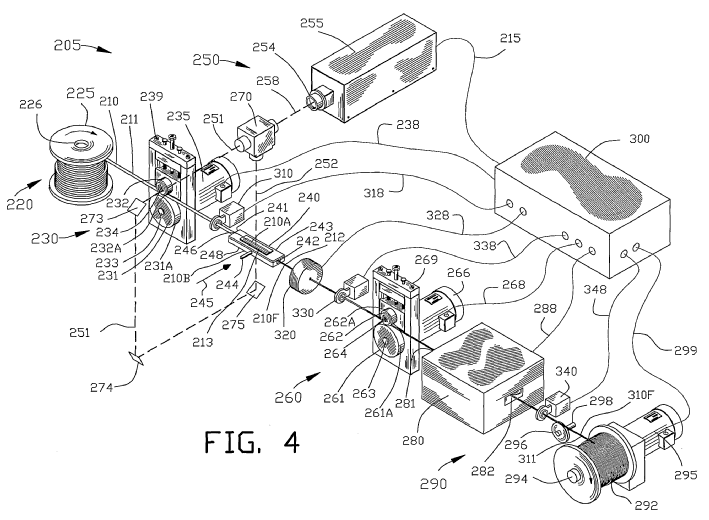

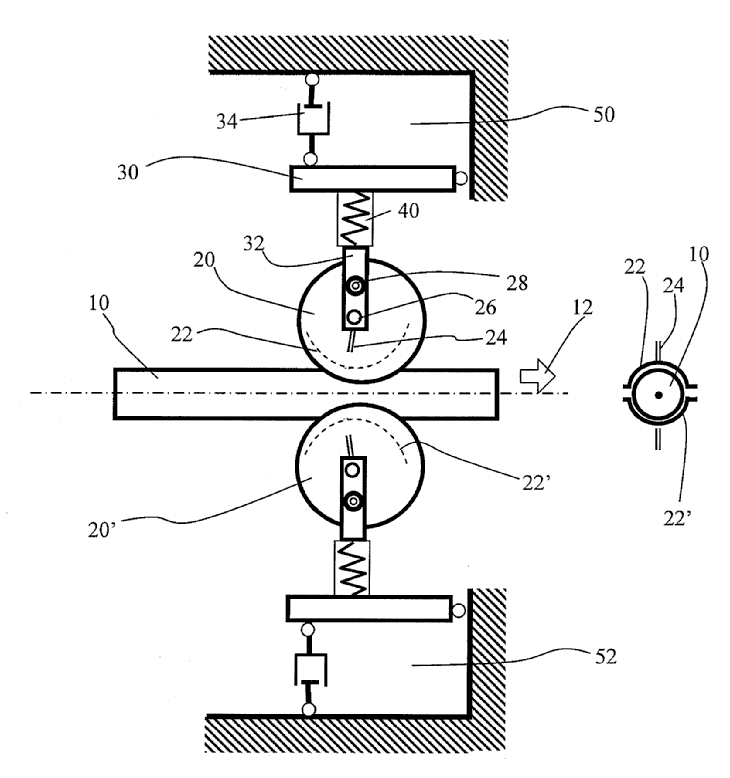

Source: US2007227221

Source: US2007227221

Attention is drawn to the following places, which may be of interest for search:

Tools for metal extrusion (i.e. mandrels and dies) | |

Rams, plungers or disks therefore | |

Containers for metal to be extruded | |

Cooling or heating work or parts of the extrusion press | |

Control or measuring devices in relation with extrusion | |

Feeding extrusion presses with metal to be extruded | |

Removing work or waste from extrusion presses; Cleaning | |

Continuous casting | |

Extrusion of plastic material |

This place covers:

All aspects relating to extrude metals with the purpose of improving the physical properties of such metals, for example, through severe plastic deformation such as ECAP and ECAE.

Attention is drawn to the following places, which may be of interest for search:

Starting from material of particular form or shape, e.g. mechanically pre-treated | |

Preliminary treatment of metal stock without particular shaping, e.g. salvaging segregated zones, forging or pressing in the rough | |

Modifying the physical properties of iron or steel by deformation by cold working | |

Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working |

Attention is drawn to the following places, which may be of interest for search:

Extrusion presses in general |

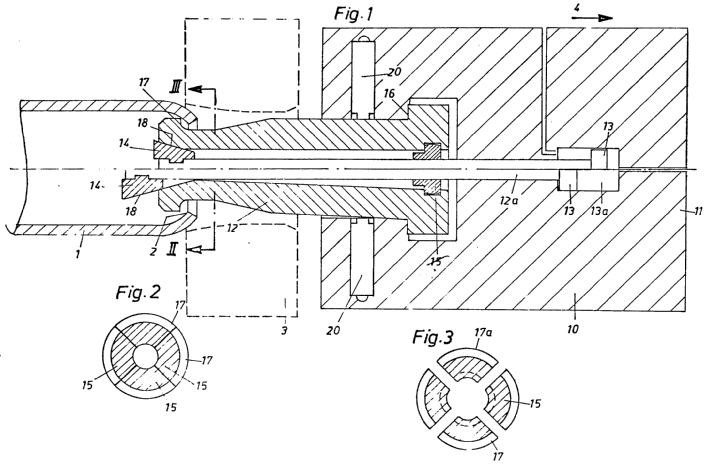

This place covers:

Dies and mandrels for metal extrusion, including dies and mandrels for coating work by extrusion or having a section variable during extruding.

The extrusion die and/or mandrel define/s the section through which the billet is forced, thereby defining the cross sectional shape of the extruded product.

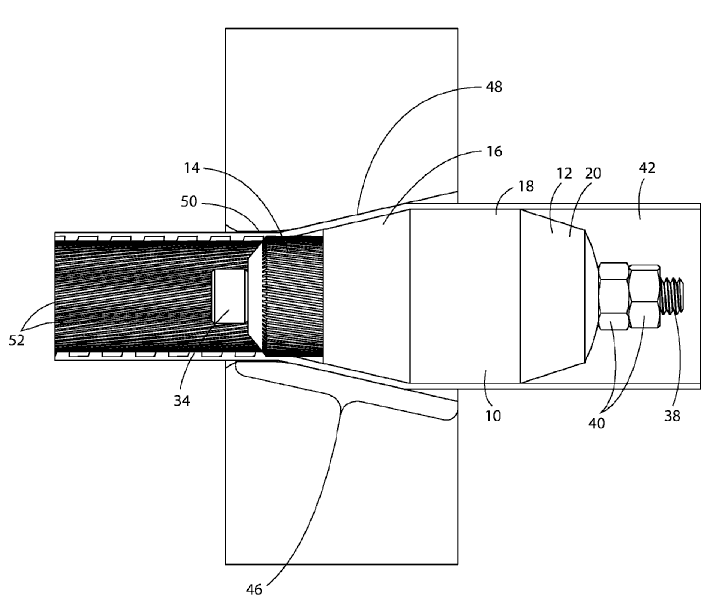

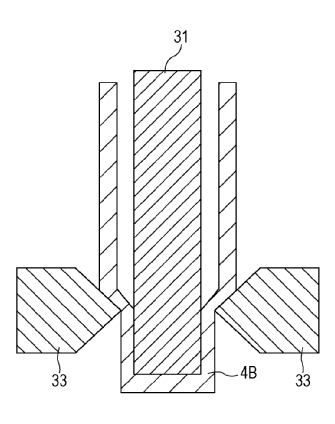

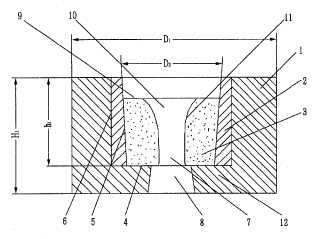

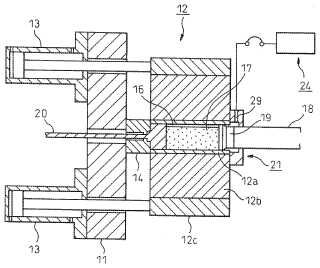

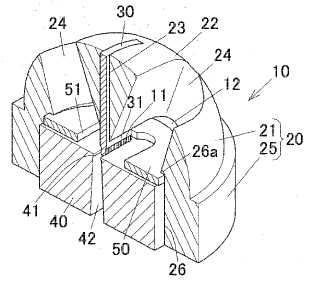

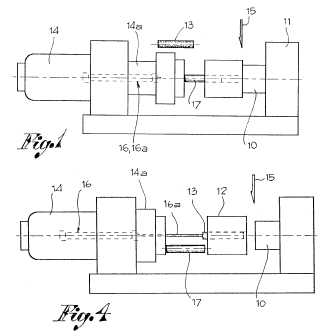

Source: WO2007029888

Source: WO2007029888

Attention is drawn to the following places, which may be of interest for search:

Extrusion devices and methods | |

Rams, plungers or disks therefore | |

Containers for metal to be extruded | |

Cooling or heating work or parts of the extrusion press | |

Control or measuring devices in relation with extrusion | |

Feeding extrusion presses with metal to be extruded | |

Removing work or waste from extrusion presses; Cleaning |

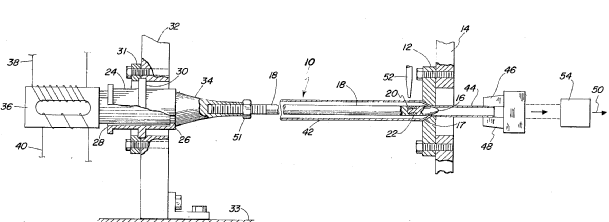

This place covers:

Rams or plungers for metal extrusion; the disks therefore as well as the dummy blocks.

The extrusion ram or plunger is normally the element applying the extrusion pressure to the billet to be extruded.

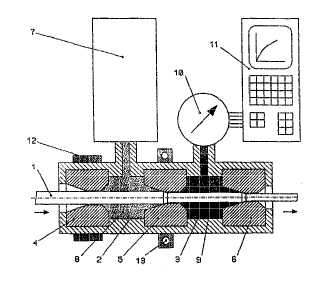

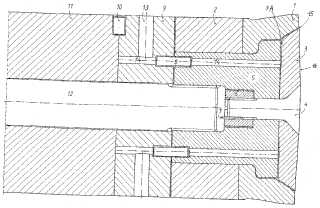

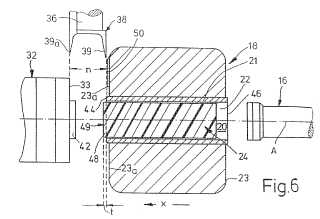

Source: DE10036463

Source: DE10036463

Attention is drawn to the following places, which may be of interest for search:

Extrusion devices and methods | |

Tools for metal extrusion (i.e. mandrels and dies) | |

Containers for metal to be extruded | |

Cooling or heating work or parts of the extrusion press | |

Control or measuring devices in relation with extrusion | |

Feeding extrusion presses with metal to be extruded | |

Removing work or waste from extrusion presses; Cleaning |

This place covers:

The container is the element into which the billet is placed and pressurized for extrusion.

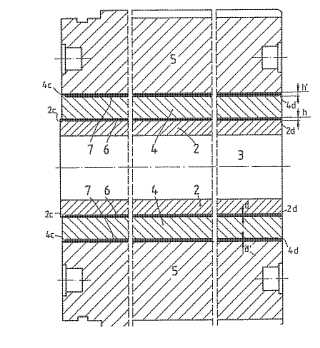

Source: DE3342617

Source: DE3342617

This place does not cover:

Containers comprising cooling or heating elements |

Attention is drawn to the following places, which may be of interest for search:

Extrusion devices and methods | |

Tools for metal extrusion (i.e. mandrels and dies) | |

Rams, plungers or disks therefore | |

Cooling or heating work or parts of the extrusion press | |

Control or measuring devices in relation with extrusion | |

Feeding extrusion presses with metal to be extruded | |

Removing work or waste from extrusion presses; Cleaning |

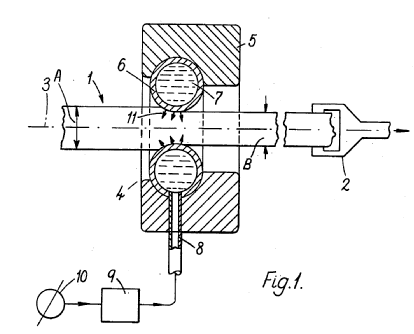

This place covers:

All aspects relating to heating or cooling in combination with metal extrusion.

Source: GB1058854

Source: GB1058854

Attention is drawn to the following places, which may be of interest for search:

Extrusion devices and methods | |

Tools for metal extrusion (i.e. mandrels and dies) | |

Rams, plungers or disks therefore | |

Containers for metal to be extruded | |

Control or measuring devices in relation with extrusion | |

Feeding extrusion presses with metal to be extruded | |

Removing work or waste from extrusion presses; Cleaning |

This place covers:

Control devices, e.g. for regulating the pressing speed or temperature of metal; Measuring devices, e.g. for temperature of metal, combined with or specially adapted for use in connection with extrusion presses.

This place does not cover:

Controlling variation |

Attention is drawn to the following places, which may be of interest for search:

Extrusion devices and methods | |

Tools for metal extrusion (i.e. mandrels and dies) | |

Rams, plungers or disks therefore | |

Containers for metal to be extruded | |

Cooling or heating work or parts of the extrusion press | |

Feeding extrusion presses with metal to be extruded | |

Removing work or waste from extrusion presses; Cleaning | |

Measuring devices of more general interest |

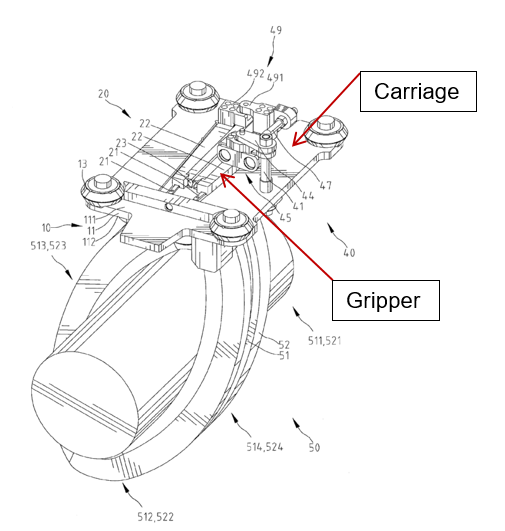

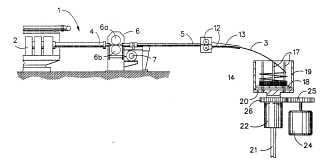

This place covers:

All aspects concerning operations or devices upstream of the extrusion press or extrusion process, and specifically linked to it, including e.g.feeding conveyors and grippers used to provide a workpiece to an extrusion press.

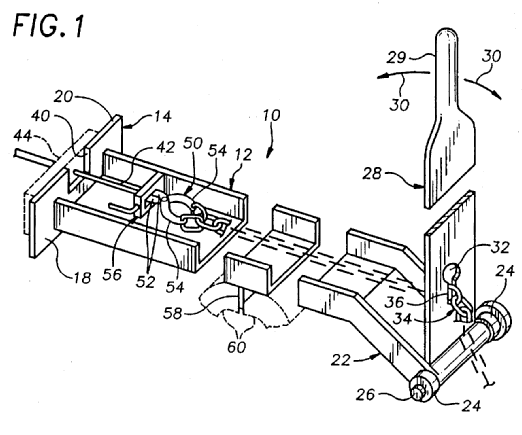

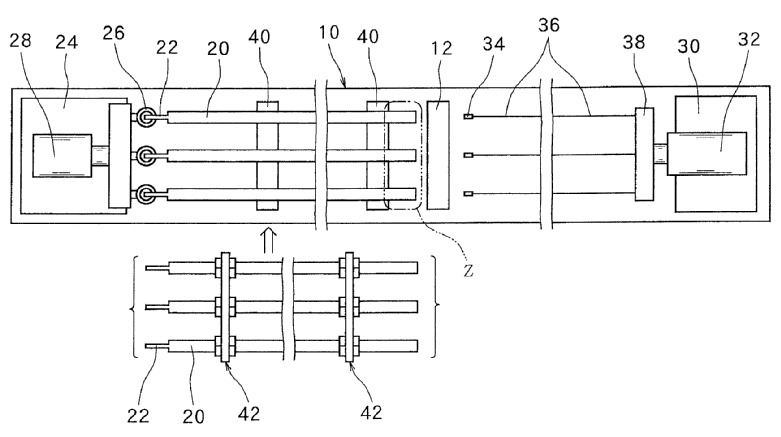

Source: EP0486436

Source: EP0486436

Attention is drawn to the following places, which may be of interest for search:

Extrusion devices and methods | |

Tools for metal extrusion (i.e. mandrels and dies) | |

Rams, plungers or disks therefore | |

Containers for metal to be extruded | |

Cooling or heating work or parts of the extrusion press | |

Control or measuring devices in relation with extrusion | |

Removing work or waste from extrusion presses; Cleaning |

This place covers:

All aspects concerning operations or devices downstream of the extrusion press or extrusion process, and specifically linked to it, including e.g.:

- Removing work or waste from extruding presses;

- Drawing off extruded work;

- Cleaning dies, ducts, containers or mandrels.

- Scrapers and scraping knives for cutting-off or removing the waste or for removing sections from the extruded work, e.g. removing a strip to create an open profile.

Source: EP0787543

Source: EP0787543

Attention is drawn to the following places, which may be of interest for search:

Extrusion devices and methods | |

Tools for metal extrusion (i.e. mandrels and dies) | |

Rams, plungers or disks therefore | |

Containers for metal to be extruded | |

Cooling or heating work or parts of the extrusion press | |

Control or measuring devices in relation with extrusion | |

Feeding extrusion presses with metal to be extruded |

Attention is drawn to the following places, which may be of interest for search:

Metal straightening in general |

This place covers:

Processes and devices for the manufacture of:

Metal sheets (covered by B21C 37/02).

Metal wires (covered by B21C 37/04).

Metal tubes (covered by B21C 37/08-B21C 37/14).

Metal tubes of special shape (covered by B21C 37/15-B21C 37/298).

Finishing tubes, e.g. sizing, burnishing (covered by B21C 37/30).

Examples of places in relation to which this place is residual:

Metal extrusion devices and methods | |

Manufacture by rolling | |

Manufacture by working or processing semi-finished sheet metal, profiles, tubes or wire | |

Bending of metal sheet along straight lines | |

Manufacture by working or processing semi-finished sheet metal, profiles, tubes orwire | |

Manufacture by casting | |

Manufacture by material-removing machine tools | |

Manufacture by welding, e.g. cladding or plating | |

Manufacture of metallic fibers | |

Manufacture by grinding or polishing | |

Manufacture by electroforming |

Examples of places in relation to which this place is residual:

Bending sheets for making tubes | |

Seaming by folding |

This place does not cover:

With helically arranged seams |

Examples of places in relation to which this place is residual:

Involving only a soldering or welding operation |

Attention is drawn to the following places, which may be of interest for search:

Sheet bending in general |

Attention is drawn to the following places, which may be of interest for search:

Sheet bending in general |

Attention is drawn to the following places, which may be of interest for search:

Welding and soldering helically arranged seams per se |

Examples of places in relation to which this place is residual:

Making heat exchangers |

This place covers:

All aspects relating to cleaning metal products, wherein the cleaning action is realized by using machines of B21C or wherein the cleaning action is used in combination with machines of B21C.

This group includes in particular, cleaning metal products, especially descaling, by metal drawing, or with methods associated to metal drawing or winding processes.

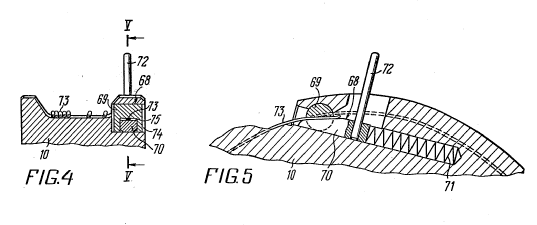

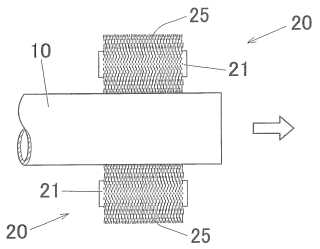

Source: WO2006200502

Source: WO2006200502

This place covers:

Separation of mandrels from work or vice-versa.

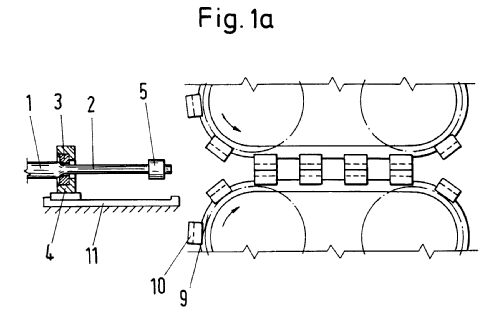

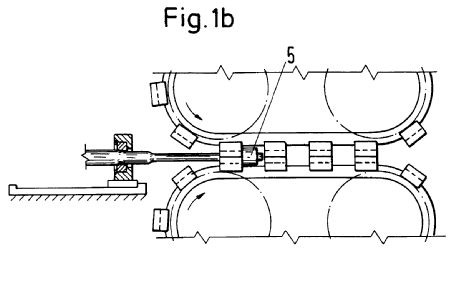

Source: JP61092708

Source: JP61092708

This place covers:

Methods and devices for coiling (winding) and uncoiling (unwinding) of metal wire, band or similar metal product.

Associated operations, like feeding or guiding the material, transferring coils, joining wire or band ends, treating the material, holding on drums or coil holders.

This place does not cover:

Coiling wire into particular form |

Examples of places where the subject matter of this place is covered when specially adapted, used for a particular purpose, or incorporated in a larger system:

Hot coilers in connection with heat-treatment apparatus |

Attention is drawn to the following places, which may be of interest for search:

Joining metal sheets | |

Unwinding welding material | |

Winding electrical elements |

Attention is drawn to the following places, which may be of interest for search:

Reels or drums |

Attention is drawn to the following places, which may be of interest for search:

Gripping means |

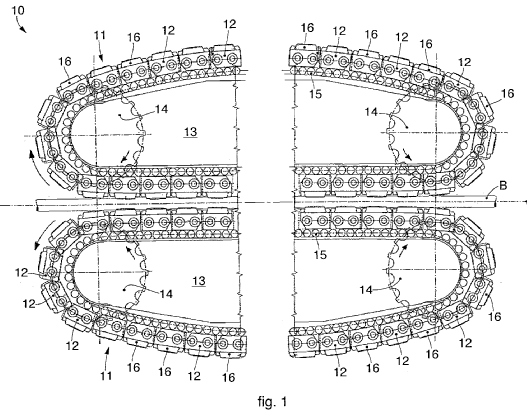

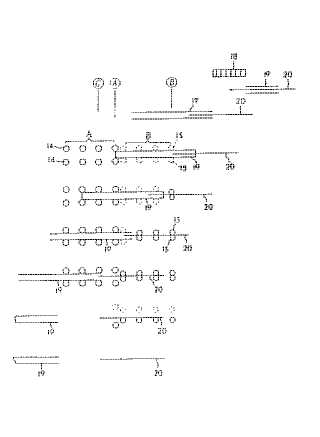

This place covers:

Devices for temporarily accumulating metallic material (e.g. metal bands or wires).

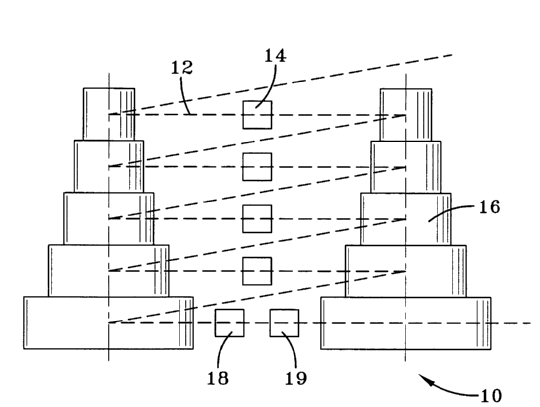

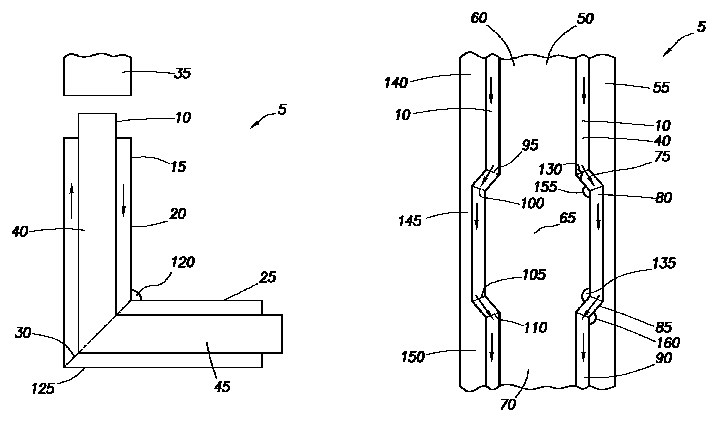

Source: DE4243409

Source: DE4243409

Attention is drawn to the following places, which may be of interest for search:

Accumulating rolled material | |

Accumulating material in general |

This place covers:

Mainly detecting flaws of metal sheets and positioning or marking said flaws.

However, this group has been conceived very generally, which is reflected in its content.

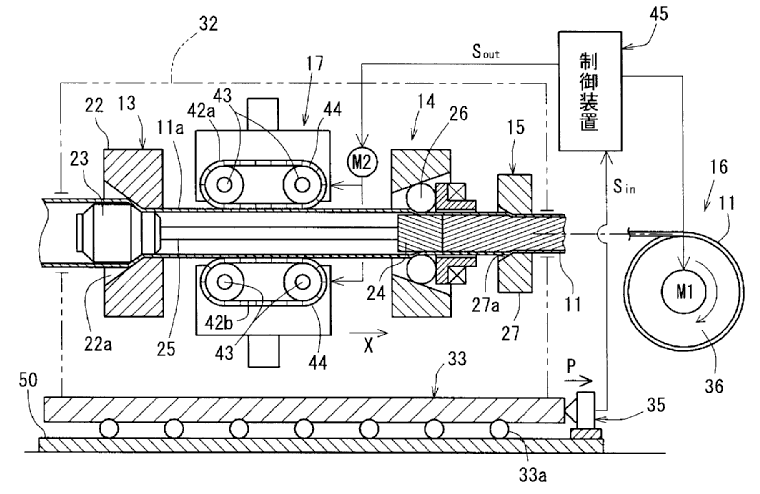

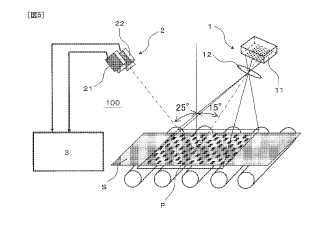

Source: WO2011145168

Source: WO2011145168

This place covers:

Subject-matter not provided for in other groups of this subclass concerning the manufacture of metal sheets, wire, rods, tubes or profiles otherwise than by rolling

Subject-matter not provided for in other groups of this subclass concerning auxiliary operations used in connection with metal-working without essentially removing material.